The 3d printer

What is 3D printing? How does a 3D printer work? Learn 3D printing

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine.

3D printing enables you to produce complex shapes using less material than traditional manufacturing methods.

Table of Contents

- How Does 3D Printing Work?

- 3D Printing Industry

- Examples of 3D Printing

- 3D Printing Technologies & Processes

- Materials

- Services

Jump to your field of interest:

- Rapid Prototyping & Manufacturing

- Automotive

- Aviation

- Construction

- Consumer Products

- Healthcare

- Food

- Education

Jump to process:

- All Technologies & Processes

- Vat Photopolymerisation

- Material Jetting

- Binder Jetting

- Material Extrusion

- Powder Bed Fusion

- Sheet Lamination

- Directed Energy Deposition

How Does 3D Printing Work?

It all starts with a 3D model. You can opt to create one from the ground up or download it from a 3D library.

3D Software

There are many different software tools available. From industrial grade to open source. We’ve created an overview on our 3D software page.

We often recommend beginners to start with Tinkercad. Tinkercad is free and works in your browser, you don’t have to install it on your computer. Tinkercad offers beginner lessons and has a built-in feature to export your model as a printable file e.g .STL or .OBJ.

Now that you have a printable file, the next step is to prepare it for your 3D printer. This is called slicing.

Slicing: From printable file to 3D Printer

Slicing basically means slicing up a 3D model into hundreds or thousands of layers and is done with slicing software.

When your file is sliced, it’s ready for your 3D printer. Feeding the file to your printer can be done via USB, SD or Wi-Fi. Your sliced file is now ready to be 3D printed layer by layer.

3D Printing Industry

Adoption of 3D printing has reached critical mass as those who have yet to integrate additive manufacturing somewhere in their supply chain are now part of an ever-shrinking minority. Where 3D printing was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology.

Most of the current demand for 3D printing is industrial in nature. Acumen Research and Consulting forecasts the global 3D printing market to reach $41 billion by 2026.

As it evolves, 3D printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.

Examples of 3D Printing

3D printing encompasses many forms of technologies and materials as 3D printing is being used in almost all industries you could think of. It’s important to see it as a cluster of diverse industries with a myriad of different applications.

A few examples:

- – consumer products (eyewear, footwear, design, furniture)

- – industrial products (manufacturing tools, prototypes, functional end-use parts)

- – dental products

- – prosthetics

- – architectural scale models & maquettes

- – reconstructing fossils

- – replicating ancient artefacts

- – reconstructing evidence in forensic pathology

- – movie props

Rapid Prototyping & Rapid Manufacturing

Companies have used 3D printers in their design process to create prototypes since the late seventies. Using 3D printers for these purposes is called rapid prototyping.

Using 3D printers for these purposes is called rapid prototyping.

Why use 3D Printers for Rapid Prototyping?

In short: it’s fast and relatively cheap. From idea, to 3D model to holding a prototype in your hands is a matter of days instead of weeks. Iterations are easier and cheaper to make and you don’t need expensive molds or tools.

Besides rapid prototyping, 3D printing is also used for rapid manufacturing. Rapid manufacturing is a new method of manufacturing where businesses use 3D printers for short run / small batch custom manufacturing.

Automotive

Car manufacturers have been utilizing 3D printing for a long time. Automotive companies are printing spare parts, tools, jigs and fixtures but also end-use parts. 3D printing has enabled on-demand manufacturing which has lead to lower stock levels and has shortened design and production cycles.

Automotive enthusiasts all over the world are using 3D printed parts to restore old cars. One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

Aviation

The aviation industry uses 3D printing in many different ways. The following example marks a significant 3D printing manufacturing milestone: GE Aviation has 3D printed 30,000 Cobalt-chrome fuel nozzles for its LEAP aircraft engines. They achieved that milestone in October of 2018, and considering that they produce 600 per week on forty 3D printers, it’s likely much higher than that now.

Around twenty individual parts that previously had to be welded together were consolidated into one 3D printed component that weighs 25% less and is five times stronger. The LEAP engine is the best selling engine in the aerospace industry due to its high level of efficiency and GE saves $3 million per aircraft by 3D printing the fuel nozzles, so this single 3D printed part generates hundreds of millions of dollars of financial benefit.

GE’s fuel nozzles also made their way into the Boeing 787 Dreamliner, but it’s not the only 3D printed part in the 787. The 33-centimeter-long structural fittings that hold the aft kitchen galley to the airframe are 3D printed by a company called Norsk Titanium. Norsk chose to specialize in titanium because it has a very high strength-to-weight ratio and is rather expensive, meaning the reduction in waste enabled by 3D printing has a more significant financial impact than compared to cheaper metals where the costs of material waste are easier to absorb. Rather than sintering metal powder with a laser like most metal 3D printers, the Norsk Merke 4 uses a plasma arc to melt a metal wire in a process called Rapid Plasma Deposition (a form of Directed Energy Deposition) that can deposit up to 10kg of titanium per hour. A 2kg titanium part would generally require a 30kg block of titanium to machine it from, generating 28kg of waste, but 3D printing the same part requires only 6kg of titanium wire.

A 2kg titanium part would generally require a 30kg block of titanium to machine it from, generating 28kg of waste, but 3D printing the same part requires only 6kg of titanium wire.

Construction

Is it possible to print a building? – yes it is. 3D printed houses are already commercially available. Some companies print parts prefab and others do it on-site.

Most of the concrete printing stories we look at on this website are focused on large scale concrete printing systems with fairly large nozzles for a large flow rate. It’s great for laying down concrete layers in a fairly quick and repeatable manner. But for truly intricate concrete work that makes full use of the capabilities of 3D printing requires something a little more nimble, and with a finer touch.

Consumer Products

When we first started blogging about 3D printing back in 2011, 3D printing wasn’t ready to be used as a production method for large volumes. Nowadays there are numerous examples of end-use 3D printed consumer products.

Footwear

Adidas’ 4D range has a fully 3D printed midsole and is being printed in large volumes. We did an article back then, explaining how Adidas were initially releasing just 5,000 pairs of the shoes to the public, and had aimed to sell 100,000 pairs of the AM-infused designs by 2018.

With their latest iterations of the shoe, it seems that they have surpassed that goal, or are on their way to surpassing it. The shoes are available all around the world from local Adidas stores and also from various 3rd party online outlets.

Eyewear

The market of 3D printed eyewear is forecasted to reach $3.4 billion by 2028. A rapidly increasing section is that of end-use frames. 3D printing is a particularly suitable production method for eyewear frames because the measurements of an individual are easy to process in the end product.

But did you know it’s also possible to 3D print lenses? Traditional glass lenses don’t start out thin and light; they’re cut from a much larger block of material called a blank, about 80% of which goes to waste. When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

Jewelry

There are two ways of producing jewelry with a 3D printer. You can either use a direct or indirect production process. Direct refers to the creation of an object straight from the 3D design while indirect manufacturing means that the object (pattern) that is 3D printed eventually is used to create a mold for investment casting.

Healthcare

It’s not uncommon these days to see headlines about 3D printed implants. Often, those cases are experimental, which can make it seem like 3D printing is still a fringe technology in the medical and healthcare sectors, but that’s not the case anymore. Over the last decade, more than 100,000 hip replacements have been 3D printed by GE Additive.

The Delta-TT Cup designed by Dr. Guido Grappiolo and LimaCorporate is made of Trabecular Titanium, which is characterized by a regular, three-dimensional, hexagonal cell structure that imitates trabecular bone morphology. The trabecular structure increases the biocompatibility of the titanium by encouraging bone growth into the implant. Some of the first Delta-TT implants are still running strong over a decade later.

Another 3D printed healthcare component that does a good job of being undetectable is the hearing aid. Nearly every hearing aid in the last 17 years has been 3D printed thanks to a collaboration between Materialise and Phonak. Phonak developed Rapid Shell Modeling (RSM) in 2001. Prior to RSM, making one hearing aid required nine laborious steps involving hand sculpting and mold making, and the results were often ill-fitting. With RSM, a technician uses silicone to take an impression of the ear canal, that impression is 3D scanned, and after some minor tweaking the model is 3D printed with a resin 3D printer. The electronics are added and then it’s shipped to the user. Using this process, hundreds of thousands of hearing aids are 3D printed each year.

Phonak developed Rapid Shell Modeling (RSM) in 2001. Prior to RSM, making one hearing aid required nine laborious steps involving hand sculpting and mold making, and the results were often ill-fitting. With RSM, a technician uses silicone to take an impression of the ear canal, that impression is 3D scanned, and after some minor tweaking the model is 3D printed with a resin 3D printer. The electronics are added and then it’s shipped to the user. Using this process, hundreds of thousands of hearing aids are 3D printed each year.

Dental

In the dental industry, we see molds for clear aligners being possibly the most 3D printed objects in the world. Currently, the molds are 3D printed with both resin and powder based 3D printing processes, but also via material jetting. Crowns and dentures are already directly 3D printed, along with surgical guides.

