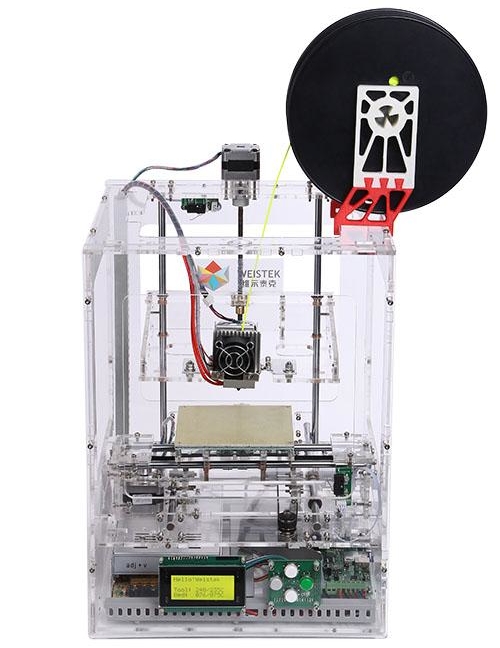

Weistek lcd 3d printer

Weistek Announces Kickstarter Launch of Weistek L6, A

| Source: Weistek Weistek

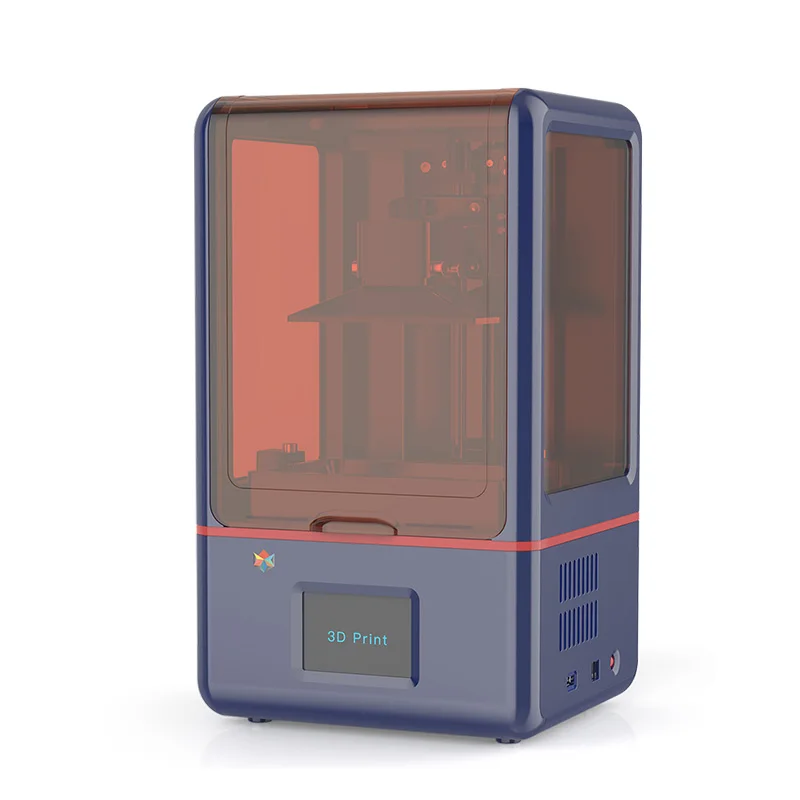

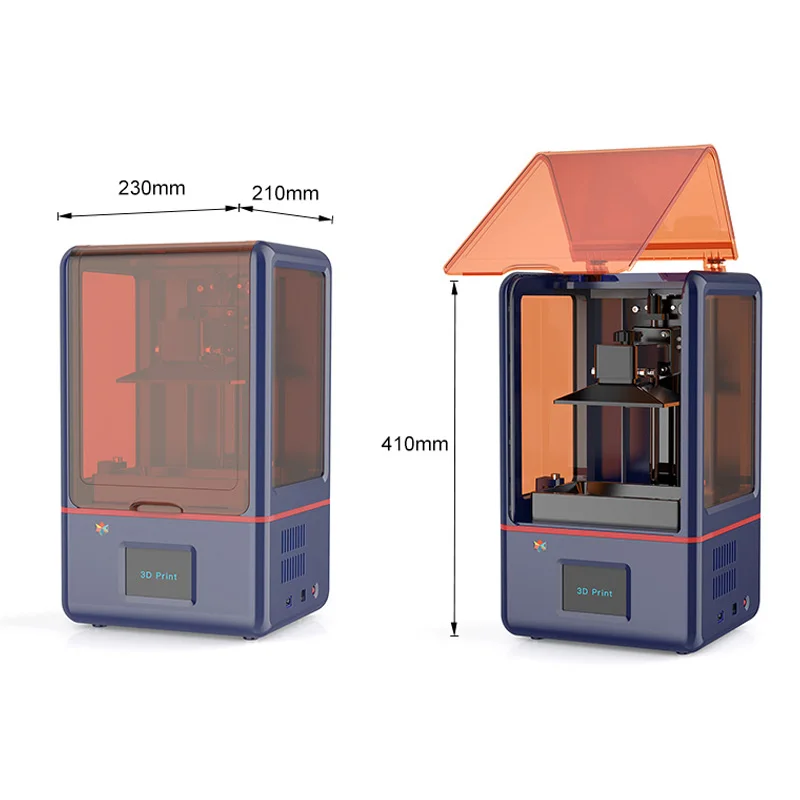

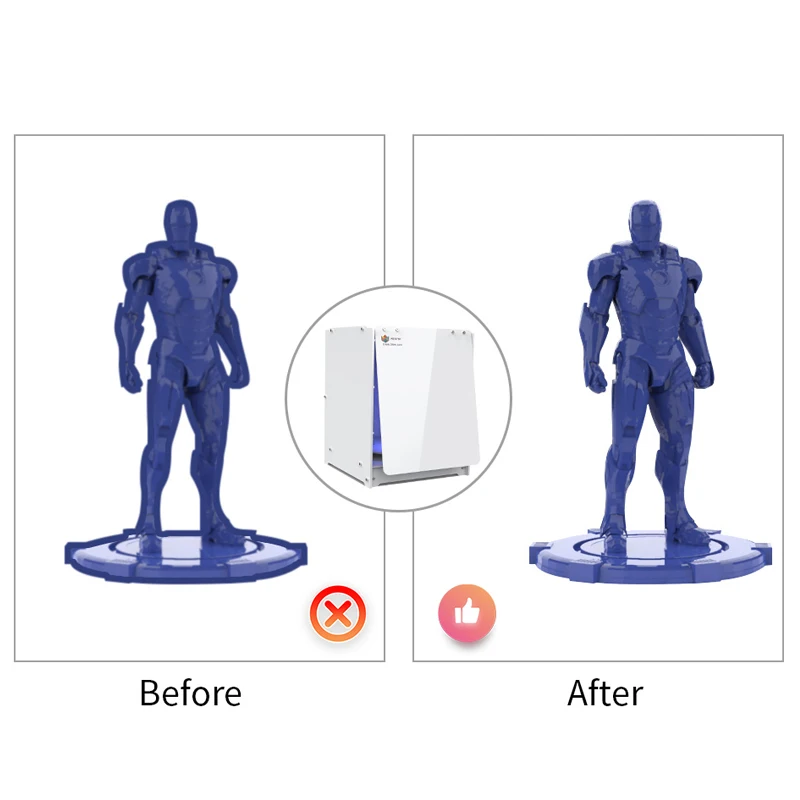

HONG KONG, Sept. 14, 2021 (GLOBE NEWSWIRE) -- Today, 3D printing innovators Weistek announced the launch of a next-generation 3D printing solution specially designed for ease of use, speed and accuracy. With 60mm/h printing speed, 2K LCD screen and unique disposable resin tank, Weistek provides a fast, affordable and eco-friendly 3D printing experience for everyone. Weistek L6 is available now on Kickstarter: https://www.kickstarter.com/projects/192159264/weistek-the-most-affordable-2k-monochrome-sla-3d-printer

3D printing technology has revolutionized art, industry and business, giving hobbyists and professionals alike the ability to quickly create virtually anything. However, until recently, affordable options for premium printing were scarce and the industrial nature of the devices and steep learning curve made many 3D printers impractical for home use. Now, Weistek has responded with an affordable, intuitive printer with special features that make it easier than ever for users to get started printing quickly and safely at home. Unlike other LCD printers Weistek L6 is designed with a unique disposable resin tank and release film that eliminates messy, toxic, and complicated printer setup and use.

