Wasp 3d print

WASP finishes 3D printing sustainable biomaterial-based ‘TECLA’ eco-habitat

0Shares

Italian 3D printer manufacturer WASP has completed the 3D printing phase in its construction of a unique eco-friendly organic house.

Nicknamed ‘TECLA,’ the fully-fabricated dwelling has been built using multiple systems at once, with each depositing natural materials into a unique supporting structure. The novel additive habitat, which was designed by Italian firm Mario Cucinella Architects, has been erected as a proof-of-concept, and a blueprint for a new sustainable housing model.

“The completion of the structure is an important milestone and shows that, thanks to the design and technologies used, TECLA is no longer just a theoretical idea,” said Mario Cucinella, the eponymous founder of Mario Cucinella Architects. “It can be a real and achievable response to the needs of living today and the future.”

“TECLA is the achievement of an unparalleled challenge that has brought the printing geometry to its physical limit.

”

WASP’s construction credentials

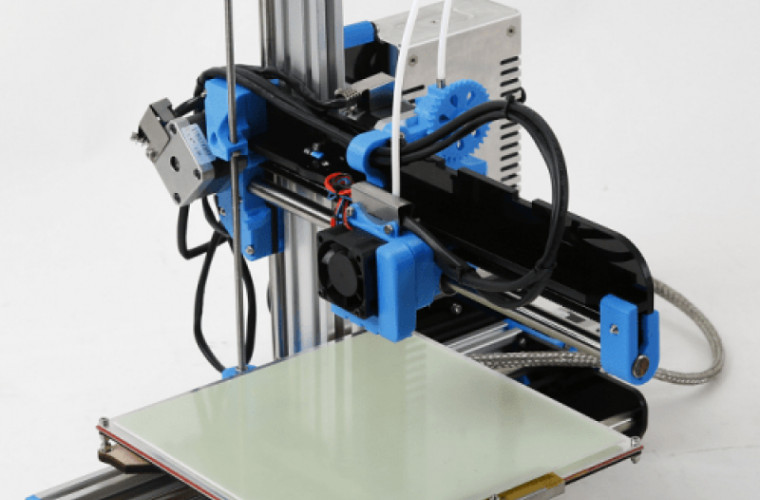

Founded in 2012, WASP (or the World’s Advanced Saving Project), is on a mission to develop digital fabrication processes that advance the principles of the circular economy. While the firm’s 3D printers have found orthopedic applications in the past, they’re more often utilized to create sustainable architecture.

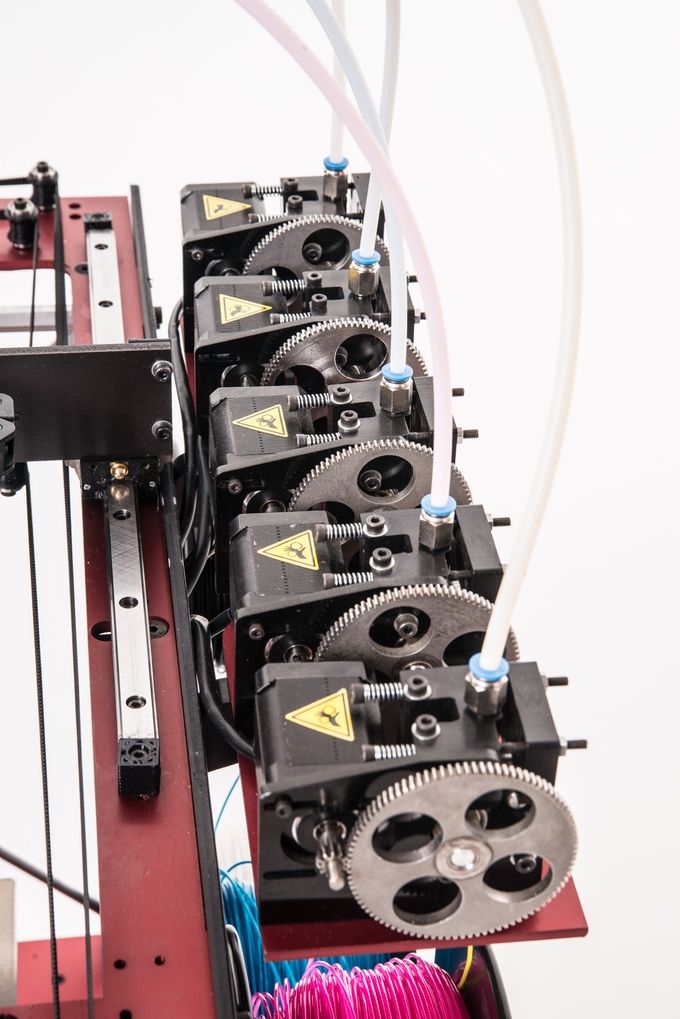

The company’s recently-launched machines include the production-oriented Delta WASP 4070 TECH and WASP 2040 systems, as well as the building-focused WASP 3MT CONCRETE. Over the last 18 months, WASP has also built a close partnership with Cucinella’s firm, in which it has sought to find construction applications for its proprietary technology.

