What are 3d printed houses made of

5 materials 3D printed houses are made of

Construction 3D printing materials offer a lot less variety than their desktop counterparts. The most popular material by far is 3D printing concrete. However, this is just a very broad term for mixtures that involve cement, fibers and other ingredients mixed in with water. Other materials include castable clay, mortar, synthetic polymers, and even regular old plastic (recycled).

ConcreteConcrete is by far the most popular construction 3D printing material. In large part this is due to the flexibility in its formulation. A number of construction 3D printer makers have also devised their own optimal formulation of 3D printing concrete that they claim is the best for use with their construction 3D printers. “Lavacrete” is one such example used with the Vulcan construction 3D printers by ICON.

Construction 3D printing concrete in many ways is similar to normal concrete, but with added fibers, super-plasticizers and other ingredients that make the concrete set in optimal time for layer adhesion between the construction 3D printing layers, as well as strength to allow for less need of steel re-enforcements.

The major advantage of using 3D printed concrete is obviously its strength, as well as its similarity to conventional concrete, which allows for transference of conventional construction material knowledge to 3D printed house construction as well.

The first human inhabited 3D printed house located in France. Developed in part by University of Nantes.The major drawback, however, is how environmentally unfriendly concrete itself is. Concrete production, or more specifically, cement production overall is responsible for more than 5% of total global CO2 emissions. Which is worse than even emissions by the airline industry.

While it is still the go-to material for construction 3D printing and 3D printed houses in general, 3D printed concrete is far from being an eco-friendly choice for the same.

In its defense however, 3D printing concrete is on a road to sustainability with research underway to make 3D printing concrete out of CO2 based binders as well as a shift to smartly designed concrete structures that would use less material for the same level of strength, thereby limiting the need for this eco-unfriendly building material.

Mortar, similar to concrete, is a mix made out of cement, sand and other minerals, designed to be used in construction. Traditional mortar is the stuff that is placed between bricks to bond them together. Construction 3D printing mortar is similar but is designed to be used to construct entire 3D printed houses.

Mortar tends to be easier to work with, and more flexible than concrete allowing for it to be made with a less environmentally damaging footprint. Mortar-based construction 3D printing is slowly falling out of practice in favor of concrete-based mixes mainly due to the added strength advantages of 3D printing concrete.

However, there are notable exceptions, such as CyBe Mortar, that is used by CyBe’s line of construction 3D printers.

3D printed house, Gaia, located in Italy developed by WASP. Photo curtesy of WASP. SoilNotably used by WASP in their Crane Wasp and BigDelta construction 3D printers, soil is simply the stuff we walk on. By engineering the material delivery pipe and nozzle of the 3D construction printer, WASP built the very first 3D printed earthen house, “Gaia”, with rice husk insulation in Italy in 2018.

By engineering the material delivery pipe and nozzle of the 3D construction printer, WASP built the very first 3D printed earthen house, “Gaia”, with rice husk insulation in Italy in 2018.

If the environment comes first and foremost in your decision making, then using the on-site soil along with agricultural fiber waste like WASP used is an excellent way of making a 3D printed house with an almost nil environmental footprint.

More than just environmentally friendly, using the soil at any site is also cost and time effective. WASP later on went to build an entire village of 3D printed earthen houses, all smartly engineered to be able to provide modern amenities in Italy based on the same principle technology demonstrated in constructing “Gaia”.

Special polymersThe beautiful thing about 3D printing technology is the potential for innovation merely through using a specialized printing material. Similar to desktop 3D printing, construction 3D printing is also home to a large number of innovations in material sciences.

While most of these in the past have dealt with making more effective 3D printing concrete. A recent trend has been towards developing entirely new synthetic polymers that can be used to construct entire houses.

PassivDom is one such example whereby they have built an entire 3D printed prefabricated house using a special insulating polymer composite. The polymer composite is so good in fact that PassivDom’s prefabricated houses can be heated and cooled with only solar energy powered equipment inside the house. PassivDom has even went as far as to cheekily call their prefab houses “Zombie proof”.

Recycled and other plasticsInterior of GAIA 3D printed house located in Italy developed by WASP. Photo curtesy of WASP.That’s right, houses made from plastic! Recycled plastic that is. Born out of a collaboration between DUS Architects and Ultimaker, the duo jointly designed and constructed a small plastic house as a means of demonstrating the viability of construction 3D printing with recycled material.

