Artec 3d scanners

Buy Handheld 3D Scanners and 3D Scanning Software at Best Price

Artec Leo Premium Pack

Ultimate 3D scanning pack that has everything you need: top-level handheld scanner, Calibration Kit, extended warranty, maintenance, software subscription, and then some.

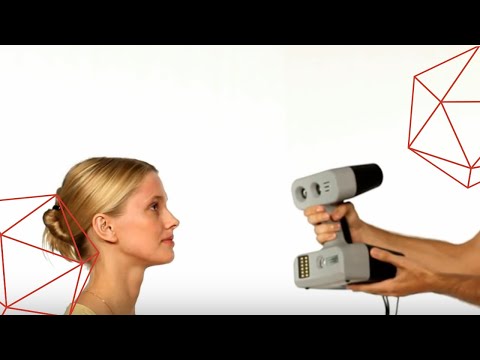

Artec Leo

Our best 3D scanner, equipped with wireless technology and an inbuilt touch screen

Artec Eva

The ideal 3D scanning solution for making quick and accurate 3D models of medium-sized objects

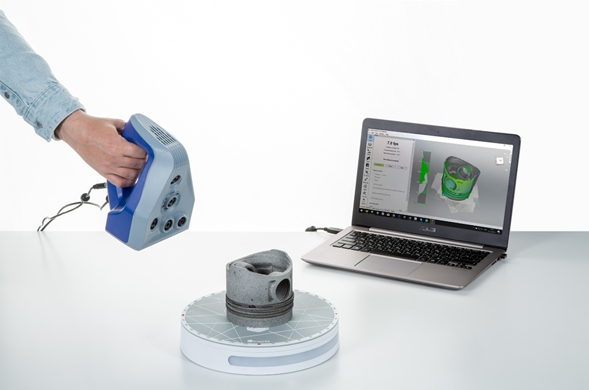

Artec Space Spider

A metrological 3D solution, perfect for capturing small objects for CAD applications and more

Artec Eva Lite

Entry level white light 3D scanner. Geometry tracking and capture only.

Artec Ray

Long range laser scanner for digitizing large objects, such as airplanes or buildings.

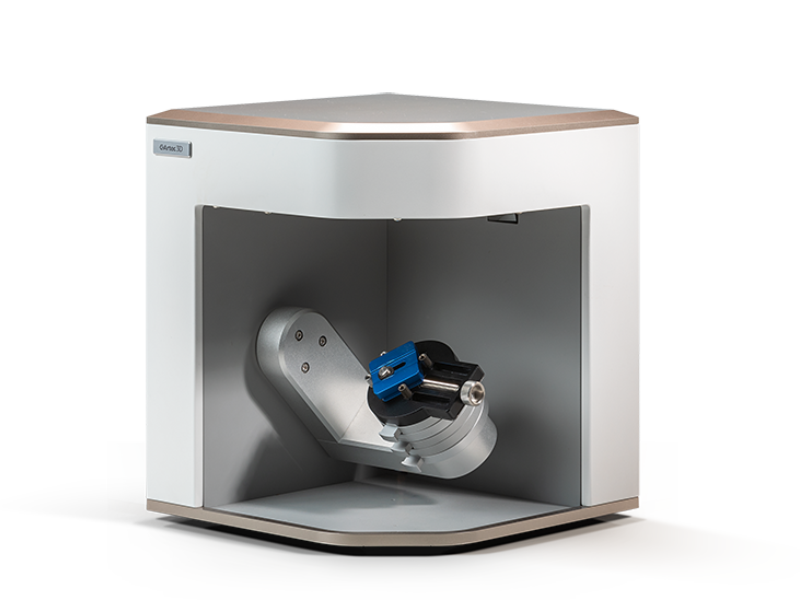

Artec Micro

The perfect metrology-grade desktop 3D scanner for quality inspection, jewelry and dentistry.

Artec Metrology Kit: Entry

Optical coordinate measuring system for inspection and engineering. Accuracy up to 4 microns.

Artec Metrology Kit: Professional

Optical coordinate measuring system for inspection and engineering. Accuracy up to 4 microns.

Upgrade Eva Lite to Eva

Get the full power of Eva’s color tracking and capture features.

Leo + Space Spider

A combo of our powerful 3D scanners. Ideal detailed capture of multiple objects.

Space Spider + Eva

Duo of professional 3D tools available at a special discounted price

Special offers

Educational packages

Artec handheld 3D scanners available at lower prices for classroom use

View more info

Geomagic Design X bundle

An all-in-one reverse engineering solution with Artec Studio and 3D engineering software

View more info

Geomagic for SOLIDWORKS bundles

Export your 3D scans directly to SOLIDWORKS and make manufacture-ready 3D models

View more info

Geomagic Freeform bundles

A winning combination for hands-on organic product design and manufacturing

View more info

Geomagic Control X bundles

An outstanding combo for extensive quality control with easy data capture and analysis

View more info

Geomagic Wrap bundles

A great solution for comprehensive exact surfacing with an extensive toolbox

View more info

Artec software

Artec Studio 17 Trial

An easy way to get started. Try Artec Studio for 30 days at no cost.

Try Artec Studio for 30 days at no cost.

See all plans

Free download

Artec Cloud

Annual, renewed automatically every year

See all plans

200 GB

12 months from date of payment

See all plans

12 months from date of payment

See all plans

Geomagic software

Geomagic for SOLIDWORKS

An ideal scan-to-CAD solution for a seamless workflow in SOLIDWORKS.

Geomagic Design X

Optimal reverse engineering software for fast conversion of 3D scan data into CAD models.

Geomagic Control X Professional

A powerful metrology solution with an advanced set of tools for a flexible workflow.

Geomagic Wrap

A versatile solution with an extensive toolbox, perfect for exact surfacing.

Optional equipment

Leo Calibration Kit

Pre-order yours today! Recalibrate your 2022 Artec Leo in your own time, and in your own environment, to ensure its accuracy always stays at its highest.

{{ getPrice() | formatPrice }}

Add to cartWhere to buy

Artec Turntable

A smart turntable for effortless 3D scanning of small objects with Artec Space Spider.

{{ getPrice() | formatPrice }}

Add to cartWhere to buy

Smart battery charger (Leo)

High-performance and intelligently designed to deliver maximum charges, while extending battery lifespan to the fullest.

{{ getPrice() | formatPrice }}

Add to cartWhere to buy

Eva/Spider battery pack

Scan anywhere for up to 6 hours non-stop. Includes a pouch, a charger, and a power cable for connecting the battery to the 3D scanner.

{{ getPrice() | formatPrice }}

Add to cartWhere to buy

Artec Eva hard case

Designed with Eva’s measurements in mind, this hard case will keep it safe during storage and transportation.

{{ getPrice() | formatPrice }}

Add to cartWhere to buy

Space Spider calibration kit

This kit is there to make sure the accuracy of your Space Spider remains at its highest at all times, even after a sudden jolt!

{{ getPrice() | formatPrice }}

Add to cartWhere to buy

Battery pack cable

Got a field scanning job lined up but your dog has chewed the cable of your Eva/Space Spider battery pack? Order a replacement in just a few clicks!

{{ getPrice() | formatPrice }}

Add to cartWhere to buy

Power supply for battery pack

No matter what extra accessory you may need, Artec 3D has you covered. Order this native power supply unit to charge your Eva/Space Spider battery pack the fastest and safest way possible!

Order this native power supply unit to charge your Eva/Space Spider battery pack the fastest and safest way possible!

{{ getPrice() | formatPrice }}

Add to cartWhere to buy

Eva/Spider USB cable

A fully tested cable featuring the connector needed for your Artec scanner.

{{ getPrice() | formatPrice }}

Add to cartWhere to buy

Eva/Spider power supply

1.8 m power supply developed exclusively for Artec 3D scanners for stable performance

{{ getPrice() | formatPrice }}

Add to cartWhere to buy

Artec USB Kit

Maximize your Artec Eva or Space Spider’s FPS rate with a USB 3.1 to Thunderbolt 3 adapter and add a 5 m extension to your scanner’s USB cord for scanning over longer distances.

