3D printed mtb parts

5 Original 3D Printed MTB Accessories

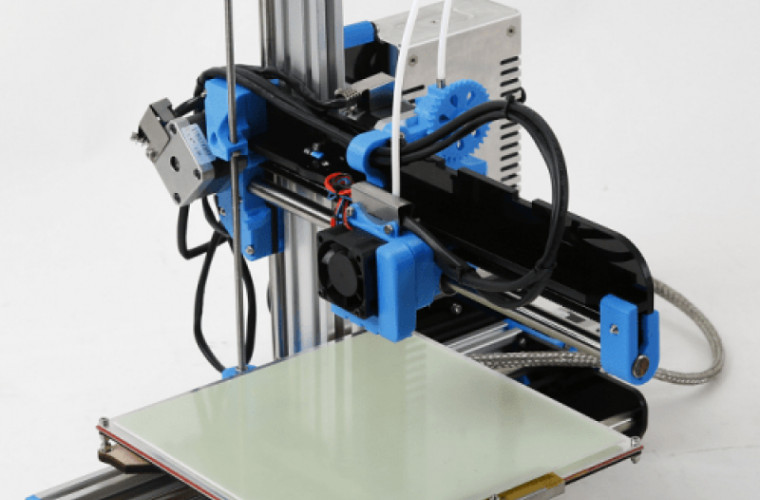

My role at Pinkbike/Outside is mostly spreadsheets, meetings, cat-herding Levy, and the occasional salty comment. But every winter I try to learn something, and in 2021 I got a MatterHackers Pulse XE and spent a bit of time learning about 3D printing. Additive manufacturing on an industrial scale has huge potential for brands like Atherton Bikes (check out our podcast with them for more additive nerding), but I’ve been even more interested in the accessories and gadget-level stuff. It’s just neat.

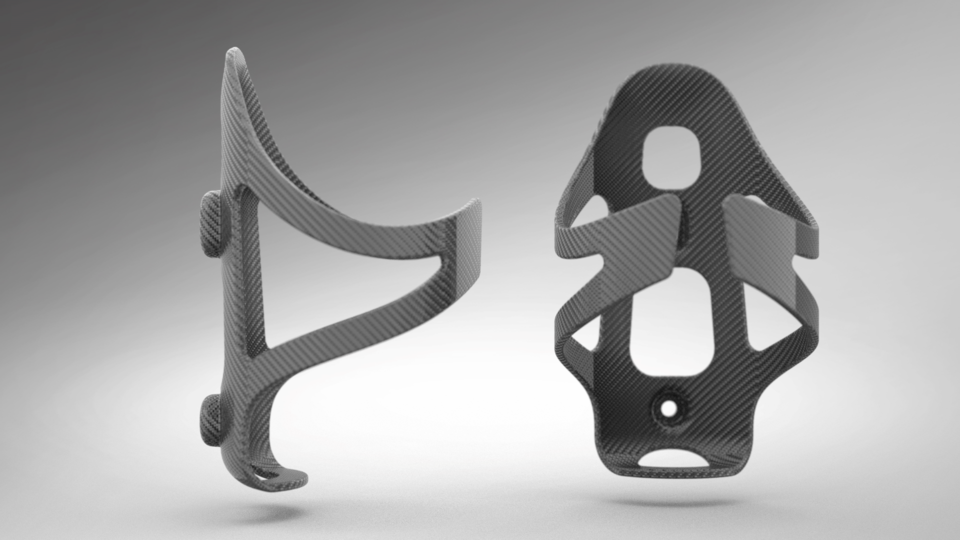

Through my very slow learning process I’ve made spacers, pedals, pump mounts, cable guides, bottle cages, and more. I’m constantly blown away at how easy it is for someone with zero engineering experience to think of something, model it on a computer, press a button, and then it just… exists?

I thought it’d be interesting to highlight a few things I’ve been messing around with, and hopefully encourage you to get out and make your own stuff. I've included STL files for a few of the designs below so anyone with a 3D printer can pull down the file and try printing them. Let me know below what you think I could improve with these designs, or what you think needs to get made!

