Tazbot 3d printer

LulzBot | Taz-6-product-page

LulzBot TAZ 6

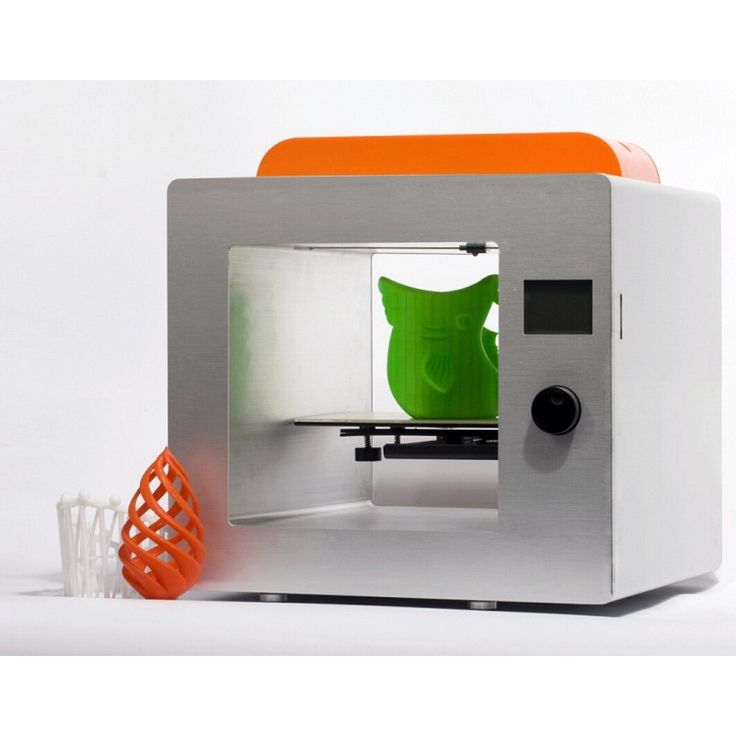

Engineers, designers, educatiors, and makers agree: The LulzBot TAZ 6 is the most reliable, easiest to use desktop 3D printer ever, featuring innovative self-leveling and self-cleaning, and a modular tool head design for flexible and multi-material upgrades. With proven 3D printing technology and one of the largest print volumes in its class, the LulzBot TAZ 6 is ready to work.

3D printing is more reliable than ever with the integrated automatic bed leveling system, all metal LulzBot v2 HotEnd, and heated PEI print surface. Withe the alll metal hot end you can take advantage of the cutting edge market for new materials. Perfect for both large and small objects the heated PEI build surface keeps your 3D printed objects in place when hot and releases when cool. With Cura LulzBot Edition, you have hundreds of quickprint profiles built in for seamless 3D printing.

See all available 3d printers!

The LulzBot TAZ series continues to grow, to see the latest 3D printer models available, visit our store page at shop. lulzbot.com and also available through our resellers .

Key Technical Specifications

- Tool Head: TAZ Single Extruder Tool Head v2.1 0.50 mm nozzle

- Layer Resolution 0.05 mm - 0.4 mm (0.002in - 0.02in)

- Max Hot End Temperature 290° C

- Level Automatic Z-Axis Compensation

- Certifications FCC, CE, WEEE, OSHWA, FSF-RYF

Print Volume Dimensions

280 mm x 280 mm x 250mm

(11.02" x 11.02" x 9.80")

Print Volume

19.600 cm³ (1,185 in³)

Full Spec Sheets and Other Resources

Large Print Volume

The LulzBot TAZ 6 has a build volume nearly the size of a basketball so you can make huge 3D prints, or 3D print many objects in a single print run, right on your desktop. Like the generations before it, the TAZ 6 boasts a spacious 280mm x 280mm x 250mm (11 in x 11 in x 9.8in) print area with a heated print surface.

