Corexy 3d printer advantages

What is a CoreXY 3D Printer? Find the Advantages & Disadvantages (2022)

What is a CoreXY 3D printer and how does it work? What are the advantages and drawbacks of the 3D printer? Read on to find out.

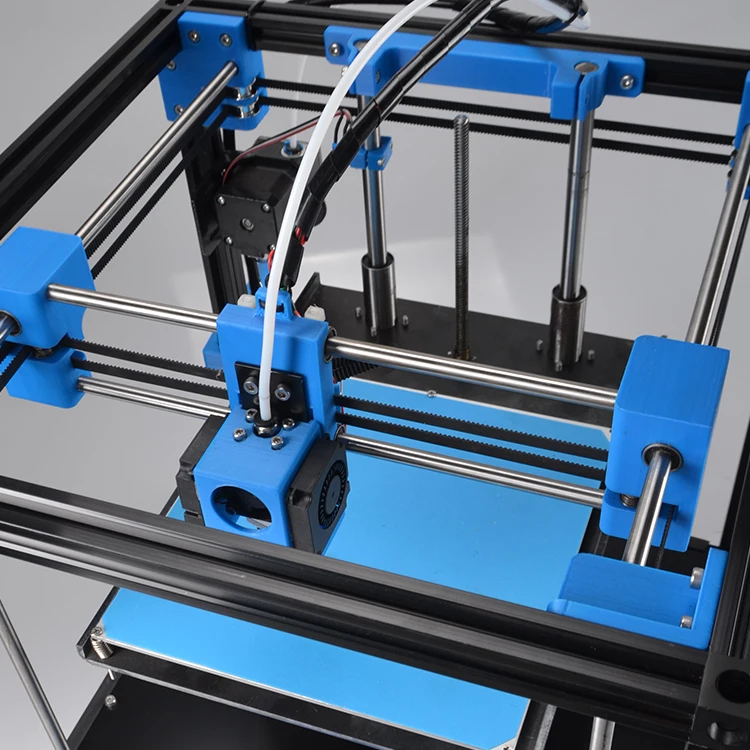

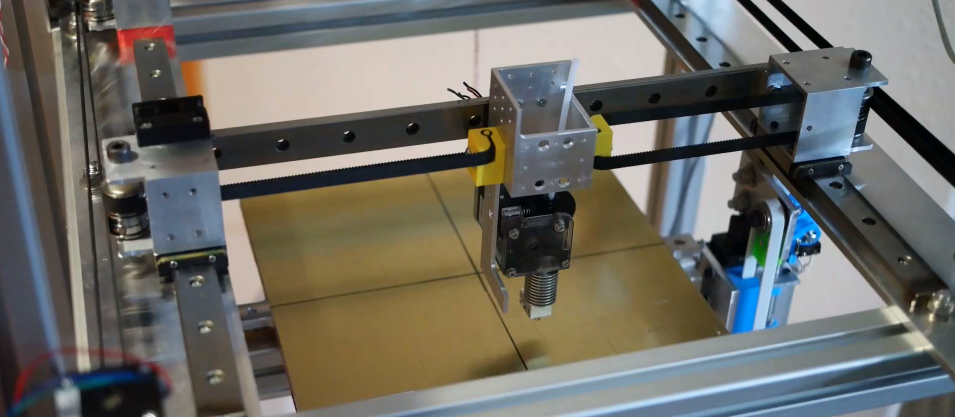

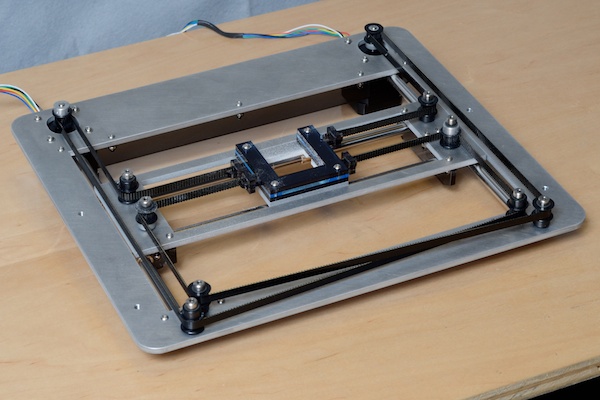

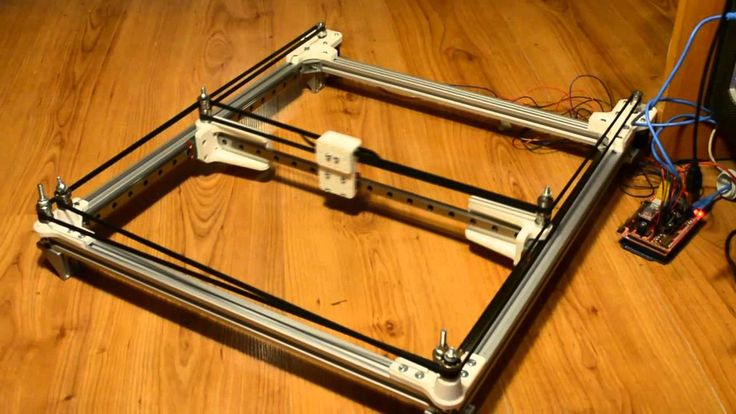

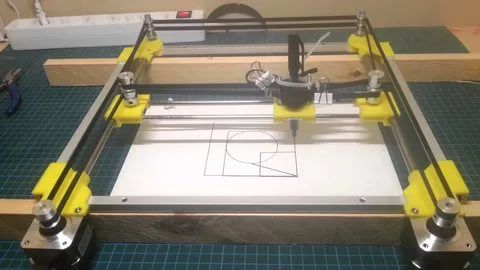

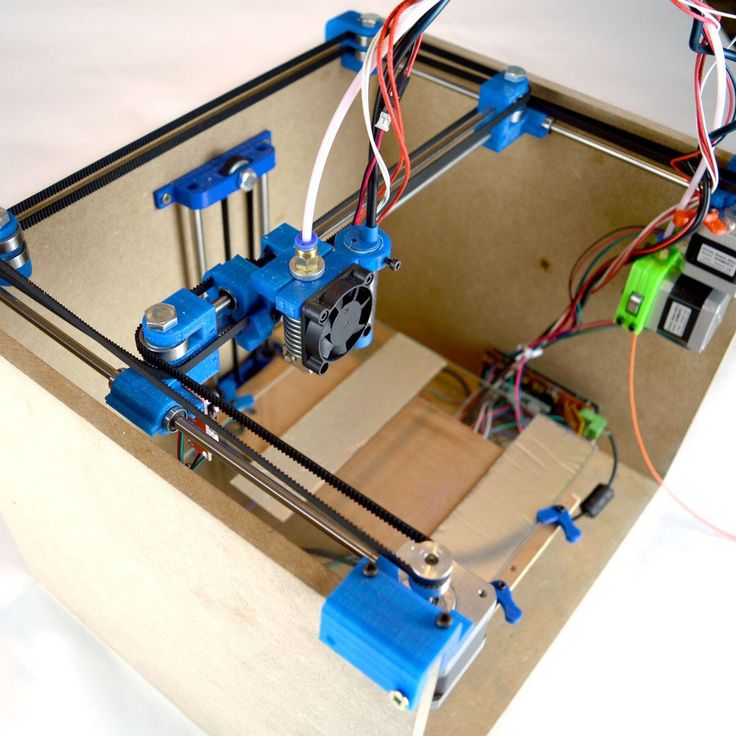

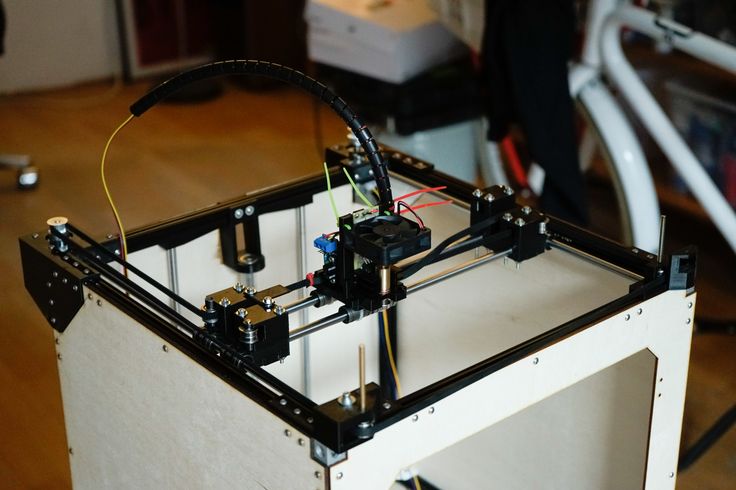

In a CoreXY 3D printer, the print head moves on the X and Y axes while the print bed only moves on the Z-axis. The printer has a longer belt and pulley system that reduces excess torque, which is responsible for faster wearing of the belts and gantry.