Presta Valve to Schrader Rim Adapter

I’ve been off the mountain bike with some injuries for a while now, so I’ve gotten a bit weird with a cargo-bike build that’s based on an Omnium Minimax. I ordered carbon rims from Light Bicycle drilled for Schrader, but forgot to order Schrader tubeless valves. I’ll eventually put some Stan's Schrader tubeless valves on, (to be honest, I might secretly be pro-Schrader valve now that wide rims are more common) but in the meantime I wanted to run these excellent 76 Projects Hi Flow tubeless valves.

The top of these valves is big enough to seal against the Schrader-sized 8mm hole in the rim, but on the spoke side there was nothing to keep the ~6mm valve centred. There’s no sealing required at the spoke side since it’s all done at the rim tape, so basically an adapter just has to centre the valve by taking up the space between valve and rim.

This was everything that home 3D printing is good for. 5 minutes with callipers and a tiny bit of basic 3D modelling, and I had an adapter printing. The only real challenge was matching the curve of the rim. I got lucky, the first one was almost right, then I chamfered a couple of edges, adjusted the radius to make it sit a little more flush, and the second try was good to go.

It cost about $0.06 to print, and saved me $30+ and a week’s wait. Even if Schrader makes sense on this bike, I’m very happy with this in the meantime.

Cobbled together in Fusion360.

STL download here. The design of the 76 Projects valve is a little thicker than others, so this should adapt most tubeless Presta valves to most Schrader rims. You do need to double check that your Presta valve is capable of sealing against the rim at the rim tape side, but if it doesn’t work you’re only out a couple of cents.

OneUp Pump Inline Mount

I started working on this OneUp pump mount for a frame builder who’s doing a very cool build for her entry to a handmade show later this year. We wanted a light, low profile pump holder that would sit in-line with the frame. I don’t know why, but mounts that stick out off the side of my bike bother me for no good reason. A long time ago I did a design that was similar to the excellent Jank Components one, but wanted something a little more minimal and with two sides further apart for more stability.

We wanted a light, low profile pump holder that would sit in-line with the frame. I don’t know why, but mounts that stick out off the side of my bike bother me for no good reason. A long time ago I did a design that was similar to the excellent Jank Components one, but wanted something a little more minimal and with two sides further apart for more stability.

Initially, I struggled to make my design actually hold the pump firmly. If I made it too tight or wrap too far around, it was hard to get into and the pump still spun in the holder—while if I made it looser or with less wrap, it popped out too easily. I’m sure the engineers here are rolling their eyes at this, but the breakthrough for me was understanding that “everything is a spring.” Once I made the holder elliptical rather than round, it held the pump firmly and wasn’t too hard to get into. Now it’s solid enough that I think I will run it without any retention on my gravel and XC bikes, but I gave it an option to run a bombproof Voilé Nano strap as well.

I'm sure there was an easier way to model this design.

The wings have 45° angles so it could easily be printed on a standard FDM (fused deposition modeling) printer. I could have dropped the whole thing lower to the frame, but that would require ultra-low, hard-to-find bolts. I decided to stick with a sensibly low 3.5mm bolt-height, and am happy with that. I think it looks decent and it’s fairly low profile.

This setup apparently mounts nicely to the back of the King Cage Side Loader. I have to check fitment because I'm not sure it'll clear on larger downtubes, but for bikes with limited space in the front triangle this could be a great way to keep the cage and pump tighter to the frame.

Details:

• 12g (a lot lighter than stock)

• Printed with NylonX filament on a MatterHackers Pulse XE FDM printer

• Fits OneUp pumps

• 64mm mount point eyelet spacing

• Integrates compactly with King Cage Side Loader

• Optional Voilé Nano strap retention

Really happy with how this one prints.

No STL download. This design isn’t quite finished and I might eventually try to sell a few of them. Here's the STL for the old original pump mount I made that works nicely on tubes with rounder profiles. Or if you want to buy an inline OneUp mount right now, check out the one from Jank Components.

Master of Fun Drink Holder

I’m guessing most of us have stuffed a beer into a bottle cage and had it flop out at some point. There are good can-specific cages out there, but I wanted something that could fit everything from Red Bull cans to wobbly pops.

Overall this was a simple design. Again I used an ellipse to give it some clamping force around each can/bottle size, but I made the drinks drop in from the top so that they couldn’t wiggle out the front.

