What can 3d printing do in the future

What does the future hold for 3D printing?

The ultimate goal of 3D printing is to give us a Star Trek-style replicator, where you can order, for example, a hot drink and the machine will assemble it for you, atom-by-atom, explained Marcel Slot – the coordinator of the EU-funded Diginova project – in a Horizon podcast.

However, don’t throw out your kettle just yet. The project forecasts that we’ll have to wait for a while before we can make a replicator.

In the meantime, though, we’ll be able to embed electronic components into 3D-printed devices, create made-to-measure bones using live cells, and in just two decades we’ll be able to start printing our own homes, Diginova believes.

The project brought together 20 research institutes and companies to compile a roadmap to analyse exactly what the future holds for digital manufacturing.

As well as 3D printing, it also looked at digital 2D printing, printed electronics and smart lighting, and how they could converge in future.

‘If you bring these communities together, you start seeing the enormous advantages of convergence of these fields,’ said Slot.

But how long will it be until we have embedded electronics, made-to-measure replacement bones and 3D-printed houses? We’ve brought together some of the best predictions into an interactive timeline looking at what the future of 3D printing could hold:

10 years

Integrated electronics and personalised drugs

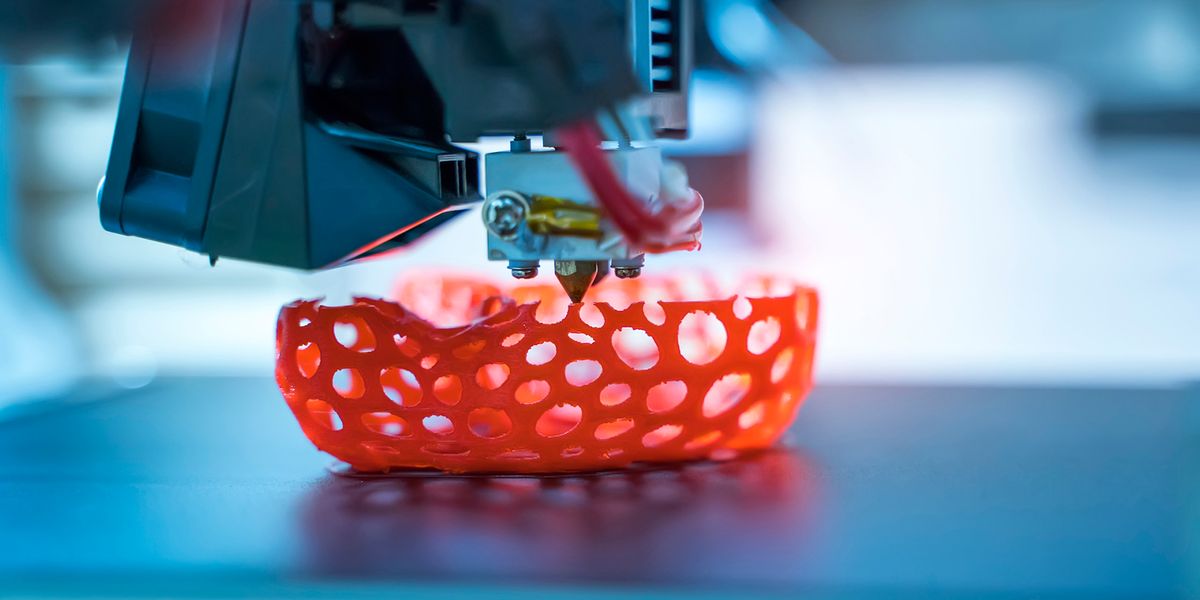

Devices will be printed with integrated electronic chips, enabling manufacturers to radically rethink the design of objects. 3D printing technology will also be used to generate a tailored prescription that includes a specific dose.

In the home, advanced 3D printers that can mix metal and plastic will be as common as microwave ovens, while warships and aircraft hangers will also be equipped with 3D printers.

In the home, advanced 3D printers that can mix metal and plastic will be as common as microwave ovens, while warships and aircraft hangers will also be equipped with 3D printers.A 3D printer that can embed 3D electronics. Image courtesy of TNO.