In October 2019, the companies began planning the TECLA eco-house, based on research from architecture specialists at the School of Sustainability. WASP also worked alongside the Architectural Association School of Architecture, with the aim of identifying ways in which its technology could be used to tackle homelessness.

Putting these findings into action, the firm then collaborated with the Rossana Orlandi gallery, and utilized its multi-printer Crane WASP system to 3D print its ‘Gaia’ bio-building. The house’s casing was created using natural soil-based byproducts, and it took just ten days to print 20 square meters of wall that was 40cm thick.

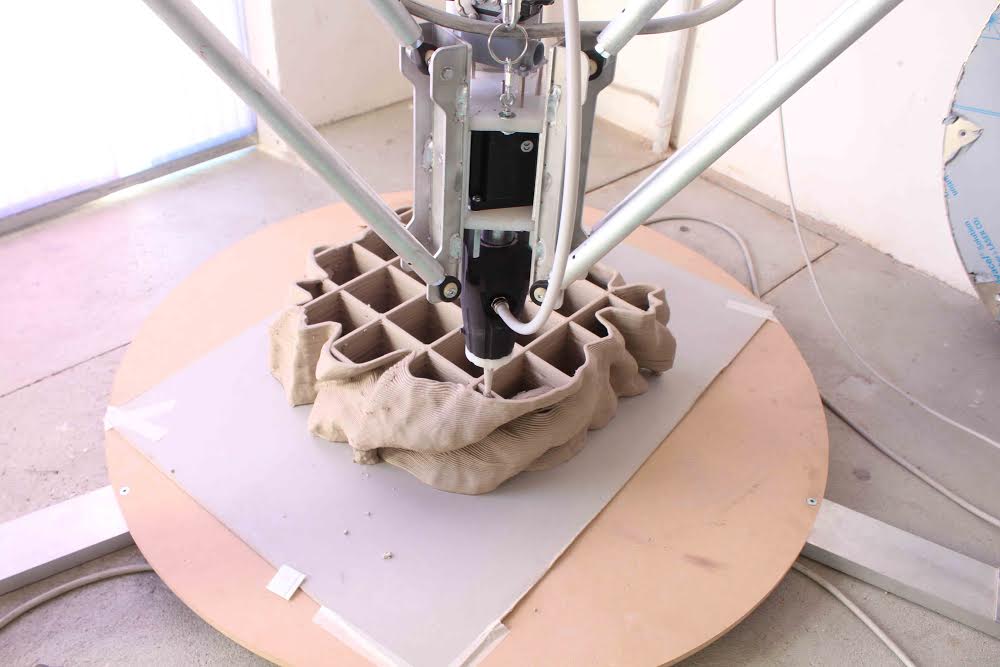

While WASP has completed the 3D printing phase of the TECLA building’s construction (pictured), it won’t be opened until later in 2021. Photo via WASP.3D printing a sustainable habitat

Building on the success of the Gaia, WASP has now teamed back up with Mario Cucincella to fabricate the TECLA using entirely-recyclable materials. The architects designed the TECLA (or technology and clay together) based on the research of its longstanding partners, and it’s currently being built in the Massa Lombarda region of Northern Italy.

The architects designed the TECLA (or technology and clay together) based on the research of its longstanding partners, and it’s currently being built in the Massa Lombarda region of Northern Italy.