Section view

The hardest part was dialling in the design for printing efficiently. I generally use an unnecessarily low 0. 1mm layer height so it builds up from the build plate (Z-axis) very slowly, but the finish looks nice and smooth. In the XY axes the nozzle I use is 0.4mm wide, which, after a bunch of frustration on my part, turns out prints 0.45mm lines of filament. You can adjust this in your slicing programs, but I don’t think any slicers adjust it dynamically during your prints. What that means is my wall thickness needed to use multiples of 0.45mm to make it print cleanly rather than struggling to fill gaps. I settled on 2.25mm walls, so 5x passes of the nozzle printing a little 0.45mm snausage of plastic.

1mm layer height so it builds up from the build plate (Z-axis) very slowly, but the finish looks nice and smooth. In the XY axes the nozzle I use is 0.4mm wide, which, after a bunch of frustration on my part, turns out prints 0.45mm lines of filament. You can adjust this in your slicing programs, but I don’t think any slicers adjust it dynamically during your prints. What that means is my wall thickness needed to use multiples of 0.45mm to make it print cleanly rather than struggling to fill gaps. I settled on 2.25mm walls, so 5x passes of the nozzle printing a little 0.45mm snausage of plastic.

The design really only works holding your cans vertically, so it’s mostly for putting on your town bike’s bars. Even with extra clamp force I think bottles would shake out if you just ran it on your downtube, but I figured it was still worth sharing. Or maybe you have an idea to make it work on a mountain bike too?

STL download here. I’d call this a work in progress still, so let me know how it works if you print one. There’s enough height for each of the sizes to hold a full bottle fairly well, but I would love for it to be even more secure. I am also not sure if this is one worth printing commercially—it costs ~$6 to print with good filament on my MatterHackers FDM system at home, but because it takes up so much build volume, doing it on a local HP system would probably cost closer to $30. Too much to sell at a reasonable price if you want a healthy margin. Maybe this would be a good candidate for injection moulding—something to learn for next winter?

There’s enough height for each of the sizes to hold a full bottle fairly well, but I would love for it to be even more secure. I am also not sure if this is one worth printing commercially—it costs ~$6 to print with good filament on my MatterHackers FDM system at home, but because it takes up so much build volume, doing it on a local HP system would probably cost closer to $30. Too much to sell at a reasonable price if you want a healthy margin. Maybe this would be a good candidate for injection moulding—something to learn for next winter?

To view this video please enable JavaScript, and consider upgrading to a web browser that supports HTML5 video

Views: 3,817 Faves: 0 Comments: 0

AirTag Tube Strap Bracket

A simple tube strap bracket was one of the first things I made when I got a 3D printer, because Kaz was lamenting that there weren’t many good options at the time. I’m also a huge fan of Project 4AGZE's 3D printed AirTag holder, and have them on most of my bikes. It’s not a foolproof bike tracking system, but for a smash and grab it’s a nice bit of extra security. It’s also helpful when the airline loses your bike for weeks on end.

I’m also a huge fan of Project 4AGZE's 3D printed AirTag holder, and have them on most of my bikes. It’s not a foolproof bike tracking system, but for a smash and grab it’s a nice bit of extra security. It’s also helpful when the airline loses your bike for weeks on end.

I wanted something that didn’t look like an AirTag holder, and I wanted to keep a tube strap bracket on my bikes that only had one spare set of bottle mounts. So I smushed the two concepts together and landed on a two-piece design with a channel for a Voilé Nano strap to hold your tube. I designed it to look as invisible and understated as possible, and if you use security Torx bolts on it, I think it’s a reasonable way to slow down a would-be thief.

Ended up being fairly low key on the bike.

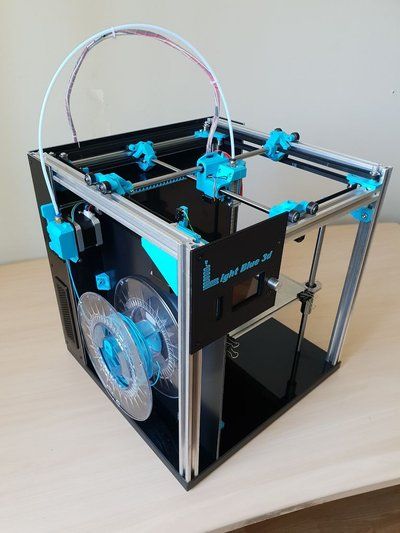

I had Tempus3D make a few with their multi-jet fusion HP machine. Love this finish.

