3D printing plastic density

The densities of all 3D printing materials

Today at Bitfab we’re going to talk about a subject that every good maker ends up wondering about: what is the density of a filament, how much is the weight of each meter, and how many meters of it are in a one kilo coil.

At first glance, it might seem silly to you; how many objects in our daily life do we need to know this data from? Practically none, but in this point it is essential, because with this data we can know exactly the amount of spent filament or if really 1kg of a material from one coil compensates us more than another.

How? We’ll tell you, so keep reading this because you’ re going to like it 🙂

📖 What do you want to read?

The density chart of all 3D materials

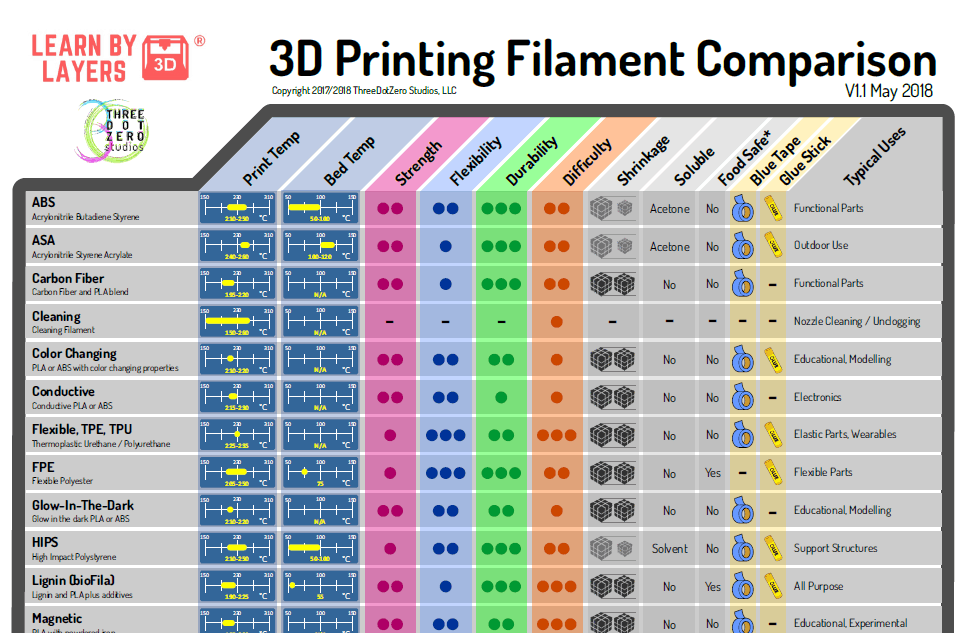

Here’s a list of different materials taken from this article on 3D printer filaments to give you an idea of what’s on the market.

In grams per cubic centimeter so you can see for yourself!

| Material | Density [g/cm3] |

| PLA | 1. |

| ABS | 1.04 |

| PETG | 1.27 |

| NYLON | 1.52 |

| Flexible (TPU) | 1.21 |

| Polycarbonate (PC) | 1.3 |

| Wood | 1.28 |

| Carbon FIber | 1.3 |

| PC/ABS | 1.19 |

| HIPS | 1.03 |

| PVA | 1.23 |

| ASA | 1.05 |

| Polypropylene (PP) | 0.9 |

| Acetal (POM) | 1.4 |

| PMMA | 1.18 |

| Semi flexible (FPE) | 2.16 |

🥁🥁🥁 Here’s also… a graphic, so you can compare!

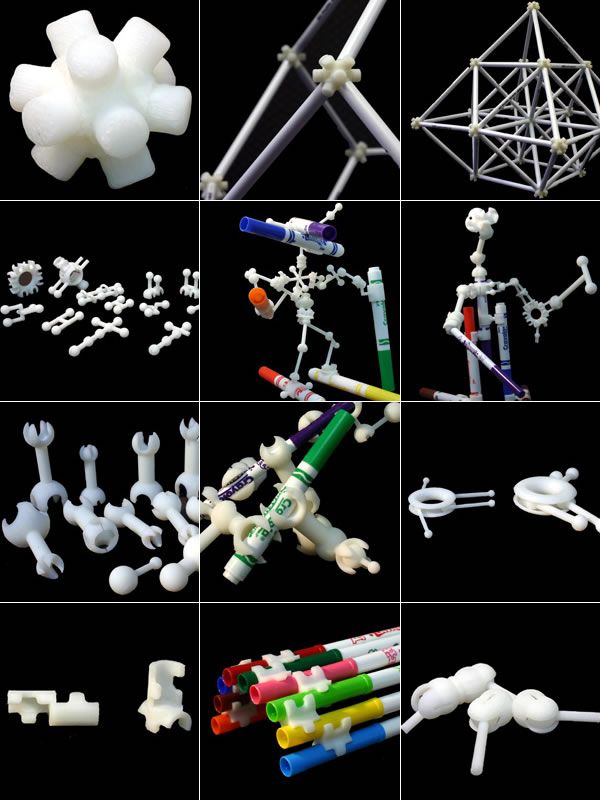

Here there are plenty of materials such as PLA, ABS, Polypropylene (PP), PETG, flexible filaments (TPU) or filaments with carbon fibre.

The lightest material for printing

Do you want to print the lightest pieces? A drone, a part for a radio-controlled plane… The lightest material used in 3D printing is Polypropylene, with only 0. 9 grams per cubic centimeter. Although we warn you: PP warping makes it quite difficult to print for large parts!

9 grams per cubic centimeter. Although we warn you: PP warping makes it quite difficult to print for large parts!

The heaviest 3D printing material

The heaviest materials on our chart are semi-flexible FPE and nylon (Polyamide), so they can affect you in applications where you are looking for lightness.

Apart from these, there are other heavier materials that we have not yet considered: metal-filled materials. There are materials filled with bronze, brass, copper, iron… which considerably increase the density of the material. These filaments usually have an aesthetic purpose and that is why we have left them out of our list of materials.

How many meters of material are there in a kilo of filament? (with chart)

The chart you were looking for to go from kilos to meters of material, to know how many meters there are in a coil, both for 1.75mm and 3mm filament.

| Material | How many meters in 1kg of material (3mm)? | How many meters in 1kg of material (1. 75mm)? 75mm)? |

| PLA | 114 | 335 |

| ABS | 136 | 400 |

| PETG | 111 | 328 |

| Nylon | 93 | 274 |

| Flexible (TPU) | 117 | 344 |

| Polycarbonate (PC) | 109 | 320 |

| Wood | 111 | 325 |

| Carbon Fiber | 109 | 320 |

| PC/ABS | 119 | 350 |

| HIPS | 137 | 404 |

| PVA | 115 | 338 |

| ASA | 135 | 396 |

| Polypropylene (PP) | 157 | 462 |

| Acetal (POM) | 101 | 297 |

| PMMA | 120 | 353 |

| Semi flexible (FPE) | 66 | 193 |

Do you want to know how we calculated this chart? This is the formula we have used. Let’s take an example of a 1.75mm coil weighing 1kg. You could do the same calculation for a 3mm coil.