The aim of the project was to demonstrate how making plastic houses could serve as a solution to housing needs in the wake of a crisis or a natural calamity.

Likewise, there is work ongoing in 3D printing buildings with bioplastics.

Tags: 3D printed house3D printingMaterials

7 of the Most Beautiful 3D Printed Houses and Cabins

From hemp fibers to rice waste, companies around the world are coming up with innovative ways to utilize unusual materials.

3D printing is having a big effect on many industries around the world, and the construction industry is no exception.

Here are seven interesting examples of proposed and in-development 3D printed housing projects from around the world. Perhaps you might want to get one printed for yourself in the not-too-distant future?

What is a 3D-printed house?The answer is, quite literally, in the name. 3D-printed houses are created using very large 3D printers that, unlike smaller hobbyist or other types of industrial units, are able to extrude concrete, plastic, or other building materials through nozzles, in order to gradually build up a 3D object the size of a house.

These printers, specifically their nozzles, are able to move in multiple planes and are specifically designed to be very robust and hardy, as they generally need to operate outdoors on variable terrain.

To date, there are various research institutions and private enterprises working on the technique, and it is believed by some that the future of the construction industry may eventually come to rely on the descendants of current giant 3D printers.

Can you print a house, and how much does it cost?

3D printed houses are still something of a novelty and are largely still in development, but you can 3D print a house for a lot less money than having one built using more traditional construction methods. For some of the projects that are currently in development, costs are somewhere in the order of $10,000, although this is for a relatively small structure.

According to a report from The Verge on ICON's operation techniques "the 3D-printed house would be made of cement and take up to one day to be printed by large, 3D printing robots. Best of all, the homes would cost just $10,000. And ICON hopes that eventually, it can bring the cost of homes down to $4,000."

Best of all, the homes would cost just $10,000. And ICON hopes that eventually, it can bring the cost of homes down to $4,000."

But it should be noted this is for a very small, 2-bed house. Larger constructions would likely cost more.

There are also some 3D homes that have been built up for less than half that.

How long do 3D printed houses last?

Since the vast majority of 3D printed houses are made from concrete, they should last a decent amount of time. With proper maintenance and continuous habitation, there is no reason they shouldn't last as long as more traditional concrete constructions.

Estimates vary, but most agree that they should at least last about 50 to 60 years.

Many 3D printed houses do have timber elements included which may be susceptible to decay over time if they are not treated or maintained properly.

Most Popular

Source: post-apocalyptic research/FlickrSome other 3D printed buildings have been specifically designed to be biodegradable, and are only intended as used for temporary accommodation, for use in disaster relief operations and other short term housing needs.

Is it possible to take up residence in a 3D printed house? Well, most 3D printed houses created to date sway towards proof of concept builds, but there are some projects around the world that are working on techniques to produce 3D houses fit for habitation.

What are some examples of 3D printed houses?

So, without further ado, here are 7 interesting examples. This list is far from exhaustive and is in no particular order.

1. These tiny 3D houses in Mexico are pretty cute

Source: New StoryIn Mexico, a giant 3D printer is being used to create an entirely new neighborhood. Each house takes around 24 hours to complete and can house a small family.

The 32.8 feet (10 mt) long printer quickly churns out the shell of every 498 ft2 (152 m2) area; the roof, windows, and interiors are fitted later. A non-profit called New Story is behind the endeavor.

They have teamed up with ICON to make use of their enormous Vulcan II printer to create the houses.

The idea is to allow low-income residents in rural areas to move out of their shacks into these new, two-bed houses. It is thought that developments like this could one day help solve the housing crisis in many areas around the world.

2. This 3D printed house can operate off-grid

Source: activehouseCalled the PassivDom House, this house was designed to be as sustainable and energy-efficient as possible. It runs entirely on solar power and can even generate its water from the moisture in the air with an optional add-on.

It is created using a large 3D printer in a factory in Nevada and could be a game-changer for small housing in the future.

The shower in the bathroom can also clean and recycle water. All around, the house is designed to use as few resources as possible. Initially, the company wasn't aiming at creating an off-grid house, but as they developed upon their ideas, the team realized that it's a feasible option.

