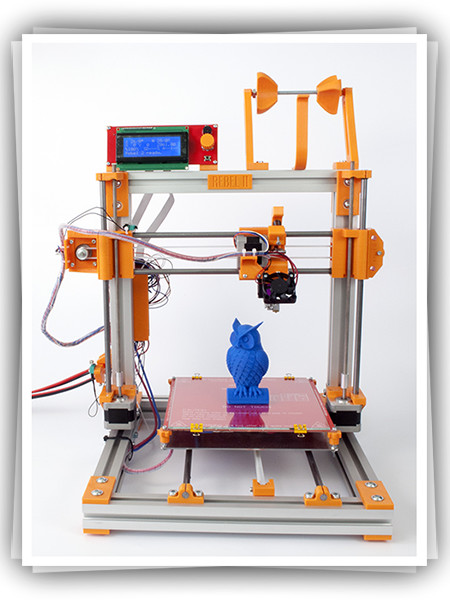

Worm gear 3d printer

▷ worm drive gear 3d models 【 STLFinder 】

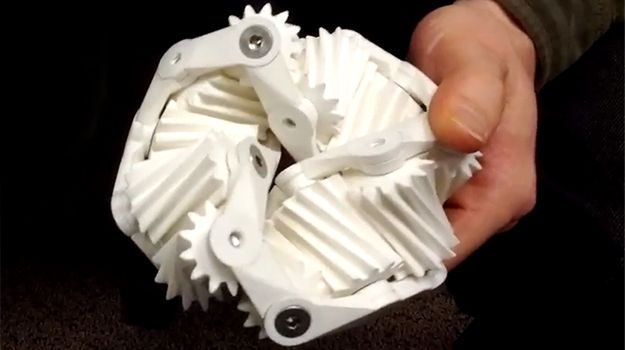

Worm Drive Gears Redux

thingiverse

This is AdditiveTech's excellent Worm Drive Gear, [Thing 2144347](http://www.thingiverse.com/thing:2144347), but with defects in the STL files corrected. (Usual flipped normals and other errors produced by software such as Sketchup. Wouldn't work...

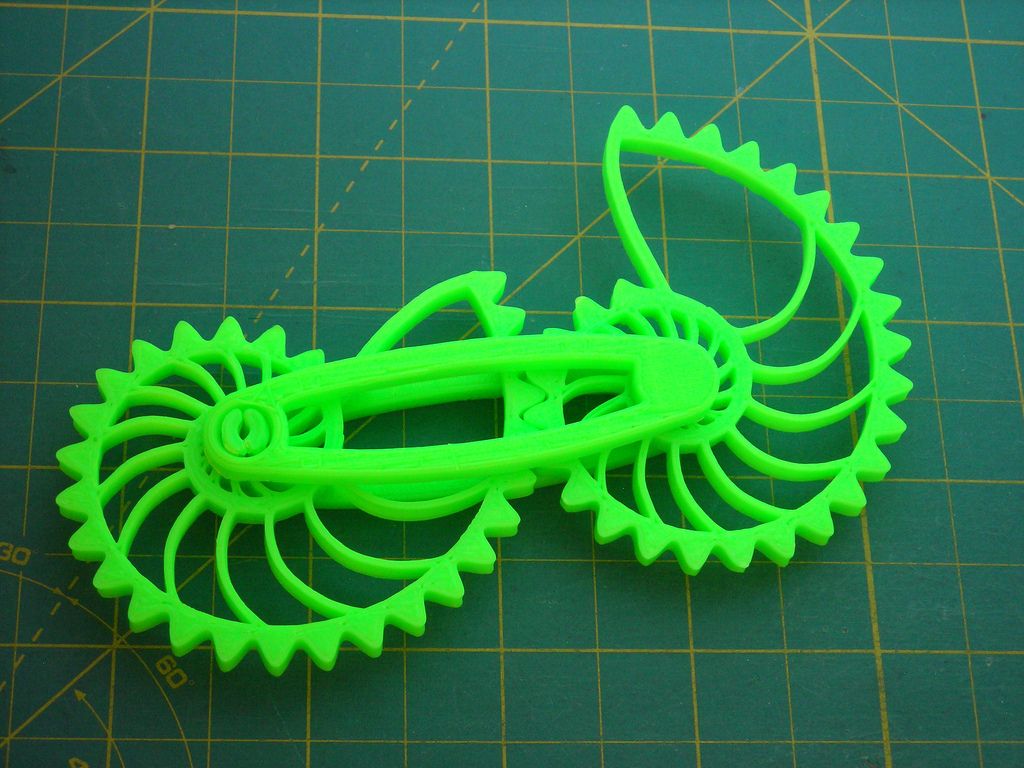

Worm Drive Gears

thingiverse

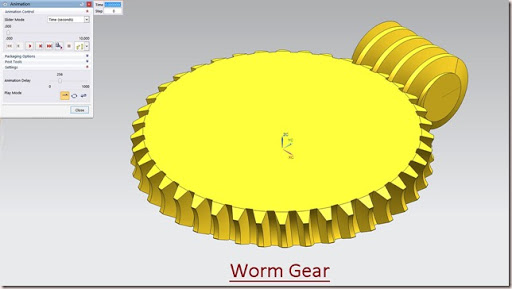

30 to 1 worm drive reduction gears. 3 parts. Could be used in a clock in addition with a 2 to 1 reduction due to ratio. The worm wheel is helical. ...https://youtu.be/VE7kmcveCOQ Print Settings Supports: Yes How I Designed. ..

ARISTOCRAFT WORM DRIVE GEAR Working

thingiverse

This object was made in Tinkercad. ...Edit it online https://www.tinkercad.com/things/3Ij36i6h5Yr

Modified Base for Worm Drive Gears Redux

thingiverse

When I printed dnewman's Worm Drive Gears Redux, the claws on the base snapped immediately when I tried to insert the screw crank. To remedy this issue, I filled the gap at the base of the claws to eliminate this weak point. I also filled the...

10:1 Worm Drive and Gear

thingiverse

I hope you like this worm gear. ...After hours of trial and error with Autodesk 123D Design, I think I got it right.

...After hours of trial and error with Autodesk 123D Design, I think I got it right.

Model of a worm drive gearing

thingiverse

A printable model of the two main components of a worm drive. With a little stand indicating the gear ratio. For the best results, the worm shaft is printed in halves and then glued together. ...