How many grams are in a meter of filament? (with chart)

The question asked the other way around: how much does a meter of 3D printing filament weighs. We have also generated a chart with all the information so that you can consult it comfortably.

| Material | How much does 1 meter of 1.75mm filament weighs? [grams] | How much does 1 meter of 3mm filament weighs? [grams] |

| PLA | 2.98 | 8.76 |

| ABS | 2.50 | 7.35 |

| PETG | 3.05 | 8.97 |

| Nylon | 3.65 | 10.74 |

| Flexible (TPU) | 2.91 | 8.55 |

| Polycarbonate (PC) | 3.13 | 9.18 |

| Wood | 3.08 | 9.04 |

| Carbon Fiber | 3.13 | 9.18 |

| PC/ABS | 2.86 | 8.41 |

| HIPS | 2.48 | 7.28 |

| PVA | 2. 96 96 | 8.69 |

| ASA | 2.52 | 7.42 |

| Polypropylene (PP) | 2.16 | 6.36 |

| Acetal (POM) | 3.37 | 9.89 |

| PMMA | 2.84 | 8.34 |

| Semi flexible (FPE) | 5.19 | 15.26 |

How much does my 3D printed part weigh?

As a curiosity, in Cura you can also see the length of filament you spend per piece in the lower part of the program.

How to calculate the density of a filament with all formulas

As we have mentioned, density is the relationship between mass and volume of something; in this case our 3D filament.

We already have the mass of the filaments, since they usually come in coils of 1[kg] of weight (minus the weight of the support). We only have to know the volume, and here comes the problem.

If we consider the filament as if it were completely stretched, it would be a very long cylinder tube, like this, where we are going to define the main measurements.

To calculate the volume of that cylindrical tube, we have the following procedure:

We have the filament radius, and we understand that it is 1.75[mm]/2. If we wanted to do a more precise calculation, we would take into account that the diameter of a filament has a tolerance of ±0.05[mm] and there are even manufacturers that reach ±0.02[mm].

The fact is that in order to do this analysis, you don’t have to take this into account, but it’s always good to know it (so you can look at it in the product specifications when you buy it).

Only length would remain and this is the one that does not normally come in the manufacturer’s specifications. However, it is usually between 335[m], although this value can vary between companies.

Finally, to calculate the density of a 1[kg] filament:

What did you think of our article on densities of 3D materials?

And this is as far as the article goes. We hope you liked it. Now you only need to read it a couple more times, and practice.

We would love if you could comment on the meters of the new filament you buy, and if the formula has really hit the nail on the head (when you finish it clearly).

Greetings and see you in the next article. Meanwhile, if you need something, you know you can count on our online 3D printing service.

PLA Filament | 3D4Makers | 3D printing

Roll over image to zoom in Click on image to zoom

Save €-20.65

3D4MakersSKU: PLAXX-2008-175-750-3D4M

9 reviews

Color: Orange (RAL 2008)

Orange (RAL 2008)

Blue (RAL 5002)

Red (RAL 3020)

Green (RAL 6029)

Black (RAL 9011)

Natural

White (RAL 9003)

Yellow (RAL 1023)

Apple Green (RAL 6018)

Sky Blue (RAL 5015)

Magenta (RAL 4010)

Light Grey (RAL 7035)

Silver (RAL 9006)

Gold (RAL 1036)

Iron Grey (RAL 7011)

Middle Blue (Pantone 7691 C)

Yellow Gold (Pantone 466 C)

Orange Fluor (Pantone 021 C)

Snow White (Pantone 656 C)

Green Fluor (Pantone 3529 C)

Leaf Green (RAL 6002)

Diameter: 1. 75mm

75mm

1.75mm

2.85mm

Weight: 750 gram

750 gram

2300 gram

Variant

Orange (RAL 2008) / 1.75mm / 750 gram - €20.65Orange (RAL 2008) / 1.75mm / 2300 gram - €50.95Orange (RAL 2008) / 2.85mm / 750 gram - €20.65Orange (RAL 2008) / 2.85mm / 2300 gram - €50.95Blue (RAL 5002) / 1.75mm / 750 gram - €20.65Blue (RAL 5002) / 1.75mm / 2300 gram - €50.95Blue (RAL 5002) / 2.85mm / 750 gram - €20.65Blue (RAL 5002) / 2.85mm / 2300 gram - €50.95Red (RAL 3020) / 1.75mm / 750 gram - €20.65Red (RAL 3020) / 1.75mm / 2300 gram - €50.95Red (RAL 3020) / 2.85mm / 750 gram - €20.65Red (RAL 3020) / 2.85mm / 2300 gram - €50.95Green (RAL 6029) / 1.75mm / 750 gram - €20.65Green (RAL 6029) / 1.75mm / 2300 gram - €50.95Green (RAL 6029) / 2. 85mm / 750 gram - €20.65Green (RAL 6029) / 2.85mm / 2300 gram - €50.95Black (RAL 9011) / 1.75mm / 750 gram - €20.65Black (RAL 9011) / 1.75mm / 2300 gram - €50.95Black (RAL 9011) / 2.85mm / 750 gram - €20.65Black (RAL 9011) / 2.85mm / 2300 gram - €50.95Natural / 1.75mm / 750 gram - €20.65Natural / 1.75mm / 2300 gram - €50.95Natural / 2.85mm / 750 gram - €20.65Natural / 2.85mm / 2300 gram - €50.95White (RAL 9003) / 1.75mm / 750 gram - €20.65White (RAL 9003) / 1.75mm / 2300 gram - €50.95White (RAL 9003) / 2.85mm / 750 gram - €20.65White (RAL 9003) / 2.85mm / 2300 gram - €50.95Yellow (RAL 1023) / 1.75mm / 750 gram - €20.65Yellow (RAL 1023) / 1.75mm / 2300 gram - €50.95Yellow (RAL 1023) / 2.85mm / 750 gram - €20.65Yellow (RAL 1023) / 2.85mm / 2300 gram - €50.95Apple Green (RAL 6018) / 1.75mm / 750 gram - €20.65Apple Green (RAL 6018) / 1.75mm / 2300 gram - €50.95Apple Green (RAL 6018) / 2.85mm / 750 gram - €20.65Apple Green (RAL 6018) / 2.85mm / 2300 gram - €50.95Sky Blue (RAL 5015) / 1.75mm / 750 gram - €20.