Most of the design was fairly simple. I used a little labyrinth “seal” to resist water and I gave it a tiny draft angle to make the two sides fit together snugly. I experimented with some bigger, more symmetrical designs, but decided on keeping it as small as possible. It does work with standard 29” tubes, but works best with Schwalbe Aerothan or other ultralight tubes.

I experimented with some bigger, more symmetrical designs, but decided on keeping it as small as possible. It does work with standard 29” tubes, but works best with Schwalbe Aerothan or other ultralight tubes.

Added small cutouts to save weight and for smuggling emergency things, because apparently that's my niche now.

The toughest part for me was nailing the fit of the AirTag into the top half of the mount. I wanted it to snap into place solidly and had a design that consistently did that on my own MatterHackers setup, but I ended up liking the design enough that I sent it off to Tempus3D in Trail BC to get printed on their industrial HP setup. On that industrial printer I found there were tiny tolerance variations that made the fit inconsistent. Nobody thinks much about manufacturing variations when buying bike stuff, but we should. It’s been a big lesson for me that design manufacturability is as important as whether or not the unit we happen to be testing is perfect.

It wasn’t the HP printer’s fault that I couldn’t get a good fit, it was that my pretendgineered design required unrealistic tolerances. I put this problem out on Instagram, and got a flood of actual engineers generously sharing ideas with me. Again the solution was that “everything is a spring.” I tightened it up, gave it a reverse draft angle (there’s probably a better word?), and used fewer contact points. Now it’s perfect every time.

Details:

• 34g (with 9” Voilé Nano strap and AirTag, or 23g without AirTag)

• Bracket + AirTag + Aerothan tube is ~130g, which is ~110g lighter than a traditional bracket + AirTag + regular 29er tube. It’s safer and cheaper to save weight on accessories and mounts than tires and rims.

• Fits an Apple AirTag to keep track of your bike

• Works best with Aerothan and Tubolito style ultralight tubes

No STL download. I kind of want to do a small run of these too, but I haven't figured that out yet. They’re not cheap to have printed commercially and I’d probably need to sell them for ~$45 with the Voilé strap, which feels a bit high. On the other hand, that’s about the same as buying a separate AirTag holder and tube strap bracket.

They’re not cheap to have printed commercially and I’d probably need to sell them for ~$45 with the Voilé strap, which feels a bit high. On the other hand, that’s about the same as buying a separate AirTag holder and tube strap bracket.

For a more modular solution you could try Project 4AGZE’s 3D printed AirTag holder and see if it works under a traditional tube strap bracket. I really like 76 Projects's Micro Piggy, it’s a lot more low profile than most. And if you like, you can download my original tube strap bracket STL here.

Climb Switch High Performance System

This was originally a gift for Mike Levy that I spent way, way too much time on, and then enough people bugged me about getting one that I did a small production run of them. It stows a Mini BIC, one hitter, and material inside your steerer tube or pump via OneUp’s EDC standard. Of course I strongly condemn any impaired riding. This is for transport of legal things only, and if anyone asks, it’s officially a fire safety kit.

The hardest part about the design was finding a way to stuff a 22.2mm OD Mini BIC into a steerer tube. Even with the threaded OneUp system, there’s almost no space. Once I figured out how to package the lighter next to the one hitter and to have it pop out the back, I had to find a way for the lighter to snap into place. I used the sparkwheel at the top as a pivot and spring to add tension. It’s not 100% intuitive, but after the first time you do it it’s easy and satisfying. The screw-on compartment for material at the bottom was also super easy, especially once Cedric from Lal Bikes made some suggestions about chamfering the start of the threads.

I think these turned out pretty well.

Low key.