2.85 PolyLite PLA

Polymaker

US $22. 99

99

LulzBot TAZ Dual Extruder v3.1 Tool Head | 0.5 mm

Shop

US$495.00

Support Included

Support for your LulzBot products is included with any LulzBot product. Our staff is extremely qualified to provide assistance and their expertise.

Home Base U.S.A

Our friendly US based support team is just a phone call or email away.

Phone: (+1-701-809-0800 ext 2)

Email: ([email protected])

3D Experts

Our in-house support has years of 3D printing experience and will help ensure that your printer is running optimally!

More Information

" If you want a serious machine, you won't find a better 3D printer on today's market - whether you need to create small pieces or one large part."

Best 3D Printers, Amazon.com"With it’s self-leveling and self-cleaning mechanisms, along with a large build envelope of 280×280×250mm, the TAZ 6 is a workhorse printer that will produce excellent prints consistently. The TAZ 6 also comes equipped with the v2 Hot End, capable of printing in a wide variety of materials ran...

The TAZ 6 also comes equipped with the v2 Hot End, capable of printing in a wide variety of materials ran...

"The TAZ 5 represented the state of the art for FDM 3D printing, and the TAZ 6 does nothing to lose that crown. It is the best FDM 3D printer we have tested. While print quality remains the same, the TAZ 6 is more reliable and easier to use than its predecessor. Plus, the self-leveling print b...

Richard Baguley, Tom's Guide"Even if you're new to printing, there really is nothing to fear as everything you need to set up and use the LulzBot TAZ 6 is in the box, from print tool kit to printed guides."

Alastair Jennings, Techradar.com"The LulzBot TAZ 6 has been the single best out-of-the-box experience of any 3D printer I've ever used... Every detail feels like it's been purposefully put there. Nothing is out of place."

Thomas Sanladerer, 3D Printing Expert"The LulzBot TAZ 6 scored very high for build quality and reliability, and that’s not surprising given the fact it received reviews describing it as “built like a tank” and “it’s metal body is rock solid. ” Furthermore, users of the TAZ 6 have almost unanimously given it 5 stars for print quali...

” Furthermore, users of the TAZ 6 have almost unanimously given it 5 stars for print quali...

"The LulzBot TAZ 6 is, in my opinion, the most complete 3D printer currently on the market."

Brent Hale, 3DForged.com"The TAZ 6 automated features and range of software options exist to make the entire printing process as stress-free and as easy as possible. It’s a perfect model for serious 3D professionals who insist on high quality, versatility, and reliability."

Best 3D Printers of 2017, 3D Insider"The auto-leveling system brought over from the LulzBot Mini is an incredibly powerful feature that will save the user a lot of headaches and downtime due to bed leveling issues."

Joel Telling, 3D Printing Nerd"The LulzBot TAZ 6 is clearly the pinnacle of development of the LulzBot TAZ printer line, with hassle-free printing due to its auto leveling and nozzle cleaning. The TAZ 6 is great for beginners and advanced users alike."

The TAZ 6 is great for beginners and advanced users alike."

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

LulzBot TAZ Pro S | LulzBot

LulzBot TAZ Pro S. 1.75mm, Single Extruder.

The LulzBot TAZ Pro S is an industrial desktop 3D printer that provides large, 1.75mm material printing with LulzBot’s award-winning reliability. Create large functional prototypes, manufacturing aids, and print-on-demand parts with easy, professional results.