15 plus years

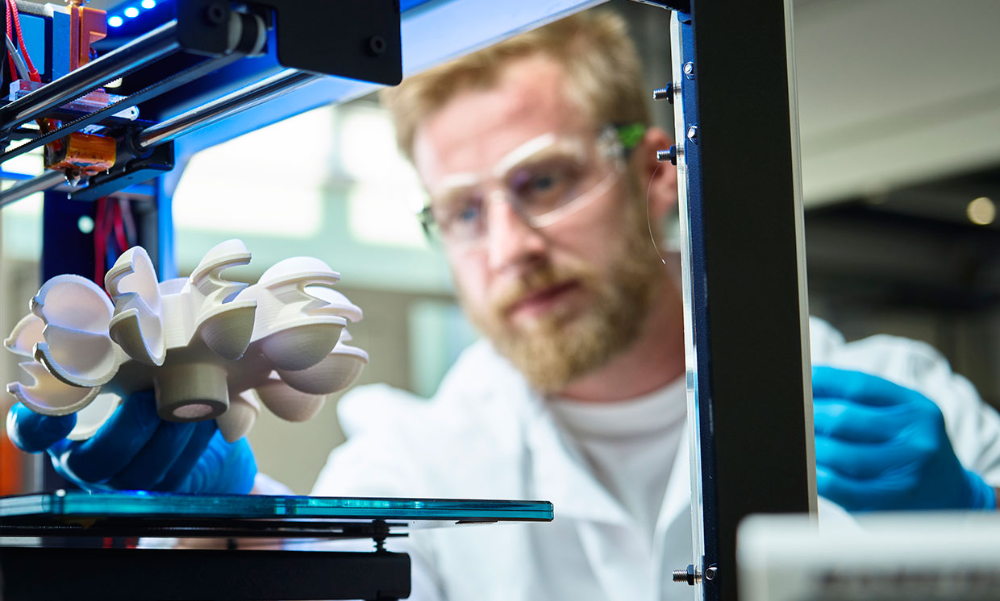

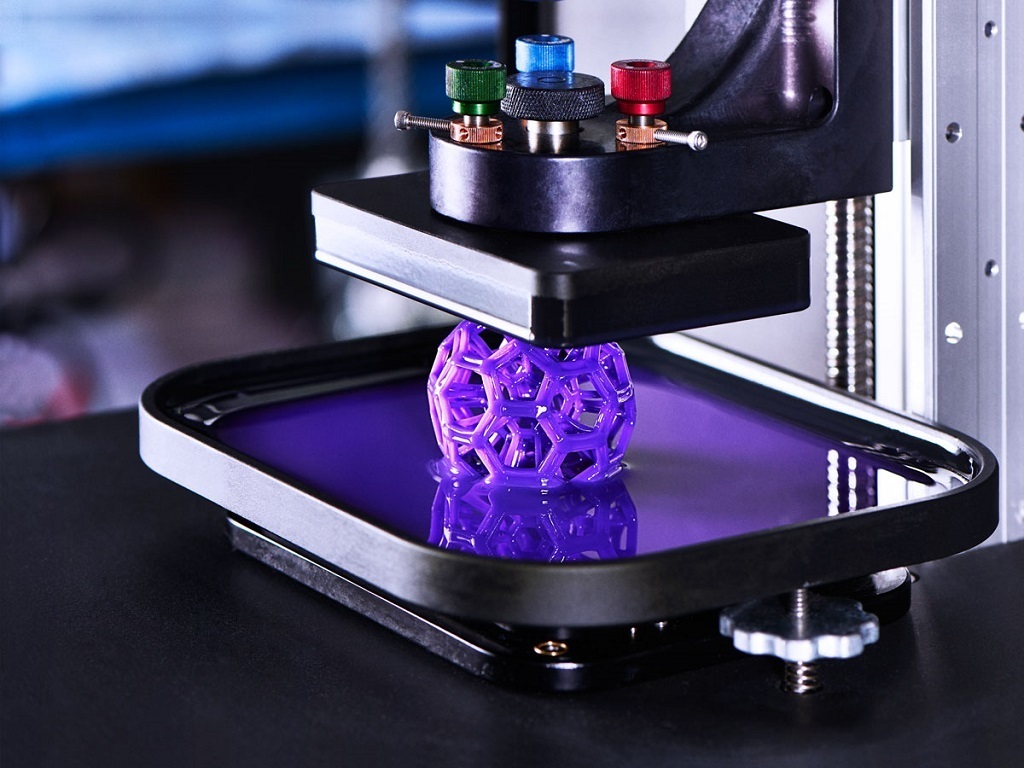

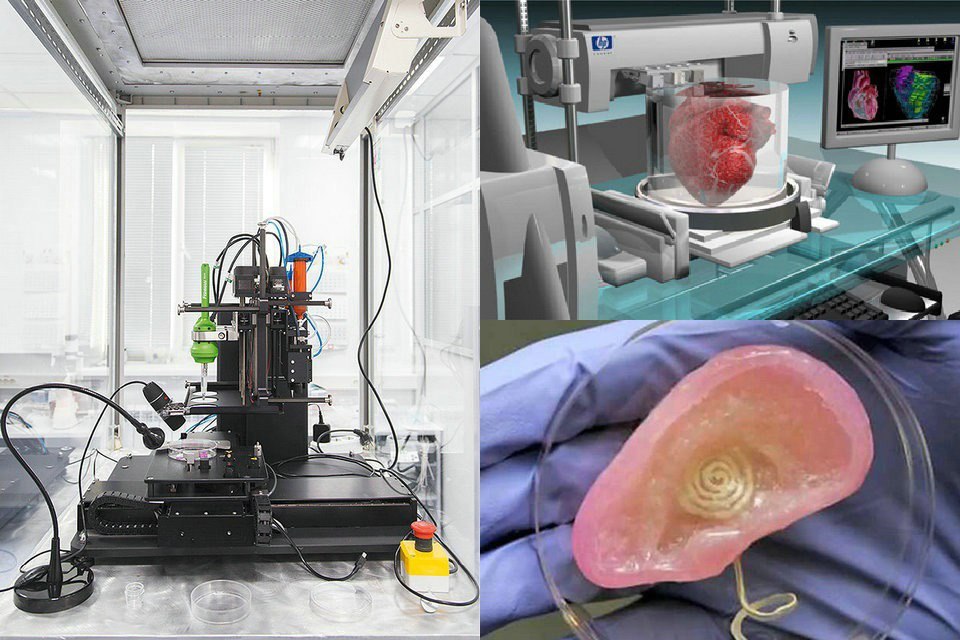

Tissue engineering scaffolds and medical microfactories

Scientists will be able to build scaffolds that are designed to fit specific parts of a damaged bone, for example, providing a framework to help the body heal itself.

