Protesis 3d printer

Top Examples of 3D Printed Prostheses

Published on April 7, 2022 by Niru K.

When it comes to industries adopting 3D printing, one of the earliest and most fervent supporters of the technologies is of course the medical sector. Indeed, AM is becoming a crucial tool in healthcare thanks to a variety of factors. This is especially the case when it comes to prosthetics. With 3D printing, the benefits are two-fold. First, of course, the prostheses can be perfectly fit to the patient thanks to the ability to customize the part. But additionally, 3D printing enables lower-cost, local production of prostheses. As the World Health Organization estimates that 30 million people worldwide are in need of prosthetics, this can help increase availability for many especially in remote regions. We took a look at some of the top examples of 3D printed prosthetics currently available.

The E-nable association

E-nable, also known as Enabling the future , is an association created in the United States by Jen Owen. The idea behind this project is to bring together makers and enthusiasts to create a network of models of prostheses in the world that can obviously be printed in 3D. The main objective is to “give a hand” to the people who need it most, thus avoiding the high cost of a traditional prosthesis. Since its creation in 2013, the association has donated 3D printed prostheses to hundreds of people around the world.

Bionico Hand, an Open-Source 3D Printed Prosthesis

The Bionico Hand project is the brainchild of Frenchman Nicolas Huchet who has used a bionic hand since he was 18 years old. After making his own, he launched Bionicohand as a way to make more for himself and others. Essentially, what he has conceived is a myoprosthesis, his own term for a myoelectric prosthetic, that can repair itself. He aims to create something designed by and for amputees that will be available open source so anyone can make their own. The project is not yet ready, though it has been in development for a number of years now. However, the proof of concept was produced in October 2021 and the goal is to transform it into a functional prototype by the end of 2022.

However, the proof of concept was produced in October 2021 and the goal is to transform it into a functional prototype by the end of 2022.

Photo Credits: Bionico Hand

Make Your Own 3D Printed Robotic Arm with Youbionic

Created by Federico Ciccarese, Youbionic is a platform that is a little different from many on our list. It is not technically designed to create prosthetics for those in need, but rather a way for young people to enter into the robotics industry. Essentially, buyers will receive a kit with everything they need to create their very own robotic arms, including 3D printing part files. These files have been designed to be easy to print as well as oriented to obtain the best results. And best of all? There are not many parts that make up an Avatar Full Arm (one of the largest available projects), leaving users will less assembly than they might expect. On the company’s website, they have a variety of cool projects that you can buy, including full arms, hands, double hands and more.

Photo Credits: Youbionic

Unlimited Tomorrow – The Name Says it All

Unlimited Tomorrow was founded in Colorado in 2011 by Easton LaChapelle who had been working on robotic limb development for a few years. However, she decided to launch into this project after meeting a little girl who wore a prosthetic limb that had limited capabilities while still being expensive. Thus, the idea of Unlimited Tomorrow and improved prosthetics was born. It aims to support people with upper limb disabilities by using additive manufacturing to produce high quality, high value, low cost bionic prosthetic arms. 3D printing allows for the process to be customizable. This happens as after the user answers a few questions, they are then sent a 3D scanner to scan the residual limb. Based on this, the prosthesis, which can also be personalized, is produced with the 3D printer.

Photo Credits: Unlimited Tomorrow

A Distinct Prosthesis with UNYQ

3D printing is used at UNYQ to use mass production to create innovative, customized prostheses. In addition to being able to develop next-generation products, additive manufacturing is also used for aesthetically pleasing and practical features. Prostheses for above and below the knee amputees offer patients revolutionary personalization in terms of color and design. Currently, they are even working on manufacturing an entire leg. UNYQ provides its patients with an app to create the 3D-printed prostheses: Color, design and surface can be selected, then measurements are taken in a clinic to finally print the prosthesis using additive manufacturing.

