3D printed high heel shoes

What Are Those? They're 3D printed high heels, of course!

As you and I know, 3D printing can be used to create practically anything. Over the last few weeks, for instance, we have discussed how 3D printing is being used to transform the lives of child amputees and children born with amelia, and how it has been used to diagnose medical defects before birth.

So let’s widen our scope a little, and take a look at how 3D printing is being used in the fashion industry right now. One application that caught our attention this week was a pair of 3D printed high heels, and here they are in all their glory:

Don’t they look absolutely fantastic?

The heels were designed by Dutch designer Troy Nachtigall, in collaboration with industrial designer Leonie Tenthof van Noorden and fashion designer Pauline van Dongen, who were all commissioned by the Dutch minister of education (pictured, above) to create an outfit for her to wear to the Netherlands’ Budget Day. The only criteria? The outfit had to be super-comfortable, because the minister was going to be on her feet all day. The trio also wanted to demonstrate what the future of footwear looks like. So naturally, they chose 3D printing to create the shoe.

The process began with a 3D body scan of the minister from three perspectives. The scans tracked how the minister walked, and they produced plenty of data that enabled Nachtigall and his team to analyse the minister’s feet very closely. This helped the team to design a shoe that was as comfortable as possible. In an interview with Deezen Magazine, Nachtigall explained:

“Using the algorithms that Leonie came up with, we invented a shoe that is stable where it needs to be stable, and soft where it needs to be soft.

They’re comfortable, and comfortability was our main goal.”