"One of the most daunting challenges for those looking to get started with SLA 3D printing is handling the resin. Most SLA 3D printers require manual filling of the resin vat with material that is toxic and irritating to the skin. Not only that, but the completed prints require washing with chemical solvents. Our goal with L6 was to eliminate this old system and create a safer, more user-friendly way to deal with resin. For L6, we begin with safe, eco-friendly plant-based resins that are non-toxic, odorless, and clean up with water. Then we designed a special disposable resin cartridge that is safe, fast, and easy to handle, making the printing process faster and hassle-free for users. This system simplifies the printing process, eliminates the need for solvents, saves time and boosts efficiency." - Weistek CEO Wenjuan Chen

Then we designed a special disposable resin cartridge that is safe, fast, and easy to handle, making the printing process faster and hassle-free for users. This system simplifies the printing process, eliminates the need for solvents, saves time and boosts efficiency." - Weistek CEO Wenjuan Chen

L6 is simple to use yet powerful enough for professional prints. It uses an ultra-accurate Z-axis Dual Linear Guide-way Structure to achieve 1.25μm resolution and 47μm XY resolution. Together with its 2K Mono LCD, the printing details and precision are greatly improved up to a maximum printing size of 131*83*150mm. The printer is Plug & Play, supports Wi-Fi, TF card and USB connection, and has a 3.5 Inch HD Color Touch Screen that simplifies the printing workflow. Weistek employs an advanced self-developed slicer software: D-Master, which offers intuitive control over intelligent printing settings with less tedious operations. It's easy to use, open source & has greater options for expandability.

