3D printer technician salary

3D printing technician | Explore careers

How to become a 3D printing technician

You can get into this job through:

- a university course

- a college course

- an apprenticeship

- working towards this role

University

You could do a foundation degree, higher national diploma or a degree in a relevant subject like:

- 3D design

- product design

- engineering

- materials science

Entry requirements

You'll usually need:

- 1 or 2 A levels, or equivalent, for a foundation degree or higher national diploma

- 2 to 3 A levels, or equivalent, for a degree

More Information

College

You could take a course in creative design, model making or engineering. This could help you to find a job with a manufacturing or 3D printing company. Courses include:

- Level 2 Certificate in Computer Aided Design

- Level 3 Award in 3D Computer Aided Design

- Level 3 Diploma in Engineering Technology

- T Level in Design and Development for Engineering and Manufacturing

Entry requirements

You may need:

- 4 or 5 GCSEs at grades 9 to 4 (A* to C), or equivalent, including English, maths and computing

- 4 or 5 GCSEs at grades 9 to 4 (A* to C), or equivalent, including English and maths for a T level

More Information

Apprenticeship

Apprenticeships relevant to this role include:

- Lean manufacturing operative intermediate apprenticeship

- Digital engineering advanced apprenticeship

- Engineering technician - product design and development advanced apprenticeship

Entry requirements

You'll usually need:

- some GCSEs, usually including English and maths, or equivalent, for an intermediate apprenticeship

- 5 GCSEs at grades 9 to 4 (A* to C), or equivalent, including English and maths, for an advanced apprenticeship

More Information

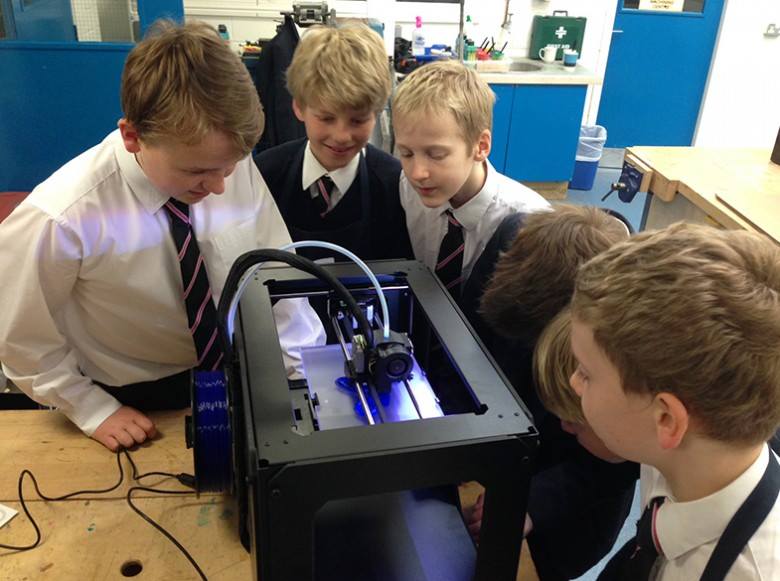

Work

You may be able to start as an assistant in a 3D print workshop and take training on the job to become a technician. Skills and qualifications in manufacturing, model making, printing, technology or design will be useful.

Skills and qualifications in manufacturing, model making, printing, technology or design will be useful.

More Information

Career tips

Learn more about the basics of 3D printing.

Further information

You can get details about working in 3D printing and design engineering from the British Printing Industries Federation and Neon.

What it takes

Skills and knowledge

You'll need:

- knowledge of manufacturing production and processes

- to be thorough and pay attention to detail

- knowledge of engineering science and technology

- the ability to operate and control equipment

- analytical thinking skills

- the ability to work well with others

- the ability to analyse quality or performance

- knowledge of maths

- to be able to use a computer and the main software packages confidently

What you'll do

Day-to-day tasks

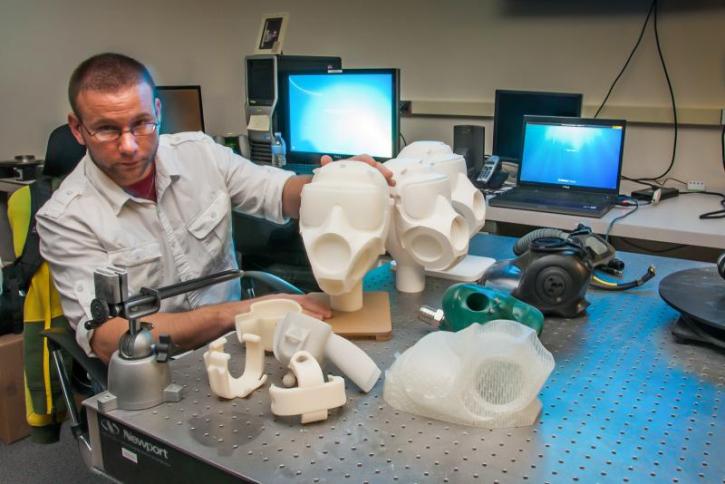

In your day-to-day duties you may:

- create estimates and quotes for parts and materials

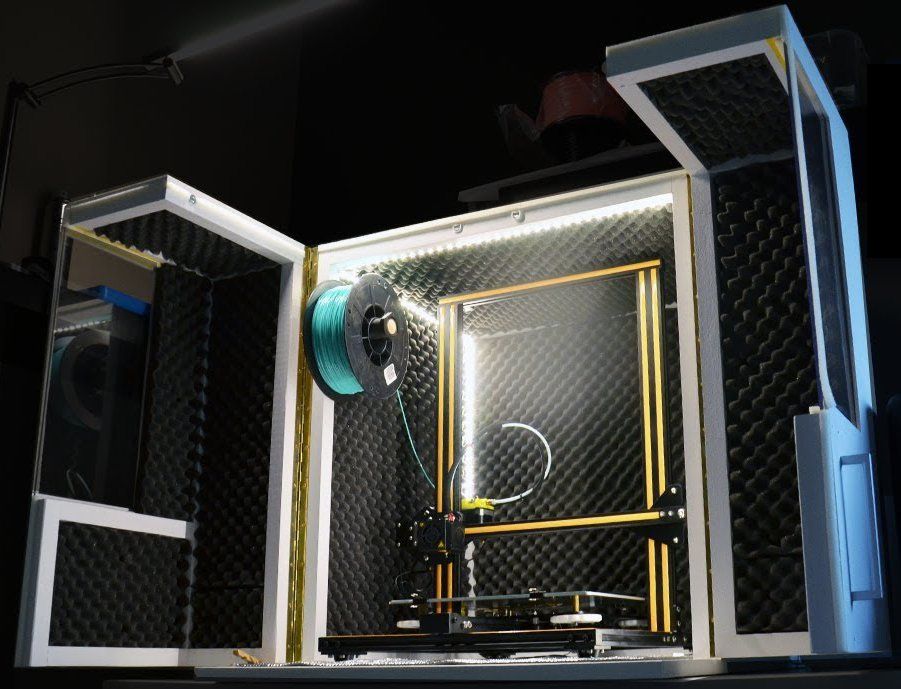

- set up machines and schedule print jobs

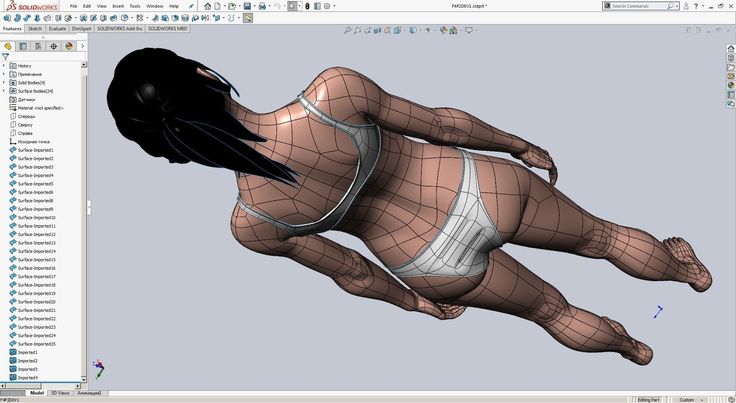

- create digital models and prototypes based on customer requirements

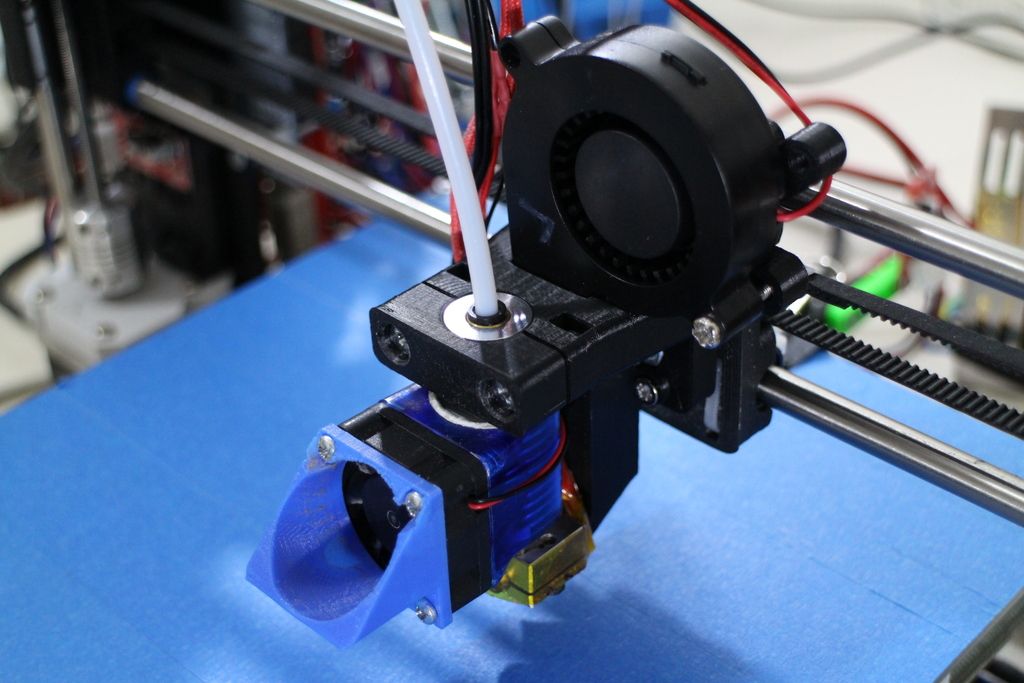

- operate 3D scanning and printing machinery

- clean, sand, polish or apply finishes to products

- inspect products to check quality

- pack items for delivery and update paperwork

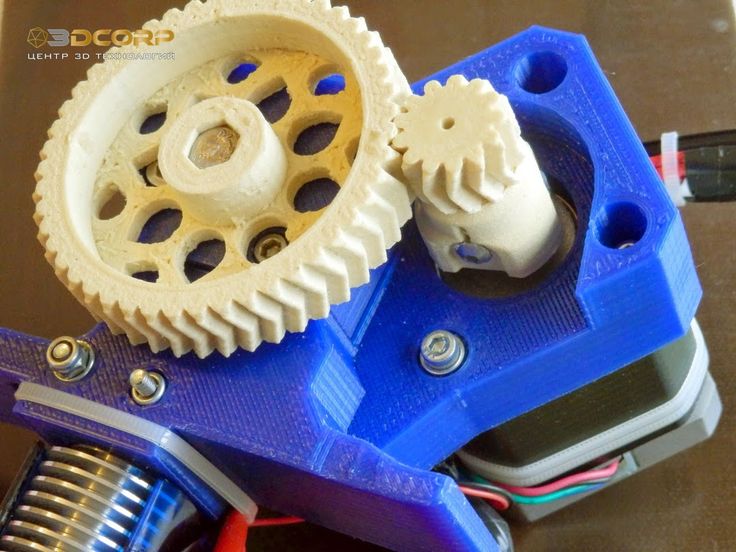

- service and repair equipment

Working environment

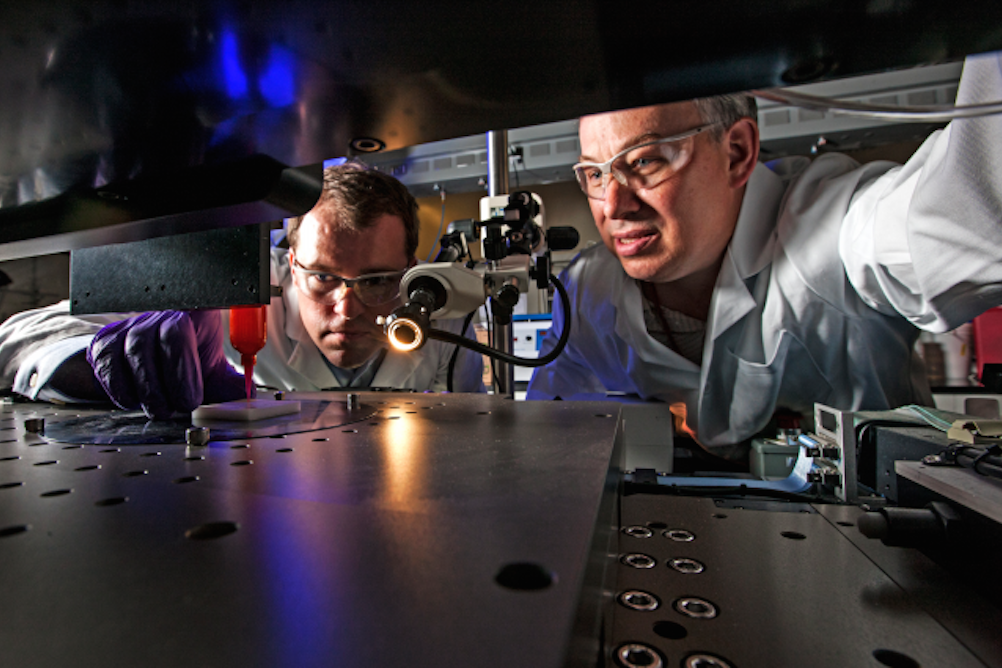

You could work at a manufacturing plant, in a factory or at a research facility.

Your working environment may be noisy.

You may need to wear safety clothing and use safety equipment.

Career path and progression

You could move into research, investigating new materials for use in 3D printing and how to make them commercially workable. You could also train to work in 3D printing software and hardware development.

You might work for a company that specialises in printing particular items, for example custom-made prosthetics, construction prototypes, or models of archaeological remains and historical buildings.

There are also opportunities in print equipment sales and training.

Current opportunities

Apprenticeships In England

Machine Operator / Shop Floor Apprentice

- Wage: £9,254.

44 Annually

44 Annually - Location: CRADLEY HEATH

Engineering Technician Mechatronics Apprentice

- Wage: £19,000.00 Annually

- Location: Heartlands Business Park, Newnham Drive, Northampton

Find apprenticeships near you

Courses In England

Level 3 Award in 3D Computer Aided Design (Eve)

- Provider: NEW CITY COLLEGE

- Start date: 21 September 2023

- Location: Rainham

Computer Aided Design

- Provider: SOLIHULL COLLEGE AND UNIVERSITY CENTRE

- Start date: 01 September 2023

- Location: Smith's Wood

Find courses near you

Jobs In the United Kingdom

The Find a job service can help you with your search for jobs and send alerts when new jobs become available.