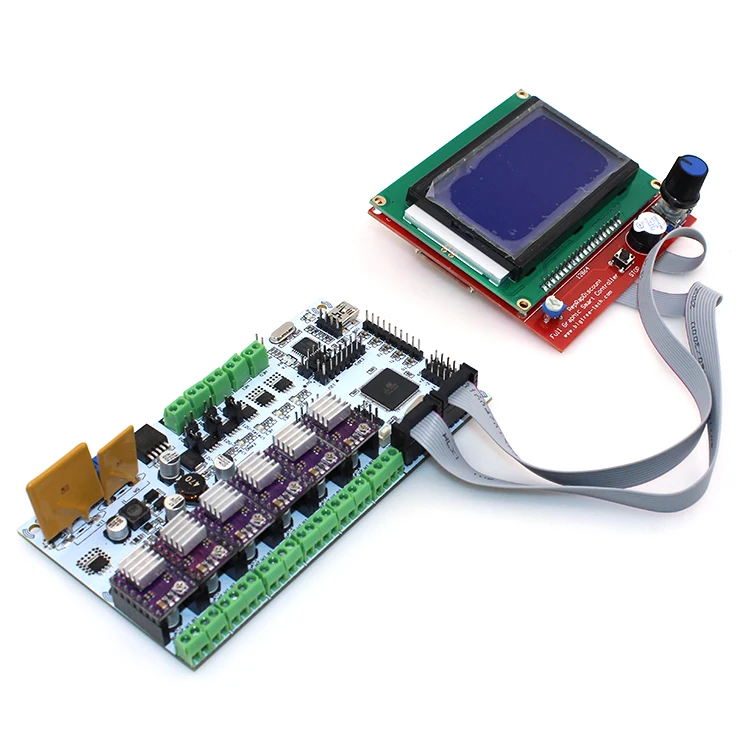

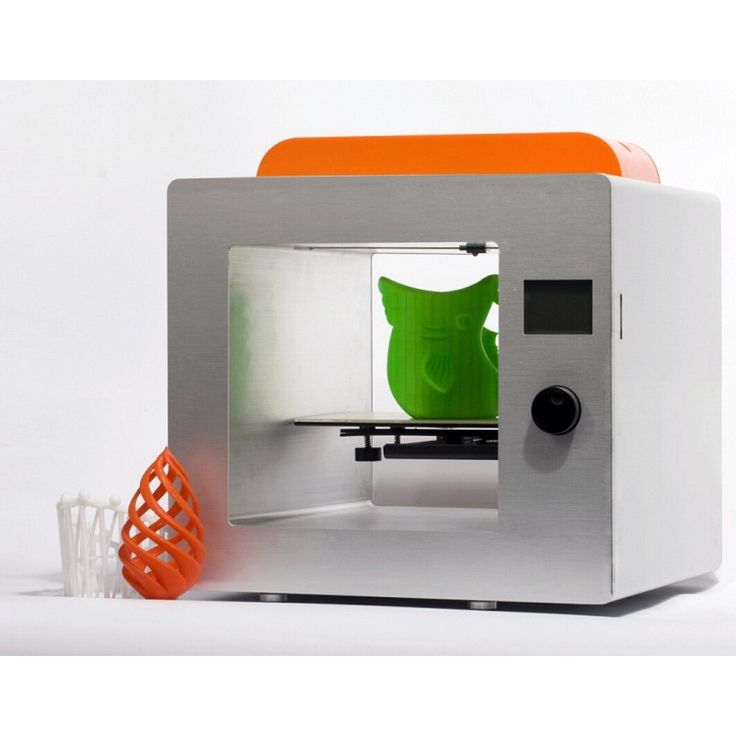

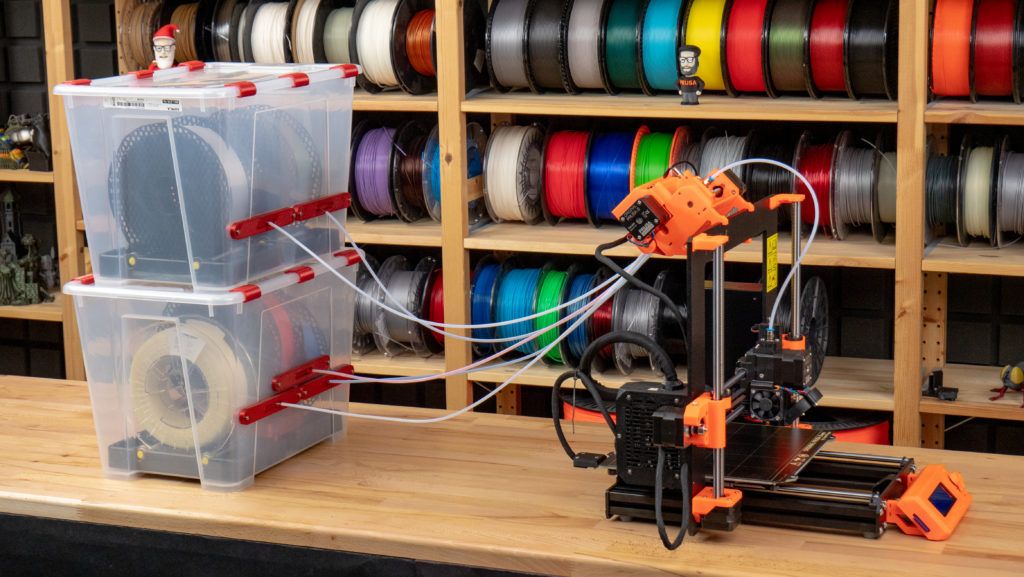

But designing the shoe was not without its challenges. The trio discovered during their scans that in order to create a shoe that’s both functional and comfortable and to achieve what they call a “behavioural fit”, they’d need a filament that’s super-soft and super-flexible. So they enlisted the help of Dutch technology company SLEM to manufacture the shoes, and they recommended the use of FilaFlex – a thermoplastic elastomer filament – manufactured by Recreus, and the superb Ultimaker 2 3D printer to create their vision.

So they enlisted the help of Dutch technology company SLEM to manufacture the shoes, and they recommended the use of FilaFlex – a thermoplastic elastomer filament – manufactured by Recreus, and the superb Ultimaker 2 3D printer to create their vision.