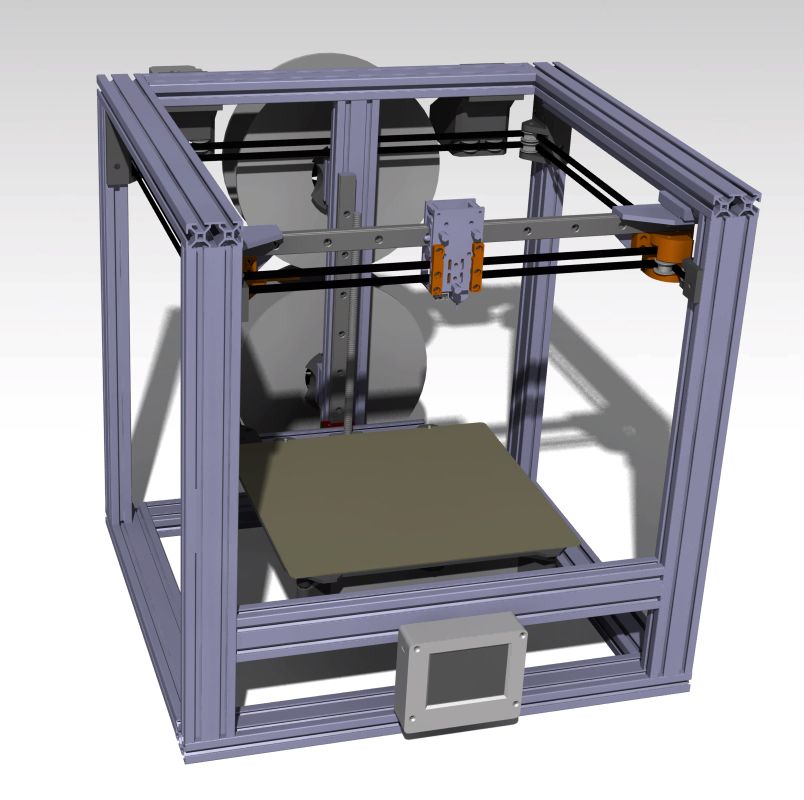

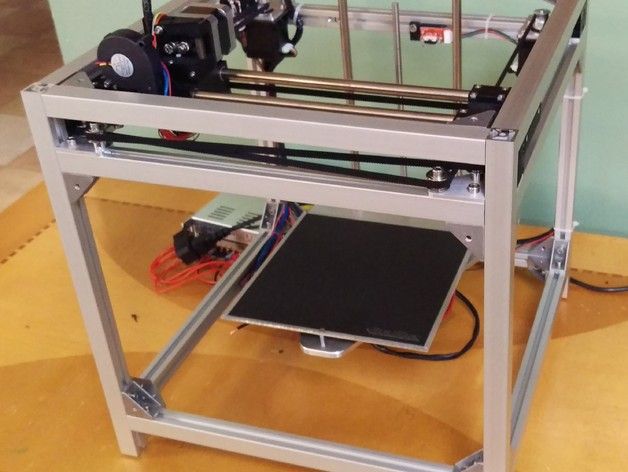

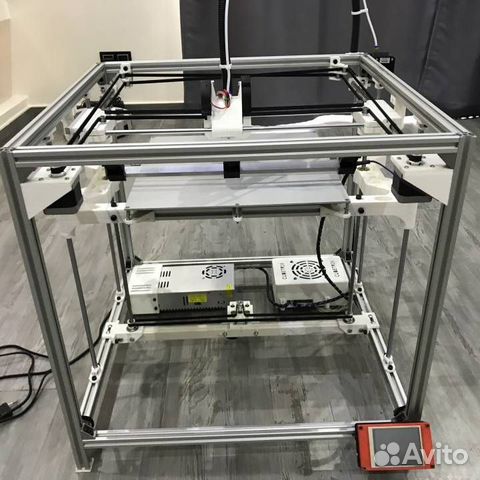

Generally, CoreXY printers are cube-shaped and feature on open design. However, some high-end models come with an enclosure.

The printer has two timing belts, each connected to a stepper motor, that move the print head. The print head moves in different directions, depending on whether the motors are spinning clockwise or anticlockwise. When only one stepper motor is activated, the print head will move diagonally.

The ways the axes move and the design of the frame give CoreXY 3D printers various advantages over their counterparts. However, there are also some drawbacks you should be aware of.

In this Guide

Advantages of CoreXY 3D Printers

Faster Print Speeds

CoreXY 3D printers generally print faster without leaving residues that can affect your model. The fast print speed is realized since there are no moving parts of the significant mass.

Other 3D printers typically have a moving gantry attached to the print bed or stepper motors. During the printing process, the gantry is moved back and forth, and this causes the printer to vibrate and consequently, the models end up with residue.

With CoreXY 3D printers, the print bed moves vertically while all the stepper motors are fixed. Therefore, the only part that will be moving during the printing process is the toolhead. Since it’s only the toolhead moving, the printer does not vibrate a lot unlike is the case with printers that have a moving gantry.

