Uci 3d printing

3D Printing, 3D Modeling and 3D Scanning Services Effective October 1, 2021

Designing a 3D object to print is done using 3D modeling software. There are many 3D modeling programs available, including professional programs like SolidWorks and Autodesk Inventor (which are available in the MRC), and free software programs like Blender, Wings3D, FreeCAD, and Sketchup. You will need to export your 3D model into .STL (STereoLithography) format in order to print it.

The UCI Libraries has one 3D scanner available at the Multimedia Resources Center in the Specialized Computing Area. Due to their learning curve, we recommend making an appointment at the MRC Desk with one of our multimedia experts if you would like to use the scanner.

How can I become authorized to use the 3D printer?

3D Printing self-service is not currently available.

Who can print?

The 3D printing service is available for use by UCI students, faculty, and staff on a first-come first-served basis.

- Students must be enrolled in the current quarter or summer session to use the service.

- Faculty and staff may use the service if they have a current university appointment.

What can I print?

The 3D printer must be used exclusively for lawful, non-commercial purposes and in compliance with all University of California policies. Users may not collect, upload, transmit, display, create or distribute content that violates or may violate any law or third-party right, including, without limitation, any copyright, trademark, patent, trade secret, moral right, privacy right, right of publicity, or any other intellectual property or proprietary right. The UCI Libraries reserve the right to decline any print request for any reason.

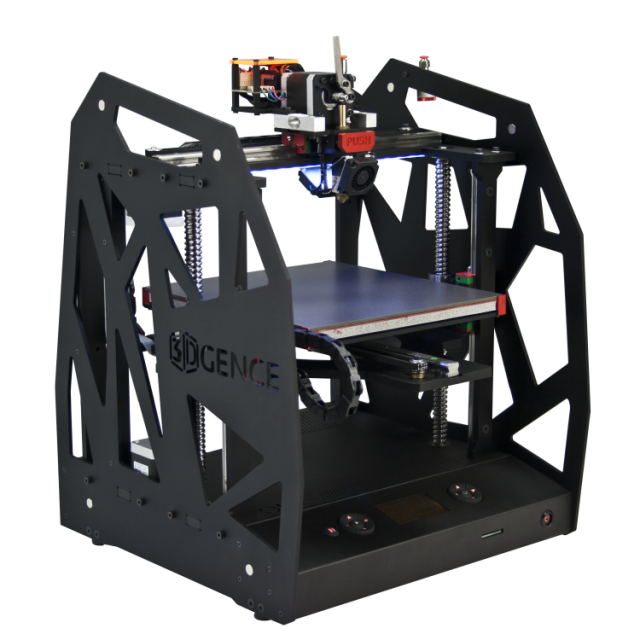

What 3D printers does UCI Libraries own?

UC Irvine Libraries has 3 Makerbot Replicator Desktop 3D printers. They use 1.75 mm polylactic acid (PLA) filament.

- Build Volume: 25.2 L x 19.

9 W x 15.0 H cm [9.9 x 7.8 x 5.9 in] or 7,522 cubic centimeters [456 cubic inches]

9 W x 15.0 H cm [9.9 x 7.8 x 5.9 in] or 7,522 cubic centimeters [456 cubic inches]

Additional specifications and information about the Makerbot Replicator can be found at the Makerbot store.

Where are the printers located?

The 3D printers are in the Open Studio at the Multimedia Resources Center in the Science Library.

How much does it cost?

Setup and printing calibration fee is $10.00. Cost per printing hours billed in full hour increments is $5.00 per hour. PLA Basic filament material color is $0.15 per gram. Seasonal filament material color is $0.25 per gram. Grand total for each project printed equals $10.00 plus (number of hours it takes to print times $5) plus Material cost

How do I design my object?

Designing a 3D object to print is done using 3D modeling software. There are many 3D modeling programs available, including professional programs like SolidWorks and Autodesk Inventor (which are available in the MRC), and free software programs like Blender, Wings3D, FreeCAD, and Sketchup. You will need to export your 3D model into .STL (STereoLithography) format in order to print it.

You will need to export your 3D model into .STL (STereoLithography) format in order to print it.

How do I print my object?

Users must bring their design to the MRC during business hours. The print object must be an .STL file on a USB flash drive formatted in NTFS or FAT32 format. All submissions are subject to approval based on scheduling and availability of the 3D printers.

What colors can I print in?

Your printed object will be printed in one solid color. Available colors vary. You will be given your choices when you fill out the 3D Printing Form.

What if I have more than one object?

Each individual object must be submitted as a seporate .STL file.

Each file must be submitted separately by filling out a separate 3D Printing Request Form available at the MRC.

How long will my object take to be printed?

The time it takes to print an object can vary widely. See our time guidelines for estimates. Using the UCI Libraries' 3D printer may take up to a week depending on the queue. For more time efficient options, check out these alternate providers. If you have more than one object and there is high demand for the 3D printer, the Libraries may choose to schedule only one printed object per person/entity per day.

For more time efficient options, check out these alternate providers. If you have more than one object and there is high demand for the 3D printer, the Libraries may choose to schedule only one printed object per person/entity per day.

How will I know when my printed object is done?

You will receive an email from the UCI Libraries and can pick up your printed object from the MRC during normal business hours. Printed objects will be held for 3 business days.

Why does my printed object look unfinished?