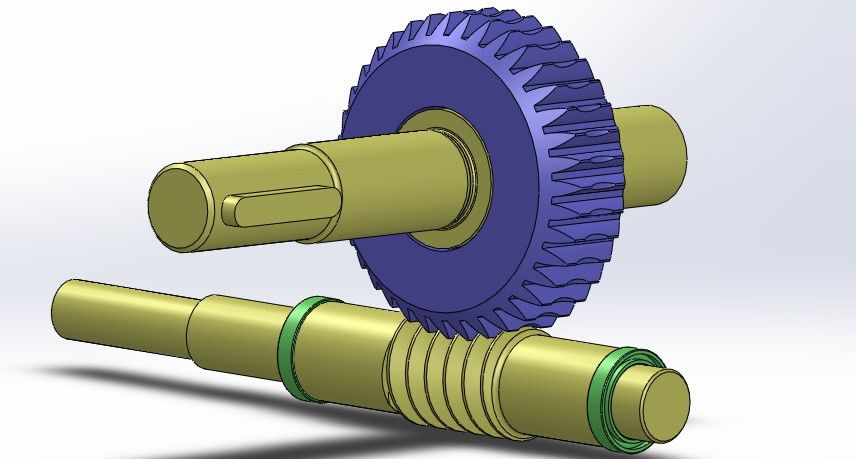

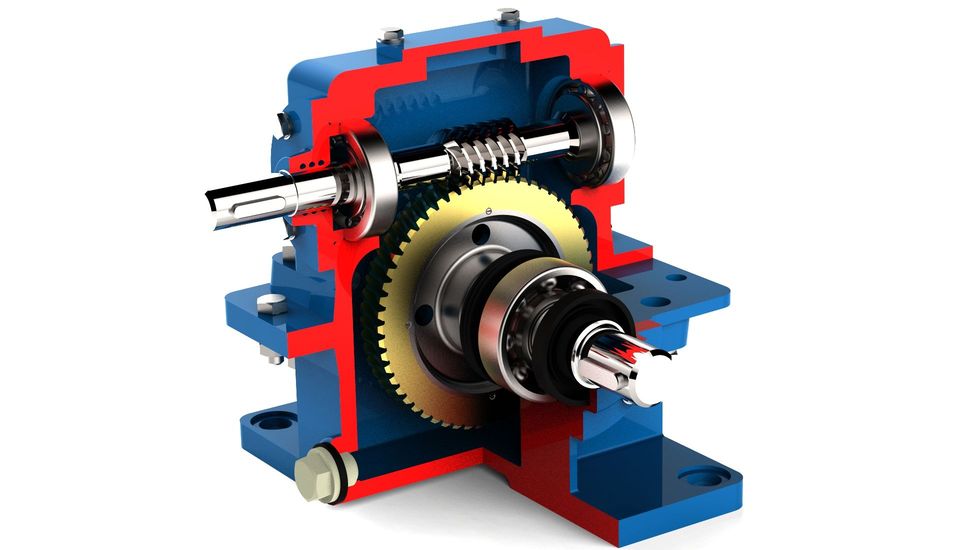

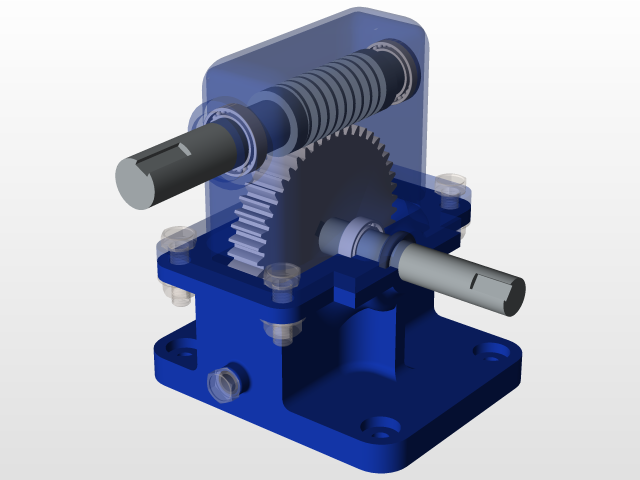

Worm Gear drive Arrangement

grabcad

Worm drive gear arrangement in which a worm meshes with a worm gear. ...Mainly used for gear reduction between non parallel and non intersecting shafts

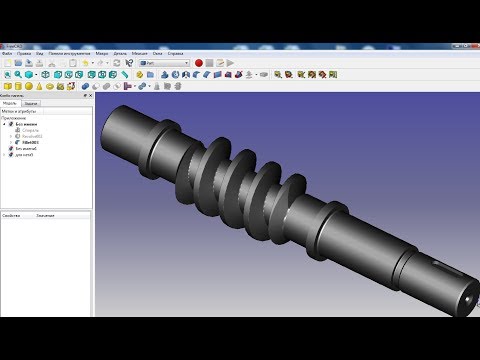

Worm gear drive

grabcad

A worm gear drive I did for my solid modeling class

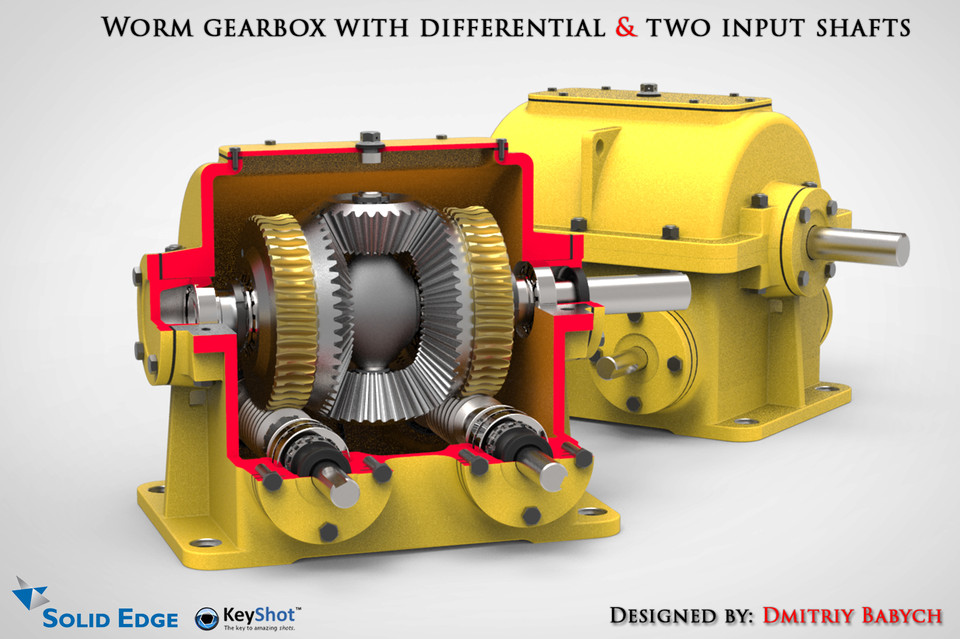

Worm Gear Drive

grabcad

A worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm gear (which is similar in appearance to a spur gear, and is also called a worm wheel). The terminology is often confused by imprecise use...

