Best beginner 3d printer kit

9 Best DIY 3D Printer Kits (2023 Update)

- Last Updated: January 19, 2023

- Pat Nathaniel

If you’re a hobbyist and a tinkerer who wants to get into 3D printing, the best way is to build your own 3D printer. You can purchase and assemble DIY 3D printer kits that combine your favorite childhood pastimes with your new obsession!

The big reason for building your own printer is the cost savings associated with it.

You might wind up saving hundreds of dollars if you opt for a DIY printer.

Creality Ender 3

Build Volume: 220 x 220 x 250 mm

Get Discount (Official Store)

Check Latest Price

Creality Ender 3 Pro

Build Volume: 220 x 220 x 250 mm

Get Discount (Official Store)

Check Latest Price

Prusa i3 MK3S

Build Volume: 250 x 210 x 210 mm

Get Discount (Official Store)

Check Latest Price

Check Kit Price

The hidden advantage is how much you’ll learn about your printer while putting it together.

An excellent way to think about it is you’re trading a few hours of your time in exchange for a deep understanding of 3D printing.

Table of Contents

- Best DIY 3D Printer Kits At A Glance

- 1. Creality Ender 3 Pro (Editor's Choice)

- 2. Prusa I3 MK3S (Best Overall - Top Pick)

- 3. Creality Ender 3 (Best Value)

- 4. Tronxy XY-2 PRO

- 5. Tronxy X5SA Pro

- 6. Geeetech A10

- 7. Anet A8 Plus

- 8. Creality CR-10 V2

- 9. Anycubic Kossel Plus

- Why DIY Printers?

- How To Build Your Own 3D Printer?

- How To Choose The Right DIY 3D Printer Kit

- Conclusion

Best DIY 3D Printer Kits At A Glance

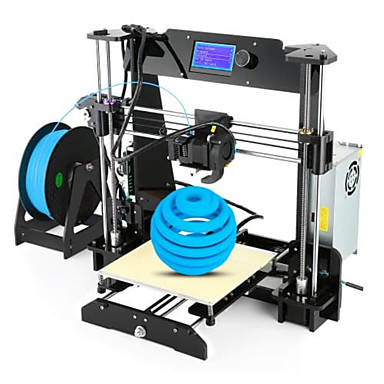

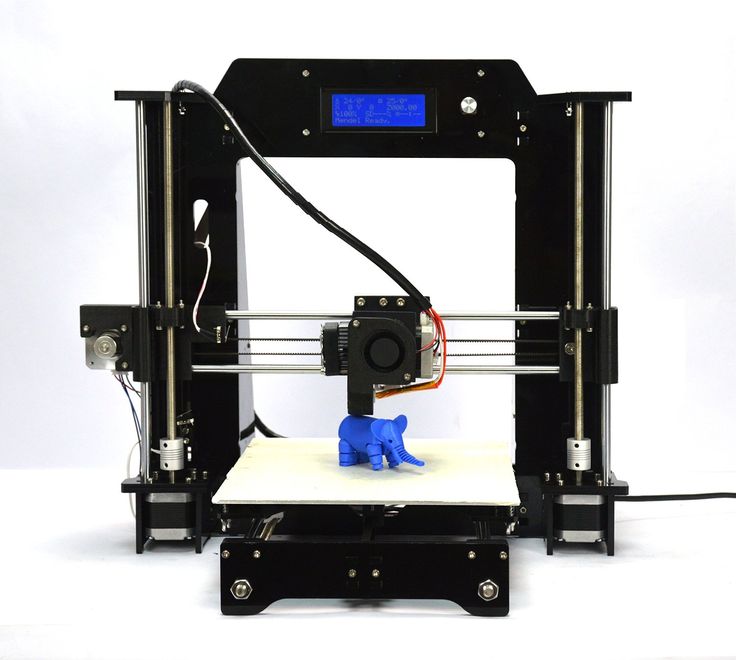

Now let’s look at some of the best DIY 3D printer kits on the market. All of these are FDM-style printers, so there’s no need to worry about resin or dangerous chemicals.

- Creality Ender 3 Pro (Editor’s Choice)

- Prusa I3 MK3S (Top Pick – Best Overall)

- Creality Ender 3 (Best Value)

- Tronxy XY-2 PRO

- Tronxy X5SA Pro

- Geeetech A10

- Anet A8 Plus

- Creality CR-10 V2

- Anycubic Kossel Plus

Quick Reference Table

| 3D Printer | Volume (mm) | Resolution (μm) | Assembly time (hrs) |

| #1 Creality Ender 3 Pro | 220 x 220 x 250 | 100 | 2 |

| #2 Prusa i3 MK3S | 250 x 210 x 210 | 50 | 7 |

| #3 Creality Ender 3 | 220 x 220 x 250 | 100 | 3-6 |

| Tronxy XY-2 Pro | 255 x 255 x 260 | 100 | 3 |

| Tronxy X5SA Pro | 330 x 330 x 400 | 125 | 4 |

| Geeetech A10 | 220 x 220 x 260 | 100 | 1 |

| Anet A8 Plus | 300 x 300 x 350 | 100 | 3 |

| Creality CR-10 V2 | 300 x 300 x 400 | 50 | 1 |

| Anycubic Kossel Plus | 180 x 180 x 320 | 100 | 4 |

1.

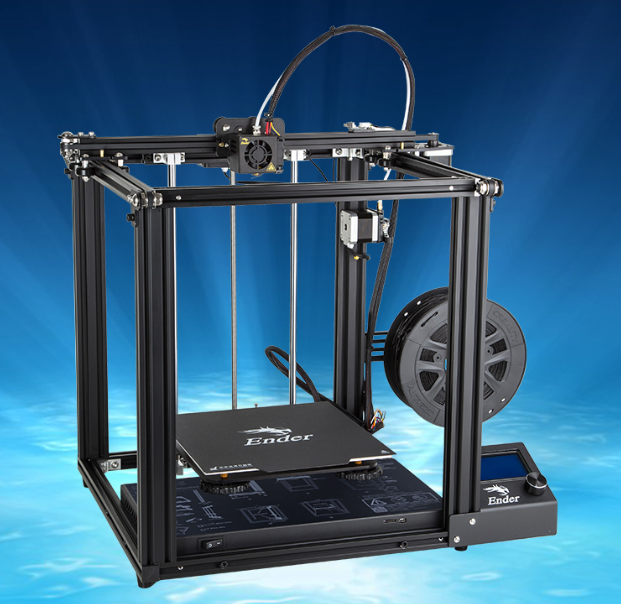

Creality Ender 3 Pro (Editor's Choice)

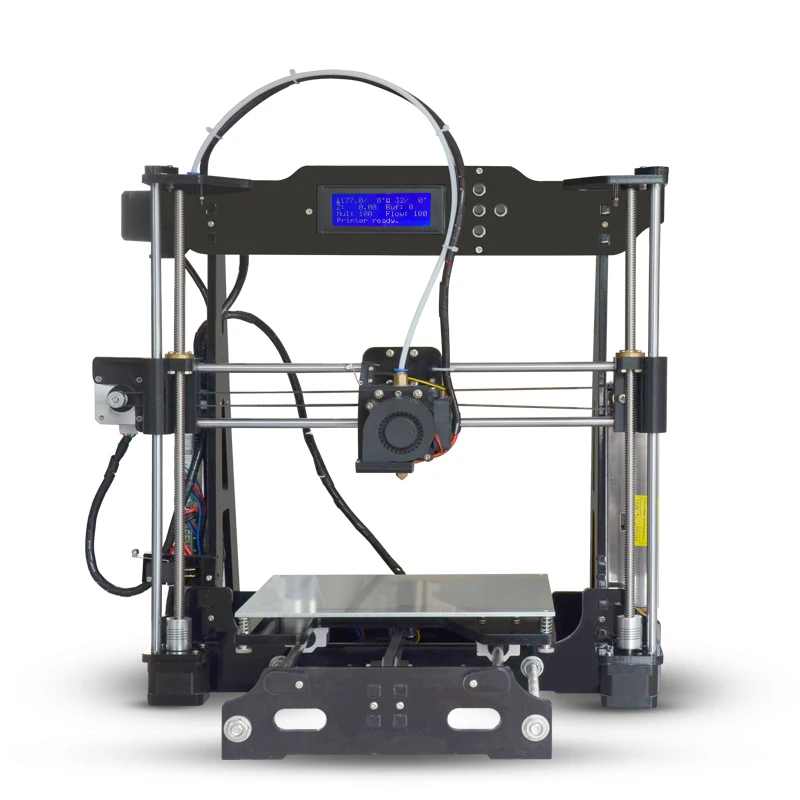

Creality Ender 3 Pro (Editor's Choice) The first 3D printer I’ve ever bought – the Ender 3 Pro is the big brother of the popular Ender 3.