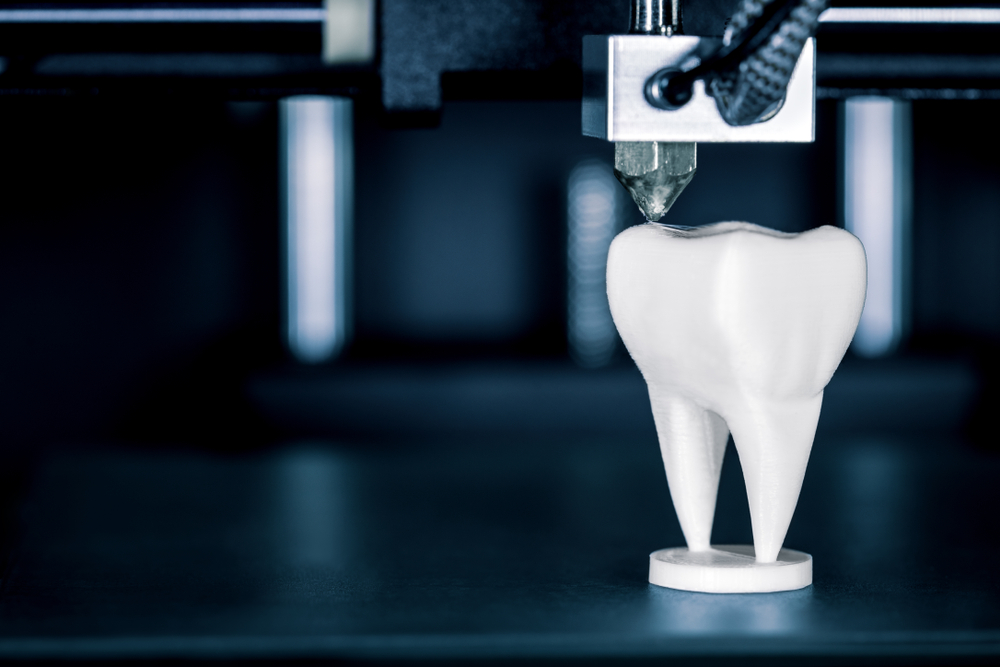

Medical microfactories would allow hospitals to print on-site, custom-made medical devices such as dental aligners, medical guides or surgical instruments, and replacement organs.

3D-printed bone scaffolding. Image courtesy of BIO-SCAFFOLDS.

Within 20 years

Mega-scale digital fabrication

Two crane-like arms could support a crossbeam that holds a printing head over a construction site.

The device could then print a building layer-by-layer using jets of concrete. Researchers believe the technology would be able to make a two-storey house in just under a day.

The device could then print a building layer-by-layer using jets of concrete. Researchers believe the technology would be able to make a two-storey house in just under a day.On the moon and in space, 3D printers could be used to create components and even print habitats for astronauts.

3D printers could one day build a house. Image courtesy of Diginova.

Decades into the future

The internet of things

3D printing could mean devices that have tiny batteries and sensors built into them. When this can be done for a reasonable cost, it will enable engineers to create an internet of things, where everyday objects can sense their environment and communicate with each other.

A leaf-shaped sonar cell. Image courtesy of Diginova.

Far future

Nanoscale digital fabrication

One day, 3D printers may be able to construct materials atom-by-atom, for example by using carbon atoms to make a lightweight material that is harder than diamond.

The technology could be used to make things like high-power fuel cells, single-molecule sensors, molecular-scale computer circuits and selectively permeable membranes.

The technology could be used to make things like high-power fuel cells, single-molecule sensors, molecular-scale computer circuits and selectively permeable membranes.Artist's impression of atoms. Image courtesy of Shutterstock/ U. Shtanzman.

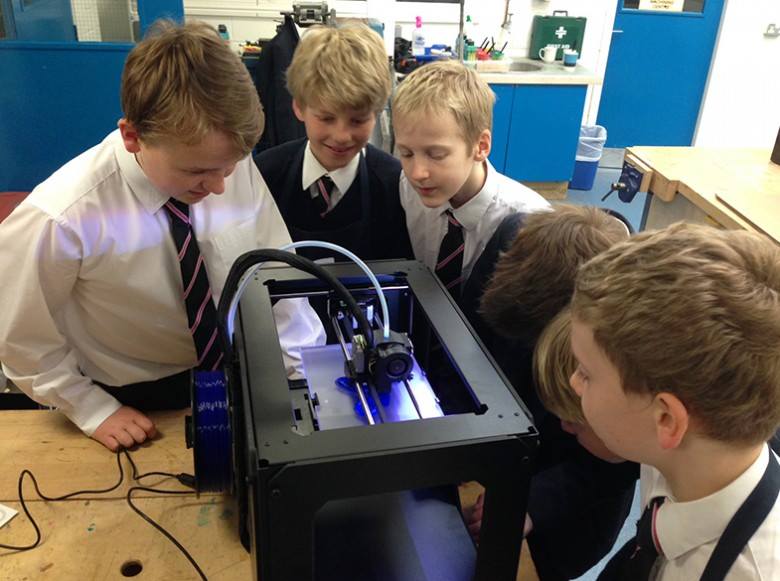

At the moment, the biggest problem is that 3D printing, or additive manufacturing as it’s known in the industry, is slow and expensive, and it is mostly used by big companies to make prototypes.

However, things are poised to change. The technology is becoming much better, and cheaper. And on top of that, researchers are developing ways to combine 3D printing with other techniques so that electronics and fibre optics can be embedded within devices.

‘There is another set of new products to be discovered basically which have these features in them, and which are not around at the moment, of course, because they cannot be made via conventional technologies,’ said Frits Feenstra, coordinator of the EU-funded SASAM project. ‘People are working on that now.’

‘People are working on that now.’

The SASAM project focussed on working out what standards and regulations are needed to drive the 3D printing industry forward, and Feenstra believes that the 3D printing sector will really take off in one or two years’ time when the basic standards are in place.

In order to work out what kind of research is required to push forward 3D printing, industry and policymakers have come together as part of the Additive Manufacturing Platform to make recommendations. The document, called a Strategic Research Agenda, suggests things like looking for new materials that would be as strong as cast metal when 3D printed, and teaching university students about 3D printing.

What Does the Future of 3D Printing Look Like?

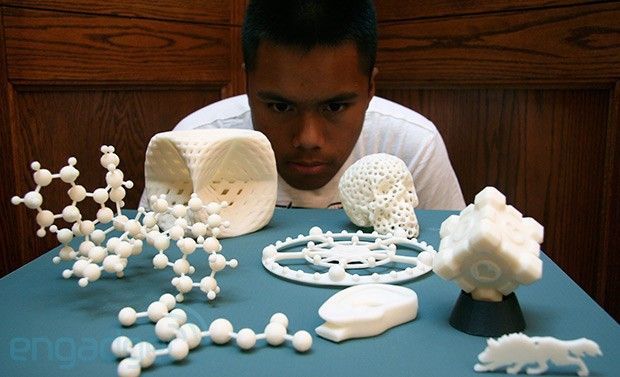

3D printing has come a long way from the early days of desktop figurines. As technology continues to evolve, the future is brighter than ever.