With the printer remaining fairly stable during the printing process, you can expect to have fewer quality problems usually experienced during 3D printing, for example, rigging and ghosting.

Compact Build

With CoreXY 3D printers, the printbed moves vertically. As a result, the printers offer the same build volume as their comparable FDM printers while having smaller dimensions. The same feature is similar to what H-bot 3D printers have.

On i3 Prusa design printers, the base needs to be around double the size of the build volume to allow the bed to move back and forth without any problems and enable the toolhead to access the whole build area. This build design makes the printers to be longer than they are wider. The longer 3D printers may pose a challenge when you want to work on some workbenches.

Overall, the CoreXY 3D printer is smaller compared to the i3 style and FDM 3D printers.

Drawbacks of CoreXY 3D Printers

Belt Problems

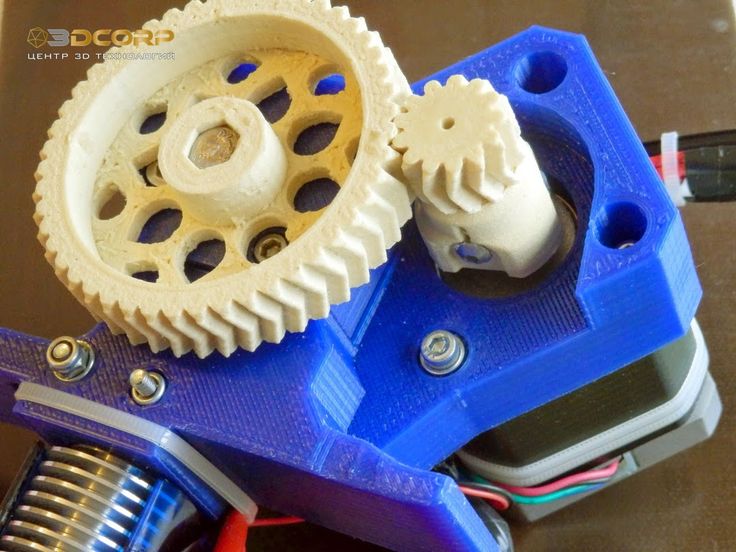

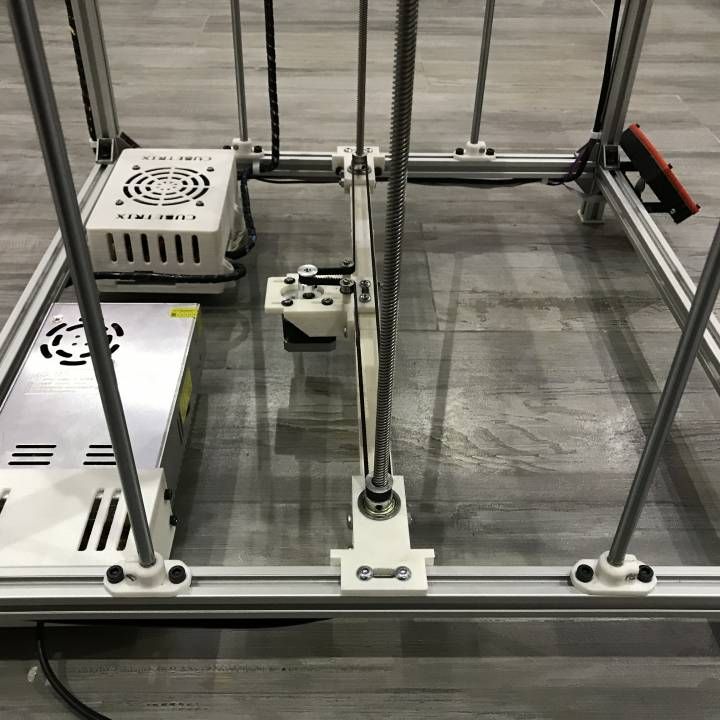

The biggest drawback of CoreXY 3D printers is that their belts can be problematic if their tension is not set up correctly. The belts are core to the working of the printer. However, their tension should be set to be just right, i. e., not too high, nor too low.

e., not too high, nor too low.