It took an embarrassing amount of trial and error to dial in the design, but once I nailed it I had Tempus3D do a small run of them with MJF and they turned out great. Since I was already doing the carriers in BC, I figured I should do the one hitters here too. Brian from Autmog makes very fancy pens on his lathe here in Vancouver. Their claim to fame is no post-processing or polishing, their stuff just comes fresh off his machines. I’m not much of a weedologist (weedographer?), so I actually had to get some user testing done before Autmog did a small run, but apparently they’re very good.

Brian from Autmog makes very fancy pens on his lathe here in Vancouver. Their claim to fame is no post-processing or polishing, their stuff just comes fresh off his machines. I’m not much of a weedologist (weedographer?), so I actually had to get some user testing done before Autmog did a small run, but apparently they’re very good.

Also fits into a OneUp pump.

link="https://www.w3.org/1999/xlink">

View this post on Instagram

A post shared by Brian Park (@brianpark4)

Production costs for the carrier, one hitter, O-rings, and shipping box ended up being slightly under $30 each to my door. I put them up for $69 USD + shipping on April 20th, and sold all 40 of them in a day and a half. Wild. Netting out ~$1500 profit was cool, but I definitely spent several hundred hours on this dumb thing because I don't know what I'm doing, so I made about half the Canadian minimum wage on it. Not about to quit my day job!

Not about to quit my day job!

I'm sure I could get costs down significantly if I went overseas, especially if I did huge volume production, but that kind of kills the point of all this iterative, small-run stuff for me. I’m not sure I’ll ever do another run, but if I do I’ll probably do it the same way as this first one.

Details:

• System weight is ~35g (including carrier, one hitter, and Mini BIC)

• Fits a standard Mini BIC lighter, custom one hitter, and material

• Nylon carrier is 3D printed using HP's multi-jet fusion tech

• 6061 one hitter is machined with no coatings or chemicals, and has fine holes

• Uses the OneUp EDC threaded top cap system only. *no affiliation with OneUp Components, but I did bring them some

• Inconspicuous and durable

I originally held a couple Climb Switches back in case I needed to replace any, but nobody’s had any issues so I may as well sell them. If you want to buy one I put the rest up on Etsy, just to try the platform. [UPDATE: they're all gone. If you want to get on a list of people to message if I ever make more, send me a DM on Pinkbike or Instagram with your email address.] For the record, Etsy sucks. They end up taking almost $15 for each sale, and I don’t think the platform brought me a single direct sale. I’ll probably sell through the ones I put on Etsy, and then if I ever do another run I’ll find a different system. Suggestions?

[UPDATE: they're all gone. If you want to get on a list of people to message if I ever make more, send me a DM on Pinkbike or Instagram with your email address.] For the record, Etsy sucks. They end up taking almost $15 for each sale, and I don’t think the platform brought me a single direct sale. I’ll probably sell through the ones I put on Etsy, and then if I ever do another run I’ll find a different system. Suggestions?

No STL download in case I ever make more. I should also mention there’s a cool Iozzo steerer tube one hitter thing worth checking out. It doesn’t need a OneUp threaded steerer and it’s a slick project.

To view this video please enable JavaScript, and consider upgrading to a web browser that supports HTML5 video

Views: 2,753 Faves: 3 Comments: 2

To view this video please enable JavaScript, and consider upgrading to a web browser that supports HTML5 video

Views: 2,712 Faves: 1 Comments: 2

I did this Ribbon Cage Nalgene side loader as a way to hold a boatload of water in a small front triangle. It was fun to learn about surface modelling but I'm not totally happy with it yet. It needs to be a little more rigid, and it'd be nice to bring the cost down. It's super annoying to print with so many supports on my home machine, and crazy expensive to print with MJF. Anyone have any suggestions?

It was fun to learn about surface modelling but I'm not totally happy with it yet. It needs to be a little more rigid, and it'd be nice to bring the cost down. It's super annoying to print with so many supports on my home machine, and crazy expensive to print with MJF. Anyone have any suggestions?