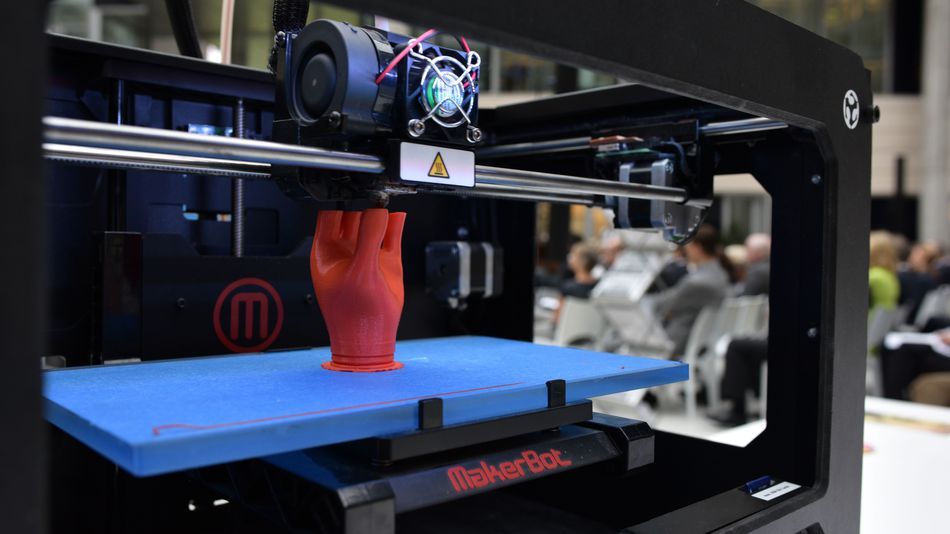

Once a novelty pipe dream but now an established technology, 3D printing (or additive manufacturing) is positioned for real, important growth. Remember the early days of 3D printing? We shared a collective excitement for model versions of the Brooklyn Bridge and iconic cartoon characters to adorn our desks. Now, 3D printing is tackling much larger issues and solving complex problems across industries of varying scales.

Remember the early days of 3D printing? We shared a collective excitement for model versions of the Brooklyn Bridge and iconic cartoon characters to adorn our desks. Now, 3D printing is tackling much larger issues and solving complex problems across industries of varying scales.