85mm / 750 gram - €20.65Green (RAL 6029) / 2.85mm / 2300 gram - €50.95Black (RAL 9011) / 1.75mm / 750 gram - €20.65Black (RAL 9011) / 1.75mm / 2300 gram - €50.95Black (RAL 9011) / 2.85mm / 750 gram - €20.65Black (RAL 9011) / 2.85mm / 2300 gram - €50.95Natural / 1.75mm / 750 gram - €20.65Natural / 1.75mm / 2300 gram - €50.95Natural / 2.85mm / 750 gram - €20.65Natural / 2.85mm / 2300 gram - €50.95White (RAL 9003) / 1.75mm / 750 gram - €20.65White (RAL 9003) / 1.75mm / 2300 gram - €50.95White (RAL 9003) / 2.85mm / 750 gram - €20.65White (RAL 9003) / 2.85mm / 2300 gram - €50.95Yellow (RAL 1023) / 1.75mm / 750 gram - €20.65Yellow (RAL 1023) / 1.75mm / 2300 gram - €50.95Yellow (RAL 1023) / 2.85mm / 750 gram - €20.65Yellow (RAL 1023) / 2.85mm / 2300 gram - €50.95Apple Green (RAL 6018) / 1.75mm / 750 gram - €20.65Apple Green (RAL 6018) / 1.75mm / 2300 gram - €50.95Apple Green (RAL 6018) / 2.85mm / 750 gram - €20.65Apple Green (RAL 6018) / 2.85mm / 2300 gram - €50.95Sky Blue (RAL 5015) / 1.75mm / 750 gram - €20. 65Sky Blue (RAL 5015) / 1.75mm / 2300 gram - €50.95Sky Blue (RAL 5015) / 2.85mm / 750 gram - €20.65Sky Blue (RAL 5015) / 2.85mm / 2300 gram - €50.95Magenta (RAL 4010) / 1.75mm / 750 gram - €20.65Magenta (RAL 4010) / 1.75mm / 2300 gram - €50.95Magenta (RAL 4010) / 2.85mm / 750 gram - €20.65Magenta (RAL 4010) / 2.85mm / 2300 gram - €50.95Light Grey (RAL 7035) / 1.75mm / 750 gram - €20.65Light Grey (RAL 7035) / 1.75mm / 2300 gram - €50.95Light Grey (RAL 7035) / 2.85mm / 750 gram - €20.65Light Grey (RAL 7035) / 2.85mm / 2300 gram - €50.95Silver (RAL 9006) / 1.75mm / 750 gram - €20.65Silver (RAL 9006) / 1.75mm / 2300 gram - €50.95Silver (RAL 9006) / 2.85mm / 750 gram - €20.65Silver (RAL 9006) / 2.85mm / 2300 gram - €50.95Gold (RAL 1036) / 1.75mm / 750 gram - €20.65Gold (RAL 1036) / 1.75mm / 2300 gram - €50.95Gold (RAL 1036) / 2.85mm / 750 gram - €20.65Gold (RAL 1036) / 2.85mm / 2300 gram - €50.95Iron Grey (RAL 7011) / 1.75mm / 750 gram - €20.65Iron Grey (RAL 7011) / 1.75mm / 2300 gram - €50.

65Sky Blue (RAL 5015) / 1.75mm / 2300 gram - €50.95Sky Blue (RAL 5015) / 2.85mm / 750 gram - €20.65Sky Blue (RAL 5015) / 2.85mm / 2300 gram - €50.95Magenta (RAL 4010) / 1.75mm / 750 gram - €20.65Magenta (RAL 4010) / 1.75mm / 2300 gram - €50.95Magenta (RAL 4010) / 2.85mm / 750 gram - €20.65Magenta (RAL 4010) / 2.85mm / 2300 gram - €50.95Light Grey (RAL 7035) / 1.75mm / 750 gram - €20.65Light Grey (RAL 7035) / 1.75mm / 2300 gram - €50.95Light Grey (RAL 7035) / 2.85mm / 750 gram - €20.65Light Grey (RAL 7035) / 2.85mm / 2300 gram - €50.95Silver (RAL 9006) / 1.75mm / 750 gram - €20.65Silver (RAL 9006) / 1.75mm / 2300 gram - €50.95Silver (RAL 9006) / 2.85mm / 750 gram - €20.65Silver (RAL 9006) / 2.85mm / 2300 gram - €50.95Gold (RAL 1036) / 1.75mm / 750 gram - €20.65Gold (RAL 1036) / 1.75mm / 2300 gram - €50.95Gold (RAL 1036) / 2.85mm / 750 gram - €20.65Gold (RAL 1036) / 2.85mm / 2300 gram - €50.95Iron Grey (RAL 7011) / 1.75mm / 750 gram - €20.65Iron Grey (RAL 7011) / 1.75mm / 2300 gram - €50. 95Iron Grey (RAL 7011) / 2.85mm / 750 gram - €20.65Iron Grey (RAL 7011) / 2.85mm / 2300 gram - €50.95Middle Blue (Pantone 7691 C) / 1.75mm / 750 gram - €20.65Middle Blue (Pantone 7691 C) / 1.75mm / 2300 gram - €50.95Middle Blue (Pantone 7691 C) / 2.85mm / 750 gram - €20.65Middle Blue (Pantone 7691 C) / 2.85mm / 2300 gram - €50.95Yellow Gold (Pantone 466 C) / 1.75mm / 750 gram - €20.65Yellow Gold (Pantone 466 C) / 1.75mm / 2300 gram - €50.95Yellow Gold (Pantone 466 C) / 2.85mm / 750 gram - €20.65Yellow Gold (Pantone 466 C) / 2.85mm / 2300 gram - €50.95Orange Fluor (Pantone 021 C) / 1.75mm / 750 gram - €20.65Orange Fluor (Pantone 021 C) / 1.75mm / 2300 gram - €50.95Orange Fluor (Pantone 021 C) / 2.85mm / 750 gram - €20.65Orange Fluor (Pantone 021 C) / 2.85mm / 2300 gram - €50.95Snow White (Pantone 656 C) / 1.75mm / 750 gram - €20.65Snow White (Pantone 656 C) / 1.75mm / 2300 gram - €50.95Snow White (Pantone 656 C) / 2.85mm / 750 gram - €20.65Snow White (Pantone 656 C) / 2.85mm / 2300 gram - €50.

95Iron Grey (RAL 7011) / 2.85mm / 750 gram - €20.65Iron Grey (RAL 7011) / 2.85mm / 2300 gram - €50.95Middle Blue (Pantone 7691 C) / 1.75mm / 750 gram - €20.65Middle Blue (Pantone 7691 C) / 1.75mm / 2300 gram - €50.95Middle Blue (Pantone 7691 C) / 2.85mm / 750 gram - €20.65Middle Blue (Pantone 7691 C) / 2.85mm / 2300 gram - €50.95Yellow Gold (Pantone 466 C) / 1.75mm / 750 gram - €20.65Yellow Gold (Pantone 466 C) / 1.75mm / 2300 gram - €50.95Yellow Gold (Pantone 466 C) / 2.85mm / 750 gram - €20.65Yellow Gold (Pantone 466 C) / 2.85mm / 2300 gram - €50.95Orange Fluor (Pantone 021 C) / 1.75mm / 750 gram - €20.65Orange Fluor (Pantone 021 C) / 1.75mm / 2300 gram - €50.95Orange Fluor (Pantone 021 C) / 2.85mm / 750 gram - €20.65Orange Fluor (Pantone 021 C) / 2.85mm / 2300 gram - €50.95Snow White (Pantone 656 C) / 1.75mm / 750 gram - €20.65Snow White (Pantone 656 C) / 1.75mm / 2300 gram - €50.95Snow White (Pantone 656 C) / 2.85mm / 750 gram - €20.65Snow White (Pantone 656 C) / 2.85mm / 2300 gram - €50. 95Green Fluor (Pantone 3529 C) / 1.75mm / 750 gram - €20.65Green Fluor (Pantone 3529 C) / 1.75mm / 2300 gram - €50.95Green Fluor (Pantone 3529 C) / 2.85mm / 750 gram - €20.65Green Fluor (Pantone 3529 C) / 2.85mm / 2300 gram - €50.95Leaf Green (RAL 6002) / 1.75mm / 750 gram - €20.65

95Green Fluor (Pantone 3529 C) / 1.75mm / 750 gram - €20.65Green Fluor (Pantone 3529 C) / 1.75mm / 2300 gram - €50.95Green Fluor (Pantone 3529 C) / 2.85mm / 750 gram - €20.65Green Fluor (Pantone 3529 C) / 2.85mm / 2300 gram - €50.95Leaf Green (RAL 6002) / 1.75mm / 750 gram - €20.65

PLA Filament (Polylactic Acid) is a biodegradable polymer coming from renewable organic resources (corn starch or sugarcane). PLA Filament is recyclable but can also be biological decomposed in composting plants. Due to a low shrinkage factor PLA will not deform after cooling, this makes the material ideal for 3D printing on FFF / FDM machines. Polylactic acid is a polyester that is built from several lactic acid units. It is colourless and transparent. PLA has a density of about 1.24 g/cc. The glass temperature is typically around 50 °C and it as a melting temperature between 80 and 150 °C. The decomposing temperature is roughly 250 °C. Polymers made of lactic acid are flammable.