It’s a great 3D printer if you like to tinker and modify, however, owning an Ender 3 Pro is a learning experience.

Because of it’s popularity you have the support of one of the largest communities of makers. If you need help with leveling your bed or calibrating your settings they’ve got you covered.

That said, a well-calibrated and upgraded Ender 3 Pro can go toe-to-toe with a Prusa’s print quality.

This kit is really easy to put together, and it quickly connects to your computer to make for easy printing. It took me about 2 hours to put together the semi-assembled kit following the 12-step pamphlet.

And that’s with leveling the bed too.

The big thing about this printer is how accurate and sturdy it is. It’s really hard to find another printer that can do what the Ender 3 Pro does at the same price point.

The Ender 3 Pro is the best 3D printer under $300.

The Ender 3 Pro is easy to use, has a lot of useful upgrades over the 3, and it has a decent build volume.

This printer is a great pick if you’re looking for an affordable, jack-of-all-trades type of printer, want a printer that’s easy to set up and use, and aren’t afraid to tinker around to achieve high-quality prints.

Get Discount (Official Store)

Check Latest Price

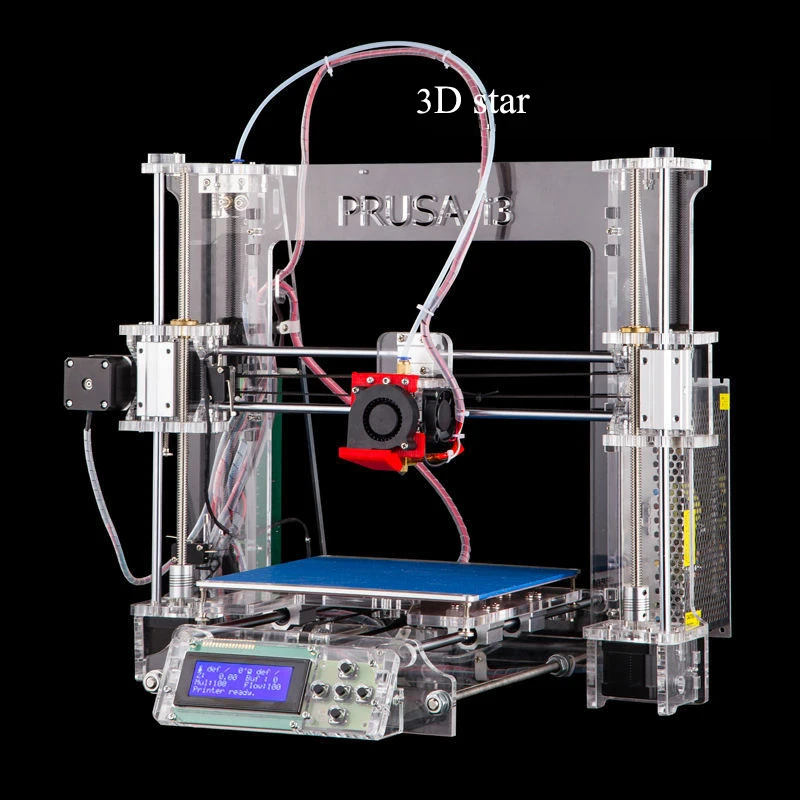

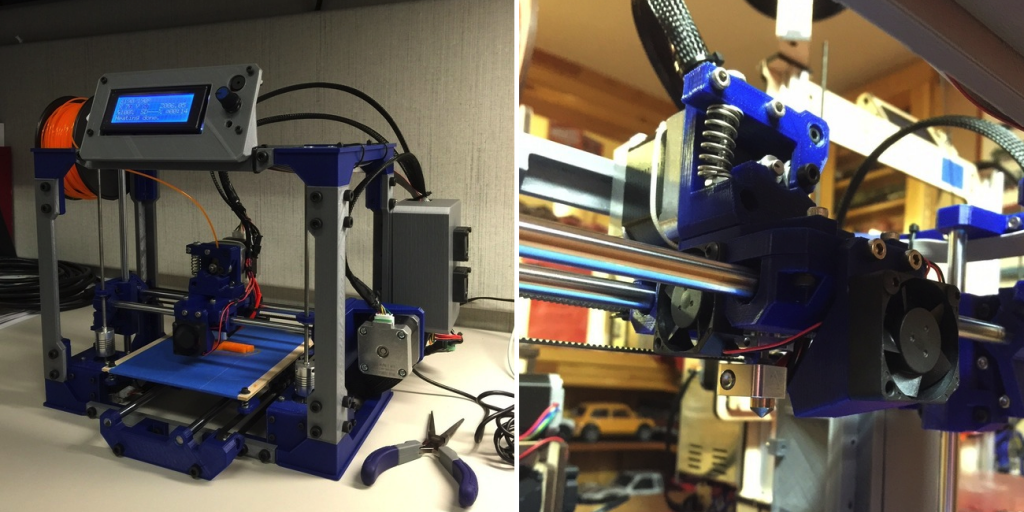

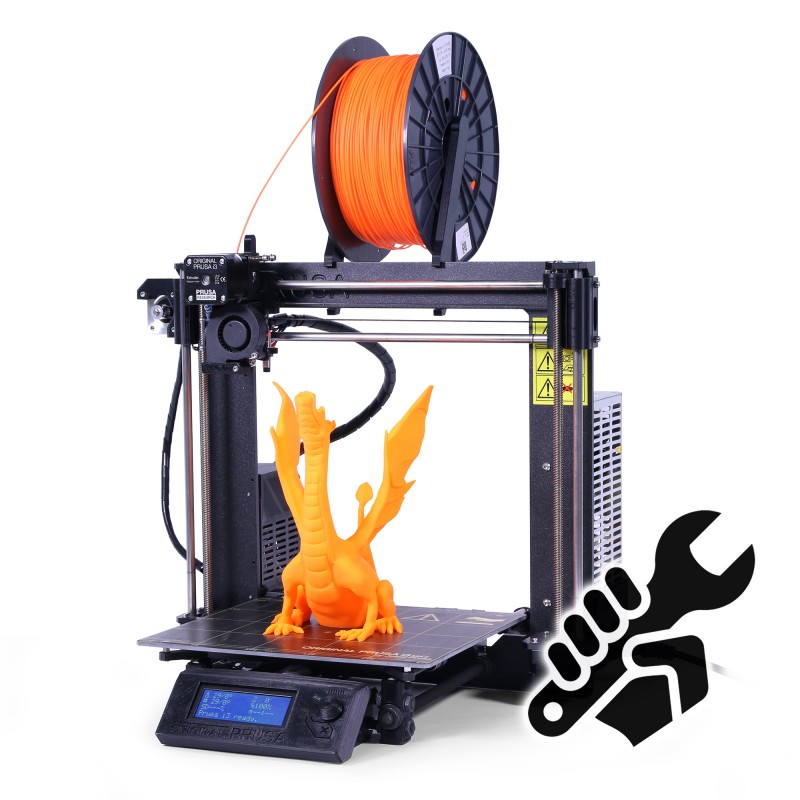

2. Prusa I3 MK3S (Best Overall - Top Pick)

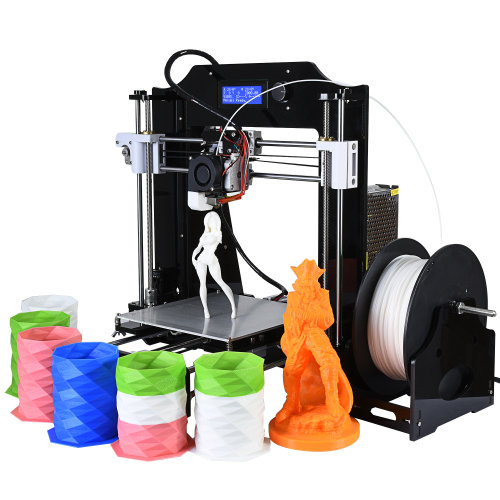

If you can afford this beast, it is hands-down the best 3D printer in its class. Prusa is the company that blazed the trail for other DIY printer companies to follow. The proof is in the fact that their printer is called the “original” – it’s so good that other people use it as a skeleton to make their own.