The terminology is often confused by imprecise use...

Worm_Gear_Drive

grabcad

Worm gear drive with electrical motor that I made based on customer product. ... Done in Creo.The gears are:Worm gear is from KHK-USA (KWGDLS2-R1)Wheel gear is from KHK-USA (AGDLM)https://www.khkgears.us/Electric motor is from Bodine-Electric...

Several Worm gear drives

grabcad

I see you like my drives

Conveyor drive with worm gear

grabcad

Concept conveyor drive with worm gear. ...In the composition of this model is Worm gear a sectional

...In the composition of this model is Worm gear a sectional

Worm gear drive 3d solidworks model

grabcad

Worm gear drive 3d SolidWorks model

Globoid Worm Gear Drive 3D print model

cgtrader

... x 7mm(height) bearing and a few 3mm screws for filament winding machine. Product includes: Worm gear drive STL files (for 3D printing) Worm gear drive 3DS files (for 3D graphics packages) Worm gear drive OBJ files (for 3D graphics packages)

Tank Track, Worm Gear Drive Cases

thingiverse

This is a left and right side Worm Gear Drive Cases and Covers for a Kyosho RFW002/RF006 High Speed Worm Gear Set, out of a Rock Force Kyosho Crawler. The Kyosho gear has a shaft Diameter of 6mm (.235"). 6mm shafting is available from ServoCity. You...

The Kyosho gear has a shaft Diameter of 6mm (.235"). 6mm shafting is available from ServoCity. You...

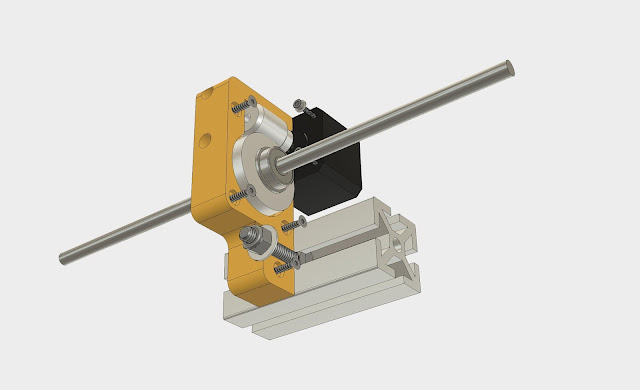

OpenPnp SMT Feeder Worm Gear Drive Test

youmagine

https://www.youtube.com/jtronicsTV?sub_confirmation=1 jtronics DIY 3D printed - SMT Feeder gear drive Test 1 For our new pick and place machine, we decided, to redesign the automatic SMD strip feeder. To get the optimal design, we tried different...

Spider Rover Dual Worm Gear Drive

thingiverse

Remix of http://www.thingiverse.com/thing:468872 Added a second worm gear and modified motor mounts for a Pololu micro gearmotor.

Fastmike Heng Long Worm Gear Drive

thingiverse

It can only be used with the "Fastmike HL Worm Gear Drive Set" that are available on eBay. The gear sets are manufactured from solid stainless steel stock with very close tolerances for the bearings. Gear set comes with aluminum spur gears that match...

Worm gear drive

grabcad

Sorry, I skipped the main innards

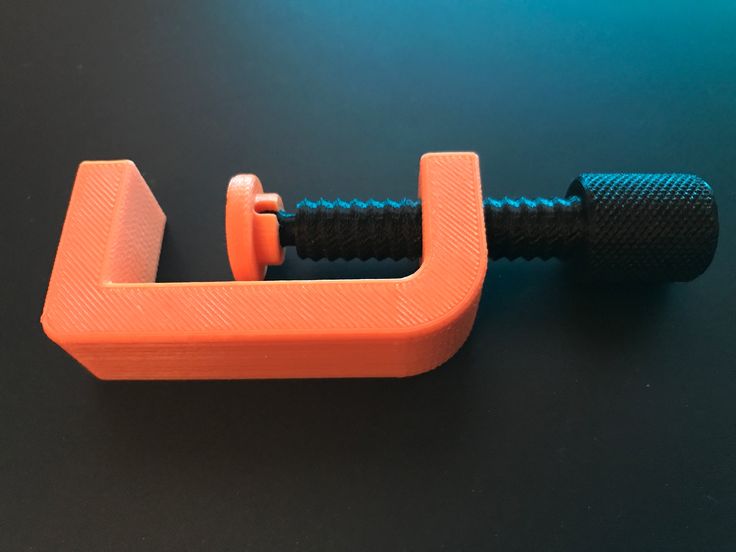

Worm Gear, CD-Drive-Motor Speed Reducer

thingiverse

Add-ons : [linear drive conversion](https://www. thingiverse.com/thing:3107269) The things you will need aditionally, 1 motor from a CD drive (or something similar) 1 fitting powersupply (3-12V works just fine) something to lock the gears in place i...

thingiverse.com/thing:3107269) The things you will need aditionally, 1 motor from a CD drive (or something similar) 1 fitting powersupply (3-12V works just fine) something to lock the gears in place i...

3D Printed OpenPnp SMT Feeder Worm Gear Drive Test

pinshape

jtronics DIY 3D printed - SMT Feeder gear drive Test 1 For our new pick and place machine, we decided, to redesign the automatic SMD strip feeder. To get the optimal design, we tried different gear stages. The goal is, to reduce the speed of the...