- Great printability

- Biodegradable

- Food contact approved

Printer settings

| Description | Value |

|---|---|

| Printer nozzle temperature | 180 - 220°C |

| Heated bed temperature | 20 - 60°C |

| Bed Adhesion | Magigoo Original on glass or a PEI Sheet |

Physical properties

| Description | Value | Test method |

|---|---|---|

| Density | 1,24 g/cc | ISO 1183 |

| Tensile strength at yield | 66 MPa | ISO 527 |

| Tensile (E) modulus | 3027 MPa | ISO 527 |

| Impact strength - Charpy method 23˚C | 3,4 kJ/m² | ISO 179 |

| Moisture absorption | 1968 ppm | ISO 62 |

| Glass transition temp | 57°C | ISO 11357 |

Measurements & Tolerance

| Size | Diameter tolerance | Roundness |

|---|---|---|

| 1,75 mm Filament | +/- 0,05mm | 95% |

| 2,85 mm Filament | +/- 0,10mm | 95% |

Additional info

To get the best results while printing we advise you to keep the 3D printer in a room where there is hardly any draft and/or temperature fluctuations. Keep the 3D printer out of the sun.

Keep the 3D printer out of the sun.

When the 3D printer is not being used it is important to keep the 3D4MAKERS PLA Filament in a bag and stored in a cool (15-25˚C) and dry room away from UV light until it is used again.

AmazonAmerican ExpressApple PayDiners ClubGiropayGoogle PayiDEALJCBMaestroMastercardPayPalPaySafeCardShop PaySOFORTVisaYour payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Country

NetherlandsUnited StatesItalyGermany---AfghanistanÅland IslandsAlbaniaAlgeriaAndorraAngolaAnguillaAntigua & BarbudaArgentinaArmeniaArubaAscension IslandAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia & HerzegovinaBotswanaBrazilBritish Indian Ocean TerritoryBritish Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCaribbean NetherlandsCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongo - BrazzavilleCongo - KinshasaCook IslandsCosta RicaCroatiaCuraçaoCyprusCzechiaCôte d’IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHondurasHong Kong SARHungaryIcelandIndiaIndonesiaIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKosovoKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacao SARMadagascarMalawiMalaysiaMaldivesMaliMaltaMartiniqueMauritaniaMauritiusMayotteMexicoMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmar (Burma)NamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorwayOmanPakistanPalestinian TerritoriesPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandsPolandPortugalQatarRéunionRomaniaRussiaRwandaSamoaSan MarinoSão Tomé & PríncipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia & South Sandwich IslandsSouth KoreaSouth SudanSpainSri LankaSt. BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSudanSurinameSvalbard & Jan MayenSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabwe

BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSudanSurinameSvalbard & Jan MayenSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabwe

Zip code

Returns

Our policy lasts 30 days. If 30 days have gone by since your purchase, unfortunately we can’t offer you a refund or exchange.

To be eligible for a return, your item must be unused and in the same condition that you received it. It must also be in the original packaging.

To complete your return, we require a receipt or proof of purchase.

Any item not in it's original condition, is damaged or missing parts for reasons not due to our error.

Any item that is returned more than 30 days after delivery

Refunds

Once your return is received and inspected, we will send you an email to notify you that we have received your returned item. We will also notify you of the approval or rejection of your refund.

If you are approved, then your refund will be processed, and a credit will automatically be applied to your credit card or original method of payment, within 14 days.

Late or missing refunds

If you haven’t received a refund yet, first check your bank account again.

Then contact your credit card company, it may take some time before your refund is officially posted.

Next contact your bank. There is often some processing time before a refund is posted.

If you’ve done all of this and you still have not received your refund yet, please contact us at [email protected].

Sale items

Only regular priced items may be refunded, unfortunately sale items cannot be refunded.

Exchanges

We only replace items if they are defective or damaged. If you need to exchange it for the same item, send us an email at [email protected] and send your item to: Oudeweg 91-95 Haarlem NL 2031CC.

If you need to exchange it for the same item, send us an email at [email protected] and send your item to: Oudeweg 91-95 Haarlem NL 2031CC.

Gifts

If the item was marked as a gift when purchased and shipped directly to you, you’ll receive a gift credit for the value of your return. Once the returned item is received, a gift certificate will be mailed to you.

If the item wasn’t marked as a gift when purchased, or the gift giver had the order shipped to themselves to give to you later, we will send a refund to the gift giver and he will find out about your return.

Shipping

To return your product, you should mail your product to: Waarderweg 56 Haarlem NL 2031BP

You will be responsible for paying for your own shipping costs for returning your item. Shipping costs are non-refundable. If you receive a refund, the cost of return shipping will be deducted from your refund.

Depending on where you live, the time it may take for your exchanged product to reach you, may vary.

If you are shipping an item over €75, you should consider using a trackable shipping service or purchasing shipping insurance. We don’t guarantee that we will receive your returned item.

PLA plastic for 3D printing

- 1 Plastic composition

- 2 PLA safety

- 3 PLA Specifications

- 4 Advantages of PLA in 3D printing

- 5 Navigation

PLA-plastic (polylactide, PLA) - is a biodegradable, biocompatible, thermoplastic aliphatic polyester, the structural unit of which is lactic acid.

PLA is made from corn or sugar cane.

Potato and corn starch, soy protein, cassava tubers, cellulose are also used as raw materials.

Today, polylactide is actively used as a consumable for printing on 3D printers.

Natural raw materials in the composition of PLA-plastic allows using it for various purposes without a threat to human health.

The production of PLA plastic significantly reduces carbon dioxide emissions into the atmosphere compared to the production of "petroleum" polymers. The use of fossil resources is reduced by a third, the use of solvents is not required at all.

PLA is usually supplied as a thin filament that is wound on a spool.

| Melting point | 173-178°C |

| Softening point | 50°C |

| Hardness (Rockwell) | R70-R90 |

| Elongation at break | 3.8% |

| Flexural strength | 55.3 MPa |

| Tensile strength | 57.8 MPa |

| Tensile modulus | 3.3 GPa |

| Flexural modulus | 2. 3 GPa 3 GPa |

| Glass transition temperature | 60-65°C |

| Density | 1.23-1.25 g/cm³ |

| Minimum wall thickness | 1 mm |

| Print Precision | ± 0.1% |

| Micron size | 0.3 mm |

| Manufacturing shrinkage | no |

| Moisture absorption | 0.5-50% |

- non-toxic;

- wide color palette;

- when printing, no need for a heated platform;

- dimensions are stable;

- is ideal for moving parts and mechanical models;

- excellent sliding of details;

- savings in energy costs due to the low softening temperature of the yarn;

- no need to use Kapton to lubricate the surface for building up the prototype;

- smoothness of the surface of the printed product;

- obtaining more detailed and completely ready-to-use objects.

