3D printing prosthetics for animals

Pet Prosthetics Get a Boost From 3D Printing

Boone Ashworth

Gear

New modeling software is helping animal health experts develop more customizable prosthetics for pets with missing limbs. Still, not all legs are created equal.

Photograph: Dive Design

Consider the three-legged dog. Maybe you own one, or have seen them in the park or in any of the billions of Dodo videos about them. Lopsided yet resilient, they evoke a kind of fawning sympathy from us humans that’s unmatched by the typical quadruped canine.

“People are drawn to specially abled pets,” says Rene Agredano, a cofounder of the pet-amputation support website Tripawds. “I think the attraction is that we just want to help them. We just want to make sure that they are given an equal chance at having a happy life. ”

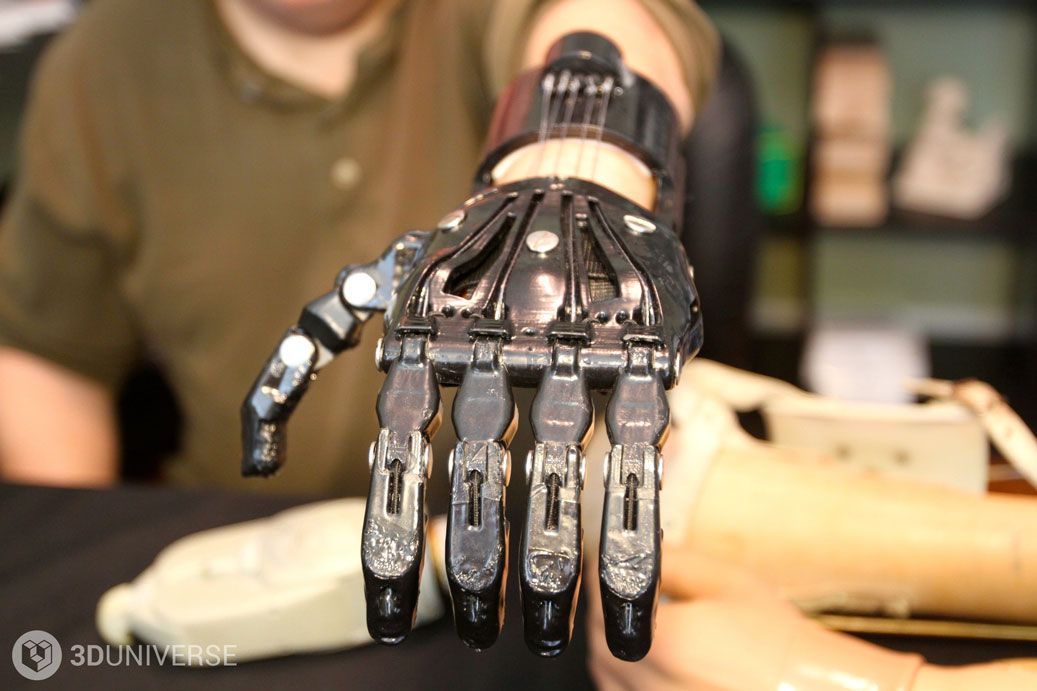

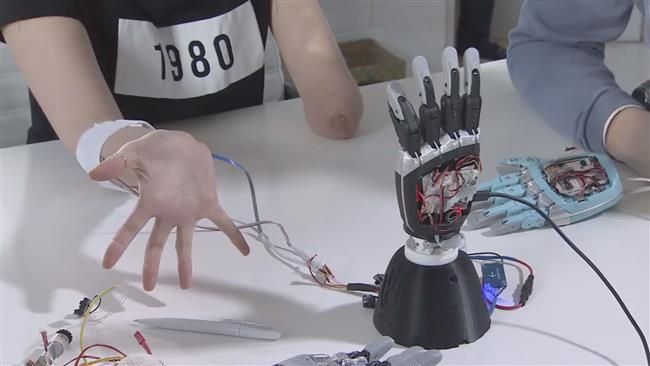

More and more, that desire to help manifests as prosthetics, especially in cases where the animal has lost more than one limb. Pets with artificial limbs have become a whole genre of feel-good videos of their own. A cat with bionic hind legs. A tortoise with wheels. The clips make the rounds on Facebook, where they add a smidge of feel-good optimism to the otherwise dour deluge that is your newsfeed. 3D printing has propelled the industry forward. Printed prosthetics can be lightweight, affordable-ish, and infinitely customizable. Doctors craft beaks for birds. High school students build artificial dog legs in their free time.

But not all pet prosthetics are created equal. And some veterinarians and people in the tripod community worry that the proliferation of easily craftable attachments could lead to unintended consequences for the critters that wear them.

Walking Distance

Dogs can lose a limb for a variety of reasons. Maybe they were born with an abnormal limb, or were hit by a car, or developed a cancerous growth that necessitated an amputation. A common quip among tripod lovers is that “dogs have three legs and a spare.” It’s true, to a point. Dogs adapt remarkably well to losing a limb, says Theresa Wendland, who specializes in animal sports medicine and rehabilitation at the Colorado Veterinary Specialist Group. But complications can arise as the animal compensates for what’s missing. In older dogs and dogs with arthritis or other mobility issues, putting extra weight on the remaining limbs can be a big problem.