When the belts are not properly tensions, they can wear faster, and this will reduce the accuracy of the printer. In some cases, the improperly tensioned belts can cause malfunctions, such as binding printer components, which will lead to poor quality prints.

Given how important the belts are, the printers need good quality belts that will not stretch or wear out quickly.

Frame Design

The frame of the CoreXY 3D printer system is stable. However, if the frame is not assembled to be perfectly square, you can end up with accuracy problems.

To solve this issue, have a set square on hand while assembling the printer. You can also add corner brackets to ensure that the frame stays square over time.

Should You Buy a CoreXY 3D Printer?

So, does it make sense to buy a CoreXY 3D printer? The answer is Yes!

The benefits of the CoreXY design are hard to ignore. This may explain why professional FDM 3D printers follow the CoreXY 3D printer design.

Also, CoreXY 3D printers tend to be compact and easier to assemble than other 3D printer systems. When you get the assemble and belt tension right, you can be sure of high-quality prints.

Are CoreXY 3D Printers Taking Over? « Fabbaloo

By Kerry Stevenson on March 9th, 2020 in learning

Tags: _temp, cartesian, concepts, corexy, mechanical, motion

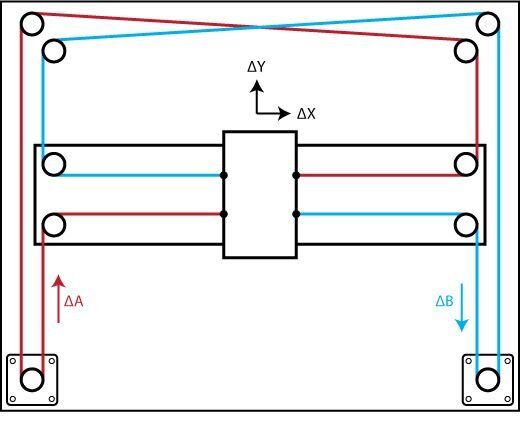

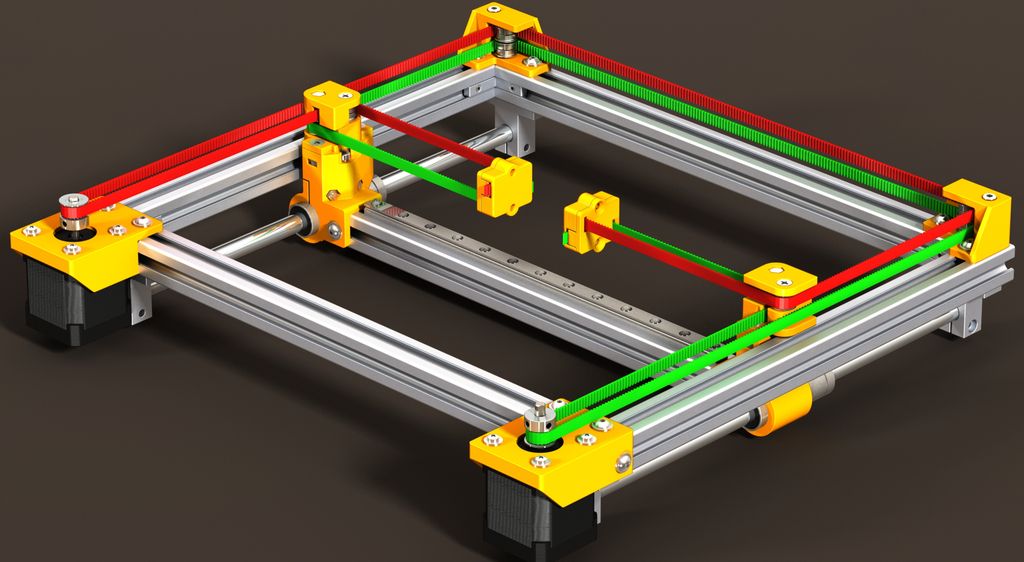

CoreXY 3D printer motion system reference diagram [Source: CoreXY.com]3D printers using the CoreXY system are increasing in number, but is this the ultimate motion system?

FFF 3D printers have several key elements:

For each of these major components there are multiple options. In the case of extruders, there are the Direct or Bowden styles, for example. Hot ends are similar, with multiple designs, and print surfaces are similarly varied.

Motion systems for 3D printers are equally diverse, with the most common being a Cartesian approach where a single motor is dedicated to each of the three axes. These motors work independently to move the hot end to where it’s supposed to be.

These motors work independently to move the hot end to where it’s supposed to be.

There are several alternative motion system designs, with perhaps the most notable — and different — being the delta robot approach. In this design there is no XYZ Cartesian geometry, but instead there is a cylindrical build volume. In a delta system, the three stepper motors used in the motion system work simultaneously to effect movement, whereas a standard Cartesian system has the motors working independently on each axis.

Another common approach is that used most notably by Ultimaker, in which two rigid axes cross the build plane and support the hot end. This approach, like the delta style, has the advantage that the print surface is not moving as is the case in some Cartesian motion system variants, such as that used on the Prusa i3 line.

More recently there has been interest in an approach known as “CoreXY”.

This is an unusual system that is quite different in that it uses two stepper motors simultaneously to effect XY motion. This is similar to the delta approach, but in a CoreXY system, the Z-axis operates independently.

This is similar to the delta approach, but in a CoreXY system, the Z-axis operates independently.

How is this done?

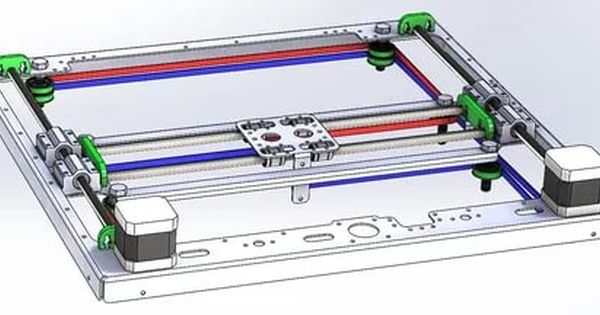

A CoreXY system uses a complex system of two long drive belts that wind their way around through a series of idlers to connect both motors to both sides of the hot end. It’s strange because if you pull on one belt manually, the toolhead moves at a 45 degree angle, not zero or ninety degrees as would be the case for a standard Cartesian system.

