3D printed foot orthotics

Why Choose 3D-Printed Orthotics? It’s All About Personalization

3D printing has come a long way since it was first commercialized over thirty years ago. It has become a go-to in many manufacturing circles, with a presence in industries such as medical, aerospace, and automotive, to name just a few. Manufacturers working under the strictest quality controls and hobbyists alike have grown to trust and rely on it because of its inherent benefits.

There are many reasons to love it — 3D printing can be cost-effective, help save time, be used to create complex structures, speed up time-to-market, and work for everything from one-off prototypes to series production.

When it comes to applications such as orthotics, some benefits stand out more than others. So, why should you choose this technology?

Make it personal

Every patient is unique. They’re built their own way, they move their own way, and they need orthotics that reflect that. This might be an issue for traditional manufacturing techniques, but not 3D printing. Because the design and printing process is entirely digital, foot and ankle experts can create a unique design, then print several pairs of orthotics simultaneously, all different from each other, making it a valid alternative for mass production.

For patients, this added level of customization lends itself to a perfect fit and happier feet with every step. That’s because every 3D printed phits orthotic begins with a CAD file, with a design based on patient data — dynamic measurements, to be precise. Instead of designing corrections based on a single scan of a patient’s foot, this technique relies on multiple, as well as gait and pressure measurements to create an average.

In doing so, foot and ankle experts can generate corrective insoles that are unique to each patient, based on their movement and the shape of their foot with greater accuracy than ever before — no more ‘one-size-fits-all’ that really fits no one — while ensuring that they remain comfortable, lightweight, and durable.

Thanks to nesting software, experts can print several unique pairs of phits simultaneously.

Accuracy and repeatability

As far as orthotics are concerned, this is a great improvement for foot and ankle experts. It allows them to build corrections into the printed base of the insole itself and apply different levels of stiffness where necessary. Unlike some traditional orthotics, this means corrective pieces are not glued on top of the insole itself, so phits are far less bulky and can be reproduced more easily.

Naturally, this improved design would be meaningless if the final product didn’t match it — but that’s no issue here. The 3D printing technique used to create phits orthotics is accurate down to 0.1mm. It would be impossible to reproduce a pair that was identical to the original by using manual techniques, and any minor differences could have a big impact on performance or patient comfort. With 3D printing, they can rest assured that the result will be the same every time.

With 3D printing, they can rest assured that the result will be the same every time.

3D-printed orthotics are accurate to 0.1mm, offering enhanced repeatability.

Made with expertise

While 3D printing offers a lot of freedom, getting the most from the technology isn’t easy. It requires a deep understanding of the process, from design to execution. Manufacturers must choose from a range of different materials and 3D printing technologies, such as selective laser sintering or fused deposition modeling (FDM), depending on the desired characteristics of their final product. If a product needs to be strong and heat-resistant or flexible and porous, there’s sure to be a combination that’s perfect for the job. Knowing where and when to use each combination comes from experience.

Thankfully, more than 30 years of additive manufacturing experience has been integrated into the Materialise Phits Suite workflow. Production is handled either by our experts at Materialise or approved partners depending on region, ensuring every pair of orthotics is 3D printed and finished to the highest possible standard.

Production is handled either by our experts at Materialise or approved partners depending on region, ensuring every pair of orthotics is 3D printed and finished to the highest possible standard.

Materialise Phits Suite and 3D printing

Having 3D printing as an integral part of the Materialise Phits Suite workflow really sets it apart for foot experts. They can expect benefits that other technologies cannot offer every time they design phits orthotics for their patients, beginning with the accuracy we mentioned earlier. The final result is guaranteed to match the design down to a margin of 0.1 mm, meaning it fits the foot exactly as intended right out of the box, with less back and forth for both parties. The same can be said for any replacements they print afterward.

For Fried Vancraen, Founder and CEO of Materialise, finding that Cinderalla fit was one of the main inspirations for venturing into the world of orthotics.![]() He and his children endured the time-consuming process of measuring and changing insoles every year before Materialise Phits Suite was born. Now, they’re more than happy with orthotics that fit all occasions and styles and which, thanks to the durability of 3D printing, they know will stand the test of time.