3. This Italian 3D-printed house is tiny but full of potential

Source: 3dwaspAn Italian 3D-printing company called WASP is building tiny houses to showcase the abilities of their revolutionary Crane WASP printer. This modular 3D printer can create homes in a variety of formats and sizes very rapidly indeed.

These new 3D printed houses, called Gaia, are 322 sq ft (30 sq mt) dwellings with a 3D printed outer shell and internal timber beams supporting each unit's timber roof. The above example was printed in situ in Massa Lombardo, which is a town in the Italian region of Emilia-Romagna in October of 2018.

The material for the house contains mud from the surrounding area and waste byproducts from rice production, such as straw and husks. Apparently, the house is also biodegradable!

4. These 3D printed houses look like something from an alien world

Source: Houben/Van Mierlo ArchitectsDeveloped through the collaboration of the Eindhoven University of Technology and Houben/Van Mierlo Architects, these 3D printed houses look like something you'd find on an alien world. They hope to produce a few units in the near future to be rented out at a reasonable price.

They hope to produce a few units in the near future to be rented out at a reasonable price.

The Dutch university is set to construct around 5 of the buildings over the next five years and each one is almost completely made of concrete.

"The project is the world's first commercial housing project based on 3D-concrete printing," said the university. "The houses will all be occupied, they will meet all modern comfort requirements, and they will be purchased and let out by a real estate company."

5. This 3D printed house is also a work of art

Source: WATGBack in 2016, a team of architects in Chicago proposed an amazing design for a 3D printed house made of printed plastic, carbon-fiber panels, and glazed walls. The team won first prize in the Freeform Home Design Challenge and for a good reason.

The design for the 3D printed dwelling is incredibly bold and, compared to other examples above, makes the most of the technology. Called Curve Appeal, the building is actually a thing of beauty.

The plan was to 3D print the building in Chattanooga in Tennessee. It is planned to be completed in 2020.

6. This Amsterdam-based company created micro 3D printed homes

Source: DUSDUS Architects are planning to build tiny 3D printed micro-homes in Amsterdam. Each tiny 26.2 ft2 (8 m2) cabin comes with its own internal bathtub and is very cozy indeed.

Each 3D cabin is built using bio-plastic and the project is intended to demonstrate how additive manufacturing can offer solutions for temporary housing solutions in disaster areas, among other applications. When the cabin is no longer needed, it can be destroyed and almost all the materials can be reused.

"The building is research into compact and sustainable dwelling solutions in urban environments," said the team behind the cabins.

7. These 3D printed houses are made out of hemp

Source: MirrecoThere are plans to build a set of hemp-based 3D printed houses in Australia in the not too distant future. Designed by the biotech company Mirreco, they hope to harness the "explosive potential of industrial hemp."

Designed by the biotech company Mirreco, they hope to harness the "explosive potential of industrial hemp."

The company believes it should be possible to 3D print the floors, walls, and even roofs of buildings using carbon-neutral hempcrete panels. The company recently unveiled its plans that were developed in collaboration with Arcforms, an architectural company based in Perth.

“The floors, walls, and roof will all be made using hemp biomass, and the windows will incorporate cutting-edge technology that allows light to pass through the glass where it is converted into electricity,” Mirreco stated.

And that's your lot for today.

For You

diy

AutoCAD is a superb engineering design tool, but did you know there are plenty of shortcuts and commands available to speed up your projects?

Christopher McFadden | 10/18/2022

science‘Let’s build the ring’: How a 360-degree image posted on Facebook inspired an ambitious sci-fi film

Paul Ratner| 10/8/2022

scienceDoes hot weather lead to increased violence? These researchers found a connection

Deena Theresa| 8/18/2022

More Stories

culture

US Air Force to unveil first new stealth bomber in 34 years, the B-21 Raider

Ameya Paleja| 10/21/2022

science

Scientists outlined one of the main problems if we ever find alien life, it's our politicians

Chris Young| 10/19/2022

innovation

The images of France’s new nuclear-powered aircraft carrier will astound you

Loukia Papadopoulos| 10/21/2022

Construction 3D printing is waiting for a breakthrough The first construction projects using this technology appeared only in 2014.

We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development.

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now?

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself.

