3D printer glue stick

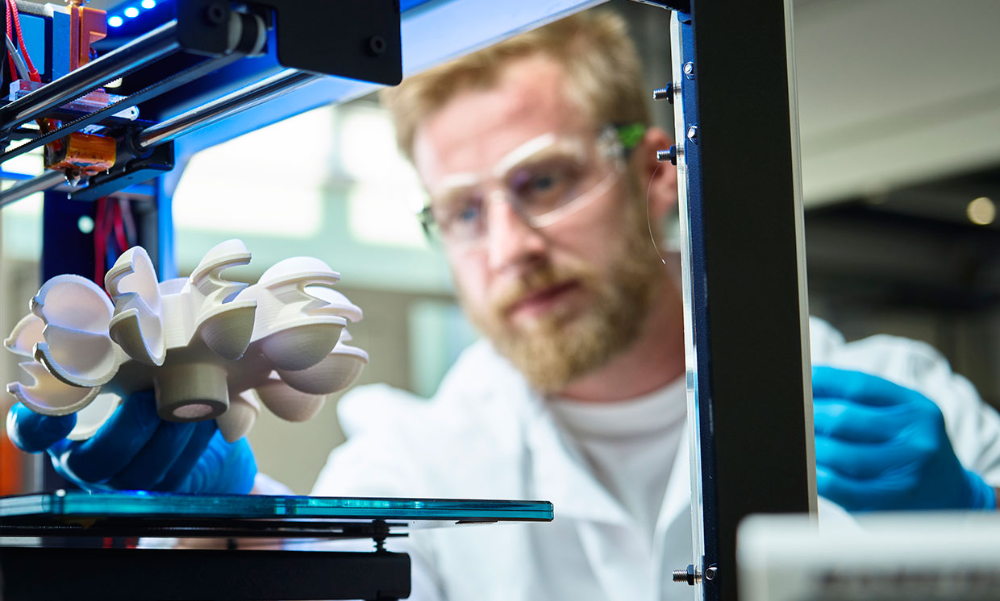

What are Bed Adhesives in 3D Printing?

One of the issues that people face when 3D printing is getting their prints to stick to the build plate. If a print does not stick to the build plate properly, then it could move during the print process which will cause it to fail.

Manufacturers have, of course, devised remedies for this. Ultimaker 3D printers have a heated build plate for better bed adhesion and reduced warping and curling (the heated plate stops prints from cooling down rapidly, avoiding contraction). Some manufacturers have taken a simpler route, though – MarkForged recommends people use an Elmer’s Glue Stick to create a sticky layer on the build plate.

The simple truth of bed adhesives – whether they are cheap glue or expensive tapes – is that all of them have the same aim: to prevent warping, curling, print failure and to reduce waste. It is important to point out though that not all materials require a bed adhesive to stick to the build plate. PLA, for instance, adheres well to a heated build plate without adhesive. However, when glue or tape is used, the risk of warping and curling is reduced considerably.

How do bed adhesives work?

Simply put, bed adhesives work by forming a stickier layer for prints to adhere to. In the case of heated build plates (which are necessary for printing materials with a higher melting point than PLA), hard materials like ABS and CPE can warp even with support structures. The reason for this is the smooth glass plate with the introduction of heat; the print material sometimes doesn’t cool quickly enough to be strong. By introducing a layer of glue, print-bed adhesion is improved, and the glue also acts as a layer of protection for the glass.

Adhesives also eliminate the risk of print movement. If a print moves just a little during the print process, then it will fail. We regularly receive questions from people asking why their prints keep failing, and it is more often than not because they aren’t using an adhesive on their build plate.

Are there alternatives to external adhesives?

It is possible to print a ‘brim’ with your print, which is a thin platform around your print that helps ensure successful adhesion. These work because your part or model will be printed on a layer of filament, rather than directly on the build plate itself. Cura, Ultimaker’s software, allows you to create a brim quickly and the brim itself can simply be cut away afterwards. However, even with a brim, we still recommend using a bed adhesive to protect the build plate.

What are the best adhesives?

We are of the belief that what works best for manufacturers and the 3D printing community will work best for you.

So, here’s a list of products and who uses them:

Elmer’s Disappearing Purple Glue Stick – Recommended by MarkForged and other brands

Cheap and effective, Elmer’s Disappearing Purple Glue Stick is used by pros and hobbyists alike to improve print bed adhesion.

UHU stic- Recommended by the 3D printing community

If you can’t get hold of an Elmer’s sick, the UHU stic is the next best thing. It works just as well, and like Elmer’s stick, it can be used with PVA support material.

It works just as well, and like Elmer’s stick, it can be used with PVA support material.