He and his children endured the time-consuming process of measuring and changing insoles every year before Materialise Phits Suite was born. Now, they’re more than happy with orthotics that fit all occasions and styles and which, thanks to the durability of 3D printing, they know will stand the test of time.

Phits orthotics will fit into many different shoes, making every situation comfortable for your patients

When asked to describe the difference between traditional orthotics and her custom-made phits, it was this durability that really stood out for marathon world record holder Paula Radcliffe:

“Well, the biggest thing is the durability. They simply don't wear out! You can keep using them, you can run a lot of miles in them, and they basically don't show much damage at all. Only the top cover wears out, and these are easily replaced. The rest, it stays there the whole time. I think it's more precise than the traditional orthotics because it's exactly the same each time it's created, and it is lighter. It doesn't deform with heat and get as soft as with the traditional ones. Sometimes with the older ones, if it was very warm, they would build up, or they would get a hole or deform a little bit. phits orthotics don't do that!"

It doesn't deform with heat and get as soft as with the traditional ones. Sometimes with the older ones, if it was very warm, they would build up, or they would get a hole or deform a little bit. phits orthotics don't do that!"

Making orthotics more sustainable

But there’s more to 3D printing than strength and style. Those seeking more sustainable options will also be impressed, particularly with powder-based technologies like SLS. In this case, the orthotics would be built layer by layer in a bed of powder, using only the necessary material, with waste reduced even further thanks to the use of 100% recycled powder. Whether your orthotics are printed by Materialise or by another local supplier, you’ll also benefit from simplified supply chains. Your design is made to order and shipped right to you, meaning there’s no middleman or storage necessary, further reducing the environmental impact.

Of course, none of this would matter if the process to actually create the orthotics was problematic, unreliable, or slow. In reality, 3D printing is nothing if not convenient. As an entirely digital manufacturing process, it can be integrated seamlessly into the digital orthotic ordering workflow — the gait is measured, the orthotic is designed in the footscan software before being sent to the printers. Foot and ankle experts can handle the entire process in Materialise Phits Suite and rest easy knowing that they’ll receive exactly what they ordered.

In reality, 3D printing is nothing if not convenient. As an entirely digital manufacturing process, it can be integrated seamlessly into the digital orthotic ordering workflow — the gait is measured, the orthotic is designed in the footscan software before being sent to the printers. Foot and ankle experts can handle the entire process in Materialise Phits Suite and rest easy knowing that they’ll receive exactly what they ordered.

Say goodbye to paperwork

An added bonus of this end-to-end workflow is the clear reduction in paperwork. Because the necessary information and data is stored in the software, it has never been easier for foot and ankle experts to follow up on their patients in later appointments. Whether they need to create replacement orthotics or wish to see how an individual’s gait has changed over time, the information they need is never more than a click away.

Naturally, data security remains paramount. All patient data is securely stored in a separate, closed system, ensuring convenience doesn’t come at the expense of privacy.

Your end-users will love it, too

When patients receive their orthotics, many may not be too concerned with how they were made or where they came from. But that can change with Materialise Phits Suite. Experts can use the software’s visualizations, charts, and reports to explain the process from start to finish, including where any potential issues may stem from and how the construction of their 3D-printed orthotic can help resolve them.

With this software, experts can easily explain how and why phits will help their patients.

And there are plenty of other reasons to be happy about getting your hands on phits, starting with what matters most — comfort. Those who wear them, like British marathon champion Charlotte Purdue, quickly notice the difference that having orthotics shaped to fit their foot will have on how they move.

“When I first wore them, I found that they fit well, and I didn’t have any problems with them,” says Charlotte. “They fit my running style completely. If they didn’t, I’d have had blisters, or it wouldn’t feel right, but it felt like they needed to be in my shoes.”

“They fit my running style completely. If they didn’t, I’d have had blisters, or it wouldn’t feel right, but it felt like they needed to be in my shoes.”

Thankfully, an insistence on comfort doesn’t mean compromising on durability or performance. Because of their high-quality materials and engineered design, 3D-printed orthotics like phits are both lightweight and strong, meaning they’ll endure heavy usage for years and weigh about half as much as traditional, milled insoles. The soft, comfortable top cover is easily replaced when wear and tear kicks in, extending the life cycle even further, meaning phits aren’t just good for the environment but for the wallet, as well.

