3D print plumbing

3D Printing Plumbing Parts and Components « Fabbaloo

By Charles Goulding on September 8th, 2021 in news, Usage

Tags: construction, custom, plumbing

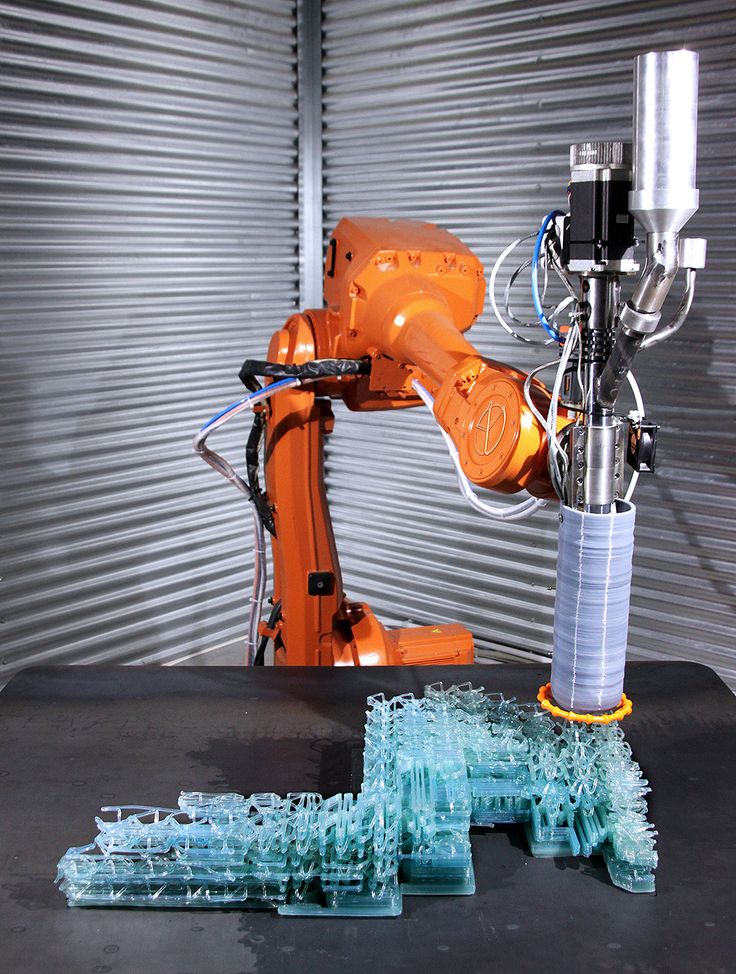

Maya Ben David: Bypass [Source: Domus]

Charles R. Goulding and Preeti Sulibhavi look at the possibilities when using 3D printing for plumbing applications.

Ever since the integration of indoor plumbing in standard homes, the industry has grown exponentially. Any home today needs indoor plumbing and with that comes many different parts and connectors. Plumbing components include piping, connectors, threaded caps, etc. There is plumbing equipment as well: sinks, toilets, baths, showers, kitchen plumbing and more. All of these items are part and parcel of modern life.

There are now more ways to 3D print plumbing parts and components than ever. Everything from valves to pumps can be 3D printed efficiently.

Copper Piping and PlumbersCopper piping is the traditional material that is used for water supply lines, although certain plastic piping materials are gaining popularity. Drain waste pipes are usually plastic and can be 3D printed. 3D printers that use thermoplastic filaments can pproduce piping that is durable and able to be used as part of a building’s plumbing system. These pipes serve to carry waste down and away from the home and allow the sewer gases to be pushed out through the roof. The common material that is frequently used for plumbing is acrylonitrile butadiene styrene (ABS). This petroleum-based material is a common thermoplastic polymer and comes in various mixes. A strong material, it is affordable and easy to shape which is perfect when inserted into a 3D printer. During 3D printing the filament slowly flows from the print head and shrinks slightly as it cools down.