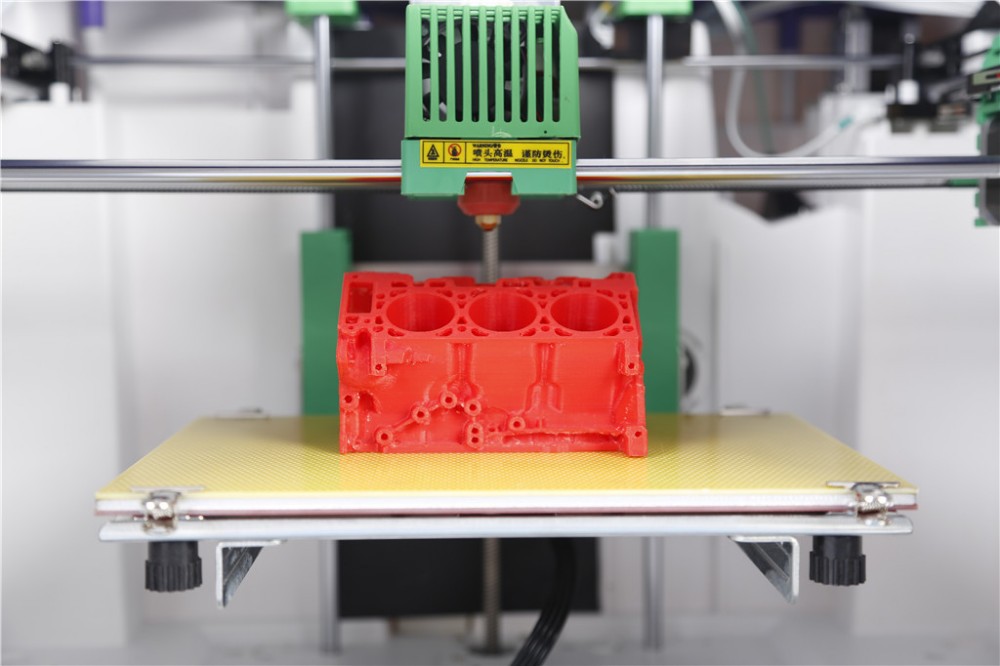

PLA plastic is ideal for 3D printing objects with great detail

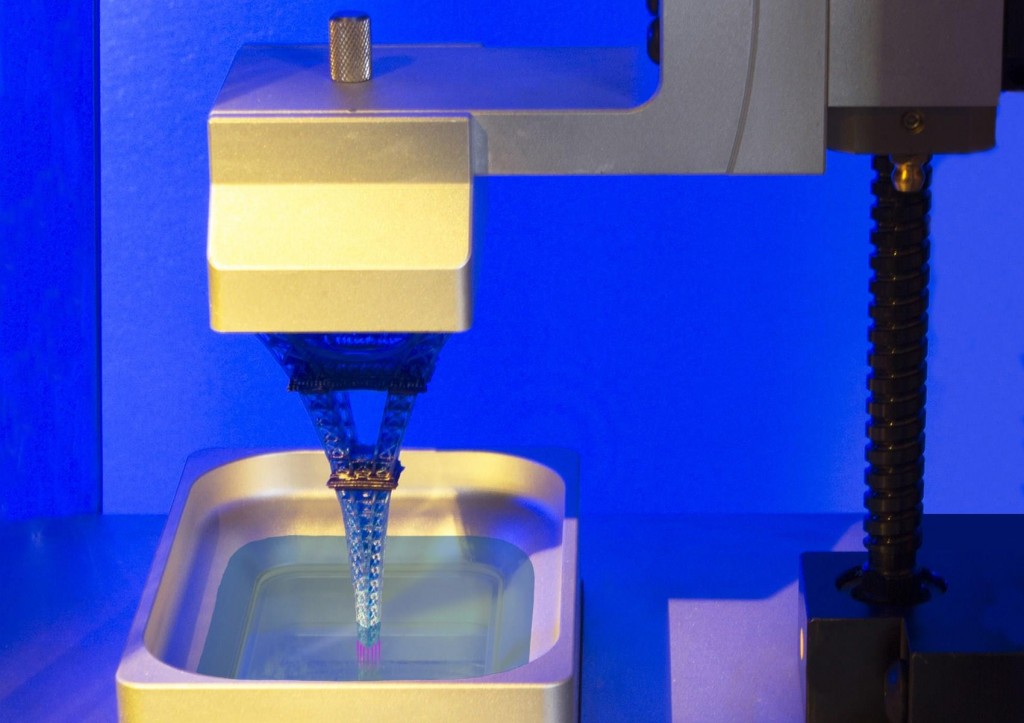

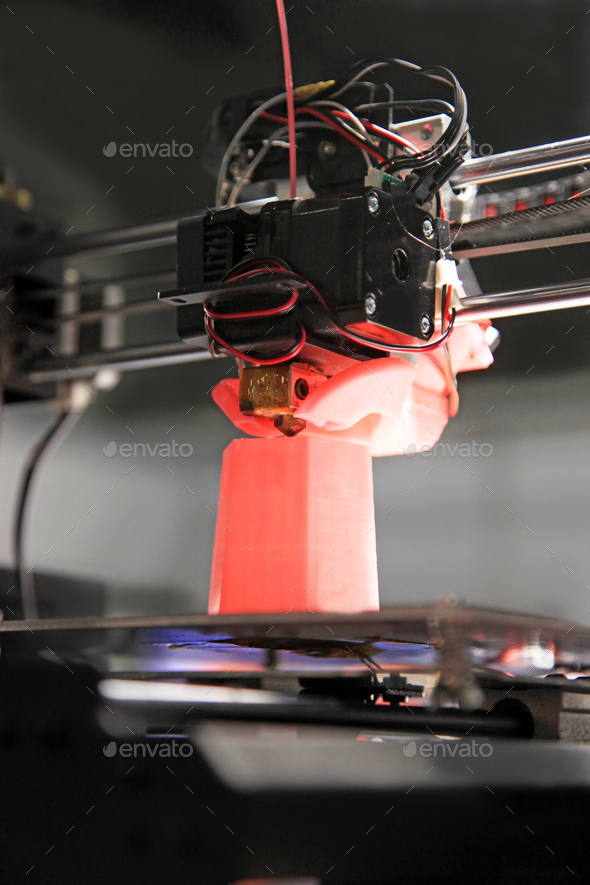

Work with PLA plastic on a 3D printer is carried out using FDM-Fused Deposition Modeling technology. The thread is melted, after which it is delivered through a special nozzle to the surface for work and is deposited. As a result of building a model with molten plastic, an object completely ready for use is created. Products made of PLA plastic are subjected to grinding and drilling, painted with acrylic. However, it is worth remembering that the item made of PLA must be handled with care due to its fragility. Another disadvantage of PLA plastic is its fragility: the material lasts from several months to several years.

PLA is an ideal material for 3D printing prototypes and products that are not expected to be used for a long time. These can be decorative objects, presentation items, and items that require meticulous detailing.