- Need a TAZ Pro S ABS+ Enclosure? Find it here ➡

Read more

| Compatibility: | LulzBot HE Tool Head | Hardened Steel | 0.5 mm LulzBot HS Tool Head | Hardened Steel | 0.8 mm LulzBot HS+ Tool Head | Hardened Steel | 1. LulzBot M175 v2 Tool Head | Carbide Coated Copper | 0.5 mm LulzBot SE Tool Head | Nickel Plated Copper | 0.5 mm LulzBot SL Tool Head | Nickel Plated Copper | 0.25 mm LulzBot TAZ Pro Dual Extruder, 2.85mm |

Full Specifications

Key Technical Specifications

- Tool Head: M175 v2 Tool Head | 1.75 mm | Single Extruder | 0.5 mm

- Layer Resolution: 0.05 mm - 0.5 mm (0.002 in - 0.020 in)

- Filament Diameter: 1.75 mm

- Nozzle Diamter: 0.5 mm

- Hot End Temperature Range: 120°C - 290°C (248°F - 554°F)

- Hot End Heatup Time: From 23°C to 210°C (73°F to 410°F) in 95 seconds

- Print Surface: Borosilicate Glass/PEI

- Max Print Surface Temperature: 120°C (248°F)

- Leveling: Automatic Z-Axis Compensation

- Calibration: Automatic X/Y/Z Offset Calibration

- Certifications: FCC, CE, RCM, ETL by Intertek (UL), CSA, OSHWA, WEE

Print Volume Dimensions

280 mm x 280 mm x 285 mm

(11. 02" x 11.02" x 11.22")

02" x 11.02" x 11.22")

Print Volume

22,344 cm³ (1,362.56 in³)

Resources

Prop. 65 warning

Zoom

Previous Next

$ 3,995 00

3995.0

Quantity

Overview

The LulzBot TAZ Pro S gives you a single extrusion 1.75mm tool head, superior 3D print quality, and easy, professional results.

- Single Extrusion tool head

- 1.75mm extruder prints a wide variety of 1.75mm filament - from TPU and nylon to PLA, ABS, and rigid carbon-filled high-strength materials.

- Dual nickel coated hardened steel drive gears provide unparalleled pushing power, lightning fast retraction, and uninterrupted material flow without fear of grinding or slipping.

- Large 280 x 280 x 285 mm build volume with heated build plate.

- Automated X/Y/Z offset calibration, nozzle wiping, and self-leveling features.

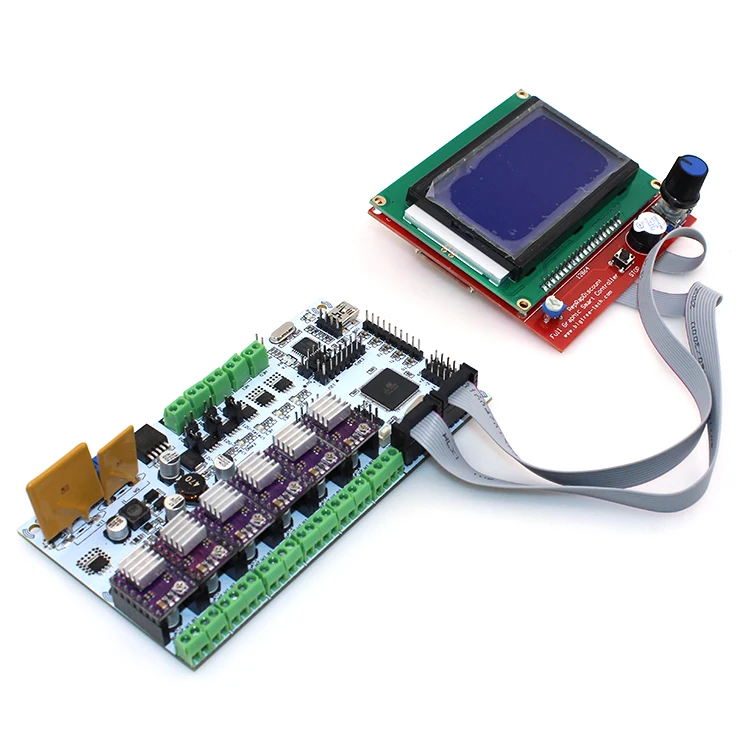

- Enhanced 32-bit electronics for greater processing power, more memory, and quiet operation.

- Filament runout detection.

- Cable chain and reinforced electrical connectors for long wire harness life.