3D Printed OpenPnp SMT Feeder Worm Gear Drive Test

cults3d

jtronics DIY 3D printed - SMT Feeder gear drive Test 1https://youtu. be/RB-CNdZ2wQc For our new pick and place machine, we decided, to redesign the automatic SMD strip feeder. To get the optimal design, we tried different gear stages. The goal is, to...

be/RB-CNdZ2wQc For our new pick and place machine, we decided, to redesign the automatic SMD strip feeder. To get the optimal design, we tried different gear stages. The goal is, to...

Electric drive conveyor with worm gear

grabcad

Electric drive conveyor with worm gear IGUS RL D-30-A0207

24V DC Slew Drive (Worm Gear)

grabcad

Products for the cable car, truck, forestry machinery, cranes and other construction machinery. ... http://www.h-fang.com.cn/products_detail/&productId=f5b6de9a-fb72-49a4-9945-98d0a8fbaccf.html

Conveyor drive with worm gear Free 3D model

cgtrader

Conveyor drive with worm gear

Worm Gear with CD-Drive-Motor to linear drive converter

thingiverse

in addition to the already existing [Worm Gear](https://www. thingiverse.com/thing:3096842) Now you can use it as a linear drive for whatever reason. Chose whatever you want the glue on version if you have already printed the worm gear. But as a...

thingiverse.com/thing:3096842) Now you can use it as a linear drive for whatever reason. Chose whatever you want the glue on version if you have already printed the worm gear. But as a...

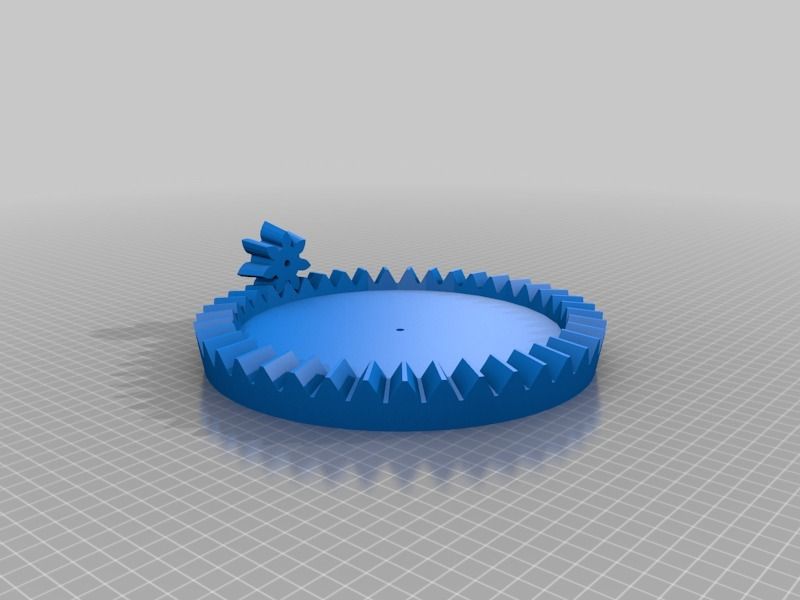

globoid worm gear drive - parametric OpenSCAD code with large ratio range

thingiverse

###Globoid worm gear drives (code expects [OpenSCAD 2018.1.6 and later](http://www.openscad.org/downloads.html#snapshots)) [meanwhile I have published a [version 2.0](https://www.thingiverse.com/thing:4197625) of this thing] Globoid worm gear drives...

Linear Actuator Worm Gear Costumized for Direct Drive

thingiverse

http://www. thingiverse.com/apps/customizer/run?thing_id=51452 Instructions Using the following options: num_teeth = 50 flange_diam = 40 slop = 0.05 ball_diam = 3.175 ball_screw_OD = 16.5862 shrink = 0.08 flange_thickness = 7 flange = 1...

thingiverse.com/apps/customizer/run?thing_id=51452 Instructions Using the following options: num_teeth = 50 flange_diam = 40 slop = 0.05 ball_diam = 3.175 ball_screw_OD = 16.5862 shrink = 0.08 flange_thickness = 7 flange = 1...

3D Printed OpenPnp SMT Feeder Worm involute sprocket Gear Drive Test

thingiverse

jtronics DIY 3D printed - SMT Feeder involute sprocket gear drive Test 1 For our new pick and place machine, we decided, to redesign the automatic SMD strip feeder. To get the optimal design, we tried different gear stages. The goal is, to reduce...