3D Printer Technician (Portland, OR) - LAIKA, LLC

Skip to main contentView 23166 Jobs

View 23166 Jobs

General Summary

The 3D Printer Technician is responsible for overseeing the set-up, maintenance, calibration, operation, and repair of the 3D Printing Rapid Prototype equipment. This position is also responsible for running and servicing the printers, as well as diagnosing issues before they become production-disrupting problems.

Job Functions

- Oversee daily printing operations and regular scheduled maintenance on all 3D printers.

- Perform advanced testing, calibration, and servicing on 3D Printing equipment.

- Work closely with 3D printing companies to troubleshoot problems, expedite repairs, coordinate part replacements, and facilitate hardware and software upgrades.

- Run R&D and beta tests on new hardware and software advancements, and provide feedback in order to keep LAIKA’s 3D printers up to date with the latest advances in 3D printing technology.

- Design, create, and maintain custom software tools to automate tasks, improve data tracking, and enhance communications between the 3D printing team and other RP team members.

- Consult with and provide feedback to RP CG Modelers, RP Fabricators, and Digi Fab Artists on how to optimize files for successful printing.

- Work with the RP Processing team to optimize the organization and delivery pipeline for printed parts.

- Train and provide guidance on printer maintenance and operations to 3D Printing Coordinators, 3D Printer Operators, and new 3D Printer Technicians.

- Responsible for recordkeeping, ordering parts, consumables and tracking parts printed.

- Provide cost reporting and estimations when appropriate.

Qualifications

- 3+ years of related experience in 3D printing.

- Advanced knowledge and skills developed through hands-on experience and/or specialized training from 3D printing hardware/software providers.

- Polyjet technology a plus – specifically the Stratasys J750, and Connex3.

- Detail oriented and organized.

- Ability to troubleshoot and solve problems.

- Ability to quickly learn custom software programs.

- Experience with Excel and Microsoft Word required to track inventory and process.

- Knowledge of both Linux and Mac operating systems.

- Maya 3D Modeling, computer programming and 3D scanning experience, a plus.

Physical Demands and Work Environment

The physical demands and work environment characteristics described here are representative of those that must be met by an employee to successfully perform the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

- Physical demands: While performing the duties of this job, the employee is required to walk; stand; sit; use hands to operate standard office equipment; reach with hands and arms; balance; stoop; talk or hear both in person and by telephone.

The employee must lift and/or move up to 15 pounds. Vision abilities include close vision, distance vision, and the ability to adjust focus.

The employee must lift and/or move up to 15 pounds. Vision abilities include close vision, distance vision, and the ability to adjust focus. - Work environment: While performing the duties of this job, the employee works under typical office conditions and is exposed to variable indoor temperatures. The noise level is usually quiet or moderate. In certain assignments, an employee may occasionally work near moving equipment and be exposed to toxic or caustic chemicals, airborne fumes and loud, prolonged noise (hearing protection required when using power tools).

Location

Hillsboro, OR

Salary

Salary is commensurate with skills and experience.

Disclaimer

The above statements are intended to describe the general nature and level of work being performed by people assigned to this classification. They are not intended to be construed as an exhaustive list of all responsibilities, duties and skills required of personnel so classified.

Please review our Employment Disclaimer and Materials Submission Agreement.

Read Full Job Description

First Name

Last Name

Email Address

Apply Now

By clicking continue you agree to Built In’s Privacy Policy and Terms of Use.

Save job

View LAIKA, LLC's full profileFind similar jobs

where to study, where to work, salary

Updated

3D printing engineer is engaged in technical support, work with equipment, software, creation of 3D models. A specialist needs to have deep knowledge of engineering, programming, and mathematics. The profession is referred to the specialties of the future. By the way, the ProfGid career guidance center has recently developed an accurate career guidance test that will tell you which professions suit you, give an opinion about your personality type and intelligence. The profession is suitable for those who are interested in physics and mathematics (see. choosing a profession based on interest in school subjects).

choosing a profession based on interest in school subjects).

Content:

- Short description

- Features of the profession

- Plus and minuses

- Plus

- Minuses

- Important personal qualities

- PROMICATION 9001

- Salary

- 3d printing engineer salary as of December 2022

- Professional knowledge

- Examples of companies with 3d printing engineer vacancies

Brief description

The profession of a 3D printing engineer has appeared quite recently, but its value and social significance cannot be underestimated. With the help of 3D printing, unique products used in medicine and industry are already being created today. Mathematicians and engineers are constantly developing more advanced technologies that make it possible to create blanks, anatomical models, souvenirs, houses, prostheses using this type of printing. And printers used for printing with biomaterials make it possible to create human skin, which has become a breakthrough in the treatment of wounds, injuries, and acceleration of the rehabilitation period.

Read also :

Complete control over 3D printing is carried out by an engineer who is an excellent programmer, technologist, biologist and even a chemist, because the profession forces him to know the composition and properties of different materials well. To work in this area, you must have a technical education, attending IT courses, lectures on modeling will be a plus. A specialist must be able to independently design a 3D model, select the necessary materials, calculate all the risks, and then print, creating products for the field of medicine, aviation, industry, etc.