- 5" full color touch screen.

- Made in USA

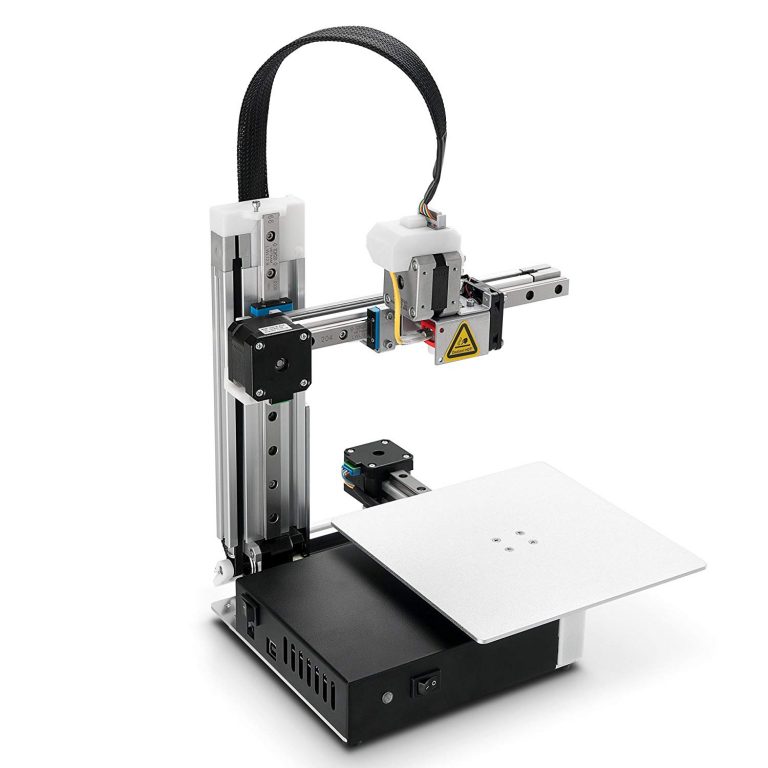

CreateBot D600 Large Professional 3D Printer

Hello everyone, the company 3Dtool is with you. Today in our review is an impressive 3D printer that takes professional 3D printing to a new level.

It proudly bears the name CreatBot D600 and comes in a fairly sturdy wooden box.

Let's start unpacking it

The printer is packaged just fine, with foam padding on all sides, all glasses sealed with packaging film to avoid scratches, and inside the moving parts are fixed with nylon ties. nine0005

nine0005

CreatBot D600 , it is no coincidence that it has these numbers in the name, because the size of its working area is 600 mm x 600 mm x 600 mm and the usable volume is 216 liters.

Also, its main advantage (besides the size) is the dual print unit with two separate extruders

The size of the working area is impressive, because there are not many FDM 3D printers on the market that can compete with the D600 in this indicator. At the same time, the dual print unit can print supports using soluble materials. Such capabilities allow CreatBot D600 to create complex models of large size. That in itself is a rare combination and is highly demanded in the market of professional 3D equipment. nine0005

Housing

The body of the printer is all metal and its overall dimensions are 915 x 845 x 1085 mm . The weight of the printer is 125 kg , which, coupled with a rather impressive rigidity, has a beneficial effect on reducing vibration during printing.

There are many opening doors and windows on the body, providing access from any side to the printed model.

With a fully closed housing, the possibility of external interference in the operation of the printer is eliminated, the noise level during operation is reduced, and the temperature inside the chamber is maintained at a constant temperature so that the product does not deform during printing. Thanks to this, the printer allows you to print with high shrinkage plastics, such as ABS derivatives or nylon, without problems. nine0005

The location for installing the material spools is at the back of the housing.