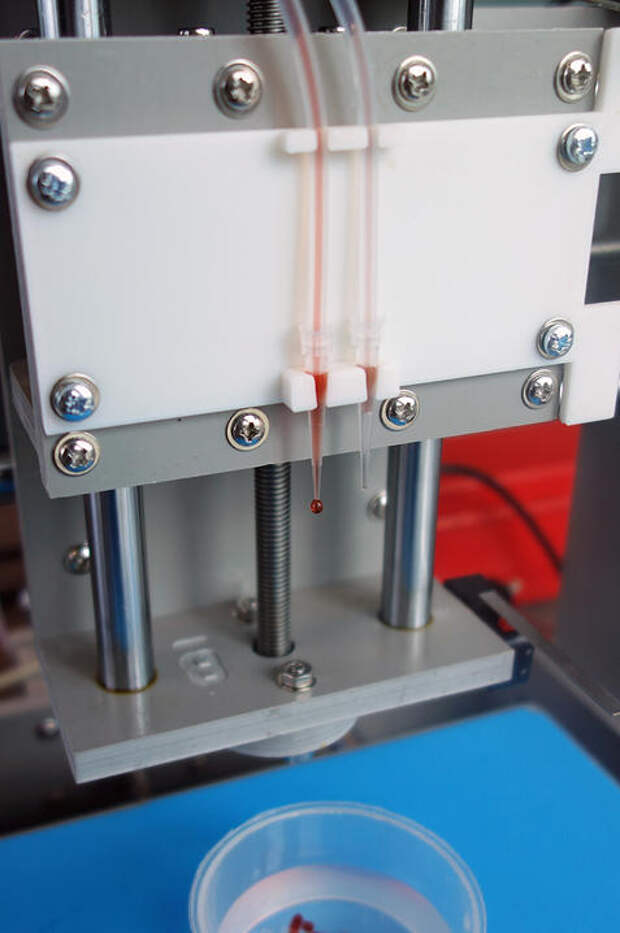

Bio-printing

As of the early two-thousands 3D printing technology has been studied by biotech firms and academia for possible use in tissue engineering applications where organs and body parts are built using inkjet techniques. Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Food

Additive manufacturing invaded the food industry long time ago. Restaurants like Food Ink and Melisse use this as a unique selling point to attract customers from across the world.

Education

Educators and students have long been using 3D printers in the classroom. 3D printing enables students to materialize their ideas in a fast and affordable way.

While additive manufacturing-specific degrees are fairly new, universities have long been using 3D printers in other disciplines. There are many educational courses one can take to engage with 3D printing. Universities offer courses on things that are adjacent to 3D printing like CAD and 3D design, which can be applied to 3D printing at a certain stage.

In terms of prototyping, many university programs are turning to printers. There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

Types of 3D Printing Technologies and Processes

The American Society for Testing and Materials (ASTM), developed a set of standards that classify additive manufacturing processes into 7 categories. These are:

- Vat Photopolymerisation

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Liquid Interface Production (CLIP)

- Material Jetting

- Binder Jetting

- Material Extrusion

- Fused Deposition Modeling (FDM)

- Fused Filament Fabrication (FFF)

- Powder Bed Fusion

- Multi Jet Fusion (MJF)

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- Sheet Lamination

- Directed Energy Deposition

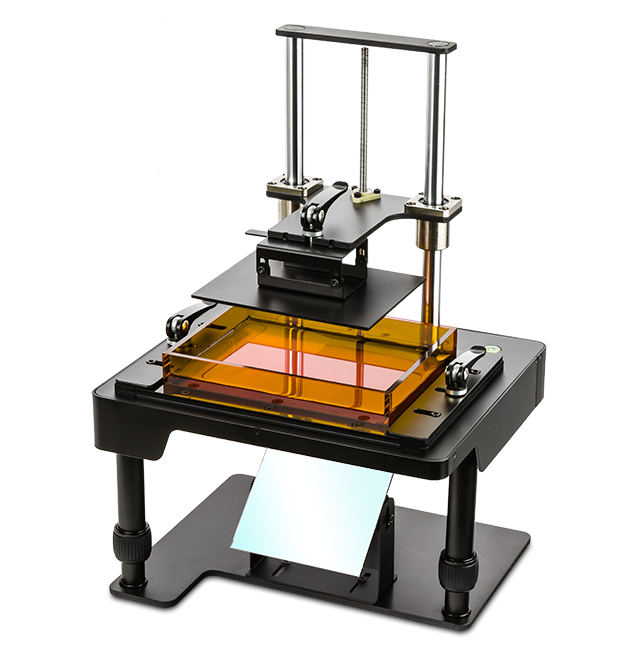

Vat Photopolymerisation

A 3D printer based on the Vat Photopolymerisation method has a container filled with photopolymer resin. The resin is hardened with a UV light source.

The resin is hardened with a UV light source.

Stereolithography (SLA)

SLA was invented in 1986 by Charles Hull, who also at the time founded the company, 3D Systems. Stereolithography employs a vat of liquid curable photopolymer resin and an ultraviolet laser to build the object’s layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and fuses it to the layer below.

After the pattern has been traced, the SLA’s elevator platform descends by a distance equal to the thickness of a single layer, typically 0.05 mm to 0.15 mm (0.002″ to 0.006″). Then, a resin-filled blade sweeps across the cross section of the part, re-coating it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, joining the previous layer. Depending on the object & print orientation, SLA often requires the use of support structures.

Depending on the object & print orientation, SLA often requires the use of support structures.

Digital Light Processing (DLP)

DLP or Digital Light Processing refers to a method of printing that makes use of light and photosensitive polymers. While it is very similar to SLA, the key difference is the light source. DLP utilizes other light sources like arc lamps. DLP is relatively quick compared to other 3D printing technologies.

Continuous Liquid Interface Production (CLIP)

One of the fastest processes using Vat Photopolymerisation is called CLIP, short for Continuous Liquid Interface Production, developed by Carbon.

Digital Light Synthesis

The heart of the CLIP process is Digital Light Synthesis technology. In this technology, light from a custom high performance LED light engine projects a sequence of UV images exposing a cross section of the 3D printed part causing the UV curable resin to partially cure in a precisely controlled way. Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Simply printing with Carbon’s hardware alone does not allow for end use properties with real world applications. Once the light has shaped the part, a second programmable curing process achieves the desired mechanical properties by baking the 3d printed part in a thermal bath or oven. Programmed thermal curing sets the mechanical properties by triggering a secondary chemical reaction causing the material to strengthen achieving the desired final properties.

Components printed with Carbon’s technology are on par with injection molded parts. Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Material Jetting

In this process, material is applied in droplets through a small diameter nozzle, similar to the way a common inkjet paper printer works, but it is applied layer-by-layer to a build platform and then hardened by UV light.

Material Jetting schematics. Image source: custompartnet.comBinder Jetting

With binder jetting two materials are used: powder base material and a liquid binder. In the build chamber, powder is spread in equal layers and binder is applied through jet nozzles that “glue” the powder particles in the required shape. After the print is finished, the remaining powder is cleaned off which often can be re-used printing the next object. This technology was first developed at the Massachusetts Institute of Technology in 1993.

Binder Jetting schematicsMaterial Extrusion

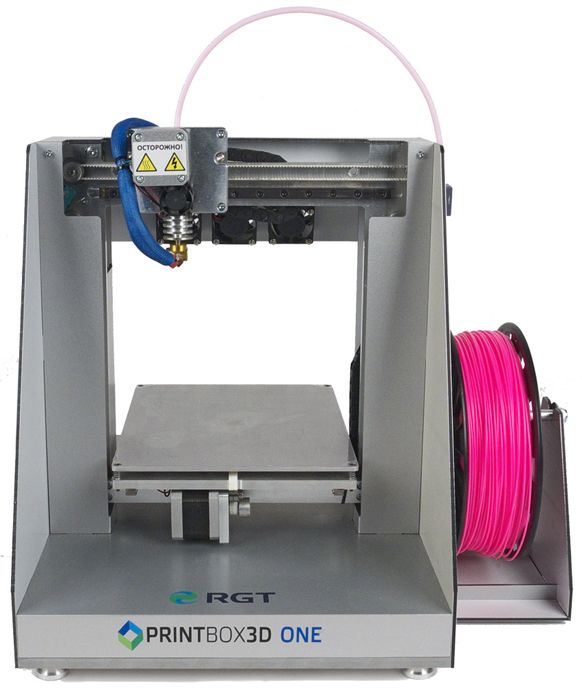

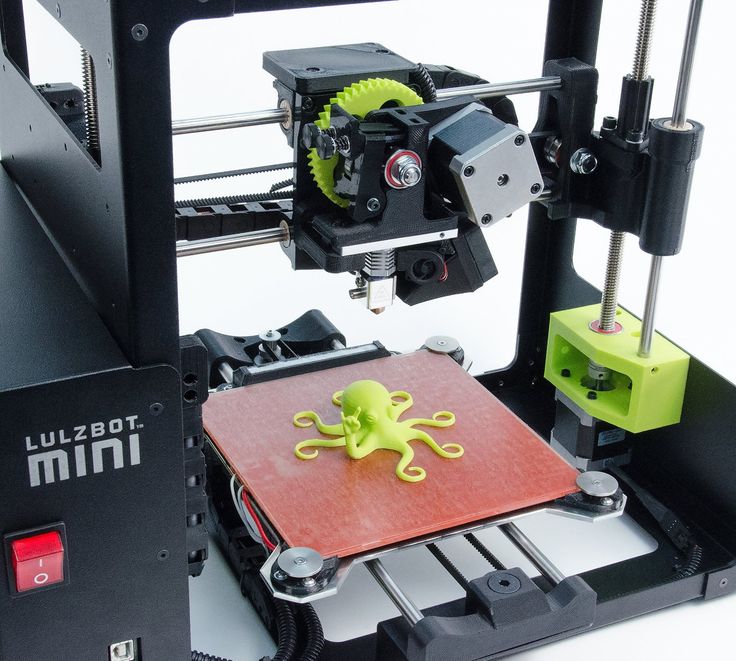

Fused Deposition Modeling (FDM)

FDM schematics (Image credit: Wikipedia, made by user Zureks)FDM works using a plastic filament which is unwound from a spool and is supplied to an extrusion nozzle which can turn the flow on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

FDM was invented by Scott Crump in the late 80’s. After patenting this technology he started the company Stratasys in 1988. The term Fused Deposition Modeling and its abbreviation to FDM are trademarked by Stratasys Inc.

Fused Filament Fabrication (FFF)

The exactly equivalent term, Fused Filament Fabrication (FFF), was coined by the members of the RepRap project to give a phrase that would be legally unconstrained in its use.