In addition to being able to develop next-generation products, additive manufacturing is also used for aesthetically pleasing and practical features. Prostheses for above and below the knee amputees offer patients revolutionary personalization in terms of color and design. Currently, they are even working on manufacturing an entire leg. UNYQ provides its patients with an app to create the 3D-printed prostheses: Color, design and surface can be selected, then measurements are taken in a clinic to finally print the prosthesis using additive manufacturing.

3D Printed Foot Prostheses from Mercuris

Mecuris is a German company dedicated to the development of CAD/CAM software solutions that, together with 3D printing, make it possible to create foot prostheses. Thanks to a digital platform, called Mecuris Solution Platform, users can create and customize their individual models to their liking, saving time and money. In fact, thanks to 3D technology and its flexibility, the company is able to reduce production costs by 75%. With this, Mecuris’ goal is to convert traditional craftsmanship into digital tools and workflows that are easy to use according to the needs of each individual, and accompanying customers in every step of the process.

With this, Mecuris’ goal is to convert traditional craftsmanship into digital tools and workflows that are easy to use according to the needs of each individual, and accompanying customers in every step of the process.

LimbForge Offers Prostheses in Remote Regions

LimbForge, a US-based non-profit organization, works on creating software, design and innovative manufacturing with 3D scanning and 3D printing. With these tools they are able to develop and deliver high quality and affordable custom prosthetics. LimbForge has developed and implemented a platform that allows clinicians to spend less time customizing devices and more time treating a greater number of patients. Its platform provides more realistic designs that help patients integrate and thrive, reduces costs and also offers ultralight prosthetics. The Limbforge platform can be used to size and implement other designs beyond its existing catalog. In fact, once a prosthetic design is in the database, it can be easily configured to fit almost any human anatomy. Notably, the platform is being used to help amputees in developing countries to gain access to high quality prostheses.

Notably, the platform is being used to help amputees in developing countries to gain access to high quality prostheses.

Photo Credits: Limbforge

3D Printing the Prostheses of the Future

Evan Kuester is an engineer, artist and designer currently working as a Senior Advanced Applications Engineer at 3D Systems. In addition to that, Kuester is pursuing a number of interesting projects using additive manufacturing. Among them is the development of prosthetics with extremely modern and futuristic designs. For example, in the photo below we see the JD-2 prosthesis model, created with the intention of further exploring the possibilities available to designers with SLS 3D printing technology. Its inner mesh-like structure is intended to reduce the weight of the prosthesis as well as to achieve a more pleasing aesthetic.

“Hero Arm”, a Hero for Life

Open Bionics was the first company in the world to launch a 3D printed bionic arm that would not only be clinically tested but also medically certified. This 3D printed arm is called “Hero Arm” and combines functionality, comfort and design. It is customizable and includes sensors to detect muscle movements, thus providing more ease to move. It would even be able to lift up to 8 kilos, a rather high weight when we know that the prosthesis is put and removed quickly. Open Bionics offers complete customisation of the prosthesis, a real advantage for the person who wears it, who can then create it in his own image. A particularly attractive point for children who often choose a prosthesis with the image of their hero!

This 3D printed arm is called “Hero Arm” and combines functionality, comfort and design. It is customizable and includes sensors to detect muscle movements, thus providing more ease to move. It would even be able to lift up to 8 kilos, a rather high weight when we know that the prosthesis is put and removed quickly. Open Bionics offers complete customisation of the prosthesis, a real advantage for the person who wears it, who can then create it in his own image. A particularly attractive point for children who often choose a prosthesis with the image of their hero!

3D Prostheses for the Needy

In Africa, many countries have a healthcare system that is unable to treat injuries caused by traffic accidents or infections, so it continues to experience a large number of amputations. That is why there are several non-profit organizations that want to bring printing technologies to anyone in need and anywhere in the world. One example is Ayúdame 3D, a Spanish organization that promotes the social value of technology through technological-social awareness programs in order to help vulnerable groups around the world. Both it and 3D Sierra Leone create 3D printed arms, free of charge, for people with disabilities. Thanks to this, they manage to improve their quality of life and that of their environment, reduce the inequality they face and provide them with greater opportunities for schooling and employability.