Weistek L6, 2K SLA 3D Printer makes 3D printing affordable and more user-friendly than ever before and lets anyone realize their creativity. L6 is available now on Kickstarter with special deals and discounts for early adopters. Learn more: https://www.kickstarter.com/projects/192159264/weistek-the-most-affordable-2k-monochrome-sla-3d-printer

Media Contact: [email protected]

Related Images

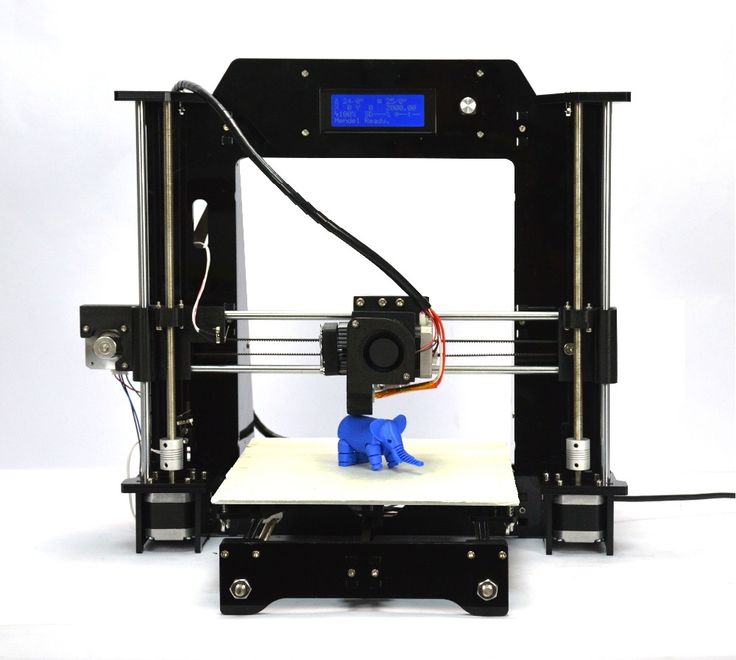

Image 1

This content was issued through the press release distribution service at Newswire.com.

- Featured Image for Weistek

Featured Image for WeistekFeatured Image for Weistek

Tags

3D Printer Kickstarter SLA5 of the Strongest 3D Printer Resins? Some Great Options to Use – 3D Printerly