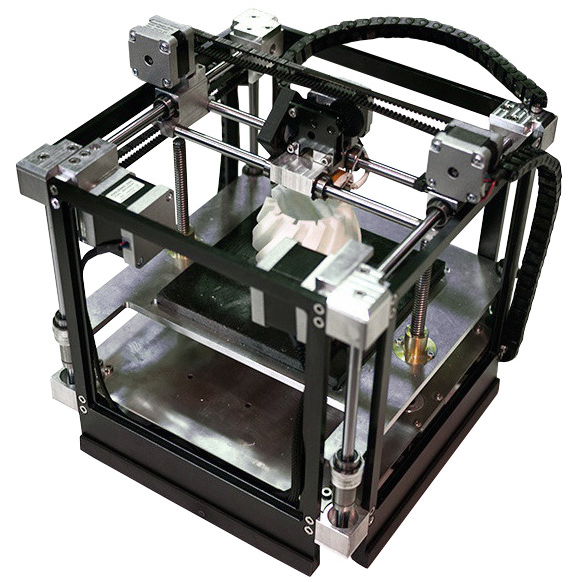

Powder Bed Fusion

Selective Laser Sintering (SLS)

SLS uses a high power laser to fuse small particles of powder into a mass that has the desired three dimensional shape. The laser selectively fuses powder by first scanning the cross-sections (or layers) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

Multi Jet Fusion (MJF)

Multi Jet Fusion technology was developed by Hewlett Packard and works with a sweeping arm which deposits a layer of powder and then another arm equipped with inkjets which selectively applies a binder agent over the material. The inkjets also deposit a detailing agent around the binder to ensure precise dimensionality and smooth surfaces. Finally, the layer is exposed to a burst of thermal energy that causes the agents to react.

Direct Metal Laser Sintering (DMLS)

DMLS is basically the same as SLS, but uses metal powder instead. All unused powder remains as it is and becomes a support structure for the object. Unused powder can be re-used for the next print.

Due to of increased laser power, DMLS has evolved into a laser melting process. Read more about that and other metal technologies on our metal technologies overview page.

Sheet Lamination

Sheet lamination involves material in sheets which is bound together with external force. Sheets can be metal, paper or a form of polymer. Metal sheets are welded together by ultrasonic welding in layers and then CNC milled into a proper shape. Paper sheets can be used also, but they are glued by adhesive glue and cut in shape by precise blades.

Simplified schematics of ultrasonic sheet metal process (Image credit: Wikipedia from user Mmrjf3)Directed Energy Deposition

This process is mostly used in the metal industry and in rapid manufacturing applications. The 3D printing apparatus is usually attached to a multi-axis robotic arm and consists of a nozzle that deposits metal powder or wire on a surface and an energy source (laser, electron beam or plasma arc) that melts it, forming a solid object.

Materials

Multiple materials can be used in additive manufacturing: plastics, metals, concrete, ceramics, paper and certain edibles (e.g. chocolate). Materials are often produced in wire feedstock a.k.a. filament, powder form or liquid resin. Learn more about our featured materials on our materials page.

Services

Looking to implement 3D printing in your production process? Get a quote for a custom part or order samples on our 3D print service page.

What is 3D printing? How does 3D printing work?

Select chapter

What is 3D printing?

3D printing and additive manufacturing

3D printing and rapid prototyping

When was 3D printing invented?

How does 3D printing work?

Additive vs traditional manufacturing

3D printing technology

The different types of 3D printing

3D printing processes

Selecting the right 3D printing processes

3D printing materials

A complete 3D printing material overview

3D printing software

What software should you use for 3D printing?

3D printing design guidelines

Design guidelines applicable for all 3D printing processes

Design guidelines for specific processes

Design guidelines for specific parts

Applications of 3D printing

Medical 3D printing

Automotive 3D printing

3D printing jewelery

What are the benefits of 3D printing?

The future of 3D printing

How to get something 3D printed

Buy a printer or use a 3D printing service?

How to decide which 3D printer to buy

How to use a 3D printing service

Further reading

The 3D printing handbook

Guides to other manufacturing technologies

What is 3D printing?

3D printing is an additive technology used to manufacture parts. It is ‘additive’ in that it doesn’t require a block of material or a mold to manufacture physical objects, it simply stacks and fuses layers of material. It’s typically fast, with low fixed setup costs, and can create more complex geometries than ‘traditional’ technologies, with an ever-expanding list of materials. It is used extensively in the engineering industry, particularly for prototyping and creating lightweight geometries.

It is ‘additive’ in that it doesn’t require a block of material or a mold to manufacture physical objects, it simply stacks and fuses layers of material. It’s typically fast, with low fixed setup costs, and can create more complex geometries than ‘traditional’ technologies, with an ever-expanding list of materials. It is used extensively in the engineering industry, particularly for prototyping and creating lightweight geometries.

3D printing and additive manufacturing

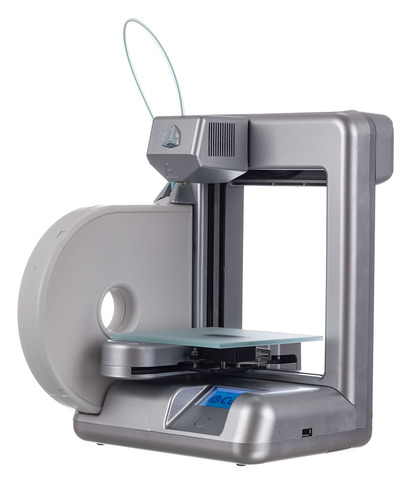

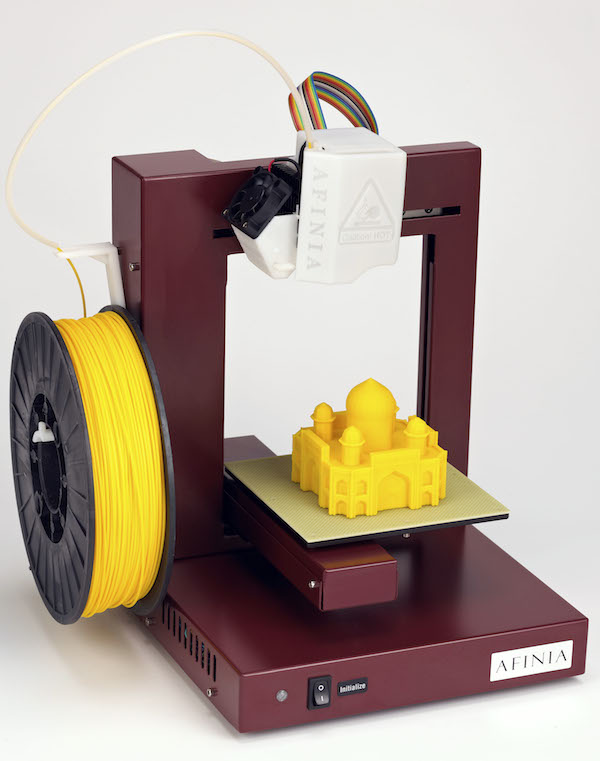

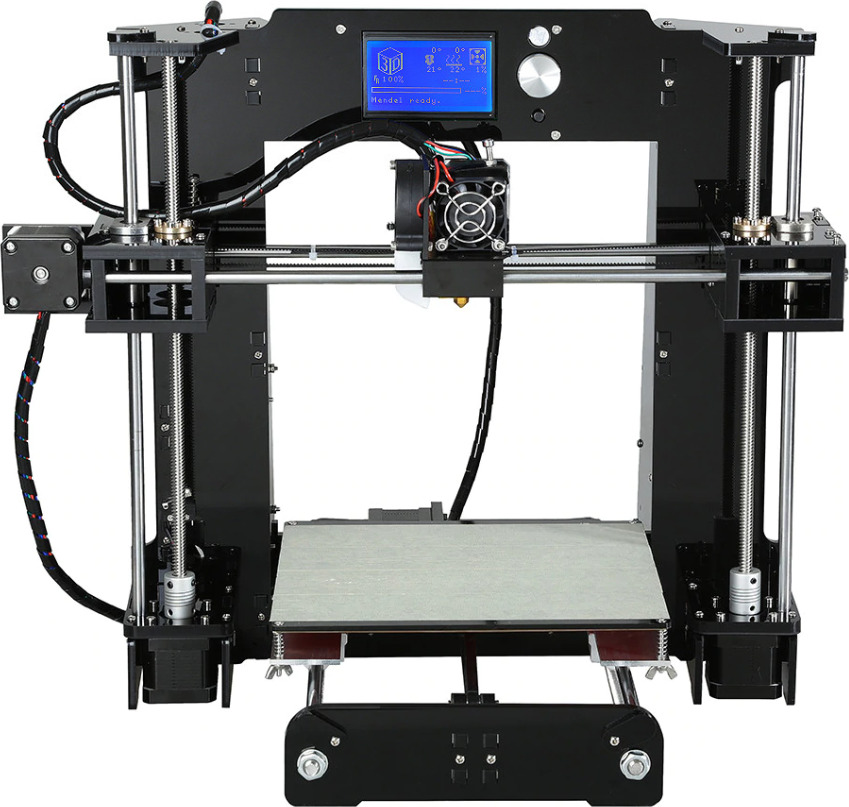

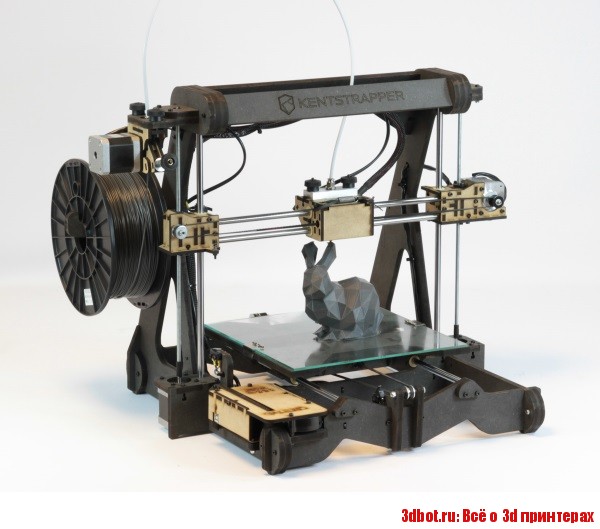

‘3D printing’ is commonly associated with maker culture, hobbyists and amateurs, desktop printers, accessible printing technologies like FDM and low-cost materials such as ABS and PLA (we’ll explain all those acronyms below). This is largely attributable to the democratization of 3D printing through affordable desktop machines that sprung from the RepRap movement, like the original MakerBot and Ultimaker, which also led to the explosion of 3D printing in 2009.