Occupation specifics

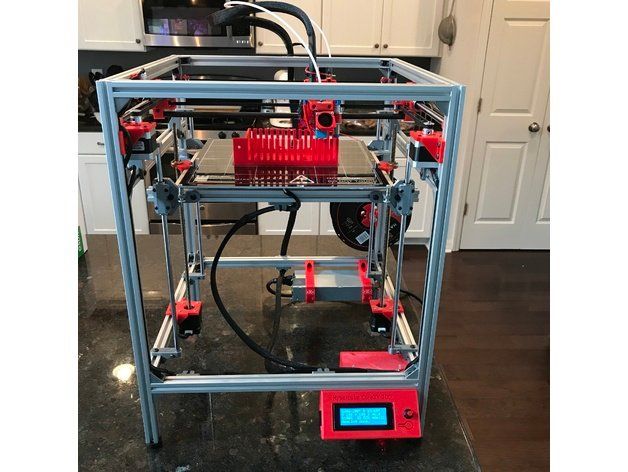

3D printing engineers use different materials for their work, computer programs and industrial 3D printers. Today, medical centers, industrial, aerospace, engineering and other industries need these specialists. There are few specialists, their work cannot be called simple, because the duties of a 3D printing engineer include:

- selection of new materials, testing;

- using modern software to improve and adjust 3D printer settings;

- preparation of layouts, development of raster images for subsequent printing;

- full print control;

- study of new technologies;

- knowledge of certification rules, requirements that are put forward for 3D models and finished products;

- documentation development, software debugging;

- selection of new equipment, training of other employees;

- equipment maintenance.

Responsibilities vary by location, but a 3D Printing Engineer must be a multi-skilled professional who is ready to quickly learn new technologies at any time and then successfully apply them in practice. Employers put forward strict requirements for engineers, because the wages of such specialists are solid. They must have at least 3 years of practical work experience, the obligatory knowledge of a technical foreign language is important. A 3D printing engineer must know the basics of economics and marketing, because his duties include optimizing workflows aimed at reducing the cost and speed of printing.

Read also:

Pluses and minuses

Pluses

- An important profession that will help save millions of lives in the future, improve the environment, and allow the rational use of natural resources.

- 3D printing engineers are unique specialists today.

- Demand in various fields.

- A specialist will have no problems finding a job in megacities.

- The salary is stable and high.

- An experienced engineer will be able to open his own production for the manufacture of souvenirs or other products.

- You can study in Russia by enrolling in a technical university.

- Lack of physical activity.

Cons

- Working sedentary, but not monotonous.

- Irregular working hours, because the creation of a large product can last for more than 5 hours.

- The cost of industrial 3D printers is high, so in order to organize your own production, you need to think about starting capital or finding an investor.

- Any mistakes made by a 3D printing engineer are associated with huge financial losses.

- Difficulties with finding work in small towns and villages.

- Work at the computer leads to a decrease in vision.

Important Personal Qualities

A 3D Printing Engineer has a lot of professional knowledge, so he must be an erudite person with an excellent memory. The character of this rare specialist should contain responsibility, curiosity, and creativity. An engineer is obliged to constantly study, a craving for both the exact sciences and linguistics is welcomed, because most of the instructions, books and technical documentation are still being created mainly in foreign languages.

The character of this rare specialist should contain responsibility, curiosity, and creativity. An engineer is obliged to constantly study, a craving for both the exact sciences and linguistics is welcomed, because most of the instructions, books and technical documentation are still being created mainly in foreign languages.

See also:

3D printing engineer training

Universities

-

140,000 ₽/year

no budget places

-

4 years

220,000 ₽/year

15 budget places

-

4 years

48 500 ₽/year

12 budget places

-

36 200 ₽/year

25 budget places

See also:

Place of work

3D printing engineers will be able to work in agencies engaged in the production of consumer goods. They are in demand in architectural companies, factories, medical centers and nanolaboratories, clothing design and manufacturing agencies. 3D printing is used in all spheres of our life, so a young university graduate will be able to choose an interesting and useful direction.

They are in demand in architectural companies, factories, medical centers and nanolaboratories, clothing design and manufacturing agencies. 3D printing is used in all spheres of our life, so a young university graduate will be able to choose an interesting and useful direction.

Salary

3d printing engineer salary for December 2022

Salary information is provided by hh.ru portal.