{{ getPrice() | formatPrice }}

Add to cartWhere to buy

Handheld 3D scanners | Portable 3D scanning solutions

Artec 3D is a global leader in 3D scanning technology, providing the best and most comprehensive 3D scanners and processing software applicable in a wide range of industries

Compare 3D scanners' specs

| Leo | Space Spider | Micro | Eva / Eva Lite | Ray | Metrology Kit |

|---|---|---|---|---|---|

| Scanner type | |||||

| Handheld, tetherless | Handheld | Desktop | Handheld | Long-range | Photogrammetry kit |

| Size of scanning object/area | |||||

| Medium to large | Small | Very small | Medium | Large to very large | Medium to very large |

| Accuracy, up to | |||||

0. 1 mm 1 mm | 0.05 mm | 0.01 mm | 0.1 mm | 0.7 mm @15 m | 0.002 mm |

| Resolution, up to | |||||

| 0.5 mm | 0.1 mm | 0.029 mm | 0.2 / 0.5 mm | 0.0125° | N/A |

| Target-free technology | |||||

| Yes | Yes | Yes | Yes | Yes | No |

| Color + geometry tracking | |||||

| Yes | Yes | Yes | Yes / No | Yes | N/A |

| Scanning software | |||||

| On-board software | Artec Studio | Artec Studio | Artec Studio | Artec Studio or Artec Remote App | Artec Metrology Kit Plugin for Artec Studio |

| 3D mesh export formats | |||||

| OBJ, PLY, WRL, STL, AOP, ASC, Disney PTX (PTEX), E57, XYZRBG OBC | |||||

An easy way to get to know our range of 3D scanners

How to choose the right 3D scanner for your specific needs. View our product overview brochure.

View our product overview brochure.

Download PDF

Need help choosing the right 3D scanner?

Chat to us today! One of our experts will give you all the info you need for choosing the right 3D scanner for your workflow.

Got a question about 3D scanners?

How can I choose the best 3D scanner for my tasks?

There are many aspects to consider when choosing a scanner for your task, such as the type of object/s that you need to scan, the required technical specifications (accuracy, resolution, texture, etc.), the price of the equipment, and many other factors. For this reason, we have created a guide that can help you better understand which 3D scanner is most suitable for what you need. Consult the guide.

Do you need to be a professional to use Artec 3D scanners?

No. We design our scanners so that any person, even with little to no 3D scanning experience, is capable of using them.

What software can I use with Artec 3D scanners?

When you buy an Artec scanner, you also need to purchase an Artec Studio software license, which allows you to process the data captured with a scanner into a final 3D model. The software is a single application which, once purchased, can be used across the entire spectrum of Artec scanners that you may be purchasing later.

The software is a single application which, once purchased, can be used across the entire spectrum of Artec scanners that you may be purchasing later.

Besides working in Artec Studio, the final model can be exported directly into Geomagic Design X and SOLIDWORKS, as well as uploaded to other reverse engineering and 3D modeling software such as Geomagic Control X, Autodesk, Blender, ZBrush, and many others.

Find more information on the compatible software and available export formats here.

Artec 3D scanners: essential tools for every phase of product lifecycle management

Originate

Dream. Delineate. Innovate.

Synergize the technical requirements of what must be, together with what could be.

From the many, focus on one: decide upon a design and move ahead.

Work up preliminary design and measurement via paper and ultimately CAD software.

Implement portable 3D scanner for creating 3D models quickly.

Review and analyze design until ready for prototyping.

Design

where it all takes shape.

First prototypes created and iteratively tested.

Enhance CAD designs with greater complexity, improved structures.

3D scanning device for accelerated capture-and-refine sequencing using 3D images.

Simulation & analyses including CAE, FEA, CFD, etc.

Detailed master design achieved, rapid prototype with precise measurement created with handheld 3D scanner.

Manufacture

Faster. Stronger. Better.

Components, tools, and materials gathered and/or sourced, quantities determined.

Creation of first run production units for in-house use.

First article inspection with handheld 3D scanners to reveal contrasts with CAD model.

Pre-production (QA) testing and accurate measurement prior to full product launch.

Employ 3D scanning to devise damage-free packaging solutions.

Support & Service

focused inquiry leading to refinement & excellence

First day of use to completion of product lifecycle.

Comprehensive reviews of manufacturing, product performance, longevity, recurring issues, failures.

Integrate feedback to evolve design, manufacturing, and development of more effective marketing and sales.

Optimize long-term support via portable 3D scanning for reverse engineering legacy and out-of-stock parts.

Bringing you the best in handheld 3D solutions since 2008

See why Artec 3D scanners are the global leader in 3D scanning technology. Used in a wide range of professional applications, our scanners are the perfect complement for your important measurement needs.

Reverse engineering

Industrial design

and manufacturing

Healthcare

Science and education

Art and design

Speed and accuracy Get the most accurate 3D images with Artec’s cutting-edge capturing and processing technology. Achieve professional results with high-speed capturing of objects and their measurements.

Portability and compatibility

Discover the limitless possibilities of 3D scanning with our portable 3D devices. Lightweight, mobile and compatible with several popular tablets, Artec scanners can be used absolutely anywhere to ensure a smooth capturing process without having to relocate objects to a particular place for measurement.

Lightweight, mobile and compatible with several popular tablets, Artec scanners can be used absolutely anywhere to ensure a smooth capturing process without having to relocate objects to a particular place for measurement.

Ease of use, no need for targets Our portable 3D scanners are engineered to easily be used by both experienced and first-time users, with expert guidance available during every stage of capture and processing. Advanced tracking ensures the best data capture possible and eliminates the need for using targets, which is a great time saver.

Scanning — Artec Studio Documentation 12

Scanner buttons and capture modes

The 3D scanner can be in one of the following capture modes (each mode has a specific color and flashing frequency of the LED on the device case if an Artec scanner is used):

Rice. 43 Shooting mode diagram (colors match scanner LED)

- Inactive - Solid green LED

-

This mode indicates that the scanner is recognized by the application or that the Stop button on the Capture panel or the button on the scanner body is pressed (see Fig.

12). In this mode, the flash of the 3D scanner does not blink.

12). In this mode, the flash of the 3D scanner does not blink. - Preview - LED flashes red.

-

In this mode, the 3D scanner captures images, but the application neither registers nor records captured frames. To start this process, click either the Preview button on panel Shooting (see Fig. 55), either the button on the scanner body, or the key

F7on the computer keyboard. This mode is useful in the following cases:-

Checking the field of view of the 3D scanner

-

Finding the best position for an object

-

Preparing for recording and working through the scan procedure

-

Texture brightness adjustment

-

- Entry - constant red LED indicator

-

This mode scans and writes data to the computer's RAM or disk. The mode can be activated by pressing the Record button on the panel Survey , or the

Space keyon the keyboard, or the button (first press for Preview , second for Record ). To pause recording, press either the Pause button on the Survey panel, or the button on the scanner body, or the 9 key0027 Space on the keyboard.

To pause recording, press either the Pause button on the Survey panel, or the button on the scanner body, or the 9 key0027 Space on the keyboard.

Selecting and preparing objects for scanning

Artec 3D scanners use the structured illumination method for 3D reconstruction. Because 3D images are captured using optical technology, some types of objects may be difficult to scan. However, certain techniques allow you to successfully scan such objects. For example, you can apply a thin layer of paint or talcum powder to transparent or dark objects. You can also use other easily removable materials or a special anti-reflective spray.

| Surface characteristics | Possible solutions |

|---|---|

| Black or very dark | Apply anti-reflective spray |

| Shiny and reflective objects | Apply anti-reflective spray, tilt scanner when shooting |

| Clear (glass, certain plastics, etc. | Apply anti-reflective spray |

| Fine edges | Add background geometry (e.g. wrinkled paper) |

Scanning techniques

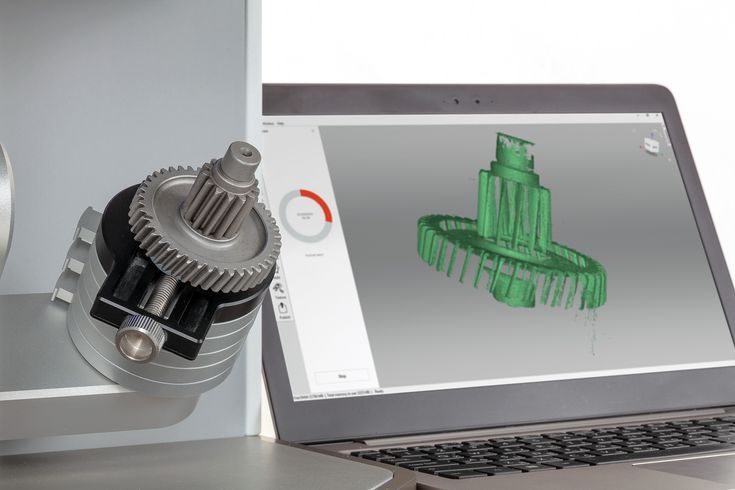

Artec 3D scanners capture objects at up to 15 frames per second to ensure that adjacent areas of the frame overlap with smooth scanner movement. Artec Studio uses features in overlapping areas to automatically align captured frames. It performs this task in real time, providing the user with immediate access to frames in a single coordinate system. This makes it possible to evaluate the scanned area after the end of the session and determine which parts of the object need additional scanning.