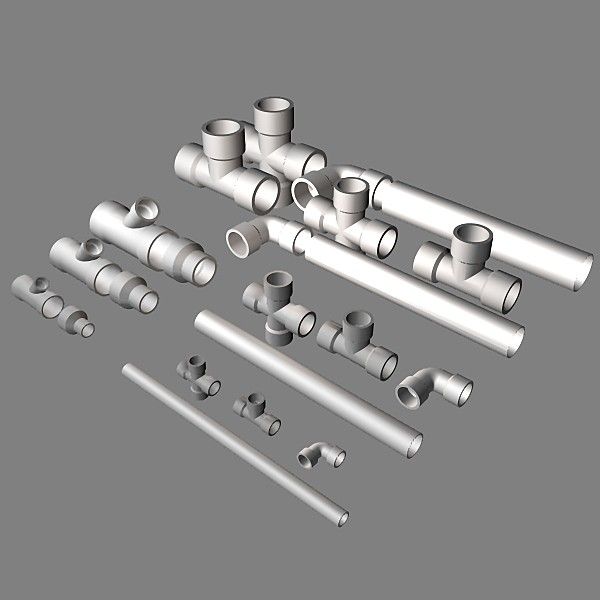

Usually, water pipes have a standardized structure to them. The fittings are 90, 45 and T shape angles and the pipes are joined together in these settings only. However, what if these pipes could be printed using additive manufacturing? By using additive manufacturing, water pipe fittings can be designed with bends that are innovative and a custom alternate solution to the typical joint bends. Using a 3D printer allows designers and construction workers to to more easily work with pipe configurations in the way they actually need. They are able to make and bend them in any fashion they choose as long as they meet the needed requirements.

Using a 3D printer allows designers and construction workers to to more easily work with pipe configurations in the way they actually need. They are able to make and bend them in any fashion they choose as long as they meet the needed requirements.

3D printed product designs are flexible and can fix any mechanical needs. Use a 3D printer to make pipe connectors. If the piping is running at a 45-90 degree angle and the connectors don’t work efficiently, then 3D print your own custom connector. These connectors hold the pipes in place and allow for rapid and simple fixes. Maya Ben David, a designer from Israel has come up with 3D printing of various piping and water systems. The Bypass project is where 3D printing is used to produce the fittings. Bypass presents a range of pragmatic solutions in a systematic way, by creating a range of possibilities for pipe fittings that are also compatible with existing standards.

A plumbing system is a network of pipes and fixtures in a building. Sometimes even the best-designed plumbing systems can have design problems. When a pipe gets clogged a cleanout is needed. Usually, a plumbing system has one or more cleanouts that can be regulated from the inside or outside of a house. An inside cleanout is usually done where grime gets clogged in the pipes such as at a joint or a point where two pipes are connected. Another location for grime to collect is where the stack pipe meets the underground building sewer. The cleanout points on the outside can easily be identified. There is a removable threaded cap that has a square fitting that can be opened with a wrench. This part can be 3D printed as well from a desktop printer.

The Research and Development Tax CreditThe now permanent Research and Development (R&D) Tax Credit is available for companies and startups developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

ConclusionInnovative approaches using 3D printing technology are helping business component designers, engineers, designers provide improved plumbing systems for plumbing supply houses. Those companies involved with 3D printing of plumbing, pipes, fixtures and accessories may be innovating for themselves and the plumbing industry.

Those companies involved with 3D printing of plumbing, pipes, fixtures and accessories may be innovating for themselves and the plumbing industry.

By Charles Goulding

Charles Goulding is the Founder and President of R&D Tax Savers, a New York-based firm dedicated to providing clients with quality R&D tax credits available to them. 3D printing carries business implications for companies working in the industry, for which R&D tax credits may be applicable.

View all of Charles Goulding's posts.