“Every time we make a pair of shoes for a person, we ask a lot of questions about who they are, what they do, and what they are going to do with these shoes,” said Nachtigall, “We’re calling it behavioural fit, because it’s about how the shoes fit, and how they behave.”

The end result for all of this attention to detail, as you can see or yourself, is spectacular. Now we’re no fashionistas, but we’d say these heels are quirky enough to warrant a looksee on the high street. The team completed the outfit with a textured top and hat and a plain skirt; here’s the minister in action:

In other 3D printing news, and sticking to our high heel theme, a design student called Jacqui Painter designed and printed her own pair of high-heeled women’s shoes for her final thesis recently. She used the mathematical Voronoi grid structure as the design motif for the shoes and as you can see below, the heels look as good as a pair of Christian Louboutin’s:

She used the mathematical Voronoi grid structure as the design motif for the shoes and as you can see below, the heels look as good as a pair of Christian Louboutin’s:

Now if that isn’t creative vision, we don’t know what is. Way to go Jacqui!

Sources: Deezen (quotes and main story), 3D Print (Jacqui Painter story). Images 1, 2, 3, 4, 5.

3d High Heels - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(313 relevant results)

The designer has created a pair of shoes completely printed on a 3d printer

Every day on the Internet, we meet information about the release of shoes into production using 3d technologies. Most of these posts are just a marketing ploy, since the products themselves are made using classical methods, and 3d printing is used for individual components, such as soles, emblems and decorative elements.

Most of these posts are just a marketing ploy, since the products themselves are made using classical methods, and 3d printing is used for individual components, such as soles, emblems and decorative elements.

Industrial designer Amadou ba Ndiaye decided to completely rethink the approach to 3d printed shoes and began work on a project called The Genesis Project. He used SLS 3D printers and 3D scanning to create two pairs of shoes - sneakers and mid-heeled women's shoes. nine0003

“3D technologies are quite popular in the footwear industry. The purpose of the Genesis project is to explore the potential of 3D printing in this area, which can become a quality replacement for classical production. In my work, I started from the ideas of Adidas Futurecraft 3D and Under Armor Architech,” says Amadou Ba Ndiaye.

High temperature polyurethane (TPU) was used to make the sneakers, and the decorative parts were cast from wax using a 3d printed mold. The gold part is completely removable and replaceable so shoe wearers can customize it to their liking. Women's shoes were also printed in TPU, while the heels and red ribbon were printed in polyamide PA 2200.

Women's shoes were also printed in TPU, while the heels and red ribbon were printed in polyamide PA 2200.

The project was brought to life by Materialize, one of the few organizations that works with TPU on its printers. Polyamide elements were manufactured by Anubis 3D, which is located in Ontario.

As mentioned, Amadou's shoes were 3D printed using SLS, and although this technology is more expensive than FDM, it allows for a higher level of detail and durability. The main goal of the project was not just to create completely 3d printed shoes, but to demonstrate the specific advantages that these technologies have. Complex elements were specially made here, which cannot be produced by any other methods. nine0003

In addition to freedom in design, Amadou Ba Ndiaye also highlights a number of additional benefits of using 3d technologies in the footwear industry, namely:

- reduced design and development time;

- eliminating the need for molds;

- flexibility of production processes;

- the possibility of design customization based on 3d scan data;

- reduce waste and reduce storage costs.

nine0024

nine0024

Amadou Ba Ndiaye is a freelance designer and has not worked on similar projects to date. He has no plans to commercialize the project, and this is even a little dreary, since the shoes turned out to be very worthy.

“I don't plan on doing my job commercially and getting serious about 3d printed shoes. My task was to demonstrate the potential of 3d printing in the footwear industry, but there are many other beautiful things in the 3d industry that need to be worked on and worked on,” says Amadou

And although Amadou was just proving his concept, you and I can only hope that sooner or later these products will be on sale.

what is available on the market today?