Go to the main page of Encyclopedia of 3D printing

Plastics for 3D printer

Contents

-

- PLA

- ABS

- HIPS

- PVA

- PETG

- SBS

- Nylon

- Soft plastics

- Decorative plastics

- Engineering plastics

- Totals

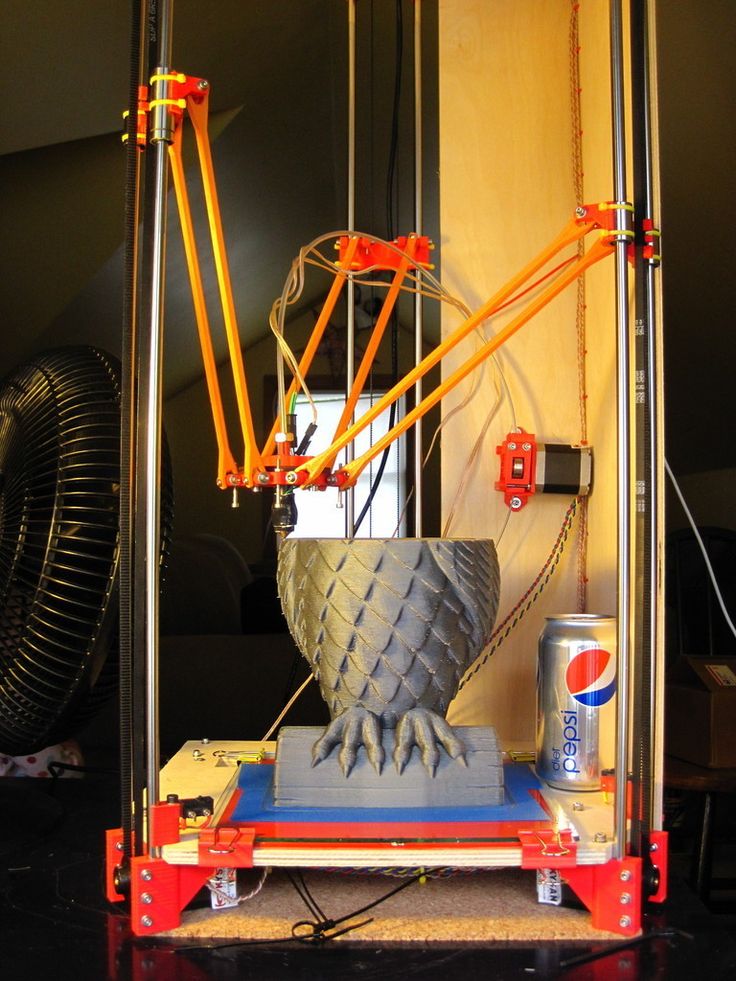

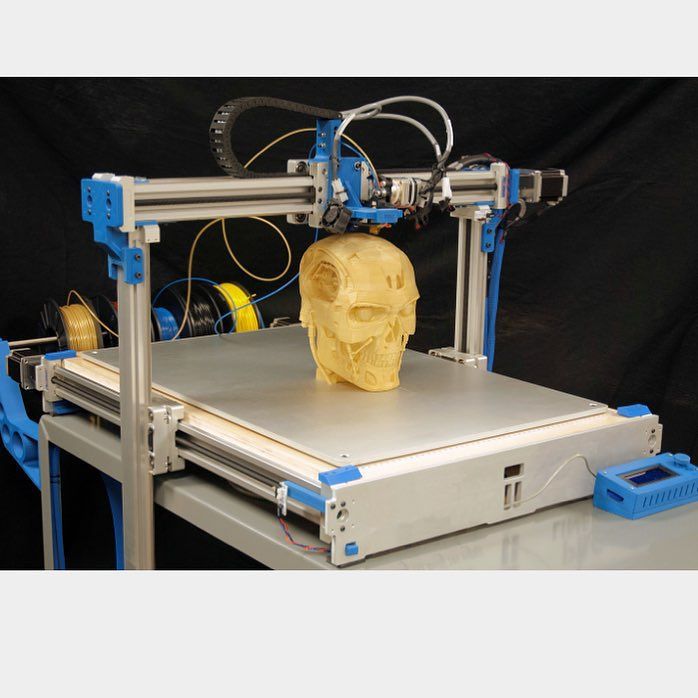

Previously, a 3D printer was more like a complex CNC machine, but now manufacturers are meeting users. Simplified and automated settings that many beginners drove into a stupor. Despite this, it can be difficult for a novice user to understand the variety of constantly appearing plastics for a 3D printer.

Previously, a 3D printer was more like a complex CNC machine, but now manufacturers are meeting users. Simplified and automated settings that many beginners drove into a stupor. Despite this, it can be difficult for a novice user to understand the variety of constantly appearing plastics for a 3D printer. The choice of plastic for a 3D printer is very important, especially when the goal is to print a functional model with certain properties. It will be a shame if the printed gear breaks almost immediately, or the decorative model quickly loses its beauty.

It is important to understand whether the printer will be able to work with the selected plastic. Some materials (most often engineering) require certain conditions for successful printing.

First, decide which model you want to print. What properties should it have? Does the model need to be durable? Or is it a master model for further replication, in which the quality of the surface is important?

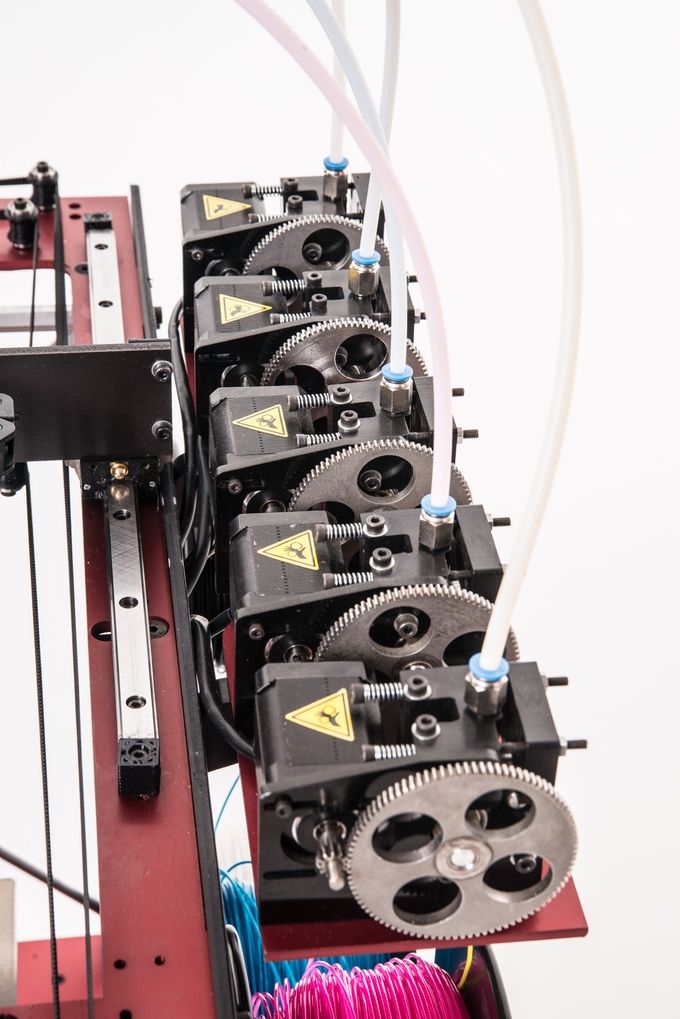

90% of 3D printers use 1.