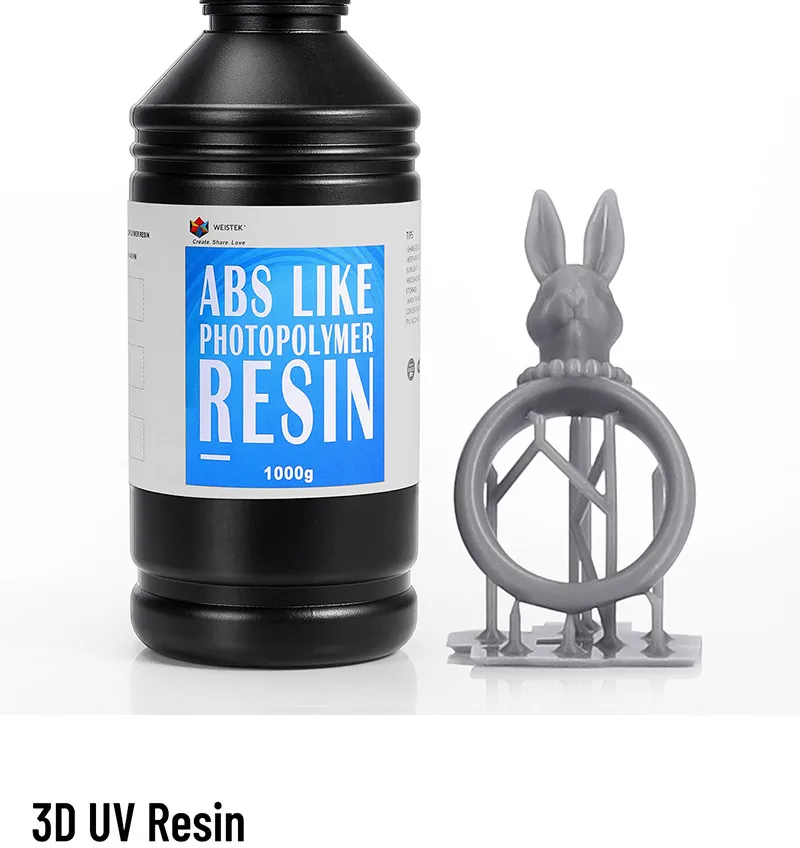

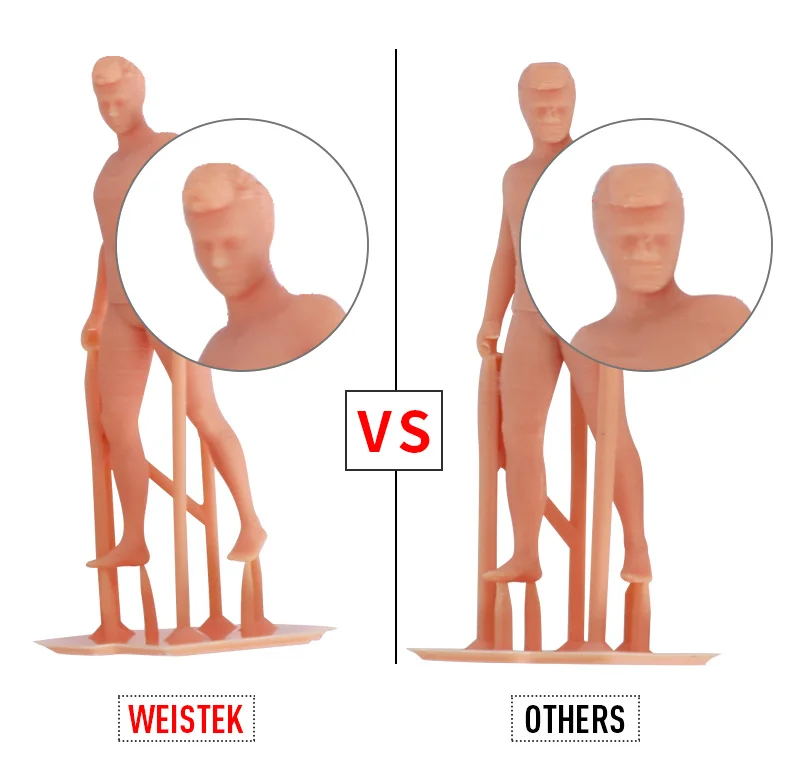

The days of weak 3D printer resin are over, especially as more people flock towards SLA 3D printing as their primary technology. It’s very possible to get strong 3D printer resins now, so I decided to write an article that can guide you on choosing some good options.

It’s very possible to get strong 3D printer resins now, so I decided to write an article that can guide you on choosing some good options.

This article is going to have options which 3D printer users go to when they need strong, functional resin 3D prints. Let’s get straight into it..

1. Siraya Tech Tenacious Flexible Resin

If you want resin that has flexibility, strength, and impact resistance, Siraya Tech Tenacious Flexible Resin is very suitable for you.

The reason why this one makes the list of one of the stronger resins is because of its mechanical properties which assist in the strength category and not breaking so easily.

Its manufacturers and users claim that a thin object printed with this resin can bend up to 180 degrees without showing any signs of breakage while the large and thick 3D prints have great strength, durability, and resilience.

It comes in a transparent yellow light color, this combination of transparency and color makes it easy for the user to check the internal structure of the 3D model and dye the print.

One of the best things about this resin is how it mixes so well with other resins to give it flexible properties, rather than solely using the flexible resin. A 50/50 mix of this resin with another is a great combination for increasing part durability.

A user even went the extra mile and rode over a 3D printed resin piece with their car, just to show how impact-resistant it is, and it actually came out in one piece.

This resin can bring amazing results if used to print 3D models in your chosen SLA 3D printer. Since this resin contains a high amount of polymers in it, it is recommended by the manufacturers to print at a high temperature, above 25°C.

Although the resin is flexible, it doesn’t actually come out as rubbery, and more like a soft plastic.

If you are tired of printing those brittle resin 3D prints, jump onboard with this high quality resin.

Check out the Siraya Tech Tenacious Flexible Resin on Amazon today for a new level of flexibility and strength.

2. Siraya Tech Blu Strong Resin

Another really strong resin, also from Siraya Tech is the Blu Strong & Precise High Resolution Resin which you can easily find on Amazon.

When we talk about performing under harsh conditions and extreme stress, this resin should do really well due to its unique tough and strong mechanical properties.

It is considered the most suitable option to print functional 3D models that require strength yet some flexibility to perform their functions. Blu resin ensures that all different factors are balanced including strength and hardness to get better results.

Users love just how smooth the surfaces are, as well as the high resolution of the resin prints.

The resin was initially formulated for the LCD 3D printers but can work for DLP 3D printers as well.

The video below showcases just how functional this resin is.

Finding resins that can actually withstand impacts and force is pretty difficult, with resin being known to be pretty brittle, where even a little drop can break a model.

With this resin on the market, you can rest assured that your 3D printed objects are durable and won’t break easily from normal use. You can even opt-in to use this resin for functional objects that require load-bearing strength.

Its strength can be estimated with the results of this test that a hook printed with Siraya Tech Blu Strong Resin was able to lift 20KG of weight without any issues.

The resin is ideally used at a temperature of 25°C or above to get a smooth finish and high-resolution prints.

Similar to the flexible resin above, this works really well when you mix it with other resins out there, a great combination being a 50/50 mix with this and Anycubic Low-Odor Eco UV Resin.

Check out the Siraya Tech Blu Strong Resin on Amazon today to get the strong and flexible resin 3D prints.

3. eSUN ABS-Like Hard Tough Resin

The eSUN ABS-Like Hard-Tough Resin is another great candidate for a very strong material for your SLA 3D printers.

- Has a hardness rating of 75-81D

- High impact resistance

- Great wear resistance

- Amazing for mechanical and functional parts

- Contains polyurethane acrylate monomers to help reduce shrinkage and improve dimensional accuracy

- Comes very safely packaged.

Parts aren’t brittle like your usual resins out there, and come with a little flex, but still being stiff overall.

Customers love just how tough and accurate the prints come out, while not shrinking or curling off the build plate.

In a nutshell, it is one of the strongest resins out there and considered a favorable option when it comes to printing 3D models that require hardness, durability, toughness, and perfection, all in a single model.

This resin is compatible and works flawlessly with most LCD 3D printers.

The volume of shrinkage during the curing process is reduced because the resin contains polyurethane acrylate monomers, this factor results in 3D printed models with high precision and perfect smooth finish.

With its rapid properties, it allows the 3D printer to print models quickly, improving the print speed, and eventually reducing the curing time.