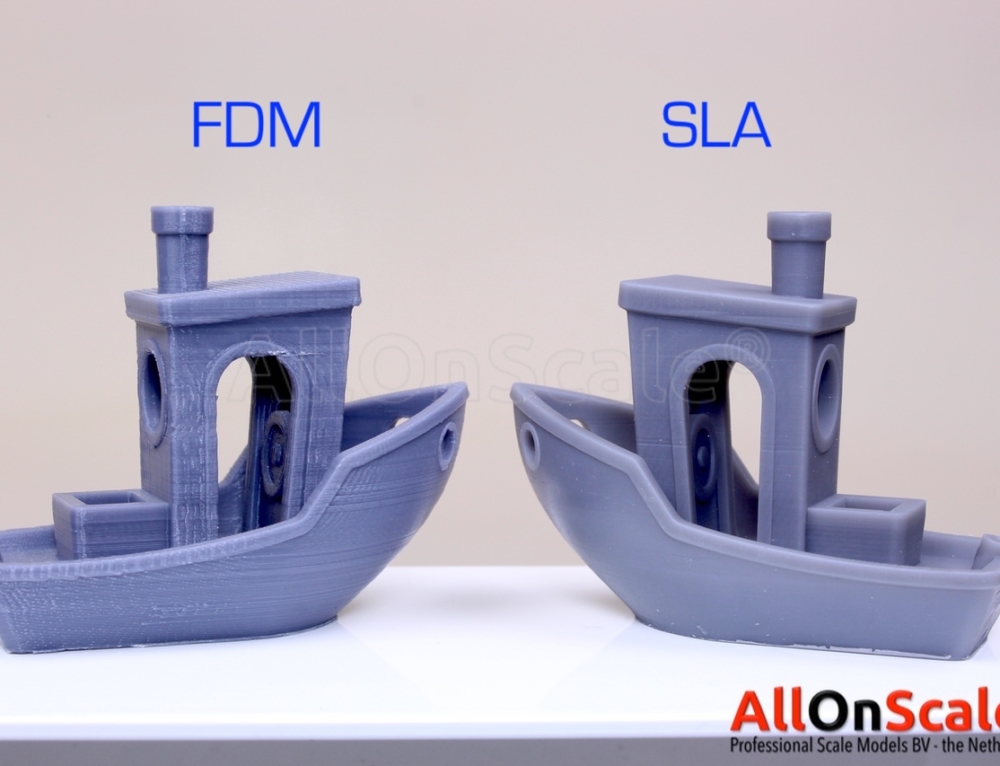

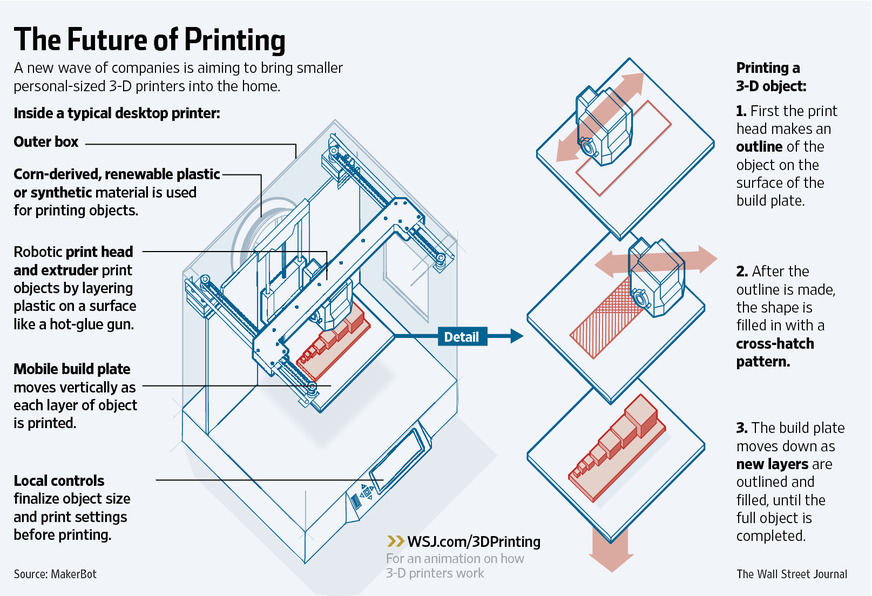

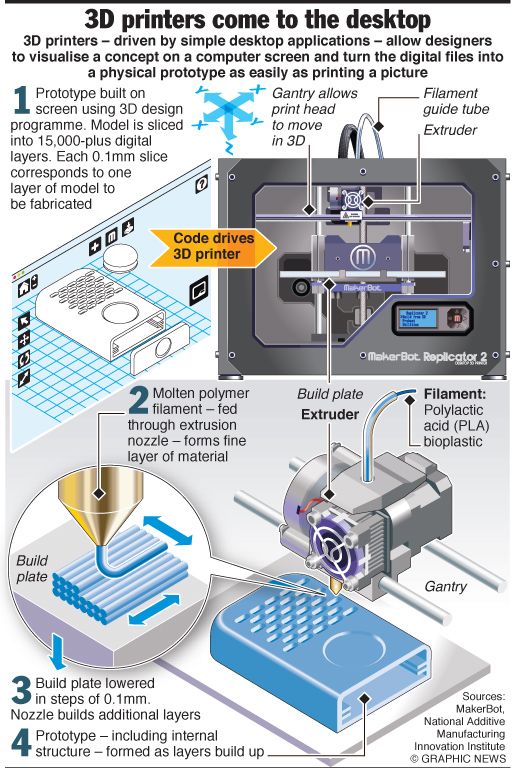

The basis of 3D printing — also called additive manufacturing — is adding layers of materials compounded to make an object. Where cutting and soldering were once required, additive manufacturing gracefully adds layers to build the same type of structures. However, these results are stronger, lighter, more temperature resistant, and require fewer parts.

Applications Showcasing What the Future Holds for 3D Printing

While there are endless examples of 3D printing being used for incredible things, here are a few examples of what the future holds:

- 3D printers have long been able to print rocket-shaped objects, but now companies in the aerospace industry are actually printing rockets.

Companies like Aerojet Rocketdyne are using additive manufacturing for rocket engine and defense system applications. These companies cite reduced lead times, affordability, and new approaches to design as factors in the decision to use additive manufacturing to deliver hypersonic flight.

Companies like Aerojet Rocketdyne are using additive manufacturing for rocket engine and defense system applications. These companies cite reduced lead times, affordability, and new approaches to design as factors in the decision to use additive manufacturing to deliver hypersonic flight.

- In healthcare, additive manufacturing is also making grand promises. 3D Systems, in partnership with CollPlant, is working on printing artificial tissues and scaffolds, advancing regenerative medicine through the use of rhCollagen as a 3D printing substrate.

- The electric vehicle industry is a similar story. Local Motors Industries, a company with only 130 employees, has already printed a 3D car that has since been discontinued. Now, they’re printing an urban electric shuttle, citing digital design advancements as a contributing factor.

At the Forefront of Evolving Technology

A generatively designed color part from the HP MJF 580 3d printer at the Autodesk Technology Center in Toronto.

Experts predict the largest industry leaps will happen in the technology facilitating additive manufacturing. Printers will likely become even faster, meaning they’ll be able to work on larger, industrial types of projects. Forbes also reports that MELD Manufacturing has designed machines that allow additive manufacturing in uncontrolled environments, which means they can operate in the field. As a result, they’re more useful in remote areas and enable a greater variety of 3D printed structures.

3D printing seeks to address efficiency problems throughout supply chains as well. Nora Toure, Founder of Women in 3D Printing, writes, “I predict there will be a countless number of companies that have adopted additive manufacturing into their supply chain commercially with a vast majority of products to be produced on-demand and locally (not necessarily through additive manufacturing, but more as a combination of manufacturing tools, including additive manufacturing).”

3D printers will also add versatility in other ways — using different materials, including metal and even ceramics, even within the same machine. Printers will be able to print one object containing multiple materials, paving the way for a significantly widened field of use.

Printers will be able to print one object containing multiple materials, paving the way for a significantly widened field of use.

Autodesk Fusion 360 and Additive Manufacturing

Integrated CAD + CAM software like Autodesk Fusion 360 will enable additive manufacturing to soar to entirely new levels. The Fusion 360 team is constantly thinking of ways to improve and enhance the additive manufacturing process. We recently announced a new method for generating additive manufacturing outcomes using generative design. This new method does a better job of meeting minimum thickness requirements, balancing design mass, and minimizing support material — without sacrificing shape quality to be fully self-supporting.

Many leading companies have explored the benefits of using generative design in tandem with additive manufacturing, including Hyundai, Panasonic, and more. Download Fusion 360 today to explore innovative additive manufacturing solutions.

Future technologies: 3D printing

General trends in technology development

The first prosthetic hand was created for Gottfried von Berlichingen, who lived in Germany in the 15th and 16th centuries and lost his right hand during one of the battles..jpg) Medieval craftsmen made an iron hand for him, which not only allowed him to look like an ordinary person, but also to hold a sword in it. Today, this hand is in the museum of the Hornberg family fortress as a reminder of how the “bionic” prostheses began.

Medieval craftsmen made an iron hand for him, which not only allowed him to look like an ordinary person, but also to hold a sword in it. Today, this hand is in the museum of the Hornberg family fortress as a reminder of how the “bionic” prostheses began.