Kinematics

Designed as a single unit with a belt, rail guides provide a high degree of positioning accuracy, higher than not only their counterparts, but even some optical printers available on the mass market. The classic kinematic scheme allows you to print, albeit a little slower than analogues at H-Bot and Core-XY systems, but much more reliable due to the direct drive of the motor along the axes. By the way, along the axis Y the printing unit moves due to the movement of two belts (one per rail), but one powerful stepper motor with a through drive

By the way, along the axis Y the printing unit moves due to the movement of two belts (one per rail), but one powerful stepper motor with a through drive

Along the axis Z , the heating table is moved by two ball screws installed at the side walls. As guides for the table, there are four cold-rolled shafts with a diameter of 16 mm .

Along the X and Y axes, block rail guides with an integrated belt are installed.

Extruder

As standard, the printer has a dual print unit with two extruders. Optionally, it is possible to install a third. The extruders are equipped with a gearbox with a gear ratio of 1:10 .

The pull mechanism is completely metal. This allows you to confidently print with any materials, which is also provided by the nozzle heating limit, right up to 400°C . The printing unit itself is made according to the classic direct extruder scheme, has an extruder tube and heating blocks similar to the Vulcan. The cold zone (ColdEnd) is forcibly blown by two small fans, the speed of which can be adjusted. nine0005

The printing unit itself is made according to the classic direct extruder scheme, has an extruder tube and heating blocks similar to the Vulcan. The cold zone (ColdEnd) is forcibly blown by two small fans, the speed of which can be adjusted. nine0005

Nozzles with a diameter of 0.4 mm are installed by default. They are interchangeable and, if necessary, you can always install other diameters suitable for your tasks (0.3, 0.5, 0.6, 0.8, 1.0 mm) .

When the power is suddenly turned off, the printer automatically remembers the current position and saves the print data, lowers the build platform and retracts the nozzle.

The platform of a heating table is made of glass ceramics. Can heat up to 100 - 110 °C . This is not as much as, for example, MarkForged printers, but allows you to use any of the most common materials for 3D printing. The adhesive on the platform is a BuildTak-like surface that securely holds even very large objects made of high shrinkage materials (eg ABS).

The calibration screws are located at the bottom of the heating table.

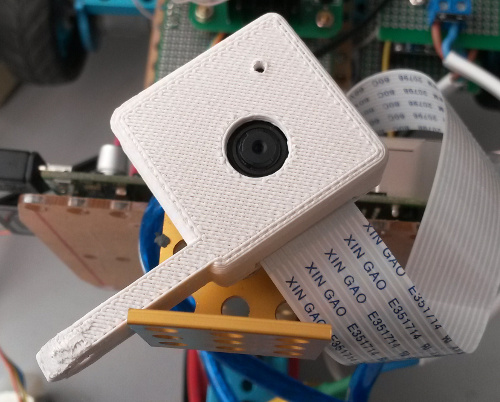

Control screen

For convenience, the printer is equipped with a 4.3” touch screen with an English menu. There are separate menus for preheating and movement along the axes. It is quite easy to handle. Intuitive icons allow you to quickly understand the tools and manage the printer, with almost one touch.

Interfaces

3D printer CreatBot D600 is equipped with a USB 1.0 port. This allows you to pair with a computer and send print jobs from it directly. However, we recommend using the USB flash drive slot to the right of the display in order to take full advantage of the device's capabilities. nine0005

Software

The printer comes with free software CreatWare based on the popular and well-known Cura 1. 5.4, which can be downloaded from the manufacturer's website.

5.4, which can be downloaded from the manufacturer's website.

It is very simple and easy to learn, so there should not be any problems in working with this software.

This 3D printer is designed to solve serious problems of printing large-sized models. The quality of workmanship and ease of use allow the CreatBot D600 to be used in professional 3D printing studios, various design and design offices 24/7. The build quality of the 3D printer is factory. All components of the 3D printer are made of high quality components. Significant advantages of CreatBot D600 include: nine0005

1) The ability to heat the extruder up to 400 degrees (Important for 3D printing with engineering plastics)

2) Reliable and accurate kinematics for a working area of this size.