Fig. 44 Scanner orientation and repaired surfaces

fig. 45 Rangefinder in window 3D view showing surfaces within the optimal range of the Artec EVA

scannerTo capture an object or scene accurately, follow these steps:

-

Pay more attention to the object on the screen than to the actual object.

-

Verify that Artec Studio can accurately align frames from the scanner. To do this, follow these steps:

-

Do not move the scanner too fast

-

Hold the object as close to the center of the field of view as possible

-

Keep the scanner oriented so that surfaces fill the field of view sufficiently (Fig. 44)

-

Try to position the scanner as close as possible to the center of the rangefinder [1] or slightly below it (closer to the object) (see Fig. 45)

-

-

If you are scanning an object in several scans, then in order to successfully combine them, do not forget to capture a common area in each of them.

-

If you are scanning an object in one scan, capture the object from all sides regardless of direction, plus a little more (360+ degrees)

-

Avoid scanning objects that may change shape during the shooting process.

In conditions where the scene changes, the system may not determine the correct position of new frames relative to those already aligned. If foreign objects got into the frame, then you must remove them later at the editing stage (see Editing scans).

In conditions where the scene changes, the system may not determine the correct position of new frames relative to those already aligned. If foreign objects got into the frame, then you must remove them later at the editing stage (see Editing scans). -

Do not record too many frames: make sure that all areas are sufficiently scanned, but do not shoot them twice, except when recording areas of overlap for successful registration.

| [1] | From a technical point of view, the center of the rangefinder is the center of the depth of view. The 3D scanner has near and far clipping planes (Fig. 11), which determine the optimal distance between the device and the object being scanned. For a visual visualization of the distance to the scanned object, Artec Studio implements tool Range finder , which is a set of translucent histograms located on the left in window 3D view (see Fig. |

Scanning procedure

-

Prepare the object and make sure it has enough geometric and textural detail (see Selecting and preparing objects for scanning).

-

Create even lighting without direct sunlight.

-

If only one scanner is connected to the computer, Artec Studio will automatically select it; otherwise, you will need to select the desired instrument from the list in section Optional panels Survey .

-

Before starting work, create a new project: use the button on the toolbar Workspace , or select the menu command File ‣ New Project, or use the keyboard shortcut

Ctrl + N. Once you have saved a project, you can load and unload scans as needed, thus controlling the use of RAM (see Working with projects for more details).

Once you have saved a project, you can load and unload scans as needed, thus controlling the use of RAM (see Working with projects for more details). -

Decide on the number of sessions needed to capture the entire subject. By using a special turntable (3rd party), you may be able to eliminate the need to turn the object by hand. Depending on your choice, you can:

-

Rotate the object itself

-

Locate so that you have access to all areas

-

Use rotary table

-

-

Press Preview or on the scanner. Point the scanner at the object, practice moving around the object, taking into account Scanning Techniques.

Note

If you want to use the Enable Automatic Removal of Support option, first point the scanner at the surface supporting the object.

-

Press Record to start recording.

-

Move the scanner smoothly while observing the process in window 3D view

-

Shoot as much as you can and pause or end the recording by pressing the Pause or Stop buttons, respectively.

Select Stop if you need to correct the object's position (see next step).

Select Stop if you need to correct the object's position (see next step). -

Rotate the object or otherwise prepare it if necessary, and then scan the remaining areas.

-

Once you have successfully captured the object from all sides, press the Stop button or on the scanner body.

Positioning modes

The program offers three positioning modes (trajectory tracking) and one option:

- Geometry + Texture, or hybrid

-

The most optimal (and standard) algorithm for 3D scanners with a texture camera. Along with the geometric information of the object, the algorithm uses texture details from images taken from the texture camera. Due to this, when using this mode, the most likely successful scanning of flat or textureless objects. The only possible drawback of the algorithm is that it consumes more CPU resources than other algorithms, and therefore the scanning speed may drop on insufficiently powerful computers.

You can use this mode with Artec MHT, Artec EVA, Artec Spider and third-party 3D sensors.

You can use this mode with Artec MHT, Artec EVA, Artec Spider and third-party 3D sensors.

Fig. 46 Texture positioning method draws a colored object (current field of view circled in green)

- Geometry

-

Standard mode for all 3D scanners that do not have a texture camera (Artec EVA Lite). The positioning method uses the object's geometry to align captured frames, making it suitable for objects with rich geometry and useless for objects with large flat, spherical, or cylindrical parts. Positioning Algorithm Geometry uses the least amount of CPU resources compared to other algorithms.

Fig. 47 Main window during survey using Geometry positioning method

- Marks

-

Special algorithm for scanning objects with special marks pasted on their surface.

- Real-time fusion (option)

-

Also available for Artec 3D scanners and third-party 3D sensors, this option “glues” the results immediately after scanning.

See also

Adjusting scan parameters

Removing a support or reference surface

Often when you capture an object, you can exclude its reference surface from the scan. Option Remove support serves this purpose. To apply this option, first specify the surface on which the object is located, and then scan the object itself. If this scenario does not suit you, uncheck the Enable automatic removal of support box.

-

Open panel Survey .

-

Verify that the Enable Automatic Support Deletion check box is selected.

-

Click Preview and aim the scanner at a surface that supports the object (eg table or floor). A gray wireframe plane appears, representing the support.

-

Once the application detects the support, the message "Now scan the object" will appear.

Important

Even if Artec Studio fails to determine the reference surface, you can still start recording.

-

Point the scanner at the object and press the Record button ()

-

Scan the object freely. You can pause and resume your session as needed.

-

Press the Stop button, all scans will move to the coordinate system with the Z axis normal to the support.

-

Close panel Shooting . After Artec Studio performs Fine registration , algorithm Delete support will remove the previously detected support surface. If not, then delete it manually.

Fig. 48 Scanning with option Enable automatic support removal

Resume scanning after path tracking is interrupted

Artec Studio records adjacent frames based on feature data on a common surface. If the scanner stops recognizing common features, it will stop recording. This situation is called path tracking abort. If this happens, simply aim the scanner at the newly scanned area. It is worth noting that there are nuances here, which we will consider below.

Table 2 lists several reasons for broken track tracking. The most common cause is moving the scanner too fast.

| Cause | Possible solutions |

|---|---|

| Scanner too fast | Move scanner slower or increase Scan speed |

| Scanner sees too few surfaces | Apply anti-reflective spray or aim scanner at most of object; increase Sensitivity Artec Spider |

| Object does not have enough signature features to successfully track trajectories | Apply masking tape or draw markers on surrounding surfaces and/or move the scanner more slowly. |

Fig. 49 Warning: Trajectory tracking aborted

Option Scanning using autobuild can make it easier to resume tracking paths (this option is enabled by default in the application settings). Note the following:

Note the following:

-

Artec Studio almost immediately switches from Trajectory Tracking Aborted (see Figure 49) to Searching for position , which appears on a green background.

-

To continue scanning, point the scanner at the area already scanned.

-

Try to keep the original orientation of the scanner towards this area

-

This does not have to be the most recent scan, but it must have enough texture elements.

-

-

If the application successfully restores trace tracking, recording will start in a new scan. This new scan will already be aligned with the previous one.

The section Scanning using autobuild describes the behavior of the system when the option is disabled.

Align new scans with those marked in the Workspace

Automerge can speed up or simplify further processing. But if you have a project with position scans Geometry + Texture and the real scene has not changed, you can continue scanning immediately:

-

Make sure option Scanning using auto build is enabled (On) in Settings (see Capture).

-

Mark previously captured scans on the panel with an icon Workspace

-

Select Geometry + Texture and check the Align new scans with those marked in the Work area on the Survey panel .

-

Click Preview, point the scanner at the already scanned area with the texture, while maintaining the original orientation of the device, then click the Record button.

-

If trajectory tracking resumes successfully, Artec Studio will align the new scan with the selected ones.

Scanning with real-time fusion

Real-time fusion is a special mode in which Artec Studio builds a 3D model directly during scanning. This is the easiest and fastest way to get a model, however, it cannot completely replace the usual workflow for processing raw scans after they have been captured. Therefore, it is not recommended to use Real-time fusion in the following cases:

-

Scanning scene is large and video memory is limited

-

Complex shapes that cannot be scanned in one session

-

The object has small geometric elements

-

High precision required

Real time fusion is available for all positioning methods.