Athletes like Charlotte Purdue use phits every day, but they’re also great for day-to-day activities.

A big step forward for orthotics

Much like the analysis and design of orthotics has come far in recent years — it wasn’t long ago that foam boxes were the only available option — the introduction of 3D printing into the workflow is doing a lot to drive the industry forward to the benefit of everyone. It’s a big step forward for those who design orthotics and an even bigger step for those who wear them.

It’s a big step forward for those who design orthotics and an even bigger step for those who wear them.

Materialise Phits Suite makes sure taking it has never been easier.

3D printing allows foot orthotics startup to get to the 'sole' of the matter

By Karen Hanna

A sore foot can be debilitating. But a startup creating orthotics using 3D printers is taking steps to ease foot pain while overcoming some of the cost and slow turnaround times that have hobbled the custom insole market.

“We decided that we were going to bring the digital process to the orthotics industry and really break down three of the main barriers that we're seeing today, and those are high cost, poor fit — not just for you, but also to your shoes — and then, inaccessibility. It's really hard to get custom orthotics today,” said Mike Schmid, the founder and CEO of inStryde, an online retailer of 3D-printed orthotics tailored to customers’ feet.

Using L1 printers from Carbon, the company has been shipping orthotics since late 2019. Recently, it updated its proprietary software, SmartFit, which customers can access through their smartphones to perform scans that provide information about their height, weight, gait and foot shape. With the upgrades, users can access the software at the company’s website at www.instryde.com without downloading an app.

Recently, it updated its proprietary software, SmartFit, which customers can access through their smartphones to perform scans that provide information about their height, weight, gait and foot shape. With the upgrades, users can access the software at the company’s website at www.instryde.com without downloading an app.

The company has “gone through a number of product revisions over the past few months to improve overall support, comfort and performance,” Schmid said.

Based on submitted scans, Carbon's Design Engine software then designs a lattice structure that matches individual users' needs, said Kelley McCarroll-Gilbert, business development director for the 3D printer maker.

“We can vary stiffness throughout to match certain characteristics and needs that they have. And then we send a file to our production partner, and they print it out on this elastomeric polyurethane material developed by Carbon," Schmid said.

An engineer with a background in the aerospace industry, Schmid began looking for a new way to make insoles after walking the proverbial mile in the shoes of someone with hurting feet. He's an ardent soccer player, and when a doctor advised him to look into custom orthotics to relieve a bout of plantar fasciitis, he initially chose to play hurt.

He's an ardent soccer player, and when a doctor advised him to look into custom orthotics to relieve a bout of plantar fasciitis, he initially chose to play hurt.

“I'm a frugal person by nature, but the custom orthotics were going to cost me $600, and they were going to take two months to get. And I was like, ‘You know what? I don't need these.’ And a few minutes into my next game, I really injured the plantar fascia in my right foot,” he said. “So, I ended up biting the bullet, paying the $600, getting the custom orthotics, and, at the end of the day, they fit me really, really well, but they were so thick, there were so many different materials layered together, that they didn't fit into my soccer cleats, so I couldn't wear them while I was playing.”

Out of that experience, inStryde was born, offering orthotics ranging from $129 a pair to $229 for two pairs.

In starting up inStryde, Schmid found Carbon’s s Digital Light Synthesis (DLS) printing process and materials fit like a glove.

The DLS process uses ultraviolet light to cure special resins — most developed by Carbon itself.

It allows inStryde and its contract printing firm to make quick iterations, without the costs and delays associated with traditional manufacturing approaches, McCarroll-Gilbert said.

"Additionally, there is the ability to scale quickly, create custom products in a highly streamlined manner, with high-performing and durable materials. For a product like inStryde’s insoles, the ability to customize at scale is key — both on the shape and size of the insole and with the potential for variable density responses in a single printed part," she said.

As one of the doctors who volunteered to provide an expert perspective to inStryde, podiatrist Deep Patel praised the company’s end product. A board-certified doctor of podiatric medicine and foot and ankle specialist, he believes inStryde’s orthotics are sufficient for most foot-pain sufferers, while representing a huge step up from over-the-counter inserts.