The issue of regulation and certification also plays an important role - this process is long and creates an additional lag.

In 2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared.

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry.

Thus, I believe that the specified time period is a fairly natural cycle of technology development, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, growing by 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

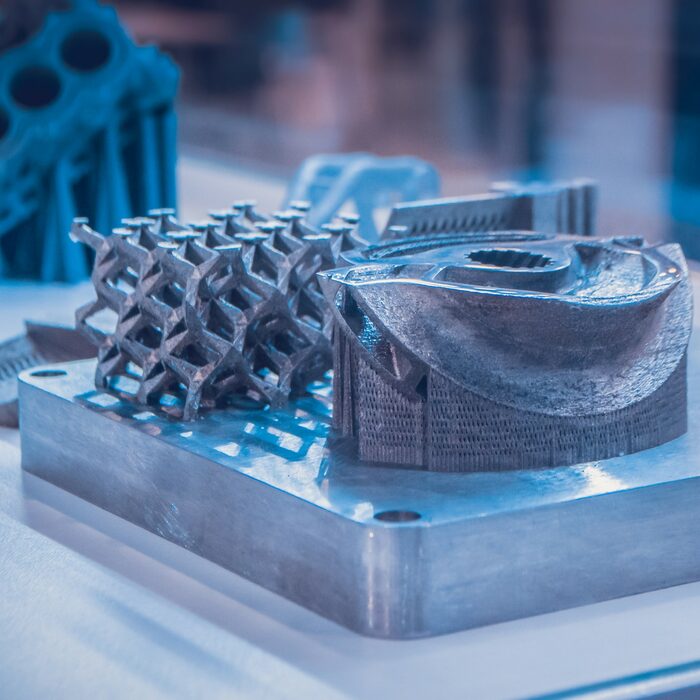

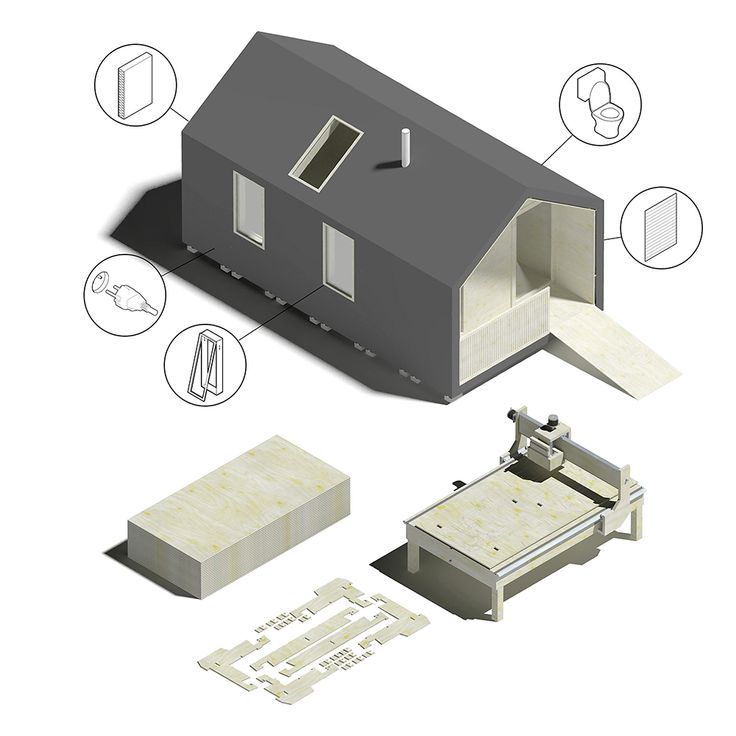

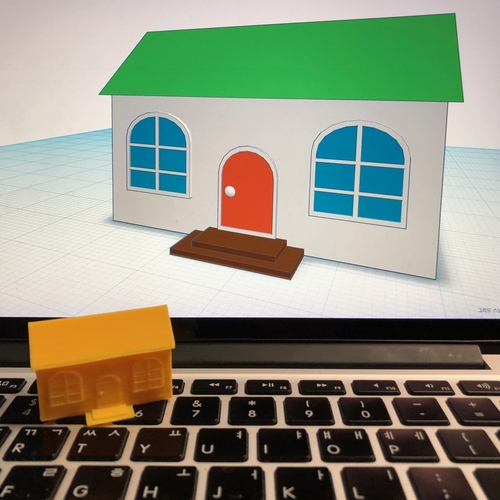

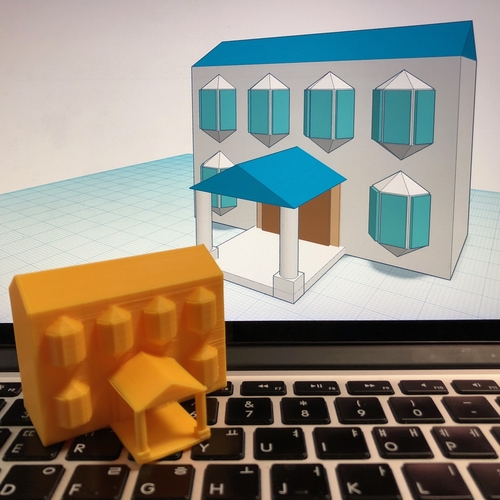

Now let's take a quick look at what the construction 3D printer is. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

Few things unite developed, developing and poor countries, everywhere their problems and tasks, but Affordable housing shortage is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

At the same time, the trend towards "green agenda " is developing, reducing CO2 emissions, building with more environmentally friendly materials, etc. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples.