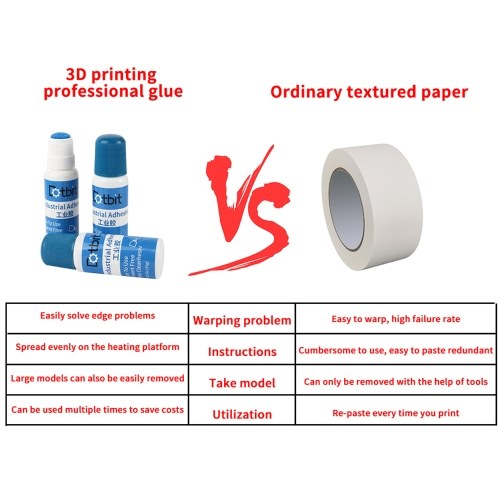

Makerbot Build Plate Tape – Recommended by Makerbot.

Makerbot’s Build Plate Tape is designed for Makerbot printers, but it can be used with any printer. The textured surface improves adhesion and lasts for several prints.

Blue Painter’s Tape – Recommended by 3D Platform

If you don’t want to use glue, the textured surface of blue painter’s tape lends itself well to bed adhesion. It can be used with PLA, ABS and high-temp thermoplastics.

Essentium’s 3D Printing Bed Adhesive – recommended by Essentium

Essentium 3D Printing Bed Adhesive is for printing nylon filaments. It works with nylon filament and other high-temp materials, formulated to reduce contraction.

Out of the above adhesives, we have had excellent results with Elmer’s Disappearing Purple Glue Stick, the UHU stic, and blue painter’s tape. Blue painter’s tape can be picked up at any hardware store, or even your local supermarket. It can be pulled away from a glass build plate easily, without leaving any residue behind, and the grippy surface is ideal for ABS and CPE. Glue sticks are another excellent option, and they don’t cost very much either.

Blue painter’s tape can be picked up at any hardware store, or even your local supermarket. It can be pulled away from a glass build plate easily, without leaving any residue behind, and the grippy surface is ideal for ABS and CPE. Glue sticks are another excellent option, and they don’t cost very much either.

Just be careful with what glue sticks you use. Elmer’s Disappearing Purple Glue Stick and the UHU stic are tried, tested and proven. We tried the Original Pritt Glue Stick but didn’t get good results and this sentiment is echoed by most people who’ve tried it.

Also, remember to calibrate your build plate periodically. Today, most 3D printers will do this for you, but you will need to calibrate manually if you have manual levelling. Having a level build plate is crucial for good bed adhesion, print quality and reliability.

Using a Glue Stick and Why It's a Staple For 3D Printing – DesignMakeShare

If you have been around 3D printing very long you have probably encountered glue stick. Glue sticks work like a magic stick to help curling problems called “Warping” and can help you achieve better Adhesion.

Glue sticks work like a magic stick to help curling problems called “Warping” and can help you achieve better Adhesion.

I am sure, you have had a 3D-print go horribly wrong because of the first layer coming loose. The issue that most people face when 3D printing is getting their 3D-prints to stick to the build plate or Bed.

If a print does not stick to the build plate properly, then it could move during the printing process which will cause it to fail.

Warping occurs when molten plastic after being molded into its 3D-print shape cools down resulting in shrinking. This typically causes the curling up problem starting at the corners.

Using a glue stick can help your print adhere stronger to the bed, eliminating warping problems due to the print not sticking to the bed. It also helps the completed pint release preventing material like PETG from bonding so well that there is a risk your build plate will be damaged upon removal.

In the rest of this article, we will take a deeper look at what glue stick has to offer and how to use it. After reading you should have a better understanding of glue stick is so popular and you may want to try it for yourself.

Why is it so popular?

So why is it so popular? Is it because glue stick offers the just right level of adhesion/release or is there something else that makes it stand out of the crowd? Yes, the adhesion/release is the primary metric for the selection of adhesive materials. But there are a number of other factors too.

Some of these factors are:

- Price of the adhesive

- Availability of the adhesive

- Ease of use of the adhesive

- Sustainability of the adhesive

- Compatibility with a number of materials.

Convenience is a major factor and my belief of why the glue stick is so popular. Not only does it work well but it can easily be picked up at a wide variety of stores and at a very reasonable cost.

Using the Good, Fast and Cheap metric, the glue stick is a rare case where you can have all 3.

Do you still use a heated bed with a glue stick?

Probably, glue stick helps with adhesion but the heated bed is still important. Many people report having luck with just glue stick on a non-heated bed, but if you are going to take on some more challenging materials or have a big print your best bet is to use a heated bed.

The heat from your heated bed helps with the adhesion of your print to the print surface but it is not always enough.