Ahead to the Future of 3D Printing

By Candace Roulo

When reviewing the history of plumbing, it’s impressive to see how pipes and plumbing systems have evolved throughout the times. But what would the Romans – known for using lead pipes to improve sanitary conditions and developing aqueducts, underground sewer systems, public and private baths and lead and bronze water piping systems – and the Egyptians – known for making copper pipes to build bathrooms, irrigation and sewages systems – think about utilizing additive manufacturing (3D printing) to make plumbing and hydronic products? It depends on how advanced the Roman or Egyptian you are asking is.

These ancient civilizations were noted as having some of the most innovative and progressive people ever, so let’s assume the Romans and Egyptians we’re asking are advanced individuals, constantly pushing boundaries.

First of all, these Romans and Egyptians would be pleased with all the advancements, noted on theplumber.com, made up to this year. They would be pleased with King Louis XIV ordering construction of a cast-iron main plumbing line to carry water from a pumping station to the palace fountains (1664).

They would be in awe of the advancements in New York City – an underground sewer was installed in 1728 and in 1830 the first public water main was installed under New York streets. By the time 1845 rolled around, they would find it fitting that drainage piping systems were installed in buildings, helping convey sewage away from these structures. They would celebrate the passing of The National Public Health Act in 1848 and the first plumbing code, nicknamed the Hoover Code, published in 1928.

Then there is the birth of the PVC pipe in central Germany. From 1936 to 1939, more than 400 residences were installed with PVC drinking water and waste pipelines in central Germany. But it wasn’t until 1950 that the systematic development of extrusion technology started. Before this time, the use of PVC pipes was not common. Starting in 1966 and due to a shortage of copper, non-metallic pipe (PVC) became part of modern plumbing systems, and now you can find PVC pipe everywhere. Chances are, our Roman and Egyptian friends would be quite impressed with this plastic pipe.

3D Printing Hits The PHVAC Industry

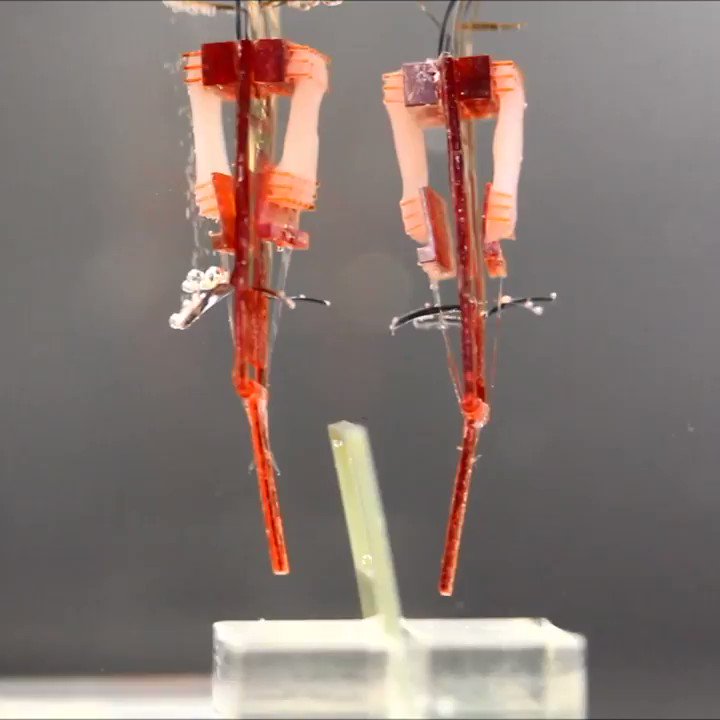

But what would really knock our ancient friends’ sandals off is additive manufacturing, also known as 3D printing! 3D printing is a process of making three dimensional solid objects from a digital file. 3D printed objects are created using an additive processes in which an object is created by laying down successive layers of material until the object is created, according to 3D Printing. com. Each layer can be seen as a thinly sliced horizontal cross-section of the object. With 3D printing it’s possible to make complex and functional shapes using less material than traditional manufacturing methods.

com. Each layer can be seen as a thinly sliced horizontal cross-section of the object. With 3D printing it’s possible to make complex and functional shapes using less material than traditional manufacturing methods.