3D printing has opened up new possibilities for the market, providing “a good balance of cushion and shock absorption and bounce back, due to its lattice technology,” Patel said.

“It is very close to a custom-molded orthotic that you would get in an office. The only difference is, in an office, a lot of times you're using older technology where you're stepping in a foam box or doing a plaster mold of your foot. But, at the end of the day, those differences are kind of minimal for most people that don't have an extreme foot type, like a very high arch or very flat arch. Most people are right in the middle,” he said. “[The inStryde process] is super because it eliminates the need to make extra trips and spend extra money, and you get a very customized product to your foot.”

The insoles have Schmid back on his feet, playing soccer again.

“Pre-orthotics, when I was playing competitive soccer, plantar fascia injury is no joke, it's very painful; it takes a lot of PT to get on the other side of. It’s a very nagging injury. Post-inStryde, I haven't really injured it,” said Schmid, who walks 1.5 miles each way to and from his office in Winston-Salem, N.C.

It’s a very nagging injury. Post-inStryde, I haven't really injured it,” said Schmid, who walks 1.5 miles each way to and from his office in Winston-Salem, N.C.

Patel, too, proclaimed an optimistic prognosis for the startup.

“I think for an initial product line, this is ... going to be very successful, and I think people are going to benefit from it tremendously,” he said.

Karen Hanna, senior staff reporter

Contact:

Carbon Inc., Redwood City, Calif., 650-285-6307, www.carbon3d.com

a

How to 3D print economical and customized insoles?

Home / Blog / Application / The importance of orthopedic steamers

30.11.2021

Content

-

- RAISE3D Cooperation with a clinical hospital and 3D printing clinic

- Production of orthopedic steles before 3D printing

- production of steam by 3D printing

- Productivity and cost of producing insoles on a 3D printer

- 3D printing rehabilitation

Orthopedic insoles appeared after the Second World War as a means of treating biomechanical diseases of the lower extremities. Orthotic insoles have become a popular treatment option due to their easy availability and wide range of uses. For example, about 9.4% of the American population, or 30.3 million Americans, currently have diabetes. More than 70% of Americans suffer from overpronation. Many who suffer from these diseases need orthopedic insoles.

Orthotic insoles have become a popular treatment option due to their easy availability and wide range of uses. For example, about 9.4% of the American population, or 30.3 million Americans, currently have diabetes. More than 70% of Americans suffer from overpronation. Many who suffer from these diseases need orthopedic insoles.

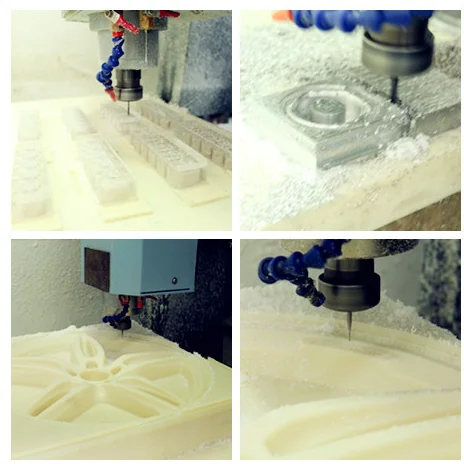

For over 70 years, the manufacturing process of orthopedic insoles has relied heavily on manual labor and CNC machining. This heavy reliance on both methods led to high costs and significant production times, as well as a constant risk of deviation in production accuracy. With the advent of 3D printing, the manufacturing process has changed a lot.

Raise3D Collaboration with Teaching Hospital and “3D Printing Clinic”