Both it and 3D Sierra Leone create 3D printed arms, free of charge, for people with disabilities. Thanks to this, they manage to improve their quality of life and that of their environment, reduce the inequality they face and provide them with greater opportunities for schooling and employability.

Naked Prosthetics and Resin 3D Printing

Based in the United States, Naked Prosthetics (NP) is a company dedicated to the development of functional prosthetic devices for hands and fingers. To do so, they rely on resin 3D printing, specifically stereolithography, with which they create these customized models adapted to the needs of each user. Thanks to 3D printing, Naked Prosthetics is able to deliver the prosthetic devices within a few weeks. As they state on their website, NP’s mission is to help people with partial amputation of fingers and hands, to change their lives positively through functional and high quality prostheses.

Photo Credits: Naked Prosthetics

A Fully 3D Printed Ocular Prosthesis

We recently learned of the UK case of Steve Verze, a Londoner, who became the first person in the world to receive a fully 3D printed ocular prosthesis. The printed prosthesis is part of a collaboration between several players in the UK and Europe, and was led by researchers at UCL and Moorfields Eye Hospital NHS Foundation Trust. The result? A prosthetic eye is impressively realistic thanks to its clearer definition and lifelike depth which was made possible with eye socket scans to ensure a good match.

The printed prosthesis is part of a collaboration between several players in the UK and Europe, and was led by researchers at UCL and Moorfields Eye Hospital NHS Foundation Trust. The result? A prosthetic eye is impressively realistic thanks to its clearer definition and lifelike depth which was made possible with eye socket scans to ensure a good match.

Lattice Medical, Fighting Breast Cancer with 3D Printing

Taking on breast cancer – that’s what Lattice MEdical, a company founded in Lille, aims to do. Founded in 2017, the company has produced a bioprosthesis called MATTISSE, which could offer an alternative to the silicone prostheses commonly used to help treat breast cancer patients. The silicone prostheses commonly used have to be replaced about every 10 years for safety reasons, which is why the MATTISSE bioprosthesis is made of an absorbable material that can be optimally adapted to the patient’s morphology thanks to the use of additive manufacturing. Lattice Medical uses FDM technology to be able to create the natural reconstruction as they regenerate the patient’s own fatty tissue.

Photo Credits: Lattice Medical

What do you think of these 3D printed prostheses? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

3D printing prosthetics in 2021: The great revolution

3D Learning Hub

See all categories

Contents:

- Introduction

- Overview of 3D printing in the medical sector

- Why is using 3D printing for prosthetics so interesting?

- They used 3D printing to develop prosthetics

- What is next?