In August 2020, the research company SmarTech Analysis presented its second study of the 3D printing and footwear market. According to the report, this industry is expected to generate over $8 billion in profit by 2030. And it must be said that additive manufacturing offers a number of advantages in the production of shoes, the most important of which is the ability to customize the final product. Consumers are looking for difference and uniqueness, and 3D technology can fill that need. They can also offer custom made products with intricate designs perfectly tailored to each individual's morphology. Thus, through 3D scanning and 3D printing, companies create more efficient sneakers, futuristic high fashion shoes, or comfortable and durable soles. Yes, it should be noted that not all shoes are always 3D printed, which is actually quite rare, but, for example, the upper or sole. In any case, 3D printing and shoes go hand in hand and the market is definitely showing great promise! For that reason, we wanted to introduce you to some of the most impressive 3D printed running shoes currently available, whether for sports, the beach, or just for work. nine0003

Consumers are looking for difference and uniqueness, and 3D technology can fill that need. They can also offer custom made products with intricate designs perfectly tailored to each individual's morphology. Thus, through 3D scanning and 3D printing, companies create more efficient sneakers, futuristic high fashion shoes, or comfortable and durable soles. Yes, it should be noted that not all shoes are always 3D printed, which is actually quite rare, but, for example, the upper or sole. In any case, 3D printing and shoes go hand in hand and the market is definitely showing great promise! For that reason, we wanted to introduce you to some of the most impressive 3D printed running shoes currently available, whether for sports, the beach, or just for work. nine0003

3D Printed Adidas Shoe Range

When it comes to 3D printed shoes, it would be remiss not to mention the offerings from famed shoe manufacturer adidas. The company has been using 3D printing since 2017, when it partnered with Carbon to create the new Futurecraft 4D shoe, , which is still on sale today. Since then, the company has continued to use additive manufacturing to create unique sustainable footwear. For example, just last year, the company launched two new 3D printed running shoes, the 4D Fusion and the adidas 4DFWD, the latter specifically designed to improve performance. According to the company, 3D printing increases productivity with the lattice structure, as well as increasing flexibility, from reducing lead times to offering reasonably priced shoes that can be fully customized. nine0003

Since then, the company has continued to use additive manufacturing to create unique sustainable footwear. For example, just last year, the company launched two new 3D printed running shoes, the 4D Fusion and the adidas 4DFWD, the latter specifically designed to improve performance. According to the company, 3D printing increases productivity with the lattice structure, as well as increasing flexibility, from reducing lead times to offering reasonably priced shoes that can be fully customized. nine0003

With Carbon DLS technology, the adidas 4DFWD shoes feature a unique 40% bio-based lattice midsole (adidas photo).

Liquid Speed from Reebok

Reebok is one of the largest and most well-known brands in the footwear industry. That's why, a few years ago, the company decided to use additive manufacturing to create soles for one of its athletic shoe collections. While the rest of the shoe was made using traditional methods, the Liquid Speed has the ultimate outsole. Reebok partnered with chemical company BASF, which used a liquid polyurethane material. A programmed robot was used to create successive layers. In addition to better performance and durability, Liquid Speed has a very original design. nine0003

Reebok partnered with chemical company BASF, which used a liquid polyurethane material. A programmed robot was used to create successive layers. In addition to better performance and durability, Liquid Speed has a very original design. nine0003

Liquid Speed design is original.

New Balance includes 3D midsole

In the same vein, New Balance is partnering with 3D Systems to develop 3D printed midsoles. DuraForm Flex is an SLS insole made from a thermoplastic elastomer material. They combine strength and flexibility and provide maximum comfort for sports shoes. 3D printing technology allows the production of complex designs that optimize cushioning and make shoes lighter. The American brand is working with Formlabs and its stereolithography technology to develop the Triple Cell platform to produce the FuelCell Echo. nine0003

The sole of the sneaker was 3D printed.