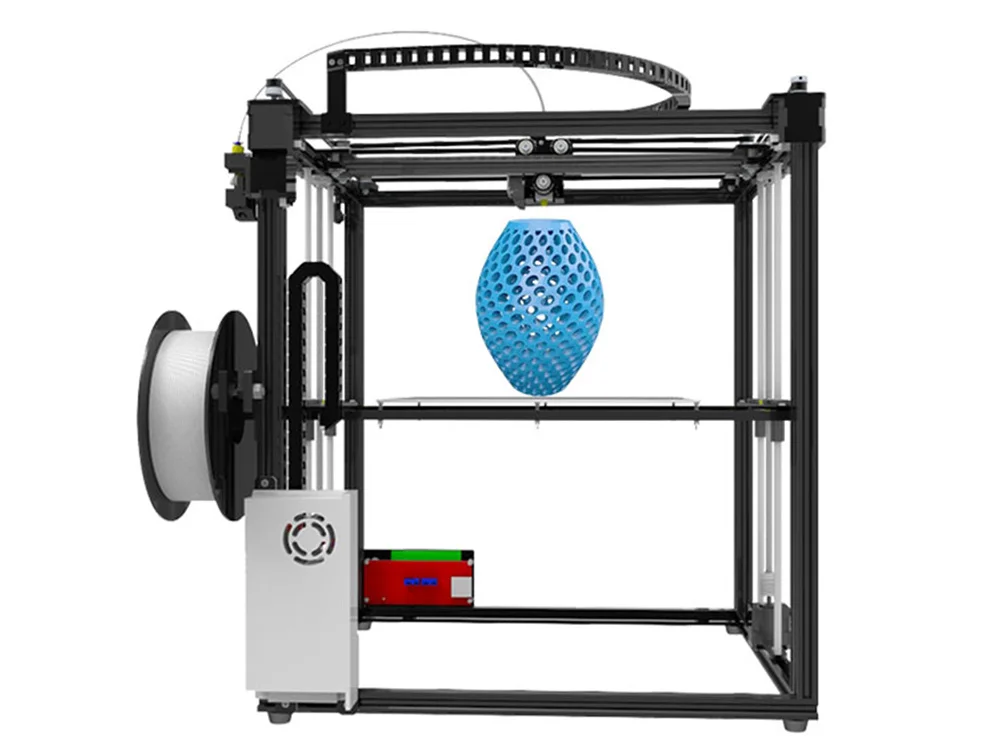

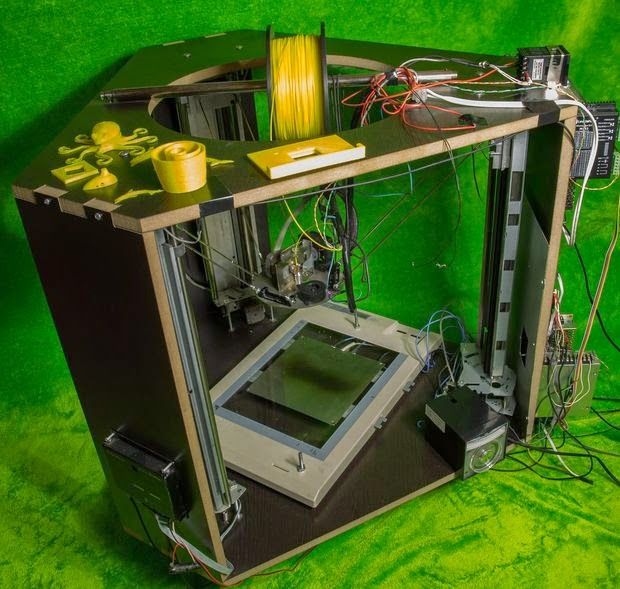

Raise3D is working with an innovative clinical hospital to bring FFF 3D printing to the production of orthopedic insoles. The hospital already had an idea of the decade-long success of 3D printing and had high demands on any insoles made using this method. As a result, it was decided to introduce 3D printing in combination with other digital technologies in the manufacturing process.

As a result, it was decided to introduce 3D printing in combination with other digital technologies in the manufacturing process.

A “3D printing clinic” has been set up at the hospital, which operates with additional technical support from the university's biomechanical laboratory. This technical support allows you to use the latest analysis, scanning and design technologies.

Insoles printed on the Raise3D E2 desktop 3D printer with ideaMaker 3D cutting software retain their high performance. Moreover, the method is cost-effective.

The hospital was satisfied with the efficiency of the process and high productivity. It was decided to use Raise3D products and the company's technical support. The Raise3D orthopedic insoles solution includes a 3D printer, model cutting software, a cutting template and plastic.

The hospital focuses on diagnosing and designing insoles, as well as improving the 3D printing process in-house. During this time, Raise3D provides technical support and advice. Raise3D helps optimize print settings and teaches you how to operate the equipment. The user-friendly interface of Raise3D hardware and software ensures that medical staff can easily operate and schedule the 3D printer, thus saving time and labor.

