Sugar lab 3d printing

Products – The Sugar Lab

Skip to contentFilters

Sort: FeaturedBest SellingAlphabetically, A-ZAlphabetically, Z-APrice, low to highPrice, high to lowDate, new to oldDate, old to new

FiltersType

Bouillon Candy & Decor Chocolates Drinks Home Chefs Sugar Cubes Vegan

(Un)traditional Hangwas

Sold Out

(Un)traditional Hangwas

From $24.99

80s Throwback Bonbons

Sold Out

80s Throwback Bonbons

From $24.99

90s Throwback Bonbons

Sold Out

90s Throwback Bonbons

From $24.99

Apple-Covered Caramels

Sold Out

Apple-Covered Caramels

$24. 99

Autumn Gourd Candy

Sold Out

Autumn Gourd Candy

$18.99

Bejeweled Spring Truffles

Sold Out

Bejeweled Spring Truffles

$27.99

Bingsu Toppers

Sold Out

Bingsu Toppers

From $24.99

Broken Heart Puzzle Chocolate Truffles

Sold Out

Broken Heart Puzzle Chocolate Truffles

$27.99

BULK-DRAFT

Sold Out

BULK-DRAFT

From $18.99

Candy Cane Dessert Shells

Sold Out

Candy Cane Dessert Shells

$24. 99

99

Candy Cane Sugar Cubes

Candy Cane Sugar Cubes

$15.00 Regular price $18.99

Chili Lime Habanero Candy

Sold Out

Chili Lime Habanero Candy

From $18.99

Craft Beer Chocolate Bonbon Flight

Sold Out

Craft Beer Chocolate Bonbon Flight

From $24.99

Cranberry Glitter Drink Drops

Sold Out

Cranberry Glitter Drink Drops

$18.00 Regular price $21.99

Crystalline Ornaments

Sold Out

Crystalline Ornaments

From $18. 99

99

Cucumber Cream Ale Bonbons

Sold Out

Cucumber Cream Ale Bonbons

From $24.99

Day of the Dead Glitter Skulls

Sold Out

Day of the Dead Glitter Skulls

$21.99

Diamond Champagne Bitters

Sold Out

Diamond Champagne Bitters

From $24.99

Diamond Glitter Champagne Bomb

Diamond Glitter Champagne Bomb

$21.99

Floral Candy Skulls

Sold Out

Floral Candy Skulls

From $18. 99

99

Gift Wrapped Dessert Shells

Sold Out

Gift Wrapped Dessert Shells

From $24.99

Glitter Floral Skulls

Sold Out

Glitter Floral Skulls

$21.99

Glitter Margarita Limes

Glitter Margarita Limes

$21.99

Halloween Sugar Cubes

Sold Out

Halloween Sugar Cubes

From $18.99

Hazy IPA Bonbons

Sold Out

Hazy IPA Bonbons

$24.99

Heart-Patterned Roses

Sold Out

Heart-Patterned Roses

$18. 99

99

Holiday Marshmallows

Holiday Marshmallows

$15.00 Regular price $18.99

Holiday Peppermint Mocha Chocolates

Holiday Peppermint Mocha Chocolates

$22.00 Regular price $24.99

Holly Jolly Glitter Skulls

Holly Jolly Glitter Skulls

$17.00 Regular price $21.99

Irish Stout Bonbon

Sold Out

Irish Stout Bonbon

$17.50 Regular price $24.99

Kimchi Bouillon

Sold Out

Kimchi Bouillon

$21. 99

99

Kimchi Bouillons

Kimchi Bouillons

$21.99

Koreatown Collection Kit

Sold Out

Koreatown Collection Kit

$49.99

Lavender Rose Sugar Cubes

Sold Out

Lavender Rose Sugar Cubes

$18.99

Love and Hex Potion Glitter Drops

Love and Hex Potion Glitter Drops

$21.99

Love Hurts Glitter Skulls

Love Hurts Glitter Skulls

$21.99

Luchador Tepache Bonbons

Sold Out

Luchador Tepache Bonbons

$24. 99

99

Lumps of Coal

Sold Out

Lumps of Coal

From $18.99

Mexican Chocolate Stout Bonbons

Sold Out

Mexican Chocolate Stout Bonbons

From $24.99

Mexican Hot Chocolate Sugar Cubes

Sold Out

Mexican Hot Chocolate Sugar Cubes

From $18.99

Orange Blossom Egg Bonbons

Sold Out

Orange Blossom Egg Bonbons

$24.99

Peppermint Mocha Chocolates

Sold Out

Peppermint Mocha Chocolates

$24. 99

99

Peppermint Mocha Valentine Bonbons

Peppermint Mocha Valentine Bonbons

$24.99

Piñata Watermelon Lemonade Candy

Sold Out

Piñata Watermelon Lemonade Candy

$18.99

Pumpkin Spice Dessert Shells

Sold Out

Pumpkin Spice Dessert Shells

From $24.99

Pumpkin Spice Drink Garnish

Sold Out

Pumpkin Spice Drink Garnish

From $18.99

Pumpkin Spice Latte Chocolates

Pumpkin Spice Latte Chocolates

$24. 99

99

Sugar Lab Launches 3D Printed Chocolates – The Sugar Lab

LOS ANGELES, Calif., January 15, 2021 -- Sugar Lab announces a new line of 3D printed chocolate truffles and bonbons, just in time for Valentine’s Day and available at SugarLab3D.com. These glamorous desserts, in never-before-seen shapes and colors, capture the extraordinary potential for beauty and customization of 3D printed confections.

Sugar Lab worked with Chef Melissa Walnock of the Culinary Institute of America to develop rich chocolate ganache recipes that are uniquely complemented by the 3D printed shells. With flavors ranging from refined to nostalgic, the truffles can pair with a champagne cocktail, an old-fashioned, or a favorite whiskey. Meanwhile, the bonbons feature throwback flavors such as s’mores and PB&J – perfect with an espresso or a glass of milk! The Valentine line also includes candies, cupcake décor, cocktail garnishes, and pastry shells that can be filled by any home chef with mousse, ice cream, or cake batter.

“Our goal at Sugar Lab is to pursue chef-led culinary innovations in partnership with our skilled digital design team, using 3D printing technology,” says Kyle von Hasseln, CEO and co-founder of Sugar Lab.

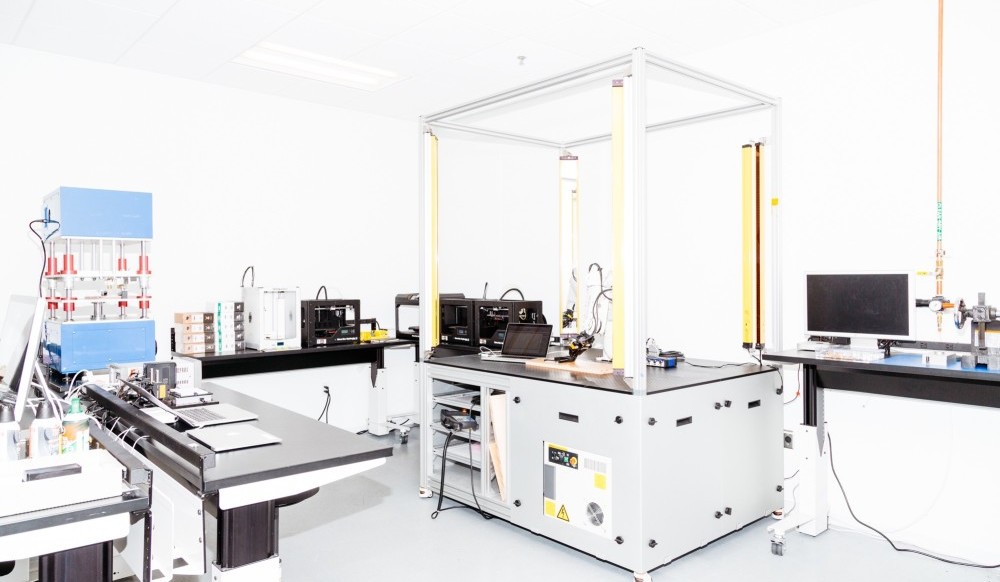

Sugar Lab, the world’s first true digital bakery, was founded in 2020 by von Hasseln and COO Meagan Bozeman in collaboration with 3D Food Designer William Hu. The company is new, but the concept has been years in the making. Von Hasseln and his wife, Liz, invented the technology in 2012, which was soon acquired by a major 3D printing manufacturer. Von Hasseln, Bozeman, and Hu became key members of the R&D team that ultimately invented the first food-safe 3D printer, in partnership with Brill, Inc.

“After years of developing the Culinary Printer, we understand its potential better than anyone,” says Bozeman. “We’ve stepped out on our own with a concept we believe in and, more importantly, with people we trust, to start this business. Our goal is to make this amazing technology accessible to chefs and consumers around the world. ”

”

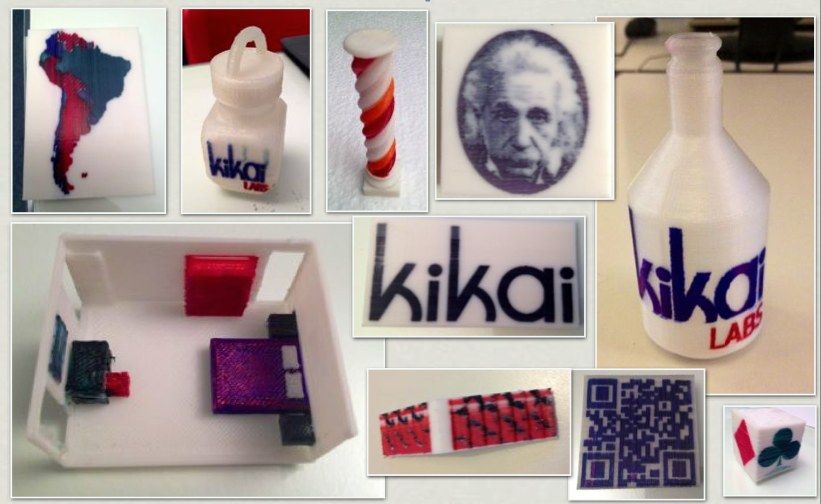

“3D printing brings so much flexibility to the table for our customers,” adds von Hasseln. “We can create complex and beautiful foods that really have to be seen to be believed. Equally significant, 3D printing allows for fast design iteration without the need for molds. This means we can quickly brand and personalize existing designs with something unique for each customer.”

Sugar Lab launched its website and first holiday line in Fall 2020. The company has since added several 3D printers to its kitchen and expanded its team. In 2021, Sugar Lab will continue to expand its product lines, focusing especially on weddings, birthdays, and other special occasions.

About Sugar Lab:

Sugar Lab is the world’s first true digital bakery, run by a small team of rogue chefs, architects-turned-designers, and tech geeks in East Los Angeles. Its parent company, Culinary Printworks – also founded in 2020 – creates custom designs and flavors for professional chefs, caterers, and major brands. Culinary Printworks and Sugar Lab products are 3D printed with the Brill 3D Culinary Studio, the world’s first food-safe, stainless steel, commercial-grade 3D printer for professional manufacturers. Sugar Lab’s kitchen operates under LA County Health Department guidelines.

Culinary Printworks and Sugar Lab products are 3D printed with the Brill 3D Culinary Studio, the world’s first food-safe, stainless steel, commercial-grade 3D printer for professional manufacturers. Sugar Lab’s kitchen operates under LA County Health Department guidelines.

To learn more, visit SugarLab3D.com and CulinaryPrintworks.com. Follow Sugar Lab on Instagram, Facebook, Twitter and LinkedIn.

Media Contact:

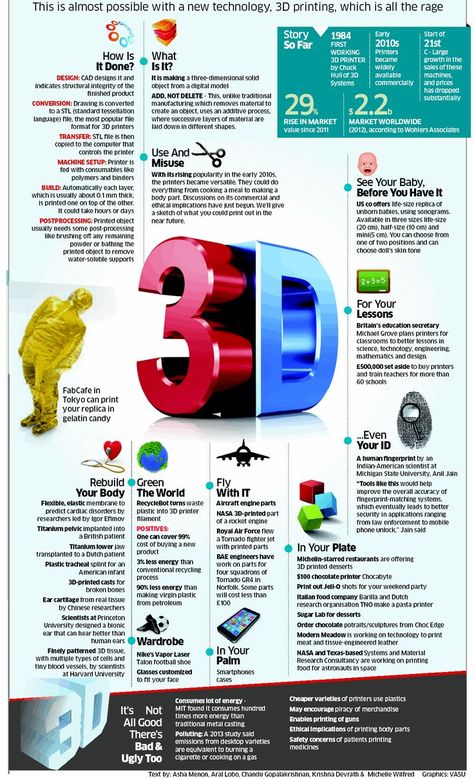

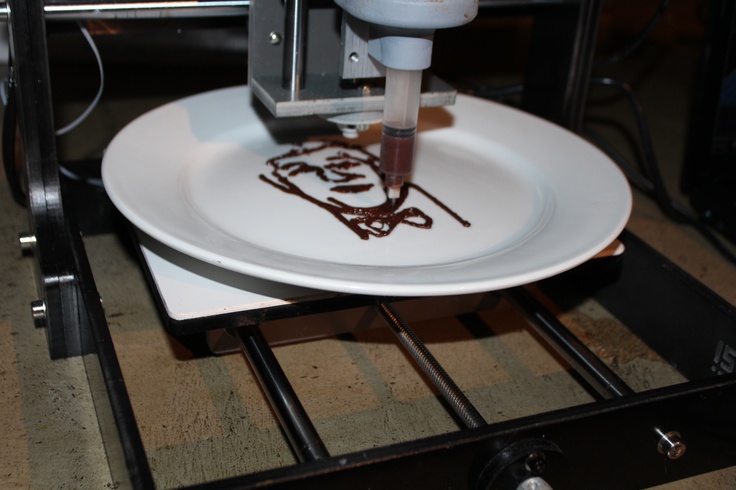

Husband and wife combined food with 3D printing and turned sugar into a three-dimensional structural substance that can interact with food in a variety of ways

Archive

Kyle von Hasseln opened the "Sugar Lab", where sugar sculptures for wedding cakes are printed on a 3D printer. In September 2013, they sold their technology to 3DSystems, a 3D printer manufacturer. The couple has worked in the fields of molecular biology and architecture in the past and now uses 3D printing technology to create the most beautiful cakes.

“To put it simply, we mix water and sugar and the mixture solidifies,” says Sugar Lab co-founder Kyle von Hasseln. They use a mixture of water and alcohol, which is applied in layers and very carefully on a sugar substrate, which is selectively soaked and solidified. The process is similar to other uses for 3D printers, but they've optimized it with the ability of sugar to dissolve and solidify, something that conventional 3D printing material can hardly boast.

A husband and wife combined food with 3D printing and turned sugar into a three-dimensional structural substance that can interact with food in a variety of ways. For example, they created a four-tiered wedding cake on a 3D printed sugar base. At TEDx Manhattan Beach, Liz and Kyle Von Hasseln talk about 3D printed desserts and how 3D printing has helped them make the impossible possible.

“The overlay options for technology, food and art are endless, and the possibilities for customization and innovation are endless,” said Liz von Hasseln.

Article prepared for 3dtoday.ru

Subscribe to the author

Subscribe

Don't want

Article comments

More interesting articles

6

Subscribe to the author

Subscribe

Don't want

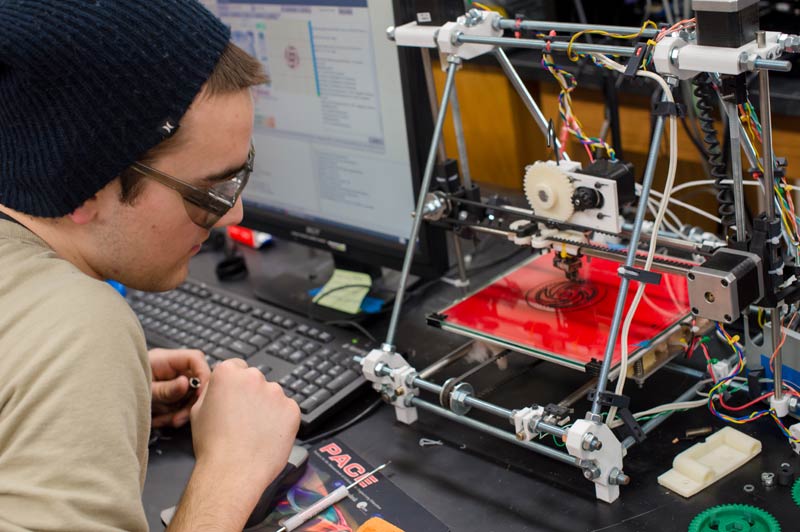

One of the newest developments in 3D printing devices has been the advent of extruders. No, it's not...

Read more

4

Subscribe to the author

Subscribe

Don't want

The progress of 3D printing in recent years has gained such a rapid speed that we will soon stop...

Read more

3

Subscribe to the author

Subscribe

Don't want

More and more RepRap 3D printers based on modeling technology are on the market today. ..

..

Read more

Read blogs

Additive technologies in medicine: a review of recent developments

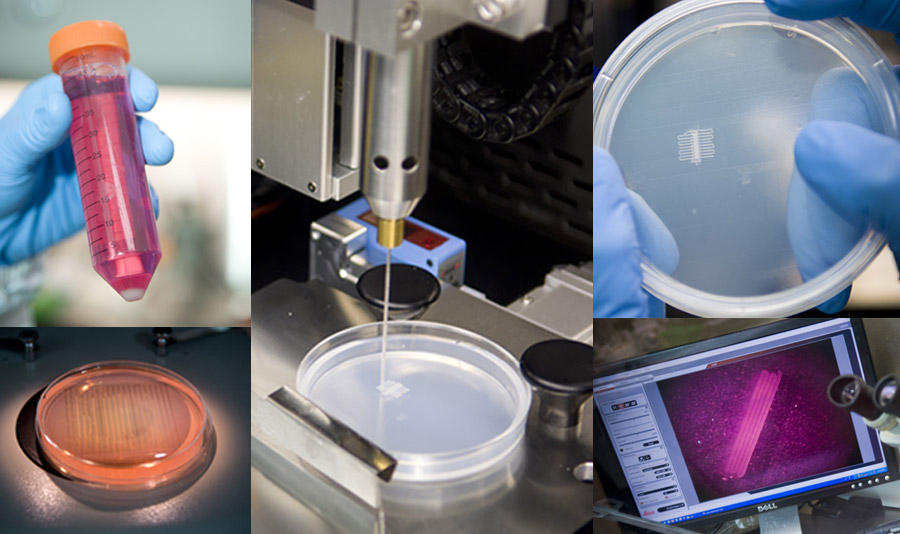

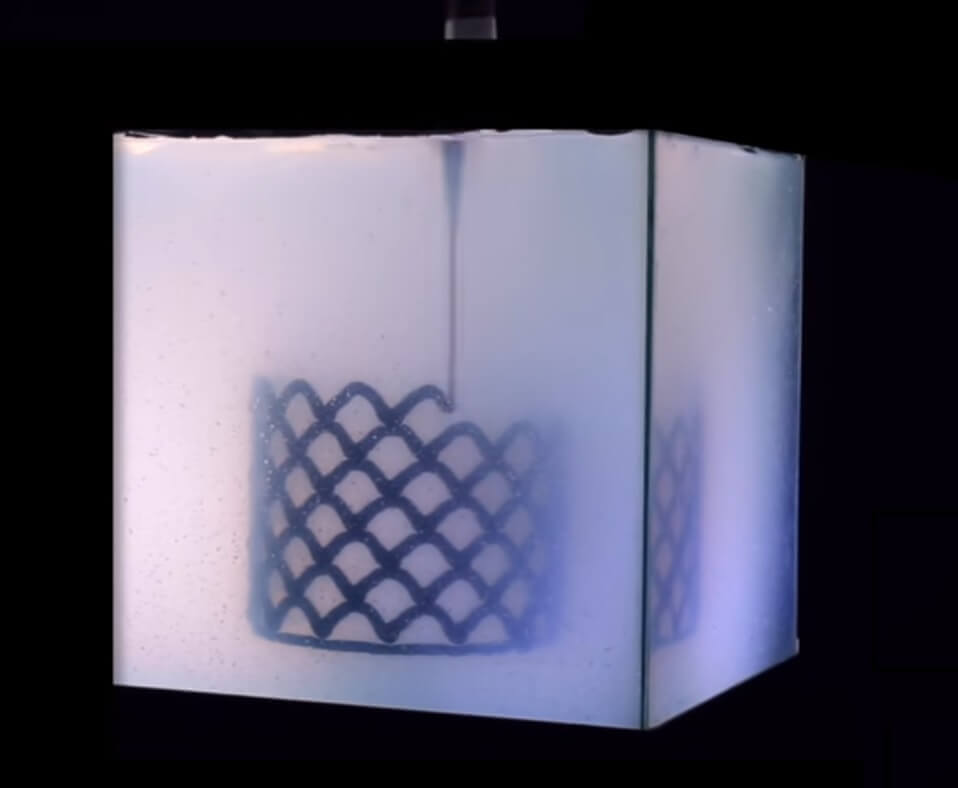

3D printing has great potential in medicine. With these technologies, it is possible to reproduce highly accurate 3D models of human organs, as well as some implants. Developers of such technologies strive to create organs in real time. At the end of August 2018, a team from the University of Minnesota announced what is claimed to be the world's first 3D-printed bionic eye. It gives great hope to patients who have lost their sight. At the end of July 2018, smartARM, which developed a self-learning robotic arm prosthesis, won the international technology competition Microsoft Imagine Cup 2018. In May 2018, it became known about the creation of a 3D printer that prints tissue from sugar for growing organs and studying tumors.

organs will be printed using a sugar 3D printer This is a development of the University of Illinois (University of Illinois). There are already 3D printers on the market that can print objects out of sugar. In contrast to these devices, the new equipment uses isomalt, a sugar substitute derived from beets and commonly found in lozenges for sore throats and coughs.

There are already 3D printers on the market that can print objects out of sugar. In contrast to these devices, the new equipment uses isomalt, a sugar substitute derived from beets and commonly found in lozenges for sore throats and coughs.

After dissolving and 3D printing, the sugar structures cool and solidify, creating a strong scaffold - carrier substrates, on the basis of which living cells are cultivated. Here one of the problems is getting material that will “leave” not earlier and not later than the right time.

Sugar 3D printing gets tricky when it comes to regenerating heart tissue. Too much pressure causes the structure to lose its shape, and too much heat causes the tissue to crystallize or burn. Isomalt is less prone to crystallization than regular sugar and does not discolor when dissolved.

Professor Rohit Bhargava, who works at the Cancer Center in Illinois, says the unique method allows the construction of thin tubes with a round cross section. Previously, this was not possible for polymers. Soluble sugar, on the other hand, helps create cylinders and tunnels that resemble blood vessels. It is through these vessels that nutrients can be transported to tissues or cells. The development of a new method will also allow the creation of channels in microfluidic devices.

Previously, this was not possible for polymers. Soluble sugar, on the other hand, helps create cylinders and tunnels that resemble blood vessels. It is through these vessels that nutrients can be transported to tissues or cells. The development of a new method will also allow the creation of channels in microfluidic devices.

University of Illinois technology can be used in areas such as medical research, biomedical engineering, and manufacturing. Experts hope that over time their 3D printer will be able to print human organs from scratch.

First 3D printed cornea

In May 2018, the first 3D printed cornea was announced. This achievement was able to boast at the University of Newcastle (Newcastle University). They can now use 3D printing to form stromal cell corneas for each individual, the researchers say.

According to the Financial Times, Newcastle University researchers have created a special bio-ink consisting of corneal stroma cells from a living donor, alginate (polysaccharide) and collagen, a protein that forms the basis of the body's connective tissue. By loading this substance into a conventional 3D printer, it was possible to print a healthy cornea in just 10 minutes. Moreover, after printing, more than 90% of the cells remained viable, and on the seventh day - 83%.

By loading this substance into a conventional 3D printer, it was possible to print a healthy cornea in just 10 minutes. Moreover, after printing, more than 90% of the cells remained viable, and on the seventh day - 83%.

British scientists have created the first 3D printed corneas for the human eye

|

The composition of the ink must be flexible, yet rigid enough for the finished cornea to hold its shape. It is also important that the cells remain alive. So far, no scientific group has been able to combine all three conditions. But now we have bio-containing stem cells ready for use,” said Che Connon, a professor in the Department of Tissue Engineering Technology from Newcastle University, who led the work on 3D printing of corneas. |

This most convex transparent part of the eyeball can suffer from infections, burns, mechanical trauma and other causes. By May 2018, about 10 million people around the world are in need of a corneal transplant to avoid losing their sight, and another 5 million people are already blind, but have a chance to recover from such a transplant. Unfortunately, donor material is always in short supply, but the development of Newcastle University scientists can solve this problem. True, the technology still has to undergo clinical trials, and it may take about 5 years before mass use, the researchers believe.

By May 2018, about 10 million people around the world are in need of a corneal transplant to avoid losing their sight, and another 5 million people are already blind, but have a chance to recover from such a transplant. Unfortunately, donor material is always in short supply, but the development of Newcastle University scientists can solve this problem. True, the technology still has to undergo clinical trials, and it may take about 5 years before mass use, the researchers believe.

Handheld Artificial Skin 3D Printer

In May 2018, researchers at the University of Toronto introduced a portable 3D skin printer designed to treat deep burn wounds. The research team notes that this is the first device that forms and positions a printed tissue sample directly at the burn site in just a couple of minutes. Read more here.

AI 3D Organ Printing Software

On April 11, 2018, biological 3D printer manufacturer Aether announced the release of artificial intelligence (AI)-based medical imaging software that will significantly advance the development of 3D organ printing. The new Automatic Segmentation and Reconstruction (ASAR) will help clinicians and researchers increase productivity through automated segmentation of organs and tissues.

The new Automatic Segmentation and Reconstruction (ASAR) will help clinicians and researchers increase productivity through automated segmentation of organs and tissues.

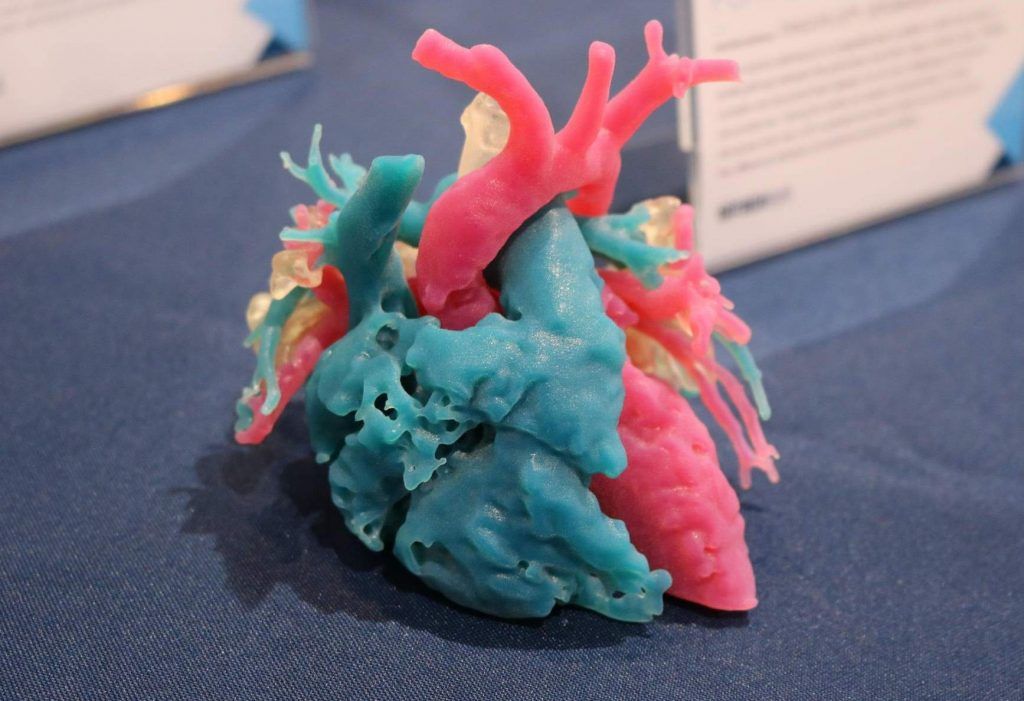

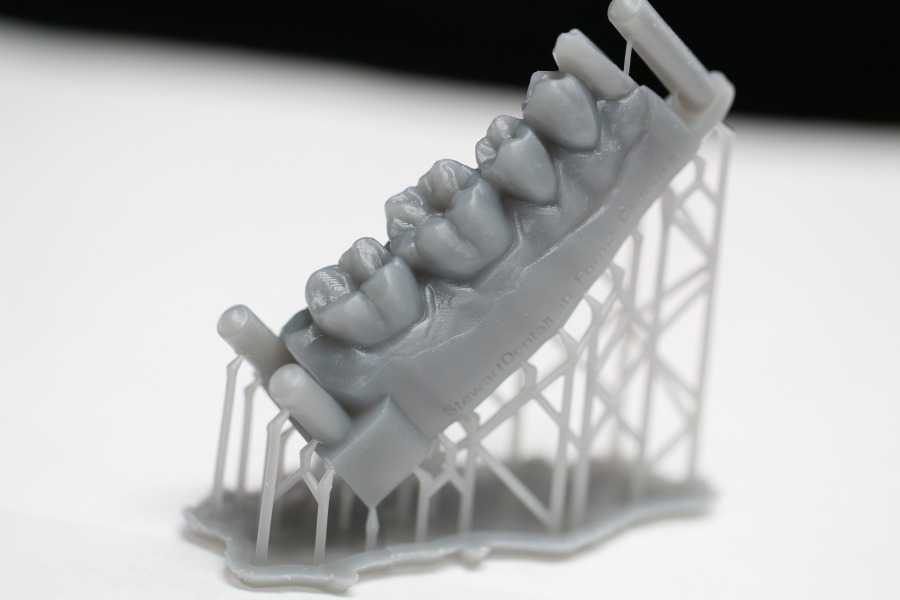

Hospitals save tens of thousands of dollars with 3D printing

In March 2018, the North Manchester Hospital (NMGH) opened a 3D printing lab to assist oral and maxillofacial surgeons in the treatment and rehabilitation of patients with head and neck cancer, facial trauma or congenital anomalies. The lab was created by reconstructive technologist Oliver Burley, who made a case for the economic benefits of a 3D lab for the hospital, as well as a fundraiser for the lab itself, software, and a $42,000 PolyJet 3D printer. The laboratory currently employs three specialists who work with nine maxillofacial surgeon consultants.

After earning a Master's degree in Reconstructive Technology, in which he studied the application of 3D printing, Burleigh presented a 3D business model to Manchester Hospital management. The first argument in her favor was cost savings, as the hospital spent $166,000 annually on 3D printing projects. On average, a hospital encounters 20 cancer cases and 8-10 injuries each year, and analysis based on these data showed that it would be cheaper to run an in-house 3D lab. Although the hospital has to pay for laboratory licensing, this amount remains fixed and does not depend on the amount of work done. The second argument was the saving of time for surgeons, who can use 3D models when planning operations. Finally, the last argument was the reduction in the delivery time of 3D models from the manufacturer.

The first argument in her favor was cost savings, as the hospital spent $166,000 annually on 3D printing projects. On average, a hospital encounters 20 cancer cases and 8-10 injuries each year, and analysis based on these data showed that it would be cheaper to run an in-house 3D lab. Although the hospital has to pay for laboratory licensing, this amount remains fixed and does not depend on the amount of work done. The second argument was the saving of time for surgeons, who can use 3D models when planning operations. Finally, the last argument was the reduction in the delivery time of 3D models from the manufacturer.

3D printing technology was invented by American inventor Charles Hull in 1983 and gradually spread to all industries

The Materialize Mimics Innovation Suite was chosen as the modeling software, and the taken ProPlan CMF; the software cost about $25,000. Burley notes that 3D models are used by the hospital in almost every case of head and neck cancer; he is confident that in five years, the 3D printing laboratory will become a must-have application for treatment and rehabilitation centers for cancer patients.

The laboratory primarily works with patients with head or neck cancer who require reconstructive surgeries, including those based on bone grafts for the reconstruction of the upper or lower jaw. The patient's head is scanned and then a virtual 3D model is created. Surgeons and laboratory specialists can review various types of reconstructive surgeries and devices in virtual reality before moving on to the design stage. Designed prostheses, rods or plates are 3D printed using metal or plastic mixtures. The final stage of the project assumes that the resulting model is sterilized and transferred to surgeons. Thanks to a wide range of instruments, the laboratory also accepts other orders and is already used by orthopedists, neurologists and rheumatologists.

The UK NHS has made significant strides in 3D printing, with Wales recently creating the world's first combined bone graft and presenting a 3D model of the operation. Experts note the prerequisites that three-dimensional printing will be increasingly used in healthcare. In February 2018, a new research center Bristol Biomedical Research Center (BRC) opened in Bristol, which is supposed to study tissue engineering technologies through bioprinting. New developments will be based on data from existing studies on the cardiovascular system and 3D printed cardiac implants.

In February 2018, a new research center Bristol Biomedical Research Center (BRC) opened in Bristol, which is supposed to study tissue engineering technologies through bioprinting. New developments will be based on data from existing studies on the cardiovascular system and 3D printed cardiac implants.

3D printed limbs being inserted into Syrian refugees

In March 2018, it was reported that a Jordanian hospital was using 3D printed limbs to treat refugees wounded in Syria. The technologies used in the project of the international medical care organization Doctors Without Borders (Medecins Sans Frontieres, MSF) make it possible to design and manufacture a prosthesis within 24 hours, and its cost is several times lower than that of traditional artificial limbs.

Since the beginning of 2017, five volunteer patients, including children, have participated in the MSF program, according to New Atlas. The project is being implemented at the MSF Reconstructive Surgery Center at Al-Mowasah Hospital in the Jordanian capital Amman, where the wounded during the military conflicts in Syria, Iraq and Yemen are being treated.

Jordan hospital uses 3D printed limbs to treat refugees wounded in Syria

|

| We do not use too complex electronic solutions, but strive to make as simple as possible, but at the same time reliable prostheses, said MSF biomedical engineer Safa Herfat in an interview with the publication. |

According to him, a 3D printed arm can cost about $20, while a conventional prosthetic upper limb costs hundreds of dollars.

In addition to the low cost and speed of production, there are other advantages. For example, a 3D-printed prosthesis can be designed to fit the individual needs of the patient and their daily tasks, from driving a car to ordinary household chores. In addition, the design can be carried out remotely, and only the limb scanning and 3D printing itself can be performed on site.

Printed prostheses are also significantly lighter than traditional ones, which is important for patients.

| If the prosthesis is heavy and bulky, the patient, most likely, does not go with it for a long time and will stop using it, - said Safa Herfat. |

MSF hopes to expand the program to other areas that need similar assistance.

3D Bioprinter for Diabetes Treatment

In early December 2017, the Australian University of Wollongong introduced a new customizable 3D bioprinter that could improve the treatment of patients with type 1 diabetes.

The inventors called the system a 3D bioprinter for pancreatic cell transplantation (PICT). The new technology was presented to the Minister of Health of South Australia and then transferred to the Royal Adelaide Hospital, which became the first clinic in the world with such equipment.

3D Bioprinter

The developers explain that the system applies a special bioink containing insulin-producing islet cells to transplantable 3D printed scaffolds. This method is expected to improve the current process of islet cell transplantation from human donors used to treat severe cases of diabetes. The new technology reduces the risk of rejection of the transplanted tissue by incorporating the patient's cells into the donor tissue.

This method is expected to improve the current process of islet cell transplantation from human donors used to treat severe cases of diabetes. The new technology reduces the risk of rejection of the transplanted tissue by incorporating the patient's cells into the donor tissue.

| The PICT bioprinter will allow us to uniquely mix donor cells with recipient cells and create new complex “organoids” for experimental transplantation,” explained Professor Toby Coates. |

In addition, the bioprinter prints several types of cells, so its scaffold structure can also include endotheliocytes necessary for the growth of new blood vessels in the transplanted islet tissue.

The Research Council has awarded a grant to the Australian Center of Excellence in Electrical Materials, chaired by Professor Gordon Wallace, and his team will now further develop and improve the 3D bioprinter delivered to the Royal Adelaide Hospital.

| Together with the team of Toby Coates at the Royal Adelaide Hospital, we plan to increase the efficiency of islet cell transplants by embedding donor materials in a 3D printed structure to protect them during and after transplantation,” said Professor Wallace. |

Middle ear 3D printing for hearing restoration

At the annual meeting of the Radiological Society of North America (RSNA) in December 2017, it was shown how 3D printing can be used to reproduce exact copies of the middle ear to restore hearing to people. The development began to be put into practice.

By converting 3D CT scans into 3D printed prostheses, surgeons have successfully placed four implants of varying sizes into human ears.

Assuming that the most likely cause of failure with an existing prosthesis is an improper fit, then being able to design a custom prosthesis that can accurately fill an air-bone gap is the least likely to result in failure, says study author Dr. Jeffrey Hirsch. Hirsch, assistant professor of radiology at the University of Maryland at Baltimore, in an interview with HCB News. “Our study shows that even at the submillimeter level, there are tiny differences in different ears that can be accurately reproduced using 3D modeling. Jeffrey Hirsch. Hirsch, assistant professor of radiology at the University of Maryland at Baltimore, in an interview with HCB News. “Our study shows that even at the submillimeter level, there are tiny differences in different ears that can be accurately reproduced using 3D modeling. |

Visual comparison between the size of a coin and a 3D printed prosthetic middle ear In this study, four surgeons performed implant placement in four different middle ears. All surgeons were able to accurately align the prosthesis model with the temporal bone containing the middle and inner parts of the ear. The chances of such an outcome with conventional prosthetics are 1:1296.

Hirsch explained that the ability to see complex anatomical relationships in 3D modeling allows for a new level of study, understanding and medical planning.

The next step for researchers will be to develop a biocompatible material. As such a platform, a group of researchers considers the use of cultured stem cells.

FDA Guidelines for Medical 3D Printing

On December 4, 2017, the US Food and Drug Administration (FDA) released new guidelines for creating medical models using 3D printers. The manual discusses in detail aspects of the design and testing of models, as well as requirements for their quality.

Although 3D printing is a relatively new technology, it has already found widespread use in clinical practice, such as replicating complex anatomical structures and simulating surgical procedures. Noticing the rapid evolution of this technology, the FDA has issued specific guidelines to help manufacturers bring 3D printed models to market more efficiently.

Example of 3D printing of a part of a skull

Based on the August 31, 2017 joint FDA workshop with the RSNA 3D printing panel of independent experts, the guidelines focus on the technical aspects of 3D printing.

Recommendations include sections on design and manufacturing process, model testing, and instruction writing. The manufacturing process section covers the technical aspects of 3D printed models. When creating models based on images, such as those obtained from CT scans, consideration should be given to the minimum image quality and resolution, image processing algorithms that can change the dimensions of the model compared to real organs, and the preservation and definability of anatomical landmarks used for adaptation. models.

The manufacturing process section covers the technical aspects of 3D printed models. When creating models based on images, such as those obtained from CT scans, consideration should be given to the minimum image quality and resolution, image processing algorithms that can change the dimensions of the model compared to real organs, and the preservation and definability of anatomical landmarks used for adaptation. models.

Model testing section provides requirements for model description, mechanical test results, dimensional measurement, material characteristics, sterilization and biocompatibility. According to the third section, each device must have instructions that will indicate the patient ID, the purpose of the model and its final design, as well as a warning about the need for a preliminary examination of the patient to rule out any changes that may distinguish the model from the real anatomical structure.

Printing Mobile Infection Detector

In October 2017, a group of American engineers and scientists developed a new "on-the-spot" infectious disease diagnostic suite that uses a conventional mobile phone and a credit card-sized diagnostic chip as a detector. The solution was created using 3D printing technologies.

The solution was created using 3D printing technologies.

3D printed mobile infection detector

Low cost, portability, and the use of a conventional mobile phone as a detector make this diagnostic complex indispensable for diagnosing infectious diseases in conditions of limited resources or when the diagnostic result is needed immediately. Integration of the diagnostic platform with modern mobile communication systems will allow for personalized treatment of patients and monitoring of the epidemiological situation.

At the same time, the time for obtaining diagnostic results is comparable to the time for conducting similar tests in a stationary laboratory - about 30 minutes. An ordinary smartphone is used to collect and interpret real-time images of the enzyme multiplication reaction, which is carried out in a silicon microfluidic chip that serves to visually display test results.

The complex itself consists of a conventional smartphone and a portable 3D-printed stand-jack containing optoelectronic “stuffing”, as well as a special interface for the smartphone camera. The application running on the smartphone collects the results of the tests carried out using the microfluidic chip and patient data, which are then transferred to the cloud database.

The application running on the smartphone collects the results of the tests carried out using the microfluidic chip and patient data, which are then transferred to the cloud database.

During demonstration tests, the complex was used for the qualitative and quantitative analysis in blood drops of infections that cause respiratory diseases in horses - Zika fever, Dengue fever and Chikungunya fever.

A robotic arm that replaces a sign language interpreter

In August 2017, the media reported on the development of graduate students from the University of Antwerp (Belgium), which could make life easier for deaf people. With the help of a 3D printer, young scientists have made a robotic arm that can act as a sign language interpreter. The invention was called ASLAN (Antwerp's Sign Language Actuating Node).

Sign language interpreters are often in short supply, which is why it was decided to create an inexpensive automated system that can translate text into sign language.

3D printed robotic arm to replace sign language interpreter

| Let's say a deaf person needs to appear in court, or a student who is hard of hearing is present somewhere in class. Here are situations in which people with hearing problems need sign language interpreters, but it often happens that these specialists are difficult to find quickly. In such circumstances, an inexpensive system such as ASLAN can be a solution, says Erwin Smet, professor at the University of Antwerp, quoted by Medgadget. |

I was talking with friends about the shortage of sign language interpreters in Belgium, especially in Flanders, where there is a need for Flemish sign language interpreters. We wanted to solve the problem. I also needed a robotics project for my dissertation, so we combined the two tasks,” adds Stijn Huys, one of the creators of the robotic sign language interpreter. |

The robotic arm assembled by the inventors consists of 25 3D printed plastic parts and is powered by 16 servos controlled by the Arduino platform, reports Tech Crunch. The developers are planning a system with two robotic arms and a face to convey emotions.

So far, there is only a prototype of the device, but enthusiasts intend to complete the project and make the materials of their work publicly available so that those who wish can make their own sign language interpreter.

Printing an artificial heart

In July 2017, the Swiss Federal Institute of Technology Zurich (ETH Zurich) unveiled a 3D printed artificial heart. At the time of the announcement, the product made of silicone was far from the stage of commercial readiness.

390 grams, 679 cc artificial heart 3D printed using investment casting. The left and right ventricles are not separated by a septum, but by a special chamber filled with compressed air. Inflating and deflating, this chamber imitates the contraction of the muscles of the human heart and pumps blood.

The left and right ventricles are not separated by a septum, but by a special chamber filled with compressed air. Inflating and deflating, this chamber imitates the contraction of the muscles of the human heart and pumps blood.

At the time of the demonstration, the artificial heart only supports 3,000 beats, which means it can work from 30 to 45 minutes. To test the work of the heart, scientists used an advanced test environment that mimics the human cardiovascular system, and a fluid that has a viscosity comparable to blood. The operation of the device was captured on video.

Our goal is to create an artificial heart that is comparable in size, shape and function to a human,” says Nicholas Cohrs, a member of the research team involved in the project. — It was a test of technical feasibility. Our task was not to create a heart ready for implantation, but to think about a new direction in the development of artificial hearts. |

By 2017, about 26 million people suffer from heart failure. Most of them are hopelessly waiting for donors to provide them with a new heart. These patients are fitted with special blood pumps that facilitate the work of the heart, but they can cause serious complications and do not provide patients with a pulse.

Printing ovaries

In May 2017, 3D printing of ovaries became known, which allowed infertile mice to give birth. Scientists intend to test the development on humans.

Scientists at Northwestern University Chicago have created an artificial ovary that allows full restoration of reproductive function. During the experiment, an infertile laboratory mouse was implanted with a prosthesis created using 3D printing. Subsequently, the mice (three out of seven) were able to feed on their mother's milk and get healthy litters.

A mouse born from 3D-printed artificial ovaries

Bioprosthetic ovaries consist of a porous gelatin ink scaffold that is filled with follicles, tiny fluid-filled sacs that store immature eggs. The recipient mouse body actually coordinated the development of ovarian tissues, and blood flow through the pores helped turn the implanted structure into a functional bioprosthesis.

The recipient mouse body actually coordinated the development of ovarian tissues, and blood flow through the pores helped turn the implanted structure into a functional bioprosthesis.

However, it is worth noting that not the entire ovary was printed, as it is too complex an organ. Scientists created the connective tissue basis of the ovary: the printer was charged with gelatin, which was obtained from collagen, one of the main proteins of connective tissue - collagen was in the form in which it is usually present in the ovaries of animals. Then, mouse follicles with eggs inside were immersed in the resulting (printed) gelatin base.

It is not yet clear whether such a prosthesis will fit a person, as female follicles are much larger and grow faster. However, scientists promise to conduct research aimed at developing the idea in a human direction.

The goal of the project is to restore fertility and endocrine health to young cancer patients who were sterilized while undergoing treatment for ovarian cancer, Northwestern University Chicago professor Theresa Woodroof said in an interview. | |

3D printed heart on a chip

At the end of October 2016, researchers at Harvard University announced the creation of the world's first 3D printed heart on a chip. The new development will allow experiments related to the work of the heart to be carried out without the participation of experimental people and animals, the university website says.

Researchers often have to work in the dark when gradual changes in the course of histogenesis and development of cardiac muscle tissue occur because there are no easy, non-invasive ways to measure the functional characteristics of the tissue, says study lead author Johan Ulrik Lind. “Integrated sensors allow researchers to continuously collect data as tissue matures and improves contractility.

The results of the study itself, conducted by scientists from the Harvard John A. Paulson School of Engineering and Applied Sciences and Applied Sciences and the Institute of Biotechnology. Visa (Wyss Institute for Biologically Inspired Engineering), published in the journal Nature Materials.

Paulson School of Engineering and Applied Sciences and Applied Sciences and the Institute of Biotechnology. Visa (Wyss Institute for Biologically Inspired Engineering), published in the journal Nature Materials.

The heart on a chip is made of a translucent synthetic material that mimics the structure and function of the heart tissue. The device contains microscopic sensors that can track the beating when the chip is exposed to various drugs and toxins released by various pathogens.

A 3D-printed organ cannot serve as a human implant, but is intended only for scientific research. Thanks to the new technology, it will be possible to reproduce hereditary diseases in the laboratory with the reconstruction of the cells of a specific patient, as well as to test various methods of treatment on artificially grown tissues in order to choose the most effective one.

Creation of 3D models of organs before operations in Dubai

In October 2016, it became known that 3D printers will appear in medical institutions in Dubai, printing accurate models of the organs of patients to be operated on. Thanks to the new technology, it is planned to improve the accuracy and efficiency of surgical operations.

Thanks to the new technology, it is planned to improve the accuracy and efficiency of surgical operations.

According to Gulf News, all hospitals under the control of the Dubai Health Authority (DHA) in the United Arab Emirates (UAE) will be equipped with equipment for 3D printing of prosthetic limbs and teeth that simulate fractures of casts and models human organs to simulate operations before direct surgical contact with the patient.

Dubai surgeons to train on 3D organ models before surgeries

UAE Vice President and Ruler of Dubai Sheikh Mohammed bin Rashid Al Maktoum said the initiative will speed up medical procedures, cut costs and help doctors plan complex surgeries.

In addition, 3D printing improves the accuracy of clinical training. We will print all models of patient organs using the basic capabilities of computed tomography to help doctors simulate operations and visualize all kinds of situations, Al Maktoum said. |

Regulators in the UAE are working to keep laws in line with the rapid development of 3D printing technology, he said. The day is not far off when customers will be able to print various items in special kiosks, so it is very important to establish clear rules for managing any kind of 3D printing, Sheikh added.

The use of 3D printers for medical applications is part of Dubai's 3D printing strategy, which aims to make the city a leading hub for the technology by 2030. All new buildings in Dubai are expected to have 25% 3D printed parts by this point.

Creation and implantation of a 3D skull

In April 2016, it became known that South Korean surgeons were able to print a skull model on a 3D printer and use it on a living person. The operation was successful and helped save a human life, according to a publication on the 3Dprint.com website.

A 60-year-old female patient was admitted to the Chung-Ang University Hospital in South Korea with a sudden headache. She was diagnosed with a subarachnoid hemorrhage. After trying in vain to stop the fatal bleeding, doctors decided to remove part of the skull to relieve the pressure on the brain caused by swelling.

She was diagnosed with a subarachnoid hemorrhage. After trying in vain to stop the fatal bleeding, doctors decided to remove part of the skull to relieve the pressure on the brain caused by swelling.

3D-printed skull successfully transplanted in South Korea

During surgery, there was a lack of blood supply to the brain at the site of the removed part of the skull, as a result of which a skull transplant was required. As a result, it was decided to implant a three-dimensional model of the skull.

Doctors from the hospital recruited experts from the Korea Institute of Industrial Technology in Gangwon Province. They scanned the patient's skull using computed tomography and created an exact three-dimensional copy of the organ. Using special equipment, the model was printed. It was made from pure titanium, which is considered to be one of the best materials for creating implants. This metal is light, strong and inert, it has a low probability of rejection by the body.

The 3D-printed skull was successfully implanted. Kwon Jeong-tek, professor of the Department of Neurosurgery at Chunan University, noted that the creation of synthetic implants and metal plates used to connect bone fragments has long been used to replace elements of the human skull, but this technology has always been imperfect.

Medical 3D Printing Software

In a webinar hosted by the Society for Imaging Informatics in Medicine (SIIM) in late March 2016, University of Utah Dr. Justin Cramer listed the main software products that can be used for 3D printing in medicine.

- Horos. This is a free program for viewing x-rays, as well as images obtained as a result of magnetic resonance imaging and computed tomography. This open source product has quite advanced 3D rendering functionality, including a surface rendering tool. Files can be exported to STL format for 3D printing. The downside of Horos is that it doesn't have the ability to segment an image—divide it into pixels to simplify and/or change the representation of an image so it's easier to analyze, Cramer said.

3D printed prosthetic hand

- Blender. This application is also open source, and one of its main strengths is a very active online community that is constantly developing new add-ons for this product. It is more functional than Horos, but harder to master, notes Justin Kramer.

- sketch up. The program allows you to model various three-dimensional objects and has a fairly wide range of possibilities. For Cramer, the most useful feature is the ability to convert STL files to the Collada format, which is compatible with the Apple iBooks application. SketchUp was once free, but by April 2016 it costs $695. Educational institutions (or those with .edu email access) can download a special version of the program for free.

- materialize. The University of Utah itself, known for its achievements in the field of 3D printing, uses CAD from the Belgian company Materialize. We are talking about the Mimics image processing program and the 3-matic product.

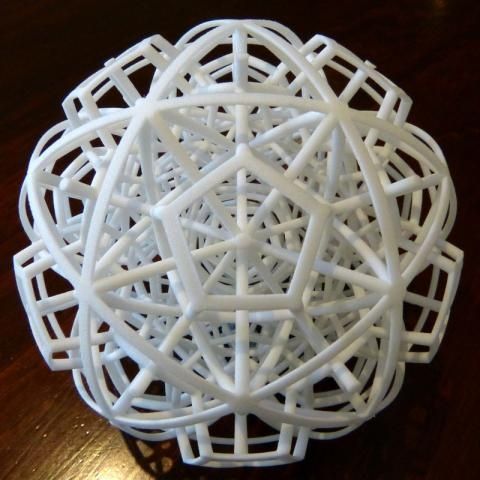

The latter allows you to change the geometry, remesh and create 3D textures, lightweight structures and conformal structures at the STL level, preparing computer models for 3D printing.

The latter allows you to change the geometry, remesh and create 3D textures, lightweight structures and conformal structures at the STL level, preparing computer models for 3D printing.

When choosing software for 3D printers, Justin Kramer recommends a simple rule: for beginners, free options are fine, but if you plan to create accurate anatomical models for professional use, then it is better to purchase a powerful paid product, since it can be used to create a better model.

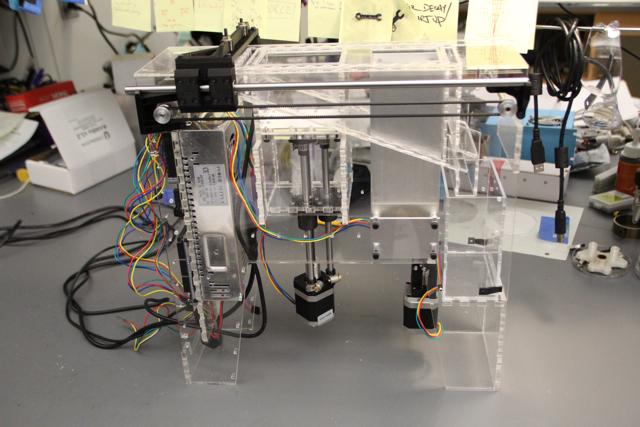

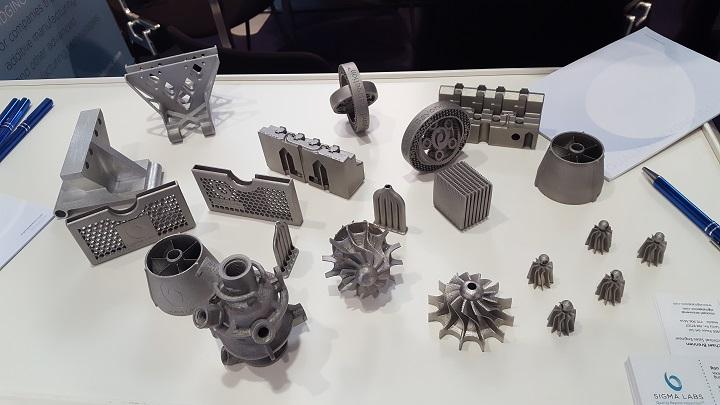

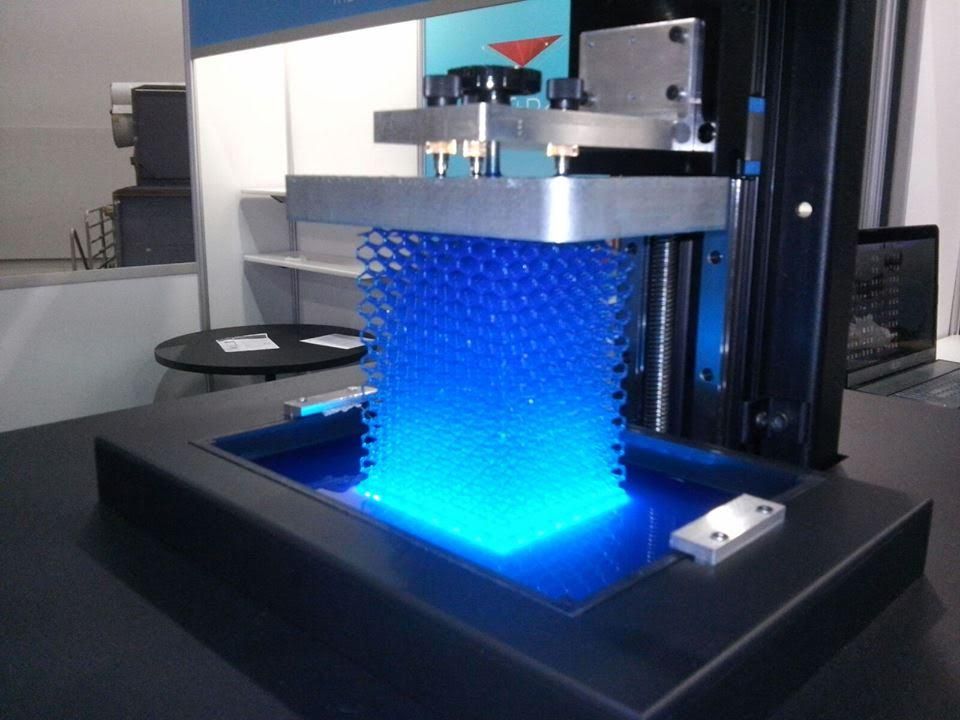

University of Utah Developments: Cheap Fused 3D Printing

At the end of March 2016, the Society for Imaging Informatics in Medicine (SIIM) held a webinar during which radiologists from the University of Utah spoke about the capabilities of their new 3D printing laboratory. Its feature is the use of inexpensive equipment.

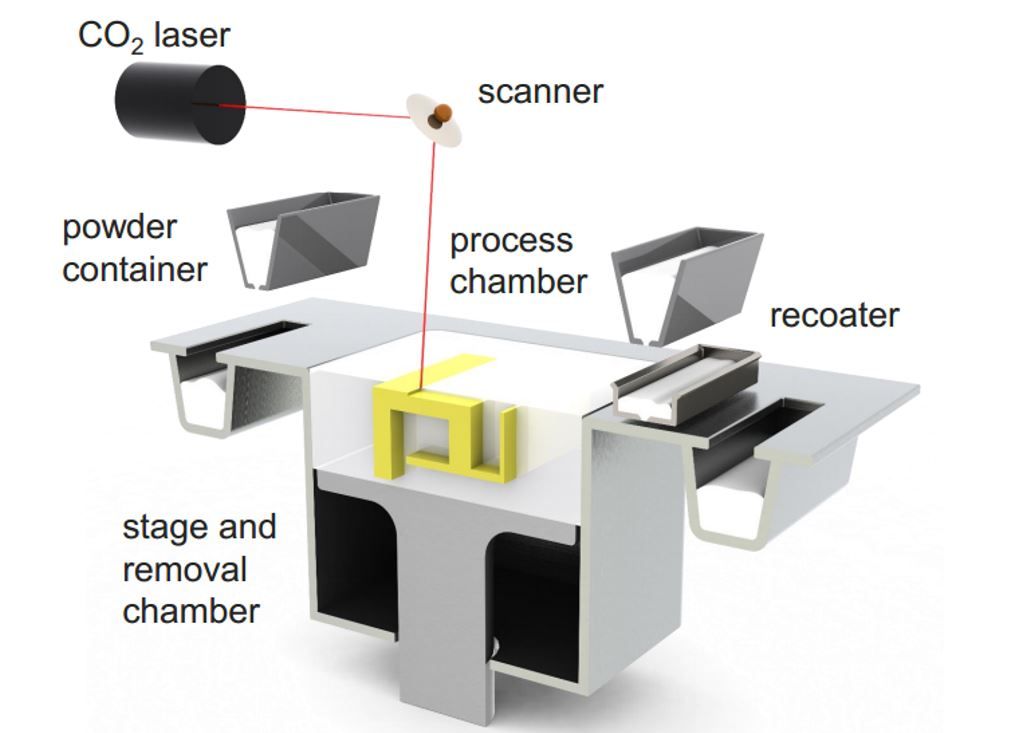

Fused deposition modeling (FDM) was selected for 3D printing. The technology involves the creation of three-dimensional objects by applying successive layers of material that follow the contours of a digital model.

| Researchers often have to work in the dark when gradual changes in the course of histogenesis and development of cardiac muscle tissue occur because there are no easy, non-invasive ways to measure tissue functional characteristics, says study lead author Johan Ulrik Lind. “Integrated sensors allow researchers to continuously collect data as tissue matures and improves contractility.

3D printed spine (left) According to Edward Quigley, Ph.D. from the University of Utah, the fusing method is a versatile and cheap way to create three-dimensional objects, which is why it is often used to develop entry-level medical 3D printers. The University of Utah has built a low cost FDM printer that can print fragile and complex anatomical models used for educational purposes. To obtain more accurate and visual prototypes, experts have added color printing modes to the equipment. However, despite all the advances, the process of modeling remains difficult: very often there is a big glitch, as a result of which the 24-hour printing of an object ends up in a pile of melted plastic, complains Quigley. |