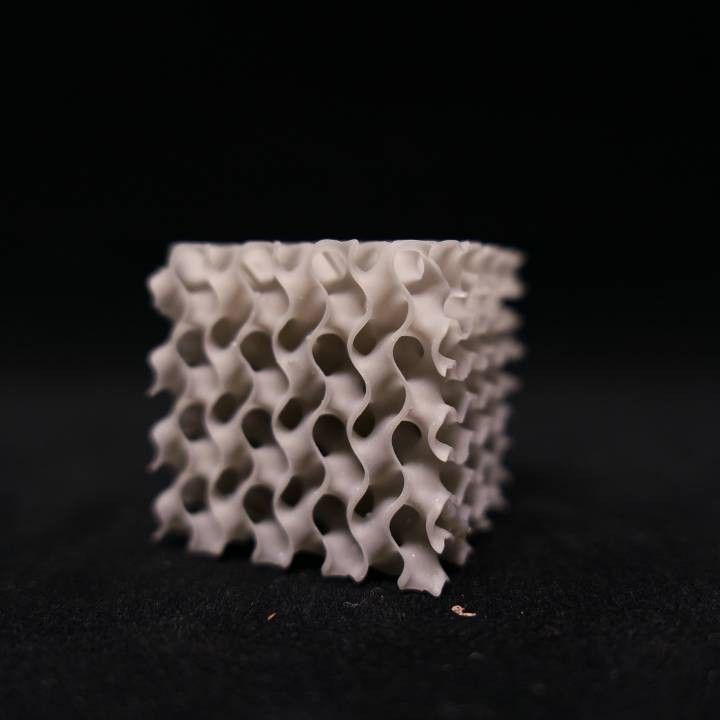

Essentially, TECLA is a self-supporting habitable structure, that can be fabricated by depositing layers of reusable and recyclable materials such as local soil, on top of one another. In theory, the resulting habitats are completely carbon-neutral, while being adaptable to any conceivable climate or conditions around the world.

“The project represents an unprecedented perspective for buildings and new settlements, in which the value of local raw materials is amplified by digital design.”

To turn the designers’ ideas into reality, WASP deployed several of its Crane 3D printers at once, which allowed it to minimize the amount of human intervention required during production. WASP’s automated approach also enabled it to maximise the process’ cost efficiency, while reducing its energy output, thus adding to its eco-friendly credentials.

During production, two synchronized printing arms, which were programmed not to collide into each other using custom software, were utilized to pick, mix and pump materials into layers. The firm’s simultaneous printing method ultimately enabled it to create dome-shaped buildings in 200 hours, using 60 cubic feet of material, and just 6kw of energy.

Although the 3D printing stage of the project is now complete, the sustainable buildings won’t be fully-installed and formally opened until later in spring 2021.

Scaling new additive heights

Over the past 12 months, a number of other firms have also leveraged construction 3D printers as a means of fabricating increasingly large, detailed and more ambitious buildings.

German construction firm PERI Group has even started 3D printing a three-storey apartment building. Although COBOD’s technology is behind the project, which in itself isn’t novel, the structure is unique in that its five constituent apartments will be rented out commercially once finished.

ICON, which is also one of 3D printing’s better-established construction companies, has also fabricated several buildings, including a fully-3D printed housing community. Using its Vulcan II system, the firm has collaborated with homelessness charity New Story to create multiple homes, with some as big as 2,000 sq. ft.

Elsewhere, firms such as Mighty Buildings have developed prefab 3D printed housing units. Currently, the firm offers pre-made kits measuring between 865 and 1440 sq. foot, but in future it aims to provide the technology to clients, allowing them to build more enterprising structures.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows WASP’s 3D printed TECLA eco-building from above. Photo via WASP.

Tags Architectural Association School of Architecture COBOD icon Mario Cucinella Mario Cucinella Architects Mighty Buildings New Story PERI Group Rossana Orlandi gallery School of Sustainability TECLA wasp

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

Wasp-inspired drones can 3D print a building

- Nature Video

Teams of aerial robots mounted with 3D printers could work together to build emergency shelters and greener homes.

- Shamini Bundell

- Shamini Bundell

View author publications

You can also search for this author in PubMed Google Scholar

You have full access to this article via your institution.

Download PDF

https://www.youtube.com/watch?v=pDKNEO0gDuE

Researchers have mounted 3D printers onto drones with the aim of creating swarms of robots that could 3D print entire buildings. The aerial vehicles were specially designed to be able to deposit a cement-like material with enough precision to build tall structures. Groups of them together could do the job even faster. The idea is that 3D printed shelters could be greener than standard construction methods, and drones could be useful in reaching difficult to access areas.