75 diameter filament. 3mm diameter is rare, but it is better to check in advance which size is used in your printer.

PLA

PLA (Polylactide) is the most popular and affordable 3D printer plastic. PLA is made from sugar cane, corn, or other natural raw materials. Therefore, it is considered a non-toxic, biodegradable material.

Extruder temperature - 190-220 degrees. Table heating is not needed, but if the printer's table has a "heater" for better adhesion, you can heat it up to 50-60 degrees. PLA is very easy to work with. The only requirement is to blow the model. There is practically no shrinkage in this material. When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

Pros:

-

Does not shrink. This makes it easy to build prefabricated or huge models without changing dimensions.

-

There are no specific requirements for a 3D printer. Any working 3D printer will do.

PLA doesn't need a heated table or a closed case.

PLA doesn't need a heated table or a closed case. -

Non-toxic. Due to this, during printing it does not smell or has a barely perceptible aroma of burnt caramel.

-

Diverse color palette.

Cons:

-

PLA is poorly sanded and machined.

-

It begins to deform already with a slight heating (about 50 degrees).

-

Fragility. Compared to other materials, PLA is very brittle and breaks easily.

-

Decomposes under the influence of ultraviolet radiation. Of course, it will not fall apart into dust, but it can become more brittle and fade.

PLA is perfect for making dimensional or composite models. For example, decorative interior items, prototyping, electronics cases, etc.

Recently, PLA+ has appeared on the market. It may differ from conventional PLA in improved performance.For example, more durable, with improved layer adhesion.

Dummy turbine

Decorative coasters

ABS

ABS (acrylonitrile butadiene styrene) is the second most popular plastic for 3D printing due to its properties, availability and low price.

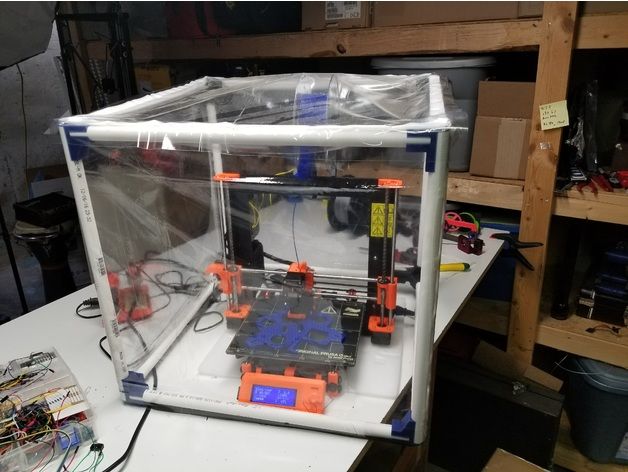

Extruder temperature - 220-240 degrees. The temperature of the table is 80-100 degrees. For printing, a heated table is required at the printer. It is desirable to have a closed chamber, because ABS "does not like" drafts. Due to a sharp temperature drop, it can “unstick” from the table or crack in layers. ABS can smell bad when printing, so it is recommended to use the printer with a closed chamber and filters, or print in a well-ventilated area.

Pros:

-

Good strength characteristics allow the production of functional prototypes from ABS.

-

Simple mechanical and chemical processing.

ABS is easy to sand and drill, and with an acetone bath you can achieve a perfectly smooth surface.

ABS is easy to sand and drill, and with an acetone bath you can achieve a perfectly smooth surface. -

It is currently the most inexpensive type of plastic for 3D printing.

-

Large selection of colors and shades.

Cons:

-

High shrinkage. Because of this, it can be problematic to manufacture overall products.

-

Printing requires a heated bed and a closed chamber. Without this, the ABS may peel off the table or crack in layers.

-

During the printing process, ABS can smell bad. Therefore, it is recommended that you print in a ventilated area or use the printer with a sealed chamber and filter.

ABS is an engineering plastic. It is suitable for the manufacture of simple functional products.

ABS after chemical treatment in an acetone bath

RU model made of ABS

ABS+ differs from conventional ABS in improved strength characteristics (elasticity, rigidity, hardness), less shrinkage and sometimes resistance to certain oils and solvents (eg gasoline).

HIPS

HIPS (high impact polystyrene) - originally conceived as a soluble support plastic for materials with high printing temperatures. For example for ABS or Nylon.

The extruder temperature is 230-260 degrees. The temperature of the table is 80-100 degrees. It is desirable to have a closed camera for a 3D printer.

Pros:

-

Less shrinkage than ABS.

-

Ease of machining.

-

The matte surface looks very advantageous on decorative products.

-

Food contact allowed (but be sure to check with a specific manufacturer for certificates)

Cons:

-

For printing, you need a printer with a heated table and a closed chamber.

-

More flexible and less durable than ABS. Because of this, it will not be possible to produce functional products.

-

Small palette of colors.

Most often, HIPS is used for its intended purpose for printing on 2x extruder printers as a support for ABS. It dissolves perfectly (though not very quickly) in limonel.

Sometimes HIPS is used as an independent material. Products from it are not very durable, but this plastic is loved for easy post-processing. HIPS can be used for models that will subsequently come into contact with food (not hot).

Using HIPS as a Soluble Support

Decorative vase made of HIPS

PVA

PVA (polyvinyl alcohol) is a material that was developed as a water-soluble support for PLA.

Extruder temperature - 190-210. Table heating is not required. PVA is a slightly "capricious" material, it is not recommended to overheat it and print at high speeds.

PVA is very hygroscopic and dissolves in normal water. Therefore, it is only used as a support for PLA or other plastics with print temperatures close to PVA.

Soluble PVA Support

Add to compare

Item added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun

Add to Compare

Product added to comparison Go

| Manufacturer | Esun

PETG

PETG (polyethylene terephthalate) combines the best properties of PLA and ABS. It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

Extruder temperature - 220-240 degrees. Table temperature - 80-100 degrees. During the printing process, the model must be well blown.

Pros:

-

Excellent sinterability of layers.

-

PETG is very strong and wear resistant. Good impact resistance.

-

Virtually no smell when printing.

-

Non-toxic.

-

Little shrinkage.

Cons:

PETG is perfect for printing functional models. Due to its low shrinkage, it is often used to make large or composite models. Due to its low toxicity, PETG is often used for products that will come into contact with food.

Cookie cutters and patterned rolling pin

SBS

It is a highly transparent material. At the same time, it is durable and resilient. SBS is a low toxicity plastic. It can be used to print food contact models.

Extruder temperature - 230 -260 degrees. Table temperature - 60-100 degrees. You can print without the closed case on the printer.

Pros:

-

slight shrinkage

-

Transparency.

After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained.

After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained. -

Easily processed mechanically or chemically.

-

Allowed contact with food.

Cons:

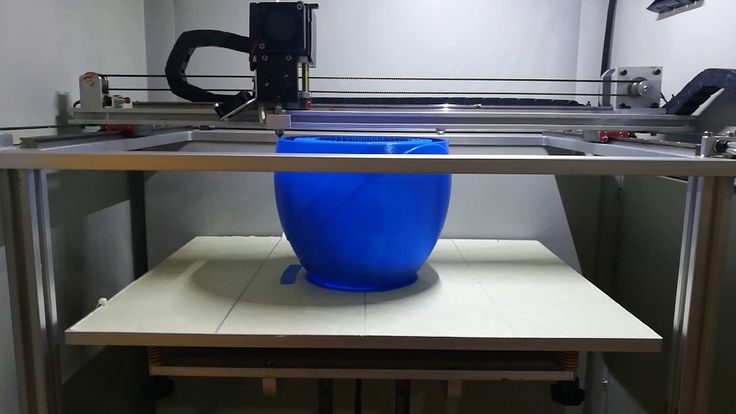

SBS is excellent for translucent vases, children's toys and food containers. Or functional things that require transparency, such as custom turn signals for a motorcycle or car, lamps or bottle prototypes.