There’s also a variant of the CoreXY approach called “H-BOT” in which only one belt is used.

The CoreXY design is more complex, so no one would use it unless there were advantages, and it turns out there is a major benefit.

Because the XY motors are attached to the belts on the side of the frame, they are not part of the moving portion of the toolhead. This means that the weight that must be moved by the system is quite a bit lighter.

The advantage is that there is less momentum when the motion system must abruptly change direction. In other words, it’s easier for a CoreXY system to make movement changes, which happen very frequently in a 3D print. In terms of print quality, this means effects such as “ringing”, a series of echo-like surface disturbances, tend to go away, as they are caused by an inability of the motion system to completely overcome the momentum of a heavy motor-laden toolhead.

In other words, it’s easier for a CoreXY system to make movement changes, which happen very frequently in a 3D print. In terms of print quality, this means effects such as “ringing”, a series of echo-like surface disturbances, tend to go away, as they are caused by an inability of the motion system to completely overcome the momentum of a heavy motor-laden toolhead.

Of course, there are some disadvantages to the CoreXY approach, and they center around the belt system.

The CoreXY belt system is necessarily much longer than a standard Cartesian system’s belts. Long belts are more subject to loosening, as a slight stretch is amplified by the longer length. Often this means the belts must be made tighter, and that’s perhaps more maintenance work to do.

The frame on which the CoreXY motion system is mounted must be quite rigid, otherwise the movements will be inaccurate. Thus a good CoreXY system should be made with a rigid metal frame and strong idlers to withstand the belt tightness.

Another disadvantage is the complexity of the calculations needed to effect the motion, which is much more complex than the simple Cartesian system. For this you likely need a higher-power controller board that can handle the extra load.

Like anything in the vast world of 3D printing, the CoreXY approach is a compromise. It may be appropriate for some applications, but not for others. Some tout CoreXY as the future, but I think it’s just another good option to consider.

Via CoreXY

TwitterKerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

View all of Kerry Stevenson's posts.

Kinematics of 3D printers: what are the best types

Kinematics of 3D printers - which device to choose?

The print quality of a 3D printer and how it works depends on several factors. One of the important indicators is kinematics. This article discusses its main types and their features.

One of the important indicators is kinematics. This article discusses its main types and their features.

- What is the kinematics of 3D printers?

- Kinds and types of kinematics

What is the kinematics of 3D printers?

Each 3D printer has its own kinematics. Models are equipped with a platform and an extruder. These parts move in a certain direction relative to each other. Kinematics in such a device means the scheme along which the extruder and platform move.

Types and types

There are five types of 3D printer kinematics. The principle of operation of the device and the method of processing the workpiece depend on their features.

Cartesian 3D printers

The most common are 3D printers with Cartesian kinematics. They are based on the Cartesian coordinate system, they work in the X, Y and Z axes. They set the coordinates by which the print head changes position relative to the platform. The printhead has limitations in terms of movement in three axes.

- The extruder moves up when the platform moves in the horizontal X or Y axis.

- The platform moves up in the Z axis, the extruder can move in the horizontal directions at this moment.

- The platform moves along one of the axes in height, the extruder rises along the other axis.

- The platform is static and does not move, the extruder moves in all three axes.

- The extruder moves along the coordinates in height, and the platform moves along the X and Y axes.

The most common options during operation are the first and second.

Cartesian kinematics has a number of advantages.

- This is a simple motion pattern suitable for hobby printing. Many budget models work on its basis.

- The printer can be produced in any dimensions, if necessary, it is upgraded.

- Consumables are freely available. Users are offered a large number of materials and colors.

- The printers can be shipped unassembled.

This feature allows beginners in the world of 3D printing to understand the principle of the mechanism.

This feature allows beginners in the world of 3D printing to understand the principle of the mechanism. - Devices based on the Cartesian system, suitable for mass production of parts. They are designed to create blanks of different sizes.

Among the shortcomings of printers built on the principle of three coordinate systems, there are two factors:

- models are bulky, after assembly they take up a lot of space on the desktop;

- The print speed is slow.

Cartesian kinematic printers suitable for hobby printing. They help beginners understand the process of work and learn how to create models.

Example of printing on a device with Cartesian kinematics.

Varieties of Cartesian kinematics CoreXY and H-Bot

CoreXY has two feed belts, while H-Bot has only one, but it is long - this is the main difference between the two varieties. The common feature in these devices based on Cartesian kinematics is that the platform moves only along the Z axis. The horizontal X and Y axes are moved by a pair of motors mounted on the frame.

The horizontal X and Y axes are moved by a pair of motors mounted on the frame.

Two motors are responsible for the movement along the horizontal axes, one motor along the vertical ones. Such kinematics is common not only in amateur printers, but also in professional ones.

CoreXY and H-Bot based 3D printers are more expensive than conventional Cartesian models. For the production of their cases, a metal alloy or composite materials are used. Rail guides unleash the potential of high-quality printing. This kinematics allows you to achieve good detail with fast printing.

The advantages of CoreXY and H-Bot are:

- high print speed;

- quality detailing of models;

- professional use grade.

But not without drawbacks:

- H-Bot is not implemented on steel shafts;

- the belt tension must be constantly monitored to avoid play;

- high cost of instruments;

- belts can wear out quickly if they rub against neighboring objects during operation, this factor must be taken into account during operation;

- the pulleys on which the belts move must be located strictly perpendicular to each other.

Cartesian kinematic printers are widely used in various industries. They are distinguished by high print detail, a durable metal case, and high-quality components.

Help! Cartesian kinematics allows you to create detailed objects at high speed.