-

Open panel Survey .

-

Select the desired positioning method.

-

Check the Real-time fusion [2] checkbox.

-

Click Preview and then Record. Follow the recommendations in the Scanning Procedure section.

-

Pause and resume the session as needed.

-

When you have finished scanning, on panel Workspace one or more raw scans appear

Eva Scan1,Eva Scan2,Eva Scan3, etc., and one model named ``Eva Scan1-Fusion``. The number of raw scans corresponds to the number of times you paused and resumed scanning (see Figure 50).

Fig. 50 Panel Workspace after using Real-time Fusion

You can open the window Settings and in section Resources configure the following parameters Real-time fusion (see Real-time fusion settings):

- Voxel size

-

The 3D resolution of the model (in other words, the step size of the triangulation mesh in millimeters.

) The smaller the value, the more geometric detail you can see and capture in 3D.

) The smaller the value, the more geometric detail you can see and capture in 3D.

| [2] | If you have selected Marks mode and cleared the Disable hybrid positioning method for .obc checkbox in the settings (see the Photogrammetry settings section), Artec Studio will also clear the Real-time fusion checkbox, because this combination of options is not supported. |

Scanning with marks

In general, no special equipment is required for imaging with the Artec scanner. If the object has hard-to-scan areas, the use of labels (tags) can be useful. In some cases, they can improve the trajectory tracking process and subsequent registration.

Placing labels

Regardless of the method you choose, you must place at least uncoded labels on the object.

Stick uncoded marks (Fig. 51) on the object following the rules:

-

Try to place them on flat areas

-

Avoid uneven surfaces

-

Do not cover important geometric elements with markers

Fig. 51 Uncoded marks on object

51 Uncoded marks on object

Note

The size of marks in is set in the Artec Studio Settings, as described in the Photogrammetry Settings paragraph. If you are using non-coded markers from the Scan Reference set, specify 5 mm for the inner diameter and 10 mm for the outer diameter. Marks of other manufacturers should be measured and the measured values of the outer and inner diameters should be entered in the corresponding fields of the settings dialog.

Place code marks if photogrammetry is selected (Using a Photogrammetry Kit (Scan Reference)).

-

Prepare the subject and the surrounding scene. All objects must remain still during measurement and scanning.

-

Place the cross (Fig. 53) on the stage, make sure it is fixed and clearly visible from all angles. Also check that all marks on it are clearly visible.

-

Place coded labels on the object and on the stage.

It is important to distribute them in such an order that at least six to eight marks are visible in each photo frame. Scattered placement is preferable, and avoid symmetry and alignment in a straight line.

It is important to distribute them in such an order that at least six to eight marks are visible in each photo frame. Scattered placement is preferable, and avoid symmetry and alignment in a straight line.

Fig. 52 Coded tags

Using only Artec 3D scanners

You do not need to have a photogrammetry kit to benefit from the tags placed on the scanned object. Artec 3D scanners can do all the work. This mode uses an extra-hybrid (Geometry + Texture + Labels) positioning method and does not require downloading file OBC .

-

Open the Survey panel in Artec Studio. Select Tags under heading Positioning method .

-

Scan the object from all sides

-

Start Global Registration

Note

Since you are scanning without loading the OBC file, the application itself registers the coordinates of the marks. You can then save the OBC file and use it for subsequent scan sessions. It is highly recommended to run Global Registration first.

It is highly recommended to run Global Registration first.

Using the Photogrammetry Kit (Scan Reference)

The combination of dedicated position marks (labels) and photogrammetric measurement results allows you to scan large areas in one go, increase surface accuracy and increase productivity by reducing post-processing time. The only drawback of this method is the need for preliminary preparation. But after scanning, you will not need to collect scanned surfaces, and you can immediately go to Gluing (See processing in Brief about 3D scanning).

This synergy is achieved through the use of an Artec 3D scanner and photogrammetry solutions. There are several third-party photogrammetry solutions on the market. One such solution is Scan Reference . Set Scan Reference includes software and hardware (see Fig. 53): a digital camera, a reference scale cross, non-coded adhesive-based marks (used by Artec Studio to match scanned data with photogrammetric measurements) and reusable magnetic coded marks ( required for automatic photogrammetric measurements in program Scan Reference ).

Fig. 53 Set Scan Reference

Set includes (from left to right): coded marks (foreground), digital camera, reference scale cross, tape spool with uncoded marks, transport case

To scan using marks, follow the instructions below:

-

Take several photos of the subject from different angles. Recommendations for camera setup, angle selection, number of shots and marks per frame can be found in the user manual Scan Reference and the FAQ article. General recommendations are as follows:

Take photos from 0.5 to 1.5 meters away with the flash on

Each photograph must include as many tags as possible and each tag must appear on at least ten photographs

The entire cross must be in the first 10-12 photographs

Capture an object from all angles

-

Remove the cross and code marks from the stage.

-

Connect the camera to a computer, copy the photographs and process them with the Scan Reference software. As soon as the calculations are completed, the results of the photogrammetric measurements of the object will be displayed on the screen. The results can be presented in the form of a table or a spatial model.

-

Save point model to

*.obcfile. This format is standard for the program. -

Open the Survey panel in Artec Studio. Select Tags under heading Positioning method .

-

Click the Load labels from file button and specify the path to the

OBCfile. -

Scan the object. When you're done, the program will collect all the scans.

Important

If you do not want textural and geometric features to make it easier to scan by marks, select the Disable hybrid positioning method for .obc check box (Photogrammetry Settings).

Using certain types of scanners

Features of scanning with Spider

Since Artec Spider has a smaller field of view compared to Artec EVA and provides higher accuracy, scanning with it can be difficult. Follow the recommendations in the Scanning Techniques section and the tips below:

-

Use a turntable whenever possible

-

Use a piece of paper with text as an artificial texture

-

Double check that the objects have not changed their shape and position

-

In some cases, try adjusting the sensitivity (see Sensitivity). Avoid extreme values.

The Artec Spider scanner is recommended to be used after it has reached its operating temperature. Immediately after connecting to a computer or power outlet, the scanner starts to heat up. When you open the panel General Survey , it displays, among other information, data on the current and optimum temperatures of the device. Warm up is faster when Artec Spider is in mode Preview . In this case, the panel Survey also displays the estimated time remaining until the scanner reaches the optimum temperature.

Warm up is faster when Artec Spider is in mode Preview . In this case, the panel Survey also displays the estimated time remaining until the scanner reaches the optimum temperature.

Note

It should be noted that Artec Spider can be used at sub-optimal temperatures, but the accuracy of the resulting surfaces may be lower in this case.

Features of scanning with third-party 3D sensors

Important

Third-party 3D sensors are only available in Artec Studio Ultimate edition!

Third-party 3D sensors (see Device appearance) are not designed to perform 3D scanning. Being universal devices manufactured using cheap components, they allow you to scan objects, but the quality of the captured surfaces and textures is much worse than in the case of using professional Artec 3D scanners (see Fig. 54). Working ranges and fields of view of all supported in Artec Studio Ultimate 3D sensors are shown in Fig. 19.

Please note the following when scanning with third-party 3D sensors:

- Good lighting is essential

-

because none of the 3D sensors has a built-in flash.

In addition, the use of these devices excludes the possibility of adjusting the brightness of the captured texture. This is why good lighting is so critical to getting an acceptable quality model. Do not over-illuminate the object, use directional light sources and fluorescent lamps. The Intel RealSense R200 is particularly sensitive to direct sunlight.

In addition, the use of these devices excludes the possibility of adjusting the brightness of the captured texture. This is why good lighting is so critical to getting an acceptable quality model. Do not over-illuminate the object, use directional light sources and fluorescent lamps. The Intel RealSense R200 is particularly sensitive to direct sunlight.

- When used with PrimeSense and Asus Xtion sensors

-

Use a special technique to help you capture surfaces with uniform brightness:

-

Click Preview

-

Point the sensor at the subject and hold it for about five seconds while it adjusts the white balance and exposure

-

Press Write button

-

Move the scanner smoothly to capture scene

-

Keep the sensor as close to the object as possible during scanning

-

- Most third-party devices work in real-time Merge mode

-

except Kinect ver.

2 . Moreover, this mode is standard for Intel RealSense 3D sensors.

2 . Moreover, this mode is standard for Intel RealSense 3D sensors.