DC worm gear motor for hydraulic pump drive

grabcad

DC worm gear motor for hydraulic pump drive ERGOSWISS

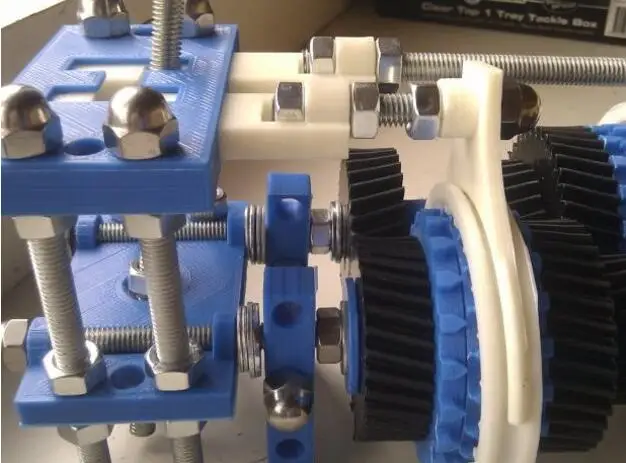

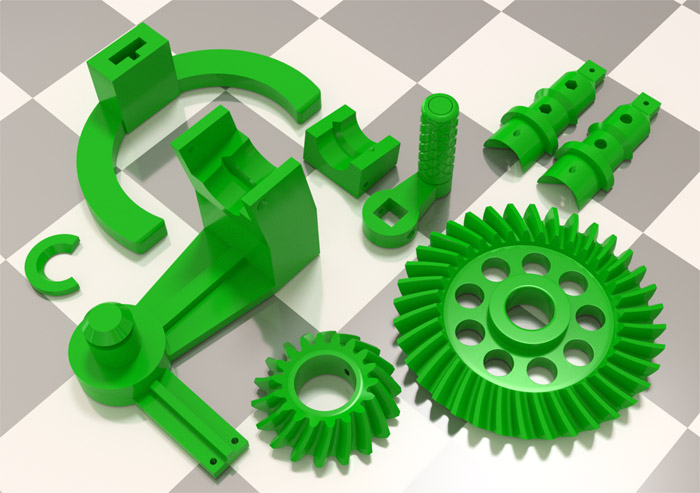

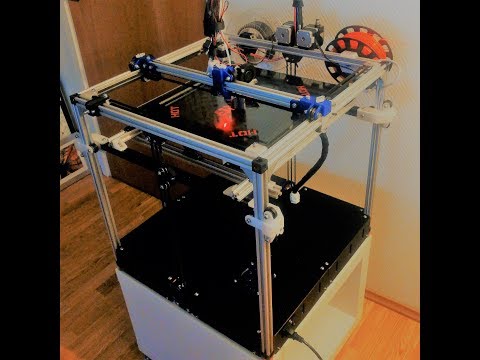

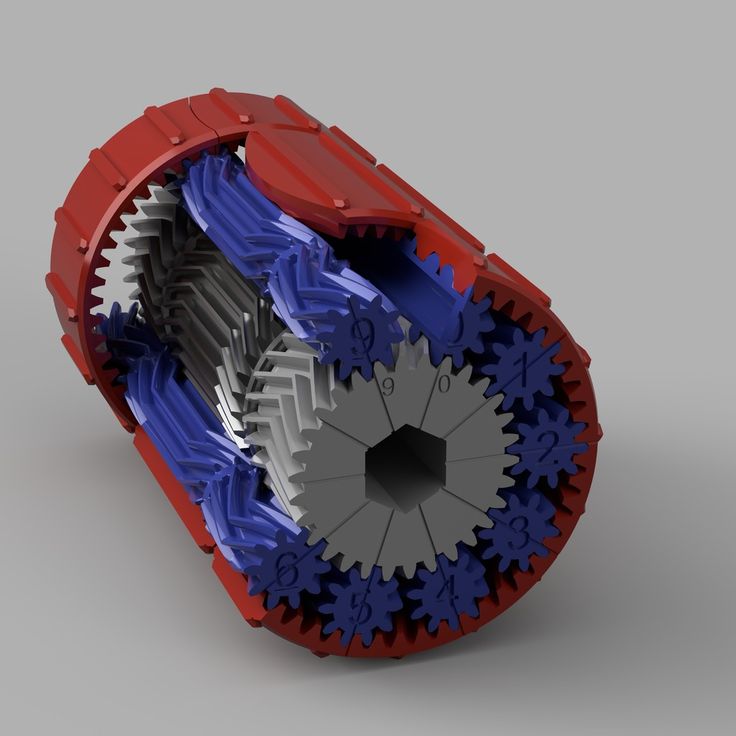

3D printed high torque gearbox - An electric hoist

The gearbox uses a 775 12V 13000 RPM (100 Watt) brushed DC-motor which it has 0. 074 Nm torque and 13000 rpm. This 3d printed gearbox had a gear ratio of 98:1. So the torque on the output shaft became 7.4 Nm or 75 kg*cm and the speed of the output shaft was about 132RPM with this gearbox. (in theory)

074 Nm torque and 13000 rpm. This 3d printed gearbox had a gear ratio of 98:1. So the torque on the output shaft became 7.4 Nm or 75 kg*cm and the speed of the output shaft was about 132RPM with this gearbox. (in theory)

The output shaft is 20 mm in diameter and thus the maximum force the gearbox can lift is 737 newtons. (75.1 kg) Since the friction of the rope would be high, I assumed a 10% loss. but this is only valid when a rope is used. If we use the torque lever on the side, there will be no such loss.

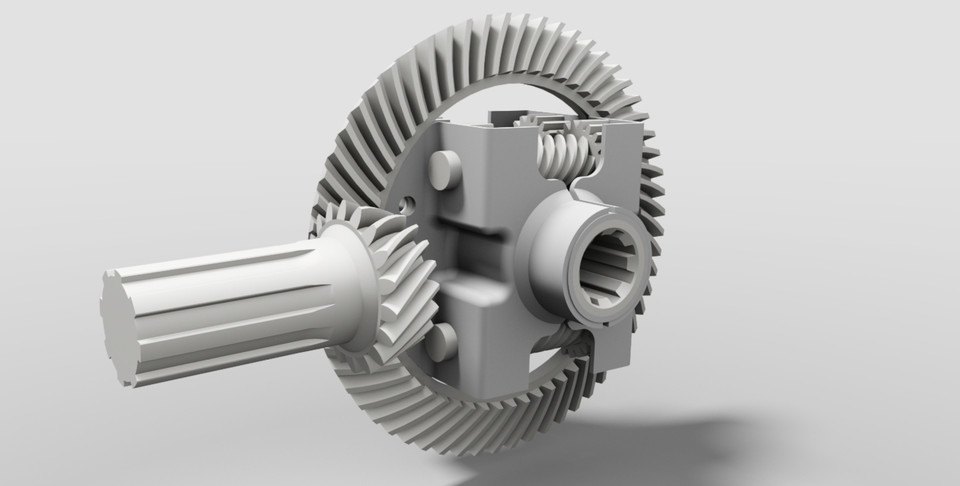

The gear ratio in the first stage is 2.61. There is also a worm gear on the same shaft. The gear ratio in the 2nd stage is 40. The shaft I use here M8 threaded rod. I used 608zz roller bearing for bearing the shaft. Output shaft has a 20 mm diameter and I used 2x6004(ORS) roller bearing to support.I used PLA....

Details

I made this 3d printed high torque worm gearbox. It called also winch, hoist or crane. The gearbox uses a 775 12V 13000 RPM (100 Watt) brushed DC-motor which it has 0. 074 Nm torque and 13000 rpm. This 3d printed gearbox had a gear ratio of 98:1. So the torque on the output shaft became 7.4 Nm or 75 kg*cm and the speed of the output shaft was about 132RPM with this gearbox. (in theory) I used PLA+ in all parts.

074 Nm torque and 13000 rpm. This 3d printed gearbox had a gear ratio of 98:1. So the torque on the output shaft became 7.4 Nm or 75 kg*cm and the speed of the output shaft was about 132RPM with this gearbox. (in theory) I used PLA+ in all parts.