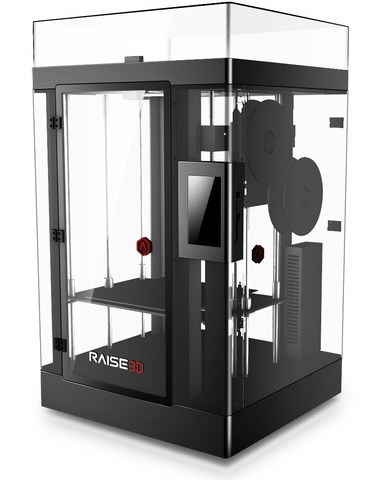

By contrast, additive manufacturing (AM) is almost always associated with commercial and industrial applications.

3D printing and rapid prototyping

‘Rapid prototyping’ is another phrase that’s sometimes used to refer to 3D printing technologies. This dates back to the early history of 3D printing when the technology first emerged. In the 1980s, when 3D printing techniques were first invented, they were referred to as rapid prototyping technologies because back then the technology was only suitable for prototypes, not production parts.

In recent years, 3D printing has matured into an excellent solution for many kinds of production parts, and other manufacturing technologies (like CNC machining) have become cheaper and more accessible for prototyping. So while some people still use ‘rapid prototyping’ to refer to 3D printing, the phrase is evolving to refer to all forms of very fast prototyping.

When was 3D printing invented?

3D printing began as an idea for accelerating industrial product development through faster prototyping. Even though there were a few patents beforehand, Chuck Hull is typically credited with the invention of the 3D printer via his Stereolithography Apparatus (SLA), patented in 1984.

SLA 3D Printing - What is SLA 3D printing?Foundations

Despite Chuck’s fame, multiple technologies were being developed in parallel in the late 1980s, and there were several companies founded in this period that was critical to the development of the technology.

- 1981 - the first patent for a device using UV light to cure photopolymers was awarded to Hideo Kodama in Japan. He designed it for ‘rapid prototyping’ as it was intended for making models and prototypes, but there was no interest and the patent was abandoned.

- 1984 - French inventors Alain Le Mehaute, Olivier de Witte, and Jean Claude André submitted a patent in which, like Hideo’s, UV light was used to cure photopolymers.

General Electric abandoned the patent citing a lack of significant business potential.

General Electric abandoned the patent citing a lack of significant business potential. - 1984 - only a few weeks after Le Mehaute, American Charles ‘Chuck’ Hull filed his own patent for an ‘Apparatus for Production of Three-Dimensional Objects by Stereolithography’, thus also coining the term ‘stereolithography’ (SLA).

- 1987 - Hull invented the STL file, and in the same year founded 3D Systems.

- 1987 - American Carl Deckard filed a patent for Selective Laser Sintering (SLS), and in the same year co-founded Desktop Manufacturing (DTM) Corp. (acquired by 3D Systems in 2001).

- 1989 - American S. Scott Crump submits a patent for Fused Deposition Modeling (FDM), and in the same year founded Stratasys with his wife.

Commercialization

From the late 1980s to the early 1990s the industry underwent very rapid commercialization. The first machines were big and expensive and their makers competed for industrial prototyping contracts with mass-market manufacturers in the automotive, aerospace, health, and consumer goods industries.

- 1987 - 3D Systems released the first commercial SLA printer, the ‘SLA-1’.

- 1992 - The FDM patent was finally granted to Stratasys, which led them to release the first FDM printer, the ‘3D Modeler’.

- 1992 - DTM released the first commercial SLS printer, the ‘Sinterstation 2000’

- 1994 - German company Electro Optical Systems (EOS), founded in 1989, unveiled its ‘EOSINT M160’, the first commercial metal 3D printer

Democratization

In the early 2000s the fierce competition for profits, developments in material science, and the ending of many patents created an environment in which 3D printing finally became affordable for the masses. This was the decade that 3D printing took off in the popular imagination - manufacturing, which had always been the domain of heavy industry and big money, came to the people.

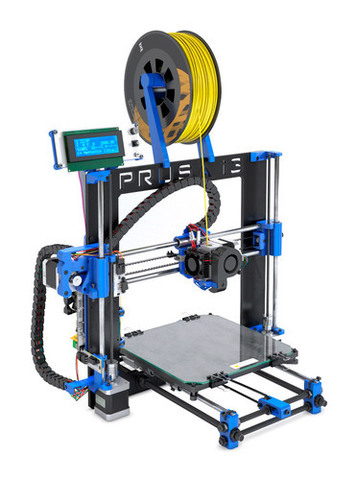

- 2005 - The open-source RepRap Project (for ‘Replicated Rapid Prototyper’) launched with the aim of creating self-replicating 3D printers capable of printing their own parts, causing popular interest in the technology to skyrocket.

- 2009 - Key FDM patents fell into the public domain and MakerBot launched their desktop 3D printer, the ‘Cupcake CNC’. It cost hundreds of dollars, not thousands, and all components were downloadable from Thingiverse, a website dedicated to the sharing of user-created digital design files.

- 2012 - Formlabs release the ‘Form 1’, the first affordable SLA printer, through a record-breaking Kickstarter campaign that raised $2.95 million in funding. They were sued by 3D Systems for patent infringement, but the case was settled in favor of Formlabs

- 2013 - Hubs launches as a peer-to-peer 3D printing service, allowing mass transactions between people buying prints and people with machines. It quickly grew to be the single biggest 3D printing platform in the world with over 50,000 printing ‘hubs’, before pivoting to focus on helping its business customers by making all forms of custom manufacturing more accessible.

- 2014 - Key SLS patents fell into the public domain, leading to a whole crop of companies making smaller and more affordable SLS printers.

Maturity

From 2018 the hype around 3D printing had largely disappeared from mass media, but interest in commercial applications for businesses of all sizes has never been higher. Today there are thousands of companies producing printers and offering all sorts of services leveraging 3D printing technology.

Learn more about the history of 3D printing

There are many articles out there, most are just fun reads. For those looking to really delve deep into history, Wikipedia and Wohler Associates are the best resources.

- Wikipedia - 3D printing

- Wohlers Report 2016 - History of Additive Manufacturing

How does 3D printing work?

Additive vs traditional manufacturing

Additive manufacturing has only been around since the 1980s, so the manufacturing methods developed before it are often referred to as traditional manufacturing. To understand the major differences between additive and traditional manufacturing, let's categorize all methods into 3 groups: additive, subtractive and formative manufacturing.

To understand the major differences between additive and traditional manufacturing, let's categorize all methods into 3 groups: additive, subtractive and formative manufacturing.

Additive manufacturing

Additive manufacturing builds up 3D objects by depositing and fusing 2D layers of material.

This method has almost no startup time or costs, making it ideal for prototyping. Parts can be made rapidly and discarded after use. Parts can also be produced in almost any geometry, which is one of the core strengths of 3D printing.

One of the biggest limitations of 3D printing is that most parts are inherently anisotropic or not fully dense, meaning they usually lack the material and mechanical properties of parts made via subtractive or formative techniques. Due to fluctuations in cooling or curing conditions, different prints of the same part are also prone to slight variations, which puts limitations on consistency and repeatability.

Subtractive manufacturing

Subtractive manufacturing, such as milling and turning, creates objects by removing (machining) material from a block of solid material that's also often referred to as a 'blank'.

Almost any material can be machined in some way, making it a widely used technique. Because of the amount of control over every aspect of the process this method is capable of producing incredibly accurate parts with high repeatability. Most designs require Computer Aided Manufacturing (CAM) to plot customized tool paths and efficient material removal, which adds setup time and costs, but for the majority of designs, it’s the most cost-effective method of production.

The major limitation of subtractive manufacturing is that the cutting tool must be able to reach all surfaces to remove material, which limits design complexity quite a lot. While machines like 5-axis machines eliminate some of these restrictions, complex parts still need to be re-orientated during the machining process, adding time and cost. Subtractive manufacturing is also a wasteful process due to the large amounts of material removed to produce the final part geometry.

Formative manufacturing

Formative manufacturing, such as injection molding and stamping, creates objects by forming or molding materials into shape with heat and/or pressure.

Formative techniques are designed to reduce the marginal cost of producing individual parts, but the creation of unique molds or machines used in the production process means setup costs are very, very high. Regardless, these techniques can produce parts in a large range of materials (both metals and plastics) with close to flawless repeatability, so for high volume production, they’re almost always the most cost-efficient.

How these methods compare

Manufacturing is complex, and there are too many dimensions for comprehensively comparing each method against all others. It is near impossible to optimize all at once for cost, speed, geometric complexity, materials, mechanical properties, surface finish, tolerances, and repeatability.

In such complex situations heuristics and rules of thumb are more valuable:

- Additive manufacturing is best for low volumes, complex designs, and when speed is essential.

- Subtractive manufacturing is best for medium volumes, simple geometries, tight tolerances, and hard materials

- Formative manufacturing is best for the high-volume production of identical parts.

Cost per part is usually the governing factor determining which manufacturing process is best. As a rough approximation the unit costs per method can be visualized like this:

Learn more about 3D printing vs CNC machining.

3D printing is becoming cheaper every year and in some instances, it is starting to compete with injection molding for cost efficiency. However it’s usually 3D printing and CNC machining that are considered interchangeable for particular jobs, so we’ve written a thorough guide comparing them side by side. Read more about 3D printing vs CNC machining.

CNC Machining vs 3D Printing - Which Do You Need?3D printing technology

With so many different 3D printing technologies on the market, it can be hard to understand the whole landscape. The International Organization for Standardization created the ISO/ASTM standard 52900 to standardize the exploding terminology around 3D printing and we’ve pulled together the most-used language into this glossary of 3D printing terms.