Downloads for some other things I've made:

• Original Nano tube strap bracket

• Raaw Madonna cable guide

• Tern GSD Strider bike rack

Final thoughts

One thing I’ve noticed is that engineers and makers are all incredibly generous with their time and ideas. Every time I post something up on my Instagram, people like Cedric from Lal Bikes, Brian from Autmog, Emory from Farside Components, the 5Dev crew, David from Matterhackers, North Shore Billet, Ben from OneUp, Em from WZRD, Ivan from Bjorn, OutsideBrendan, Trickstuff, and lots more have hit me up with ideas, suggestions, and encouragement. This whole community of people who make things is really welcoming and supportive of each other. That’s so damn cool.

That’s so damn cool.

Now you tell me, what should I make next? What would you improve on the next iterations of these designs? Should I do another of these stories sometime or are you altogether over my dorking out on additive manufacturing?

🚲 Best STL files 3D printed for Bike・Cults

🚲 Best STL files 3D printed for Bike

Download free Bike Accessories 3D files

Find out a selection of valve cap, mounts, holders and racks for your bike to make with a 3D printer. There are so many accessories for bikes and they can be really expensive, 3D printing is a great way to reduce the cost! 3D printing is also a great solution to invent ideas to make daily live on your bike easier.

Customizable Bike Mount for Modular Mounting System

Free

3D Printed Bike

Free

Wall Rack

Free

mountain bike wall mount

Free

GoPro bike mount

Free

Bicycle Water Bottle Cage

Free

Stand Phone For Bike

Free

Water Bottle Holder

Free

Pizza Valve Cap

Free

Stormtrooper Valve Cap

Free

Coffee Cup Holder

Free

Brompton logo tap

Free

Presta valve cap with thread _ Presta Cap valve with thread

Free

Smartphone Support Magnetic Bike

€0. 50

50

bike flashlight mount

Free

GoPro Handlebar Mount (customizable)

Free

MOUSQUETON

Free

Handelbar mount for Samsung S5 with wireless Qi charging - weather proof

Free

bike support go pro diameter 32 mm

Free

SR Suntour fork top cap socket (FAA122 replacement)

Free

Bike Light

Free

Triathlon extension

Free

Smartphone bike holder

Free

Bar-End bike Plugs

Free

Saddle mount for "Smart LED / Planet Bike" lights

Free

Bike FlashLight Quick Release Mount

Free

iPhone 6 Holder

Free

Draisienne bike (IKEA hack collection) by Andreas Bhend and Samuel N.

Bernier

BernierFree

The Bicycle Bubble Machine

Free

iPhone XS/6s Holder for GARMIN Mount (eTrex/Oregon/Colorado Series)

Free

Pinces pantalon pour le velo - Cycling Trouser Clips

Free

TUTUGO | Coffee Cup Valve Caps

Free

Mud Bike

Free

bike holder

Free

Fizik ICS Integrated Clip System Saddle adapter for Planet Bike / SMART Led Lights

Free

Clamping Knob For M8 Nut

Free

Deer Bike Rack

Free

iPhone 6 Plus Holder

Free

bike cleaning wheel

Free

Bead buddy for bicycle tire installation

Free

Bicycle Stand - 2 Part for use on the Road

Free

Graziella Back Light Mount

Free

Lightweight press-fit MTB handlebar plugs

Free

Yet Another Bicycle Flashlight Holder

Free

Beach umbrella holder for your bike

Free

Bike Attachment for iPhone 5, 4 and 4S

Free

GoPro clamp mount

Free

Bike Handlebar Cup Holder - Pint Glass or Coffee

Free

Here is our selection of the best STL files for Bike, all these accessories are from the 3D file library Cults and are perfectly 3D printable.

This collection includes free 3D files of Bike accessories. The numerous 3D models will adapt perfectly to all types of bike: Mountain bike, city bike or racing bike. No restriction on the type of bike so you can even modify the size or shape of the 3D files to fit the shape of your bike or its frame.

The 3D designers who propose their creations on the 3D file download platform Cults have therefore competed in ingenuity to facilitate your daily life on a bike. For example you can easily hook your phone to the handlebars, carry your water bottles or attach a GoPro on your bike. Once you get home, there are printable 3D solutions that will allow you to store your bike. You can even stand out by 3D printing customizations for your bike such as valve caps 3D printed in the shape of a pizza or a Lego man's head!