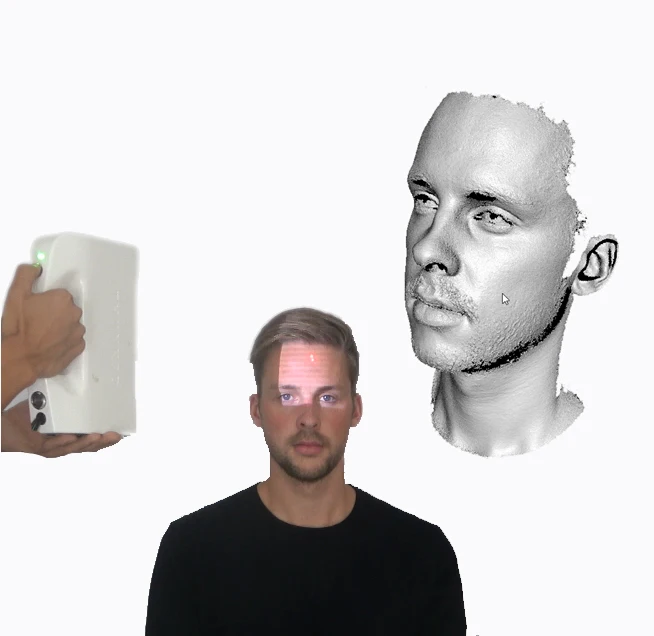

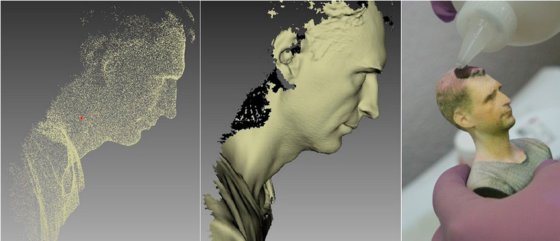

Fig. 54 Filmed and processed object

(scan of Artec EVA on the left and PrimeSense on the right)

MHT scanning features

The flash lamp in the Artec MHT scanner has a very high but still limited number of cycles, so always be sure to turn off the scanner when not in use. Do not leave the scanner on at the maximum (15 frames per second) frame rate for a long time. Artec Studio will automatically turn off the Artec MHT scanner after five minutes of continuous operation. The optimal operating/idle time for the scanner is 3/7 minutes, i.e. 3 minutes of scanning and 7 minutes of inactivity. This will significantly increase the life cycle of the flash.

Scan settings

55 Artec Studio Capture panel

Adjust texture brightness

Note

This option is only available for Artec 3D scanners with a built-in texture camera.

Texture brightness can be adjusted in mode Preview . By moving the slider, you can increase or decrease the brightness of the frames captured by the color camera (see Fig. 56). Note that texture brightness affects texture quality as well as track tracking stability. Also follow the recommendations in Table 3.

By moving the slider, you can increase or decrease the brightness of the frames captured by the color camera (see Fig. 56). Note that texture brightness affects texture quality as well as track tracking stability. Also follow the recommendations in Table 3.

| Surface color | Recommendation |

|---|---|

| Dark or black | Brighten up |

| White or light colors | Reduce brightness |

Fig. 56 Brightness setting for color camera

Brightness decreased on the left and increased on the right (slider of the panel Survey is shown at the top for convenience)

Sensitivity

You can adjust the Sensitivity of the Artec Spider scanner if the application fails to restore certain surfaces. Increasing the sensitivity will make it easier for the scanner to capture black, reflective, translucent, and thin objects (such as human hair). The higher the sensitivity, the noisier the recorded surfaces will be. High values may also slow down the scanning speed. For Eva and other Artec scanners, this option is configured automatically.

Increasing the sensitivity will make it easier for the scanner to capture black, reflective, translucent, and thin objects (such as human hair). The higher the sensitivity, the noisier the recorded surfaces will be. High values may also slow down the scanning speed. For Eva and other Artec scanners, this option is configured automatically.

Texture frame rate

Set the texture frame rate using the corresponding slider in the Settings dialog (see Texture recording mode and Fig. 152).

Turn off the scanner's flash

If you are unable to use the scanner's flash due to circumstances, follow these steps.

Fig. 57 Influence of ambient light on shooting results

Left: flash off, ambient light rather weak; the result is a dark texture. Right: flash off, ambient light improved; the result is a good texture.

Note that turning off the flash must be compensated by sufficient ambient light. According to our data, with the flash turned off, a texture of acceptable quality can be obtained if the illumination of the scanned surface is at least 1000 lux. Compare models (Fig. 57) taken under different lighting conditions.

Compare models (Fig. 57) taken under different lighting conditions.

To get a textured model without using the scanner flash, follow these steps:

-

Open panel Survey , click on the link Advanced

-

Turn off texture flash by checking the Turn off flash check box

-

Create good outdoor lighting. Do not use fluorescent lamps.

-

Press Preview and point the scanner at the object

-

Adjust the Texture Brightness and Exposure Time for the texture. In most cases, values should be chosen as low as possible, since increasing the brightness can cause texture noise, and increasing the exposure time can cause blurring (loss of clarity). Instead of adjusting the sliders, try to improve the lighting even further.

-

Shoot a scene

-

To obtain a textured model, perform the required processing as described in Data Processing

-

Adjust the texture settings for the resulting model as described in Adjusting Texture.

Pay special attention to the Hue and Saturation sliders. By moving the Hue slider, you can correct unwanted texture colors.

Pay special attention to the Hue and Saturation sliders. By moving the Hue slider, you can correct unwanted texture colors.

Exposure time setting

You can adjust the exposure time for the texture in mode Preview . Adjust this setting along with Texture Brightness. Increasing the exposure time can cause blurring of the texture. Do not change the default value unnecessarily.

Disable texture recording

Clear the Do not capture texture check box if you do not want to store texture information in your scans. It is located on the panel in section Advanced and turns off both the texture camera and the scanner flash. Note that this option is not available for the Artec EVA Lite scanner. Don't forget to check the box when finished shooting without texture. Otherwise, the next time you want to start normal shooting, the hybrid positioning method may not be available.

Important

Simply using the positioning method Geometry is not enough to stop the application from writing the texture. Make sure you uncheck the box of the same name.

Make sure you uncheck the box of the same name.

Decrease scan speed

Artec EVA captures objects at up to 15 frames per second, while Artec Spider at up to 7.5. The default values guarantee comfortable scanning with smooth movements. However, if this speed is not to your liking, you can reduce it. In this case, Artec Studio will record fewer identical frames and register them faster. To do this, use the slider Scan speed on panel Survey .

Important

Reducing the scan speed can make shooting difficult. Use the slider only when absolutely necessary.

Additional settings

- Set your own scan name and initial scan number

-

by entering your own values in the fields Scan name and Start from , as well as changing the state of the smth checkbox. These values form the name of the scan on panel Working area (see Fig. 80, left). So, the default values "Eva Scan" and the number "1" can be changed, for example, to "Snapshot" and "14".

- Set up scanned data backup to disk

-

Enable shooting mode with simultaneous writing of scanned data to disk by checking the Save a copy of the scan to disk checkbox. The option is available only if you are working with an already saved project (see Saving a project) and can be useful when capturing a large amount of data on a workstation with insufficient RAM.

- Specify the delay (in seconds) before recording

-

using the Delay before starting recording field in section Advanced of panel Survey . Then, after pressing the Record button, the application will delay the immediate start of recording for a specified number of seconds. To remove the delay, set the value to zero.

- Reduce the setpoints Working area limits

-

with sliders Middle (mm) and Far (mm) on panel Survey in section Optional . There you can only reduce the range within the given bounds.

- Set the working area limits (in millimeters)

-

By default, Artec Studio knows the values of the minimum and maximum limits of the working distance range for the device, within which clipping planes should be located. These values are tied to the type of connected device and provide good quality of the scanned 3D data. However, the operating range limits of Artec L scanners and 3D sensors can be overridden if scanning accuracy is of secondary importance. To do this, in the settings dialog on page Survey set the Redefine depth range checkbox, and then enter new boundaries of the scanning range (more about survey settings in the Survey section).

Warning

Non-standard values for the scanner operating range can result in loss of accuracy.

- Set panel hide Capture during scan

-

To enlarge the viewing window during scanning, the program automatically closes panel Survey as soon as you start recording using the Artec EVA or Artec Spider scanner.

The Hide this panel during scanning check box is located in section Advanced and is unchecked by default.

The Hide this panel during scanning check box is located in section Advanced and is unchecked by default.