A common quip among tripod lovers is that “dogs have three legs and a spare.” It’s true, to a point. Dogs adapt remarkably well to losing a limb, says Theresa Wendland, who specializes in animal sports medicine and rehabilitation at the Colorado Veterinary Specialist Group. But complications can arise as the animal compensates for what’s missing. In older dogs and dogs with arthritis or other mobility issues, putting extra weight on the remaining limbs can be a big problem.

Photograph: Dive Design

Photograph: Dive Design

“It really impacts their spinal mobility,” Wendland says. “They have to change the range of motion in their other limbs. They have to pull themselves forward in ways that are very unnatural.”

Prosthetics, if made right, can restore that range of motion. But as heart melting as it is to see a three-legged dog return to running on four legs, it’s not easy to build a proper puppy peg leg. Wendland, who works with the orthopedic and prosthetic company OrthoPets to help dogs adapt to their new limbs, says that it’s an involved process that takes time and technical know-how.

As with human prosthetics, an animal prosthetic has to be individually tailored to the build of the wearer. That means factoring in the animal's size, weight, height, stance, and gait. (A kit for a doberman won’t fit on a dachshund.) To do that, orthopedists have to study the animal’s movements and try to mold a limb that will sync up with the others. While techniques vary, a standard process is to make a plaster cast, design the prosthetic based on photos and video, then build it out with durable thermoplastics and metal. From there, they tweak the finer details by hand until it works with the animal. The process can take weeks.

Most Popular

There’s also the matter of the amount of the limb that needs replacing. The ideal spot to put a prosthetic, Wendland says, is as low on the limb as you can go. But if the whole limb is gone and there’s no obvious point to attach a prosthetic, it gets much trickier.

A Leg Up

3D printing has long been hailed as a manufacturing revolution in many industries, prosthetics among them. And now, a New Jersey–based design firm called Dive Design thinks it’s the solution to full-limb replacement. It has partnered with a company called Bionic Pets that builds exactly what its name implies: accessibility tech for pets. Derrick Campana, who runs Bionic Pets, has long built pet prosthetics by hand. (He’s even got a show about it called The Wizard of Paws, which airs on Brigham Young University's television channel.) About a year ago, he invited Dive Design heads Alex Tholl and Adam Hecht to his lab in Virginia to look at how he could improve the process.

And now, a New Jersey–based design firm called Dive Design thinks it’s the solution to full-limb replacement. It has partnered with a company called Bionic Pets that builds exactly what its name implies: accessibility tech for pets. Derrick Campana, who runs Bionic Pets, has long built pet prosthetics by hand. (He’s even got a show about it called The Wizard of Paws, which airs on Brigham Young University's television channel.) About a year ago, he invited Dive Design heads Alex Tholl and Adam Hecht to his lab in Virginia to look at how he could improve the process.

“Something that kept coming up was the need for full limb prosthesis development,” Tholl says. The limbs that Campana had been building used too many resources and required too much labor to be manageable. Plus, Tholl says, “With the waste that was involved, it just didn’t make financial sense. For us, that’s when the wheels started turning.”

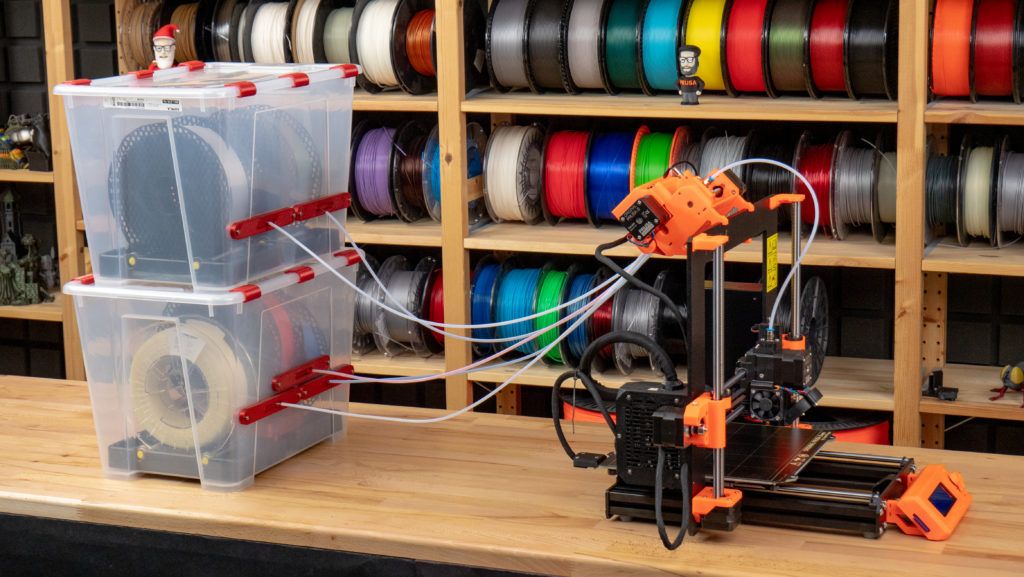

The first step was to find the right software to build the 3D models. Dive Design's intern, Julio Aira IV, a mechanical and biomedical engineering student at Penn State, had a student license to a modeling program developed by a company called nTopology. The others at Dive Design piggybacked off that pseudo-bootlegged software and went to work. (Their software licenses are now up to date.) The nTop Platform lets users build 3D models and simulate how they might function in the real world. That means designers can stress test and map movements of the limb before ever printing it out. The software is not limited to cute animal projects; the government defense contractor Lockheed Martin is an investor, and nTopology has designed optical components for defense tech companies like Raytheon as well. (The intricate jackets that fit the prosthetic to the dog's body were designed and customized with another 3D design company called Landau Design+Technology.)