🚲 Best Bicycle 3D Printable STL Files・Cults

🚲 Best Bicycle 3D Printable STL Files

Free Download Bicycle Accessories 3D Files

A selection of valve covers, mounts, holders and racks for your bike that you can make with 3D printer. There are so many bike accessories out there and they can be very expensive, 3D printing is a great way to cut costs! 3D printing is also a great solution for inventing ideas that will make everyday life on your bike easier.

There are so many bike accessories out there and they can be very expensive, 3D printing is a great way to cut costs! 3D printing is also a great solution for inventing ideas that will make everyday life on your bike easier.

Customizable Bike Mount for Modular Mounting System

Free

3D Printed Bike

Free

Wall Rack

Free

mountain bike wall mount

Free

GoPro bike mount

Free

Bicycle water bottle cage

Free

Stand Phone For Bike

Free

Water Bottle Holder

Free

Pizza Valve Cap

Free

Stormtrooper Valve Cap

Free

Coffee Cup Holder

Free

Brompton logo tap

Free

Presta valve cap with thread _ Presta Cap valve with thread

Free

Smartphone Support Magnetic Bike

0,50 €

bike flashlight mount

Free

GoPro Handlebar Mount (customizable)

Free

MOUSQUETON

Free

Handelbar mount for Samsung S5 with wireless Qi charging - weather proof

Free

bike support go pro diameter 32 mm

Free

SR Suntour fork top cap socket (FAA122 replacement)

Free

Bike Light

Free

Triathlon extension

Free

Smartphone bike holder

Free

Bar-End bike Plugs

Free

Saddle mount for "Smart LED / Planet Bike" lights

Free

Bike FlashLight Quick Release Mount

Free

iPhone 6 Holder

Free

Draisienne bike (IKEA hack collection) by Andreas Bhend and Samuel N.

Bernier

Bernier Free

The Bicycle Bubble Machine

Free

iPhone XS/6s Holder for GARMIN Mount (eTrex/Oregon/Colorado Series)

Free

Pinces pantalon pour le velo - Cycling Trouser Clips

Free

TUTUGO | Coffee Cup Valve Caps

Free

Mud Bike

Free

bike holder

Free

Fizik ICS Integrated Clip System Saddle adapter for Planet Bike / SMART Led Lights

Free

Clamping Knob For M8 Nut

Free

Deer Bike Rack

Free

iPhone 6 Plus Holder

Free

bike cleaning wheel

Free

Bead buddy for bicycle tire installation

Free

Bicycle Stand - 2 Part for use on the Road

Free

Graziella Back Light Mount

Free

Lightweight press-fit MTB handlebar plugs

Free

Yet Another Bicycle Flashlight Holder

Free

Beach umbrella holder for your bike

Free

Bike Attachment for iPhone 5, 4 and 4S

Free

GoPro clamp mount

Free

Bike Handlebar Cup Holder - Pint Glass or Coffee

Free

Here is our selection of best stl files for bike, all these accessories are taken from 3D Cults library files and 3D printed beautifully .

This collection includes free 3D files of bicycle accessories. Numerous 3D models of are perfect for all types of bikes: mountain, city or racing bike . There are no restrictions on the type of bike, so you can even resize or reshape the 3D files to match the shape of your bike or frame.

So 3D designers offering their creations at 3D file upload platform Cults compete in ingenuity to make your daily life easier on the bike. For example, you can easily attach your phone to the handlebar, carry water bottles, or attach your GoPro to the bike. Once you get home, there are 3D printable solutions that will allow you to store your bike. You can even stand out by 3D printing custom decorations for your bike, like the 3D printed valve caps in the shape of a pizza or Lego man's head!

3D printing a bike on a 3D printer? Now it's real!

Feb52016

3D printing bicycle

Much has been said about the benefits and prospects of 3D printing for both large-scale production and the average consumer. 3D printers successfully print a variety of parts and components, interior items and exclusive objects. At the same time, the efforts of developers are aimed not only at improving the quality of printing and expanding the scope of its application, but also at increasing accessibility among the population. Everything is moving towards the fact that after some time 3D printers will be so popularized that they will become an ordinary piece of furniture for almost everyone.