Over the past few years, 3D printing in the medical industry has moved from science fiction to practical applications, with its earliest and simplest use being in the manufacture of implants. The main advantage of such implants is the ideal size that fits a particular patient - because before it is made, a 3D scan and a model of the necessary organ are made. The fabric is created on a 3D printer using the same technology as conventional printing, but different types of cells are used instead of plastic. For example, three types of cells are used to create a liver prototype: hepatocytes, stellate cells, and epithelial cells.

There is already a patient in the United States who has a part of the skull printed: a successful operation was performed in the state of Connecticut. At the same time, the speed with which the 3D implant was made is amazing - only 2 weeks have passed from the day of the 3D scan to the operation. Entire organs have already been printed at Princeton University: for example, a bionic ear, which not only looks like a real one, but also contains an antenna sensitive to sound waves and living cells.

At the same time, the speed with which the 3D implant was made is amazing - only 2 weeks have passed from the day of the 3D scan to the operation. Entire organs have already been printed at Princeton University: for example, a bionic ear, which not only looks like a real one, but also contains an antenna sensitive to sound waves and living cells.

With the help of 3D printing technology, temporary crowns for dentistry, parts of the liver for transplantation, and the like are made. Probably, one of the most important aspects of using 3D printing technology is the production of individual prostheses, which not only perfectly repeat the shape and anatomical features of a particular person, but also contain microscopic holes to increase their strength.

Today, several models of artificial arms and legs with a fairly high functionality have been developed and printed, allowing even small objects to be used. These models differ slightly from each other, but what they have in common is the high price, which makes them out of reach for most people with disabilities. However, enthusiasts are already developing models using cheaper materials that can be made at home using 3D printers.

However, enthusiasts are already developing models using cheaper materials that can be made at home using 3D printers.

For example, at the age of 14, Colorado schoolboy Easton LaChapelle created his first robotic prosthetic hand at home, and eight years later he founded Unlimited Tomorrow, which focused on the production of modern technological prostheses. Such robotic prostheses, perfectly adapted to human needs, can be created using a 3D printer at a cost much less than those that exist on the market today. So the story of the iron hand of Baron von Berlichingen continues through half a millennium.

...

Impact on society, economy, state

First of all, prosthetics as such allows to keep people with disabilities as an active part of society - this is the basis of inclusion, which is of particular importance in our modern society. And 3D printing allows you to significantly expand the boundaries of both prosthetics and transplants for people who need it, but it is far from being limited to these possibilities.

Already, Aimee Mullins, who is perhaps the most famous athlete and model in the world, is changing her height and forming her own identity with the help of prosthetic legs. In addition to her, one can recall Victoria Modesta, a British singer and fashion model with an amputated left leg below the knee, who turns her own prosthesis into part of her image.

It became possible to print upper limb prostheses on a 3D printer for victims of military conflicts, in particular, for refugees from Syria. The cost of such prostheses does not exceed $20, while the usual price is several hundred. In addition, printed prostheses are lighter than traditional ones, which is also important.

In addition to limb prosthetics, which is already being done more or less massively with the help of 3D printing, another direction of its development has appeared: for example, printing cells for transplantation into the pancreas. The first bioprinter for such printing has already been transferred to the Adelaide clinic (Australia) and is being used to treat patients with diabetes.

It is also now possible to 3D print the middle ear and restore hearing to a person - the relevant successful research was carried out at the University of Maryland in Baltimore. With the help of 3D printing technology, it is possible to achieve submillimeter level accuracy, which allows to successfully perform operations that, using conventional technologies, are successful in the number of 1 in 1,300 cases.

And, finally, 3D printing technology in the near future will make it possible to successfully fight infertility — at least, this is evidenced by the first experiments on mice that were printed with an artificial ovary, which made it possible to restore reproductive function. It is worth noting that scientists have not completely created the ovary, but only its basis, since the entire ovary is still too complex in structure to reproduce.

The mass technology of 3D printing in medicine, according to the famous American inventor and futurist Ray Kurzweil, will become only after 2030. And in 15 years, a technology may appear that will allow creating new organs for a person inside the body.

And in 15 years, a technology may appear that will allow creating new organs for a person inside the body.

...

General trends in technology development

The development of 3D printing technology could not leave such an industry as construction aside. Over the past few years, several projects of 3D printers have been presented that can print housing from various materials.

WASP (World's Advanced Saving Project) has unveiled a 12-meter high Big Delta 3D printer designed to build low-cost housing using local materials.

3D Print Canal House was launched in Amsterdam in 2017, a three-year project in which an international team of partners from various sectors worked together to 3D print a full-size house printed on a large mobile Kamermaker 3D printer designed by the architects. The aim of the project is to revolutionize the construction industry and offer new customized housing solutions around the world.

In Minnesota, StroyBot was created, a 3D printer for printing houses from cement mortar, the inventor of which is Ukrainian Andrey Rudenko. He was the first to print the first 3D hotel room for the Lewis Grand Hotel in the Philippines back in December 2015.

The Chinese company ZhouDa in 2015 created a 3D villa from six 3D modules weighing approximately 100 kilograms each in just three hours (however, it is worth noting that the printing of finished elements took longer). An interesting fact is that for the production of this villa, materials obtained from industrial and agricultural waste were used. The printed house can withstand an earthquake up to 9 points, is not afraid of water and fire.

Another Chinese company, Winsun, printed a standard 5-storey house and a 1,100-square-meter luxury villa to demonstrate its own capabilities. The main advantage of building in this way is significant savings in building materials, which can be 30-60% due to the use of recycled materials, and the cost of 1,100-meter villa is only $161,000.

In Russia, the Spetsavia company from Yaroslavl, using its own model of the S-1160 3D printer, prints building elements using standard cement grade 500, which is available for sale in any building materials store. The working surface of the construction 3D printer is 10x11x2.7 meters.

American architectural firm WATG offers Curve Appeal and Branch Technology design development for construction using 3D printing technology. In doing so, WATG uses the experience of the Case Study Houses program (1945-1966), who studied light and cheap technologies for building in the post-war years. To date, technologies have been added to the old experience that can make houses energy efficient.