Dive Design's intern, Julio Aira IV, a mechanical and biomedical engineering student at Penn State, had a student license to a modeling program developed by a company called nTopology. The others at Dive Design piggybacked off that pseudo-bootlegged software and went to work. (Their software licenses are now up to date.) The nTop Platform lets users build 3D models and simulate how they might function in the real world. That means designers can stress test and map movements of the limb before ever printing it out. The software is not limited to cute animal projects; the government defense contractor Lockheed Martin is an investor, and nTopology has designed optical components for defense tech companies like Raytheon as well. (The intricate jackets that fit the prosthetic to the dog's body were designed and customized with another 3D design company called Landau Design+Technology.)

Photograph: Dive Design

Most Popular

“The biggest thing is iterating,” Hecht says. “When you're doing something new, you never have the perfect idea immediately. It's always a lot of trial and error. So the faster we can go through the process of creating things and testing things in the real world, the better solution we’re going to have.”

“When you're doing something new, you never have the perfect idea immediately. It's always a lot of trial and error. So the faster we can go through the process of creating things and testing things in the real world, the better solution we’re going to have.”

Dive Design’s process is similar to building standard orthopedics: Study the dog, take measurements, model it out, and then build from there. But 3D printing lets the engineers quickly adapt and change the physical product in ways that are far less feasible with traditional prosthetics. If a particular joint or lattice that makes up a support isn’t working, they can rework it in a matter of hours.

Bionic Pets' Campana says the rapid iteration afforded by 3D printing is especially beneficial for younger animals, since the patient may need many devices as its body grows. "A new device may be needed, but we do not need to make a cast or redesign," he says in an email. "We can just resize the file and reprint."

“I’m kind of borderline obsessed with this kind of work,” Aira, who works on modeling and developing the prosthetics, says. “We’re really just scratching the surface of how we think about 3D printing and how we think about everything around us. It’s really amazing what we’re going to be able to do and how we’re going to be able to take advantage of these technologies.”

“We’re really just scratching the surface of how we think about 3D printing and how we think about everything around us. It’s really amazing what we’re going to be able to do and how we’re going to be able to take advantage of these technologies.”

Hit a Stride

While that enthusiasm may be in high supply, labor and expertise doesn’t come cheap. Wendland says the prosthetics on which she’s consulted typically fall somewhere between $1,800 to $2,000. Bionic Pets’ prices are still expensive, but more reasonable: $850 for a partial limb and $1,750 for a full limb. These hefty price tags may be familiar to pet owners who have experienced the sticker shock of an astronomical vet bill. So the ability to make inexpensive prosthetics is no doubt appealing.

Photograph: Dive Design

Most Popular

Wendland says she’s had people reach out to her who want to 3D print DIY prosthetics for their own dog, or for a school project. But the kind of materials people are able to utilize in their home printer likely aren’t going to meet the same standards as something that is professionally made.

But the kind of materials people are able to utilize in their home printer likely aren’t going to meet the same standards as something that is professionally made.

“What makes me a little nervous about 3D printing is that people start to get this idea that anybody can make a prosthetic,” Wendland says. “I just see potential for harm with something like that. I love that people are excited about it and that they want to help, but there’s a lot that has gone into the training and the people who are actually doing this for a living and making this happen in a functional way.”

Photograph: Dive Design

An animal might look cute with its artificial limb in an Instagram video, but if that prosthetic hasn’t been carefully crafted by people with the orthopedic knowledge to properly customize it, there’s a risk of it causing more harm than if there was no prosthetic at all. Let’s say a dog moves with the assistance of a wheeled cart. If the wheels are placed too far back, it can create excess stress on the spine. Place them too far forward, and the dog’s constantly tipping over onto its face. A leg prosthetic that doesn’t fit properly can cause sores and ulcerations where the bone meets the skin, sometimes resulting in internal damage in the leg.

Place them too far forward, and the dog’s constantly tipping over onto its face. A leg prosthetic that doesn’t fit properly can cause sores and ulcerations where the bone meets the skin, sometimes resulting in internal damage in the leg.

Prosthetic builders like Dive Design, Bionic Pets, and Ortho Pets have to work in close consultation with orthopedic veterinarians to ensure that their creations aren’t actively detrimental to the animal. Pet prosthetics are a new enough phenomenon that there isn’t a lot of research to definitively show what works and what doesn’t. For now, orthopedic surgeons and builders just have to rely on clinical experience.

Regardless of the type of prosthetic, one thing the animal can't avoid is the need for rehabilitation. It can take weeks or months of physical rehab for a dog to become comfortable with a prosthetic. That means more vet visits, more investment and expenses.

Wendland hasn’t worked with Dive Design’s models specifically, but she says these types of full-limb assistive devices have their place. But it’s important for every pet owner who finds themselves considering one to know their options.

But it’s important for every pet owner who finds themselves considering one to know their options.

“Depending on the situation, I almost wonder if that money wouldn't be a little bit better spent towards good rehabilitation,” Wendland says. “Maybe acupuncture for secondary muscle soreness, things like that, to keep a dog mobile. But I would absolutely consider these for a dog where they have problems with the other leg. I think this is a great use of 3D printing.”

Correction Dec. 21, 9:00 a.m: Updated language to clarify the difference between nTopology and its software. The company is nTopology and the software is nTop Platform. Also clarified the role of Landau Design+Technology, who worked to design and customize the prosthetic jackets.

More Great WIRED Stories

📩 Want the latest on tech, science, and more? Sign up for our newsletters!

Get rich selling used fashion online—or cry trying

The 8 best books about artificial intelligence to read now

Hold everything: Stormtroopers have discovered tactics

I tested positive for Covid-19.

What does that really mean?

What does that really mean?Gift ideas for people who just need a good night’s sleep

🎮 WIRED Games: Get the latest tips, reviews, and more

🏃🏽♀️ Want the best tools to get healthy? Check out our Gear team’s picks for the best fitness trackers, running gear (including shoes and socks), and best headphones

Boone Ashworth is a staff writer on the WIRED Gear desk, where he also produces the weekly Gadget Lab podcast. He graduated from San Francisco State University and still lives in the city. Currently, he has opened too many browser tabs.

Topics3-D printingdogsrobotics

More from WIREDExamples of How 3D Printed Prosthetics & Orthotics Are Helping Animals

Published on August 20, 2021 by Alexandrea P.

3D printing is known to reach across industries and help everyone around the world, and this includes animals! We decided to take a closer look down at some of the animals that have had their lives saved or helped thanks to the power of 3D printing. Just like with humans, 3D printing has numerous applications for helping animals who have lost limbs or other important body parts. Thanks to increasingly cheaper technologies as well as accurate scans, many different animals have had the opportunity to have a customized 3d printed prosthetics or orthotics, significantly improving their lives. Though this list is by no means exhaustive, we took a look at some of our favorite examples below.

Just like with humans, 3D printing has numerous applications for helping animals who have lost limbs or other important body parts. Thanks to increasingly cheaper technologies as well as accurate scans, many different animals have had the opportunity to have a customized 3d printed prosthetics or orthotics, significantly improving their lives. Though this list is by no means exhaustive, we took a look at some of our favorite examples below.

The Shellter Project

Paris Shelton, the hermit crab, was forced to abandon its natural habitat due to a shortage of shells, forcing the crustaceans to make homes out of any trash that they can find, such as glass bottles. In response to this situation, which affects not only Paris Shelton but many hermit crabs, Makerbot launched the Shellter project. This community initiative is designed to give these marine animals a new home through 3D printing, while still being environmentally friendly. To accomplish this, they enlisted the help of makers to design new shells. The designs were then 3D printed and integrated into the environment of the crabs and hermit crabs, saving their lives.

The designs were then 3D printed and integrated into the environment of the crabs and hermit crabs, saving their lives.

Using Thingiverse, Makerbot and TeamUSA called on fellow makers to reach into their creativity to create new shell designs, which are then uploaded onto Thingiverse using the tag “SHELLTER”. From here, the team 3D prints the shells and incorporates them into their crab habitat (or crabitat) at the Botcave in Brooklyn, New York. Using their crabitats, they are able to see the preferences of the crabs, helping them to end the current hermit crab crisis.

Photo Credits: Makerbot

Wadddles the duck and his 3D-printed prosthetic

Born with a deformed leg, Waddles the duck was lucky enough to cross paths with Derrick Campana, a prosthetist specializing in animals. In order to help Waddles, the prosthetist 3D printed an artificial leg for the duck. To achieve this, he first made a mold of the paw, then scanned and modeled the mold, before finally printing the prosthesis assuming that it would act as the paw. If the duck had difficulty adapting to it at first, it now walks perfectly and doesn’t hesitate to lean on it when necessary!

If the duck had difficulty adapting to it at first, it now walks perfectly and doesn’t hesitate to lean on it when necessary!

3D printed horseshoes

CSIRO was the leader in making 3D printed horse shoes. Though they have less of an impact on quality of life, they are still important 3D printed prosthetics for animals (photo credits: CSIRO)

Horse shoes are very specific pieces that you would never imagine could be 3D printed. Well, think agin, they don’t just already exist, they have actually been met with quite a lot of acceptance. Specifically, it was the Australian company CSIRO that manufactured 3D printed horseshoes called “Titanium Shoes”. The project uses titanium instead of aluminum to create lighter racing shoes that allow horses to have a better performance. This also involved 3D scanning technologies that digitize the animal’s hoof so that the parts can be 3D modeled with dedicated software. The scanning process takes only a few minutes and, for one horse, custom shoes can be made and printed the same day.

The scanning process takes only a few minutes and, for one horse, custom shoes can be made and printed the same day.

Turbo the Chihuahua

The now Instagram-famous Chihuahua Turbo Roo was born without his two front legs and was unable to walk or to run or keep up with his other doggy buddies. A viral moment with the adorable two-legged pup caught the attention of an aerospace engineer in San Diego, who then designed and 3D printed Turbo Roo’s wheelchair harness then added rollerblade wheels. Thanks to his 3D printed wheels, Turboro is now always on the move.

AKUT the Loggerhead Turtle

AKUT-3 the loggerhead turtle from Turkey met a sad fate after a devastating boating collision that left him without about 60 percent of his jaw, leaving him without the ability to eat and with little chance of survival in the wild. But, thanks to Turkish company BTech Innovation which specializes in medical prostheses, AKUT-3’s 3D printed titanium jaw gave him a new lease on life.

But, thanks to Turkish company BTech Innovation which specializes in medical prostheses, AKUT-3’s 3D printed titanium jaw gave him a new lease on life.

The process to help AKUT started much as it would have with any human patient. The turtle’s carers at Pamukkale University’s Research, Rescue and Rehabilitation center sent scan images of the damaged jaw to Btech Innovation who then were able to create a customized implant made out of medical-grade titanium (the preferred material for many prosthetics, including those that are 3D printed) for the turtle, what may have been the first 3D jaw created for a wild species.

The surgery for AKUT’s new jaw lasted 2.5 hours and was performed by both surgeons and veterinarians. Following his surgery, it seems that his body has accepted his new jaw and though there have not been many updates, it is likely that once he returned his strength, he was returned to the wild which was the teams’ ultimate goal.

Photo Credits: Btech Innovations

Alaska the Guinea Pig

In Toronto, Canada, Alaska the Guinea Pig was able to gain her mobility back after having one of her front legs amputated due to a post-birth uterus infection. Alaska’s owner was able to enlist the help of the digital design technician using the Toronto Public Library’s Ultimaker 2+ 3D printer to create a wheelchair for her tiny pet. While local veterinarians could only offer wheelchair options for larger animals, Alaska was able to get a custom wheelchair 3D printed that would support her 700 gram frame.

Alaska’s owner was able to enlist the help of the digital design technician using the Toronto Public Library’s Ultimaker 2+ 3D printer to create a wheelchair for her tiny pet. While local veterinarians could only offer wheelchair options for larger animals, Alaska was able to get a custom wheelchair 3D printed that would support her 700 gram frame.

Photo Credit: Toronto CTV News

DiveDesign 3D Printed Helmet for Bo the Baby Goat

Born with a large hole in his skull which left his brain tissue exposed, Bo the Baby Goat is able to keep his brain protected thanks to his custom TPU helmet by Dive Design. Since Bo is still a growing billy goat, he needs to have a new helmet every few weeks as his head size changes. DiveDesign used a 3D scan and sent Bo a new helmet this summer!

Photo Credit: Goats of Anarchy

Beak by 3D Systems (Grecia the Toucan)

Grecia has the dubious honor of being the first toucan to receive a 3D-printed beak. Hailing from Costa Rica, Grecia had the misfortune of being attacked by teenagers, though the perpetrator was never found. Unfortunately, this incident caused her to lose more than half of the top of her beak. Though devastating regardless, this was particularly a problem for Grecia. For toucans, their beaks are an integral piece of their anatomy enabling them to not only eat and speak, but also regulating the temperatures of their bodies.

Unfortunately, this incident caused her to lose more than half of the top of her beak. Though devastating regardless, this was particularly a problem for Grecia. For toucans, their beaks are an integral piece of their anatomy enabling them to not only eat and speak, but also regulating the temperatures of their bodies.

Because of the brutality of the attack, many were not sure that she would survive. However, her spirit inspired people to look into ways to get her a new beak, including a 3D-printing company from the US who decided they could help. In order to create her new prosthetic beak, the team used scanned the beak of another Toucan who had passed, the beak was then made of nylon and assembled in what was likely an SLS machine, though more details were not released. In any case, Grecia’s rehabilitation was successful thanks to 3D-printing and she even went on to become a symbol against animal abuse in Costa Rica.

Grecia’s beak is yet another example of how 3D printed prosthetics can help animals (photo credits: Bob J Galindo – Own work, CC BY-SA 4. 0, via Wikipedia Commons )

0, via Wikipedia Commons )

Alejandro Colli’s Free 3D Printed Prosthetics for Pets

More and more 3D printing is being seen for its use for making 3D printed prosthetics for pets who before might not have had any options. One such person is Argentinian computer engineering study Alejandro Colli who works to help injured dogs by making them 3D-printed prosthetic limbs. Like many of the younger generations, his project started on twitter where he launched a call to his followers announcing that he would be making 3D printed prosthetics for dogs specifically. After reaching out to a nearby veterinary hospital, he started making his first protoytpes.

The first actual prosthetic he made took several months before it was ready to be tried on an animal, though he was able to become quicker as time went on. He gave away the prosthetics for free and has sent to various countries in South America, including Argentina, Panama, Mexico, Colombia and Chile.

Photo Credits: Alejandro Colli

Mr.

Stubbs, the alligator with a 3D printed tail

Stubbs, the alligator with a 3D printed tailThis American alligator, named Mr. Stubbs, lost his tail several years ago while being illegally transported by a group of animal traffickers. After some time without being able to find him a suitable prosthesis, a team of experts turned to 3D technologies to give the animal a better quality of life. They used an Artec 3D scanner to create a specialized appendage for the alligator. The high precision accuracy allowed them to make the animal a well-fitting tail fully customized for its size and body composition. Fortunately, Mr. Stubbs readily adopted the new prosthesis and quickly integrated it into the way he moves his body.

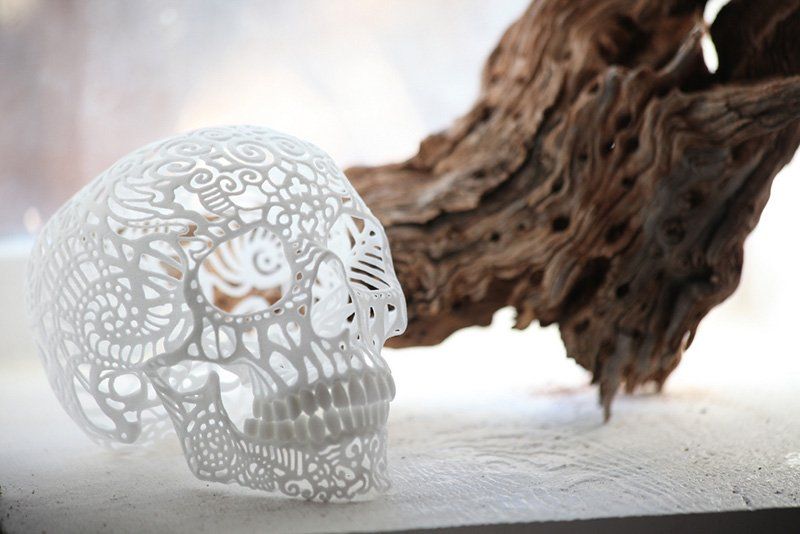

Fred the Tortoise and the “Animal Avengers”

In yet another case of 3D printed prosthetics for animals, or more specifically amphibians, in Brazil, Fred the tortoise received his very own 3D printed tortoise shell, a first in the world of 3D printing. After losing 85% of his shell as a result of a forest fire, a group of volunteers at the “Animal Avengers”, recreated his shell using forty photos that were taken of healthy tortoises. Printed 4 times, the pieces required 50 hours of printing and used a plastic filament to print with an FDM desktop printer. The shell was then painted by a volunteer artist to help make the shell look more realistic. After, Fred was able to feel at home in his new home and continue living a long and happy life with his other tortoise friends.

After losing 85% of his shell as a result of a forest fire, a group of volunteers at the “Animal Avengers”, recreated his shell using forty photos that were taken of healthy tortoises. Printed 4 times, the pieces required 50 hours of printing and used a plastic filament to print with an FDM desktop printer. The shell was then painted by a volunteer artist to help make the shell look more realistic. After, Fred was able to feel at home in his new home and continue living a long and happy life with his other tortoise friends.

Photo Credits: Noticias

Bagpipes the Penguin

Following a run in with a fishing line in 2007, Bagpipes the penguin’s leg was left too damaged, with the only real choice being to amputate it. Since then, he had been hopping around on one foot at his home at the International Antarctic Centre in Christchurch New Zealand. After almost 10 years of him hobbling around, in 2016, they enlisted the help of Professor Dr. Clucas from the University of Canterbury in New Zealand to design and print a prosthetic to help give an old bird a new life.

During the creation process of the leg, Dr. Clucas ran into some difficulties during the scanning process of his leg, as he wouldn’t stop moving and wiggling it, ultimately complicating the process. After finally getting the perfect scan, the 30 hour printing process began. Using a plastic to create his foot, Dr. Clucas continues to make improvements with newer models such as making it easier to clip it on, as well as a rubber material to improve his grip. Thanks to 3D printing and Dr. Clucas, Bagpipes can now continue to live a full life, going from wobbling to waddling.

Photo Credits: Christchurch Antarctic Centre

What do you think of these 3D printed prosthetics for animals? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly newsletter to receive all the latest 3D printing news straight to your inbox!

3D printing and veterinary medicine: life-saving printed prostheses

When zookeepers at ZooTampa were performing a routine checkup on a 25-year-old hornbill, they discovered a lesion at the base of the skull, a yellow, helmet-like growth on the bird's head. Further examination revealed that the bird, named Crescent, was suffering from life-threatening cancer.

Further examination revealed that the bird, named Crescent, was suffering from life-threatening cancer.

The helmeted hornbill is one of the world's endangered bird species, driven out of its habitat by deforestation and hunting for its helmet. Found only in the Indian subcontinent and Southeast Asia, the hornbill is one of ZooTampa's main attractions. nine0003

A cancerous tumor near the bird's skull could not be removed because it contained part of the bird's sinuses. The team wanted to see if the cancerous tumor could be removed and replaced with a 3D printed replica made specifically for this bird. Patient-specific prostheses and devices have already been used in human surgery, but have never been used in hornbills. Is this possible, and if so, what materials would be safe for the bird?

“Clinical literature shows that human outcomes are improved with prostheses, medical devices, and surgical guides,” said Gaurav Manchanda, director of medical market development at Formlabs. "We are very pleased that our technology was able to bring the same benefits to Crescent" .

"We are very pleased that our technology was able to bring the same benefits to Crescent" .

ZooTampa says the 3D printed "spare beak" was created by Formlabs using BioMed White Resin. This material is an opaque white material for biocompatible applications requiring prolonged skin contact or brief mucosal contact. Unique to Formlabs SLA 3D printing materials, this medical grade material is approved for short-term contact with tissue, bone, and dentine. nine0003

“Formlabs provided the material, and the USF Health Radiology 3D team printed the surgical guide and new helmet for Crescent on the Formlabs Form 3B 3D printer ,” ZooTampa said.

“It was very surprising when Crescent began to preen just hours after the operation” added ZooTampa, “Formlabs resin was found to be compatible with the yellow grease secreted by the glands above the tail of the bird, which gave the new scale the same bright sheen , which was originally " .

Over the past few years, 3D printing has experienced explosive growth in the medical field. Hospitals are rapidly innovating with their own 3D printing, delivering personalized care on demand with more innovative workflows, patient-matched surgical instruments, and visual aids for diagnosis and education.

Hospitals are rapidly innovating with their own 3D printing, delivering personalized care on demand with more innovative workflows, patient-matched surgical instruments, and visual aids for diagnosis and education.

Veterinarians and veterinary schools have also taken notice, realizing that many of the same methods and workflows can be used with animals. nine0003

At the Michigan State University College of Veterinary Medicine, patients of all shapes, sizes and types can enter the door. For Dr. Daniel Marturello, DVM, MS, DACVS and Associate Professor of Small Animal Orthopedic Surgery, this means every day can be different. Some days he may be working in the clinic, taking in dogs and cats with broken bones, skeletal deformities, or torn ligaments, and other days he's in the operating room helping to heal these patients and get them back on the road to recovery. nine0003

In one particularly difficult case, a dog was brought in with a crushed shin very close to the knee. Because the fracture was so close to the joint, it was difficult to see the full extent of the damage on an x-ray. Dr. Marturello printed a tibia fracture using White Resin on a Form 3 3D printer, sterilized the models and made them safe for use in the operating room.

Because the fracture was so close to the joint, it was difficult to see the full extent of the damage on an x-ray. Dr. Marturello printed a tibia fracture using White Resin on a Form 3 3D printer, sterilized the models and made them safe for use in the operating room.

“We were able to rotate around the bone during the operation, which helped us get a more tangible 3D view of the fracture model. This is important because in surgery we only see one side. Having this printed bone, given the angle of the fracture, was very helpful, and although it was a really difficult case, the dog did a great job. It really helps to take the operation to the next level.” . Dr. Marturello said.

Veterinary use cases like 3D printing, such as ZooTampa, illustrate how powerful 3D printing can be in saving the lives of beloved animals. With an ever-growing library of materials, Formlabs Medical is at the forefront of patient care. Whether it's a bird, dog, or human, 3D printing is enabling the future of medical care so that clinical innovators at the forefront can quickly solve even the most non-traditional problems. nine0003

nine0003

10 amazing 3D printed prostheses for... animals

One of the most interesting applications of additive technologies has been veterinary prosthetics. One after another, there are stories of animals affected by the elements, bipedal ill-wishers or birth defects, to the aid of which people armed with 3D technologies come. The 3Dtoday.ru portal has prepared for PM ten examples of the use of 3D printing that humanity can be proud of.

Tatyana Fam nine0003

Titanium beak for Gigi parrot

Do not self-medicate! In our articles, we collect the latest scientific data and the opinions of authoritative health experts. But remember: only a doctor can diagnose and prescribe treatment.

A long-tailed macaw named Gigi suffered from severe beak deformities that prevented feeding. The problem was compounded by the fact that these magnificent parrots feed on seeds and nut kernels, and in order to crack the shell, the beak must be very strong. It was decided to abandon the plastic prosthesis: a team of Brazilian veterinarians and 3D printing experts resorted to selective laser sintering technology and made a new beak from a lightweight and durable titanium alloy. nine0003

It was decided to abandon the plastic prosthesis: a team of Brazilian veterinarians and 3D printing experts resorted to selective laser sintering technology and made a new beak from a lightweight and durable titanium alloy. nine0003

New shell after wildfire

Another Brazilian patient was a tortoise named Fred, who miraculously survived the wildfire. The tortoise shell was so badly damaged by fire that veterinarian Rodrigo Robello remembered the notorious Freddy Krueger. The new protective armor was 3D-printed, with the inside surface modeled after photographs of Fred's damaged shell and the outside surface after photographs of healthy turtle relatives. The shell was made from four parts, fastened together after transplantation. The result is quite prosperous: Fred recovered from severe pneumonia caused by smoke inhalation, and now walks in the garden, flaunting a new outfit. Veterinarians are in no hurry to release the patient, deciding to first make sure that the new shell is comfortable and durable, and at the same time paint it in more natural colors. nine0003

nine0003

Save Ziggy the Border Collie

A border collie named Ziggy has gone through one misfortune after another. First, he lost one leg after a severe fracture. The brave puppy did not succumb to despondency and learned to walk on three legs, but soon began to experience pain in the remaining front leg. The cause was improper bone development due to shifted weight. Scientists from the University of Queensland decided to fight for the dog to the last and performed several operations to eliminate bone deformities and restore a joint damaged by arthritis. To plan complex procedures, doctors resorted to 3D models obtained using computed tomography, and so that the injured paw, fixed with a retainer, could rest and heal, a special stroller was printed for Ziggy. nine0003

Romina is still running

A whippet named Romina was hit by a lawnmower, losing one of her legs in a horrific accident. It happened in Brazil in 2013, and now Mexican researchers from the University of Valle have taken up the treatment of the dog: Romina has become a tester of inexpensive veterinary prostheses being developed by scientists. An accurate model of the stump was obtained using 3D scanning, and a custom sleeve was designed based on the results. The final version of the prosthesis will be very similar to the prototype in the illustration, and its design will be made of aluminum or carbon fiber. The prosthesis should help the dog regain the ability not only to walk, but also to run and even jump, which is important for dogs of this breed that can reach speeds of 70 km/h. According to the researchers, thanks to 3D technologies, it takes only one day to make such a prosthesis. nine0003

It happened in Brazil in 2013, and now Mexican researchers from the University of Valle have taken up the treatment of the dog: Romina has become a tester of inexpensive veterinary prostheses being developed by scientists. An accurate model of the stump was obtained using 3D scanning, and a custom sleeve was designed based on the results. The final version of the prosthesis will be very similar to the prototype in the illustration, and its design will be made of aluminum or carbon fiber. The prosthesis should help the dog regain the ability not only to walk, but also to run and even jump, which is important for dogs of this breed that can reach speeds of 70 km/h. According to the researchers, thanks to 3D technologies, it takes only one day to make such a prosthesis. nine0003

3D printed rhino horn

Sometimes the fight to save animals takes unexpected turns. Damien Verno, director of South Africa's Inverdurn Wildlife Sanctuary, is suggesting stripping rhinos of their main ornament. The reason for such a seemingly strange initiative was the high mortality rate of white rhinos already on the verge of extinction at the hands of poachers. In order to protect the animals, it is necessary to deprive hunters of the desire to kill rhinos, removing from the equation valuable horns, because of which the unfortunate giants suffer. But what about the rhinos themselves, deprived of their main means of protection? Verno proposes to replace the horns with 3D-printed prostheses made of aluminum and plastic - fully functional and useless to anyone but rhinos. The idea has already been tested in practice, and the director hopes that soon the greedy hunters will leave his wards alone. nine0003

The reason for such a seemingly strange initiative was the high mortality rate of white rhinos already on the verge of extinction at the hands of poachers. In order to protect the animals, it is necessary to deprive hunters of the desire to kill rhinos, removing from the equation valuable horns, because of which the unfortunate giants suffer. But what about the rhinos themselves, deprived of their main means of protection? Verno proposes to replace the horns with 3D-printed prostheses made of aluminum and plastic - fully functional and useless to anyone but rhinos. The idea has already been tested in practice, and the director hopes that soon the greedy hunters will leave his wards alone. nine0003

Holly's high-tech horseshoes

Ten-year-old mare Holly received the first of its kind podiatric horseshoes. For three years, the unfortunate horse suffered from chronic laminitis, a disease caused by poor blood circulation that causes destruction of the tissue that connects the bone to the hoof, resulting in lameness or even complete loss of mobility due to unbearable pain. Often the owners have no other choice than euthanasia. Fortunately, Holly managed to avoid a terrible fate: 3D printing experts from CSIRO came to the aid of the animal, designing and printing special therapeutic horseshoes made of titanium alloy. nine0003

Often the owners have no other choice than euthanasia. Fortunately, Holly managed to avoid a terrible fate: 3D printing experts from CSIRO came to the aid of the animal, designing and printing special therapeutic horseshoes made of titanium alloy. nine0003

How a cat beat cancer

A nine-year-old cat named Cyrano fell victim to cancer in one of his paws. A serious struggle unfolded for the cat's life: Cyrano became the first animal to undergo chemotherapy. The treatment was successful, the tumor went into remission, but the cat's paw was too seriously damaged to recover on its own. Veterinarians considered the possibility of amputation, but came to the conclusion that moving a 12-kilogram cat on three legs is fraught with yet another health problem. There was only one option left: knee arthroplasty, which had never before been used to treat cats. However, the operation was successful, and a special 3D printed implant was made from a medical cobalt-chromium alloy by direct selective sintering (DMLS) methods. nine0003

nine0003

3D Printed Sea Turtle Orthosis

A green sea turtle named Ogie suffered a severe limb injury. It was not possible to establish exactly how the wound was received, but one of the flippers was cut to the bone, and the bone itself was crushed. After the operation, the flexible limb needed to be fixed, which veterinarians Craig Harms and Emily Christiansen did with a 3D printed brace made of hard plastic and rubber. Augie wore the brace for forty days, after which the brace was removed, and some time later, the recovered turtle was released into the wild. nine0003

Buttercup learns to walk and swim

Buttercup, a duckling, was born with a severe limb deformity that caused unbearable pain when walking. The Novacopy 3D printing bureau came to the aid of the bird. The company's specialists scanned the left paw of Buttercup's sister, Minnie, and then printed out a mold for imprinting a silicone paw.