Some cases require glue on the print surface for even better adhesion. Heating temperature depends upon the material used.

The need to use the glue also depends upon the material along with the shape of your 3D-Print.

For materials like Nylon and Acrylonitrile Butadiene Styrene (ABS), it is recommended to always use glue because to help with adhesion to the build surface.

Do you need to reapply after every print?

No, oftentimes a single application is adequate to work for multiple prints. You should apply a layer of glue every 1-5 prints for the optimum results, but some people have reported upto 10 prints before reapplying the glue.

You should apply a layer of glue every 1-5 prints for the optimum results, but some people have reported upto 10 prints before reapplying the glue.

When you are applying glue, make sure you apply it to the entire area of the bed where the part will be printed.

There are some conditions that may require you to re-apply the layer of glue. For example, if the glue layer becomes uneven, you should completely clean the build platform and re-apply to avoid a print failure.

It is also dependent on the glue and on your tolerance for messy undersides on your prints.

It's fairly common for some of the glue to come off with the print, so if you want a perfectly smooth bottom layer, your best bet may be to clean the build surface and apply glue for every print.

To wash and re-apply the glue stick is pretty easy. You can also freshen up the glue with a gentle spray of water and re-dry, or have more glue added on top. But all that comes down to your preferred workflow, determined through trial and error.

How is the cleanup?

Cleanup is very simple and can be done with just water and a rag/towel. Adhesive such as glue is easy to clean up and won’t require much effort to get off the bed (Much less effort than to get yourself out of the bed, ha ha).

If you can, remove the bed from the printer, and then carefully wet the bed platform with water, then you should easily be able to scrape or wipe the glue off the bed.

The Bed should be completely dry before you put it back in to use.

Is glue stick required?

The simple answer is No, but it does help. The exception would be with Polyethylene Terephthalate Glycol (PETG) where you want to use some sort of release agent to prevent damaging the bed surface.

Glue stick is compatible with almost any type of filament you can find. PETG, PLA, ABS, and Nylon are all well suited for use with a glue stick.

Hybrids also work well on glue stick and have similar performance as the pure fimalements.

Is there anything else that hits the sweet spot of bond and release?

Hairspray is another popular option offering easy availability, low cost, and good adhesion/release. The big disadvantage here is that I find it to be very messy to apply.

Aquanet is the brand most often referenced in the 3D printing Community.

Blue Painters Tape is another common solution and is well liked within the 3D printing community. The issue I most often have with blue tape is its durability.

The tape ends up tearing while removing prints and I have to replace it fairly frequently.

The market is quickly beginning to fill with products to address this need. Some popular names you will find include: Magigoo, Dimafix, Build Plate Wizard with more being brought to market all the time.

And again about adhesion... (glue sticks part 2)

3D printing

here: http://3dtoday.ru/blogs/mister-magomedov80-yandex-ru/adhesion-kalyakaexperience123/

This site has written a lot of articles about adhesion agents for 3D printing. I would also like to contribute my little bit, in connection with which I purchased several different samples of glue sticks (more precisely, all the samples that I could find on sale).

I would also like to contribute my little bit, in connection with which I purchased several different samples of glue sticks (more precisely, all the samples that I could find on sale).

I want to clarify that the tests are carried out on a ZAV printer, in a heat chamber, with ABS 'Prostoplast' plastic, at a temperature of 230/95.

The first sample is 'ErichKrause' pencil glue (the most common glue is a pencil in all stationery stores), which, upon arrival at home, was the very first smeared in two layers on a clean, washed 4-mm mirror.

A model of a classic spinner was sent to print, which was already on a flash drive. The first layer went perfectly, the part did not come off, even in the absence of a skirt. Given that the area of adhesion of the print to the mirror was minimal... the glue stick did the job!

I am very satisfied with the initial print using this sample. The second print of the same model, in the same place was successful! The part didn't come off!

Next, for test printing, I chose the model http://www. thingiverse.com/thing:802145 the so-called 'gyroscope'.

thingiverse.com/thing:802145 the so-called 'gyroscope'.

'Gyroscope'

Let's move on to the next test participant. Sample #2 is a strange triangular shaped glue called 'De Vente'. Glue of lilac color with an unpleasant smell. Applied to the mirror in two layers, the first print went well. The second print in the same place came out just as well. Fingerprints are removed from the mirror without difficulty. This adhesive is usable.

Sample #2.

Sample #3 'Silwerhof' glue stick This glue sample is based on PVP. Glue is applied easily to the mirror. The plastic adhered perfectly on the first print and also stuck on the second print without any problems. The prints come off the mirror with difficulty.

sample no. 3.

sample no. 4 glue stick 'A+'. This glue is designed for gluing paper, cardboard and fabric. The glue is applied to the mirror with difficulty and sticks strongly. In this connection, it was applied in one layer. The adhesion of this sample is weak, the plastic does not stick well even at the first printing (although for some reason I had hopes for it :)). Glue in the trash!