The different types of 3D printing

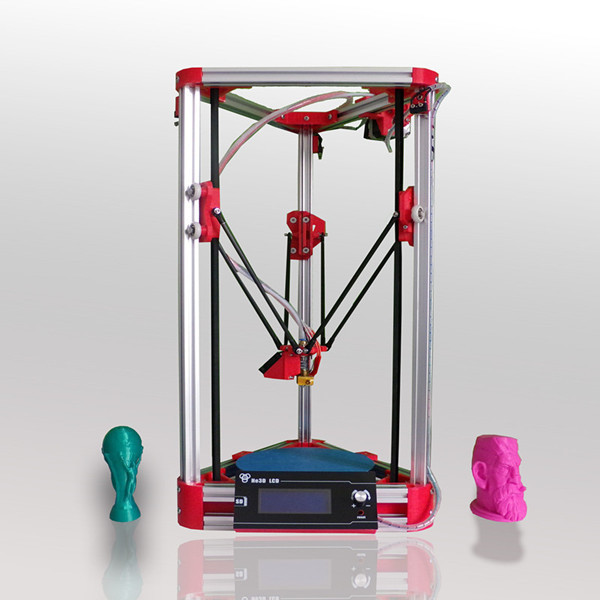

3D printers can be categorized into one of several types of processes:

- Vat Polymerization: liquid photopolymer is cured by light

- Material Extrusion: molten thermoplastic is deposited through a heated nozzle

- Powder Bed Fusion: powder particles are fused by a high-energy source

- Material Jetting: droplets of liquid photosensitive fusing agent are deposited on a powder bed and cured by light

- Binder Jetting: droplets of liquid binding agent are deposited on a bed of granulated materials, which are later sintered together

- Direct Energy Deposition: molten metal simultaneously deposited and fused

- Sheet Lamination: individual sheets of material are cut to shape and laminated together

Click here to download a high-resolution version of this poster.

3D printing processes

There are seven main 3D printing processes. Within each type of process there are unique technologies, and for every unique technology there are also many different brands selling similar printers.

Vat photopolymerization

Photopolymerization is the process of a photopolymer resin being exposed to certain wavelengths of light and becoming solid.

Stereolithography (SLA), direct light processing (DLP) and continuous direct light processing (CDLP) are additive manufacturing processes that fall under the category of vat photopolymerization. In SLA, an object is created by selectively curing a polymer resin layer-by-layer using an ultraviolet (UV) laser beam. DLP is similar to SLA but uses a digital light projector screen to flash a single image of each layer all at once. CDLP is a lot like DLP but relies on the continuous upward motion of the build plate. All vat photopolymerization processes are good for producing fine details and smooth surface finishes, making them ideal for jewelry and medical applications.

All vat photopolymerization processes are good for producing fine details and smooth surface finishes, making them ideal for jewelry and medical applications.

Benefits

- Smooth surface

- Fine details

- Good for prototyping of IM

Limitations

- Brittle

- Usually requires supports

- UV sensitive

- Extensive post processing required

Powder bed fusion

Powder bed fusion (PBF) technologies use a heat source to induce fusion (sintering or melting) between the particles of a plastic or metal powder one layer at a time. Selective Laser Sintering (SLS), electron beam melting (EBM) and multi jet fusion (MJF) all fall within this technology. The metal 3D printing processes selective laser melting (SLM) and direct metal laser sintering (DMLS) also use powder bed fusion to selectively bind metal powder particles.

Benefits

- Strong parts (nylon)

- Complex geometry

- Scalable (fits size)

- No support

Limitations

- Longer production time

- Higher cost (machines, material, operation)

Material extrusion

Material extrusion technologies squeeze a material through a nozzle and onto a build plate, layer by layer. Fused deposition modeling (FDM) falls under this category and is the most widely used 3D printing technology.

Fused deposition modeling (FDM) falls under this category and is the most widely used 3D printing technology.

Benefits

- Fast

- Low cost

- Common thermoplastics

Limitations

- Rough surface finish

- Anisotropic

- Usually requires supports

- Not scalable

- Limited accuracy

Material jetting

Material jetting technologies use UV light or heat to harden photopolymers, metals or wax, building parts one layer at a time. Nano particle jetting (NPJ) and Drop-on-demand (DOD) are two other types of material jetting.

Benefits

- Realistic prototypes

- Excellent details

- High accuracy

- Smooth surface finish

Limitations

- High cost

- Brittle mechanical properties

Binder Jetting

Binder jetting uses an industrial printhead to deposit a binding adhesive agent onto thin layers of powder material. Unlike the other 3D printing technologies, binder jetting does not require heat.

Unlike the other 3D printing technologies, binder jetting does not require heat.

Benefits

- Full-color options

- Range of materials

- No support

- No warping or shrinking

Limitations

- Low part strength

- Less accurate than material jetting

Direct energy deposition

Direct energy deposition (DED) creates 3D objects by melting powder material as it is deposited. It is mostly used with metal powders or wire and is often referred to as metal deposition. Laser engineered net shape (LENS) and Electron Beam Additive Manufacture (EBAM) also fall within this category.

Benefits

- Strong parts

- Range of materials

- Larger parts

Limitations

- High cost

- Poor surface finish

Sheet lamination

This technology stacks and laminates thin sheets of material to make parts. There are a few different types of lamination to choose from: bonding, ultrasonic welding or brazing.

Benefits

- Fast

- Low cost

- No support structures necessary

- Multi-material layers

Limitations

- Post processing is required

- Limited materials

- Finishing may vary

The whole landscape of additive manufacturing technologies can be summarized in a simple tree-diagram:

Click here to download a high-resolution version of this poster.

Our article on The Seven Official Types Of 3D Printers gives a broad overview of how each type of printer works, the materials available, the price and speed of printing, geometric properties (size, complexity & resolution), mechanical properties (accuracy, strength & surface finish) and common applications.

Looking for more in-depth information on the topic? We also wrote a handbook on 3D printing. If you’re a professional looking to truly master the key aspects of 3D printing, this book is for you.

Selecting the right 3D printing processes

Selecting the optimal 3D printing process for a particular part can be difficult as there’s often more than one suitable process but each one will produce subtle variations in cost and output. Generally there are three key aspects to consider:

Generally there are three key aspects to consider:

- The required material properties: strength, hardness, impact strength, etc.

- The functional & visual design requirements: smooth surface, strength, heat resistance, etc.

- The capabilities of the 3D printing process: accuracy, build size, etc.

These correspond to the three most common methods for selecting the right process:

- By required material

- By required functionality or visual appearance

- By required accuracy or build size

For an in-depth look at how to use these methods read our complete guide to Selecting the right 3D printing process. The following comparison guides will also help inform your decision.

- HP MJF vs. SLS: A 3D printing technology comparison

- Industrial SLA/DLP vs. desktop SLA/DLP

- Industrial FDM vs. desktop FDM

3D printing materials

A complete 3D printing material overview

The number of available 3D printing materials grows rapidly every year as market demand for specific material and mechanical properties spurs advancements in material science. This makes it impossible to give a complete overview of all 3D printing materials, but each 3D printing process is only compatible with certain materials so there are some easy generalizations to make.

This makes it impossible to give a complete overview of all 3D printing materials, but each 3D printing process is only compatible with certain materials so there are some easy generalizations to make.

Thermoplastic and thermoset polymers are by far the most common 3D printing materials, but metals, composites and ceramics can also be 3D printed.

Another way of categorizing materials is by their properties: cheap, chemically resistant, dissolvable, flexible, durable, heat resistant, rigid, water resistant, UV resistant. Many industrial applications require durable plastics such as Nylon 12, and most hobbyist applications use either PLA or ABS, which are the most common materials used in FDM 3D printing.

For a more thorough overview of each of the main 3D printing materials see these articles.

- FDM 3D printing materials compared

- PLA vs. ABS: What's the difference?

- SLA 3D printing materials compared

- 3D printed injection molds: Materials compared

3D printing software

3D printing starts with software and there are many different programs to aid with each stage of the design and printing process, from 3D modelling, to print simulations and slicer programs.

What software should you use for 3D printing?

The two main methods of 3D modelling are ‘solid modelling’ and ‘surface modelling’, and there are different CAD software packages for each approach. Solid modelling refers to the creation of virtual objects through defining and joining 3D shapes that are usually predefined and to which refined surface details are added later. Surface modelling is similar except the designer starts with 2D surfaces and shapes them in ‘freeform’ to create 3D shapes.

Both approaches can produce exactly the same output, but solid modelling is faster for simple and non-organic shapes, whereas surface modelling is faster for more organic shapes. SolidWorks, Fusion 360 and Rhino 3D are the most popular software with professionals, and there are many free programs for amateurs.

Other useful 3D printing software include print simulation tools and file error fixers.

3D printing design guidelines

The exact best practices and rules of thumb vary between the different 3D printing technologies, but there are certain features you always need to pay attention to:

- Supported wall thickness

- Unsupported wall thickness

- Supports and overhangs

- Embossed and engraved details

- Horizontal bridges

- Holes

- Connecting or moving parts

- Escape holes

- Minimum feature size

- Minimum pin diameter

- Maximum tolerance

The process-specific design rules for each of these features are summarized in the graphic below:

Click here to download a high-resolution version of this poster.

Design guidelines applicable for all 3D printing processes

What can’t 3D printers do? Understanding and overcoming 3D printing geometry limitations What are the key design elements for 3D printing? What are supports in 3D printing? When and why do you need them? How does part orientation affect a 3D print? Practical design tips for additive manufacturing What is dimensional accuracy in 3D printing and how do you achieve it? How important is layer height for 3D printing? 3D print better parts with the right layer thicknessDesign guidelines for specific processes

How to design parts for FDM 3D printing How to design parts for SLA 3D printing How to design parts for SLS 3D printing How to design parts for material jetting 3D printing How to design parts for metal 3D printing How to design parts for binder jetting 3D printing What are the optimal shell and infill parameters for FDM 3D printing?Design guidelines for specific parts

How do you design enclosures for 3D printing? A step-by-step guide How to design living hinges for 3D printing How to design interlocking joints for fastening 3D printed parts How do you design snap-fit joints for 3D printing? How do you assemble 3D-printed parts? Practical tips on threads & screws for 3D printingApplications of 3D printing

3D printing is exceptionally useful for prototyping. Speed is everything in prototyping, and the ability to move from CAD to print with close to zero set up costs means 3D printers can produce parts fast and have great unit economics for single-part and small runs.