By now, I’m sure you’ve all seen 3D printed plumbing fixtures, such as the Grid Sink faucet by Kallista and the Vibrato Bathroom 3D faucet from DXV by American Standard (our Greek and Egyptian friends would love the design of these high-end faucets).

Besides producing these eye catching, in-front-of-the-wall products, 3D printing is useful for some in-back-of-the-wall products, too. According to 3DPrinting.com, 3D printers can be used to create pipe connectors and threaded caps. But 3D printing’s real niche in the PHVAC industry is not to create common pipes and pipe fittings, but to create custom and hard to source parts – many that are no longer on the market – such as new handles for the Hoffman No. 7 steam radiator valve or Warren Webster type W valve handles.

Below, watch Hoffman No. 7 steam radiator valve handles being produced with a 3D printer.

According to a PHVAC business owner, who is also a contractor, the ability to 3D print hard to source parts – like old faucet stems – for the plumbing side of the business would be of value and the possibilities of 3D printing would seem endless. But our ancient Roman and Egyptian friends might wonder how manufacturers will protect proprietary patented information and where does this leave wholesalers and distributors.

The PHVAC business owner doesn’t know how manufacturers would like to reveal detailed proprietary patented information while losing the revenue otherwise gained in the sale of those parts, but believes that in the future, a monetary exchange will take place to have the patented information directly inputted into contractors’ 3D printers with a limited number of uses.

The ancient Romans and Egyptians want wholesalers to keep abreast of this technology. According to the article “Additive Manufacturing – Wholesale Distribution Trends #12” by Paul St. Germain, distributors must keep an eye on this technology as it advances and consider its application to their business.

“For example, they should consider its applicability to service parts and repairs, especially for slow-moving inventory items, particularly in the automotive, aerospace and marine sectors. At some point, it may become feasible and more practical to print out replacement parts rather than buying and stocking them,” writes St. Germain.

Even though St. Germain writes about automotive, aerospace and marine distributors, wholesalers and distributors in the PHVAC industry need to take his advice and think about how 3D printing may affect the future of their specific industry and how they can evolve their businesses.

The construction industry may not be moving ahead with this technology as quickly as other industries, but there is definitely a place for 3D printing in the PHVAC industry. Our Roman and Egyptian friends visiting us in 2019 believe it’s only a matter of time before 3D printing disrupts the construction and PHVAC industry. Wholesalers and distributors need to stay on their toes, keep up with the technology, and evolve with it.

Our Roman and Egyptian friends visiting us in 2019 believe it’s only a matter of time before 3D printing disrupts the construction and PHVAC industry. Wholesalers and distributors need to stay on their toes, keep up with the technology, and evolve with it.

Candace Roulo, a graduate of Michigan State University’s College of Communication Arts and Sciences, is a technical writer covering topics in the mechanical contracting and manufacturing industries.

Related Posts:

13 BEST CONSTRUCTION 3D PRINTERS OF 2019

A 3D construction printer is a machine that can build houses by applying material (concrete) layer by layer. The paste type material used, in this case concrete or earth, is forced through the nozzle in layers to print buildings.

Concrete 3D printing in the construction industry saves time, effort and material when compared to traditional methods. However, it is important to note that 3D printers are not yet capable of creating a fully functional home, only the frame and walls can be created, other elements such as windows, electricity or plumbing must be installed separately. Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations.

Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations.

To provide a complete overview of the construction 3D printer market, we have listed the top 12 construction 3D printing solutions. Some of them are 3D printers already available for sale, while others are still in the prototype stage or provide 3D printing services for external structures.

HOW TO BUILD A 3D PRINTED HOUSE?