Delta Printers

Delta kinematic printers differ from their competitors in a number of ways. The table remains stationary, and three fixed axes are used to move the print head at once. In such devices, there is no division into the X, Y and Z axis. To move the carriage sideways, you need to lower one axis, and raise the rest.

Help! In the production of 3D printers, the Delta kinematics has not yet found wide distribution. This is a promising direction, which is currently being developed by developers.

Already existing delta printers offer the following advantages.

- Small dimensions.

Devices do not take up much space on the desktop, they are tall, but not wide.

Devices do not take up much space on the desktop, they are tall, but not wide. - High print speed. Models can process 300–400 mm/s.

- A new approach to blank production. The equipment does not print using the same technology as Cartesian. It is interesting to watch the process of processing the model.

Deltas also have a few disadvantages.

- Calibration complexity. A lens is formed on the printed surface, due to which it is impossible to fully calibrate the printing process. This is the main factor slowing down the mass introduction of kinematics.

- Poor accuracy. High print speeds sacrifice accuracy. All axes perform small movements, errors occur.

- Computing power requirement. Deltas are equipped with 32-bit boards, which is why they do not support interaction with 8-bit systems.

- The frame must be rigid. This is necessary to avoid backlash, deviations and distortions.

- Not all extruders will fit. Deltas have weight restrictions, so direct type extruders are not allowed.

Printing accuracy remains high.

On deltas, you can build high-quality vertical models, even with large dimensions. There are no protruding parts on the body, which allows you to independently increase its rigidity.

Polar

The polar kinematic scheme is presented only by one company - Polar. The essence of this technology lies in the fact that it does not have positioning along the X, Y and Z axes. The position of the extruder is set by the angle and radius. The platform of polar 3D printers is round in shape, it moves only along the horizontal axis and only rotates in a circle. The extruder moves up and down.

The advantages of 3D printers based on polar kinematics are:

- the ability to create large objects;

- high energy efficiency;

- material savings;

- small dimensions.

But there are also disadvantages:

- low printing accuracy, which was started by Polar representatives;

- platform does not warm up during operation;

- material handling restrictions - ABS plastic cannot be processed.

Polar printers are less accurate than Cartesian and Delta printers. The manufacturer recommends using such models for educational purposes; they are not yet suitable for professional printing.

Printing example shows that accuracy cannot be achieved. All features are blurred, the figure lacks sharpness and clarity.

With robotic arms

Printers with robotic arms are a design with a mechanically programmable extruder gripper arm. This is a multifunctional robot: it can carry out welding, painting, milling, etc.

The extruder can move in different directions: in layers, along complex paths in three dimensions, at different angles. Thanks to this set of functions, it is possible to create complex designs.

The main advantages are:

- versatility: the device can perform several types of tasks when replacing the extruder;

- are suitable for industrial applications: you can print large objects with almost no size restrictions.

But there are also disadvantages:

- low accuracy: such equipment is inferior to Cartesian kinematics;

- large size: devices take up a lot of work surface space.

These models are not suitable for professional 3D printing. They can be considered as an object for a hobby or a tool for it. For industrial purposes, such devices work only when high precision in the execution of parts is unimportant.

SCARA

SCARA (Selective Compliance Articulated Robot Arm) is a kinematics based on horizontal rotation of the platform. The movement is achieved by the articulation of the linkage mechanism.

These instruments are highly accurate and repeatable, and operate with a minimum of noise and vibration. SCARA also surpassed the Cartesian models in terms of processing detail: the difference is that the former work noticeably faster.

Advantages of such kinematics:

- print accuracy;

- high workpiece processing speed;

- small dimensions and weight.

But there are also disadvantages:

- stiffness restrictions in the area of the X and Y axes;

- high cost;

- is not the widest area of use.

SCARA kinematic devices are devices that combine the functions of a 3D printer and a manipulator. Device actions are programmed through software or an installed mobile application.

The choice of kinematics for 3D printers depends on the requirements for technology and application.

- Cartesian models remain the most common. They combine high accuracy, good speed, small dimensions. They can be used for amateur 3D printing. They work in a Cartesian coordinate system, the platform and the extruder move along the X, Y, Z axes.

- CoreXY and H-Bot are varieties of Cartesian kinematics. They are highly detailed blanks, suitable for professional use. Their disadvantage is the complexity in the process of operation. The user must constantly ensure that the belts do not come into contact with foreign objects and are well tensioned.

- Delta printers are uncommon models whose weak point is print accuracy. In the process of working with the device, there are problems with calibration, as well as with the choice of extruder.

- Polar printers are produced by only one company - Polar. These devices cannot provide high accuracy of the workpiece, so they are used only for educational purposes. During operation, the platform does not warm up, which limits the choice of materials.

- Robotic 3D printers are versatile devices that are used for more than just model making. Such devices can mill, weld, paint. The technique is inferior in accuracy to the Cartesian varieties.

- SCARA is one of the modern kinematics, which can not be used in all areas. It features high precision and good printing speed, it can be used as a professional instrument. The main disadvantage of SCARA is its high price.