Its hard and tough properties provide good adhesion of the print to the build plate and allow you to detach the model easily after completion.

This resin has been specially created and designed for LED light source 3D printers to provide the best quality results, so you can rapidly cure prints with ease.

The models printed with this resin will have a very clear and brilliant color effect because of its high-quality pigments.

Check out the eSUN ABS-Like Hard Tough Resin on Amazon today to get the resin 3D prints of high toughness and strength.

4. Peopoly Moai Tough Resin

Peopoly Moai Tough Resin is a great option for people who want to print 3D models that can withstand extra wear and tear.

You can get this resin in a wide range of colors as it can be used in a variety of applications especially in engineering, dental, and jewelry applications

Most of the resins out there that are used for SLA 3D printers can bring the best quality prints with perfect details and finish, but they usually lack high strength and inferiority.

Printing your models with Peopoly Moai Tough Resin should allow you to get the best quality and tensile strength at the same time. It remains a bit soft during the printing process and may need additional supports and high temperature.

While the 3D print is submerged in the water container, this resin usually requires at least 30 minutes of UV light post-curing process. The more you cure the print, the tougher, stronger, and durable it will be.

I wrote an article about How to Cure Resin 3D Prints in Water so definitely check that out to improve the strength and quality of your models.

Check out the Peopoly Moai Tough Resin today to get the resin 3D prints of high toughness and strength.

5. Liqcreate Tough-X Resin

This amazing resin is designed to be compatible with all the UV resin LCD and DLP 3D Printers within wavelengths of 385nm to 405nm range. It is an engineer-grade photopolymer resin that comes in a black opaque color.

You are sure to be satisfied with the unmatched strength, high impact and chemical resistance, as well as its impressive mechanical properties.

It is considered one of the best options when it comes to printing types of strong end-products such as industrial spare parts, functional models, weight lifting hooks, and many other heavy-duty products.

The Liqcreate Tough-X Resin has 150% elongation properties making it worth buying to get robust, persistent, and high-performance 3D prints.

It is recommended that you shake the bottle well before using the resin and letting it rest for up to 10 minutes after shaking it properly, this will allow the air bubbles to escape the bottle.

This resin can also be poured back into the bottle, but you have to make sure that there are no cured resin residues left behind in the resin as they can cause issues with the next prints.

Make sure you wear nitrile gloves and other safety equipment while working with the resin.

Check out the Liqcreate Tough-X Resin today to get the resin 3D prints of high toughness and strength.

Premium Tough Resins

If the resins above don’t satisfy you, though they most likely will, you have even more options out there.

One really great place I found where you can get some serious resins is the iMakr High Strength Resin website.

The cool thing is how you can filter the resins out by “Type”, consisting of:

- High-Strength

- Flexible

- Dental

- Castable

- Biocompatible

- High Resolution

- Ceramic Resin & more

Although they pack some serious strength and quality, you are going to have to foot the premium bill that comes with it.

An example is the EnvisionTEC E-RigidForm Resin for strong, hard and stiff parts, which work great for prototypes and end-use. 1kg of this resin costs over $300 and that is tax excluded!

It does have a Hardness Shore D of 87 and 120-126 MPa flexural strength.

How to Make Resin Prints Stronger

One of the best ways to make resin 3D prints stronger is to increase your exposure times. Resin prints that have more exposure tend to come out stronger. You can also use a lower layer height to increase strength, but you’ll want to use a lower exposure time to account for the lesser amount of resin being cured.

Many people discovered that you can actually add a flexible or tough resin along with your standard resin to increase the strength of your resin 3D prints. You only need to add in around 3 parts of standard resin to 1 part of flexible or tough resin.

This means you’ll have a 75% and 25% split between these two different resins.

Check out the video below by Monocure 3D for a great explanation of some of these tips to make resin prints more durable.