The output shaft is 20 mm in diameter and thus the maximum force the gearbox can lift is 737 newtons. (75.1 kg) Since the friction of the rope would be high, I assumed a 10% loss. but this is only valid when a rope is used. If we use the torque lever on the side, there will be no such loss I choose to go for helical gears on this one because they produce a lot less noice than regular spur gears and the forces on the teeth are transferred more gradually. The helical gears I used have a 1 mm module and a 23 degrees helix angle. I chose a low helix angle to avoid too much axial force. The pinion gear on the motor is 13 teeth and the counter gear is 34 teeth. Thus theoretically the gear ratio in the first stage is 2.61. There is also a worm gear on the same shaft. I fixed the gears here on the shaft with a cotter pin. The shaft I use here M8 threaded rod. I used 608zz roller bearing for bearing the shaft. At the same time, high axial force will occur on this shaft due to the worm gear. I fixed this shaft with 1, 2 or 3 mm spacers. I used whichever fit. The worm gear I used in this project has 40 teeth. So the gear ratio in the worm gear mechanism is 40. Here there is a really high torque increase in one stage.Output shaft has a 20 mm diameter and I used 2x6004(ORS) roller bearing to support this output shaft.I was able to test the gearbox to a torque of about 43 kg*cm.During testing none of the gears broke, they were all printed in PLA. The weak link in this design the helicel pinion gear (red one) used in the first stage on the motor shaft. This gear tend to slip under high loads, while lowering the load but this didn't occur when i performed the test where it pulled 43kg*cm of torque so it should be fine to at least this torque rating.At the first car test, the gearbox could not fully pull the car because the road was bumpy.

I fixed the gears here on the shaft with a cotter pin. The shaft I use here M8 threaded rod. I used 608zz roller bearing for bearing the shaft. At the same time, high axial force will occur on this shaft due to the worm gear. I fixed this shaft with 1, 2 or 3 mm spacers. I used whichever fit. The worm gear I used in this project has 40 teeth. So the gear ratio in the worm gear mechanism is 40. Here there is a really high torque increase in one stage.Output shaft has a 20 mm diameter and I used 2x6004(ORS) roller bearing to support this output shaft.I was able to test the gearbox to a torque of about 43 kg*cm.During testing none of the gears broke, they were all printed in PLA. The weak link in this design the helicel pinion gear (red one) used in the first stage on the motor shaft. This gear tend to slip under high loads, while lowering the load but this didn't occur when i performed the test where it pulled 43kg*cm of torque so it should be fine to at least this torque rating.At the first car test, the gearbox could not fully pull the car because the road was bumpy. At the same time, the rope broke. Then I went home and I do not give up:) Because I knew the gearbox could pull the car. Theoretically this was possible and as you can see in the video…I do not recommend using it in the professional field. Because you can't trust to plastic parts!Regardless, it was a very entertaining project. By the way it would be great if you make the accent out of steel :D

At the same time, the rope broke. Then I went home and I do not give up:) Because I knew the gearbox could pull the car. Theoretically this was possible and as you can see in the video…I do not recommend using it in the professional field. Because you can't trust to plastic parts!Regardless, it was a very entertaining project. By the way it would be great if you make the accent out of steel :D

Below are all the parts I used in this project:

12V DC 775 Motor(100 Watt)

608zz bearing x3

6004 bearing x2

20 mm aluminium shaft

M8 threaded rod

Cotter pins

2x30—x4

3x50—x1

STL files for plastic parts: https://www.thingiverse.com/thing:4790867

Editable source files: https://www.cgtrader.com/3d-print-models/hobby-diy/mechanical-parts/3d-printed-high-torque-gearbox-worm-gearbox-electric-hoist

-

1

Step 1

View all instructions

Enjoy this project?

ShareSTL file Worm gear・3D printing template to download・Cults

The best files for 3D printers in the Tools category

Wasp Trap (redesigned!)

Free

Flexbot-quadcopter

Free

Cotton swab holder

€1.68 -12% 1. 48 €

48 €

Workbee CNC/Endurance Laser Adapter

Free

X-Acto knife holder for pegboard

Free

simple pocket caliper

free

Light vice

0.51 €

Bestsellers in the Tools category

Spartan pen holder

1,80 €

Ender 3 S1 Air duct for stock fan

1,20 €

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc.

1.77 €

Paint stand with scissors

5.25 €

Grinder | Grinder

€1.50

Quick print stackable parts containers / storage boxes

2. 91 €

91 €

ARTEMIS -> Shop for Alligator 2 || 6.5" arrows || Repeating crossbow

6.25 €

Phone holder

2.46 €

3D printed wave transmission (harmonic drive)

4.99 €

PET-Machine, make your own plastic bottle filament at home!

15 €

SUPERBOX

1,50 €

GEAR AND DRIVE

€9.50 -40% 5.70 €

209 Flash Bang / Ukrainian Hot Potato

0,95 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2,84 €

Fire hydrant storage container

1. 90 €

90 €

Cut-Man - PET bottle cutter with handle!

€3.49

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us in keeping the activity going and making future designs is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

An extremely long service life of worm transmissions with improved sliding properties

Test parameters:

- Point 4.

9NM

9NM - resistance: hard-anodized aluminum

- Duration: two months

Estimation

► POM (turning processing): Full failure through 621,000 cycles

► IGLIDUR I6 (laser sintering): Small wear and tear of

3D printed gears based on high quality iglidur polymers

► Predictable service life

► All geometries available: special shapes and interchangeable elements

► Improved tooth root geometry for longer service life

► Self-lubricating properties: dry operation thanks to solid lubricants

Service life up to 5 times longer than conventional polymer gears

Tried and tested: iglidur gears show significant longer service life compared to gears due to traditional polymers made by machining or injection molding.

Which material is best for which type of transmission?

- iglidur I3 is characterized by increased strength and is especially suitable for spur gears, as well as helical bevel gears, the material can be used for all other types of wear-resistant transmission mechanisms.

- iglidur I6 has improved sliding properties, making it ideal for worm gears or other gears requiring food grade requirements.