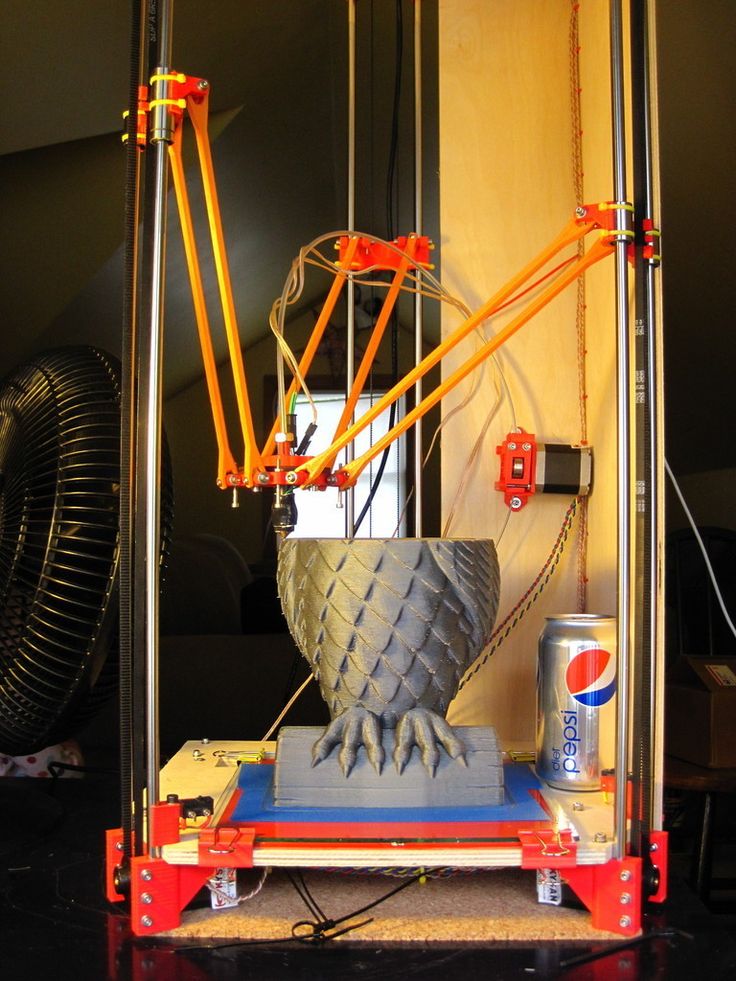

Construction 3D printers use extrusion technology. Some construction 3D printers are similar to FFF/FDM desktop 3D printers, only larger (gantry style), while others consist of a rotating mechanical arm.

In both cases, paste-type components such as concrete are used as the filament. The material is ejected from a special nozzle to form layers. In simpler (very) extrusion of pasta is like using a bag to dispense frosting on a cake.

The printer builds foundations and walls layer by layer. The base is literally the printer's build plate. However, some concrete 3D printers are used to 3D print brick molds. Once molded, the bricks are stacked on top of each other manually (or with a robotic arm).

However, some concrete 3D printers are used to 3D print brick molds. Once molded, the bricks are stacked on top of each other manually (or with a robotic arm).

Benefits of building 3D printing

• Eco-friendly : 3D printed houses can be built with sustainable materials. What's more, some construction 3D printers use solar energy and emit little CO2.

• Affordable: 3D construction printers can build affordable housing, providing great relief to people in poor areas or after natural disasters.

• Scalability: 3D construction printing reduces certain construction costs. For example, the cost of 1 square meter of wall using traditional construction methods is approximately $75, while for an Apis Cor house 3D printer it is only $27.

• Efficient: Because materials are 3D printed on demand, machines produce less waste. In addition, 3D construction printers can complete the foundation of a house in less than a few days, while traditional construction methods take weeks or even months.

• Design flexibility: Curved walls and unique facades can be easily created with a 3D printer

Disadvantages of 3D construction

• Expensive initial investment: These 3D printers can sometimes cost up to a million dollars.

• Partially Built Houses : Only house frames are built. The 3D printing process is usually paused to manually install plumbing, wiring, and fittings.

• Rough Appearance : The exterior of most 3D printed houses is not as smooth as traditional houses.

• Lack of Certification: Construction sites are regulated by law and there are important safety standards that must be met, which can be difficult with 3D printing methods (different repeatability, dimensional stability, etc.).