Glue in the trash!

Sample No. 4.

Printing result with sample No. 4.

Sample No. 5 'ErichKrause Joy' glue stick, which was also hoped for, did not fit for printing at all, the plastic did not stick at all. Summary: in the trash!

sample no. 5.

sample no. 6 'Hatber' glue stick applied easily, first print and second print went well.

swatch no. 6.

swatch no. 7 'De Vente' gel adhesive stick, colorless, pleasant smelling, applied with great difficulty and in a thick layer, therefore, it was applied in one layer. However, this did not prevent the plastic from sticking to the surface perfectly, on the first print and the second! This glue remains as a 'helper';)).

Sample no. 7.

left side of mirror smeared with sample no. 6, right side with sample no. 7.

sample no. . The part comes off with difficulty. This glue goes to 'helpers'.

Sample No. 8.

Sample No. 9 PVP-based glue stick 'Alingar', I was not satisfied with this glue, the first print was unsuccessful, I didn't even start the second one.

Sample No. 9.

And the last one....

glue stick 'Tukzar' apparently Turkish) is not suitable for printing, throw it away!

Good luck everyone! Thank you for your attention).

Follow author

Follow

Don't want

38

More interesting articles

DrProg

Loading

11/08/2022

1456

9

Subscribe to the author

Subscribe

Don't want

We continue to reveal the incredible opportunities of enterprises from China, to...

Read more

0

Subscribe to the author

Subscribe

Don't want

Ones Technology is a research and development center under the Ministry of Industry of Turkey. According to G...

According to G...

Read more

Leoluch

Loading

09/07/2015

358531

346

Subscribe to the author

Subscribe

Don't want

Good afternoon, dear visitors of the portal.

Today I decided not to leave in art...

Read more

Overview of glue sticks and adhesion varnishes for beginners

Hello, dear readers of the portal 3d today.

For a long time I wanted to write an article about those means for plastic adhesion that I tried myself. The materials I chose were glue sticks and hairsprays, because. they are the easiest and most enjoyable to use. The article was rather published for beginners to look for their own remedy, so there are no revelations here.

1) Gingko glue stick "Work-Home-Office-Creativity" from "Uncle Liao" from China.

The worst I've ever seen on the road to good adhesion. It dries quickly, everything peels off and bends, you need to smear it with enough oil to have at least some effect.

Pluses:

- forms a continuous film after several applications;

- quite common (at least in the Tula region).

Cons:

- poor adhesion, and that says it all.

Subjective rating: 2/10.

2) Erich Krause glue stick, originally from sunny Russia.

Definitely a skill to work with, parts often come off the table.

Pros:

- available almost everywhere.

Cons:

- mediocre adhesion.

Subjective assessment: 4/10.

3) Mega fixation hairspray "Taft three weather" from Schwarzkopf Professional.

Slightly better than the previous sample, but not much.

Pros:

- not pronounced.

Cons:

- very afraid of drafts when printing with ABS plastic.

Subjective rating: 5/10.

4) Extra strong hairspray Delight from Russia. Sold in various wholesale stores and Magnet.

Pros:

- the price is 50 rubles. For a huge balloon that will last forever.

Minuses:

- even with a little effort, it is torn off even from a hot table, but it is suitable for printing with certain reservations.

Subjective rating: 6/10.

5) Oriflame "More" Swedish hairspray.

I got it quite by accident. It glues well, although sometimes the skirt starts to peel off very slowly, but if the print is less than 5 hours, then it's okay.

Pros:

- compact;

is very sticky and slow drying. After finishing in the evening, you can print on the old varnish pass in the morning.

Cons:

- slightly sticky surface of the part after tearing it off the table;

- now it is quite difficult to get it.

Subjective rating: 7/10.

6) Nelly Spanish strong hold varnish.

Was very widely known in narrow circles of 3D printers.

Pros:

- strong adhesion;

- compact size unlike other varnishes.

Cons:

- strong adhesion, oddly enough. The students, having gone too far with varnish, tore off the cold part along with pieces of glass.

is the biggest minus. This varnish is no longer produced. Therefore, it can only be bought from old stocks.

Subjective assessment: 8/10.

7) Magic glue stick "Kalyaka-malyaka".

Here's our favorite purple. Many recommend it, and, as it turned out, for good reason. There are no problems at all. It was possible to glue medium-sized parts without a skirt at all with an open ABS plastic table.

Pluses:

- one application is enough for several times;

- strong adhesion, but easy separation from a cold table.

Cons :

- not found.