Users may see imperfections in their printed objects. Small bumps or holes and rough edges at the base of an object may occur with 3D printing. Imperfections can be cleaned up with fine sand paper, file and/or tools. The Makerbot Replicator is very accurate but there may be some instances where objects do not fit precisely together. Objects are built from the ground up and in certain instances prints will require support material and / or rafts to ensure proper printing. Support materials is often needed if the design has large overhangs or parts suspended in mid-air. Rafts are often used as support at the base of the model. Users may receive their print job with the raft still on. These are easily removable by the user. Staff will not be responsible for removing materials and / or rafts. All finishing must be done by the user outside of the Libraries’ buildings. See our tips for finishing a printed object.

Support materials is often needed if the design has large overhangs or parts suspended in mid-air. Rafts are often used as support at the base of the model. Users may receive their print job with the raft still on. These are easily removable by the user. Staff will not be responsible for removing materials and / or rafts. All finishing must be done by the user outside of the Libraries’ buildings. See our tips for finishing a printed object.

Is there somewhere else I can print my object?

Check out these alternate providers.

How can I find out more about Self and 3D Printing Full Services?

If you have more questions about 3D printing email [email protected] or visit the MRC during business hours.

FABWorks – UCI Manufacturing

Feb. 7, 2022: FAB Works is now open for users! Please wear a mask while working in FAB Works. Also note that some equipment has been taken off-line as we work to install additional safety measures for certain machines.

Offering experiential learning opportunities, FABWorks is a facility that reinvents the way people create and innovate. As part of UCl’s Institute for Design and Manufacturing Innovation (IDMI) in the Samueli School of Engineering, FABWorks offers space in the Calit2 Building where users can design and fabricate almost anything, providing access to a host of machines and technical staff ready to offer machine training and design help.

Among FABWorks’ prosumer grade (above consumer grade) equipment are 3-D printers and scanners, networked computer-controlled milling machines, laser cutters, electronics development and diagnostics equipment, industrial sewing machines and more. The FABWorks space offers expanded opportunities for those interested in hands-on, advanced-manufacturing experience and creates a hub where creativity can propel next-generation technologies.

To contact us for information or to schedule a reservation, you may email or call us. You can learn about our equipment using the drop-down menu below. Email or call to check availability and send us a reservation request. Please be aware that this is a lab space and as such, closed toed shoes and long pants are a requirement. If you are a new user to FAB Works you will be asked to read and sign the Access Agreement Form

You can learn about our equipment using the drop-down menu below. Email or call to check availability and send us a reservation request. Please be aware that this is a lab space and as such, closed toed shoes and long pants are a requirement. If you are a new user to FAB Works you will be asked to read and sign the Access Agreement Form

Phone: (949) 824-5667

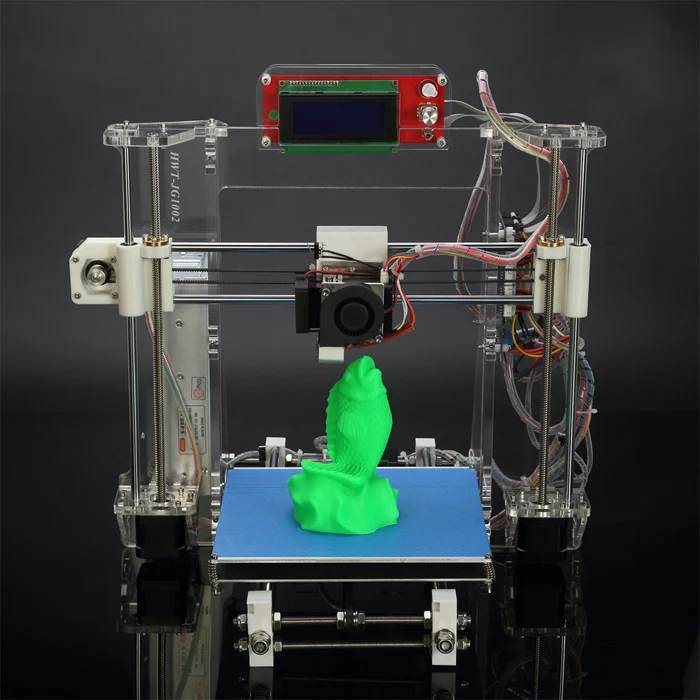

Flashforge creator 3d printer

FLASHFORGE Creator

Category

Consumer Level FDM 3D Printer

Materials

-1.75 mm diameter spools of ABS filaments

**No outside printing material unless special arrangements are made; all 3D printing material is provided by the lab**

Features

-Kapton tape for ease of part removal

-Print volume of (8.9” x 5.7” x 5.9” )

-Print speed of 150 mm/s

-Max temperature of 315 degrees F

-Layer-to-layer resolution of .20mm

UCI Price

$4. 00/hr

00/hr

Non-UCI Price

$5.00/hr

epilog fusion m2 / laser cutter for small to large projects

Epilog Fusion M2

Category

Cut and Etch Flat Materials

Materials

Engrave: Wood, Acrylic, Fabric, Glass, Paper, Rubber, Plastic

Cut: Wood, Acrylic, Fabric, Paper, Rubber, Plastic

Features

-A 32”x20” engraving area

-Engraves and cuts through various materials

-Vector bed allows for ease in home relocation for complex shapes

-Large viewing door with LED lighting

-Handles material up to 13.5″

-Cuts precise designs and graphics made by computer software

-Requires a vector file input

UCI Price

$8.00/hr

Non-UCI Price

$10.00/hr

**Users must provide their own material. FABWorks does not carry any spare material for purchase. Time charged for the laser cutter is for the duration you have exclusive access to the machine, not the time that the laser is cutting. Have your designs ready to cut to minimize your usage time.**