Introduction

Overview of 3D printing in the medical sector

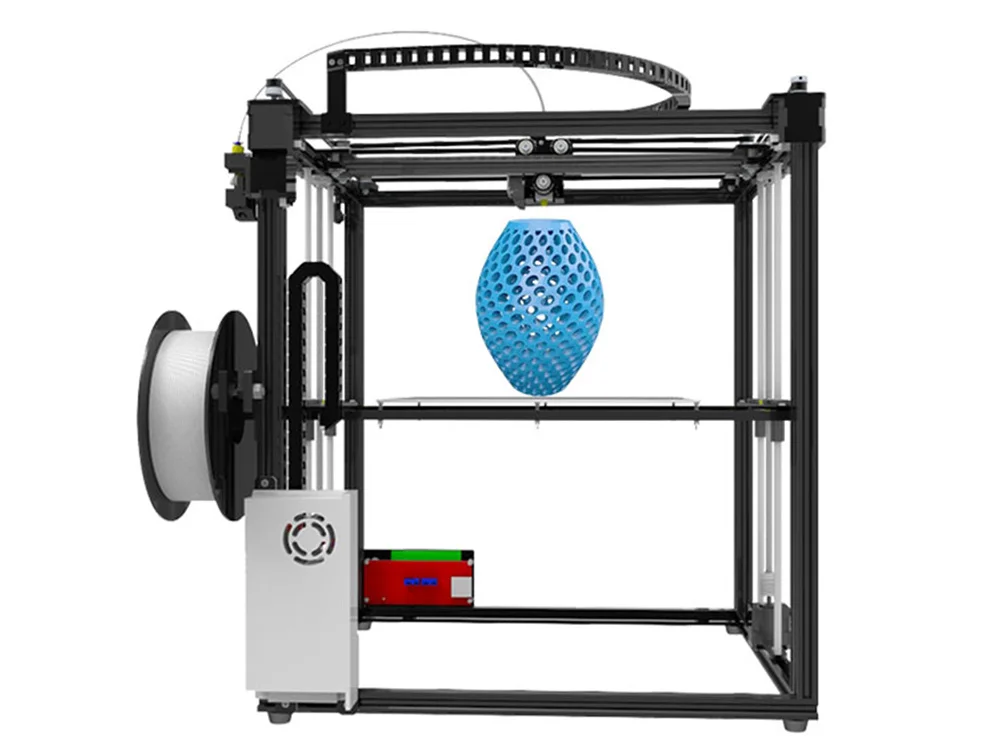

The medical sector benefits from the wide range of advantages offered by Additive Manufacturing. Thanks to the mass-customization opportunities and the flexibility of the manufacturing and design processes, 3D printing becomes a real alternative for this sector. In the future, this manufacturing technology could be used to replace human organ transplants, significantly speed-up surgical procedures, but also produce cheaper and more adaptable versions of required surgical tools. Using technology to rethink and improve the way we produce medical devices leads to great opportunities.

Thanks to the mass-customization opportunities and the flexibility of the manufacturing and design processes, 3D printing becomes a real alternative for this sector. In the future, this manufacturing technology could be used to replace human organ transplants, significantly speed-up surgical procedures, but also produce cheaper and more adaptable versions of required surgical tools. Using technology to rethink and improve the way we produce medical devices leads to great opportunities.

This technology can also improve the lives of those reliant on prosthetic limbs. That is a fact, we can notice a growing interest in adapted orthopedic insoles, orthosis, and prosthetics manufactured using additive manufacturing.

Why is using 3D printing for prosthetics so interesting?

Manufacturing prosthetic is expensive

Thanks to the constant evolution of 3D printing technologies, the medical industry is facing new challenges. In its own way, 3D printing is revolutionizing the field of rehabilitative medicine and tackling a particular issue: prosthetics. According to NGO LIMBS, only 5% of the nearly 40 million amputees in the developing world have access to prosthetic devices or assistance. Many companies such as Unyq are using the advantages of generative design and additive manufacturing to create a brand new approach to prosthetics both in terms of form and functionality. Indeed, some companies are focusing on bringing these advantages to the developing world, to the amputees in environments that lack the medical infrastructure or resources. The goal here is to support the labor-intensive and expensive prospect of traditional prosthetic manufacturing.

According to NGO LIMBS, only 5% of the nearly 40 million amputees in the developing world have access to prosthetic devices or assistance. Many companies such as Unyq are using the advantages of generative design and additive manufacturing to create a brand new approach to prosthetics both in terms of form and functionality. Indeed, some companies are focusing on bringing these advantages to the developing world, to the amputees in environments that lack the medical infrastructure or resources. The goal here is to support the labor-intensive and expensive prospect of traditional prosthetic manufacturing.

Manufacturing adapted and quality devices for amputees is actually a struggle all over the world, as these prosthetics are expensive and most of the time, poorly adapted to the patient’s particularities. New technologies such as this one can also be a major advantage for prosthetists, helping them in the development of customizable prostheses. From the creation of 3D printed prosthetic hands to functional wrists, solutions can be offered with additive manufacturing. Engineers and researchers are opening new possibilities for prosthetics

Engineers and researchers are opening new possibilities for prosthetics

Advantages of 3D printing prosthetics

- Innovation: Innovate without worrying about the limitations of traditional manufacturing

Thanks to 3D printers, rapid prototyping has never been so easy. Iterate your ideas and projects faster thanks to this technology. Going further than traditional prosthetics manufacturing will enable great future developments.