Speed is everything in prototyping, and the ability to move from CAD to print with close to zero set up costs means 3D printers can produce parts fast and have great unit economics for single-part and small runs.

For printing production parts, speed and price are also important, but the characteristics most commonly exploited are design freedom and ease of customization. In aerospace and automotive, topology optimized structures with a high strength-to-weight ratio are used for high-performance parts, and components that previously required assembly can be consolidated into a single part. In healthcare, customization is critical - most hearing aids manufactured in the US are made almost exclusively using 3D printing. In manufacturing, low-run injection molds can be 3D printed from stiff, heat-resistant plastics instead of machined from metal, making them much cheaper and faster to produce.

Medical 3D printing

There are many applications for 3D printing in the medical industry, and each year doctors and scientists come up with new and creative ways to use this fast-growing technology. The speed and versatility of 3D printing makes it perfect for developing customized prosthetics and implants and patient-specific replicas of bones, organs and blood vessels. It is also used for 3D printing surgical tools, anatomical models, personalized medical equipment and a range of other life-saving innovations.

The speed and versatility of 3D printing makes it perfect for developing customized prosthetics and implants and patient-specific replicas of bones, organs and blood vessels. It is also used for 3D printing surgical tools, anatomical models, personalized medical equipment and a range of other life-saving innovations.

Automotive 3D printing

In the automotive industry, automakers use 3D printing to test form and fit, to experiment with aesthetic finishes and make sure that all parts operate and interact as intended. It also provides a flexible solution for the quick turnaround of jigs, fixtures and grips; creating bellows; engineering complex ducting; and rapidly manufacturing complex, lightweight mounting brackets.

3D printing jewelery

There are a few reasons that so many designers use 3D printing to create jewelry. The technology allows jewelers to produce very complex, highly customizable designs, sidestepping some of the limitations of previously popular jewelry making techniques such as CNC machining, handcrafting and lost-wax casting. Today, precious metals can be 3D printed in a variety of patterns and designs quickly and cost effectively.

The technology allows jewelers to produce very complex, highly customizable designs, sidestepping some of the limitations of previously popular jewelry making techniques such as CNC machining, handcrafting and lost-wax casting. Today, precious metals can be 3D printed in a variety of patterns and designs quickly and cost effectively.

To learn more about the many different applications of 3D printing, check out these articles.

- 3D printed rapid tooling

- 3D printing for grips, jigs and fixtures

- 3D printing low-run injection molds

- Producing low-cost cast metal parts using 3D printing

What are the benefits of 3D printing?

3D printing is an exceptional tool for custom parts and rapid prototyping with a unique set of advantages but also lags behind traditional manufacturing in some ways. The key benefits and limitations can be summarized as follows:

Benefits

- Very low start-up costs

- Very quick turnaround

- Large range of available materials

- Design freedom at no extra cost

- Each and every part can easily be customized

Limitations

- Less cost-competitive at higher volumes

- Limited accuracy & tolerances

- Lower strength & anisotropic material properties

- Requires post-processing & support removal

For a more thorough overview read our article about the benefits and limitations of 3D printing

The future of 3D printing

So where is 3D printing today? Is the hype over? Yes, and now the technology is reaching maturity. Hubs has been around since 2013, and we’ve produced a 3D Printing Trend Report every year since 2017. Over those years we’ve watched the technology reach the height of the hype cycle, drop through the ‘trough of disillusionment, and bounce back to where it is now - on the ‘slope of enlightenment.

Hubs has been around since 2013, and we’ve produced a 3D Printing Trend Report every year since 2017. Over those years we’ve watched the technology reach the height of the hype cycle, drop through the ‘trough of disillusionment, and bounce back to where it is now - on the ‘slope of enlightenment.

The hype of the previous years was based on the idea of widespread consumer adoption. This was a misleading interpretation of where the technology could add value to the world. The most promising applications of 3D printing are in very specific roles in the world of manufacturing.

To understand where 3D printing is headed in the next few years, consult the most recent version of our annual 3D printing trend report.

- Hubs 3D Printing Trend Report - Most Recent Report

- Hubs 3D Printing Trend Report - Past Trends

How to get something 3D printed

3D printing has come a long way since its inception and it’s now very easy to get something 3D printed quickly and affordably.

Buy a printer or use a 3D printing service?

3D printing has come a long way since its inception and it’s now very easy to get something 3D printed very fast for pretty cheap.

Should you buy your own 3D printer or use an online service? It’s an important decision to make, so we’ve collected arguments for both sides to help you make the right choice.

| Buy a 3D printer if… | Use an online service if… |

|---|---|

| You need to print regularly, but not in huge volumes (10-25 times a week) | You will need only a few (less than 10) or large volumes (25+) of parts printed per week |

| You have one specific application in mind for the printer | You want to print using multiple processes and materials, including industrial printers |

| You are ready to make a sizeable investment | You want to access the latest technologies at all times |

| You are prepared to set up, tinker and optimize your machine | You prefer to focus your time on designing and perfecting your models |

| You have the necessary space and time to install and operate the printer | You want to test and learn first before deciding what printer to buy |

How to decide which 3D printer to buy

If you’ve decided it’s a good idea to buy your own 3D printer, you may be overwhelmed by the range of choices now available. To help people make sense of the 3D printer market, we reached out to our entire customer base and our global network of 3D printing service providers to find out about the 3D printers they own and their experiences in using them.

To help people make sense of the 3D printer market, we reached out to our entire customer base and our global network of 3D printing service providers to find out about the 3D printers they own and their experiences in using them.

With reviews from more than 10,000 3D printer owners, who’ve completed about 1.48 million prints on 650+ different 3D printer models, our research is the most comprehensive 3D Printer Guide available.

Read our guide to finding the best 3D printer for you.

How to use a 3D printing service

At Hubs, we’re building the smartest manufacturing solution on the planet. One of our main offerings is our 3D Printing service.

When you upload a part to our online 3D printing service our proprietary pricing algorithm gives you a quote in a matter of seconds. As you specify your requirements the price will update automatically, and if you’re happy with the price and the lead times you can submit the order in just a few minutes.

Further reading

If you have more questions about 3D printing, check out our Knowledge Base and filter on ‘3D printing’ to see everything all at once.

The 3D printing handbook

If you’re interested in diving deeper into any of the topics covered above, we literally wrote the book on 3D printing. If you’re a professional looking to truly master the key aspects of 3D printing, this book is for you. It provides practical advice on selecting the right technology and how-to design for 3D printing, based upon the first-hand experience from the industry’s leading experts.

Here’s what Tony Fadell (creator of the iPod and founder of Nest) had to say about it:

“The Handbook” will help to guide you on your own path as you look to leverage 3D printing and its potential to create your own breakthrough products, that hopefully will change the world.

Every designer and engineer should keep it close as it paves your way into new manufacturing technologies that will spur your creativity and unlock your ideas as they become reality. Creation is changing, manufacturing is changing and design is changing, turn the page, it's time to stay ahead...

If you’re ready to purchase, The 3D Printing Handbook is available on Amazon. Or, if you like, you can download the first two chapters for free first.

Guides to other manufacturing technologies

Hubs' online manufacturing service offers more than just 3D printing. We also offer CNC machining, injection molding, and sheet metal fabrication, and to try to help our customers understand all these technologies we’ve written guides similar to this one for each of them.

Learn more about other manufacturing technologies

10 Benefits of a 3D Printer: Save Time and Money

More recently, 3D printing has been viewed as something completely new. The technology was underdeveloped, the hardware was too expensive for widespread use. But only a few years have passed, and the situation has changed radically. Not only did more and more 3D printers begin to appear in stores, but also some enthusiasts began to assemble this equipment themselves.

The technology was underdeveloped, the hardware was too expensive for widespread use. But only a few years have passed, and the situation has changed radically. Not only did more and more 3D printers begin to appear in stores, but also some enthusiasts began to assemble this equipment themselves.

1. Economy

Although large-scale projects with thousands of 3D printed parts are not cheap, they are still much more profitable than other technologies. Many manufacturers use 3D printing for small runs or for prototyping. Plastic can also be used for injection molding, but casting small batches can require expensive equipment. But even in this case, manufacturers can produce cast 3D parts several times cheaper than using aluminum.