Have your designs ready to cut to minimize your usage time.**

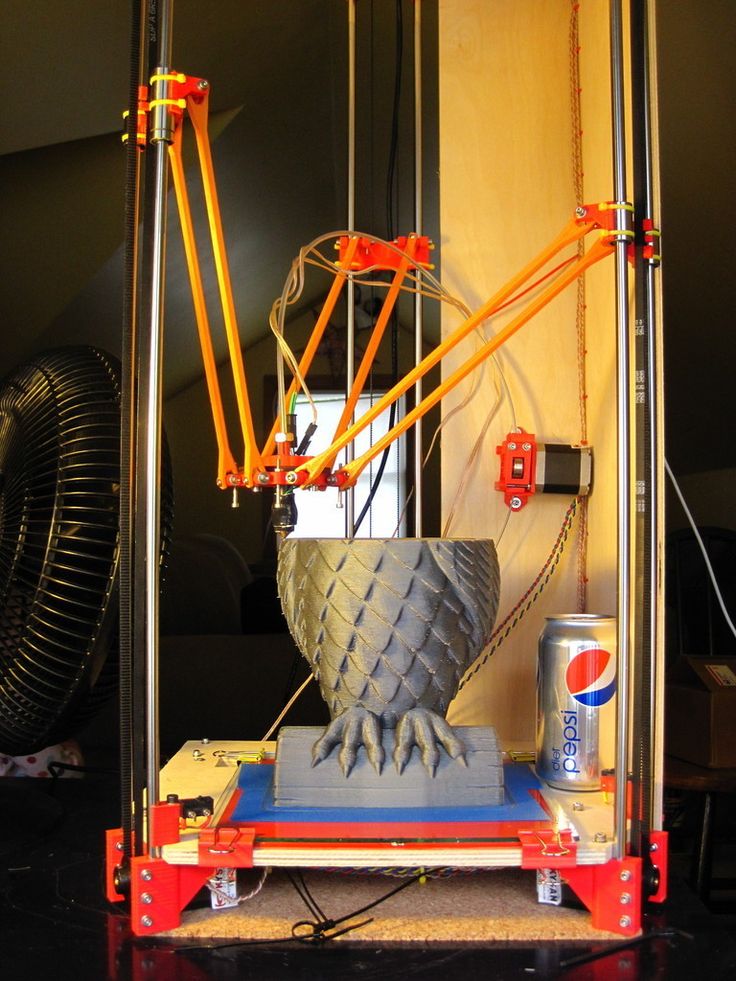

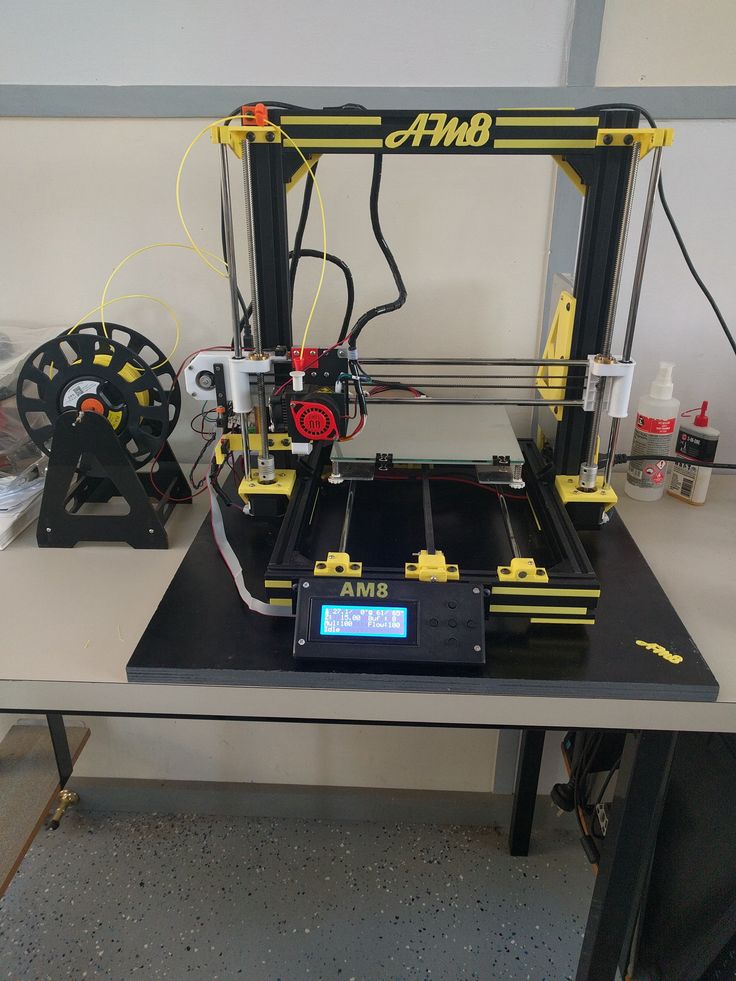

lulzbot taz 6 / FDM 3D printer for large or flexible filament projects

LulzBot Taz 6

Category

Consumer Level FDM 3D Printer

Materials

-3 mm diameter spools of ABS/PLA/TPE/TPU nylon filaments

-Filaments can be found at http://airwolf3d.com/shop/filament

**No outside material unless special arrangements are made; all 3D printing material is provided by the lab**

Features

-Print Area: 11.02 ” x 11.02″ x 9.8″

-Print Tolerance: 0.0039 in (0.1mm) in the X and Y axes.

-Print speed up to 7.9 in./sec

-Layer Thickness: 0.002 in – 0.02 in) dependent on nozzle size.