The i3 MK3S is the most expensive kit on this list because it is fast, reliable, and super easy to use.

Compared to the Ender 3 Pro the Prusa i3 MK3S has automatic bed leveling so your prints can be beauties on the first try.

This printer also has a magnetic print bed, a new extruder, a ton of sensors, and a lot of features.

There are two versions of this printer:

- The fully assembled unit and the…

- DIY kit version

You can save over $200 if you get the DIY kit version.

It took me about 6 hours to assemble the kit. The kit comes with detailed setup instructions and you can also supplement this with more info on their site. Additionally, this printer has plenty of info available online from different forums and videos (YouTube is your friend!) that will detail exactly how to assemble it.

This 3D printer is super easy to use because of the iterations that the company has gone through to bring this printer to market. It’s worth mentioning that this printer is open source, so you can feel free to tinker and experiment with your setup.

It’s worth mentioning that this printer is open source, so you can feel free to tinker and experiment with your setup.

If you’re into exceptional print quality right out of the box then the Prusa i3 MK3S is for you. It is a reliable, well built machine that performs consistently with minimal maintenance. On the rare cases you need help or advice, Prusa also offers tech supports and a community of passionate fans.

- Check out more beginner-friendly 3D printers here

Check Official Website

Check Latest Price

Check For Kit Price

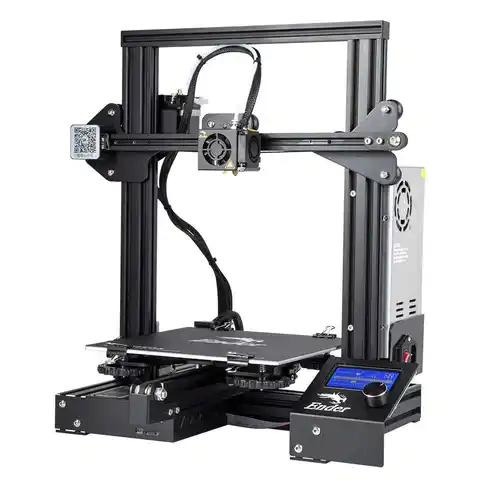

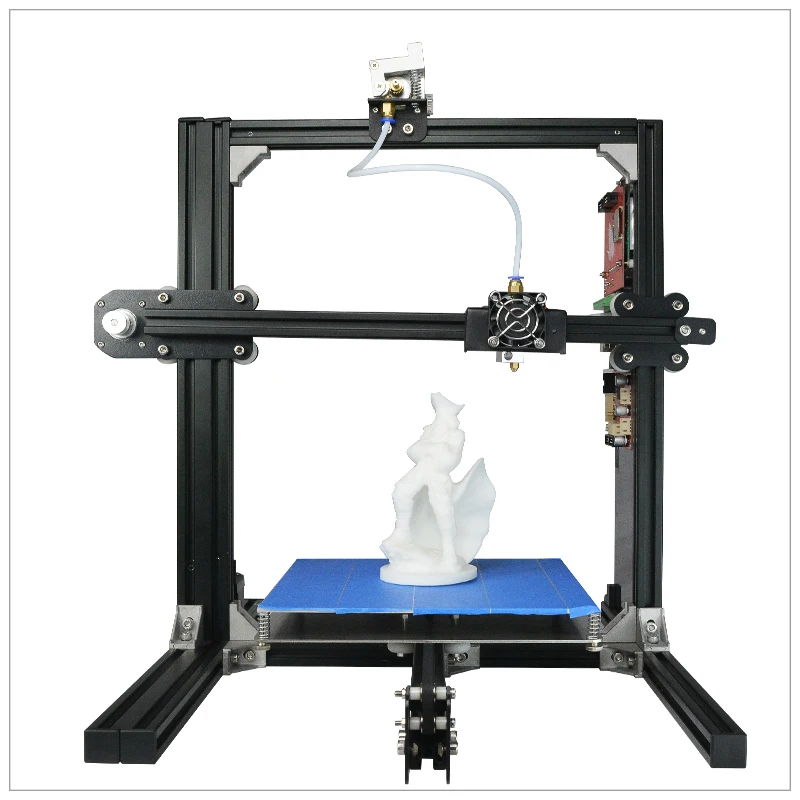

3. Creality Ender 3 (Best Value)

There’s a reason why this printer is was our #1 choice in the best 3D printer under $200 review.

No 3D printer seems to fuse quality and affordability quite like the Ender 3. With the right settings and patience, this printer can achieve quality as good as printers 4x the price.

With the right settings and patience, this printer can achieve quality as good as printers 4x the price.

The older generation of the Ender 3, it has all the quirks you’d expect from the old guard.

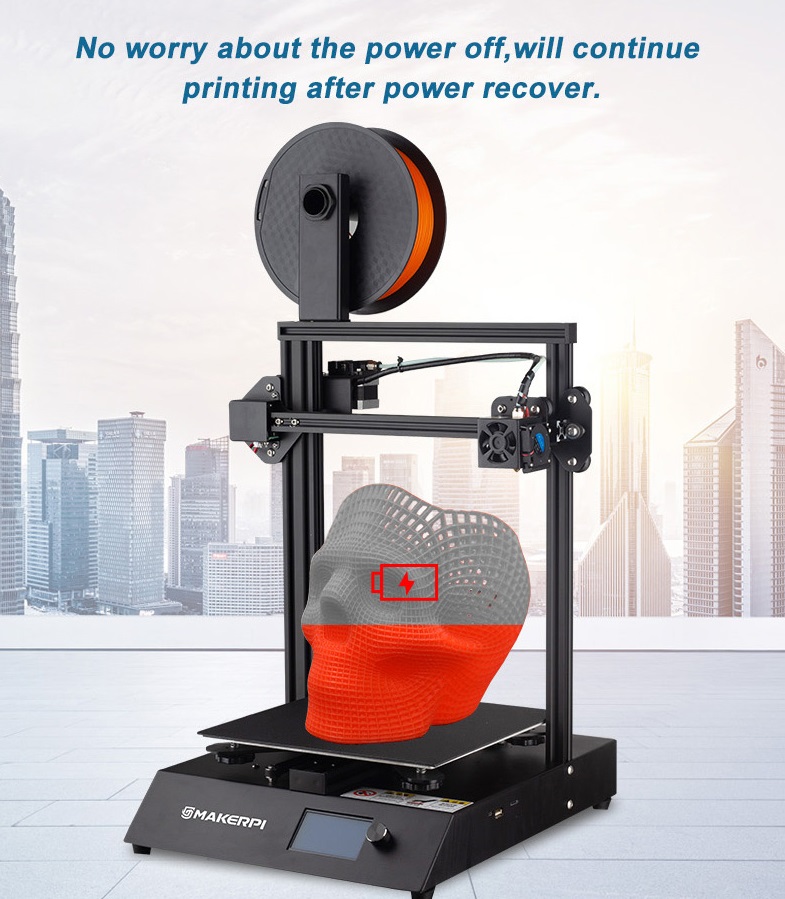

Like the Ender 3 Pro, it allows you to continue printing after losing power. Likewise, the heated built plate allows for easier printing and lets you print tougher filament materials.

You can read more about the Ender 3 vs. Ender Pro here.

This 3D printer is perfect for beginners and tinkerers who want to get their hands dirty. And who want the best bang for their buck.

Get Discount (Official Store)

Check Latest Price

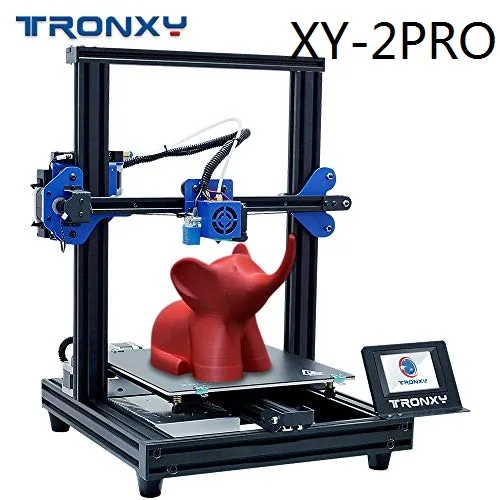

4. Tronxy XY-2 PRO

Next up is the XY-2 PRO from Tronxy.