Troubleshooting

| Problem | Possible solution |

|---|---|

| Geometry + Texture switch not available on panel Shooting . | Most likely you scanned without a texture. Uncheck Do not strip texture under Optional . |

| Noisy areas are visible in the resulting model. | You probably did not scan the damaged areas properly, or the scanner was too far from the object. Rescan them. |

| Error Trajectory tracking aborted repeats | Make sure Scan using auto-build is enabled (On) in Application Settings and use the positioning method Geometry + Texture . |

Artec 3D scanners

3D scanning on the example of the Eva model

We have already got acquainted with the Artec Studio program ourselves and introduced the readers, and now we have become the owners of the Artec Eva 3D scanner (albeit for a while). The second Spider model currently in production is based on the same principles, but has a number of design differences to achieve greater accuracy.

But before proceeding to a detailed description, let's make a short digression into the technology of 3D scanning.

Some general information

To obtain a mathematical model of an object, that is, its three-dimensional image in electronic form, we need to “feel” the object in one way or another and transfer the result to a computer processing program.

Contact scanners

You can literally feel with a mechanical probe, which is available in contact scanners. The probe, equipped with a touch sensor, moves and measures the height or depth of the object at each point of the coordinate grid specified from the control program. The carriage mechanism and service program may also allow for angular movements/calculations to account for cavities or holes in the object.

The carriage mechanism and service program may also allow for angular movements/calculations to account for cavities or holes in the object.

It is clear that the model will more accurately match the original object, the smaller the grid step, but the scanning time will increase proportionally, which for large and rather complex objects can be many hours and even several days.

To some extent, the process can be speeded up programmatically by automatically detecting the complexity of the terrain and changing the grid step accordingly: for complex areas, reduce, increasing accuracy, for simple areas, increase, reducing time. But it will still not work to complete the scan in a few minutes instead of several hours or a day.

However, in some cases, you can wait to achieve the goal, but there are more significant limitations associated with the design features. It is clear that the probe must move along three axes with the help of some kind of drive, and if the minimum step of this drive, which determines the accuracy, can be made sufficiently small along any of the axes (tens of micrometers), then the limiting movement cannot be very large, before just because then the scanner itself will have the same dimensions. Two meters at least along two axes can still be realized, and there are such examples; 2.5–3 meters along each axis is already more difficult, including because a cube with a side of three meters can not be placed in every room. Therefore, such devices are most often used to scan objects that are large in two axes and much smaller in the third, such as bas-reliefs.

Two meters at least along two axes can still be realized, and there are such examples; 2.5–3 meters along each axis is already more difficult, including because a cube with a side of three meters can not be placed in every room. Therefore, such devices are most often used to scan objects that are large in two axes and much smaller in the third, such as bas-reliefs.

In addition to the size, the limited applicability of such scanners is associated with the presence of mechanical contact: the scanned object must be sufficiently hard, durable and, of course, remain motionless not only for a long time, but also when touching the probe, that is, small light objects will have to be then fix, but this is not always possible. In addition, the object will have to be placed in the working volume of the scanner - it is difficult to imagine a design capable of driving a probe along the same bas-relief located high on the wall of a building.

Finally, we can only talk about digitizing geometry, of course, a contact scanner cannot fix any color textures.

However, this technology has a positive side: an engraving or engraving-milling machine can be quite easily turned into a contact scanner, and the price of the “machine + scanner” combine will not be much higher than that of the machine itself. True, the availability of advanced software for working with 3D models can give a noticeable increase in cost, but this is quite a common situation.

Non-contact scanners

Much more versatile and, of course, more compact are non-contact scanners, which instead of mechanical contact perceive reflections of some kind of radiation from an object. Moreover, they may well reproduce not only the shape, but also the color of the surface.

Since the scanned objects are usually located in places where there is lighting - natural or artificial, it is quite logical to use the reflection of the available light in the visible range of the spectrum. Passive 3D scanners are based on this, which are, in essence, a specialized version of a familiar video camera. However, the lighting that is quite acceptable for shooting a movie may not be enough to accurately reproduce the details when scanning, moreover, the object is usually unevenly lit. Of course, you can use special illuminators such as those used in photo studios, but this is not cheap, and most importantly, both compactness and mobility are lost.

However, the lighting that is quite acceptable for shooting a movie may not be enough to accurately reproduce the details when scanning, moreover, the object is usually unevenly lit. Of course, you can use special illuminators such as those used in photo studios, but this is not cheap, and most importantly, both compactness and mobility are lost.

Therefore, most non-contact scanners have their own source of radiation, even the cheap Kinect sensor we reviewed in the previous review has its own infrared emitter.

In addition to infrared, other sources of radiation, up to ultrasonic, can be used: a long time ago well-known echo sounder used to study the relief of the bottom of reservoirs, also a 3D scanner of its kind. But, of course, the resolution will depend on:

- the propagation speed of the emitted waves, which will determine the maximum number of samples per unit time;

- wavelengths: to distinguish the details of the object, the dimensions of which are comparable to the wavelength, simply will not work.

For ultrasonic vibrations, these parameters are sufficient to determine the relief of the bottom of a lake or river, where it is not necessary to distinguish between millimeters and centimeters. But to scan objects or even small areas of the earth's surface, a shorter wavelength will also be required (the length of ultrasonic vibrations with a frequency of 40 kHz in air is 8 mm), and radiation should propagate faster - remember that in air the speed of sound is almost five times less than in water, and is approximately 330 m / s, that is, with a distance to the object of tens of centimeters and meters, we will be able to make only a few hundred measurements per second, having received information about only a few hundred points.

Therefore, laser emitters are often used. The speed of light is enormous, and many tens and even hundreds of thousands of measurements can be made per unit time, and the wavelength of a semiconductor laser usually does not exceed a micrometer.

Two methods are possible here; one is similar to echolocation - the distance is calculated from the time it takes for the laser beam to travel to the point and back. Such scanners can be used from a very long distance, but their resolution is limited by the accuracy of calculating the time interval: it takes a little more than three picoseconds (3 10 −12 s). It is very difficult to make accurate measurements of values of this order, and therefore very expensive, so you have to sacrifice resolution, which determines the scope of devices based on this principle: scanning large objects like buildings, for which a few extra millimeters do not play a special role.

Much better accuracy can be achieved by using the triangulation method, a term that GPS users have probably heard. With regard to scanners, this means the following: the emitter and the camera on the body are separated, and the beam is sent at a certain angle relative to the camera. Thus, a triangle is obtained, the base of which is formed by the emitter and the camera, and the apex is a point on the surface of the object. Based on the offset of the reflection formed by the lens on the camera sensor from this point, it is possible to calculate the angle between the incident and reflected rays; knowing the angle and length of the base, you can very accurately calculate the distance to the point of the object. True, such a technique works well only at relatively short distances, much shorter than when measuring by the beam transit time.

Based on the offset of the reflection formed by the lens on the camera sensor from this point, it is possible to calculate the angle between the incident and reflected rays; knowing the angle and length of the base, you can very accurately calculate the distance to the point of the object. True, such a technique works well only at relatively short distances, much shorter than when measuring by the beam transit time.

To speed up the process, a stripe is often used instead of a dot, but there is another method - the use of structured illumination, when the radiation source applies a grid rather than a dot or stripe to the object. A camera located slightly away from such a projector perceives the reflection of this grid and, from the detected distortions, calculates the distance to each point in the field of view. Due to this, both high speed (you can analyze the entire field of view at once) and better accuracy are achieved. This is the method used in Artec scanners.

The easiest way to use visible light emitters - laser or LED. However, they cannot be used to capture photorealistic color textures, so if the scanner has a texture camera, it either, like in Kinect, uses the light available in the room (but it may not be enough, and besides, subsequent color correction will most often be required), or has its own light source, unrelated to the one used to define the geometry of the object.

However, they cannot be used to capture photorealistic color textures, so if the scanner has a texture camera, it either, like in Kinect, uses the light available in the room (but it may not be enough, and besides, subsequent color correction will most often be required), or has its own light source, unrelated to the one used to define the geometry of the object.