Read the paper: https://www.nature.com/articles/s41586-022-04988-4

For more stories like these sign up for the Nature Briefing: An essential round-up of science news, opinion and analysis, free in your inbox every weekday.

doi: https://doi.org/10.1038/d41586-022-03012-z

-

Making a microscopic swarm move through a maze

-

Birds gliding through bubbles reveal aerodynamic trick

-

March of the microscopic robots

-

How flying snakes stay stable while gliding through the air

-

Watch this shape-shifting magnetic material catch a ball on command

-

How cuttlefish wear their thoughts on their skin

-

New 3D printer makes multi-material robots

Subjects

- Physics

- Zoology

- Materials science

Latest on:

Jobs

-

Postdoctoral Position (m/f/div) in Advanced Tumoroid Biology

Ludwig Maximilians University of Munich (LMU)

Munich, Bavaria, Germany

-

MSCA PhD fellow in Developing Efficient Methods for an Accurate Energy Ranking of Molecular Crystals

University of Luxembourg

Luxembourg, Luxembourg

-

Full Professorship (W3) for ‘Primary Cancer Prevention’ (f/m/d)

German Cancer Research Center in the Helmholtz Association (DKFZ)

Heidelberg, Germany

-

Full Professorship (W3, endowed professorship) for ‘Molecular Cancer Prevention’ (f/m/d)

German Cancer Research Center in the Helmholtz Association (DKFZ)

Heidelberg, Germany

build an eco-house like a potter's wasp

3D print: build an eco-house like a potter's wasp

It looks like a sea urchin shell. But in fact, another animal provided the template for Tecla, an eco-house that can be built with 3D printing: its design is centered on the nest of a pottery wasp that places its eggs in a globular clay house, which they place on branches or walls erected .

But in fact, another animal provided the template for Tecla, an eco-house that can be built with 3D printing: its design is centered on the nest of a pottery wasp that places its eggs in a globular clay house, which they place on branches or walls erected .

Pottery wasp nest.

Tecla, Visualization

Prefabricated buildings from a bird's eye view.

Tecla under construction

The outer and inner domes were built at the same time.

The project is a collaboration between Italian 3D printing company Wasp and Mario Cucinella Architects.

As for the tiny wasps, 3D printing at home also uses fabric from its immediate environment: the earth. As such, according to its creators, it is "composed entirely of reusable and recyclable materials". They were carbon neutral, adapted to any climate and any location setting. In addition, the house is designed in such a way that it can stand on its own or be combined into larger formations depending on the needs.

One construction site, several 3D printers

Currently located in Massa Lombarda, near Ravenna, Tecla prototype is realized. 3D printing work has recently been completed. They built a small house with several 3D printers that worked simultaneously. Since the structure consists of an outer and an inner dome, the load-bearing structure, roof and shell can be implemented in parallel.

According to a joint media announcement between the company and the architects, Wasp 3D printers can move over an area of 50 meters. Therefore, it was possible to print structures in any form within a few days.

If everything goes according to plan, the cottage will be completed this spring3D printing: build an eco-house like a potter's wasp

It looks like a sea urchin shell. But in fact, another animal provided the template for Tecla, an eco-house that can be built with 3D printing: its design is centered on the nest of a pottery wasp that places its eggs in a globular clay house, which they place on branches or walls erected .

Pottery wasp nest.

Tecla, Rendering

Bird's eye view of completed buildings.

Tecla under construction

The outer and inner domes were built at the same time.

The project is a collaboration between Italian 3D printing company Wasp and Mario Cucinella Architects.

As for the tiny wasps, 3D printing at home also uses fabric from its immediate environment: the earth. As such, according to its creators, it is "composed entirely of reusable and recyclable materials". They were carbon neutral, adapted to any climate and any location setting. In addition, the house is designed in such a way that it can stand on its own or be combined into larger formations depending on the needs.

One construction site, several 3D printers

Currently located in Massa Lombarda, near Ravenna, Tecla prototype is realized. 3D printing work has recently been completed. They built a small house with several 3D printers that worked simultaneously. Since the structure consists of an outer and an inner dome, the load-bearing structure, roof and shell can be implemented in parallel.

Since the structure consists of an outer and an inner dome, the load-bearing structure, roof and shell can be implemented in parallel.

According to a joint media announcement between the company and the architects, Wasp 3D printers can move over an area of 50 meters. Therefore, it was possible to print structures in any form within a few days.

If everything goes according to plan, the cottage will be completed this spring

3D printing: build an eco-house like a potter's wasp

It looks like a sea urchin shell. But in fact, another animal provided the template for Tecla, an eco-house that can be built with 3D printing: its design is centered on the nest of a pottery wasp that places its eggs in a globular clay house, which they place on branches or walls erected .

Pottery wasp nest.

Tecla, Rendering

Bird's eye view of completed buildings.