- February 17, 2020

- 9979

Get expert advice

3D printers with different kinematics: comparison, pros and cons

Author: Vasily Kiselev, owner and managing director of Top 3D Group

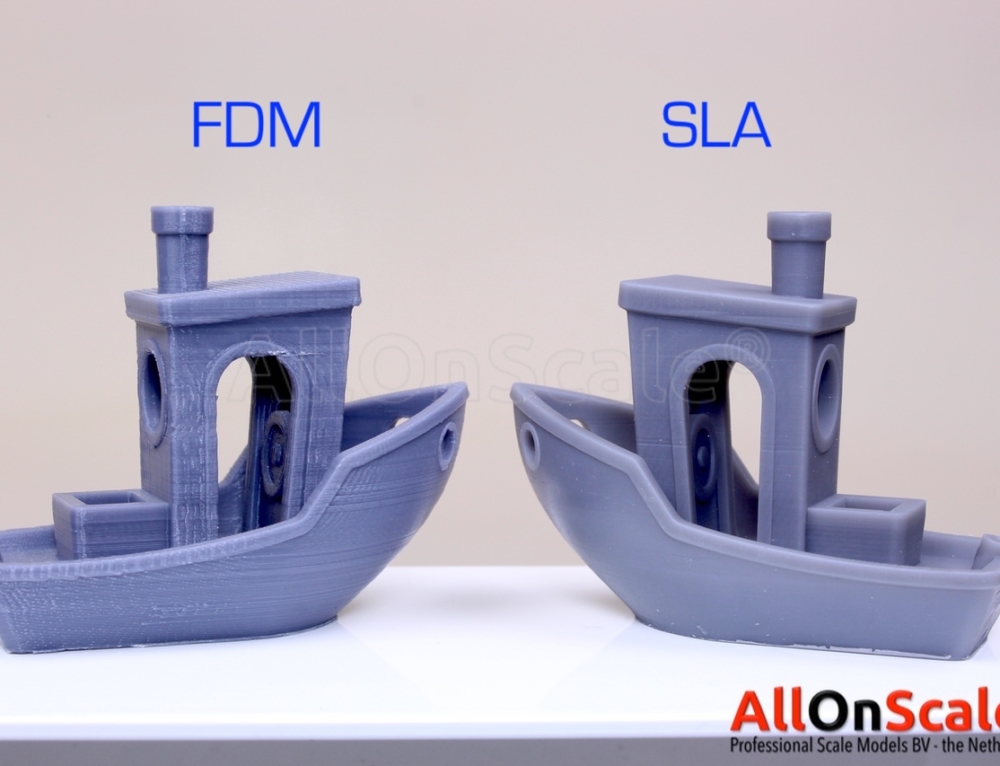

There are many printing technologies for 3D printers: digital LED projection (DLP), laser stereolithography (SLA), selective laser sintering (SLS) , thermal sintering (SHS), etc. In this article, we talk about the features of FFF technology, about the printers that use it, and about its strengths and weaknesses.

In this article, we talk about the features of FFF technology, about the printers that use it, and about its strengths and weaknesses.

Introduction

FFF (Fused Filament Fabrication) printers, also known as FDM (Fused Deposition Modeling) printers. They are devices for creating three-dimensional objects, as the name implies, by layer-by-layer application of molten thermoplastic to the working surface. FFF printers are used for both commercial and home model printing.

Types of kinematics of 3D printers

Each 3D printer has its own kinematic scheme, according to which the mechanical parts of the device are set in motion: platforms and extruders. Below we will look at four types of FDM 3D printer: Cartesian, Delta, Polar, and Robotic Arm.

In the FFF / FDM 3D printer market, Cartesian kinematic devices are the most common. Based on the Cartesian coordinate system, this technology works on the basis of three axes - X, Y, Z. The movement of the mechanical parts of the device is carried out along one or more of them, i.e., the coordinates specified along the axes implement the pattern of movement and position of the print head relative to the platform .

Based on the Cartesian coordinate system, this technology works on the basis of three axes - X, Y, Z. The movement of the mechanical parts of the device is carried out along one or more of them, i.e., the coordinates specified along the axes implement the pattern of movement and position of the print head relative to the platform .

The number of options for moving the print head and platform is limited:

-

The platform moves along one of the horizontal axes - X or Y, the extruder moves along the other and in height.

-

The platform moves in height, along the Z axis, and the extruder moves in two planes, forward-backward and left-right.

-

The platform moves along one of the axes and in height, the extruder - along the other axis.

-

The platform is stationary, the extruder moves in all three axes.

-

Platform moves in XY direction, extruder moves in height.

The second scheme is the most common - when the platform for printing moves along the Z axis (up and down), and the extruder works in two dimensions, along the XY planes.

Advantages of Cartesian

Of all the types of FDM 3D printer kinematics, Cartesian ones show almost perfect results stability. FDM consumables are low cost and come in the widest range of colors and materials. Often, Cartesian 3D printers are used for commercial purposes - for printing on order and for the sale of household objects, souvenirs and jewelry.

Cartesian 3D printers have long and firmly established themselves in the lives of hobbyists and professionals of 3D printing. Therefore, there are many thematic communities on the network with comprehensive information about the design of printers, working with them and creating models, from simple to complex.

Cartesian models can be decomposed for printing, which allows you to create 3D printed objects of any size, not limited by the volume of the printer. Many 3D printers come as a build kit. For beginners and those who do not want to understand the printer device, manufacturers supply ready-made devices. With them, you can print models almost after unpacking.

Many 3D printers come as a build kit. For beginners and those who do not want to understand the printer device, manufacturers supply ready-made devices. With them, you can print models almost after unpacking.

Varieties of CoreXY and H-Bot Cartesian kinematics

These kinematic diagrams are often found in commercial applications. Differ in original methods of positioning of an extruder. In both kinematics, the platform moves up and down.

Source : smoothieware.org

H-Bot 3D printer kinematics are based on similar mechanics, but with a different belt drive. In this case, there is only one belt and it is stretched in a shape resembling the letter H (ash) circled around the contour, for which the scheme was called ash-bot.

Source : smoothieware. org .

org .

One example of such 3D printers is the Designer X PRO. This model is fast because thanks to the JetSwitch function, printing with 2 materials has become even faster (up to 5 seconds in normal mode and 250 ms in draft mode). And the newly designed print head with 1 micron accuracy, frame structure, precision mechanics and next-generation hardware platform will allow you to print high-quality models comparable to industrial products. Possesses function of the two-material press. The software has full control over the process, which minimizes errors and increases the productivity of the 3D printer.