Raise3D helps optimize print settings and teaches you how to operate the equipment. The user-friendly interface of Raise3D hardware and software ensures that medical staff can easily operate and schedule the 3D printer, thus saving time and labor.

Through a combination of 3D printing and a digital manufacturing process, the clinic hosts a complete insole manufacturing process in-house. Every month, patients from all over the country come to the clinic, and their number continues to grow.

Manufacture of orthopedic insoles before 3D printing

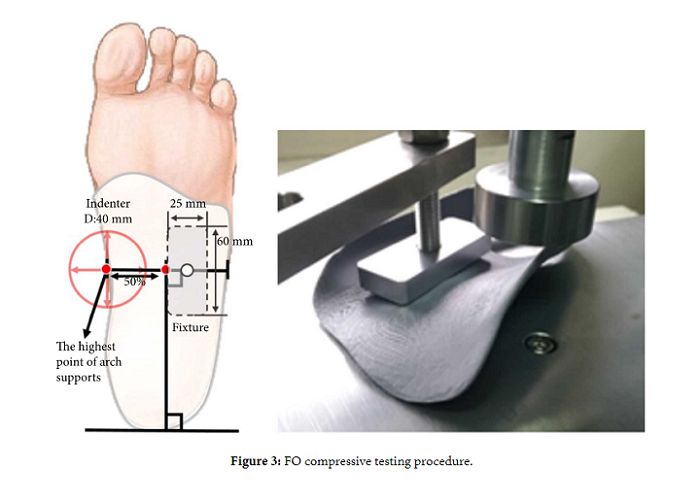

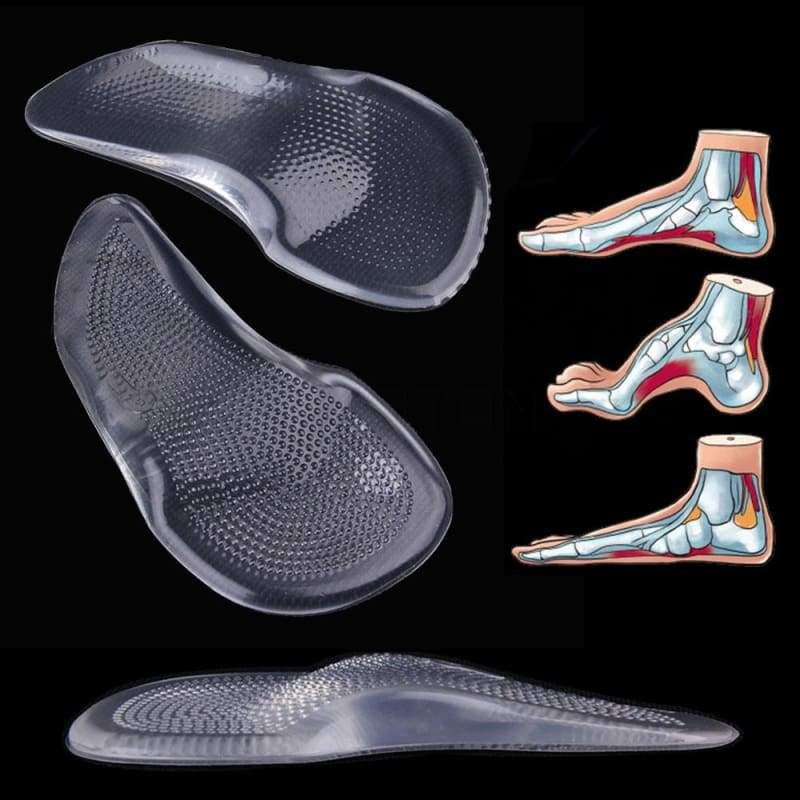

The traditional process for custom-made orthopedic insoles is complex because each pair of insoles is unique. The insoles must have different mechanical properties in different parts of the sole to help correct a person's posture. For example, a person with uneven arches and overpronation will need different arch support for each foot. The traditional method usually involves forming and stacking different sheets of material on top of each other. Each leaf is shaped, assembled and polished. Even when using CNC machines, this process requires a lot of manual labor.

Each leaf is shaped, assembled and polished. Even when using CNC machines, this process requires a lot of manual labor.