Russia 30000–120000 RUB

Moscow 60000–150000 RUB

Professional knowledge

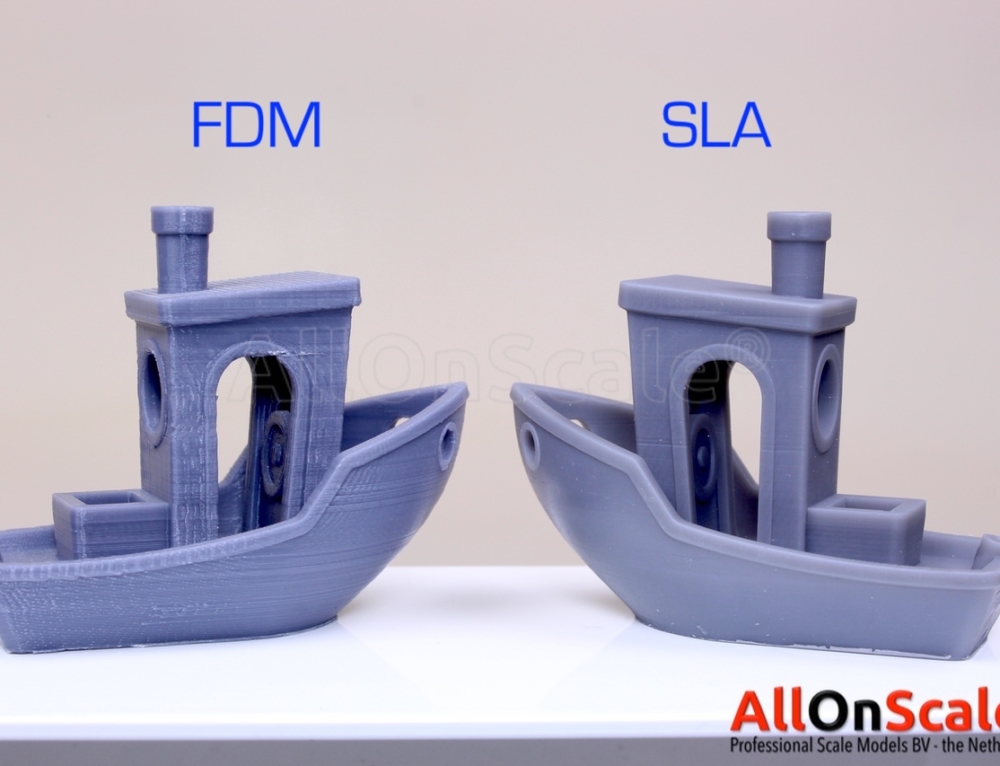

- 3D printing technologies (SLA, FDM and others).

- 3D modeling.

- 3D printing materials (PLA, ABS and others).

- Slicers for preparing for 3D printing, working with software (Autodesk 3ds Max, SolidWorks, Autodesk 123D Design and others).

- Knowledge of the specifics of different models of equipment.

- Features of processing printed 3D models.

- English.

Read also:

Examples of companies with engineer vacancies 3D-print

REC Wiki "who are earned on 3D-printing

ready 3D printer? Okay, but before diving head first into the business, it would be nice to understand exactly how 3D printing is changing the face of the industries around us in order to find its niche. Let's watch.

Let's watch.

The market is growing

From Bugatti to Adidas, 3D printing is making its way into one industry after another, influencing not only design processes but also manufacturing processes. Even the pandemic did not stop the development of the additive market. The situation turned out to be twofold: on the one hand, many manufacturers of 3D printers and consumables suffered losses due to reduced demand, but already bounced back in 2021, as more and more enterprises began to resort to localized additive manufacturing of components due to problems with global logistics . It's time to join the trend and row money with a shovel. A shovel, by the way, can also be printed.

The main applications of 3D printing technologies are prototyping and additive manufacturing. As a prototyping tool, 3D printing helps speed up the development and refinement of products, and as an additive manufacturing tool, it allows you to make final products. Prototyping with 3D printing greatly accelerates the work of designers, providing low-cost, functional prototypes for enterprises of all sizes. In manufacturing, 3D printing is used for mass customization, on-demand production, and even distributed production.

In manufacturing, 3D printing is used for mass customization, on-demand production, and even distributed production.

3D printing is everywhere you look

As the subtitle suggests, there is no hiding from 3D printing, it is already everywhere. On the other hand, adoption rates vary from industry to industry. 65% of the use of additive technologies is in engineers working on the creation of new industrial and consumer products.

Example: Three-quarters of American and German automotive companies, including BMW, Ford, Volkswagen, Audi, Porsche, Mercedez-Benz and General Motors, are already actively using 3D printing technologies in the mass production of tooling, parts and spare parts. But the matter is not limited to cars alone: medicine, the service industry, architects, artists, and so on and so forth have picked up an additive fever. And what do they do, you ask? Now let's show.