3D printed walls. Today, when we talk about 3D printing houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are built as fixed formwork, which significantly saves the amount of cement used , and this, in turn, reduces the cost of construction and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

Eco-concrete with the addition of polymers is being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.![]()

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds.

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany.

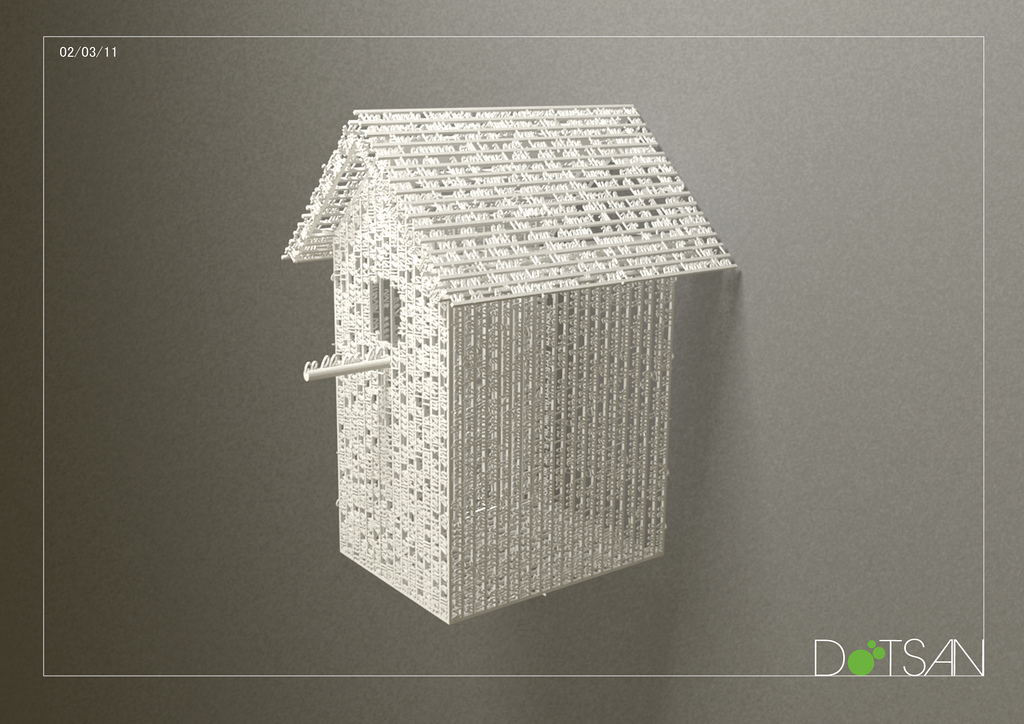

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element. That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards.

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project.

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the shop, after which the object is transported to the installation site.

Construction takes place in the shop, after which the object is transported to the installation site.