3D printed insoles

Because all it takes to 3D print is a workbench, computer software, and a 3D printer, the clinic can do the entire process in-house. The only thing medical staff need to know is a few relevant settings that can be configured with a few clicks.

Raise3D's E2 desktop 3D printer prints one pair of insoles completely in about 2 hours with no additional labor required. With additional support for RaiseCloud, Raise3D's cloud-based 3D printing management software, hospital operators can remotely monitor print progress in real time. Because RaiseCloud is a cloud-based platform, it can always be accessed over the Internet, greatly increasing the efficiency and flexibility of print management.

Productivity and cost of producing insoles on a 3D printer

3D printed insoles have better performance than conventionally made insoles. For example, 3D printed custom insoles have an open structure, making the insole lightweight and breathable. Another benefit is that 3D printed insoles have a more precise and flexible stiffness distribution on the inside. This is very important for effective treatment. Raise3D 3D printed insoles use TPU material, which has better mechanical properties, namely durability and strength, especially when compared to traditionally made insoles. The patient will feel constant support throughout the entire time the 3D printed insole is worn.

For example, 3D printed custom insoles have an open structure, making the insole lightweight and breathable. Another benefit is that 3D printed insoles have a more precise and flexible stiffness distribution on the inside. This is very important for effective treatment. Raise3D 3D printed insoles use TPU material, which has better mechanical properties, namely durability and strength, especially when compared to traditionally made insoles. The patient will feel constant support throughout the entire time the 3D printed insole is worn.

High performance 3D printed insoles are also cost effective to manufacture, especially when compared to the cost of producing conventional insoles. This is because the cost structure of 3D printing is different from traditional manufacturing. For example, by adopting 3D printing, a hospital can reduce the need for various types of equipment and tools. This saves on asset costs and workspace costs. It also reduces labor and material costs.

Rehabilitation with 3D printing

3D printing is changing personalized rehabilitation by being cost effective, reducing waste and improving patient comfort. In addition to insoles, other 3D printed medical products are already being used, including prostheses and orthoses. Through the combined efforts of Raise3D and healthcare professionals, other areas of medicine can also benefit greatly from 3D printing.

Retrieved from : https://www.raise3d.com/case/how-to-3d-print-economical-and-customized-orthotic-insoles/

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

#Application

Share

all materials

Do you have any questions?

Our experts will help you with the choice of 3D equipment or accessories, consult on any questions.

3D Printing Solutions for Custom Orthopedic Insoles with Formnext 2017 / Sudo Null IT News

At Formnext 2017, we got acquainted with solutions for manufacturing custom custom insoles using 3D scanning and printing methods. These technologies will help create sports and therapeutic shoes that are ideal for each customer, reduce fatigue during increased and prolonged loads on the legs, and reduce the risk of developing flat feet.

These technologies will help create sports and therapeutic shoes that are ideal for each customer, reduce fatigue during increased and prolonged loads on the legs, and reduce the risk of developing flat feet.

How it was done before

Scanning in the shoe business is not new for a long time, but before we saw examples of its use only in the selection of shoe sizes and for the initial diagnosis of flat feet - it was difficult to expect more with flat two-dimensional foot scanning, although more convenient and accurate than taking measurements manually, but giving in fact, no more information than a footprint on paper.

Orthopedists use 2D flat scans to take measurements, and the insoles themselves continue to be made using traditional methods. This is how it is done, for example, in the Ortek network of orthopedic salons.

Without a 3D scan of the foot, as well as information about the dynamics of movement and the distribution of load on the foot, the information about the legs is incomplete to ensure the most individualized approach - after all, the output is an accurate size, but without other individual features. Because of this, orthopedists have to resort to outdated methods such as manual measurements, impressions and mold making. All this not only stretches in time, but also significantly increases the cost of the process.

Because of this, orthopedists have to resort to outdated methods such as manual measurements, impressions and mold making. All this not only stretches in time, but also significantly increases the cost of the process.

The complex solutions described in this article are designed to significantly speed up and reduce the cost of manufacturing insoles, as well as remove the influence of the human factor on the accuracy of size matching.

3D printing has also been used in the manufacture of shoes, but there was no talk of such deep personalization.