3) The presence of 2 extruders in the base.

4) Factory assembly

If you need a printer with a large print area, we recommend 100% for consideration.

You can order the CreatBot D600 3D printer from our company. Delivery time 6 weeks. nine0005

Link to equipment: https://www.3dtool.ru/product/3d-printer-creatbot-d600/

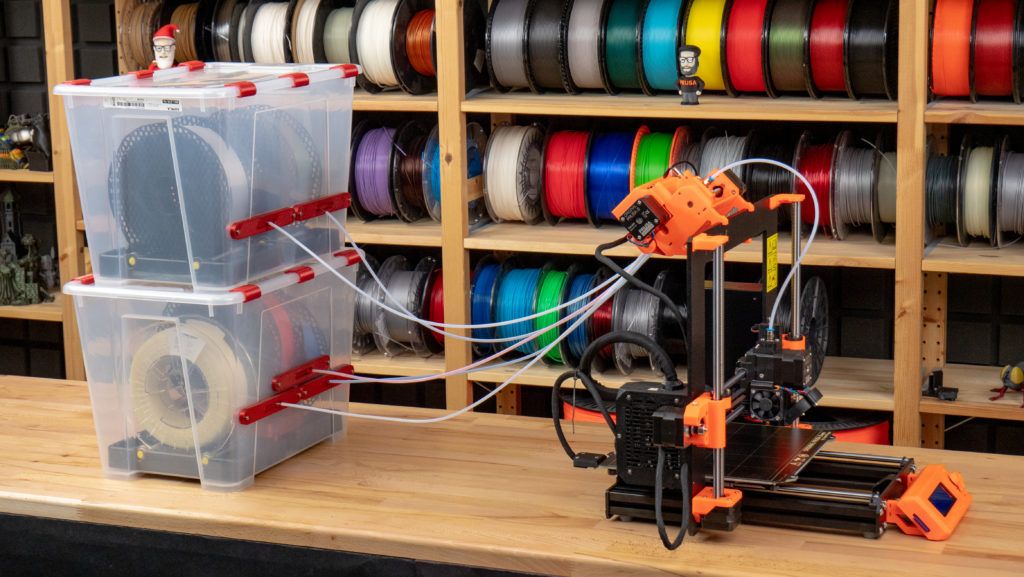

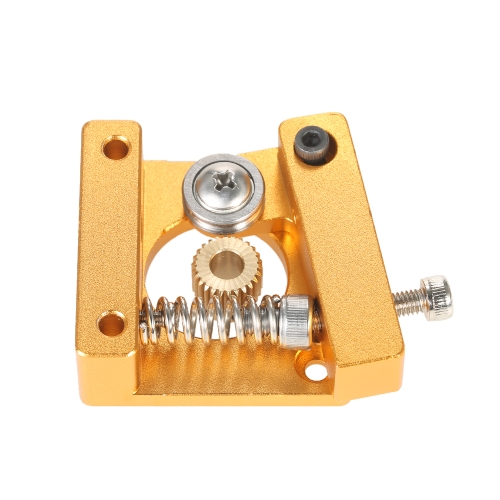

Universal Direct extruders for 3d printers from KingRoon

This time on the review there are two small boxes designed for 3D printers. The name is already clear, these are two different direct extruders from KingRoon for Ender-like printers. According to the description, they were designed for bolt-in-bolt installation without alterations and printing different parts, we'll see.)

In general, these two hotends are technically similar, but slightly different. Let's start in order, from the first.

This model was called TypeA in the lot. It, like the second one, comes completely complete, with a platform for installation, wheels, a thermistor, a heater, a radiator fan and airflow for the printed part. And everything is covered with a decorative casing made of aluminum. The kit even has an adapter wire for the engine, so that you can simply remove the native motor and connect a new one to the connector of the native wire. nine0005

The kit even has an adapter wire for the engine, so that you can simply remove the native motor and connect a new one to the connector of the native wire. nine0005

We disassemble and see, inside is a typical Titan extruder + E3dV6 hotend (of course, a clone, but not bad). The part is blown by a fan 4010 and a directional nozzle printed on the printer.