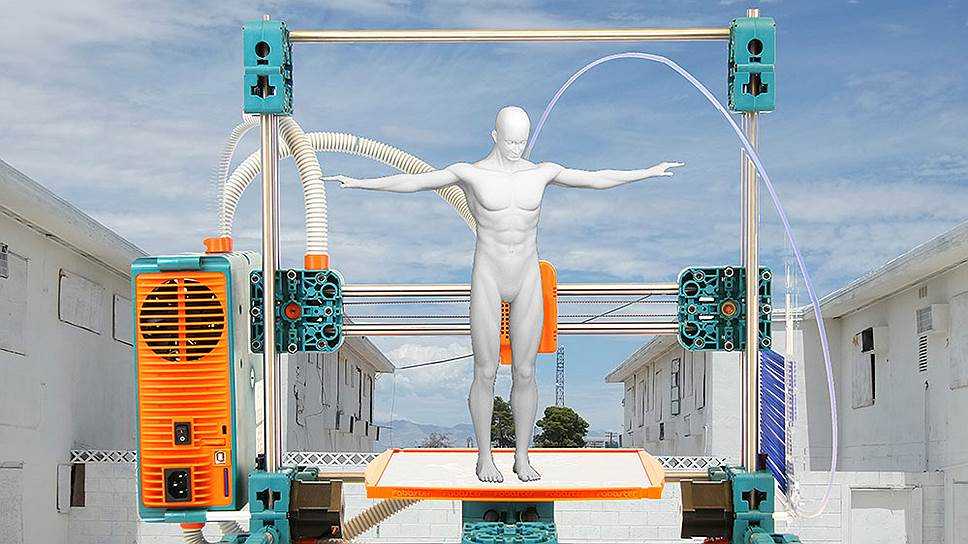

Construction

3D printing is a new word in construction. "Office of the Future" is a demonstration project in Dubai carried out by the Chinese company WinSun in 2016. Six meters high, thirty-six long, twelve meters wide, plus 50% savings on labor. For everything about everything, including decoration and landscaping - seventeen days. The emirs have big plans: the same Saudi Arabia intends to build one and a half million houses to solve the housing crisis, actively attracting developers of construction 3D printers. It is understandable, because the salaries of local builders are high, and the economy should be economical.

Six meters high, thirty-six long, twelve meters wide, plus 50% savings on labor. For everything about everything, including decoration and landscaping - seventeen days. The emirs have big plans: the same Saudi Arabia intends to build one and a half million houses to solve the housing crisis, actively attracting developers of construction 3D printers. It is understandable, because the salaries of local builders are high, and the economy should be economical.

The Dubai 3D printing office was just one of the first wake-up calls, and now, six years later, construction 3D printing is being mainstreamed by companies such as ICON, Apis Cor, COBOD, AMT-Spetsavia. The illustration above shows a series of low-income homes built by Texas-based ICON in their native Austin. The houses are small, only thirty-seven square meters each, but are equipped with a bedroom, a living room, a fully equipped kitchen and a bathroom.

And this is one of the projects of the Russian company 3D4art: a pavilion with a 3D printed concrete cat was erected on a private plot in Yaroslavl and serves as a summer kitchen. 3D4art uses 3D printers developed by the local company AMT-Spetsavia, which is also engaged in construction, in parallel with the production of additive technology. Now AMT-Spetsavia is busy building a whole 3D-printed village, in total it is planned to build twelve houses according to individual projects.

3D4art uses 3D printers developed by the local company AMT-Spetsavia, which is also engaged in construction, in parallel with the production of additive technology. Now AMT-Spetsavia is busy building a whole 3D-printed village, in total it is planned to build twelve houses according to individual projects.

“From a hardware point of view, a construction 3D printer is not much different from conventional 3D printing with molten plastic. These are the same CNC machines, only construction 3D printers are larger. However, they allow realizing any architect's fantasy: the printer doesn't care what to print - a simple rectangular building or a house with curved facades, turrets and columns. And to automate the process as much as possible, thanks to which the time for construction is reduced by one and a half times compared to the traditional one,” said Alexander Maslov, General Director of AMT-Spetsavia.

Tissue engineering and organs

No one has yet learned how to print working livers, but the process is underway. For example, Prellis Biologics is working on methods for 3D printing of functional organs, including hearts, livers, kidneys and lungs, and the Russian company 3D Bioprinting Solutions has already conducted several bioprinting experiments in space.

For example, Prellis Biologics is working on methods for 3D printing of functional organs, including hearts, livers, kidneys and lungs, and the Russian company 3D Bioprinting Solutions has already conducted several bioprinting experiments in space.

Even if the technology is not yet ready for 3D printing of organs for transplantation, it is already useful, allowing the growth of living tissue samples for toxicological research in the development of new pharmaceuticals, as well as research in the treatment of various dangerous diseases, such as cancer.

Cars and motorcycles

Finding and buying a four-wheeled classic is not so difficult, if you have money. It is more difficult to bring the often rusty collection of no longer produced parts up to standard. Mercedes has found a simple solution by offering owners of older cars, including the legendary 300 SL coupe, 3D printed parts. Ride for health.

The Russian studio Box3D went in a slightly different direction, customizing cars and motorcycles. In some cases, the company immediately prints parts on 3D printers using durable composites, such as REC X-Line filaments, in others, it prints master models from PETG, from which matrices are removed, and carbon or fiberglass parts are made from matrices. The illustration above is one example. This is a custom motorcycle Giotto 31 based on Harley-Davidson V-Rod. All plastic parts are printed in PETG with fiberglass reinforcement.

In some cases, the company immediately prints parts on 3D printers using durable composites, such as REC X-Line filaments, in others, it prints master models from PETG, from which matrices are removed, and carbon or fiberglass parts are made from matrices. The illustration above is one example. This is a custom motorcycle Giotto 31 based on Harley-Davidson V-Rod. All plastic parts are printed in PETG with fiberglass reinforcement.