CONSTRUCTION 3D PRINTERS: OVERVIEW

We divide construction 3D printers into three categories: house building 3D printers that you can buy, prototype concrete printers, and concrete 3D printing services.

Home 3D printers available

AMT printers

Pictured: AMT S-6044 Long and AMT S-300

), 11 x 31 x 80 (maximum)

• Material: Concrete / Clay / Gypsum

• Country: Russia

Equipment manufactured by AMT-SPETSAVIA - workshop and field portal construction 3D printers (COP-printers, Construction Objects Printing): and from small-format (for printing small architectural forms ) to large (for printing buildings up to 30 floors high). Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

BetAbram P1

• Assembly size : 1.6 x 8.2 x 2.5 m

• Material : Concrete

• Country : Slovenia

BetAbram is a small Slovenian team that has been working on building 3D printing equipment since 2012. Their flagship home 3D printer, the BetAbram P1, is currently in its second iteration and is available with additional printheads: basic, "Orto" for smoother layers, and rotatable for more design options.

COBOD BOD2

• Build size : 11.98 x 45.07 x 1.53 m

• Material : Concrete

• Country : Denmark

This construction 3D printer is fast, with a speed of up to 18 meters per minute. BOD2 is modular and can be adapted to various sizes. COBOD is a 3D Printhuset company.

Constructions-3D 3D Constructor

• Assembly size : 13 x 13 x 3. 8 m

8 m

• Material : Concrete

• Country : France Their 3D Constructor machine is mobile thanks to its rubber tracks and fits in a 20ft shipping container for easy transportation from one construction site to another.

CyBe Construction CyBe RC 3Dp

• Assembly size: 2.75 x 2.75 x 2.75 m

• Material: Concrete

• Country: Netherlands This easy-to-use 3D printer is capable of reaching heights of up to 2.75 meters and only requires two people to operate.

ICON Vulcan II

• Build Size : 2.6 x 8.5 x ∞ m

• Material : Concrete

• Country : United States

ICON wants to revolutionize the construction industry with its Vulcan II printer. The whole process is designed to be user friendly with a tablet-based interface, and the ICON Lavacrete concrete mix is optimized for easy printing.

MudBots Concrete 3D Printer

• Build Size : 1.83 x 1.83 x 1.22 m (minimum)

• Material : Concrete

• Country : United States of Mudts003 Concrete 3D Printers USA. Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length.

Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length.

According to MudBots, their 3D printers can print a small house in just 12 hours and cut costs by 70% compared to traditional building methods.

Stroybot2

Build Size : 10m x 15m x 6m

Material : Concrete

Country : United States

StroyBot, also known as the Rudenko 3D Printer, is a versatile mobile design printing system supplied as a build kit user. On average, he can print a 100 square meter house in 48 hours (walls only).

WASP Crane WASP “Infinity 3D Printer”

• Build Size : Ø 6.3 x 3 m

• Material : Concrete / Earth materials

• Country : Italy

WASP Crane is an evolution of the previous WASP construction printer 12MT. This open source builder is modular and multiple Crane printers can work together on the same project, giving theoretically endless 3D printing possibilities.

Concrete printers work projects

Apis Cor 3D printer

• Assembly size : 8.5 x 1.6 x 1.5 m

• Material : Concrete

• Country : United States

Apis Cor, a 3D based construction company Francisco and claims to be able to 3D print a house in less than 24 hours. Their Apis Cor printer is similar to a robotic arm and won first place in NASA's 3-stage 3D printing competition.

Batiprint3D 3D Printer

• Build Size : -

• Material : Concrete / Other

• Country : France

Batiprint 3D made headlines internationally when it completed the Yhnova 3D print shop in Nantes, France. Their 3D printer not only prints cement but also insulating foam, making it one of the most complete 3D building solutions.