UCI Price

$5.50/hr, plus material cost ABS: $0.07/g | NinjaFlex: $0.10/g

Non-UCI Price

$7.15/hr, plus material cost ABS: $0.09/g | NinjaFlex: $0.13/g

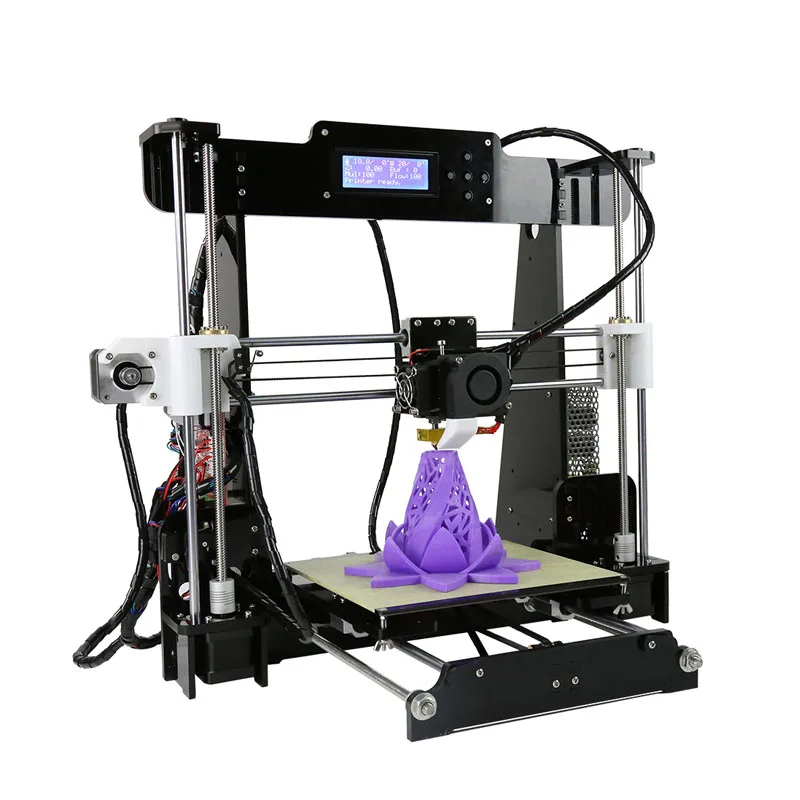

ultimaker 3 / FDM 3D printer for tough parts with soluble support

Ultimaker 3

Category

FDM 3D printer

Materials

-Nylon, PLA, ABS, CPE, CPE+, PVA, PC, TPU, 95A, PP, and Breakaway

**No outside material unless special arrangements are made; all 3D printing material is provided by the lab**

Features

-XYZ accuracy: 12. 5, 12.5, 2.5 microns

5, 12.5, 2.5 microns

Build area

-Build speed: < 24 mm³/s

-Build volume, left or right nozzle: 8.8 x 8.5 x 7.9 inches

-Build volume, dual extrusion: 7.8 x 8.5 x 7.9 inches

UCI Price

$5.50/hr, plus material cost: PLA: $0.12/g | Nylon: $0.16/g | PVA: $0.18/g

Non-UCI Price

$7.15/hr, plus material cost: PLA: $0.15/g | Nylon: $0.21/g | PVA: $0.23/g

camm1-pro vinyl cutter / cutter for custom decals or stencils

CAMM1-Pro Vinyl Cutter

Category

Cutter for Custom Decals or Stencils

Materials

Vinyl, reflective vinyls, twill, masks for paint, heat transfer, and sandblasting

Features

-Accepts material from 2 to 27.5 inches wide

-Cutting speeds up to 20 inches per second

-Driven by a digital control servo motor

-Cuts precise designs and graphics made by computer software

-Requires a vector file input

UCI Price

$5. 00/hr

00/hr

Non-UCI Price

$6.00/hr

**Users must provide their own material. FABWorks does not carry any spare material for purchase.**

electronics lab / tools and supplies for circuitry projects

Electronics Lab

Category

Tools and Supplies for Electronic Circuits

Materials

Circuit board, solder, wires, connectors, electrical components

Features

-Soldering iron to secure small circuit connections

-Dremel 3000 to sand and grind small parts

-Oscilloscope and function generator

-Pliers

-Wire cutters

-Wire strippers

UCI Price

$5.00/hr

Non-UCI Price

$6.00/hr

**Users must provide their own material. FABWorks does not carry any spare material for purchase.**

epilog mini laser cutter / laser cutter for small to medium projects

Epilog Mini Laser Cutter

Category

Cut and Etch Flat Materials

Materials

Engrave: Wood, Acrylic, Fabric, Glass, Paper, Rubber, Plastic

Cut: Wood, Acrylic, Fabric, Paper, Rubber, Plastic

Features

-Vector Cutting Table provides better cutting quality

-Vacuum Hold-Down for thin, warped materials

-Laser increments as small as . 02 mm

02 mm

-Engraving area 18″ x 12″

-Handles material up to 4″ thick

-Cuts precise designs and graphics made by computer software

-Requires a vector file input

UCI Price

$8.00/hr

Non-UCI Price

$10.00/hr

**Users must provide their own material. FABWorks does not carry any spare material for purchase. Time charged for the laser cutter is for the duration you have exclusive access to the machine, not the time that laser is running. Have your designs ready to cut to minimize your usage time.**

formlabs form 2 / high resolution photopolymer printer for small parts

Formlabs Form2

Category

SLA Photopolymer printer

Materials

Photopolymer resin

Features

-Interactive touchscreen

-Build volume: 5.7 x 5.7 x 6.9 in. 9145 X 145 X 175 mm)