- Customization: Create adapted prosthetics

The customization part is the most important argument here. Getting adapted devices and prosthetics will benefit the patients and improve their quality of life during a limb loss. Customizable functional prostheses creation is now possible thanks to 3D printers.

- Cost: Why are 3D printed prosthetics cheaper?

Once again, developing such a complex project as prosthetics is expensive with traditional manufacturing techniques. Especially if you want to adapt it to the morphology of the patient, additive manufacturing appears to be the most efficient technique to get low-cost prosthetics. It is becoming a life-changing solution to produce prosthetics in areas where the access to such devices is complicated, or impossible.

Especially if you want to adapt it to the morphology of the patient, additive manufacturing appears to be the most efficient technique to get low-cost prosthetics. It is becoming a life-changing solution to produce prosthetics in areas where the access to such devices is complicated, or impossible.

No minimum of order, no need to build an expensive mold, you only need a 3D file to print your project. Prosthetics are better, and more efficient while custom-made. However, customization is quite expensive with traditional manufacturing.

They used 3D printing to develop prosthetics

Several 3D printed prosthetics projects have already been developed all around the world. See how 3D printing materials and technologies are helping to create functional artificial limbs. Here are a few examples of 3D printed prosthetics:

3D printed prosthetic arm providing feedbacks

Lorenzo Spreafico is a student at the University of Leeds. He created a prosthetic arm with vibrotactile feedback. The student implemented pressure sensors at the tip of each finger of the prosthesis, this means the amputee can feel when they’re touching something. This prosthetic arm is his final year project in the Product Design bachelors at the University of Leeds in the UK. Thanks to additive manufacturing, Lorenzo Spreafico was able to lower the price of the device! The first prototype, called T1 is under €3,500. The student explains: “There is a huge gap in the development of prostheses: although we are developing extremely advanced technology to simulate human movement and dexterity, there is much less work done when it comes to simulating human touch“.

The student implemented pressure sensors at the tip of each finger of the prosthesis, this means the amputee can feel when they’re touching something. This prosthetic arm is his final year project in the Product Design bachelors at the University of Leeds in the UK. Thanks to additive manufacturing, Lorenzo Spreafico was able to lower the price of the device! The first prototype, called T1 is under €3,500. The student explains: “There is a huge gap in the development of prostheses: although we are developing extremely advanced technology to simulate human movement and dexterity, there is much less work done when it comes to simulating human touch“. Hand prosthetics

This might not come as a surprise to you, but it is a topic worth mentioning. According to research done by Amputee Coalition, on average there is an amputation done every 30 seconds, and life after such a procedure is hard. But there are people out there using the latest technology innovations to help others. E-nable is a global network of passionate volunteers who help amputees. Thanks to 3D printing, amputees can have a new E-nable device in a short amount of time. The prosthetic hand is fully customized, matching the limb of the user, costs only a fraction of normal prosthetic costs, and dramatically improves the life of the amputee. Bringing all those aspects together in one product was impossible before Additive Manufacturing. Prosthetics are either cheap, but not functional and not personalized, or personalized and very expensive and they always take a lot of time to produce. 3D printing is truly changing the world of medicine and engineering.