The most progressive and innovative today is the D-Shape system, which was developed by Enrico Dini. It allows the creation of full-sized sandstone buildings without any human intervention using a stereolithographic process that requires only sand and a special inorganic substance. At the same time, the resulting material makes it unnecessary to use reinforcement to reinforce the structure, and at the same time it cannot be externally distinguished from artificial marble, and chemically it is 100% environmentally friendly.

At the same time, the resulting material makes it unnecessary to use reinforcement to reinforce the structure, and at the same time it cannot be externally distinguished from artificial marble, and chemically it is 100% environmentally friendly.

...

Impact on society, economy, state

3D printing techniques may lead to a cultural revolution, as what seemed impossible just a few years ago is already being realized in concrete projects. Cheaper construction through 3D printing technologies and the use of recycled industrial waste can enable poor people around the world to get their own homes. The infrastructure of social protection and rehabilitation may also experience irreversible changes due to the spread of these technologies.

New construction technologies will not only make it possible to build buildings cheaper and faster, which is already possible, but will also change the structure of society as a whole. New urban formations will be constantly expanded with innovative construction works and supplemented with new structures to meet the needs of the people. This constantly changing organism at every moment of time will be somewhat reminiscent of Web 2.0 technologies, with the help of which wiki sites are formed, but everything will no longer be online, but offline.

New urban formations will be constantly expanded with innovative construction works and supplemented with new structures to meet the needs of the people. This constantly changing organism at every moment of time will be somewhat reminiscent of Web 2.0 technologies, with the help of which wiki sites are formed, but everything will no longer be online, but offline.

In order to build a house, it will no longer be necessary to call workers and construction equipment. It will be enough to order the necessary file with a housing project, adjust it according to your own wishes and call one construction robot that can print and assemble a house from suitable materials.

At the same time, the spread of 3D printing technology will lead to the development of "smart" and "green" cities that will be friendly to the environment, which will be significantly different from the globalized economy of today, which can be replaced by the hyperlocal and personalized economy of the new time.

...

General trends in technology development

3D printing technology is not new enough compared to other technologies - its active development is in the 2010s, although the patent for this technology was obtained as early as 1984. The use of this technology was delayed due to a lack of business prospects according to the French General Electric Company, but already in the 90s the first commercial companies began to appear in the United States that applied it.

Today, 3D printing is used in manufacturing, medicine and, of course, as a hobby, as the cost of 3D printers has decreased by orders of magnitude. And one of the opportunities for the development of technology has become the personalization of things.

More than 50,000 projects can be found on Thingiverse, a collection of 3D models for the general public — from one of the simplest models, such as a spoon holder that can be useful among kitchen utensils, to a scale model of a shark skull in the form of cufflinks or puzzles . However, these are far from the only designs that can be personalized — anyone can print their own watch band, orthopedic insoles, docking station, iPhone case, or shower curtain rings.

However, these are far from the only designs that can be personalized — anyone can print their own watch band, orthopedic insoles, docking station, iPhone case, or shower curtain rings.

At the moment, the main limitation for 3D printing is the material, since most home printer models work with photopolymers. However, with the wider use of other materials in everyday life, personalization of things in the near future can achieve much more.

Swedish supercar manufacturer Koenigsegg has already announced that it uses a lot of 3D-printed components in the production of its One:1 hypercar. In May 2015, Airbus reported that the Airbus A350 XWB has over 1,000 parts that were also created using this technology. Therefore, in the near future, we will be able to print a car or even an airplane according to our own preferences using 3D printers.

Separately, it is worth mentioning that 3D printers make it possible to print firearms — and this may lead to a new discussion in society on the realization of the right to the protection of the individual. In the United States, there have already been attempts to combat the spread of 3D printer weapon models, but each ban only contributes to the spread of information. A certain compromise in the United States was the permission to print firearms, which can be determined by traditional methods (for example, a metal detector). However, for example, the UK government has already stated that the production of 3D weapons will be illegal in the kingdom.

In the United States, there have already been attempts to combat the spread of 3D printer weapon models, but each ban only contributes to the spread of information. A certain compromise in the United States was the permission to print firearms, which can be determined by traditional methods (for example, a metal detector). However, for example, the UK government has already stated that the production of 3D weapons will be illegal in the kingdom.

Thus, we see how the evolution of new technology raises a whole layer of old problems (patents, intellectual property, copyright, industrial design rights) - all this should be reconsidered as part of the development of 3D printing. However, the spread of technology, and, above all, the ability to independently assemble a 3D printer and thus, under the conditions of regulation, be “invisible” to the state, requires the construction of new rules of the game.

...

Impact on society, economy, state

3D printing technology is one of the breakthrough technologies in modern society today. For a long time there have been disputes that it is this technology that, through personalization, will change the mass consumption market of many products. If there is a massive adaptation of this technology to the market and society, then, indeed, many products can be printed on their own at home 3D printer, and not spend money on their purchase. In the meantime, even after several years of its active development, it remains in the sphere of interests of geeks and lovers of creating something with their own hands.

For a long time there have been disputes that it is this technology that, through personalization, will change the mass consumption market of many products. If there is a massive adaptation of this technology to the market and society, then, indeed, many products can be printed on their own at home 3D printer, and not spend money on their purchase. In the meantime, even after several years of its active development, it remains in the sphere of interests of geeks and lovers of creating something with their own hands.

An important factor influencing innovative development in general, which must be taken into account, is the use of industrial 3D printing, which makes it possible to reduce the cost of components and make them easily replaceable. Theoretically, it is in such small personalization that the vector of economic development in the coming years may lie, when the goods will be produced by industry, however, the personalization of things will be given to buyers.

Another factor that has been actively discussed for some time now is the even greater blurring of the boundaries between home and work with the spread of 3D printing technology. At the same time, for businesses, this technology opens up opportunities to spread the design of new things around the world, which can lead to changes in the delivery of goods. At the same time, production becomes as local and personalized as possible, since each owner of a 3D printer will be able to show their individuality. Already, anyone can buy custom Nike cleats that are 3D printed from scans of the customer's feet.