Vases are perfectly printed with a thick nozzle (0.7-0.8) in one pass (printing in 1 wall or spiral printing in a slicer).

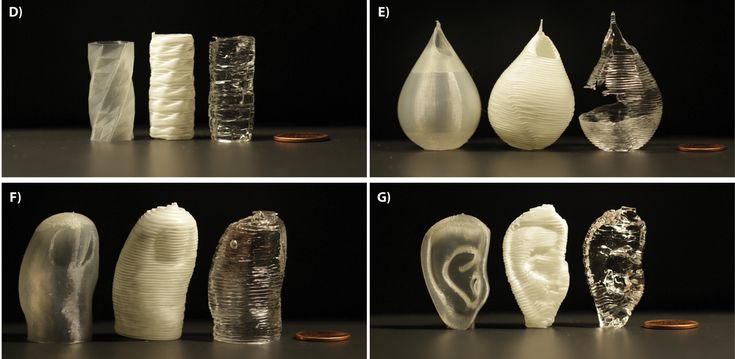

Models of bottles after chemical treatment

Nylon

Nylon (polyamide) is considered the most durable material available for home 3D printing. In addition to good abrasion resistance and strength, it has a high slip coefficient.

Extruder temperature - 240-260 degrees. The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

Pros:

-

High strength and wear resistance.

-

High slip factor.

-

Heat resistance compared to other 3D printing plastics.

-

High resistance to many solvents.

-

Good for mechanical processing. Perfectly polished and drilled.

Cons:

Nylon is perfect for making wear-resistant parts - gears, functional models, etc. Sometimes nylon is used to print bushings.

Nylon gear

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun

Add to compare

Product added to compare Go

| Manufacturer | Bestfilament |

Soft plastics

FLEX (TPU, TPE, TPC) is a material similar to silicone or rubber. It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

FLEX are printed at a temperature of 200-240 (depending on the material). A heated table is not required. On printers with direct material feed (feed mechanism on the print head), there are usually no problems with printing. On a bowden feeder (the feed mechanism is located on the body), printing with very soft plastics can be difficult. Usually it is necessary to additionally adjust the clamping of the bar. The main nuance is the very low print speeds - 20-40mm.

Pros:

Cons:

Depending on the type of FLEXa, the models can be flexible or rubber-like. This material, depending on its softness, can be used to print gaskets, insoles, belts, tracks or other models that require flexibility or softness.

FLEX belt

Trainers with flexible soles

Wheel for RC model

Decorative plastics

Decorative plastics are PLA plastics with various fillers (wood or metal shavings). Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Extruder temperature - 200-220 degrees (depending on the manufacturer). A heated table is not required.

Pros:

Cons:

-

Some fillers (eg clay) are abrasive. For such plastics, the standard brass nozzle cannot be used. Will have to buy a harder steel nozzle.

-

Some decorative plastics can clog the small nozzle (0.4 or less). For them, you need to use a “thicker” nozzle.

Depending on the filler, different material properties are obtained. Plastics that use only dye do not require additional processing. Materials with "fillers" may sometimes require additional post-processing.

Plastics with metal fillers after printing must be processed with a metal brush. Then the Metal content will show through and the model will resemble a metal casting.

Plastics with metallic powder

These plastics are often used for printing key chains, decorative models and interior details.

If the plastic has a high content of wood dust, then it is recommended to use a larger nozzle diameter (0.5 or more), a smaller nozzle can quickly become clogged during printing.

Wood-filled plastic ground

Plastic key rings with copper dust

Engineering plastics

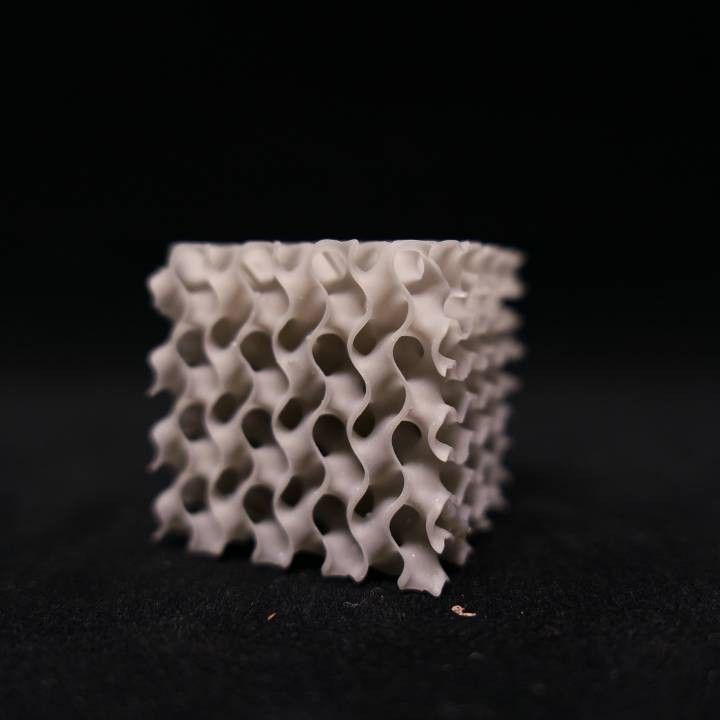

These are nylon-based plastics with fillers that improve strength, heat-resistant and other characteristics, help to achieve less shrinkage of the material. For example - carbon fiber, carbon fiber or fiberglass.

Extruder temperature - 240-300 degrees (depending on the manufacturer). Table temperature - 90-110 degrees. Since plastics are based on nylon, the requirements for printing are similar. This is a heated table and a closed printer case.

Pros:

-

Hardness and strength.

-

Low flammability or non-combustibility.

-

High precision due to low shrinkage.

Cons:

3D printers use brass nozzles, some plastics can quickly “waste” it during printing. For such materials it is recommended to use steel nozzles.

These are highly specialized plastics used for a specific task, depending on the filler. For example, functional parts that do not lose their shape when heated, are resistant to many solvents, etc.

Functional Carbon Fiber Composite Prototype

Composite frame

Polycarbonate ashtray

Totals

This is of course not the whole list of materials for 3D printing. There are many highly specialized engineering and decorative plastics for specific tasks.

Manufacturers are constantly trying to replenish the range of materials for 3D printing. Already familiar materials are improved for more comfortable printing. There are many interesting decorative plastics imitating different materials - ceramics, clay, wood, metals.

And of course, the assortment of engineering plastics is constantly updated. Now there are many interesting materials for highly specialized tasks - for example, burnable plastic with a low ash content for subsequent casting in metal.

Burnout plastic

Before buying a coil, read the information on the website of the manufacturer or seller. There you can find some nuances of printing for a particular plastic. The manufacturer indicates the recommended temperature range on the box. Sometimes, for quality printing, it is recommended to print several tests to adjust the temperature settings, retract, etc.

Try to store the started coil in silica gel bags..jpg)