-Layer thickness (Axis resolution): 25, 50, 100 microns

UCI Price

$6. 00/hr, plus material cost: $7+$0.30/ml

00/hr, plus material cost: $7+$0.30/ml

Non-UCI Price

$7.80/hr, plus material cost: $9+$0.40/ml

next engine 3d scanner / digital scanner for real world objects

NextEngine 3D Scanner

Category

Digital 3D Scanner for Real World Objects

Materials

Item to be scanned of any size, shape, or material

Features

-Able to scan with a .005 inch accuracy

-Creates rich, full color scans

-Desktop size (8.8”x3.6”x10.9”) and approximately 7 lbs

-Made of aluminum and polycarbonate

-Includes auto drive that can rotate objects up to 20 lbs

-Includes part gripper that can hold objects that would fall if unsupported

UCI Price

$6.00/hr

Non-UCI Price

$7.00/hr

**Users must provide their own material. FABWorks does not carry any spare material for purchase.**

.

Tormach PCNC 440

Category

CNC Machining

Materials

Wood, plastic, foam, sheet aluminum, steel, titanium

Features

-Cast Iron Frame and Table

-Dovetail Ways

-Ball Screws

-10,000 RPM R8 Spindle

-10″ x 6. 25″ x 10″ Work Envelope

25″ x 10″ Work Envelope

UCI Price

$19.00/hr

Non-UCI Price

$25.00/hr

**Users must provide their own material. FABWorks does not carry any spare material for purchase. Time charged for the CNC machine is for the duration you have exclusive access to the machine, not time time that machine is cutting. Have your designs ready to cut to minimize your usage time.**

.

Stratasys uPrint SE

Category

High Resolution 3D Printer with Soluble Support

Materials

ABS plastic and SR-30 Soluble as a support material

**No outside material unless special arrangements are made; all 3D printing material is provided by the lab**

Features

-Provides a water soluble support material

-Build size of 8”x6”x6”

-Windows compatible

-Layer thickness of .010 in or .013 in

-Easy to use software: CatalystEX

UCI Price

$13.00/hr, plus material cost ABS: $4. 88/cubic in or SR: $6.00/cubic in.

88/cubic in or SR: $6.00/cubic in.

Non-UCI Price

$17.00/hr, plus material cost ABS: $6.34/cubic in or SR: $7.80/cubic in

.

Woodshop Tools

Category

A Variety of Tools for Light Woodwork Projects

Materials

Wood

Features

-Compound sliding miter saw

-Band saw

-Drill press

-Belt sander

-Scroll saw

UCI Price

Free

Non-UCI Price

$1.30/hr

**Users must provide their own material. FABWorks does not carry any spare material for purchase.**

.

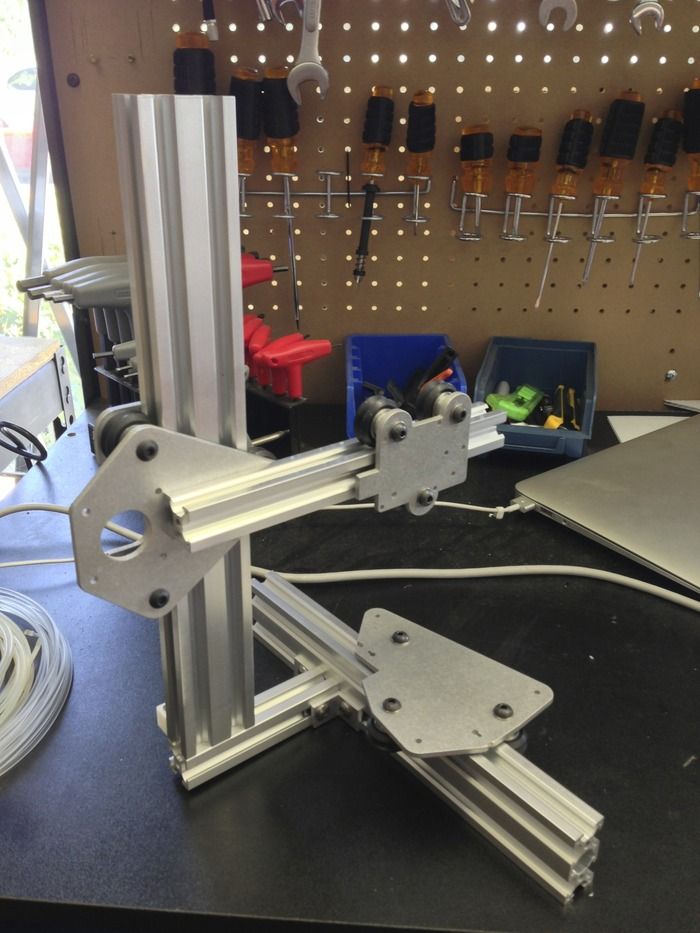

Shapeoko 3

Category

CNC Machining

Materials

Wood, plastic, foam, aluminum

Features

-1.25 hp spindle and NEMA-23 stepper motors

-Aluminium frame & hardware

-Cutting area 16″(X), 16″(Y), 3″(Z)

-Operating System: OS X 10.9 or higher, Windows 7, 8, 8.1, 10

UCI Price

$4. 00/hr

00/hr

Non-UCI Price

$5.00/hr

**Users must provide their own material. FABWorks does not carry any spare material for purchase.**

.