And this is a very extreme example from the USA - the Czinger C21 hypercar with a structure made of carbon fiber and 3D-printed titanium parts made using selective laser metal powder fusion (SLM) technology. The machine is equipped with a hybrid power plant based on a turbocharged V-engine with a capacity of 925 hp. With. with the main drive to the rear wheels and auxiliary to the front. From zero to one hundred kilometers per hour Czinger C21 accelerates in just 1.9 seconds. Last year, the prototype set a new lap record at Laguna Seca and improved the previous best time set by the McLaren Senna by a full two seconds. The company plans to produce just eighty of these cars, costing about $1.7 million each.

The company plans to produce just eighty of these cars, costing about $1.7 million each.

Shoes and fashion in general

Sooner or later the day will come when you will put on freshly printed underpants in the morning. Think this is a joke? Maybe. However, the same Adidas brand is already actively pursuing the idea of mass distributed additive manufacturing of shoes. Each has its own size, its own shape, its own color, and even at the place of residence. The company has already released several sneaker models with comfortable and resilient 3D printed soles made on Carbon's high-speed photopolymer 3D printers.

Bicycles

This is the Arc Bicycle, a 3D printed bicycle designed by Delft University of Technology students and manufactured by MX3D. And the uncle on a bicycle is the Minister of Economy of the Kingdom of the Netherlands Henk Kamp, who tested the novelty at the Innovation Expo in Amsterdam. It's a well-known fact: the Dutch love 3D printers and bicycles. Especially when 3D printers are printing bicycles, for the perfect synergy. The frame of this two-wheeled vehicle was printed by an industrial multi-axis robotic arm that fuses metal wire.

Especially when 3D printers are printing bicycles, for the perfect synergy. The frame of this two-wheeled vehicle was printed by an industrial multi-axis robotic arm that fuses metal wire.

And this e-bike has a carbon fiber composite frame, but also 3D printed. Such bikes are produced under the Kimoa brand, founded by the famous racing driver Fernando Alonso. The production is carried out by the Californian company Arevo, which has developed a special 3D printer: an additive system prints a combination of thermoplastics and continuous reinforcing fibers.

Instead of a thermal block, a laser emitter is responsible for melting the polymer, and immediately after application, the melt and the reinforcing thread are pressed by a roller, increasing the isotropy. Thanks to the multi-axis positioning system, the reinforcing threads can be overlapped, and the high power-to-weight ratio of the system makes it possible to work even with refractory structural thermoplastics such as polyetheretherketone (PEEK).

Food

Who wants a delicious cake? Only cakes are not simple, but made according to intricate 3D printed forms. These sweets were invented by a former Ukrainian architect, and now a confectioner Dinara Kasko. The unusual shape of the cake was obtained using a silicone mold made from a 3D printed master model. With 3D modeling in Grasshopper 3D, Dinara was helped by a friend, Ukrainian artist Andrey Pavlov, who is engaged in general and architectural design.

Fashion

Let's get back to our clothes. Dutch designer Anouk Wipprecht knows the safest way to ride the subway. This 3D-printed "spider" outfit not only flatters the figure, but can tear apart anyone who will unravel their hands. We have warned you. But there are other options: go to the store in such a dress, elegantly lean on the counter and ask: “How much?” Discount guaranteed.

And now to space

When someone enthusiastically mentions "space technology", they mean 3D printing. Seriously. We have already mentioned 3D Bioprinting Solutions, but NASA has long appreciated the possibilities of 3D printing, operating the second FDM 3D printer on board the ISS and even funding the development of 3D printers for printing in outer space. The Russian "space" polymer 3D printer (pictured above) is due to leave for the ISS on June 3, 2022.

Seriously. We have already mentioned 3D Bioprinting Solutions, but NASA has long appreciated the possibilities of 3D printing, operating the second FDM 3D printer on board the ISS and even funding the development of 3D printers for printing in outer space. The Russian "space" polymer 3D printer (pictured above) is due to leave for the ISS on June 3, 2022.

SpaceX's rockets and spacecraft are powered by 3D printed engines, and California-based startup Relativity Space is already gearing up to launch the first 3D printed orbital launch vehicle.

Relativity Space relies on at least two 3D printing technologies: for example, engines are manufactured using selective laser sintering technology using industrial 3D printers from the German company Electro Optical Systems (EOS GmbH), and fuel tanks are printed by an additive system of its own design - a robotic complex Stargate on hybrid technology of laser-plasma deposition of welding wire. Through the use of robotic manipulators, the system is easily scaled up, allowing you to create large-sized products.

The first flight of an experimental Terran 1 rocket with a payload mock-up is scheduled for June 2022. The company estimates the cost of one launch at twelve million dollars, and the production time for serial samples is only two months.

Architecture

And I'm walking, walking on… a 3D printed bridge. Not so unexpected: 3D printed bridges have been built in Spain, the Netherlands and China. These are all reinforced concrete structures, although there are also plastic ones, but the engineers of the already mentioned Dutch company MXD3 designed an all-metal steel bridge.

The bridge was installed in the center of Amsterdam in the summer of 2021. The opening ceremony turned out to be quite funny: Her Majesty Queen Maxima deigned to press the big green button, thereby graciously giving the red ribbon to be torn to pieces by a robot-manipulator armed with scissors. Why such an honor fell to the robot is quite understandable: the robots did the bulk of the physical work, armed with welding machines.