- iglidur I8-ESD suitable for the manufacture of gears that must have antistatic properties, e.g. for ATEX zones

Equipment of our customers with 3D printed gears

- 9021

Polymer gear for engine tuning

The Formula Student Team from Weingarten near Ravensburg was also looking for specially designed polymer gears for racing cars. Gears were used as chain tensioners as part of the chain drive, so they had to be especially strong. Unfortunately, the production of gears of non-standard sizes takes a lot of time, the classic production process on a metal-cutting machine is a time-consuming undertaking. igus® 3D printing service made it possible to deliver and test polymer gears in less than 72 hours. The material used was iglidur® I6, which has the special wear properties of - it retained its full functionality after 1 million cycles in the test lab, making it ideal for use in race car construction. In this case, the special components produced by additive manufacturing not only managed to be delivered to the customer in the shortest possible time, but they also turned out to be more durable and economical.

igus® 3D printing service made it possible to deliver and test polymer gears in less than 72 hours. The material used was iglidur® I6, which has the special wear properties of - it retained its full functionality after 1 million cycles in the test lab, making it ideal for use in race car construction. In this case, the special components produced by additive manufacturing not only managed to be delivered to the customer in the shortest possible time, but they also turned out to be more durable and economical.

3D printed race car gears

Layered Polymer Gears for Silent E-Bikes

Strong, wear-resistant, no relubrication required: polymer properties outperform metal

For e-bike construction, low weight and quiet operation are especially important for components.

" The standard metal gear makes a lot of noise during operation. We removed it and gave it to igus® for 3D printing using iglidur I3 material. Everything was simple and fast. We used the 3D printing service, downloaded the appropriate

Everything was simple and fast. We used the 3D printing service, downloaded the appropriate

3D printed chain sprocket for electric bicycle

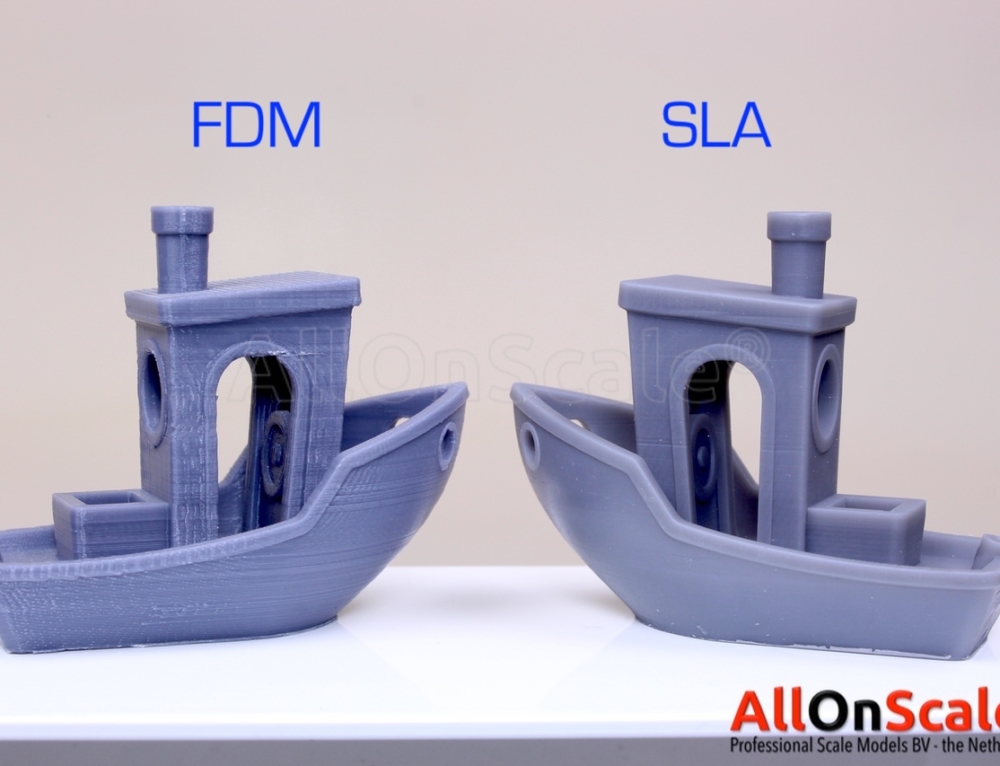

3D printed resin gears for prototyping

iglidur® I6 gear train for electric vehicle charging system

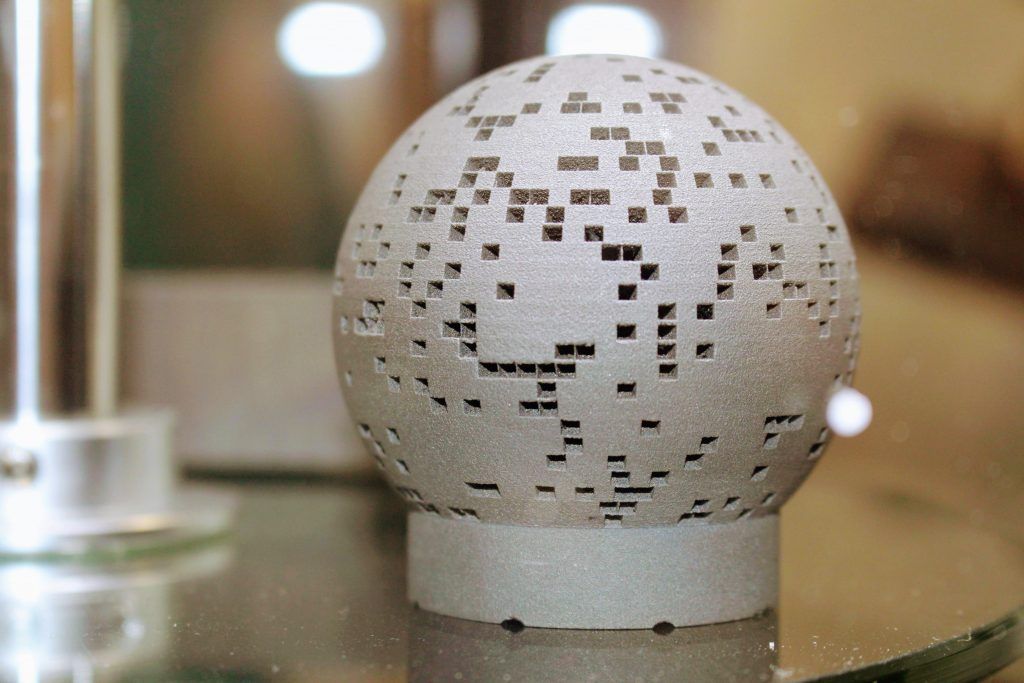

Easelink, a Graz-based company, has developed "Matrix Charging", a charging system that automatically connects to the underside of an electric vehicle to charge it while parked. To develop an economical and high-quality system, the designers chose prototype gears made from iglidur® polymers using additive manufacturing technology. The igus® 3D printing service ensured fast delivery, testing and development of simple elements until the perfect result. iglidur® I6, a particularly wear-resistant and lubrication-free laser sintered powder material, is ideal for the construction of gears, shafts and other heavily loaded components that typically require regular lubrication and maintenance as well as frequent replacements.