It has a reasonable price tag, a good print volume, and it looks pretty cool. It also has a sensor that detects when you’re out of filament, and it automatically stops the print.

It also has a sensor that detects when you’re out of filament, and it automatically stops the print.

It has auto-leveling, which makes the setup for printing more convenient. As a bonus, the folks at Tronxy put a touchscreen on this printer! These features are almost unheard of from a printer at this price point.

The XY-2 PRO is one of the easiest DIY 3D printer kits to assemble and start. If you have any problems, you can refer to their included instruction manual.

If you’re still stuck, you can use your lifetime technical support that comes with every purchase of a Tronxy kit. This means that their service technicians will help you with any questions or problems you have.

Check Latest Price

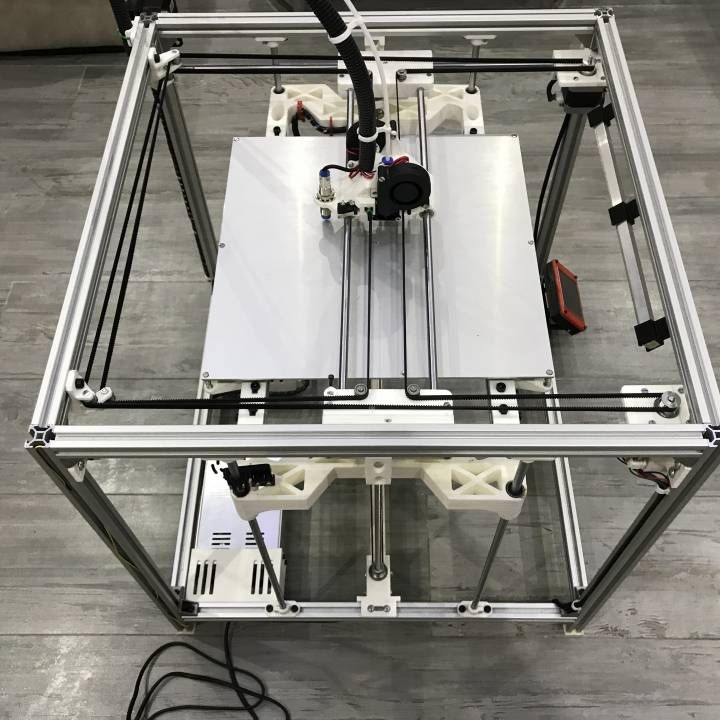

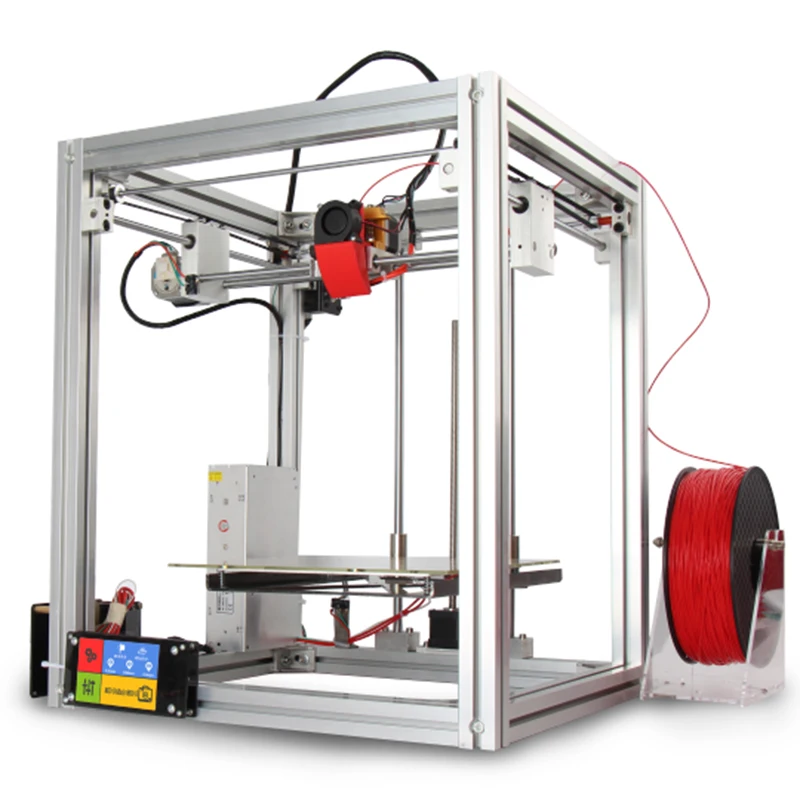

5. Tronxy X5SA Pro

Looking at another printer offered from Tronxy, the X5SA Pro is an upgraded version of their smaller printer.

The build volume is enormous on this guy (in fact, the largest on this list), and the price tag is still really fair for what you get – granted it’s pricier than others on this list.

When they released the X5SA, there were some concerns that were voiced by the 3D printing community. Tronxy was quick to fix them and released the X5SA Pro with all of the fixes.

Some of the fixes include a more robust x-axis, more stability overall, better materials used for the framework, fewer vibrations, and better precision.

The assembly time is around 4 hours, and it offers the same technical support that the XY-2 PRO offers. If the price tag is shocking, compare this printer to a premade model that might cost double the price.

What you get in this printer is a reliable workhorse. It has the same great features and touchscreen that the XY-2 PRO offers, this one is just a lot larger and sturdier.

Check Latest Price

6. Geeetech A10

The A10 from Geeetech is more of a middle-of-the-road type of printer. The price, build volume, and resolution is all in the middle of this list.

It also includes a sensor for when your filament runs out, and it will allow you to print remotely.

Building it is pretty easy, too. There’s a lot of resources online to help guide you through the process. This is a good pick if you aren’t crazy about either extreme of the printers available.

If you’re looking for a DIY 3D printing kit that has a little bit of everything, the A10 is a good pick.

Check Latest Price

7. Anet A8 Plus

At first glance, you’ll notice the A8 Plus has a big build volume, a great display, and sturdy metal framework. These are the leading factors of why the price point is a little higher than others on this list.

You also get a heated build plate and a nozzle hot enough to print most commercially-available filaments. The machine is very robust and sturdy, which leads to better accuracy than the standard A8.

The wiring and assembly will take around 3 hours and isn’t that difficult based on our experience. If you get stuck, there are countless posts about how to assemble and troubleshoot your machine. This is largely due to how popular the brand and printer are.

If you get stuck, there are countless posts about how to assemble and troubleshoot your machine. This is largely due to how popular the brand and printer are.

Overall this is a good pick if you are looking for a bigger printer that’s sturdy and reliable.

Check Latest Price

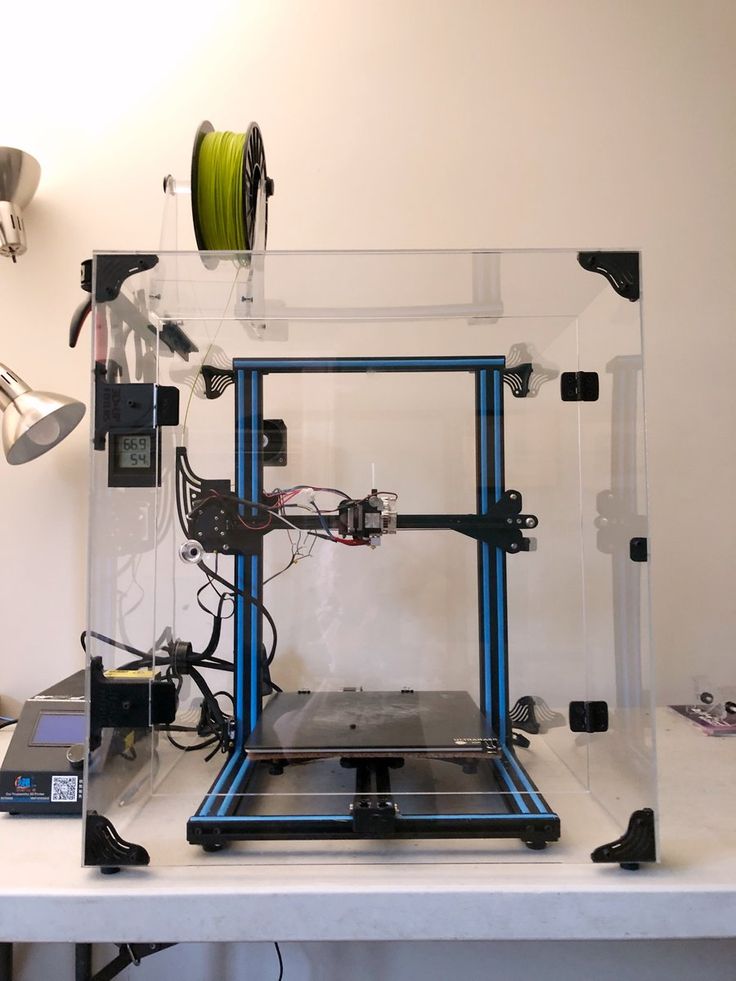

8. Creality CR-10 V2

You were warned, there’s more Creality on this list! This slot is reserved for the CR-10 V2 from them, their biggest and baddest version.