Janome Sewing Machine

Category

Sawing Machine For Light Projects

Materials

Fabric and thread

Features

-Supports 18 stitches including a one-step buttonhole

-Stitch length and width adjustment located in front of machine

-Maximum stitch width of 6.5mm

-Utilizes a 5 piece feed dog feed system

-Precision fabric control and extra high lift presser allows for thicker projects

UCI Price

$3.00/hr

Non-UCI Price

$4.00/hr

**Users must provide their own material. FABWorks does not carry any spare material for purchase.**

University of California, Irvine

2302 Calit2 Building

Irvine, CA 92697-2800

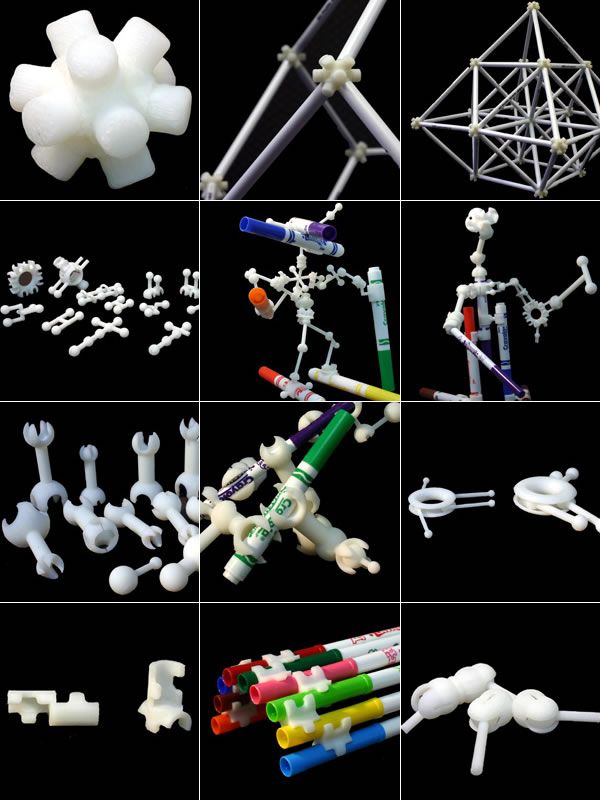

3D printing made it easier to create tensegrity structures

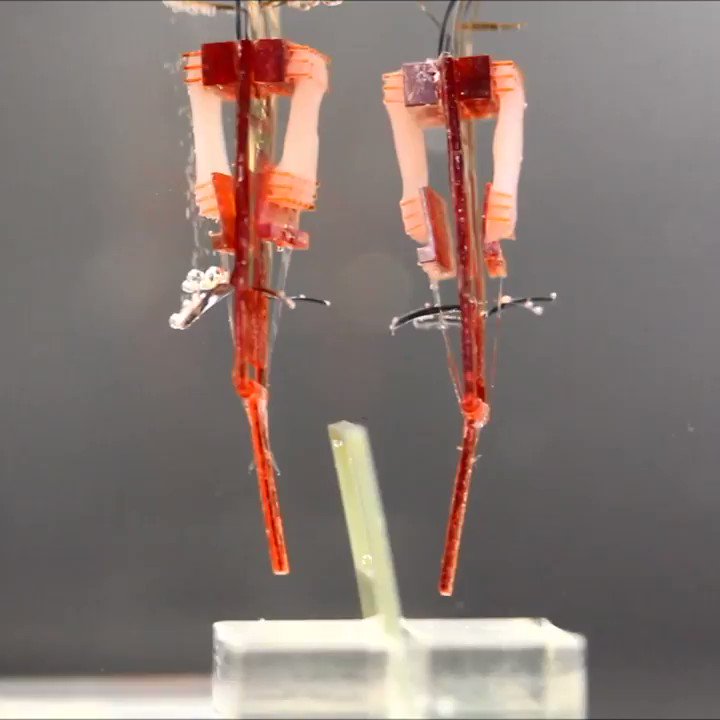

South Korean engineers proposed to print tensegrity structures on a 3D printer. First, the printer prints a billet made of consumable plastic with rigid frame elements inside, and then an elastic material is poured into the prepared channels, which acts as cables. After that, the consumable material is removed and only the tensegrity structure remains. The method made it possible to create small but complex structures that would be difficult to assemble with conventional methods, as well as a robot with magnetic elastomer tensegrity legs. An article about the method was published in the journal Science Robotics .

First, the printer prints a billet made of consumable plastic with rigid frame elements inside, and then an elastic material is poured into the prepared channels, which acts as cables. After that, the consumable material is removed and only the tensegrity structure remains. The method made it possible to create small but complex structures that would be difficult to assemble with conventional methods, as well as a robot with magnetic elastomer tensegrity legs. An article about the method was published in the journal Science Robotics .