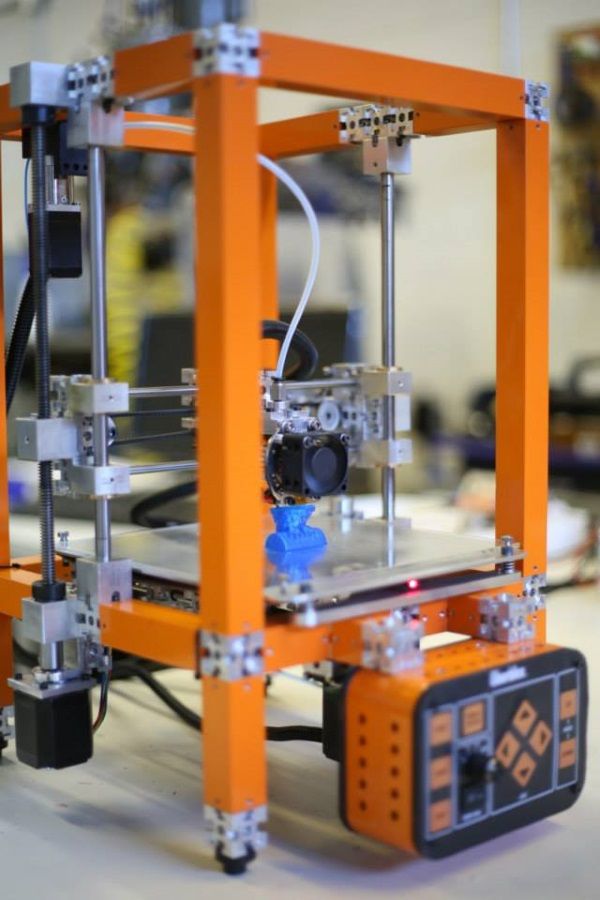

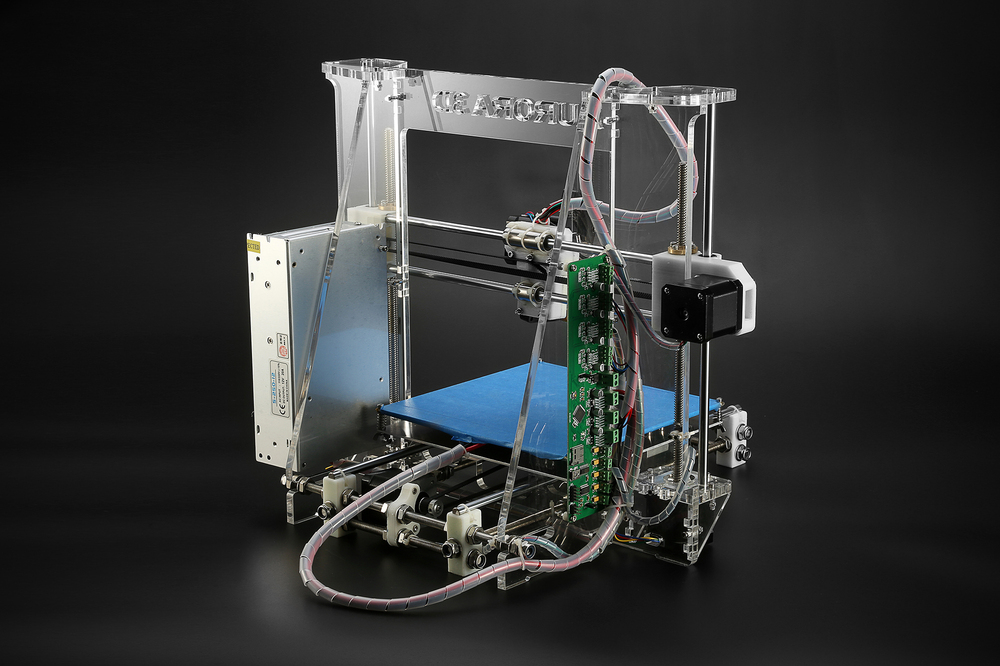

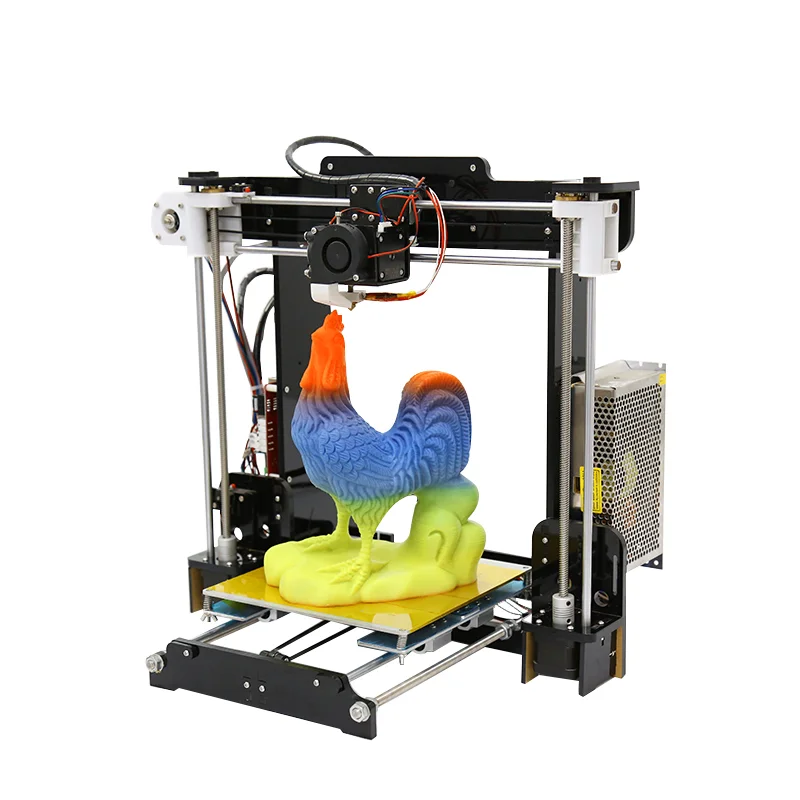

Prototype parts printed on Prusa i3 Bizon 3D printer, layer height 0.1mm, PLA material

2. Faster production cycle

Compared to traditional production methods, the entire process can take weeks or days, and most products are printed in hours. Some manufacturers have even begun to make parts to order, which has also allowed them to optimize their warehouse capacity and resource management scheme, making them more flexible. With this new approach, the manufacturer does not need to store every single part or component, they can simply be printed as needed and immediately put into action.

Some manufacturers have even begun to make parts to order, which has also allowed them to optimize their warehouse capacity and resource management scheme, making them more flexible. With this new approach, the manufacturer does not need to store every single part or component, they can simply be printed as needed and immediately put into action.

Miniature parts printed by Wanhao Duplicator 7 photopolymer 3D printer, layer height 0.5mm, photopolymer resin material

It not only affects the reputation of the company in its industry, insufficient technical control can lead to injury to employees and customers. Since 3D printing uses a completely different production method than most machine tool operations, the process has significantly fewer weaknesses and flaws overall.

Model printed on Picaso Designer X PRO 3D printer, 0.2 mm layer, ABS materials, HIPS

4. Less waste

The press is gaining more and more support in the form of supporters of the "green" movement. Because 3D printing produces significantly less waste than traditional processing, the technology is more environmentally friendly while reducing costs. 3D printing has even made its way into the textile industry, allowing clothing and prototypes to be printed.

Because 3D printing produces significantly less waste than traditional processing, the technology is more environmentally friendly while reducing costs. 3D printing has even made its way into the textile industry, allowing clothing and prototypes to be printed.

Hercules Strong 3D printed yacht steering parts. Details printed in 15 hours with a 0.5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

5. Greater customization

3D printed products are also highly customizable. Parts can be printed not only with light plastic, some next-generation models may also have a metal coating. As a result, objects are not only aesthetic, but also functional. In addition, they can acquire thermal and chemical resistance. The existing metallization method can also be used for plastic.

Functional parts printed on Hercules. Material ABS, nozzle diameter 0.5 mm, layer height 150 µm, filling 100%. The model consists of 3 parts: the body and 2 halves of the latch, after printing and processing, the parts were glued together with acetone.

The model consists of 3 parts: the body and 2 halves of the latch, after printing and processing, the parts were glued together with acetone.

6. Customer Accessibility

If some craftsmen set up small mechanical workshops, for example, in garages, then most of us cannot afford such a luxury. 3D printing allows you to bring a significant part of the manufacturing process directly into the home, made possible by the availability of user-grade 3D technology. While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly.

Technical wing caps in REC RUBBER or REC FLEX. The models are printed on a Prusa i3 Steel 3D printer.

7. High complexity

In most cases, when it comes to complex parts and elements, the manufacturing process imposes certain limitations. Techniques used in casting and finishing objects may not be subtle enough for sophisticated design details. 3D manufacturing processes make it possible to implement almost any design solution, regardless of its complexity, and in a reasonable time. This not only eliminates the extra assembly steps required with traditional methods, but also provides more freedom to create future-proof designs.

3D manufacturing processes make it possible to implement almost any design solution, regardless of its complexity, and in a reasonable time. This not only eliminates the extra assembly steps required with traditional methods, but also provides more freedom to create future-proof designs.

Zenit 3D Printing Big Details From Engine 3D Printer

8. Less risk

While there are inherent risks associated with these new technologies, in terms of day-to-day business, 3D printing risks are significantly lower than with traditional manufacturing methods. Not only is 3D printing much cheaper when it comes to testing a new design or product, the printed prototypes themselves can stir up investor and customer interest and get them to decide whether to proceed with mass production of a product, whether it is worth the time and effort required.