S-Squared ARCS VVS NEPTUNE

• Build Size : 9.1 x 4.4 x ∞

• Material : Concrete

• Country : United States

S-Squared, also known as Square3D "4D printing", which aims to provide fast, reliable, environmentally friendly and affordable housing for poor areas. ARCS VVS NEPTUNE is one of the company's working models, but it will not be available for commercial sale.

ARCS VVS NEPTUNE is one of the company's working models, but it will not be available for commercial sale.

Construction printing services

Contour Crafting 3D Printing System

• Material • Material: Concrete

• Country: United States

This automatic construction system is capable of 3D -printing large buildings and high -high infrastings. Contour Crafting (also known as CC Corp) aims to improve the effectiveness of disaster relief through concrete admixture technology.

XtreeE 3D Printer

• Build Size : -

• Material : Concrete

• Country : France

XtreeE develops custom 3D printing solutions for construction, engineering and architectural design. This startup is located in France and has already completed a number of 3D construction projects.

GROHE introduces the first 3D printed metal faucet |

- GROHE is the first of Europe's leading sanitary ware manufacturers to offer 3D printed faucets.

- Limited edition GROHE Allure Brilliant and Atrio 3D faucets.

- Design without boundaries

For a long time, 3D printing was considered the technology of the future. Today, 3D printed components have become the new standard for premium brands in the automotive and aviation industries.

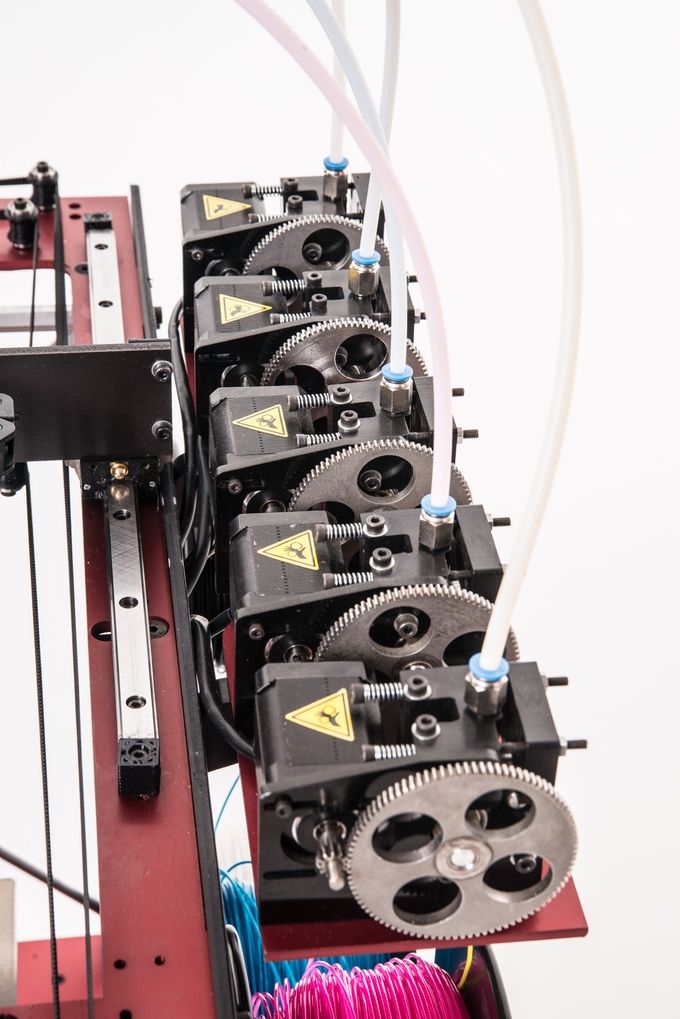

GROHE pioneered the sanitary sector with two innovative faucets GROHE Atrio Icon 3D and GROHE Allure Brilliant Icon 3D , made using 3D metal printing technology. As a leading manufacturer of integrated solutions for the bathroom and kitchen, the company has perfected 3D printing technology to work with metal, achieving the perfect balance between high technology and fine craftsmanship. This made it possible to push the boundaries of industrial design and launch even more customized bathroom fittings. GROHE is shaping the future of water through innovative technology, design and production methods.