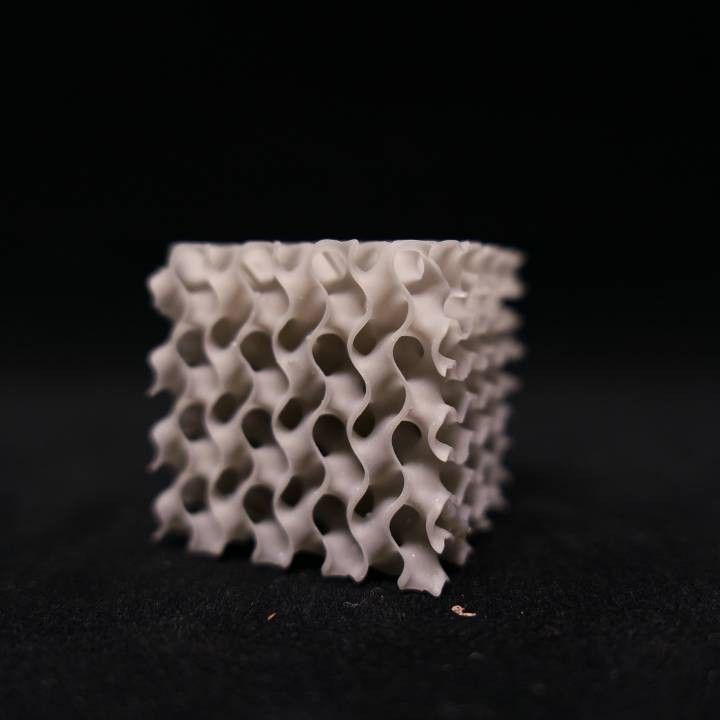

Tensegrity, or stressed integrity, is a type of structure consisting of rigid and flexible components. As a rule, these are rods and cables that connect the ends of the rods to each other. The main distinguishing feature of tensegrity structures is that the rigid rods do not touch each other and are suspended on cables. Due to this, the cables work in tension, and the rods only in compression, but not in bending. As a result, such structures have a high ratio of rigidity to mass, they are resistant to deformations, and are also able to redistribute deformation from one part to the entire structure.

Although some projects with tensegrity design already exist (for example, a robot that is resistant to dropping from a helicopter), in general it cannot be called popular - despite all the advantages. This is partly due to the fact that not all materials are suitable for it, and also such a design is difficult to assemble from a variety of elements, as well as to select the desired tension.

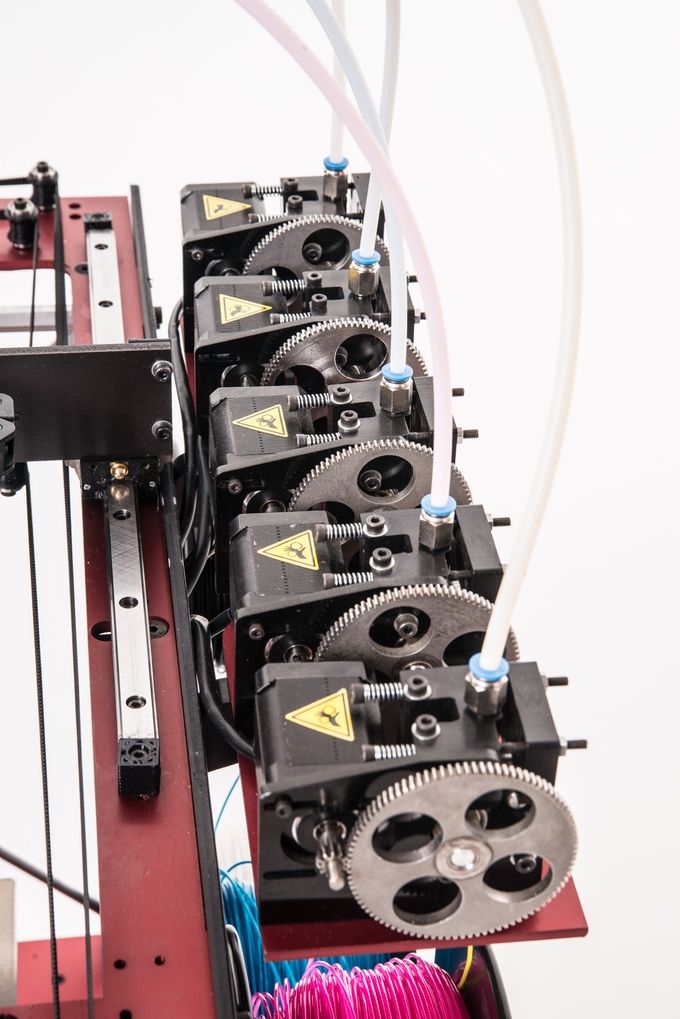

Researchers from the Ulsan National University of Science and Technology, led by Jiyun Kim, proposed not to assemble tensegrity structures from individual elements, but to print on a 3D printer in the form of a single structure. The method consists of two stages. On the first, a printer with two printheads simultaneously prints a consumable matrix made of polyvinyl alcohol, and inside it are polylactide rods and empty channels for cables. At the second stage, it is necessary to pour the cable material into the empty channels of the already frozen matrix, and then, when it also hardens, remove the polyvinyl alcohol. Engineers used PDMS, PBAT or a mixture of them as a material for cables, as well as ferromagnetic particles of iron oxide dissolved in them. This allows you to control the deformation of the material not only mechanically, but also non-contact with the help of a magnetic field.

Engineers used PDMS, PBAT or a mixture of them as a material for cables, as well as ferromagnetic particles of iron oxide dissolved in them. This allows you to control the deformation of the material not only mechanically, but also non-contact with the help of a magnetic field.

In most prototypes of tensegrity structures, the authors used a base cell with a hexagonal prism structure, which, depending on the tasks, was connected to other similar cells into a column or torus. They showed many different examples of the use of such structures and their capabilities. For example, tensegrity with cables that respond to a magnetic field can be used for programmed folding, and reversible: when a magnetic field appears, the balance of tension and compression is disturbed, and the structure folds, but returns to its original form when the field is turned off.

Another notable example is a five-legged crawling robot with tensegrity legs. Each of them consists of five hexagonal prisms with alternating direction. At the base of the legs, two motors are installed, connected to the side or central part of the end of the leg through a rope. When winding the central rope, the leg is shortened due to alternating prisms, and when winding the side leg is bent down. Thanks to this, a robot with such legs was able to walk around the floor, turning in the right direction.