Parameters of Artec scanners

The specifications of Artec 3D scanners declared by the manufacturer are shown in the table.

| Artec EVA | Artec Spider | |||

| Working distance, m | 0.4 - 1.0 | 0.17 - 0.3 | ||

| at close range | 214 × 148 | 90 × 70 | ||

| at a long distance | 536 × 371 | 180 × 140 | ||

| Angular field of view (B × W, degrees) | 30 × 21 | |||

| CADROV frequency, cadrov/ | premises, 9009 16 | to 7. 5 5 | ||

| Exhibiting time, with | 0.0002 | 0.0005 | ||

| Data collection speeds/s | to 200000 | to 1,000,000 | ||

| 3D, mm | to 0.5 | to 0.1 | ||

| accuracy, mm | to 0.1 | to 0.05 | ||

| Source Source | LAST (NOT laser) | blue diode diode blue diode blue diode (not laser) | ||

| The ability to shoot a texture | Yes | |||

| Resolution of the texture chamber | 1.3 MP | |||

| Color | 24 bits per pixel of the gag) , mm: | 262 × 158 × 64 | 190 × 140 × 130 | |

| Weight (net), kg | 0.85 | 0.85 | ||

| Retail price indicated on the manufacturer’s website | € 13 700 | € 15 700 | ||

| ¹ excluding connected cables and connectors | ||||

We note that there is another EVA Lite, different from EVA from EVA. lack of a texture camera; its price is almost 30% lower - €9700, but there is only one base, and the owner of Eva Lite, having saved up some money, will be able to upgrade to Eva. True, you won’t be able to save money: the upgrade will cost exactly the difference between the prices of Eva and Eva Lite.

lack of a texture camera; its price is almost 30% lower - €9700, but there is only one base, and the owner of Eva Lite, having saved up some money, will be able to upgrade to Eva. True, you won’t be able to save money: the upgrade will cost exactly the difference between the prices of Eva and Eva Lite.

Some parameters require comments.

Resolution in 3D - the minimum size of an object that the scanner is able to distinguish, or the minimum distance between two elements of an object at which they are recognized separately.

Accuracy: An error detected by scanning a reference sample whose size is known to an accuracy of plus or minus 20 micrometers (according to the VDI2634 standard). The procedure is carried out for each copy of the scanner, and a certificate is included in the kit, which indicates the measurement results. And the table shows the maximum value for this type of scanner.

Consumption - naturally, the given value is the maximum power consumption in the mode when all scanner mechanisms are used, including the backlight of the texture camera. The average consumption during actual operation, of course, will be noticeably less. When powered by AC power through a standard adapter, this does not matter, but when working "in the field", when the scanner is powered by some kind of battery, battery life is a very important factor.

The average consumption during actual operation, of course, will be noticeably less. When powered by AC power through a standard adapter, this does not matter, but when working "in the field", when the scanner is powered by some kind of battery, battery life is a very important factor.

Appearance, working parts

Scanners are shaped like a small iron: soleplate, easy-to-grip handle with buttons and outgoing cables (there are two of them: interface and power), base for installation on a table or other plane when not in use.

This iron is made of plastic and is very light: the weight of the device is only 0.85 kg (excluding cables), so even a woman's hand can manipulate it.

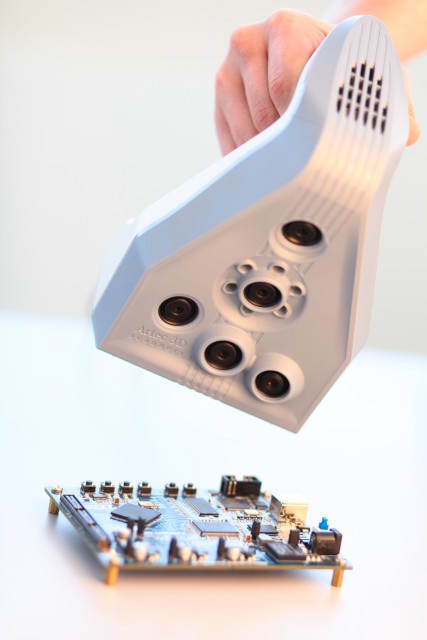

The sole houses the cameras and lighting organs.

In the center is a color texture chamber surrounded by twelve white LEDs. In the lower part there is a 3D camera, in the upper part there is a flash (or projector) of structured illumination for recording geometry, also with white radiation.

Spider also has a texture camera in the center, only there are six smaller LEDs (obviously, this is due to the reduced range of working distances). But there are as many as three 3D cameras, and with increased resolution, due to which a greater scanning resolution is achieved. There is only one flash (projector) of structured illumination; it uses a blue glow diode.

At the top of the Eva is a ventilation grille that exposes a small fan that draws air into the case. It starts to rotate immediately after turning on the power, but its speed depends on the temperature inside the case, that is, on the mode of operation. When scanning, the noise becomes quite noticeable: we measured at a distance of 0.5 meters, simulating the distance to the head of the operator who holds the scanner in his hand, and our sound level meter showed 51.5-51.7 dBA. In an office space where several people are actively working, such noise will not be very noticeable even to the operator. In a quieter room, the situation is different, especially when you consider that when scanning, constant clicking is added to the sounds from the fan, accompanying the backlight on and off at the frame rate of the shooting; however, even here the volume cannot be called annoying, perhaps not very comfortable.

There are two things related to the fan. Firstly, do not turn off the power of the scanner immediately after scanning is completed - its “offal” is still quite hot; you should wait until the fan speed drops to a minimum. Secondly, of course, along with the airflow created by the fan, dust will inevitably get inside the scanner, so you should avoid using Eva in dusty places.

Spider also has a grille at the top, but without a fan. Apparently, a significantly smaller number of backlight LEDs, along with a reduced maximum frame rate when shooting, do not create such significant heating inside the case as in Eva.

Both models are controlled by three-position rocker buttons, which differ in form, but not in functionality. They not only put the scanner into one mode or another, but also control the Artec Studio program: a single click on Play / Pause will open the program's Capture panel and start the preview mode, subsequent clicks switch both the scanner and the program from the Record mode to Preview and back. Clicking on "Stop" during the shooting will stop the process, and pressing it twice will also close the "Shooting" panel in the program.

Clicking on "Stop" during the shooting will stop the process, and pressing it twice will also close the "Shooting" panel in the program.

I must say that we just lacked such buttons when we worked with the Kinect sensor when writing the previous review. But Artec scanners could use one more button - power off, especially Eva with its constantly running fan. This would allow extending the battery life when powered by an optional battery (we will talk about it below), and for Eva it would be easy to make the action of such a button dependent on temperature and turn off the power only after the fan switches to a lower speed.

There is also an LED indicator, the color and mode of illumination (steady/blinking) indicating the current mode. We will not list in detail - the possible states of the indicator are described in the Artec Studio user manual.

The base of the scanner has a threaded hole that allows the device to be mounted on standard photo tripods.

Eva also has RJ-12 6P6C connectors, which are quite unexpected for a 3D scanner, marked as In and Out. They are designed to synchronize multiple scanners when they work together using a 4-wire cable. The connection method is also described in the manual.

They are designed to synchronize multiple scanners when they work together using a 4-wire cable. The connection method is also described in the manual.

Equipment, options

Now about the equipment, which may differ slightly in different regions - first a brief listing, then details.

Scanners are always supplied with two interface cables (one spare) and an external power supply, the socket of which corresponds to the type accepted in the region of delivery.

Spider includes a calibration kit.

The scanners come in a well-printed quality cardboard box with a carrying handle. True, we got a test sample without packaging, so we cannot provide photos and judge by the materials that are on the Internet. In Russia, scanners come with bags similar to those used for photographic equipment, but a client who wants to save money can refuse such a bag. In other countries, Spider scanners are supplied in hard cases, Eva - in boxes.

The shape of the power supply is familiar from countless laptops and netbooks, providing 12V output up to 5A.

1.1m long 220V cable; the output cable is longer - 1.95 m, it is connected to the scanner with a connector equipped with a union nut for reliability. Near this connector there is a ferrite ring to suppress RF interference.

The standard 2.9 meter USB 2.0 interface cable is also equipped with ferrite rings, but at each end. It connects to the scanner with a Mini-USB connector, which has an L-shaped shape.

The port for it is located in a recess - this not only allowed the connector to fit into the dimensions of the scanner, but also prevented it from falling out from an accidental jerk (unless, of course, the jerk is too strong).

Optional 16000 mAh battery (59.2 Wh to be exact) is available. Of course, this is not Artec's own development: readers of our Power Supply section are already familiar with such models, however, for Artec, the battery is equipped with a convenient case fastened to a waist belt, but most importantly, a connecting cable with a rather specific connector. Unfortunately, the price of such a battery is very high, but this is a common situation for any options offered by the manufacturer of any device.

Unfortunately, the price of such a battery is very high, but this is a common situation for any options offered by the manufacturer of any device.

You can purchase either a hard case or soft bag to transport the Eva scanner, which came in a regular carton. The prices for them are also not the most humane, especially for a case. We got the bag, although it is somewhat different than shown on the manufacturer's website, and we can say that it is quite convenient: there are several internal and external pockets, a shoulder strap and the possibility of attaching it to a belt. This bag will fit the scanner itself with cables, and the AC adapter, and there will be room for an optional battery.