Pushing the limits: water as a visual experience

The redesign of the existing GROHE Atrio and Allure Brilliant collections with the latest Icon 3D technologies takes the company to new levels of design and comfort.

Michael Siam , GROHE Vice President of Design, said: “ We believe that true innovation always requires bold solutions. There is nothing unattainable, you just need to set a goal. GROHE Icon 3D paves the way for the future of design. By applying metal 3D printing technologies to the manufacture of faucets, we have pushed the boundaries of the real. This technology allows us to create mixers in small quantities according to the wishes of our customers. Now nothing is impossible for us0045".

Thomas Fuhr , Managing Director of GROHE AG, added: “ To stay ahead of the curve in the industry, we invest not only in research and development, but also in innovative production technologies. Metal 3D printing symbolizes a new era for "Made in Germany" products. We focus on our core product and use the entire manufacturing process to make it – unlike most of our competitors. It is important for us to maintain the GROHE quality mark even when we are making products on a 3D printer. That is why we have developed our own technology and a unique formula of metal granules for printing ".

That is why we have developed our own technology and a unique formula of metal granules for printing ".

GROHE's 3D steel printing process eliminates all unnecessary frills and achieves a pure form that redefines the very concept of materiality. Minimalism with an emphasis on the original essence of the faucet not only takes the process of interacting with water to a new level, but also allows you to use resources more efficiently.

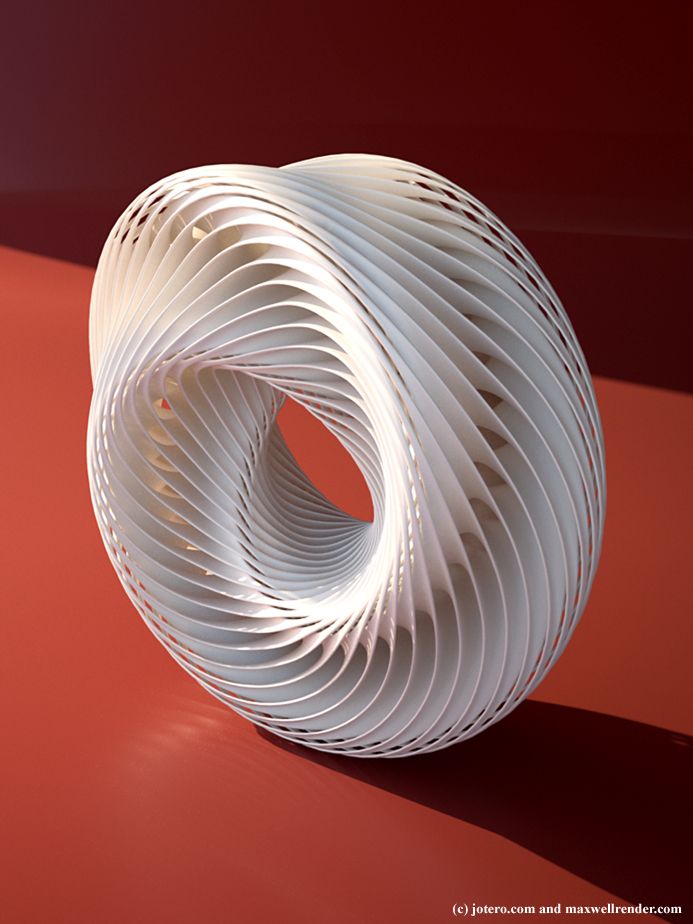

GROHE Atrio Icon 3D with its delicate curved spout and GROHE Allure Brilliant 3D with its hollow body make the flow of water appear to be an optical illusion. Faucets become an art object - a kind of sculpture made of brushed steel.

The union of digital technology and excellence creates unique products

GROHE Icon 3D is the union of new digital technology and the highest standards of handicraft. All components of the mixer are printed from metal on a 3D printer using the technology of laser melting of the material in the powder layer.