At the base of the legs, two motors are installed, connected to the side or central part of the end of the leg through a rope. When winding the central rope, the leg is shortened due to alternating prisms, and when winding the side leg is bent down. Thanks to this, a robot with such legs was able to walk around the floor, turning in the right direction.

The authors note that 3D printing will allow not only to create more complex structures than those created by conventional methods, but also to take advantage of 3D printing (the ability to quickly create many prototypes with well-defined parameters and select the best designs) and design optimization methods.

3D printing has been used before to create lattice structures controlled by a magnetic field, but in a different way. For example, in 2018, a group of American scientists presented a method for creating lattices from hollow tubes, inside which it is necessary to pour a magnetorheological fluid. This structure allows you to control the rigidity of the structure using a magnetic field, without changing the shape of the structure, unlike the new method of Korean engineers.

Grigory Kopiev

Found a typo? Select the fragment and press Ctrl+Enter.

3D printing will pave the way for a new era in the design and combination of optical materials.

A new method for 3D printing chalcogenide glass could lead to a revolutionary breakthrough in the production of infrared optical components at a low cost.

A team of researchers from the Center for Optics Photonique et Laser (COPL) at Laval University (Quebec, QC, Canada) has created a 3D printed chalcogenide glass. The material is used to make optical components that operate at medium infrared wavelengths. The 3D printing capability of this glass enables the fabrication of complex glass components and optical fibers for new types of low-cost sensors, telecommunications components, and biomedical devices.

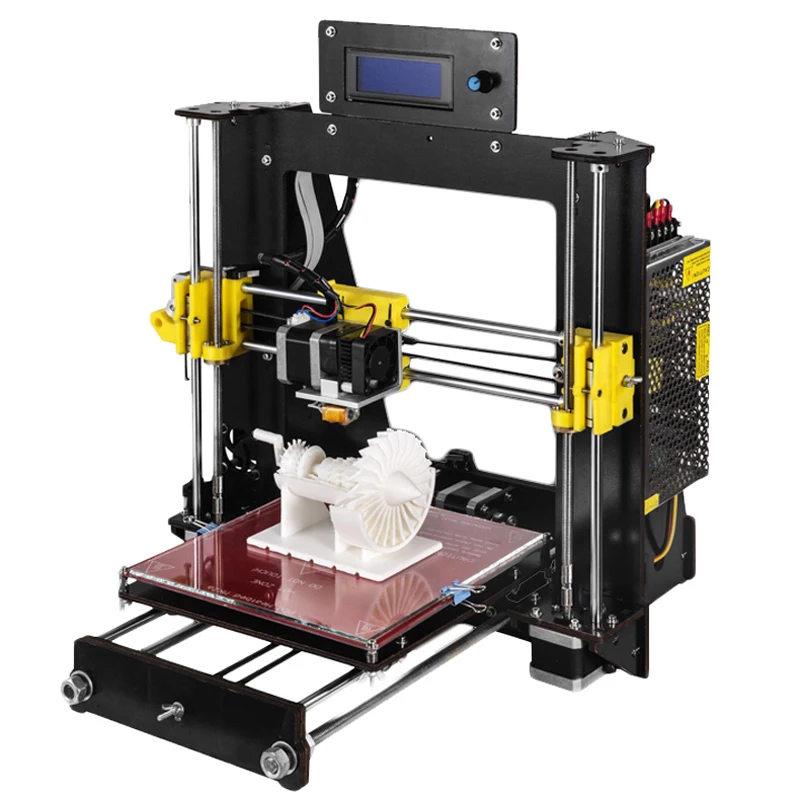

In an article describing the work, research team leader Patrick Larochelle and his colleagues described how they modified a commercially available 3D printer for glass extrusion. The method is based on the widely used method Fused deposition simulation in which a plastic filament is melted and then extruded in layers to create detailed 3D objects.

The method is based on the widely used method Fused deposition simulation in which a plastic filament is melted and then extruded in layers to create detailed 3D objects.

“3D printing of optical materials will pave the way for a new era of design and material combination for the production of photonic components and fibers of the future,” says Yannick Ledemi, member of the research team. "This new method has the potential to lead to a breakthrough in the efficient production of infrared optical components at low cost."

Chalcogenide glass softens at a relatively low temperature compared to other glasses. Recognizing this, the research team increased the maximum press temperature of the commercial 3D printer from 260°C to 330°C to allow the chalcogenide glass to be extruded. They produced chalcogenide glass fibers with dimensions similar to commercial plastic filaments used with a 3D printer. Then, the printer was programmed to create two patterns with complex shapes and sizes.

“Our approach works very well for soft chalcogenide glass, but alternative methods are also being explored for printing other types of glass,” says Ledemy. “This could allow components to be made from multiple materials. Glass can be combined with polymers with specialized electrical conductive or optical properties to create multifunctional 3D printing devices.”

3D printing would also be useful for making fiber preforms - a piece of glass that is pulled into a fiber - with complex geometries, or multiple materials, or a combination of them. Once the design and manufacturing methods are precisely defined, 3D printing can be used to produce low-cost, high-volume infrared glass components or fiber preforms.

“3D printed chalcogenide components would be useful for infrared thermal imaging for defense and security purposes,” says Ledemy. "They will also enable the sensors to be used in pollutant monitoring, biomedicine and other applications where the infrared chemical signature of molecules is used for detection and diagnosis.