Formnext 2017 once again showed us that in this area, additive technologies are used more and more effectively.

How it's done now

The first solution presented is Ecco Quant-U. This is a complex for scanning feet and printing insoles. An Ecco employee told us how the process itself takes place.

Ekko uses the Volumental orthopedic scanner.

It can scan the fullness of the foot like a normal 3D shoe scanner, and show the size of both feet, the height of the arch of the foot, the difference in the shape of the right and left foot.

This is what is already being used in stores - visitors come in from the street, scan their feet and the seller can immediately tell them which shoe models suit them, which ones will fit perfectly on the leg, and immediately let them try on the right ones.

Buyers usually know their size, and the seller can compare this size with scan results. Ecco shoes are usually slightly larger than other brands of the same size.

Shoes are personalized in the following way: scan data and data obtained from a second source are used - these are special shoes with sensors that are given to the client and asked to walk. Sensors transmit information about the gait to the program: a change in the position of the leg, a change in pressure on different parts of the foot when walking.

A special algorithm correlates scanner data, gait sensor data and measurements to create a digital model.

Based on this model, a unique insole is printed that is most suitable for each specific foot.

This is not an ordinary insole, it is an inner layer that completes the boot, not complements it.

Ekko produces a range of special shoes designed for use with these insoles.

This is a 3D printed silicone. The insoles are printed on special printers.

Who helped

The printing process is developed together with German RepRap. Their LAM printer is the most suitable for printing silicone insoles.

Special silicone developed for the project by Dow Chemical. This company uses additives in its materials that improve the mechanical properties of plastic - its elasticity, strength, durability. Such an experience came in very handy. The knowledge gained by the Swedish company Volumental, which has been developing shoe 3D scanners for several years, also came in handy.

Electronics and software manufacturers also participated.

How much will it cost

The estimated initial cost is 400 euros, but before that a pilot batch of 50 orders must be produced in order to get user feedback. After all, all the feedback that is now received from Ecco employees, professional shoe testers and biomechanics from the University of Santa Barbara.

After all, all the feedback that is now received from Ecco employees, professional shoe testers and biomechanics from the University of Santa Barbara.

Application

As long as it's a comfort product. Comfortable sports shoes with such insoles become even more comfortable, they provide maximum support for a healthy foot.

If you need corrective shoes, it is best to consult an orthopedist, but if you are healthy and need shoes to reduce stress and fatigue, this is the right option.

In the future, when the manufacturer has partners from the medical industry, or a licensed medical company acquires this solution and uses it in its activities, the topic will be developed.

FitStation is a project of Superfeet and HP. This solution is both for selecting shoes from existing models, and for creating personalized insoles for shoes.

How it's done

The idea is this: the consumer comes to a special kiosk, fills in the necessary data - such as gender, age, weight. Then comes the scanning process.

Then comes the scanning process.

For scanning, a specialized True Form 3D RSscan Tiger 3D shoe scanner is used, or rather, an HP Fitstation kit.

First, each leg is scanned in turn.

The client places their foot into the scanner, where a 3D image is taken.

This is how an accurate digital foot model is created, with its unique geometry and all dimensions.

The next step is gait scanning: you need to walk several times on a special sensory mat.

The result shows the dynamic distribution of the load when walking, how the leg moves, how the weight is distributed on different parts of the foot to achieve balance.

Next, the user needs to answer several questions of the program, including: the purpose of the order - will it be shoes for training or competition, with what frequency and intensity will the shoes be used, what problems are known when using other shoes - where it usually presses, where rubs.

This will be used by the program in order to offer the best solution.

Further, the data from the scanner and pressure meter are processed and compared with the parameters of existing shoe models from the catalog. This allows you to choose the most suitable model, taking into account its geometry.

The catalog contains shoes from different manufacturers, the buyer has the freedom of choice.

Another possibility for the client is to submit a unique insole design for 3D printing.

Just click "buy" and enter your home address and bank card details - the order is sent to production, where it is printed on an HP Jet Fusion 3D printer from PA 12 material and sent directly to the buyer's home.

Application

The SafeSizeME3D software is responsible for modeling the insole in FitStation and selecting shoes according to individual parameters.

This software has been designed with most normal feet in mind, primarily for sports shoes.