Tecla under construction

The outer and inner domes were built at the same time.

The project is a collaboration between Italian 3D printing company Wasp and Mario Cucinella Architects.

As for the tiny wasps, 3D printing at home also uses fabric from its immediate environment: the earth. As such, according to its creators, it is "composed entirely of reusable and recyclable materials". They were carbon neutral, adapted to any climate and any location setting. In addition, the house is designed in such a way that it can stand on its own or be combined into larger formations depending on the needs.

One construction site, several 3D printers

Currently located in Massa Lombarda, near Ravenna, Tecla prototype is realized. 3D printing work has recently been completed. They built a small house with several 3D printers that worked simultaneously. Since the structure consists of an outer and an inner dome, the load-bearing structure, roof and shell can be implemented in parallel.

According to a joint media announcement between the company and the architects, Wasp 3D printers can move over an area of 50 meters. Therefore, it was possible to print structures in any form within a few days.

Therefore, it was possible to print structures in any form within a few days.

If everything goes according to plan, the cottage will be completed this spring3D printing: build an eco-house like a potter's wasp

Teaserbild-Quelle: Mario Cucinell Architects / WASP

It looks like a sea urchin shell. But in fact, another animal provided the template for Tecla, an eco-house that can be built with 3D printing: its design is centered on the nest of a pottery wasp that places its eggs in a globular clay house, which they place on branches or walls erected .

Pottery wasp nest.

Tecla, Rendering

Bird's eye view of completed buildings.

Tecla under construction

The outer and inner domes were built at the same time.

The project is a collaboration between Italian 3D printing company Wasp and Mario Cucinella Architects.

As for the tiny wasps, 3D printing at home also uses fabric from its immediate environment: the earth. As such, according to its creators, it is "composed entirely of reusable and recyclable materials". They were carbon neutral, adapted to any climate and any location setting. In addition, the house is designed in such a way that it can stand on its own or be combined into larger formations depending on the needs.

As such, according to its creators, it is "composed entirely of reusable and recyclable materials". They were carbon neutral, adapted to any climate and any location setting. In addition, the house is designed in such a way that it can stand on its own or be combined into larger formations depending on the needs.

One construction site, several 3D printers

Currently located in Massa Lombarda, near Ravenna, Tecla prototype is realized. 3D printing work has recently been completed. They built a small house with several 3D printers that worked simultaneously. Since the structure consists of an outer and an inner dome, the load-bearing structure, roof and shell can be implemented in parallel.

According to a joint media announcement between the company and the architects, Wasp 3D printers can move over an area of 50 meters. Therefore, it was possible to print structures in any form within a few days.

If all goes according to plan, the cottage will be completed this spring

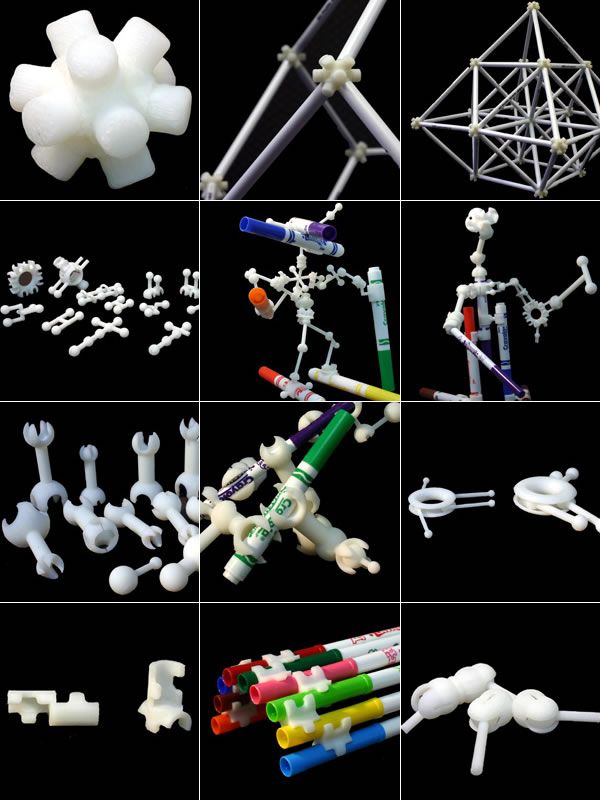

OCA Ventures and Kaplan bet on 3D printing

A group of Chicago-based investors and entrepreneurs is committed to helping US manufacturers start using 3D printing in manufacturing.