Construction 3D printing, or, as it is also called, additive construction, has just appeared, and I want to believe in its bright future. There are many prerequisites for this, but a lot still needs to be done for success. First of all, it is necessary to develop principles for designing houses for building 3D printing. Then it is necessary to attract top architects to create landmark projects, which can be followed by the mass introduction of a new and very promising technology. Construction 3D printing could help solve the global housing shortage and bring more automation to other areas of construction.

Alexander Kornveits

Expert in the field of additive technologies and 3D printing, head of Tsvetnoy Mir

Read an article about the first 3D printed houses?

3D printing has been used in construction for several years now. In this article, you will learn about the first real houses printed on 3D printers.

In this article, you will learn about the first real houses printed on 3D printers.

3D printing of houses is still quite new to the layman. While construction 3D printing technologies have been developed for many years, only a few "real" projects have already seen the light of day. We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream.

There are many benefits to 3D printing. For example, the cost of a 3D printed house can be much lower. And it will take much less time to build.

In order to draw a line under what has already been achieved in this area and show some interesting projects, we have devoted an article to the "first" and the best. These projects will always remain milestones in the 3D construction printing industry as they set the stage for future advances in the field.

First 3D printed house in Germany

Germany is a country often associated with cutting-edge engineering, so let's start our list with Germany's first ever 3D printed house.

The house itself is located in Beckum, a city that is partly located in North Rhine-Westphalia, next to Holland and Belgium. This is the first 3D printed house to be fully certified to official building codes. This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe.

The project is the result of a collaboration between German construction company Peri and Danish construction 3D printing firm COBOD. Peri is a large corporation that operates not only in Germany, but throughout the EU. Its portfolio includes many products, including scaffolding and formwork solutions that every construction site needs.

Peri followed the construction 3D printing segment for many years before acquiring a stake in COBOD in 2018. Now they are pushing the technology together and further. The construction of the house in Beckum began two years after the acquisition of the share.

For 3D printing at home, a BOD2 modular 3D printer from COBOD was used. The printing itself took just over 100 hours.

The printing itself took just over 100 hours.

• Built: (started) September 17, 2020

• Commissioned: summer 2021

• Where: Beckum, North Rhine-Westphalia, Germany

• By: Peri, COBOD

First occupied 3D printed home in the US

Several homes have been printed in the US, but this home is the first officially occupied home, according to CNN. Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

From a distance, you might think that this is an ordinary house. However, when approaching it, the layered structure of the concrete walls becomes noticeable. After all, 3D printing creates an object in layers.

Surprisingly, the 111.5 square meter concrete structure of the house (was printed in about 12 hours, significantly faster than traditional construction methods would allow.

The house was reportedly bought by April Springfield, who lives there with her son and dog She bought the house through Habitat for Humanity's housing program, and given that the nonprofit's goal is to help solve the global housing crisis, it makes sense to use 3D printing to create affordable homes that will make many people's dreams of home ownership come true. 0003

0003

• Built: 2021

• Commissioned: December 22, 2021

• Where: Williamsburg, Virginia, USA

• By: Alquist 3D, Habitat for Humanity Peninsula, Greater Williamsburg

The first five-story 3D printed house

This project, made by the Chinese company WinSun, is a real record holder. It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

The house is located in Suzhou Industrial Park in Jiangsu province in eastern China. It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

Looking at WinSun designs, you can't help but notice that they don't look like they've been 3D printed. Usually 3D printed structures are gray in color, the layer lines are clearly visible. But WinSun adds color and makes walls smoother. Nowhere is it stated how the company achieves the smoothness of the walls, but we assume that the workers smooth them by hand. WinSun projects are not like the ones we're used to.

WinSun projects are not like the ones we're used to.

• Built: Winter 2014

• Commissioned: Not specified

• Where: Suzhou, Jiangsu, China

• By: WinSun

First 3D printed biodegradable house

Can you guess that there is rice in the walls of this house?

Most 3D printed buildings are made from concrete mix. But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

WASP developed the sustainable blend in collaboration with Ricehouse, a company that specializes in using natural and agricultural materials such as clay and rice in construction.

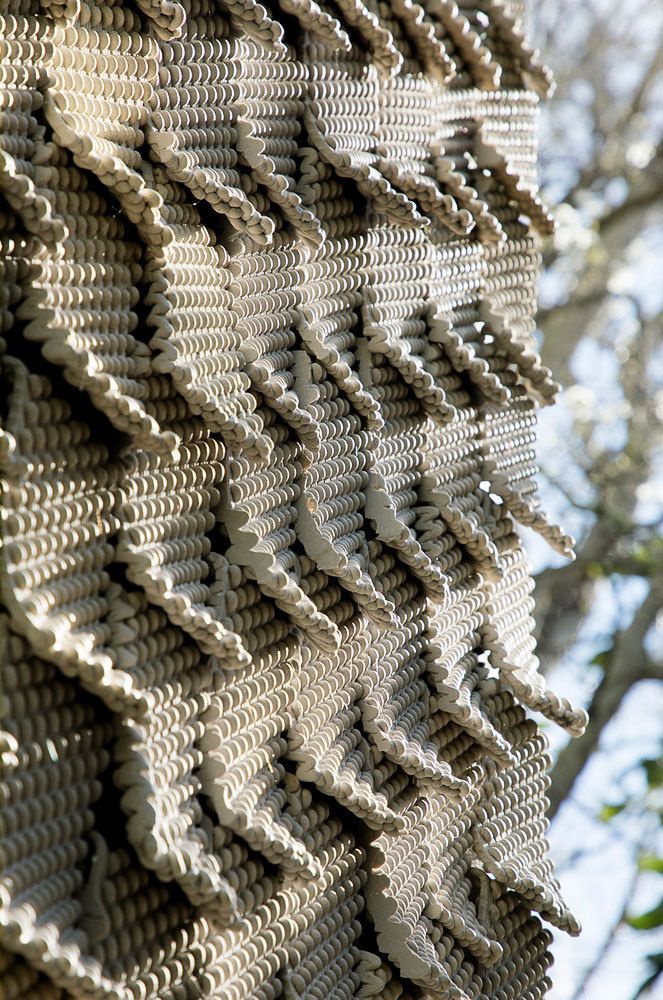

The house is named Gaia in honor of the ancient Greek goddess of the earth. In fact, 25% of the mixture contains local soil, 10% hydraulic lime, 25% rice husks and 40% crushed rice straw (a by-product of rice production at harvest).

An innovative solution not only in terms of material, but also in the design of the walls themselves. The specific corrugated structure was used to provide ventilation on warm days as well as insulation on cold periods, virtually eliminating the need for air conditioning.

Gay's house is small - about 20 square meters. The wall printing took only 10 days, while the estimated materials cost is just under $1,000.

• Built: not specified

• Commissioned: October 7, 2018

• Where: Massa Lombarda, Ravenna, Italy

• By: WASP, Ricehouse

AirBnB's first 3D printed home

The perfect weekend getaway.

You can find many different types of accommodation on AirBnB, but what about a 3D printed home?

The so-called Fibonacci house is the first 3D printed house to be offered for booking through AirBnB. Considering that it is located in rural British Columbia, it will be a wonderful place to stay.

Although the Fibonacci house looks small, it has a lot to offer vacationers. About 35 square meters is enough to accommodate up to four people.

About 35 square meters is enough to accommodate up to four people.

The concrete walls of the house were designed and printed by Dutch 3D printing firm Twente. 20 concrete parts were produced offsite in just 11 days. The material was produced by Laticrete. The parts were later transported and assembled at their current location.

• Built: 2020

• Commissioned: Not specified

• Where: Kootenays, British Columbia, Canada

• By: Twente Additive Manufacturing

First 3D printed houseboat

Prvok is not only the first 3D printed house in the Czech Republic, but the world's first floating 3D printed house on a pontoon.

The project was implemented by the start-up company Scoolpt. The concrete structure of the houseboat took only 22 hours to print.

Approximately 43 square meters of living space divided into bathroom, bedroom and living room with kitchen. Weight isn't usually discussed in the context of houses, but given that this one is on water, it's interesting to note that Prvok weighs 43 tons.

The house is equipped with a built-in recirculating shower and tanks for drinking and municipal water and has a service life of at least 100 years.

• Built: June 2020

• Commissioned: August 18, 2020

• Where: Prague, Czech Republic

• By: Scoolpt

Europe's first 3D printed residential house

Not every 3D printed house has visible line layers.

More often than not, 3D printed houses are demos made to show what the technology can do. For most of them there is no information about the actual residents. But in 2017, the couple did move to live in a 3D printed house located in Nantes, France. Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

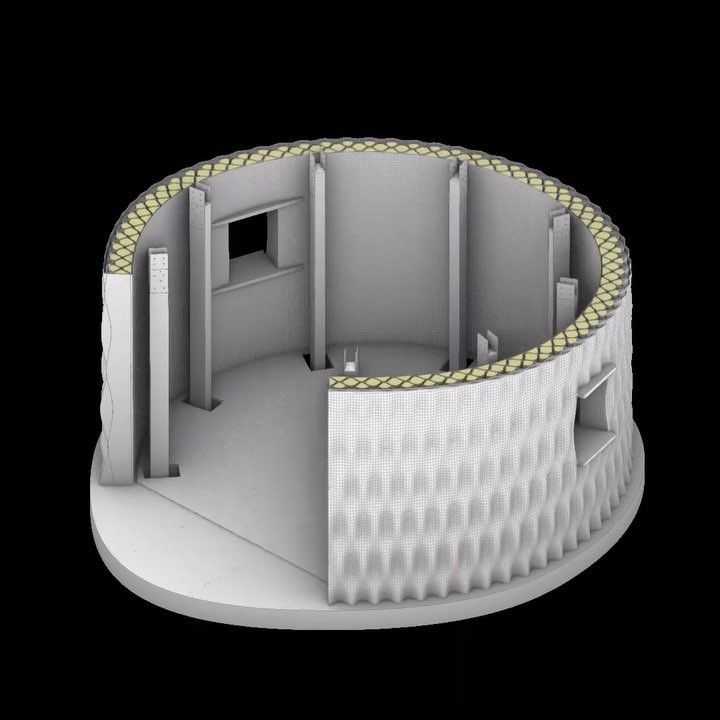

The house is a project of the University and the Laboratory of Digital Sciences of Nantes. An interesting aspect of the project is the special technique used in its construction by BatiPrint3D. Instead of 3D printing a concrete structure, the robotic arm created wall shells using polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

Later, these membranes were filled with concrete.

It took a total of 54 hours to print. It took a little over 4 months to complete the construction. Mainly due to the fact that the rest of the components were created using conventional means. House area - 95 square meters.

• Built: 2017

• Commissioned: March 2018

• Where: Nantes, France

• By: University of Nantes, Nantes Digital Science Lab

India's first 3D printed house

This building was built in a couple of days.

India's first ever 3D printed house was completed back in 2020. The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The significance of this project lies in its possible impact on the solution of the housing crisis worldwide and in India in particular. The ability to build such a house within a few days and at a low cost cannot be underestimated.

House 55.7 sq.m. with a spacious layout, one bedroom, combined kitchen and living room.

The concrete structure of the house was 3D printed off site and the parts were later transported and assembled on campus. The foundation, meanwhile, was built using the conventional method of pouring concrete into the ground.

• Built: 2020

• Commissioned: Not specified

• Where: Chennai, India

• By: Tvasta Construction

Africa's first 3D printed house

Back in 2019, in the Moroccan city of Ben Guerir, Spanish firm Be More 3D created Africa's first 3D printed house. The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

Be More 3D printed house 32 sq.m. in about 12 hours, took first place and received the title of the most innovative startup.

Be More 3D didn't stop building in Africa and later created the first 3D printed house in Spain and developed its own concrete 3D printer in partnership with several corporations from the automation and materials industries.

• Built: 2019

• Commissioned: Not specified

• Where: Ben Guerir, Morocco

• By: Be More 3D

First 3D printed home for sale in the US

Last on our list is the first 3D printed home for sale in the US.

This house was printed in the same place by SQ4D, a company specializing in the development of robotic building systems. The building was printed with SQ4D's Arcs concrete extrusion system and has a 50-year warranty on the printed structure.

Living area of 130.7 sq.m. with three bedrooms and two bathrooms. There is also a garage for 2 cars.

The house was listed for sale in January 2021 for $299,999. Considering the size of the house and the fact that it is priced 50% below the cost of comparable newly built houses in the same area, the deal is pretty good.

• Built: 2020

• Commissioned: 2021

• Where: Riverhead, New York, USA

• By whom: SQ4D

Translation source: https://m.