Thanks to 3D printing, amputees can have a new E-nable device in a short amount of time. The prosthetic hand is fully customized, matching the limb of the user, costs only a fraction of normal prosthetic costs, and dramatically improves the life of the amputee. Bringing all those aspects together in one product was impossible before Additive Manufacturing. Prosthetics are either cheap, but not functional and not personalized, or personalized and very expensive and they always take a lot of time to produce. 3D printing is truly changing the world of medicine and engineering. Leg prosthetics

Looking absolutely stunning and even impossible Exo by William Root breaks the boundaries of logic. He brings a new level of the esthetics of prostheses. His prosthetic leg is not only beautiful but also fully functional. First of all the designer improved the time-consuming process of manufacturing a prosthesis. Normally, the amputee had to have a mold done of his limb, then a cast was made, vacuum form, check for fit, assembly, and then adjustments were done. Of course, the tedious process has to be repeated again until the fit is just right. When it comes to 3D printing, you scan the limb, adjust the 3D model, and then print the design. Simple, fast, and effective. And in addition to that, it is beautiful. The prosthesis can be fully customized for the user, comfortable, and expressing their character.

Of course, the tedious process has to be repeated again until the fit is just right. When it comes to 3D printing, you scan the limb, adjust the 3D model, and then print the design. Simple, fast, and effective. And in addition to that, it is beautiful. The prosthesis can be fully customized for the user, comfortable, and expressing their character. Hero Arm

Hero Arm is a project developed by Open Bionics, who aims to turn disabilities into superpowers with 3D printed bionic arms for children and adults. Using Selective Laser Sintering 3D printing, with Nylon PA12, they develop prosthetics covers inspired by superheroes such as Iron Man, or fictional universes such as Star-Wars or Frozen.Manufacturing prosthetics in remote areas

Guillermo Martínez is the founder of Ayúdame3D, he went from building robots to building prosthetics hands. At first, it was just for fun, and now, Guillermo Martínez helps people in Kenya by developing prosthetic limbs helping amputees living a more normal life. The founder explains : “I went there, tested out the prostheses, and saw that people were getting to grips with it quickly after using it. It felt great. I considered stopping there, but I loved the feeling of being able to help others so much that I decided to start Ayúdame3D.” (Source Business Insider) Resources in Kenya are limited, Guillermo Martinez managed to create hands costing only $50 thanks to 3D printing.

The founder explains : “I went there, tested out the prostheses, and saw that people were getting to grips with it quickly after using it. It felt great. I considered stopping there, but I loved the feeling of being able to help others so much that I decided to start Ayúdame3D.” (Source Business Insider) Resources in Kenya are limited, Guillermo Martinez managed to create hands costing only $50 thanks to 3D printing. Millie: the first-ever dog with a 3D printed prosthetic leg in Australia

People are not the only ones whose lives changed thanks to Additive Manufacturing. We already talked about a few animals such as a penguin and a duck with a prosthesis, now it’s time for Millie, the greyhound from Australia. She’s a rescue dog, which was kicked out because of a bad paw. Unfortunately, professional prosthetics cost 10 000$ and they are not as personalized. The owners turned to Autodesk, a leader in 3D modeling and CAD software. With Fusion 360 they designed a new, ideally-fitting prosthesis and then 3D printed it. Most of all, 3D printed prosthesis matches exactly the needs of Mille and her limb. It doesn’t cause her any discomfort and allows her to play and be a happy pup. It was also a quick process, and on top of everything was much cheaper.

Most of all, 3D printed prosthesis matches exactly the needs of Mille and her limb. It doesn’t cause her any discomfort and allows her to play and be a happy pup. It was also a quick process, and on top of everything was much cheaper.What is next?

The future of 3D printed prosthetics

It is definitely bright! As you’ve seen in this article, the presented examples show how beneficial Additive Manufacturing is to the medical industry. 3D printing prosthetics are cheaper by thousands of dollars. They are also much more comfortable, fitting exactly the limb, not causing pain to the user, and they are highly customized. This level of personalization has never been achievable before.

Do you have a prosthetics manufacturing project?

Using an online service bureau such as Sculpteo, there is no minimum order quantity, from a single object to 10 000+ parts, you can 3D print the exact amount of parts you need. With 10+ years of expertise in additive manufacturing for production and prototyping, Sculpteo is also offering rigorous quality control. With our online 3D printing service, you get professional 3D printing at your fingertips with +75 materials and finishes to develop your most ambitious projects, such as prosthetics. We’ll take care of the rest in our industrial ISO 9001 factory.