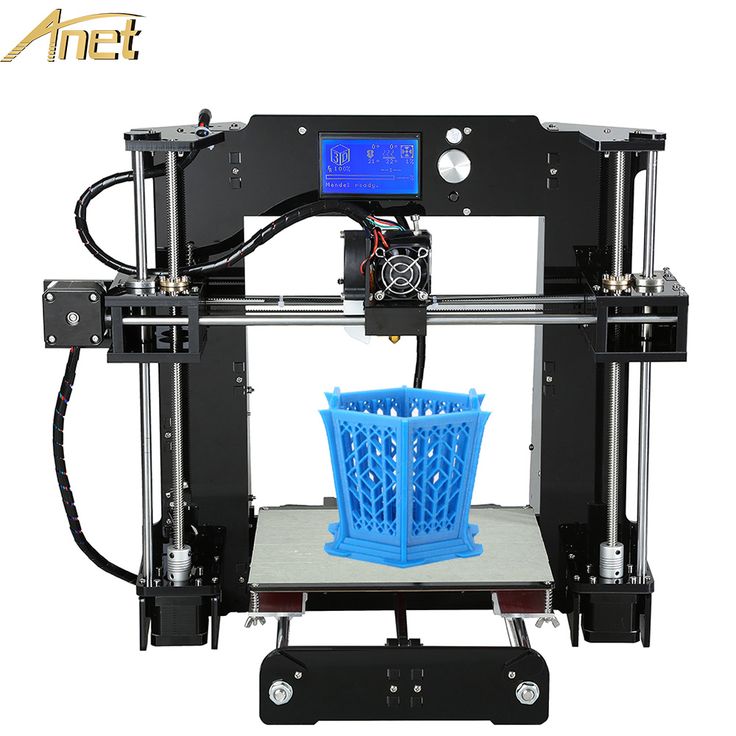

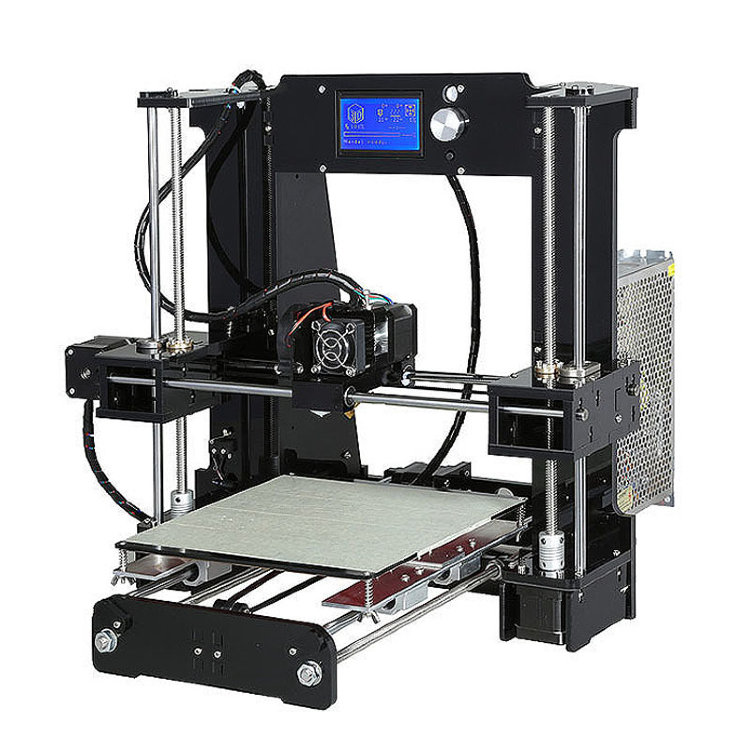

Wanhao Duplicator i3 3D Printer Miniature Printing

9.

Variety of materials

Variety of materials The materials used in today's 3D printers are much more diverse than most raw materials in traditional production methods. 3D printing also provides the ability to mix different substances, a luxury that is not always available with conventional methods. Although many 3D printer manufacturers offer their own, very limited set of sources, 3D printers can work not only with original materials, allowing you to simulate ceramics, metal, glass and more.

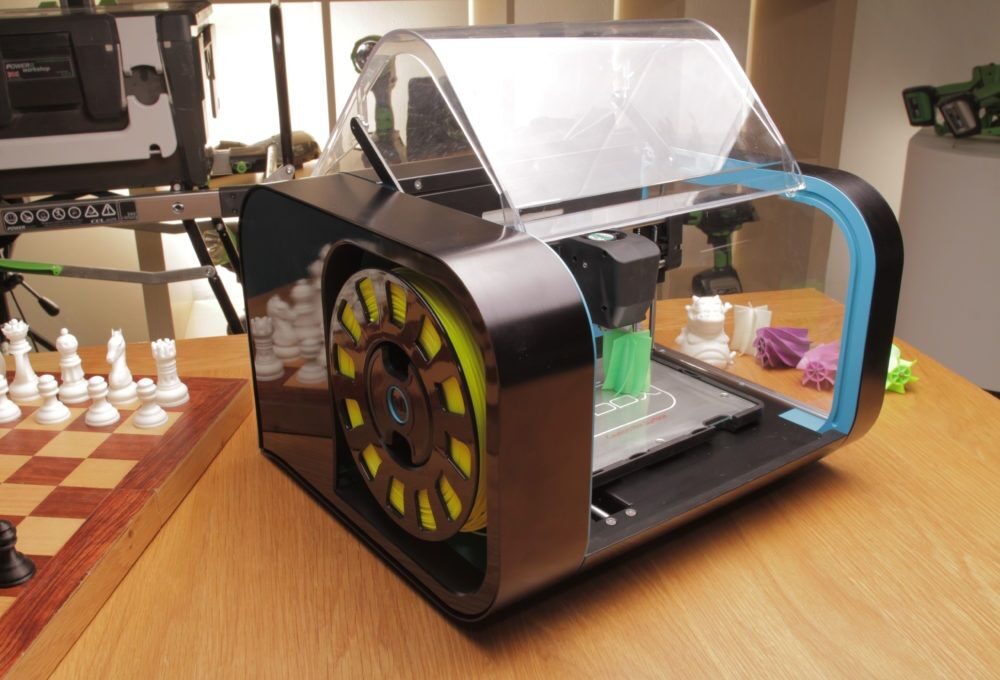

Wanhao D6 3D Printer PEGT, ABS-PC, PLA, SBS

The manufacturer not only needs to clearly understand what the customer wants, the manufacturer must also be able to explain what he himself can. Drawings, diagrams, diagrams are all good, of course, but there is nothing better than a real prototype that you can hold, look at and study. The fact that the materials are inexpensive, coupled with the short prototyping time on today's 3D printers, helps a lot during the prototyping phase, keeping all stakeholders connected.

THE PAST, PRESENT AND FUTURE OF 3D PRINTING

Despite a relatively slow start, the concept of 3D printing is finally gaining momentum and popularity among manufacturers and customers. We already see a lot of benefits of 3D printing, including shorter production cycles, more complex designs and improved quality, and the peak of the popularity and functionality of this technology is yet to come.

What material does the 3D printer print with? Plastic for 3d printer.

Layer-by-layer printing of three-dimensional models is made from a variety of materials, be it plastic, concrete or metal, and even hydrogel, chocolate and living cells.

For 3D printing, the use of ABS plastic is most optimal. Acrylonitrile butadiene styrene (official name ABC plastic ) is valued for its lack of foreign smell, toxicity, in addition, it is impact resistant, flexible and elastic. The material begins to melt from 240 to 248 degrees Celsius. Plastic goes on sale in a powdered state, or in the form of bobbins with plastic threads wound around them. Despite the fact that plastic does not tolerate direct sunlight, models made from it are famous for their durability. Plastic for a 3D printer can be bought in our online store.

Plastic goes on sale in a powdered state, or in the form of bobbins with plastic threads wound around them. Despite the fact that plastic does not tolerate direct sunlight, models made from it are famous for their durability. Plastic for a 3D printer can be bought in our online store.

Unlike ABC plastic, which models are opaque, acrylic is used to create transparent objects. But acrylic is more capricious in the process of use: the melting point of acrylic is reached later, which means that it will take more time and energy to heat up, and at the same time it quickly cools and hardens. The very process of manufacturing the product is laborious, since heated acrylic contains a lot of air bubbles that can distort the finished product.

Concrete applied for 3D printing , improved, and has a formula that differs from the formula of conventional cement by 5%. The “printing” of a residential building with an area of 230 m2 on a 3D printer will take no more than 20 hours, during which it carefully “lays out” building blocks and structures from concrete.

The use of hydrogel for 3D printing was successfully tested by scientists from the University of Illinois, who used a 3D printer to print miniature (5-10 mm) biorobots. Living cells isolated from the tissue of the heart muscle were placed on them, which, spreading through the hydrogel, set the biorobot in motion. The speed of such a biorobot is 236 µm/s. As planned by scientists, in the future, with the help of such biorobots, tumors and toxins in the body will be detected and neutralized, and they will also be used to deliver medications to diseased human organs.

There are 3D printers that use ordinary office paper as a material. Pre-cut layers of paper are applied one on top of the other and attached with glue. Paper models are cheap enough that they are accessible to users, but at the same time, paper models are not durable and not aesthetically pleasing. Models created in this way are ideal for prototyping in computer projects.

Gypsum used for 3D printing is a fragile, short-lived material, but at the same time it has a low cost. Therefore, models made of plaster are mainly suitable for presentations, perfectly conveying the shape, structure and size of the original product. The resistance of gypsum to heat treatment makes it possible to use it in the foundry as samples for casting.

Therefore, models made of plaster are mainly suitable for presentations, perfectly conveying the shape, structure and size of the original product. The resistance of gypsum to heat treatment makes it possible to use it in the foundry as samples for casting.

Fans of natural wood and products made from it will also enjoy 3D printing, as there is a specially designed “wood” fiber that contains wood and a polymer, and its properties are similar to polyactide (PLA). Outwardly looking like natural wooden models with the smell of fresh wood, they are quite strong and durable. Currently, the material can only be used in the RepRap self-replicating printers.

3D printing with ice is perhaps the most exotic way of making small figures today. The temperature at which the figures are printed is quite low and is -22 degrees Celsius, and the printing material is water and methyl alcohol heated to 20 degrees Celsius.

The pleasant soft sheen and high strength of the metal are far ahead in quality of any plastic used in 3D printing, therefore light and precious metal powders are successfully used in this area. Copper, aluminum and its alloys, gold and silver in powder form are used for printing, adding fiberglass and ceramic inclusions to them.

Copper, aluminum and its alloys, gold and silver in powder form are used for printing, adding fiberglass and ceramic inclusions to them.

Nylon printed parts are similar in many ways to ABS plastic parts, but are softer and more practical. Nylon manufacturing technology is more capricious, in particular, it has a longer curing period, the printing temperature reaches 320 degrees Celsius, and it is more toxic.

3D printers of the near future will be able to print shaped chocolate molds, which should be in high demand in restaurants and pastry shops.

It is also impossible not to mention polycaprolactone, the most popular consumable for 3D printing. This material is so valued for its excellent physical properties and the possibility of being used in various printing technologies.

Of the plastic materials for printing, it is also worth highlighting polycarbonate (hard plastic), polylactide material obtained from biomass, sugar beet or corn silage, polypropylene, polyphenylsulfone, which came from the aviation industry, and an unsurpassed leader in the field of 3D printing, used in any of its areas - polyethylene low pressure.