Differences of SLA/DLP/LCD printers, printing examples, application

- Principle of operation

- PLASS

- BESSISE

- 0014

- Best DLP Printers

- Principle of operation

- Plus

- Bessions

- Printing

- Best LCD Printers

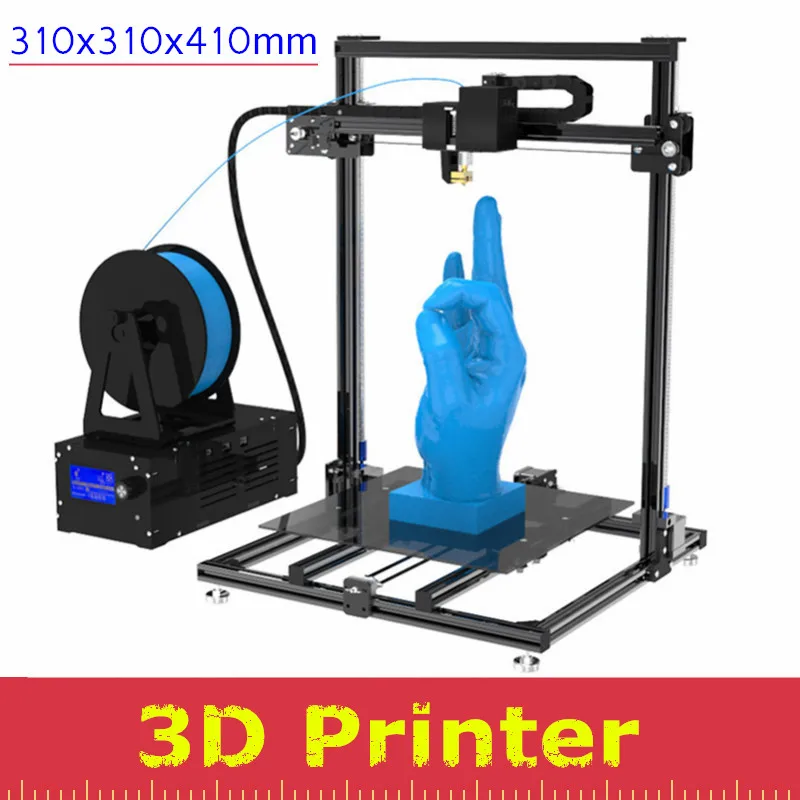

Currently, photopolymer printers can work on one of three technologies - SLA, DLP or LCD. Each of the technologies has its own advantages and disadvantages.

Each of the technologies has its own advantages and disadvantages.

In order not to make a mistake with the choice of model, you need to understand which technology is suitable for printing specific products. For example, for a jeweler and a dentist, the main criterion will be accuracy, and for a person who plans to print figurines for his hobby, the quality of the surface and the not very expensive cost of consumables.

SLA

SLA is one of the first patented 3D printing technologies. It was patented in 1986 by Charles Hull. DLP and LCD are similar in basic principles to SLA, but appeared much later.

How it works

As a material for printing, SLA printers use photopolymer resins - light-sensitive polymers that harden under the influence of a certain spectrum of UV radiation.

A laser beam is used as a “hardener”, which is focused on the desired point with the help of mirrors. The beam sequentially “draws” a slice of the model. So gradually, layer by layer, the model is “grown” on the desktop.

So gradually, layer by layer, the model is “grown” on the desktop.

How SLA technology works

There are two options for the location of the printed table - top and bottom.

Top table

It visually looks like an inverted FDM machine, the model is printed upside down on such a machine. The table moves during printing from the bottom up, the laser module is located at the bottom of the machine, under the polymer bath. The bottom of the bath is usually made of silicone - it transmits UV radiation well and practically nothing sticks to it.

Top position printer model

This is the most popular desktop SLA printer solution.

Table down

The laser module is located at the top of the printer above the resin bath, and the printing table, during printing, gradually lowers down, plunging into the resin.

Industrial SLA with table bottom

This arrangement is traditionally used in industrial machines with a large print area. The only inconvenience is that the bath must always be filled with a photopolymer. And when changing the type of resin, you will have to completely drain the entire photopolymer and thoroughly wash the bath.

The only inconvenience is that the bath must always be filled with a photopolymer. And when changing the type of resin, you will have to completely drain the entire photopolymer and thoroughly wash the bath.

Pros

-

Large selection of consumables. Due to the growing popularity of photopolymer printing, many specific resins have appeared - from soft flexes to photopolymers with increased strength characteristics (for example, there is a very strong, biocompatible photopolymer for making temporary dental crowns).

Cons

-

Expensive consumables.

Print example

Cardiac muscle printed on Formlabs Form 3

SLA printed rings

Prototype Spoon

Butterfly figurine printed on Formlabs Form 3

Technical model

Snow shovel prototype. Made on Formlabs Form 3L

Made on Formlabs Form 3L

Top SLA printers

The leader in the production of SLA printers is Formlabs. In the Formlabs lineup, you can find both small desktop models and professional machines with a large print area.

Form 3

Formlabs Form 3

Specifications:

-

XY resolution: 25 µm

-

Laser spot size: 85 µm

-

Laser power: One 250mW laser

-

Working area size: 14.5×14.5×18.5cm

-

Layer thickness: 25 – 300 µm

This printer can be compared to a small professional machine. Despite its small dimensions, it can easily cope with the most complex models.

Formlabs Form 3L

Formlabs Form 3L Versus Form 3

-

XY resolution: 25 µm

-

Laser spot size: 85 µm

-

Laser power: One 250mW laser

-

Working area size: 33.

5×20×30cm

5×20×30cm -

Layer thickness: 25 – 300 µm

This printer allows you to print large format models or quickly produce small batches of products.

With the advent of faster and cheaper technologies, SLA printers have become less popular. They are mainly used in industries with high requirements for quality and print stability.

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Formlabs |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Formlabs |

DLP

DLP technology is based on the principles of SLA, but instead of a laser, a projector is used as a source of UV radiation.

How it works

The material used is photopolymer resin, but unlike SLA, the light source is not a beam, but a DLP projector. This significantly speeded up printing, because the projector, unlike the beam, illuminates the entire layer at once.

How DLP technology works

The projector is located at the bottom of the printer, under the resin tank. The bottom of the container is usually made of a transparent, wear-resistant film. Such a film transmits UV radiation well, practically nothing sticks to it, and if it breaks, it can be easily replaced.

Pros

Cons

-

Parasitic light is possible. Exposure of the entire layer at a time can cause parasitic illumination of the resin.

-

projector resource. The projector is the heart of a DLP printer. Be sure to pay attention to the resource of the projector. For example, FlashForge Hunter claims a minimum projector life of 50,000 hours. This is a lot.