Rapid gear prototyping with laser sintering technology

Previous NextWear test for 3D printed products

iglidur polymers are more wear resistant than PLA, ABS and other materials and manufacturing processes

Comparison of 3D printing resins

Why 3D printing at igus?

More information about

- Our materials

- additive manufacturing

- Services and support

3D printing information

3D printing news

Industrial 3D printing innovations. New products and services for additive manufacturing based on wear-resistant polymers.

Overview of our innovations

FAQ: Q&A

iglidur 3D printed worm gears

What is iglidur I6 and why is it a great material for worm gear design?

iglidur I6 is a laser sintered material specially developed for the production of worm gears. In addition to the common advantages of all iglidur polymers, such as wear resistance and no need for lubrication, iglidur I6 has special sliding properties that increase the functionality of the worm gear. The idea of developing such a material came from the design engineers who created our robolink robotic arm. In tests, worm gears made from iglidur I6 have repeatedly proven to be more wear resistant than other 3D printed polymer worm gears. Polymer worm gears are suitable for industrial applications only if they are made from high quality polymer. Early tests with PLA and ABS materials failed because the high coefficient of friction caused components to wear relatively quickly. It is for this reason that designers began to develop new polymers with the required properties. Special versions are available for high temperature or food processing applications. Wear tests on these materials confirm that they exhibit a high degree of wear resistance. The characteristics of the iglidur I6 material can be found here.

In addition to the common advantages of all iglidur polymers, such as wear resistance and no need for lubrication, iglidur I6 has special sliding properties that increase the functionality of the worm gear. The idea of developing such a material came from the design engineers who created our robolink robotic arm. In tests, worm gears made from iglidur I6 have repeatedly proven to be more wear resistant than other 3D printed polymer worm gears. Polymer worm gears are suitable for industrial applications only if they are made from high quality polymer. Early tests with PLA and ABS materials failed because the high coefficient of friction caused components to wear relatively quickly. It is for this reason that designers began to develop new polymers with the required properties. Special versions are available for high temperature or food processing applications. Wear tests on these materials confirm that they exhibit a high degree of wear resistance. The characteristics of the iglidur I6 material can be found here.

Advantages of worm gears made by 3D printer

The most important advantages are wear resistance properties, impact strength, internal elasticity to reduce surface pressure, exceptional impact strength, automatic lubrication properties, corrosion resistance, quiet operation, no need for maintenance, as well as good properties for emergency operation. The most important criterion for the use of a polymer. Special materials have excellent wear resistance and hardness; high precision, detailed surface treatment; and extremely long service life, which also characterizes the work of worm gears made from them.

Advantages of polymer worm gears over metal counterparts

In principle, polymer gears are designed to run without additional lubrication, so worm gears made from iglidur on the printer run without lubrication. The user benefits greatly as downtime and maintenance costs are greatly reduced when high quality polymer worm gears are used. The 3D printer manufacturing method provides design engineers with a more flexible approach than turning and milling metal or polymers. Worm gear geometry can be perfected first and compromises deferred until later. The improved geometry means it takes more time to design polymer worm gears than milled gears. Surface pressure and wear properties are significantly reduced due to large contact areas.

The 3D printer manufacturing method provides design engineers with a more flexible approach than turning and milling metal or polymers. Worm gear geometry can be perfected first and compromises deferred until later. The improved geometry means it takes more time to design polymer worm gears than milled gears. Surface pressure and wear properties are significantly reduced due to large contact areas.

Which equipment is best suited for metal gears?

Usually a worm wheel is used at the outlet of the gearbox. Traditionally, it is made of a copper-tin alloy. This material has excellent properties in dry conditions when interacting with steel components. This is an important argument in favor of the use of metal worm gears in conditions where a large amount of heat is generated or high torque is transmitted. Worm gears made of metal are also often part of the cooling and lubrication circuits. In many cases, the worm is made from hardened steel and is used in conjunction with a worm gear made from a softer metal such as brass or bronze. However, self-lubricating polymers for the manufacture of worm wheels are increasingly being used.

However, self-lubricating polymers for the manufacture of worm wheels are increasingly being used.

Worm wheel or worm gear design requirements

The design of the worm gear and worm gear requires a very precise unification of the tooth profile geometry. This is necessary to transmit the specified torques, as well as to ensure wear resistance and abrasion resistance of the tooth profile. Simple and cost-effective technologies for the production of piece products and small batches of products are important if the found design solution is to be transferred to a computer and 3D printing systems, which makes them commercially attractive.

Worm Gear Material Combination

Hard anodized aluminum gear worms are particularly suitable for heavy duty applications. However, the corresponding gear worms, which are 3D printed by igus in iglidur I3, are strong enough for normal loads, as the material is highly resistant. Another significant advantage is also the absence of restrictions on the design of forms, since even complex and rare forms of the worm mechanism, such as globoid screws, can be made on a 3D printer, and quickly and inexpensively.

Another significant advantage is also the absence of restrictions on the design of forms, since even complex and rare forms of the worm mechanism, such as globoid screws, can be made on a 3D printer, and quickly and inexpensively.

What is a worm gear?

The worm gear is the counterpart to the worm in the worm gear. Since the sliding properties are especially important for worm gears, they are usually made of bronze. 3D printing worm gears from high-quality polymers costs many times less and, importantly, is faster, and at the same time has comparable characteristics.

What is a worm gear?

Worm gears are used where reliable, precise and quiet gearbox operation is required. Quiet and durable operation is of particular importance. Worm gears can be used to realize axial movement between the drive and the power take-off. On a small area, a significant force is transformed. Therefore, the main applications for worm gears are conveyor systems, robotics, profile processing, separators, extruders, mining machines and rowing machines.