3D printers successfully print a variety of parts and components, interior items and exclusive objects. At the same time, the efforts of developers are aimed not only at improving the quality of printing and expanding the scope of its application, but also at increasing accessibility among the population. Everything is moving towards the fact that after some time 3D printers will be so popularized that they will become an ordinary piece of furniture for almost everyone.

3D printing bike

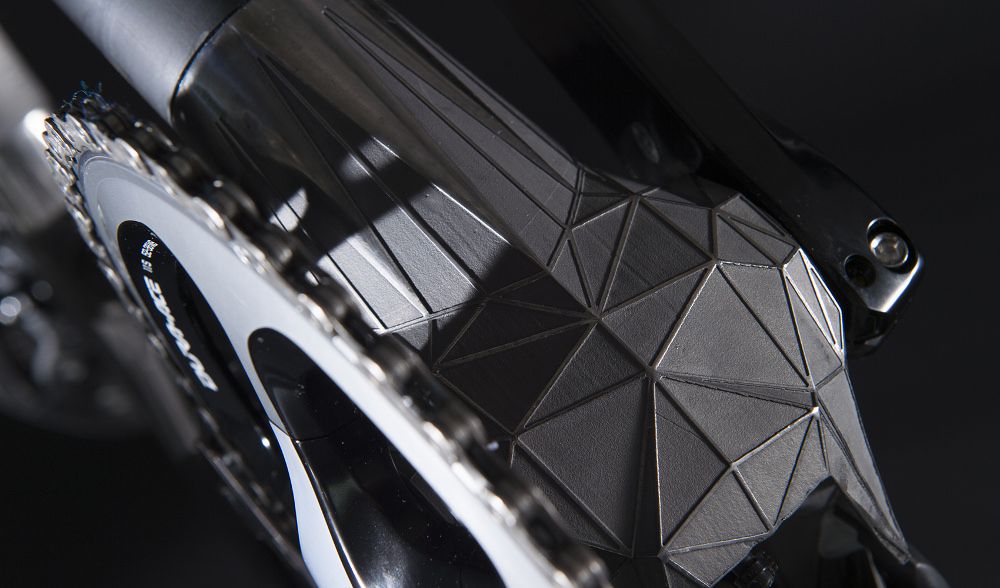

Along with the development of 3D printing itself, new and improved consumables are also being developed, thanks to which it becomes possible to start printing previously inaccessible objects. For example, ColorFabb, a major manufacturer of 3D printing composites, announced the invention of a new plastic fiber that will greatly expand the technology's capabilities. The firm presented material through 3D-printed parts for a racing bike. ColorFabb's intention was to demonstrate the ability of 3D printed components to be as affordable as they are durable and functional.

3D printed bike

“This bike concept was designed to demonstrate that a 3D printed racing bike could be produced on a conventional, commercially available 3D printer using new composite materials. The goal of the project was to use the bike in real life, under standard circumstances,” says the ColorFabb team. “We also want to bring 3D printing closer to the industry. This bike serves as an inspiration to other engineers, showing what can be done with 3D printing today and making your own project with this technique.”

3D printed bike

Using XT-CF20 carbon fiber, the team produced a bike with a reasonable weight and an extremely strong frame. XT-CF20 is a variety of Amphora's unique 3D resin, designed specifically for 3D printing. The team chose it to try and bring this bike concept to life due to its excellent stiffness and elongation ratios.

“The bike concept focuses on printing functional elements that will be subjected to mechanical stress,” the team explains.

3D printed bike

Due to time constraints, they decided to stop printing the bike entirely, and instead decided to print only the corners and then connect them to the pipes.

The benefits of the new material are truly enormous. It opens up a wide range of possibilities for design and development. In the future, everyone will be able to model a bike according to their own requirements and print a 3D model on their own 3D printer, which is a great solution, especially given the trend towards a reduction in the number of cars and the growing public interest in environmental conservation.

3D printed bicycle

The ColorFabb team has successfully tested the printed version of the bicycle and claims that it functions perfectly in all standard situations and is fully usable in everyday life.

“This is something completely new. From now on, everyone can print their own bike frames at home. With some SOLIDWORKS skills, you can also design your own customized version for improved ergonomics,” says development team member Steven Schurmann regarding the files that are available on Thingiverse, GrabCad, and YouMagine.