Printing example

A batch of rings printed with DLP technology

Ring patterns printed on FlashForge Hunter

Props for miniatures 28 mm

Jaw model made on FlashForge Hunter

Best DLP Printers

FlashForge Hunter

Specifications:

-

XY Resolution: 0.

0625mm

0625mm -

Print speed: 10mm/h

-

Light source: 405nm LED

-

Working area size: 120x67.5x150 mm

-

Layer thickness: 0.025-0.05mm

FlashForge is renowned for the quality of its printers. Hunter is no exception. It turned out to be a good “workhorse” capable of solving a variety of tasks.

DLP technology is used less and less. It is being stubbornly replaced by more affordable 3D printers based on LCD technology.

LCD

LCD technology is the youngest among photopolymer printers. Initially, LCD appeared as a more affordable analogue of DLP technology, suitable for home use.

The first LCD printers had a number of unpleasant children's sores (uneven illumination of the working area, etc.), which over time were resolved or compensated. With the development of technology, in addition to models for home use, devices have appeared that are not inferior in accuracy to DLP and can be used for production tasks.

How it works

The technology almost completely copies DLP, only LEDs are used instead of a projector. Under the bath is an LCD display (similar to the display of a smartphone or tablet), which dims in some places, allowing light to pass through only in the right places.

How LCD technology works

Since the module with the screen and LEDs is located at the bottom of the printer, the bottom of the resin tank is transparent. As with DLP, transparent film is usually used.

Pros

Cons

-

Less accurate. Budget models are good for printing miniatures or figurines, but their accuracy may not be enough for, for example, jewelry.

-

The print quality may not be the same over the entire printable area. Since an array of LEDs is used as the UV source rather than a single light source, the work area may be illuminated unevenly. This problem can be solved programmatically or physically.

Print example

Small miniature made with Anycubic Photon Mono

Troll printed on LCD machine

Model switchgear busbars made of soft polymer

Castle model made on Phrozen Sonic Mini 4K

Figurine made with Anycubic Photon Zero

Troll printed on LCD printer

Best LCD Printers

Anycubic Photon Zero

Anycubic Photon Zero

Specifications:

-

LCD display resolution: 854x480 px

-

XY Positioning Accuracy: 0.1155mm

-

UV wavelength: 405 nm

-

Working area size: 97x54x150 mm

-

Layer thickness: 0.

01-0.2mm

01-0.2mm

Budget model focused on home use. Good for home use.

Anycubic Photon Mono

Specifications:

-

LCD display resolution: 2560x1620 (2K)

-

XY Positioning Accuracy: 0.051mm

-

UV wavelength: 405 nm

-

Working area size: 130x80x165 mm

-

Layer thickness: 0.01-0.15mm

Anycubic Photon Mono is already a more serious device. Thanks to the LCD display of higher resolution, it was possible to increase the accuracy and quality of the finished models.

Phrozen Sonic Mini 4K

Phrozen Sonic Mini 4K

Specifications:

-

LCD resolution: 6.1" 4K Mono LCD

-

XY positioning accuracy: 35 microns

-

UV wavelength: 405 nm

-

Working area size: 134x75x130 mm

-

Layer thickness: 0.

01-0.30mm

01-0.30mm

Mono LCD matrix, with high resolution, allows you to print very quickly and accurately.

Wanhao GR1

Specifications:

-

LCD resolution: 6.3" 2K HD

-

XY Positioning Accuracy: 0.055mm

-

UV wavelength: 405-410nm

-

Working area size: 140x78x200 mm

-

Layer thickness: 35-100 microns

The larger working area allows you to make more models at once, and a special UV-LED matrix ensures uniform illumination.

LCD printers are successfully capturing the market by displacing more expensive DLP and SLA printers. This of course contributes to their availability and a wide variety of models.

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Wanhao |

Application

Dentistry

Precision is very important in dentistry. A slight distortion of even 0.1 mm can make the painstaking work of making a crown or prosthesis useless.

A slight distortion of even 0.1 mm can make the painstaking work of making a crown or prosthesis useless.

Jaw model

3D printed aligner

In addition to the accuracy of the printer, the material chosen also plays an important role. It is necessary to use special resins with a small percentage of shrinkage.

Jewelery

The full potential of photopolymer printers is revealed in the jewelry industry. In addition to precision, detail and perfect surface quality are very important.

Ring made of burn-out photopolymer

From model to finished product

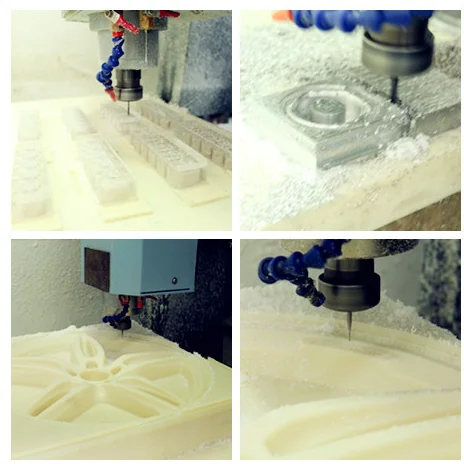

Previously, such products had to be very painstakingly cut by hand or made from wax on high-precision CNC machines. Now it is enough to make a digital model and, with the help of a printer and burnt resin, quickly produce the required number of products ready for casting.