The thermal barrier in the hot end is installed with Teflon inside to the very nozzle. This is a classic solution for low-temperature plastics (as it is in Ender3 itself and installed from the factory). If you print PLA, PETG then this is the best solution. Now there are a lot of variations in the form of titanium, bimetal, but traffic jams with such plastics can happen with them. Teflon won't have that problem. nine0005

I used to print with similar combinations, should easily cope with Pla, Petg, Sbs, Flex and ABS, etc. Gear Titanium allows you to use a thin motor, and therefore lightening the printhead.

Let's move on to the second one, TypeB. Everything is also assembled, just decoratively closed. Everything is done neatly. But the main thing is what's inside.

Everything is also assembled, just decoratively closed. Everything is done neatly. But the main thing is what's inside.

And in this variant is a typical Titan Aero. In the photo, I attached to a similar hotend from TriangleLab. Visually, from the differences - Kingrunovskiy black, otherwise everything is the same. The build quality is ok. It's not bad, and not the quality of the original E3d, it's normal. There are no complaints. There is also a thermal barrier with Teflon up to the nozzle. The only Trianglab uses the more common V6 thermal barriers. nine0005

In general, both hotends are made quite well, both should print exactly the same and should be installed without modifications at all on dry-tables, in which the head moves on “wheels”. This is what we will check.

I don't have Ender3 to put there. But there is an old drygostol that has been waiting for repair for a long time. I took these hot ends on it, I will try to put it.

Speaking of drygost. I got it as a barter for a long time, I had already seen it before. Only then it still worked, I got it no longer working. The printer was called SteadyTech ProX. The model is sooooo uncommon in Russia, it can be found more often in the west. Europe, USA for example. But when I “felt” him while still working, he seemed very familiar to me. For example, the cover of the X-axis limit switch, this pure Aquila from Voxelab (aka FlashForge). And when turned on, he sang a song the same as my old FlashForge Inventor, and the menu was almost 1k1. And all the electronics are marked, and begin with typical FF ...

I got it as a barter for a long time, I had already seen it before. Only then it still worked, I got it no longer working. The printer was called SteadyTech ProX. The model is sooooo uncommon in Russia, it can be found more often in the west. Europe, USA for example. But when I “felt” him while still working, he seemed very familiar to me. For example, the cover of the X-axis limit switch, this pure Aquila from Voxelab (aka FlashForge). And when turned on, he sang a song the same as my old FlashForge Inventor, and the menu was almost 1k1. And all the electronics are marked, and begin with typical FF ...

I'm guessing FlashForge made printers for this company, and just branded them. But these are assumptions.

Most importantly, we have a carriage typical of Ender-like printers. And the frame is quite rigid for such printers, FF did their best.

Actually, you need to fix it first. The story is like this. On the hot end, the wires were “on the snot” and at some point the part came off the table, wrapped around the hot end, shorted the wires and burned out the board. Processor and transistor (I assume for heating). Plus, the native hotend was already outdated (MK10), and there was no desire to mess with it. I decided to leave the mechanics, only going through it, and put all new electronics. nine0005

Processor and transistor (I assume for heating). Plus, the native hotend was already outdated (MK10), and there was no desire to mess with it. I decided to leave the mechanics, only going through it, and put all new electronics. nine0005

I didn't want to buy a new board, after looking through spare parts stock I found a new set of board and screen with Ender4. After counting all the connectors, I realized that they would be with my head and I could connect everything. For the screen, I printed a cover and screwed it into place of my own. Connected everything to the board. The native power supply is installed with a high-quality low-profile 24v 350W, I'll leave it. I configured Marlin for this printer and uploaded it to the board.