OCA Ventures and several angel investors invest $2.8 million in Impossible Objects, a 3D printing startup led by former Navteq CEO Larry Kaplan. The Northbrook-based company is developing new 3D manufacturing techniques using technology developed by serial entrepreneur Robert Schwartz.

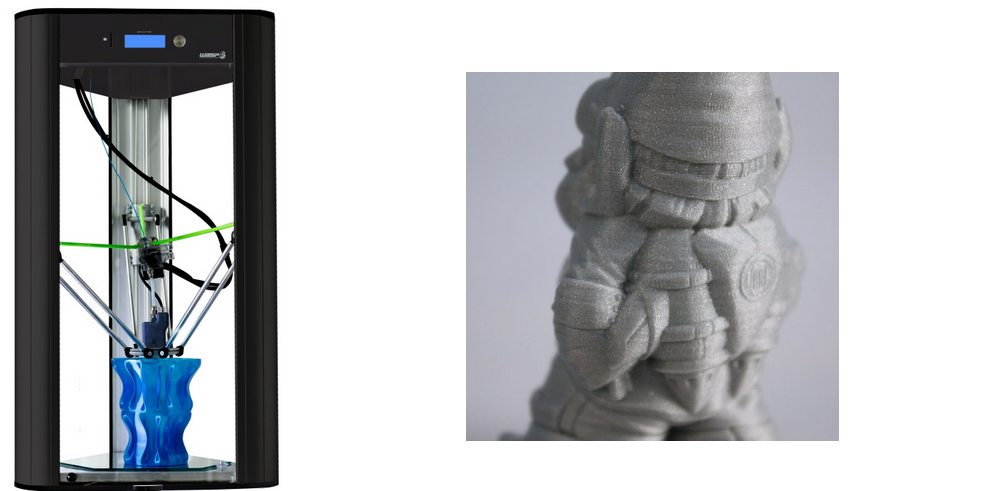

"Technology used today is 20 years old," says Kaplan, 51, who left Chicago-based Navteq after it was sold to Nokia. "They're great for prototyping, but too slow for mass production."

"Parts produced using 3D technology were not as good as those created using the traditional production method. In order to change production, it is necessary to overcome the problems of 3D printing products, namely: increase the speed of creation, use a wider range of materials with excellent physical and mechanical properties".

The company, which currently employs five people, already manufactures some items for several customers, including small aircraft parts and turbine impeller blades in materials such as carbon fibre, Kevlar and fiberglass. But the company's long-term goal is to sell equipment and materials to manufacturers who, with the help of this equipment, will produce goods themselves. The company's work is focused on industries such as aerospace, automotive and medical sectors that already work with composites.

But the company's long-term goal is to sell equipment and materials to manufacturers who, with the help of this equipment, will produce goods themselves. The company's work is focused on industries such as aerospace, automotive and medical sectors that already work with composites.

Schwartz, who previously ran the family business and later founded a company that licensed software to Intel, is an MIT laboratory advisor. He started working on 3D printing technologies five years ago.

"I met Bob a couple of years ago," said Kaplan, who also served as an advisor to the OCA and worked with Eudora, an asset management company headquartered in New York. - "I was very pleased with our cooperation with him, and gradually the situation developed in such a way that we became interested in working together. It was the most interesting thing that I saw during my time at Navteq."

However, a 3D business is a long-term business. The development of new technology, in particular, production equipment, is an extremely expensive undertaking. But the OCA, which recently launched its $100 million fundraising program, has made such big and risky bets before. Previously, the company became one of the contributors to Chicago-based Cleversafe, which developed a new technology for data transmission and storage.

But the OCA, which recently launched its $100 million fundraising program, has made such big and risky bets before. Previously, the company became one of the contributors to Chicago-based Cleversafe, which developed a new technology for data transmission and storage.

Other investors in Impossible Objects also include Armando Pauker, partner at Apex Venture Partners in Chicago, and Len Wagner, managing partner at Deer Valley Ventures in Park City, Utah.

One potential asset for Impossible Objects could be UI Labs, which is developing next-generation manufacturing technologies at its Institute for Digital Manufacturing and Design Innovation on Chicago's Goose Island.

While 3D printing is best known as a DIY manufacturing method and prototyping tool, several other companies such as Stratasys in Minnesota and 3D Systems in Rock Hill, South Carolina are already doing 3D equipment for production purposes.

"Repeatability and reliability in 3D technologies should be addressed," says Federico Sciammarella, assistant professor of mechanical engineering at Northern Illinois University in DeKalb.