Prototyping

Printing prototypes, making master models, etc.

Helmet and other photopolymer prototypes

Prototype housings

FDM technology is not suitable for everything. Sometimes you need to quickly make a model of a future product with a smooth surface, professional photopolymer printers can easily cope with this task.

Hobby

Affordable photopolymer printers have become a great help for miniature lovers. It is much easier to model and print a 28 mm action figure of your favorite hero than to make it by hand for a long time and painstakingly.

Soviet motorcyclist in 28mm scale

“Spare parts” for miniature 28mm

And large decorative figurines are more accurate compared to FDM printing. After the LCD printer, you do not have to sand the model for a long time to smooth out the layers.

bust of a girl

Modeling

For large and sketchy layouts, FDM printers can be used, but their accuracy is not enough for making small parts. Having a 3D model, you can quickly make a very accurate and detailed layout of a building or an entire block.

Model of the statue of V.I. Lenina

Printed and colored building layout

Summary

Despite all the advantages of photopolymer printers, there are small nuances that are common to all technologies.

Washing the model. After printing, the model must be washed from resin residues. The best way is an ultrasonic bath with alcohol, sometimes you can get by with a glass of isopropyl alcohol and a brush.

“Illumination” in the UV chamber. After rinsing, the model must be “additionally illuminated” in a UV chamber, otherwise the polymer will not gain the strength declared by the manufacturer.

To illuminate the model, you can use a regular UV lamp or a manicure machine. They will cost less than professional dryers, although it may take more time to “light up”. Before buying, make sure that the lamps shine in the desired UV spectrum.

strength of polymers. Despite the huge variety of resins, they are still inferior in strength to the plastic filaments used by FDM printers. The exception is some highly specialized resins.

For some, these nuances can be significant disadvantages, but despite this, photopolymer printers are used both as home printers and as work machines in various fields.

#Useful

Expert in additive technologies and 3D printing with over 5 years of experience.

Share

all materials

Do you have any questions?

Our specialists will help you with the choice of 3D equipment or accessories, consult on any questions.

90,000 PEOPOLY offers LCD-SLA 3D printer PhenomNews

Subscribe to

Subscribe

I do not want

4

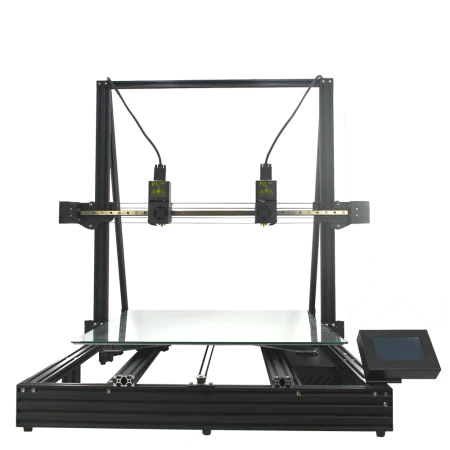

PEOPOLY-PEOPOLIO TOLEMOLIMENT 3D-printer PHENOMS using the PHENOM technology. a large building area and at a fairly affordable price.

a large building area and at a fairly affordable price.

A Hong Kong fledgling company has made headway by offering relatively inexpensive stereolithographic laser 3D printers - first the Moai, a virtual direct counterpart to Formlabs' popular Form and From 2 systems, and then the bigger, but cheaper version of the Moai 200 than US competitors. The new model is called The Phenom has an even larger build area and is cheaper than the previous model. How can this be? It's simple: from laser 3D printing, developers have switched their attention to LCD mask stereolithography with LED backlight.

This is to be expected, as LCD-SLA (or MSLA, as Peopoly calls it) technology, due to its relatively low cost, coupled with high performance and scale flexibility, is developing faster and in higher demand than other options for stereolithography - using lasers or digital projectors. The Phenom 3D Printer delivers all of these benefits, with usable desktop volume reaching an impressive 276x155x400mm, roughly three times the size of Formlabs' latest and more expensive Form 3 laser stereolithographic 3D printer. Layering is done with a 12.5-inch 4K resolution LCD and a 405nm UV LED array.

Layering is done with a 12.5-inch 4K resolution LCD and a 405nm UV LED array.

According to the developers, the resolution in the horizontal plane reaches 72 microns with a minimum layer thickness of 20 microns. Layers are illuminated as a whole, and not point by point, as is the case with laser systems, and this gives an increase in performance, especially noticeable on systems with a large build area. It takes about twenty-four hours to 3D print with full use of the usable volume. The life of the matrix is estimated at 300-500 hours. As long as you don't exceed the recommended 3D printing settings in terms of backlight intensity and layer thickness, the lifespan can exceed a thousand hours, and replacement dies are offered for $100 each.

The bottom of the cuvette is covered with the usual fluorinated ethylene propylene (FEP, FEP) film. When printing large-sized models, the photopolymer will have to be added manually, since an automatic replenishment system is not yet provided, but it is planned to be added. Peopoly Phenom 3D printers are offered at a selling price of $1,799. More information is available on the manufacturer's website at this link.

Peopoly Phenom 3D printers are offered at a selling price of $1,799. More information is available on the manufacturer's website at this link.

Detailed analysis in the Tested program:

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Article comments

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

In July, the international isolation experiment SIRIUS-21 ended in Moscow, which lasted 240 days.