With our online 3D printing service, you get professional 3D printing at your fingertips with +75 materials and finishes to develop your most ambitious projects, such as prosthetics. We’ll take care of the rest in our industrial ISO 9001 factory.

Upload your 3D file and get your free instant quote!

Any question? Feel free to contact us to discuss your project, our 3D printing expert are here to help you develop your project.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

3D printing in prosthetics - Center for 3D printing and prototyping

3D printing prosthetics3D printing in prosthetics

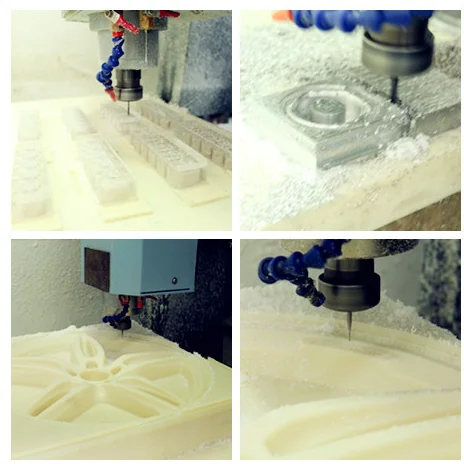

3D printer is a universal peripheral device with which you can create various physical objects of almost any direction. Thanks to layered technology, the device allows you to print three-dimensional objects from various types of plastic, metal, plaster, etc. Recent discoveries have led to the fact that the printer for creating three-dimensional models began to be used in prosthetics. Although the direction itself is not new: prostheses printed in this way have already been used in dentistry. The device allows you to easily print the missing body part from a convenient and environmentally friendly material. Developments in this area were carried out for more than one year. The main goal of the researchers was to learn how to create an ideal prosthesis that will fit in all respects, including comfort and appearance.

Thanks to layered technology, the device allows you to print three-dimensional objects from various types of plastic, metal, plaster, etc. Recent discoveries have led to the fact that the printer for creating three-dimensional models began to be used in prosthetics. Although the direction itself is not new: prostheses printed in this way have already been used in dentistry. The device allows you to easily print the missing body part from a convenient and environmentally friendly material. Developments in this area were carried out for more than one year. The main goal of the researchers was to learn how to create an ideal prosthesis that will fit in all respects, including comfort and appearance.

The need for a perfect prosthesis

An ideal prosthesis is one that will provide functionality to the missing limb without looking intimidating. Printing prostheses on a 3D printer has many advantages. One of the indisputable advantages is the speed of printing. Compared to the conventional process, the time that specialists spend on making a prosthesis using a 3D printer is much less. In addition, this approach also makes it possible to reduce the cost of manufacturing products. This is because the amount of manual labor is significantly reduced.

In addition, this approach also makes it possible to reduce the cost of manufacturing products. This is because the amount of manual labor is significantly reduced.

Features of prostheses created on the printer

Of course, such prostheses differ from the usual ones in many ways. If this is a high-quality product, then the process of its manufacture has certain difficulties, because the design itself is a complex mechanism, which is usually assembled by hand after manufacture. Modern possibilities make it possible to create not only reliable prostheses, but also durable ones. In addition, the decisive factor is the appearance. To do this, specialists need a digital layout in which they need to accurately prescribe the necessary parameters. Only in this way will an ideal prosthesis be created that maximally repeats the anatomy of the human body. To analyze physical data, a 3D scanner can be used, and based on the data obtained, create the prosthesis itself already on the printer.

Finally, we can highlight the main advantages of prostheses created on a 3D printer.

If you are interested in the articles on our website, then maybe you should subscribe to the newsletter? Then you can receive our articles directly to your inbox. We promise you that we will not spam your inbox. Our tactic is different - to interest a person in our field in order to expand the circle of our potential like-minded people and clients.