ECCO and its customizable insoles

ECCO is a Danish footwear manufacturer with many years of experience in the industry. In 2019, the company launched the Quant-U service aimed at customizing shoes using 3D printing. Using the 3D foot scanning process, it is possible to determine the orthopedic fit required for each individual. With this device, ECCO develops 3D printed insoles tailored to the needs of its customers. This part is made of silicone, a material that provides stability as well as a sufficient degree of cushioning. In addition, the company says the insoles are easy to replace and machine washable. nine0003

In 2019, the company launched the Quant-U service aimed at customizing shoes using 3D printing. Using the 3D foot scanning process, it is possible to determine the orthopedic fit required for each individual. With this device, ECCO develops 3D printed insoles tailored to the needs of its customers. This part is made of silicone, a material that provides stability as well as a sufficient degree of cushioning. In addition, the company says the insoles are easy to replace and machine washable. nine0003

Photo Credit: ECCO Quant-U

Wiivv goes towards the client

Wiivv is a young Canadian company that specializes in the production of 3D printed soles and flip flops that are fully adapted to the wearer's morphology. Thanks to the smartphone app, the user can directly scan their foot, send their data to the company and receive a customized solution in a few weeks. Take flip-flops, for example: Wiivv can use 3D printing to personalize certain elements of the shoe, such as straps or a vertical strap. The goal, of course, is to offer the user more comfort. The company is equipped with a machine park in San Diego, and products are manufactured using SLS technology. nine0003

The goal, of course, is to offer the user more comfort. The company is equipped with a machine park in San Diego, and products are manufactured using SLS technology. nine0003

Wiivv Fully Customizable Slippers

3D printed sustainable shoes

How best to combine fashionable shoes with a responsible approach to the environment? With additive manufacturing! Chris Margetts, founder of The Sole Theory and fashion brand Humans Are Vain, uses recycled textiles to make his 3D printed shoes. He explains: “There is a lot of demand for more sustainable products. There is no doubt that there will be consumers who will want to buy these shoes when we launch them on the market.” He deliberately uses fibers from clothes he once loved to make composite materials. Thus, they can be used as a 3D printing material to create new shoes. The fibers are shredded and turned into filament for the ZYYX Labs 3D printer.

Photo Credits: The Only Theory

HERON01 fully 3D printed trainers

Attention sneaker lovers, the 3D printed HERON01 is sure to please the public. This shoe was completely made by additive manufacturing by the American company Heron Preston, named after its founder Heron Preston Johnson. For this model, the founder of Heron01 paid special attention to the theme of sustainability, since no glue or toxic materials were used in the production process. We also managed to do without the use of seams, which means that shoes can be completely recycled. The scraps and scraps can eventually be used to make a new product. A design idea that goes beyond traditional shoemaking is also reflected in the shoe's features: low ankle cutouts, printed scales and textures, and a bird's foot pattern on the sole. nine0003

This shoe was completely made by additive manufacturing by the American company Heron Preston, named after its founder Heron Preston Johnson. For this model, the founder of Heron01 paid special attention to the theme of sustainability, since no glue or toxic materials were used in the production process. We also managed to do without the use of seams, which means that shoes can be completely recycled. The scraps and scraps can eventually be used to make a new product. A design idea that goes beyond traditional shoemaking is also reflected in the shoe's features: low ankle cutouts, printed scales and textures, and a bird's foot pattern on the sole. nine0003

Sneakers HERON01 (photo HERON01)

Natives shoes and 3D printed shoes

Canadian manufacturer Native Shoes launched the Liquid Printed Natives project with the goal of designing everyday items using advanced techniques such as additive manufacturing. As part of this, the company used liquid rubber to 3D print shoes. The manufacturer says it has used 50% recycled ethylene vinyl acetate (EVA) material to achieve more flexibility and a more stretchy appearance. What stands out about the Native Shoes project is the speed of production: the company explains that 3D technology has significantly reduced production time compared to traditional methods. They also offer consumers a high level of customization. nine0003

The manufacturer says it has used 50% recycled ethylene vinyl acetate (EVA) material to achieve more flexibility and a more stretchy appearance. What stands out about the Native Shoes project is the speed of production: the company explains that 3D technology has significantly reduced production time compared to traditional methods. They also offer consumers a high level of customization. nine0003

Shoes will be 3D printed directly in a tray containing a reusable water-based viscous gel formula.