The build volume is massive, and the printer is sturdy. Like other Creality DIY kits, the assembly time is around an hour and is really well-explained.

So easy, in fact, it’s easy to forget that it’s a DIY kit.

A lot of people will claim that this printer is the best kit option around the $450 price range, and it’s hard to disagree.

The printer also boasts pinpoint accuracy with its prints. Overall it’s hard to find fault with this printer, and the community is in love with it.

Overall it’s hard to find fault with this printer, and the community is in love with it.

This printer is the perfect option for people who are a little more serious about their kit, people looking to print large items such as cosplay armor or props, and people who need an easy-to-use and assemble printer.

Get Discount

Check Latest Price

9. Anycubic Kossel Plus

The last printer on this list is the Kossel Plus from Anycubic. This printer might look a little funkier than the other printers, and that’s because it’s a delta printer.

These don’t work like traditional xy (or cartesian) style printers.

The benefit of a delta printer is you won’t have printing problems associated with slack in the belts.

There’s a lot to explore when it comes to delta printers. To simplify things, when it comes to DIY 3D printer kits, the Kossel Plus is the best delta option.

The framework is sturdy, and the assembly is really straightforward with a lot of videos and articles online about assembly.

The assembly is essentially 7 parts being put together. The extruder and heated build plate get hot enough to print almost any commercially sold filament. Kossel Plus is a very accurate unit and is a fun technology to watch print.

Overall this printer is great for anyone who wants to improve accuracy and precision in their prints. It’s also a good pick if you want a conversation piece since it’s an atypical 3D printer.

Get Discount

Check Latest Price

Why DIY Printers?The big reason for building your own printer is the cost savings associated with it. You might wind up saving hundreds of dollars if you opt for a DIY printer. The hidden advantage is how much you’ll learn about your printer while putting it together. An excellent way to think about it is you’re trading a few hours of your time in exchange for a deep understanding of 3D printing.

An excellent way to think about it is you’re trading a few hours of your time in exchange for a deep understanding of 3D printing.

The actual process of building your own 3D printer is going to vary from kit to kit. The overall idea is you’re building it from scratch and doing everything except for the coding. The kits will include all of the pieces and detailed instructions for putting them together. It’s a lot like a Lego set.

For most of the kits, you just need to screw pieces together and connect some ribbon cable between pieces. For the most part, it’s no different than building a piece of furniture from IKEA, with some added steps after for troubleshooting.

No matter which kit you decide to go with, it will come with instructions, and there will be videos and blogs online to help you along the way.

How To Choose The Right DIY 3D Printer KitAs you’re going to see soon, there’s a lot of different options for DIY 3D printer kits. So how do you pick the perfect one? Ultimately it comes down to what you’re looking for in a 3D printer. The criteria for picking a DIY 3D printer kit is the exact same as if you were to buy a printer off-the-shelf, the only difference is that you have to build these printers yourself.

So how do you pick the perfect one? Ultimately it comes down to what you’re looking for in a 3D printer. The criteria for picking a DIY 3D printer kit is the exact same as if you were to buy a printer off-the-shelf, the only difference is that you have to build these printers yourself.

You’ll see that these DIY kits have a wide range of prices, build volumes, precision, and features. Additionally, some printers have added features that lead to more convenient or reliable prints. Before you read some of the product reviews, you might want to think of some applications you’ll be using your printer for.

While you’re reading along, take a look at the highlighted features and consider if they are meaningful to you in your application. Now, there is something to keep in mind. Since these are all DIY kits, there are “assembly times” associated with each printer. This is how long it might take you from when you receive the package to when you make your first print.

Keep in mind that the printer only has to be assembled once, then it will be ready for continued use. In other words, along assembly time shouldn’t deter you from buying a printer that has great specs and features that you’re looking for. Refer to our product review table and take a look at the specific reviews below!

In other words, along assembly time shouldn’t deter you from buying a printer that has great specs and features that you’re looking for. Refer to our product review table and take a look at the specific reviews below!

Our pick

Creality Ender 3 Pro

Best Overall

No 3D printer seems to fuse quality and affordability quite like the Ender 3 Pro. With the right settings and patience, this printer can achieve quality as good as printers 4x the price. Great for beginners and tinkerers.

Get Discount on Creality3D

and Amazon

ConclusionThere’s a lot to consider when it comes to picking the best DIY 3D printer kit. Hopefully, the information here will help you make the most informed decision to make sure you get exactly what you’re looking for! Keep in mind the different features and attributes that you’d prefer for your printing projects and take a look at the printers on this list to see which will best meet your needs.

Pat Nathaniel

Pat is the editor-in-chief at Printing Atoms. He has a BS in Mechanical Engineering from the University of Florida and wants to spread the word on 3D printing. When he's not writing, he likes to tinker with his Ender 3 Pro, test filament brands, and scuba dive.

Best 3D Printer for Beginners 2022 [The Ultimate 3D Printer Guide]

3D printing is a particularly difficult hobby to get into; there are confusing terms thrown around left and right, a million printers available, and enough specifications for each to make your head spin. It doesn’t have to be this, way, though!

Today’s article is dedicated to finding the 3D printers with the easiest operation and simplest configuration. We’ll examine each individually, highlight its strengths and weaknesses, and ultimately, say why it’s a good choice for novices. Take a look at the best 3D printers for beginners below:

Table of ContentsShow

The 10 Best 3D Printers For Beginners In 2022

Buyer’s Guide

Before we jump right into our reviews, it’s important for beginners to know what to look for in a 3D printer. That’s why we’ve created a short guide to some of the things that will have a large impact on your printing.

That’s why we’ve created a short guide to some of the things that will have a large impact on your printing.

Build Area

The build area of your printer refers to the maximum allowable space for printing. You might see it listed as a series of dimensions (for instance, 5 x 5 x 5”) or it might be provided as a volume (such as 5”3 or five cubic inches). In these examples, both printers would have the exact same build area size.

Now, bear in mind that this doesn’t refer to the biggest items you can build. By including clips or other attachment mechanisms, you can combine several individual prints to create something far larger.

Printing Materials

While most basic, beginner-level 3D printers use PLA and ABS filament, more expensive models usually allow you to use a wider range of materials. For instance, you may be able to print with carbon-fiber or wooden filaments, water-soluble support materials, or even glass.

The problem is that these coarser materials can damage your extruder. That’s why if your printer supports these filaments, you’ll likely need to upgrade to a metal extruder head. These are available relatively cheaply, and help guarantee an identical print every time.

That’s why if your printer supports these filaments, you’ll likely need to upgrade to a metal extruder head. These are available relatively cheaply, and help guarantee an identical print every time.

You may also want to consider different support materials. Some, like PVA, dissolve in water, leaving clean edges without any further processing. If your printer only supports PLA or ABS, however, you’ll be stuck using simple snap-off supports like those found in plastic model kits. For general printing, this isn’t an issue, but if you want a more professional end product, we recommend a printer with support for more filament types.

Print Speed

Often, you’ll see print head speed listed in millimeters (mm). This number lets you know how far the print head can move in a single second. Higher speeds are better, but this isn’t a true depiction of how quickly you’ll be able to print. For this, you’ll have to find the “print speed” listing.