There was once a magnet on the table, I think there was a Pei sheet once. I wiped everything and put ordinary glass (which was in stock) and secured it with brackets. On the bottom cover, I put a fan to blow the board and drivers and put everything back together. Now you can put the hotend. nine0005

Now you can put the hotend. nine0005

The native platform in all fixtures completely coincides with the new hot end. Even the slots for mounting the strap are deeper, so there are more variations for mounting on different printers. Therefore, I simply removed the remnants of my native hotend and installed a new one. I decided to put Titan Aero. I always liked him better at work. At least the distance from the feed gear to the nozzle is shorter and it cools better. Although the latter is not so critical for a thermal barrier with Teflon up to the nozzle. On them, even with poor airflow, problems are extremely rare. nine0005

The wires are very long. I think on Ender3 it will fit perfectly and the wires will be with a margin. I have a slightly different story, the print height reaches 40cm, and the table is 33*33cm. Therefore, the wires were not enough for me a little, and I extended them. But on a standard printer with a field of 23 * 23 * 25, I think everything will be installed with a margin.

Well, the printer is assembled, everything is installed. Hotend looks neat, nothing superfluous.

But now you need to print. Initially, I calibrated the steps of the hotend in the firmware, and for each plastic I picked up the adjustment of the flow, the temperature of the print. nine0005

First, I started printing PETG. Nozzle 0.4, layer height 0.3mm (if I'm not mistaken). Movement speed 140, print speed 60. But I set the acceleration on the printer two times more than the standard Ender ones, because it's too slow. Nevertheless, the printer is large and prints slowly on it for a very long time.

This is Voronov's test cube. In general, for this printer on those parameters, everything is quite worthy. Even the bridge from below without supports printed quite well. The overhangs also turned out well. nine0005

The next thing I decided to try was Esan's TPU. I was wondering how the hotend would handle soft plastics. But there were no surprises. Everything was printed the first time. And the print quality is quite decent for soft materials.

Everything was printed the first time. And the print quality is quite decent for soft materials.

Abs I did not test on the printer, because it needs a closed chamber. But what I did not print is PLA. On the one hand, it is easy to print, sticks easily, no camera is needed. But it needs good airflow to print. I was wondering how the blowing of the hotend would cope with it. I didn't have regular PLA, but I did have wood, Wood by Eryeone. nine0005

Nozzle also 0.4, layer height 0.2. The printer did a good job too. The airflow turned out to be quite sufficient for PLA as well. There is a slight “ringing” on the details, but these are no longer problems of the hotend, these are problems of the mechanics of the printer. This is a completely different story.

What can I say in summary. The

Hotend does indeed bolt-on-bolt to drygotables as promised in the product description.

The quality of workmanship and materials is a solid four. Of course, these are not top solutions in the form of original E3d, not even TriangLab that make quality things, and not even BIQU h3 from Bigtreetech. Yes, this is not a Dual gear like BMG. This is an old, proven Titan Extruder, on which I printed for a very long time on my "combat" printers and I had no complaints about them. Pretty omnivorous, and chew problematic materials that float in minus diameter. nine0005

Yes, this is not a Dual gear like BMG. This is an old, proven Titan Extruder, on which I printed for a very long time on my "combat" printers and I had no complaints about them. Pretty omnivorous, and chew problematic materials that float in minus diameter. nine0005

But also the price. For ~ 2t.r we get quite a decent set of direct extruder, which I bought and installed. In many other options, you either need to find ready-made 3D models for rework, print, buy something (for example, bolts) and assemble and install everything. Or measure and model everything in place and print.

I think these hot ends are perfect for those who have “hook hands”. Who is not confident in their abilities and knowledge of alterations or does not want to spend time on this. Let's take a typical printer who bought a printer to print some of his hobby details on it and does not want to delve deeply into the printer's devices, but wants to improve the quality of printing. And print the same flex for example.

2 mm

2 mm