Print example:

Delta printers Delta printers both externally and in the way of implementing the mechanics differ from Cartesian ones. The main difference lies in the way the extruder moves relative to the desktop. Delta kinematics, compared to Cartesian models, has a higher print speed, but less accuracy at the edges of the model. Other benefits: Small size. The design is high, but in length and width does not take up much space. No protruding parts. You can independently increase the rigidity of the frame and close the case. Possibility to build high vertical models. High price category. Difficult to self-assemble. It will be difficult for beginners to assemble the structure accurately enough, so it is recommended to use ready-made solutions that come assembled. The specifics of working with polar coordinates: less common software and more expensive electronics, because higher requirements for the processing power of the filling. One example of such a 3D printer is the Tevo Little monster. It is mainly used for commercial activities, design, advertising and educational purposes, and is also used as a home 3D printer. Differs in the high speed of the press and small dimensions. Works with many materials: PLA, ABS, Flexible PLA, HIPS, WOOD, PVA, Nylon. Print example: Source : https://twitter.com/ A rather new but interesting polar kinematic scheme is introduced to the market by the company of the same name Polar. As the name implies, printing uses a polar coordinate system - instead of the usual XYZ, the positioning of the extruder is set by radius and angle. Source : http://www.purdue3dpc.org The platform of such 3D printers is round, rotates in a circle and moves entirely along one horizontal axis, while the extruder moves only up and down. Polar 3D printers allow you to create large objects while saving money through high energy efficiency. They still have low accuracy, but in the long run, perhaps the manufacturer will be able to solve this problem. Source : https://about.polar3d.com/ These 3D printers include the Polar 3D model. In this 3D printer, there is no heating of the print bed, which makes it difficult to use ABS. It has modest dimensions, good performance, but low accuracy compared to delta printers and models with a Cartesian coordinate system. The manufacturer recommends purchasing a model for educational purposes. Print example: 3D printers with robotic arms This is a design with a mechanical programmable gripper with a replaceable extruder. If we are talking about large industrial specimens (and there are also more compact ones), then, in addition to the functions of a manipulator and a 3D printer, such a robot can perform welding, milling, painting and other operations. Source : http://www.dubox.me/ Although the mechanics of 3D printing with a robotic arm is mainly used in industry, there are models for individual use, with a wide range of functions. Dobot Magician Educational Robot Arm has many functions. It can draw, write, grab and move objects, perform laser engraving, etc. Work example: SCARA SCARA (Selective Compliance Articulated Robot Arm) - kinematics based on the movement of the working unit in a horizontal plane due to rotation in the joints of the lever mechanism. The devices built on this scheme are distinguished by very high accuracy and repeatability, much higher than that of traditional robotic arms, low noise and vibration levels, and compactness. If we talk about Cartesian and SCARA robots of comparable size and mass, then scara is usually not only more accurate, but also faster. At the same time, these devices are expensive, have limited rigidity in the XY axes, a smaller area of work and freedom of movement. An example of such kinematics is the Dobot M1 robotic arm. This is a compact desktop robot that combines the functions of a 3D printer and a manipulator. Actions are programmed through the software installed on the computer or a mobile application. It has interchangeable heads for printing, engraving, soldering and assembling. Working example: Source : https://thegadgetflow. The advantages of 3D printers with a robotic arm are obvious - such a printer is not limited by the volume of the working chamber, which it does not have - with the same print area, the device itself takes up much less space. Source : https://spectrum.ieee.org/ The extruder can move not only in layers, as in desktop printers, but also along complex paths in three dimensions, and at different angles, which facilitates the process of creating complex designs. A definite plus is also the fact that these are usually universal designs, when replacing the extruder with other blocks, they perform many tasks. In terms of printing accuracy, manipulators will not compete with Cartesian 3D printers, but due to their versatility and large size, industrial robots are actively used in 3D printing in industrial environments, where they are almost indispensable. Miniature desktop robots are good primarily as a visual aid, as well as a hobby object or a tool for it. When choosing a device before buying, first of all, decide on the goal - why do you need a 3D printer? Business, work or play? The versatility of FFF/FDM 3D printers is that they are suitable for different applications. Whether you want to learn 3D printing and acquire a new hobby, live out your creative fantasies or start a business, there is a suitable machine for each of these goals, you just need to choose. You can purchase a suitable device and consumables at https://top3dshop.ru, a retail division of Top 3D Group, a leading integrator of additive equipment in Russia. And also on the site: https://top3dshop.com, if you do not live in the CIS countries. List of sources used: What are the advantages of the FDM technology? - Professional 3D Printers // [Electronic resource]: dddrop. Application of FDM three-dimensional printing technology in the digital manufacture of custom edentulous mandible trays // [Electronic resource] : Scientific Reports - Electron. Dan. – nature.com – Access mode: https://www.nature.com/articles/srep19207 (Accessed: 08/03/2019). Reconstruction and Development of a 3D Printer Using FDM Technology // [Electronic resource] : Procedia Engineering - Electron. Dan. – sciencedirect.com – Access mode: https://www.sciencedirect.com/science/article/pii/S1877705816311651 (Accessed: 08/03/2019). Catalog // [Electronic resource] : 3D Printers - Electron. Dan. – top3dshop.com – Access mode: https://top3dshop.com/3d-printers/ (Accessed: 08/03/2019).

Advantages and disadvantages of delta bots  The reason is that all three attachment points are involved in the movement of the extruder, their motors work simultaneously, which leads to the accumulation of errors in the positioning of the coordinates.

The reason is that all three attachment points are involved in the movement of the extruder, their motors work simultaneously, which leads to the accumulation of errors in the positioning of the coordinates.

Polar 3D printers  Imagine a turntable - the printer's printhead works like a pickup stylus moving across a record. The only difference is that here the “plate” not only rotates, but the “needle”, on the contrary, is limited in movement.

Imagine a turntable - the printer's printhead works like a pickup stylus moving across a record. The only difference is that here the “plate” not only rotates, but the “needle”, on the contrary, is limited in movement.

Pros and cons of polar mechanics

com/

com/

Analysis of robotic kinematic schemes

Conclusion

com - Electron. Dan. – dddrop.com – Access mode: https://www.dddrop.com/fdm-technology/ (date of access: 08/03/2019).

com - Electron. Dan. – dddrop.com – Access mode: https://www.dddrop.com/fdm-technology/ (date of access: 08/03/2019).

Learn more