Now, it’s worth noting that the print speed listed will be the fastest that your printer allows. There are usually two settings: speed and quality. As you might expect, the faster you print, the lower the overall quality of the item. If precision and fine details are your number one priority, you’d be better off with a slower speed.

There are usually two settings: speed and quality. As you might expect, the faster you print, the lower the overall quality of the item. If precision and fine details are your number one priority, you’d be better off with a slower speed.

Layer Height

Usually, the printer’s supported layer heights will be listed in microns. The thinner the layer, the less obvious it will be, and the smoother the finish. On the other hand, with the thinnest layers, you can expect a print to take a lot longer to finish.

You’ll usually find the layer height that best allows you to compromise between speed and print quality early on. Afterward, you’ll know which setting works best for more detailed objects and which is best for everyday printing.

Calibration

Usually, before you can begin printing, you first have to calibrate the machine. There are various different components that require your attention: the print bed has to be leveled to ensure a perfectly flat surface, the print arm has to be perfectly positioned, and the step distance has to be set to avoid printing a far larger (or smaller) item than intended.

In recent years, printers have begun to automate these processes so you don’t have to. Some include automatic-leveling functionality, while others come pre-configured out of the box. Generally, you can expect to pay a little more such models, but as we’ll show below, it’s still possible to find them at a reasonable price.

Entry Level 3D Printers

In this section, we’ll be discussing low-cost 3D printers that are excellent for beginners. Without further ado, let’s begin with the XYZPrinting da Vinci Mini.

At around $180, the XYZPrinting da Vinci Mini as among the cheapest 3D printers on the market. This doesn’t mean it’s low-quality, though! In fact, it boasts wifi connectivity, a generous build area, and even an auto-leveling bed. You are limited to using PLA and PETG filaments but we think that’s a reasonable trade-off considering this model’s low price point.

This is about as simple as 3D printers come. You’ll find modeling software and starter filament included in the box, and since the da Vinci Mini calibrates itself, you can go from unpacking to printing in as little as 20 minutes. XYZPrinting even offers 30 free printing tutorials on their website to help novices out.

XYZPrinting even offers 30 free printing tutorials on their website to help novices out.

Even the interface is easy to use. Printing is performed with a single button, and various colored LEDs alert you to any errors as they occur. This product is designed for beginners, and it shows.

This printer retails for about $190 but has the smallest build area of any on our list. What gives? Well, the Monoprice Select Mini offers more freedom than most: thanks to its heated plate, you’re free to print with almost any material be it PLA, ABS, PVA, or even wood.

Sounds complicated right? It’s really not. This printer ships fully assembled and ready to go. It works with any PC or Mac, and even includes an SD card (and wifi support) so you can move your models across effortlessly. Sure, it’s a little slower than most, but it’s also far smaller, meaning you don’t need a dedicated space for it on your desk.

The only real problem with this printer is that some materials need an enclosure to print well, which this model doesn’t have. That said, it’s easy enough to create your own and in a pinch, even a plastic tub will work.

That said, it’s easy enough to create your own and in a pinch, even a plastic tub will work.

The Comgrow Creality Ender 3 is a printer that you build yourself. Wait, don’t leave! This model only takes about half an hour to assemble, and this is a large part of why such a high-quality printer can retail for about $239. This is a surprise in itself since the Ender 3 includes many traits most printers don’t, like the ability to resume a print after a power cut.

This printer has it all: wifi support, fast travel speeds, a colossal build area, and even a fast heat up time (around five minutes to reach 110°C). The downside is that you’re limited to using PLA filament, but this is the most beginner-friendly material of all, so it’s not really an issue.

There’s an advantage here too. By building your printer piece-by-piece, you’ll have a greater understanding of what exactly each component does. This makes maintenance easier in the long term, so while there’s undoubtedly a bit of a learning curve, the Creality Ender 3 might not be such a bad idea.

The Kossel Mini is another DIY printer, one that retails for about $260. Notice its unique shape: the circular build plate is perfect for those looking to build larger models like figurines or interlocking parts. Better still, it’s incredibly easy to upgrade thanks to its simplistic design.

Although it looks a little basic, there’s actually a good amount of functionality here. The bed is heated, so you won’t have issues with material sticking to it. It’s even capable of leveling itself, which means that there’s very little fuss or configuration required when you’d like to get started.

Again, you’re limited to using PLA filament. That said, with a little tweaking and upgrading, there’s no reason you shouldn’t be able to use other materials too. As a result, the Kossel Mini is an extraordinary choice not only for 3D printing newcomers but also those looking for a long-term project.

One of the great things about this printer is that it’s so modular. This means that if one part stops working, it’s a simple matter to order and install a replacement. This prevents lengthy warranty processes, and ensures your printer is never out of action for more than a few days at a time.

This prevents lengthy warranty processes, and ensures your printer is never out of action for more than a few days at a time.

Mid-Range 3D Printers

If you’re willing to spend a little more, you can greatly increase the functionality and ease of use that your 3D printer provides. Don’t believe us? Check out the products below to see for yourself!

The FlashForge Finder is one of the most popular 3D printers around, and for good reason. It offers a decent build volume, wifi connectivity, and even runs quieter than most, at around 50dB. You can only print with PLA, but as this is a beginner-friendly model, that’s to be expected.

Don’t understand calibration? No problem! The Finder makes it as easy as can be by simply telling you to tighten various screws until you hear a beep. This takes all the guesswork out of getting ready to print and allows you to focus on the fun part – the actual creation process.

This printer can be controlled via its 2.5” touchscreen or remotely on your PC. The menus are simplistic and easily understandable, written in plain English, so anyone can use them. Also included are various tools you might need, such as an unclogging tool and Allen wrenches.

The menus are simplistic and easily understandable, written in plain English, so anyone can use them. Also included are various tools you might need, such as an unclogging tool and Allen wrenches.

There’s no need to worry about safety, either. The non-heated build plate relies on adhesive surfaces to prevent sticking, and means you can’t burn yourself my mistake. With wifi compatibility, SD card and USB support, and even the ability to send models from cloud storage, the FlashForge Finder has everything you’ll ever need.

You’d be forgiven for thinking that this futuristic-looking printer cost more than it does! At around $230, the MOD-t is reasonably priced, but better yet, it’s also pretty strong. For instance, it boasts a 50-micron print layer; that’s half the size of numerous similarly-priced printers!

We really liked that this model can start printing right out of the box. Just import a model via wifi or SD card, add some PLA filament, and you’re good to go. The build area is a good size, although not cubic in shape. On the plus side, it is enclosed, meaning you’re less likely to see prints ruined by temperature fluctuation.

On the plus side, it is enclosed, meaning you’re less likely to see prints ruined by temperature fluctuation.

The print speed doesn’t seem that fast at first glance, but remember: this is an entry-level machine. Since you won’t be building massive items, the speed is less crucial. What really matters is getting the nicest finish, and luckily, the MOD-t makes this as easy as possible, even for inexperienced users.

If the previous products seem a little too simplistic, the Anycubic I3 Mega might be just what you need. It requires you to connect a couple of cables before use, striking a balance between full-DIY printers and ready-to-go models. It includes additional helpful features too, like filament detection, print-resume tech, and a non-stick build plate.

You’re not limited to PLA either. This printer can use PLA, ABS, HIPS, and wood-based filaments, allowing you to plan and create far more imaginative pieces than most other beginner-oriented models. With 50 micron layers and a print speed of about 60mm/s, the I3 Mega offers the best of both worlds.

Note the massive build area: it absolutely dwarfs that of many of this printer’s rivals. For less than $400, you can find a 3D printer capable of printing almost anything you can imagine. Sure, the upfront cost is a little higher, but you won’t have to upgrade for several years at least.

If you want the most options, you want the Wanhao Duplicator i3 Plus. It supports more than 15 different filament types, offers a gargantuan build area, and features a 3.25” touchscreen for easy operation. The best part? This printer retails for around $420, far less than most models with similar functionality.

Most of the common stumbling blocks are already taken care of. For instance, the heated bed prevents sticking, the fan prevents overheating, and the steel frame provides more than enough stability. You’re limited to transferring files via USB or SD card, but that’s nothing too unusual, particularly in a mid-budget printer.