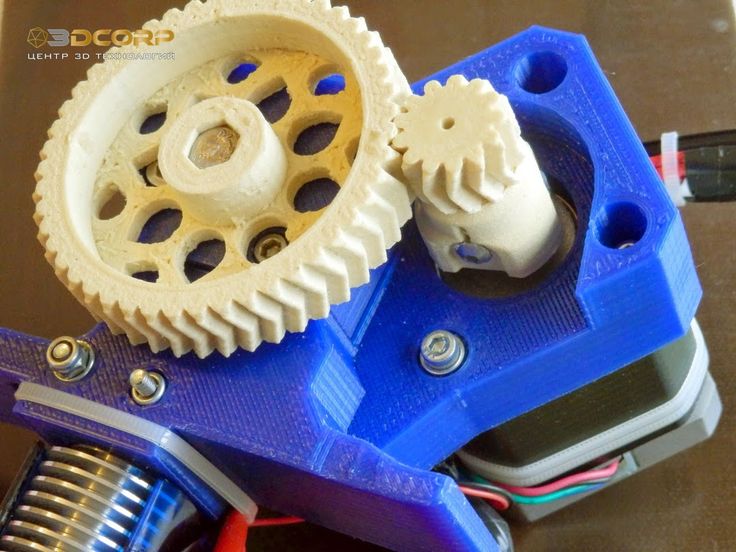

Building a 3D printer that can self-replicate sounds most fantastic—but such developments are already underway under the RepRap project, which allows you to print parts of yourself (however, it still needs a person to assemble!).

For the state, the development of 3D printing technology means greater trust in citizens, since it will be difficult to create total control over the spread of technology. At the same time, home production of things will change both the employment of the population and the structure of tax payments. The democratization of the means of production may raise many new questions: the processing of nanomaterials, the regulation of intellectual property, the proliferation of weapons, and others like that.

At the same time, home production of things will change both the employment of the population and the structure of tax payments. The democratization of the means of production may raise many new questions: the processing of nanomaterials, the regulation of intellectual property, the proliferation of weapons, and others like that.

Also, society will face many new challenges — for example, there are already fewer people working in manufacturing in the United States than they receive unemployment benefits. A decrease in the share of industrial production due to its automation and the spread of 3D printing can further exacerbate the problem of unemployment among the productive population, causing a wide public outcry.

Globally, the least developed countries and societies are more in need of 3D printing technology, as it allows you to create the necessary tools for local needs and at the same time not spend time and money on delivering the necessary industrial goods.

what's next for 3D printing

The prospects for 3D printing

Even now, the prospects for 3D printing are extremely promising. Scientists are actively developing existing 3D printing techniques, developing new technologies and types of materials, and finding new areas of application. Many call 3D printing the technology of the future, and for good reason. The technique is able to completely turn the usual way of life, changing the way most things are produced. In fact, a 3D printer is a real multifunctional factory, small and compact. Due to this, the future of 3D printing can definitely be called successful.

3D printers can significantly reduce production costs, thereby reducing the cost of products. Judging by the growing trend towards the popularization of 3D technologies, raw materials for 3D printing will become the main commodity unit in the future. In general, the prospects for 3D printing are defined for many areas. And now we will try to reveal them as much as possible.

The Future of 3D Printing

If you try to imagine the future of 3D printing, your imagination paints a rather interesting picture. Given the great interest of scientists in the 3D bioprinting technique, which is one of the most promising 3D printing technologies, the production of artificial organs on a 3D printer is not far off. It is also safe to say that the future of 3D printing will bring us dramatic changes in areas such as:

- Construction. 3D printing of houses, or contour construction, attracts many with its futurism and simplicity. The first steps in this direction have already been taken. The pioneers in 3D printing of houses were the Chinese, followed by the government of Dubai who discovered contour building. The first 3D printed office building has already been built in this city of the future, and an entire block is planned to be printed in the near future. And just recently, the first printed house in Europe was created on a 3D printer;

- Electronics.

When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason. Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer;

When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason. Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer; - Automotive and aerospace industry. The future of 3D printing is largely based on its ability to reproduce almost any element of varying complexity. In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars.

- Pharmaceutical industry. Yes, yes, you can imagine. The future of 3D printing is in the manufacture of tablets and other medicines. This is confirmed by epilepsy pills legalized in the USA, made according to a special technique.

The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one.

The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one. - Food industry. 3D food printers are gradually gaining space in cafes and restaurants. While this is probably one of the most raw 3D printing technologies out there, it has potential. Food 3D printers are especially interesting for the possibility of making food for astronauts, as well as the freedom to display culinary talent. This is confirmed by the amazing 3D-printed desserts of our compatriot.

Other questions and answers about 3D printers and 3D printing:

- Finance Which 3D printer manufacturers are best?

- Finance Which 3D printer is better to buy?

The future of 3D printers

Now let's try to imagine the future of 3D printers. There are several important points to be noted here. Below we list the most likely scenarios for the future of 3D printers.

- Improving the reliability and quality of instruments. Surely, many users are looking forward to this, because most of the existing models of 3D printers cannot boast of uninterrupted operation and the absence of printing errors;

- Large distribution. It is certain that the future of 3D printers will please us with their popularization. Even now, one can observe a growing trend towards the use of 3D printing in almost all areas of industry. In parallel with the fact that more and more users learn about the possibilities of technology, the demand for desktop 3D printers is also growing;

- Availability. In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices;

- Enlargement of the construction area.

3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft;

3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft; - Expanding the range of available materials. The future of 3D printers depends a lot on 3D printing materials, because more means more possibilities. The development of special equipment and related materials is being carried out by many companies, and news about the release of new polymers is constantly appearing.

3D technologies of the future

Summing up, it remains to consider only 3D technologies of the future. These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting.