3D printer candle molds

3d Candle Mold - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

How 3D Printed Candles Can Light Up The World « Fabbaloo

By Charles Goulding on May 25th, 2020 in Design

Tags: candle, design, lighting

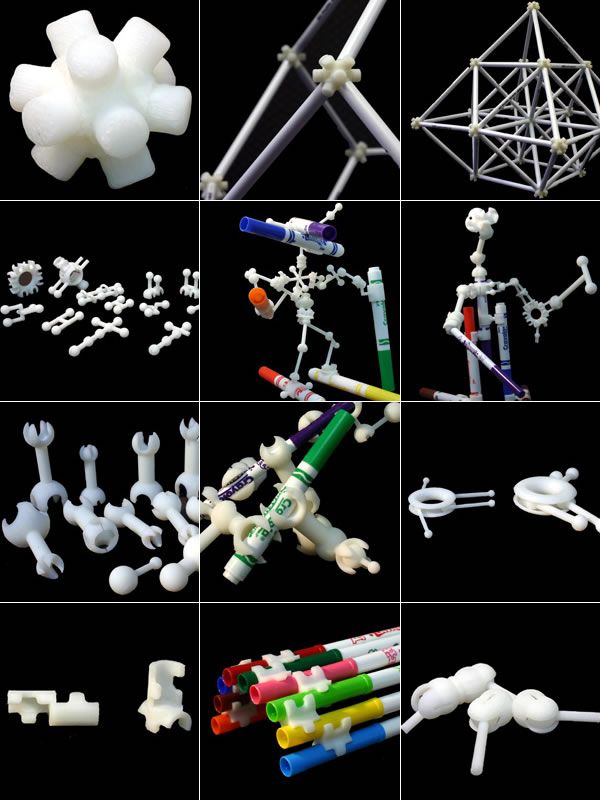

3D Printed Candle Holder [Source: LukeK via Pinshape]Charles R. Goulding and Mindy Zhu examine the ways 3D printing is helping candlemaking stay alight.

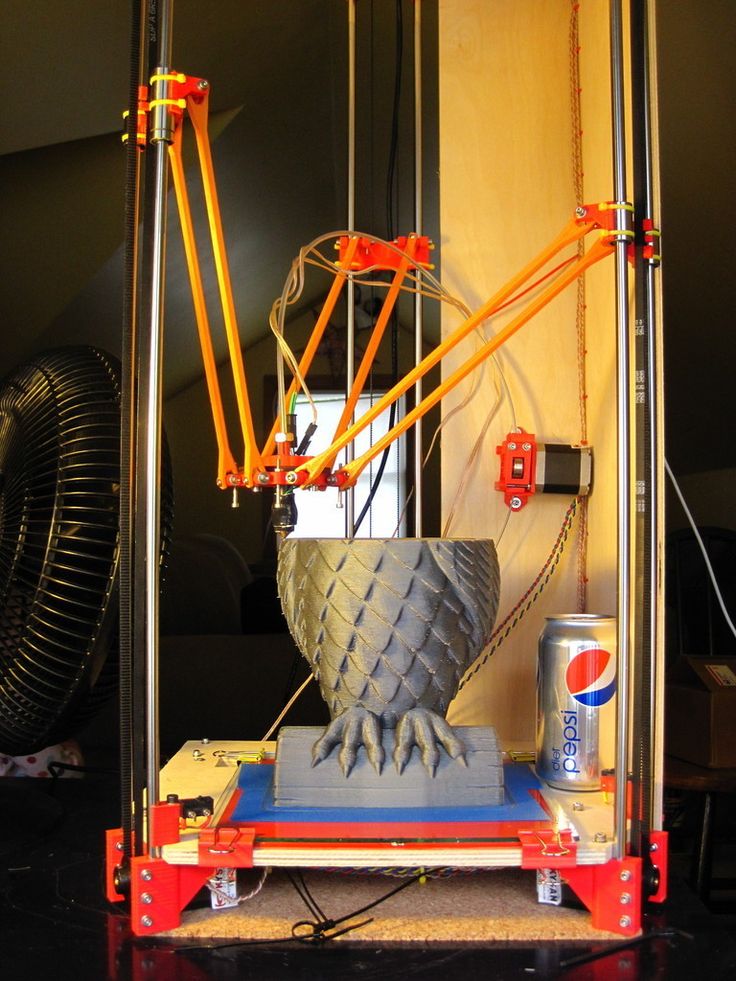

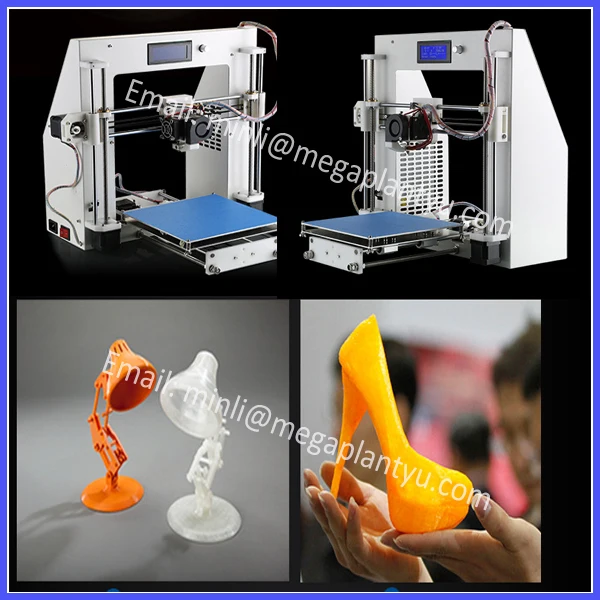

3D printed candles are lighting up the world. Candle companies are now using 3D printing technology to develop new and improved candle production processes, in addition to product testing. Candle molds, holders and covers can be made using 3D printing methods. The U.S. retail candle industry is estimated at approximately $3.14 billion annually, and with the advancement of 3D printing technology, the candle industry is continuing to grow.

One of the reasons 3D printing is being integrated in the candle industry is for its ability to overcome design limitations for new products and improve the production process. Companies can utilize 3D printing to create custom candle molds and candle holders to achieve more intricate shapes and details in end products. Using CAD software, a designer can create a completely custom candle mold and then actualize the design with 3D printing. Due to its versatility, low cost and melting point, PLA plastic could be then used to cast a higher-quality silicone mold, which has the ability to engulf any fine details of the print, and produce paraffin wax candle products. Integrating 3D printing is a viable solution for producing candles and candle holders with more complex structures and geometries.

Integrating 3D printing is a viable solution for producing candles and candle holders with more complex structures and geometries.

Companies and retailers that are using 3D printing to design new candle products may be eligible for federal R&D Tax Credits.

Le Bon Marché

Le Bon Marche: Selfie Candles [Source: iMakr]One such company, Le Bon Marché, has teamed up with a 3D printing company iMakr to sell 3D printed candle selfies called “Scandles”. Customers are able to book a 3D scanning session and take selfies which would be turned into a high quality, completely personalized wax candle. After 3D scanning takes place, a 3D printed plastic model is used to cast a silicone mold that is then used to create a completely customized candle.

The Research and Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes.![]() Qualified research must meet the following four criteria:

Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

The candle industry is one of many that can benefit from 3D printing technology. It can be used to improve candle production processes, whether it is for prototyping purposes, creating custom molds or producing the end product itself. Companies that are integrating 3D printing methods to create new or improved products and processes should consider taking advantage of federal R&D Tax Credits.

It can be used to improve candle production processes, whether it is for prototyping purposes, creating custom molds or producing the end product itself. Companies that are integrating 3D printing methods to create new or improved products and processes should consider taking advantage of federal R&D Tax Credits.

By Charles Goulding

Charles Goulding is the Founder and President of R&D Tax Savers, a New York-based firm dedicated to providing clients with quality R&D tax credits available to them. 3D printing carries business implications for companies working in the industry, for which R&D tax credits may be applicable.

View all of Charles Goulding's posts.

3D wax printing: advantages, features, equipment

Basics of 3D

Casting

Jewelry industry

3D printers

Author: Viktor Naumov

Author: Viktor Naumov

Wax 3D printing vs traditional technologies | Wax 3D printers: advantages, disadvantages, applications | Wax 3D Printing Technology | FlashForge WaxJet: large-format machines for creating high-precision models | Order a consultation and printing services

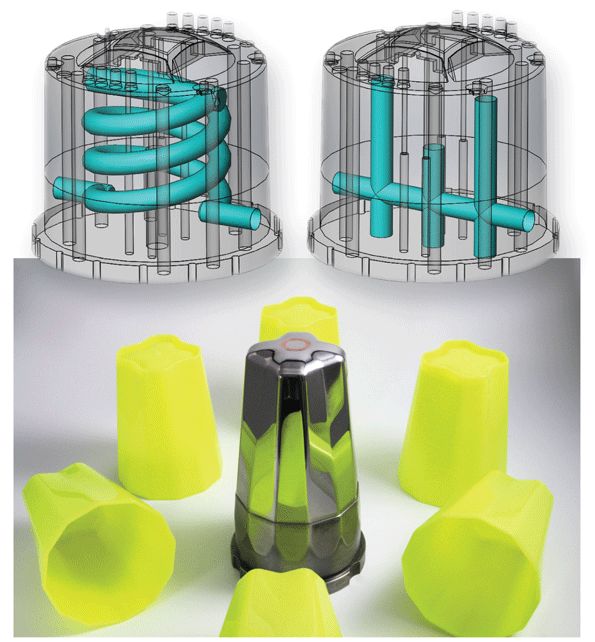

Wax is an environmentally friendly, non-contact, soluble material commonly used in the manufacture of investment casting products. A casting mold is removed from the investment model, into which molten metal is then poured and the final product is obtained.

A casting mold is removed from the investment model, into which molten metal is then poured and the final product is obtained.

Wax 3D printing vs traditional technology

For traditional casting, as well as for other classical technologies, the advent of 3D printing was a turning point: additive methods immeasurably expanded the possibilities of production, making it possible to significantly optimize the technological cycle in enterprises of various industries.

Wax, characterized by good meltability (at temperatures above 60°C) and requiring simple post-processing, has become one of the most affordable and popular materials used in 3D printing. Today, even in a typical office or laboratory setting, you can install an additive machine and print high-quality wax models that closely match CAD models around the clock.

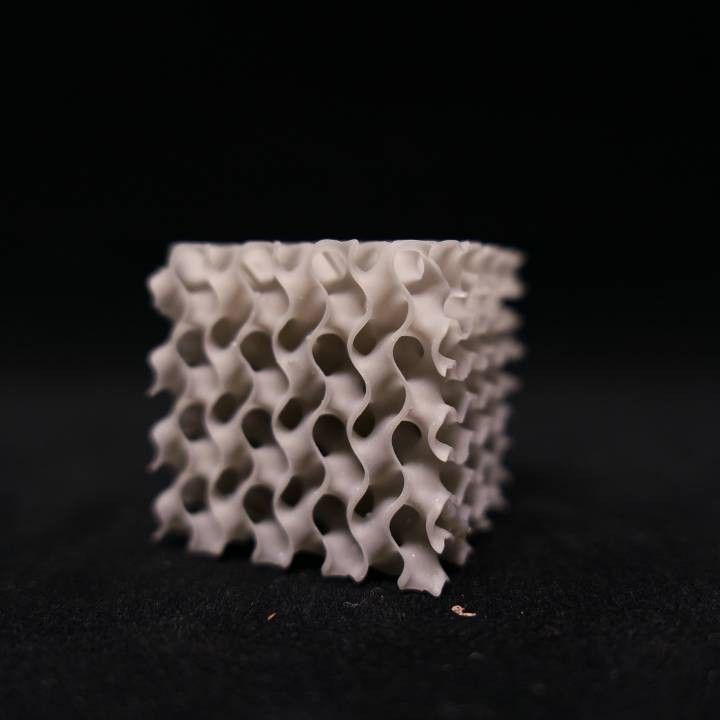

Thanks to the high performance of 3D wax printers, an enterprise can reduce the time it takes to make prototypes by several times, and sometimes even dozens of times, and, accordingly, reduce production costs. Models printed from wax are distinguished by high precision, perfectly even and smooth surfaces, as well as the finest detail, which makes it possible to create products of complex shapes and textures that cannot be made using traditional technologies.

How to make a casting mold in a week? Read the history behind wax and photopolymer 3D printed gas valve models.

Wax 3D Printers: Advantages, Disadvantages, Applications

Pluses

- High print speed.

- High level of detail for the production of geometrically complex products (printed layer thickness up to 16 microns).

- Ability to simultaneously manufacture parts of different configurations on the same platform.

- Perfect model accuracy (up to 0.

1016 mm per 25.4 mm part size).

1016 mm per 25.4 mm part size). - Convenience and ease of use.

- Possibility of continuous operation.

Cons

-

Fragile and vulnerable to sunlight models.

-

Primarily functional prototyping.

-

High cost of consumables.

Wax models on the FlashForge WaxJet 400 build platform

Where is 3D wax printing used?

Wax 3D printing is used to create functional prototypes, tooling molds, and investment casting master patterns in areas such as jewelry, manufacturing, consumer goods, automotive, aviation, and medicine.

In particular, wax 3D printers are used to create:

- industrial components for the automotive and aerospace industries, mechanical engineering and instrumentation;

- items of jewelry and watch industry;

- prostheses and other medical devices;

- art objects, souvenirs.

Order a 3D test print of your product for free! Other services available - find out more and apply online:

Order service

Wax 3D printing technology

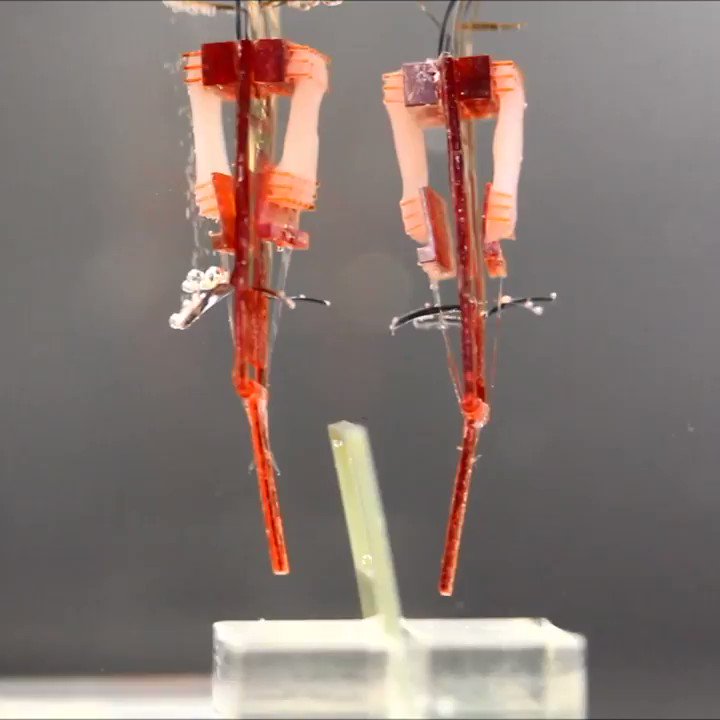

Wax 3D printers use multi-jet printing (MJP) technology. One of the features of this method is that the protruding parts of the product require supporting structures - they are easily removed at the end of the printing process or dissolve themselves.

When comparing wax and photopolymer, the latter wins in terms of the quality of the printed model, strength and cost, however, in terms of the quality of the final molded product, the advantage is definitely on the side of the wax.

MJP technology works in much the same way as conventional inkjet printing. The layer is applied by a print head with a large number of tiny nozzles through which the model material is fed onto a horizontal platform.

3D printed wax models and finished jewelry

Steps of the wax printing process

- The material is melted in a heated cartridge.

- The printhead applies wax to the build platform at the desired location.

- The build platform is lowered in the chamber by the thickness of the layer, and the process of applying the material is repeated layer by layer until the model is completely built.

- Wax solidifies immediately upon contact with the build platform.

- Models are removed from the build platform.

- Supports are removed with a special solution.

- The model is drying.

When printing with wax, two types of materials are used:

- harder (melting at about 70°C) - model wax for product printing;

- is softer or fusible - for creating supports.

Read on our blog: 3 Case Studies of Additive Manufacturing in Investment Casting

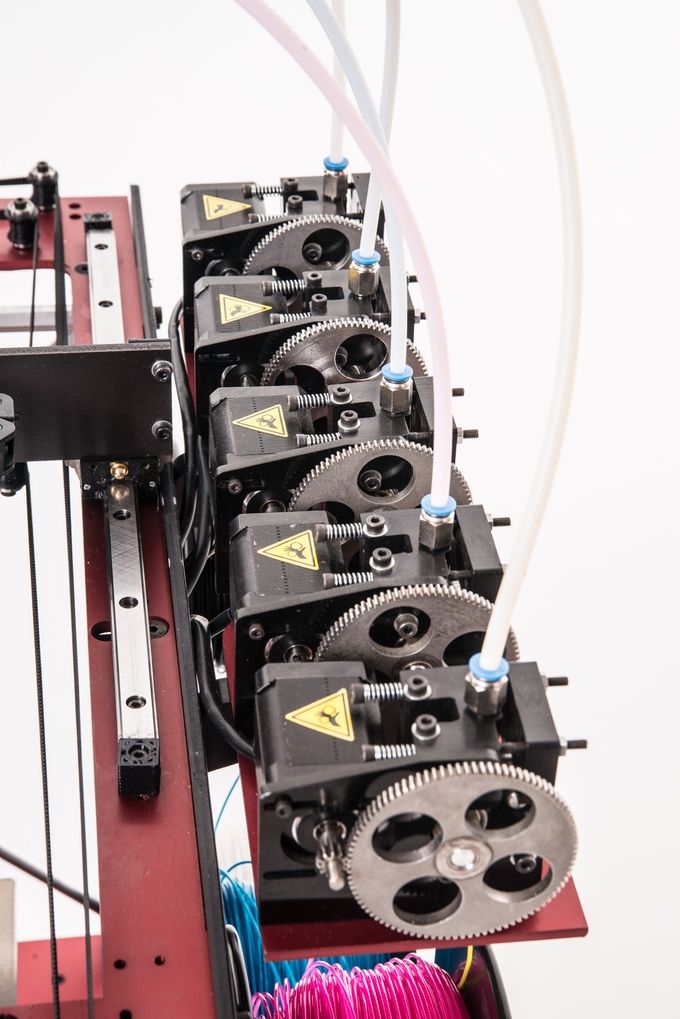

FlashForge WaxJet: Large Format Machines for Precision Modeling

Introducing professional MJP printers from the Chinese manufacturer FlashForge WaxJet 400 and 410. This is a line of large-format machines for printing high-precision and extremely smooth waxes up to 289 x 218 x 150 mm in size. The inclusion of WaxJet in the process will reduce production costs by 20-30% compared to a traditional casting cycle and create products 2.5 times faster than with classical methods.

This is a line of large-format machines for printing high-precision and extremely smooth waxes up to 289 x 218 x 150 mm in size. The inclusion of WaxJet in the process will reduce production costs by 20-30% compared to a traditional casting cycle and create products 2.5 times faster than with classical methods.

Benefits of the WaxJet 400 and 410

printers- Increased productivity: print up to 180 (WaxJet 410) or 360 (WaxJet 400) items per day.

- High resolution 1200 x 1200 x 1600 dpi and a layer thickness of only 16 microns.

- An ideal choice for printing jewelry, industrial tools, watches and souvenirs, as well as investment casting in aviation.

- Automatic material loading system.

- Stable material supply due to the immobility of the main print module with a movable build platform.

- An enclosed build chamber that isolates the printing process from external influences such as dust, microscopic debris, or excess moisture.

- Compatible with two kinds of materials: 100% purple wax and white support wax material.

- Easy management and maintenance of 3D printers.

Read our review of WaxJet wax printers

WaxJet 400 3D printer example: impeller

Print time: 4 hours 38 minutes

Wax Model Weight: 7.18g

Application: For In713c

Alloy Turbine Casting Benefits compared to the traditional process: 80% faster time to market, 45% less labor

So, wax 3D printing will allow your business to achieve better efficiency by saving time and money on designing and manufacturing prototypes and master models for casting.

Are you convinced by the benefits of wax 3D printing?

Learn more about implementing 3D technologies, get detailed advice, order a demonstration of equipment or 3D printing services you can contact iQB Technologies : we have been successfully implementing 3D solutions for industry and business since 2006. Contact us: +7 (495) 223-02-06, [email protected] .

Contact us: +7 (495) 223-02-06, [email protected] .

Article published on 05/19/2022, updated on 09/23/2022

All about injection of plastics and plastics into silicone molds, production of silicone molds

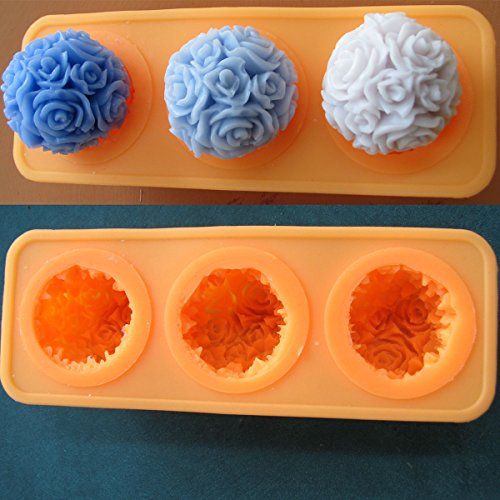

One of the specifics of the production activity of the company "3D Print spb" is the production of silicone molds for injection, which are one of the most important stages in the process of prototyping and replicating various products.

Silicone casting (vacuum casting) - Obtaining products by pouring a two-component material through a silicone mold. Casting technology is a fast and popular way to create products from polymer materials. Plastics, rubber-like foam materials and wax are poured into silicone.

Vacuum casting technology in silicone molds is used for:

- Product prototyping;

- Checking the performance of the product and testing the design;

- Replication, small-scale and piece production;

- Obtaining exact copies and master models;

- Reconstruction of damaged parts or cases.

The type of mold for casting is selected depending on the casting technology, on the task, as well as on the characteristics of the material of the mold itself and the product being cast.

Silicone molds are of open and closed type, split and compound, block, etc., the most important thing in the process of making molds for casting is to obtain a casting of the required quality as a result.

How we create silicone molds

- In the casting process, the master model (if required) is first prepared and refined to the required size and quality of its surface, in accordance with the technological characteristics of the material used for the mold and future castings.

- Technological elements are formed on the prototype: sprues, fasteners, bulges. Deep holes and grooves are determined, which, in order to increase the accuracy of the structure, need to be strengthened.

- Next, we prepare the formwork and mortgages. We seal the formwork and fix the master model in it, if necessary, we process it with a special release agent.

It is important that the volume and dimensions of the technological container exceed the dimensions of the resulting form.

It is important that the volume and dimensions of the technological container exceed the dimensions of the resulting form. - We prepare the material for pouring - we knead the silicone and perform the evacuation (degassing) of the material.

- The prepared silicone mixture is then poured into the prepared formwork.

- Silicone molding takes place under process vacuum, which removes air and gas bubbles from the liquid mixture.

- The process of polymerization (hardening) of the silicone mold occurs at a certain temperature and lasts, depending on the material, from 1 day to a week.

- The hardened mold is cleaned and dried. And prepared for use as mold

Two types of silicone molds

Tin-based silicone molds

These silicone molds can be used to mold technical plastic parts, cases, souvenirs and decorative items. Also, adhering to the methods of casting, we use plastics intended for industrial products, which have specific properties for specific tasks.

Platinum based silicone molds

Silicones for creating detailed pieces, can be used for casting wax, resins, polyurethanes, but will not work with latex, sulfur and some other compounds. These molds can also be used for molding food products such as chocolate, jellies or mousses.

Features of work

The advantage of casting is that the strength of the silicone mold is sufficient to perform casting in silicone of a limited batch of products. The maximum number of pouring cycles depends on the type of silicone, shape and materials used for replication. The optimal choice of this technology is suitable for a circulation of up to 500-1000 pieces of products.

We make silicone molds to order:

- Molds for casting bodies and parts;

- Molds for molding souvenirs;

- Molds for casting technical articles;

- Molds for decorative articles;

- Injection molds;

- Molds for injection of plastics/plastics/polyurethanes;

- Silicone molds for plaster and artificial stone;

- Silicone molds for candles and soaps, etc.

Get advice on the cost of manufacturing silicone molds for casting, and place an order by e-mail [email protected]

What materials we pour into silicone

in silicone - in general terms, they told how the process of creating molds, pouring plastic or other materials takes place. Today we will talk about what can be made in this way and what products you will get as a result.

General purpose plastic

Two-component plastic can be molded into anything with a master pattern and silicone. Its original color is white, so with the help of pigments it can be given any uniform color. The most popular is black, but we are not limited in color selection.

Polyurethanes

Available in different hardness, can also be used for casting concrete. Vibrant colors can be achieved by adding pigments.

Polyurethane is a flexible material that comes in various forms. It can be hard or soft and finds use in a wide range of applications such as rollers and tires, automotive parts, coatings and insulation.

Polyurethane is also an elastomer, a material that returns to its original state after stretching. Polyurethane is also resistant to contact with chemical liquids, oils, UV rays, bacteria and fungi.

The most common method for the production of polyurethane products is casting. It is used to manufacture products such as bushings, cuffs, rings, bearings, self-lubricating parts, suspension parts, sealing elements for hydraulic and pneumatic mechanisms.

In the creation of products from this polymer by casting, three technologies are used: rotational casting, free mold casting and injection molding.

The choice of a mold for polyurethane casting depends on the planned tirade of products - we make periodic, small quantities of products into silicone molds, and we pour large, monthly circulations into molds.

Polyurethanes are an inexpensive, high performance elastomer which combine the performance advantages of high-tech plastics, metals and ceramics with the resilience and flexibility of rubber.

- Polyurethane castings are abrasion resistant, resilient and oil and grease resistant. Polyurethanes are often chosen when it comes to resistance to mechanical stress: tensile, load-bearing, impact, tear, compression and durability.

- Cast polyurethanes are strong, flexible materials that can retain their original shape for a long time.

- Polyurethane does not interact with other materials and can therefore be used in conjunction with steel, aluminium, fiberglass and plastic.

- Polyurethane parts can be made in different Shore hardnesses.

- In contrast to plastic, polyurethane is less brittle and is therefore the preferred choice for high production loads.

You can place an order for polyurethane casting by e-mail: [email protected] Selection of silicone for mold

Silicone also comes in different hardness and is selected depending on the casting technology. It can be used to mold completely different materials from wax to concrete. There is also silicone for removing molds from the face, hands and other parts of the human body.

There is also silicone for removing molds from the face, hands and other parts of the human body.

Other types of molds

We also manufacture metal molds for injection molding, steel and aluminum. This method is suitable for quickly casting large runs of identical parts.

Food grade silicone and food grade silicone molds

Food grade silicone is a type of silicone that can be used to mold, for example, chocolate, marmalade or other confectionery. It is non-toxic and contains no chemical excipients or by-products, making it completely safe. The silicone molecule is made up of silicon and oxygen. Because of its resilience, non-porous surface, and inertness, food grade silicone is sometimes referred to as "soft glass".

How are food grade silicone molds made?

The process of making a silicone mold is quite simple: we take a plastic master model of the finished product (or several, if necessary, so that several products can be poured into the mold at once), pour in a mixed two-component substance, wait for curing and dry. After a day, you can already get a ready-made silicone mold for casting your needs!

After a day, you can already get a ready-made silicone mold for casting your needs!

Our silicone is not only suitable for molding food, it is also used for molding prototypes for jewelry or souvenir molding. The silicone casting method is ideal for casting small batches of products, not reaching thousands of copies. Otherwise, casting through a steel or aluminum mold is used, but this is not suitable for food casting.

We can also do soap, bombing for Vann or any plastic products. Plastic molding through a silicone mold or mold significantly reduces the cost of the finished product and saves you time, allows you to get the same, circulation products. For plastics, we also have dyes that color the entire mass at once. Forms can also be given almost any color.

More about plastic injection molding technology

A large selection of polyurethane resins allows foundry workers to choose the most suitable material for the customer in terms of physical and mechanical properties. As a rule, during the casting process, all polyurethane resins can be tinted with pigment, thereby the caster can get a high-quality “colored” product at the output, and the customer can get a high-quality product.

As a rule, during the casting process, all polyurethane resins can be tinted with pigment, thereby the caster can get a high-quality “colored” product at the output, and the customer can get a high-quality product.

To create a quality silicone injection mold you need:

- Quality Prototype

Quality silicone with high customer satisfaction. (It can also be tear rates, increase or decrease in the number of castings, the softness of silicone affects which difficult part will be cast, etc.) If the prototype is filled with non-degassed silicone, bubbles formed during agitation can stick to the surface of the prototype, creating an unnecessary cavity. When filled with polyurethane plastic, this bubble will appear as a build-up on the casting. Or another option is possible. The bubble does not stick, but is very close to the surface of the prototype and a thin wall is formed between the prototype and the bubble. After 10-15 castings, the wall begins to deform in the direction where the casting is located, thereby forming shells on the surface of the casting.

Well, now I'll tell you about the pitfalls that may lie in wait for you when ordering molding in a silicone mold.

Myth:

- The silicone mold is as cool as it is, even high-quality materials do not hold more than 35 removals . This indicator can be increased by treatment with special aerosols, i.e. before each pouring of polyurethane, treat the silicone mold and lubricate it with certain components.

- Any type of polyurethane can be poured into any silicone. It is not recommended to use polyurethanes and silicones from the same manufacturer. This must be specified when ordering. Why? A chemical reaction is a chemical reaction, silicone is not eternal, you can kill the mold even after 2 castings.

- Silicone molds are made by all and sundry! If you think like that, then everyone does it, but then everyone should receive a quality product!

Trust professionals, let your silicone mold be more expensive, but the technological process of its production will not be disturbed! Let your mold be made of high quality silicone! Let your prototype be highly accurate and of high quality! Then you will get the maximum performance in terms of the number of castings, you will receive the highest quality castings and all this in the shortest possible time.

Cold rejection method - what is it?

We often receive requests for the manufacture of products in small batches, but with rather short deadlines and high quality requirements. Printing a series on a 3D printer is not always profitable for a client, and a large print run is not needed. What to do in this case?

We offer the optimal solution in this case - to make a silicone mold and cast products by cold curing. Fast, affordable and retains all the necessary quality. Now consider what is needed for this.

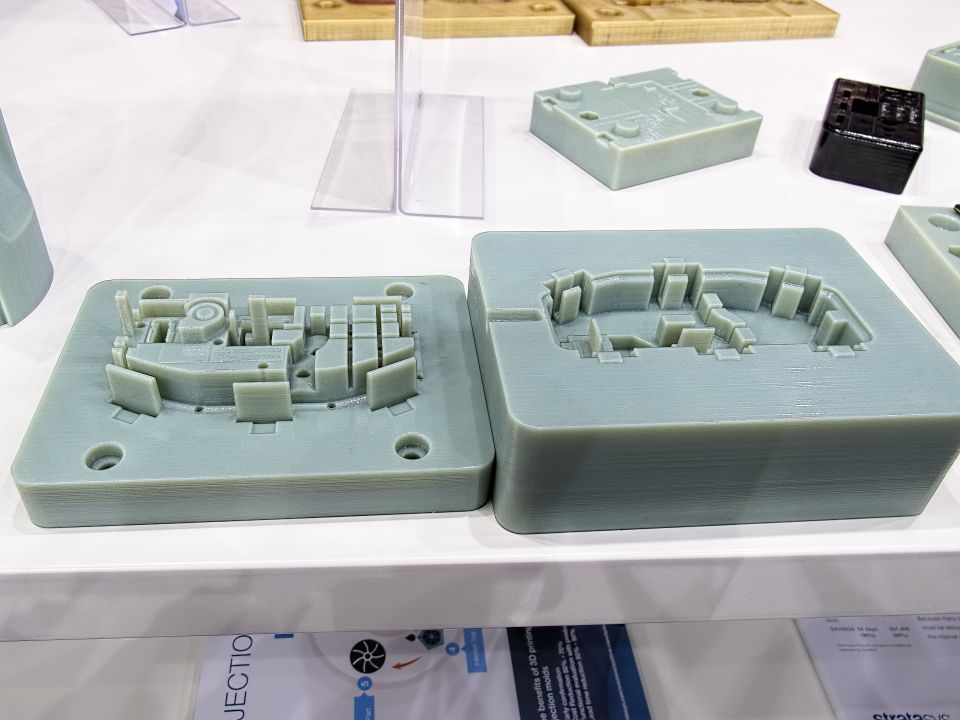

- Master model. Many do not understand what it is and why it is needed. The master model is used as a cast to create a mold, into which plastic is then poured and the finished product is obtained. There are many types of molds according to the manufacturing method and you can see a few examples in the photo. A product you already have can act as a master model, the shape will repeat its silhouette exactly. It can also be 3D printed.

- Silicone mold making. Next, a silicone mold is made from the master model, repeating its external dimensions. The resource of the form is limited, but it will withstand a small circulation, which is required, for example, for an experimental batch of products.

- Plastic injection. After the silicone mold has hardened and dried, plastic can be poured into it. Curing time depends on the material. On average, it takes an hour for us to see the first casting. You can also add any pigment to the plastic and get the desired color.

- Finished product. We can do various works - from souvenirs to technical parts, and the advantage of casting in this case is affordable cost and high quality. Contact us!

What happens

Molding plastics and rubber-like materials into silicone molds is still a relevant and interesting technology that can be used to make a wide variety of products, both technical and decorative. One of the most popular requests at the moment is the casting of cases through silicone molds, since most often our customers do not need a large circulation of products, but they need functional, working parts with a good surface and which can withstand certain loads.

One of the most popular requests at the moment is the casting of cases through silicone molds, since most often our customers do not need a large circulation of products, but they need functional, working parts with a good surface and which can withstand certain loads.

We pour both plastic and rubber components into silicone, as well as finished products, one-piece or multi-piece bodies. We cope with thin-walled products, parts of complex shapes, make master models (by 3D printing or milling), select the necessary materials and final color.

Work begins with a 3D model or drawing, according to which we select the optimal manufacturing process. The production of parts by casting is a fast process, but an important component is the preparatory work. If you already have a master model from which we can remove the silicone mold, then the finished parts can be received within a few days. If not, it may take a certain amount of time to make a master model, depending on its complexity and manufacturing technology.

Dimensions for two-component plastic injection do not matter much, we pour both small parts and large, overall products into silicone. Small-scale plastic injection is suitable for those who need small batches both once, and once a month, quarterly or yearly - we pack and store master models and molds in a warehouse to use them when our customers need them.

In small-scale production, the technology of molding into silicone is most beneficial for the manufacturer, due to the low cost of silicone and the speed of reproduction of the form. Often, in small-scale production, making an expensive metal mold is not cost-effective, resource-intensive, and it takes tens or even hundreds of times more time to produce such a mold.

Production of premium plastic products

Production! How loud it is! It's a pity that they uprooted it, only dealers of Chinese junk, European "quality goods" remained. And it's very close! I'll tell you how they make such a man. It's actually a bodybuilding cup.

And it's very close! I'll tell you how they make such a man. It's actually a bodybuilding cup.

Here it should be said that in fact, this man is not bronze. This is an imitation of bronze plastic. Each client has their own wishes and budget. Each technical task has its own scope of work and its price.

- The first thing a sculptor does is sculpt a model. First, this is a plasticine model, after that the sculptor removes the silicone mold from the plasticine and casts the future master model in plaster. Gypsum is polished, brought to mind and becomes a full-fledged master model. The finished master model is ready for further production.

- Now we define the parting line on our figurine. The parting line is a very important part, because if it is not defined correctly, the part will hardly come out of our mold, and thus the life of the silicone mold can be reduced. We put the parting line)))

- Plasticine holds its shape well and adheres well to the master model.

We put a “sausage” along the contour of the figure))). This is a special device "KEY". It is designed for precise positioning of 2 halves of the silicone mold. And also this type of key makes it possible to tightly close the silicone mold at the junction. I recommend it to everyone who makes composite forms.

We put a “sausage” along the contour of the figure))). This is a special device "KEY". It is designed for precise positioning of 2 halves of the silicone mold. And also this type of key makes it possible to tightly close the silicone mold at the junction. I recommend it to everyone who makes composite forms. - Now with gasoline and a cotton swab we remove the remains of plasticine on the master model. We also cover the burrs on the plasticine parting line, the future silicone mold.

- Now it's time for the silicone. We use 2-component cold curing silicone. We will make a cortical form, so we will apply silicone with a brush. This method saves a lot of money, but not time))). We have nowhere to hurry... We carefully coat the fine detailing on the master model with “Pokes”. We repeat the procedure several times until the silicone is 5-10 mm thick.

- After that, we leave the silicone alone until complete polymerization, and make a cortical part of gypsum to support the shape, it can be reinforced by adding a bandage or gauze.

- We do the same with the second half. after that, we disassemble our silicone mold and enjoy the result.

- Now, having thoroughly dried the silicone mold, you can start pouring plastic. (Two component polyurethane). Let's go….. Non-stop)))

- Brave guys jump out of the silicone mold like hot cakes)))) As they say, first you harness for a long time, then you go fast))) . Now there is very little left. Remove flash. Flash is plastic residue on the parting line of a silicone mold. Delete…

- Now we paint the figurines and put them on the podium. Actually the Prize is ready. In the following articles, I will definitely tell you how to do without painting, and immediately, when pouring plastic into a silicone mold, achieve the effect of metal (bronze, silver, gold).

- Actually, on this note, we end our story about how the creation and preparatory work for casting into silicone molds takes place. Now, you can see the photo report of the process of our work!

We bring to your attention another work of the foundry on the theme of cinema. This is the same Stalingrad project.

This is the same Stalingrad project.

Not only do the pistols completely repeat the texture of the original, they are also made of rubber. I personally held this props in my hands, and from a distance of 30 cm I did not distinguish that this was not an “iron” pistol. Only when you take it in your hands you understand - "toy".

I don't think the stuntmen on the set will deal with anti-stress and think about how these rubber weapons are made. But one thing is for sure - safe to use. It's a pity that this was not the case in our time. Pistols and machine guns we planed from a wooden board. Casting in silicone is indispensable with a circulation of less than 1000 units. Quality at the highest level.

Making a mold for silicone casting

A mold for casting is a life-size product with which a silicone mold is made. The master can be made by hand, which is suitable for artistic casting and replication of an exclusive product, can be made by milling or printed on a 3D printer.