So what makes this a good choice for beginners? Simply, it makes printing as easy as possible. There’s very little manual configuration required, and as this is a popular model, you can easily find help on a Wanhao-dedicated forum. There’s no mess, no stress – just high-quality 3D prints.

There’s very little manual configuration required, and as this is a popular model, you can easily find help on a Wanhao-dedicated forum. There’s no mess, no stress – just high-quality 3D prints.

We were pleased to see that this printer comes with a one-year warranty. After all, while relatively inexpensive, it’s still a significant investment. Wanhao’s support affords you peace of mind, and if anything goes wrong, you can consult their FAQs or contact support via phone, email, or post.

Premium 3D Printers

While not everyone will be able to afford the following products, they offer additional functionality that lower-cost models don’t, while being easily accessible for people who’ve never used a 3D printer before.

Now, we know what you’re thinking: I don’t want to spend around $650 on my first 3D printer. Bear with us, though, because spending a bit more to get a high-quality product the first time means you’ll save money down the road. And believe us, the QIDI TECHNOLOGY 3DP is absolutely a high-quality printer.

The first thing which sets it apart is there are two extruders. This means you can either print twice as fast or use two different materials for a striking contrast. You could even mix ABS and PLA if you like since this model supports both.

Models not quite right? With this printer, you don’t necessarily need to fire up the CAD software. Instead, you can slice and edit your models directly using this printer’s minimalistic, easy-to-use onboard controls. With a heat-resistant, warp-resistant frame, you’ll get exceptional prints every time.

Finally, because you can choose an enclosed or ventilated build area, you’ll find that fewer prints fail. This, in turn, saves you money as you’re not wasting as much filament. Sure, these materials are fairly inexpensive, but the costs definitely start to build up, particularly if you plan to use the QIDI for several years.

The Dremel Digilab 3D20 puts user safety above everthing else. This model costs under $600 and features a fully-enclosed build area (which is particularly spacious), as well as a non-heated bed and third-party certification. Best of all, though, it places particular emphasis on consistency.

Best of all, though, it places particular emphasis on consistency.

In practice, this means that you’re limited to using proprietary PLA filament. You might be a little disappointed by this, but it does essentially guarantee that prints only fail very infrequently. Plus, this filament is guaranteed to be non-toxic, plant-based, and recyclable, so it’s safe for kids and pets.

There’s no assembly required, either. In fact, the Digilab 3D20 is ready to print straight out of the box. It even comes with a small spool of filament, although only enough for a couple of prints at most. Model manipulation is as simple as can be, thanks to this printer’s compatibility with popular software like Cura.

As if this wasn’t enough, the 3D20 also includes a one-year warranty and access to a responsive, US-based customer support line. Reliable, high-quality prints, safety as a top priority, and exceptional customer support? What more could you ask for? How about a full-color touchscreen? Oh wait, that’s included too.

Best 3D Printer for Beginners: The Verdict

While all of the printers mentioned above are excellent for beginners, you’re probably wondering which is the best overall, especially since you’ve seen how advanced some 3D printers can be. Well, it wasn’t easy but we finally came to the decision that the FlashForge Finder is better for most users.

Our reasoning is simple: it’s an inexpensive, reliable printer that offers a good degree of freedom without being overwhelming to novices. Not only that but with automatic calibration, it takes the busywork out of printing. This makes it more appealing to kids, but also helps prevent user frustration, which is never a bad thing.

Which 3D printer to choose for home and hobby use

A few years ago, 3D printers were bulky industrial machines, but now 3D printing is becoming more accessible for home use. When buying their first printer, many are disappointed. This may be due to the unsatisfactory quality of the resulting models or the complex setup and maintenance of the 3D printer.

In the reviews that are found on the Internet, printers are often shown after a lot of upgrades or a long selection of settings for printing. This is not at all the result that a beginner who first got acquainted with 3D printing will get.

In order not to be disappointed, before buying, you need to understand which model is suitable for your tasks. First of all, it is worth deciding what the printer will be used for. What is the main property that finished products should have? What is more important, the physical properties of the model or the ideal surface and detail? Not only the model depends on this, but also the technology by which the 3D printer will work.

Which technology to choose? FDM or LCD?

If you need to make a small detailed figurine with a perfectly smooth surface, you should pay attention to models that work on LCD technology (LCD works on a principle similar to DLP - Digital Light Processing or “digital light processing”).

LCD prints using a photopolymer resin that cures under UV light. This makes it possible to produce without deformation, even small and thin products that cannot be manufactured using FDM technology.

Resin model

Now on sale there are many photopolymer resins with different properties. A few years ago the choice was not great. Basically, finished products were not strong enough for use in functional models. Now engineering resins have begun to appear on sale. Products from them are not inferior in strength to models made using FDM technology from ABS or even nylon.

If it is necessary to produce large products with different properties, or the tasks will be very diverse, then the choice is with FDM technology. But it is important to understand that finished products will not have a perfectly smooth surface. Of course, you can polish the model, but this is additional time and labor costs.

FDM technology builds a model using molten plastic filament, which is fed from the print head. The print head (extruder) “grows” the model layer by layer on the printing table.

The print head (extruder) “grows” the model layer by layer on the printing table.

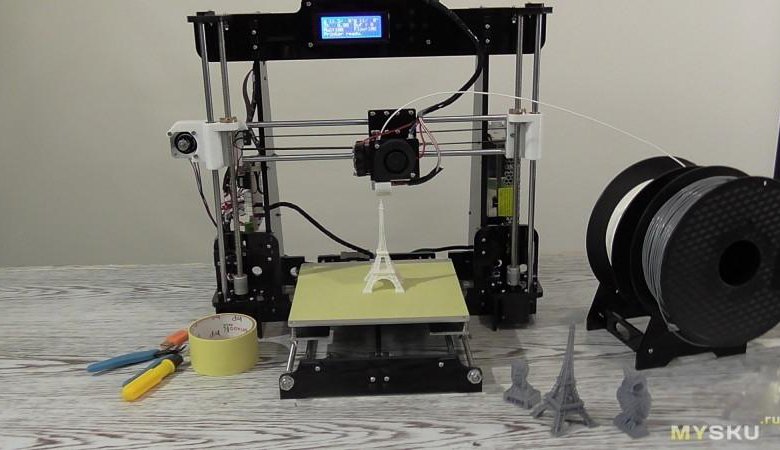

FDM Models

FDM technology became widespread much earlier than DLP. Thanks to this, a wide variety of 3D printers and consumables for them has appeared. You can find many decorative plastics that mimic various materials, or engineering plastics for making functional models or mock-ups.

Choosing an LCD printer

Photopolymer printers work on one of 3 technologies - DLP, LCD or SLA.

As home printers, devices based on LCD technology are usually used due to their availability and low price.

Printer design

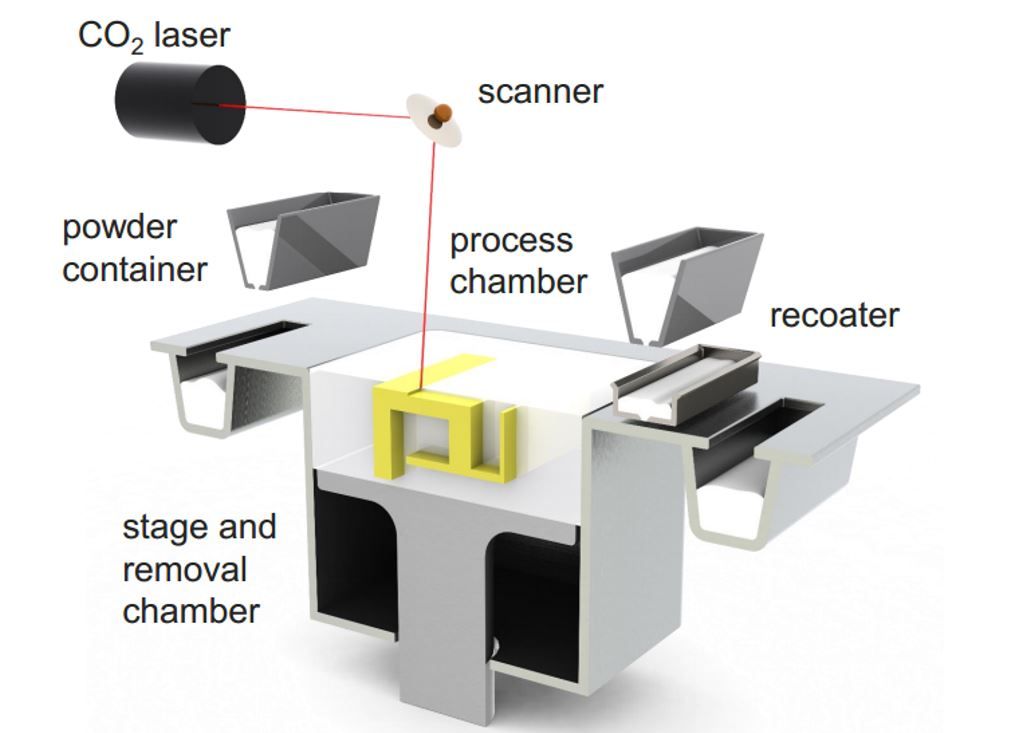

SLA technology appeared the very first among photopolymer printers. With the help of a point-focused beam, the desired areas of the resin are gradually illuminated. This is repeated layer by layer.