Eco sandals

We continue this trend of 3D printed sandals with the Organic collection, designed by young fashion design student Lucy Treitnarova. In collaboration with materials manufacturer Fillamentum, she 3D printed the outsole of the sandal, onto which she sewed several organic fabrics made from fibers extracted from pineapple or coconut leaves. The printed outsole needed to be strong enough to withstand this fabric, so Lucy opted for TPU, which is flexible enough yet resistant to abrasion and wear. It also has the ability to be recycled, which is a key ingredient for a young woman. nine0003

It also has the ability to be recycled, which is a key ingredient for a young woman. nine0003

Mycelium shoes, futuristic shoes

Created by design studio Ica and Kostika, the pair of Mycelium sneakers is completely 3D printed on an SLS machine. Quite impressive in shape, size and design, it does not go unnoticed on the street - besides, only 5 pairs were created. Its designers claim that these 3D printed shoes are very comfortable because they are fully adapted to the human foot: a 3D file is created from the scanned data. nine0003

Only 5 pairs were created

Hilos 3D Printed Eco Shoes

Portland-based startup Hilos was founded in 2019 and wants to change the way shoes are made by combining technology and craft. Through additive manufacturing, the company hopes to solve environmental problems while producing quality shoes. Made from selective laser sintering of TPU, these recyclable shoes are known for their flexibility and durability. The company admits that with the help of 3D printing, it can bring new product lines to market in as little as two weeks, while the industry average takes 12 to 15 months. nine0003

The company admits that with the help of 3D printing, it can bring new product lines to market in as little as two weeks, while the industry average takes 12 to 15 months. nine0003

ATHOS 3D printed climbing shoes

The ATHOS climbing shoes, developed by a group of students in Barcelona, are becoming more and more popular. This type of shoe, also known as "climbing shoes", must fit the athlete's foot perfectly to improve traction and prevent slipping. Usually, to make sure they fit well, athletes wear climbing shoes that are smaller than the size of the foot, which causes pain and deformity of the foot. That's why the ATHOS team wanted to create bespoke mountaineering shoes that would meet the needs of every climber. For this, HP MultiJet Fusion 3D printing technology and BASF TPU material were used. The process of getting ATHOS shoes is very simple: just scan your feet with 3 photos, customize the shoes to your liking and once you get them home you can start climbing! nine0003

Photo: ATHOS

Pleko Carbon Fiber Running Shoe

The brainchild of Italian middle distance runner Miro Buroni and Diadora, the Pleko shoe is made up of many 3D printed components. The 3D printed parts include the insole, outsole, studs and ribs. Designed from composite materials, carbon fiber to be exact, and through a powder sintering process, these various elements have made it possible to produce a shoe that is flexible, resistant to wear and, above all, customizable. Indeed, thanks to 3D scanning and race simulation software, shoe designers can offer athletes a reliable and comfortable solution. nine0003

The 3D printed parts include the insole, outsole, studs and ribs. Designed from composite materials, carbon fiber to be exact, and through a powder sintering process, these various elements have made it possible to produce a shoe that is flexible, resistant to wear and, above all, customizable. Indeed, thanks to 3D scanning and race simulation software, shoe designers can offer athletes a reliable and comfortable solution. nine0003

Photo : CRP Technology

3D Printed Dance Shoes

The Purmundus Challenge 2021 was won by start-up company Act'ble, which collaborated with top athletes to develop new pointe shoes. Designed for classical ballet and contemporary dance, the shoe is called the New Pointe Shoe Sole. These shoes are expected to last five times longer than traditional pointe shoes. It was designed to greatly reduce the physical pain that dancers experience during ballet. To make the shoes, the team 3D-printed the sole, but didn't specify what process or materials they used.