Benefits of 3D printed prostheses

- Price;

- Strength;

- Appearance;

- Manufacturing speed;

The cost of high-quality prostheses used in medicine is quite high, but further development of this direction will make it possible to make products more massive and significantly reduce their price. The price of domestic prostheses printed on a 3D printer is much lower than their foreign counterparts, which makes it possible for a middle-income family to purchase them.

9Ol000 footwear productionDo you think a prosthesis printed on a 3D printer can fully perform the necessary functions?

Maybe

Can not

Related videos:

3D printing in dentistry for the manufacture of dentures

Modern additive printing technologies allow the production of a wide variety of products for an incredible range of applications. Medicine, in particular the field of dentistry, has long been no exception and is using the achievements of technological progress for the benefit of its patients with might and main, becoming digital.

Benefits of using a 3D printer

Clinics everywhere are moving to intraoral scanning, abandoning analog, uncomfortable for the patient methods of making an impression. Some are not limited to diagnostic manipulations at all, transferring the stages of modeling and manufacturing of single works under their own roof and partially refusing laboratory services. In this case, a 3D printer for dentistry is indispensable in the manufacture of orthodontic and temporary orthopedic structures. Mouth guards, night guards, surgical templates for operations and even the printing of dentures, whether they be single crowns, bridges or even removable basic dentures - all this is under the power of dental 3D printing.

Mouth guards, night guards, surgical templates for operations and even the printing of dentures, whether they be single crowns, bridges or even removable basic dentures - all this is under the power of dental 3D printing.

Comparison of the main 3D printing technologies used in dentistry

Laboratories do not stand aside and improve the manufacturing methods and range of dental products and services. The use of laboratory scanning eliminates the error that may occur during the manufacture of a plaster model. If desired, the model can be produced on a dental printer from a photopolymer, which is always less troublesome and faster. Gingival masks, individual trays, and any orthopedic constructions - the 3D printer opens up new horizons for dental laboratories.

If we talk about the main methods of manufacturing dental products on a 3D printer, then these will be:

- SLA, or the so-called stereolithography, in which the laser beam polymerizes the material, quickly passing through each point of the object;

- DLP, or layer-by-layer illumination process, in which the projector illuminates the photopolymer layer by layer using ultraviolet radiation, transforming it into a future product.

_1400x0_16a.jpg)

Regardless of the printing method, the final properties of the work will depend on the material from which it is made, the very "resin".

When talking about photopolymers, one cannot fail to mention NextDent. The company is a subsidiary of the Dutch manufacturer of plastics for prosthetics Vertex. NextDent pioneered the field of biocompatible 3D printing resins and was soon bought out by global additive technology giant 3D Systems.

The range of 30 unique NextDent photopolymers is the widest of any supplier of dental materials. A range of aesthetically accurate colors enable dental labs and clinics to achieve a close match of finished products to the patient's teeth and gums. 3D printing materials from NextDent are biocompatible and certified in accordance with the requirements of the European Union, which makes them widely used. Photopolymers meet the requirements of the European Medical Device Directive (93/42/EEC), approved by the Food and Drug Administration (USA) and certified in many other countries.

With such a promising line of dental resins in its portfolio, 3D Systems, as the inventor of 3D printing and a recognized industry leader, could not do without using its own revolutionary technologies in a new field for itself. This is how the first 3D printer for dentists NextDent 5100 appeared, specially designed for the manufacture of products from biocompatible photopolymers.

Its hallmarks are speed and ease of use. Incredibly fast in the production of dental work of any complexity, the NextDent 5100 will allow you to print more than 70 temporary crowns in 25 minutes. Or to make a whole prosthesis in front of the patient in just an hour.

NextDent Denture 3D+, a class IIa biocompatible material, was created for the fabrication of removable denture bases. This material has significantly less shrinkage than the already used, standard PMMA materials. Shrinkage can be avoided using software, resulting in a perfectly suitable base for a removable denture. Excellent mechanical properties make it possible to surpass the quality of traditional methods of manufacturing removable dentures.