The price of an additional USB cable is more or less adequate (in case two complete ones are not enough) - of course, if you do not compare with penny USB cables, which only the slowest devices can work with.

Situations are quite possible when the length of the standard USB cable may not be enough, and the idea of using extension cords comes up. You can try, but no problems are guaranteed. The main thing: the extension cord should not be cheap, of which there are plenty on sale; the cable used in it must be no worse than in the "native" cable - Shielded High Speed USB 2.0, section 28AWG / 1P + 24AWG / 2C. Here, the first designation 28AWG / 1P defines the wires in the twisted pair of the Data line - the smaller the value, the larger the cross section and the longer the length can be if there are no problems; the second designation 24AWG / 2C defines the wires in the Power line, and therefore it is not so critical for a scanner powered by its own power supply. Of course, this extension should not be too long, and the presence of ferrite rings at its ends is also very desirable.

You can try, but no problems are guaranteed. The main thing: the extension cord should not be cheap, of which there are plenty on sale; the cable used in it must be no worse than in the "native" cable - Shielded High Speed USB 2.0, section 28AWG / 1P + 24AWG / 2C. Here, the first designation 28AWG / 1P defines the wires in the twisted pair of the Data line - the smaller the value, the larger the cross section and the longer the length can be if there are no problems; the second designation 24AWG / 2C defines the wires in the Power line, and therefore it is not so critical for a scanner powered by its own power supply. Of course, this extension should not be too long, and the presence of ferrite rings at its ends is also very desirable.

Installing the Artec Eva 3D scanner

Having unpacked the scanner, we connect the cables to it - the interface cable, correctly laying it in the recess, and the power supply (we fix it with a union nut). We connect the power supply to a 220 V socket, and the USB connector to the USB 2. 0 port of the computer. We wait until the system informs about the completion of the installation of drivers (they are included in the Artec Studio distribution kit), after which Artec 3D Camera and Artec Color Camera should appear in the device manager.

0 port of the computer. We wait until the system informs about the completion of the installation of drivers (they are included in the Artec Studio distribution kit), after which Artec 3D Camera and Artec Color Camera should appear in the device manager.

But after that, the scanner is not ready for use yet, it must first be activated (for us, who received the scanner for a while, the term changes to “rent”). To do this, launch Artec Installation Center (AIC), which is also installed with Artec Studio; in its "Scanners" window, a line appears with the name "Artec Scanner EV" (for Eva), followed by a serial number - it can be compared with the one on the base of the scanner (in the test copy it is written by hand, printed on commercial samples).

We make sure that the computer is connected to the Internet, and press the button "Activate ( we have Rent )" at the end of the line. After a few seconds, the button is replaced by the inscription “Activated ( Rented )”:

Unlike the program itself, activating the scanner does not mean it is linked to a specific computer, but only to an account on my. artec3d.com . If you need to use the scanner on another computer (where, of course, Artec Studio must be installed), then this can be done, just run AIC on it.

artec3d.com . If you need to use the scanner on another computer (where, of course, Artec Studio must be installed), then this can be done, just run AIC on it.

That's it, you can start working - the scanner should appear in the Artec Studio program. If it is supposed to scan on a computer that is not connected to the Internet for security reasons, then offline activation is also possible, which we talked about in the previous review.

Recall: in "Settings - Survey" for all scanners, except for Spider, not the model name is displayed, but the type in accordance with the coverage area; so, for Eva we will see "Scanner Type M".

And this is not just a line indicating the presence of a certain scanner: at the same time, the optimal processing algorithms for it are selected, the limit values of some adjustment ranges are set, and the possibility of setting certain parameters appears or, conversely, disappears. For example, for Eva, unlike Kinect, in the shooting settings you can set the brightness of the texture, adjust the sensitivity and turn off the flash, and the frame rate (or scan speed) can no longer be set above 15 frames per second.

Correction and calibration

If the scanner was subjected to shocks and shaking during transportation, you can start by checking: it is enough to point the scanner at a right angle at a light, even, uniform surface (wall, floor, tabletop) from a distance within the operating range, and not in the near or far zone - for Eva it is 60–80 cm, and in the preview mode of Artec Studio, evaluate the geometry of the rectangle observed in the 3D view window. Of course, it is unlikely to be ideal, but if its shape is approximately the same as in the right screenshot, then everything is in order, and the presence of distortions in the left screenshot indicates the need for correction.

Correction is performed using the Diagnostic Tool installed with Artec Studio. Its use is described in detail in the manual, so we will not dwell on this, and will only say that for Eva the procedure is quite simple.

The only remark is that for some reason the interface of the utility is not fully Russified; We hope that this phenomenon is temporary, and in subsequent versions all messages in it will be in Russian.

If you cannot achieve an acceptable result using the utility, you will have to contact the service center.

Scanning

A few general remarks

Despite the small weight of the scanner, holding it in a high or horizontally outstretched hand for a long time is not so comfortable, for example, try holding a liter milk carton in this position yourself. Therefore, it is better to choose the location of the object so that its height is approximately at the level of the operator’s stomach or chest, and horizontally it is at a distance from it within the limits indicated in the table plus the length of the half-bent arm. Actually, the operator himself will quickly understand all this from personal experience.

When taking a picture, avoid fast movements, even if it is just turning the scanner 90 degrees around the horizontal axis: an audible signal will immediately follow and an alert that trajectory tracking has been interrupted.

To avoid this, you need to learn how to press the Play/Pause button in time. There is also a useful mode “Continue scanning from marked scans”: if you select some of the scans made in previous sessions in the workspace, the program will combine new scans of the same object with them.

There is also a useful mode “Continue scanning from marked scans”: if you select some of the scans made in previous sessions in the workspace, the program will combine new scans of the same object with them.

Recording will not work for a long time: the scanner heats up and goes into pause mode. The optimal ratio during work is 3 minutes of recording, then a 7-minute break; with shorter breaks, the recording steps will have to be made shorter.

Sometimes there is not a pause, but rather a freeze, and in the “Shooting” panel, the message “Camera not connected” may even appear. It is more often not overheating that is to blame here, but the USB port: check if another device is connected to the same USB controller, try connecting the scanner to the port located on the I / O port panel of the system board, and not on the front panel of the case (and USB 2.0, not 3.0), and of course remove the USB extension cable if one is used. If this still happens, then the scanner can only be returned to working condition by turning off and then turning on its power with a restart of the program.

A battery hung on a waist belt or in a bag on the shoulder, we would classify as a must have even when working indoors: of course, the scanner is already “tied” to the computer with a USB cable, but another cable that goes through power supply to the nearest outlet, only adds to the inconvenience during operation. Each of the cables, when moving, strives to catch on to something, so it is better that at least one of them does not dangle on the floor, but is fixed on the operator.

If we are talking about working "in the field", when scanning is carried out not on a desktop computer, but on a laptop, then the battery becomes an absolute necessity. Judging by our own research on such batteries, the battery life of the scanner will be estimated at several hours, especially considering that continuous scanning will still not work (not only because of the danger of overheating, but also because you need to periodically check the scanned), and in standby mode, the scanner consumes much less power than indicated in the specifications table.

This is confirmed by the practice of using - not our own, very modest, but people who worked with the scanner on expeditions. There are reviews on the manufacturer's website, we will only highlight two points in them. The first one is quite optimistic: so, for two days of active use of the scanner, the battery charge was not fully used. The second confirms our conclusion about the desirability of the power off button: in between scans, we had to unplug the cable from the battery, which gave a noticeable battery savings.

A little bit about overheating: the review from the expedition mentions that even at an ambient temperature of +35 °C, the scanner could work continuously for 400 seconds. True, it is not specified whether only geometry or geometry + texture was filmed.

We tried it: at a room temperature of +24 °C, the scanner worked without turning off for 10 minutes in geometry and texture capture mode at a frame rate displayed in the Capture panel of 10–12 fps. Overheating did not occur, the process was stopped by us. True, no scans were made before that for at least half an hour, i.e. the scanner was at room temperature. The handle turned out to be the hottest part - it became noticeably warm, and after the process was stopped, the fan switched to minimum speed in less than half a minute.

Overheating did not occur, the process was stopped by us. True, no scans were made before that for at least half an hour, i.e. the scanner was at room temperature. The handle turned out to be the hottest part - it became noticeably warm, and after the process was stopped, the fan switched to minimum speed in less than half a minute.

After a five-minute break, the scanner worked for another 3.5 minutes in the same mode, after which it stopped due to overheating. It took him only 2-3 minutes to return to working condition.