How SLA 9 works0018

Since the surface of the model is perfectly smooth, SLA has become used in the jewelry and dental industries.

Pros:

Cons:

DLP technology appeared later than SLA, but it is very similar to it. The main difference is that the light source is not a focused beam, but a projector. This made it possible to illuminate the entire layer at once, which significantly accelerated the production of models. The quality of the surface was slightly inferior to SLA, but modern DLP printers, in terms of the quality of models, are almost as good as SLA technology.

How DLP works

Pros:

-

Faster production of models due to the illumination of the entire layer

-

Consumables are slightly cheaper than SLA

-

High surface quality (although may be inferior to SLA)

Cons:

LCD technology is the youngest of all. The DLP principle is taken as a basis, but an LCD display is used as a matrix or illumination pattern. LEDs are used as a source of UV light in LCD technology. Thanks to inexpensive components, we managed to get a simple, but high-quality and affordable photopolymer printer.

LEDs are used as a source of UV light in LCD technology. Thanks to inexpensive components, we managed to get a simple, but high-quality and affordable photopolymer printer.

How the LCD printer works

Pros:

-

small cost

-

Cheap parts

Cons:

-

Low accuracy compared to SLA and DLP (for jewelers and dentists, the quality of LSD prints may not be enough, although more and more accurate models appear with the development of technology)

-

Possible stray light

-

The quality of models may decrease at the edges of the printable area (this can be corrected programmatically)

Resins that are used as a consumable for photopolymer printing can smell strongly and unpleasantly during operation. Try to use the printer in a well-ventilated area, or choose a printer with a sealed cabinet and filter.

When choosing an LCD printer, pay special attention to the rigidity and positioning accuracy of the platform along the Z axis. If there are poor quality guides along the Z axis or even a slight play, then the surface quality of the finished model may turn out to be sloppy or the model will turn out to be unevenly striped.

Rating of the best LCD 3D printers for home

Anycubic Photon Mono

This is an LCD printer with a matrix that allows you to increase the speed and accuracy of printing. Anycubic Photon Mono will be a good helper for hobbyists and modellers.

Anycubic Photon Mono SE

Anycubic Photon Mono SE has an unusual parallel light source. This minimizes distortion at the edges of the printable area. You can effectively use the entire working area of the machine and produce many small models at a time.

Phrozen Sonic Mini 4K

Model with high resolution LCD display and large print area. The monochrome display transmits UV rays better and allows you to print much faster than similar devices with a conventional display. The manufacturer claims a screen life of more than 2000 hours. Phrozen Sonic mini 4k is suitable for almost any task.

The monochrome display transmits UV rays better and allows you to print much faster than similar devices with a conventional display. The manufacturer claims a screen life of more than 2000 hours. Phrozen Sonic mini 4k is suitable for almost any task.

Wanhao GR1

Wanhao GR1 has high precision and large print area (140x78x200mm). The manufacturer tried to reduce distortion at the edges of the display, this allows you to make the most of the entire work area. High precision and large print area make Wanhao GR1 not only for hobby use, but also for production.

Anycubic Photon Zero

Small and very budgetary LCD device. Its resolution and small working area (total 97x54x150 mm) is enough for printing small miniatures, figurines or small engineering models. Anycubic Photon Zero is a good choice for beginners who want to get into photopolymer printing without spending a lot of money.

Choosing an FDM printer

If you plan to produce large and diverse functional models or experiment, a 3D printer that prints using FDM technology is an excellent choice.

First, decide on the size of the printable area and the properties that the finished model should have. After all, some materials require a closed chamber or good airflow to work.

Some printer models can be “upgraded” in the future. For example, if necessary, purchase spare parts for a closed case, put a nozzle of a different diameter, or change the thermal barrier to an all-metal one. But not all manufacturers provide for the possibility of such upgrades.

Printer design

Despite the same principle of operation, there are several different mechanics, which have their pros and cons.

Kinematics “Prusa” (Prusa)

Perhaps the most popular kinematics among home FDM devices. Mainly due to its simplicity and low cost. The main feature is the table that moves along the Y axis, while the extruder moves along the rest of the axes. Because of this, such kinematics was nicknamed “dragstol”.

Prusa kinematics

Pros:

Cons:

-

Slow print speeds.

A massive table with a model is forced to constantly move along the Y axis, because of this, print quality will be worse at high speeds.

A massive table with a model is forced to constantly move along the Y axis, because of this, print quality will be worse at high speeds. -

Some models have design flaws (for example, insufficient frame rigidity), they can be fixed, but for this you have to be a little inventor. Or find a ready-made solution on the Internet.

This category also includes 3D printers with console kinematics. The same prusa, only halved. Because of this, the frame is less rigid, but the printer itself is more compact.

Kinematics Ultimaker

The extruder moves along the X-Y axes, and the table only along the Z axis. All motors are trying to be fixed on the body to lighten the weight of the moving mechanisms, thanks to which it is possible to achieve high print quality at high speeds.

Ultimaker kinematic diagram

Pros:

Cons:

H-BOT or Core-XY

These are 2 similar but more complex kinematics - the table moves only along the Z axis, and the extruder along the X-Y. But to move the extruder, 1 or 2 long belts and 2 stepper motors work in concert.

But to move the extruder, 1 or 2 long belts and 2 stepper motors work in concert.

Example Core-XY kinematics

Pros:

-

High print quality

-

High print speeds without loss of quality.

-

Can be easily closed completely

Cons:

MakerBot Kinematics

Similar to Ultimaker kinematics, but one of the motors is located on the Y or X axis carriage.

Pros:

Cons:

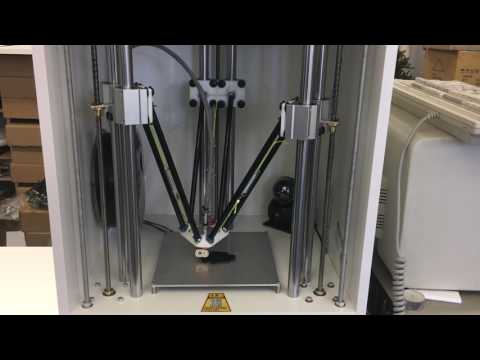

Delta

Deltas do not have the usual XYZ axes. There are 3 columns in the deltas, along which the carriages move, and the position of the extruder in space is calculated using a complex formula. The table is usually statically fixed to the body.

Delta printer example

Pros:

Cons:

Nuances of choosing an FDM 3D printer

In addition to kinematics, when choosing a printer, it is important to take into account some design features.

One or two extruders?

Two extruders can be used for dual color printing, but most commonly the second extruder is used for solvent support printing. If you need to print complex parts with internal cavities, then you should choose a dual extruder printer.

Closed or open printer?

Printing of functional models and parts uses plastic, which usually requires a closed chamber. If you plan to print functional prototypes or various models, you should look at printers with a closed chamber.

Bowden or direct?

There are 2 types of material supply to the print head of the printer - bowden and direct.

In a bowden, the feed mechanism motor is located on the printer body. This allows you to reduce the weight of the extruder and print at higher speeds without losing quality. But because of the long tube, printing with very soft plastics can be problematic.

Bowden feed pattern

In direct feeding, the motor and feed mechanism are located on the extruder. This increases the weight of the print head, but allows you to print with any kind of plastics.

This increases the weight of the print head, but allows you to print with any kind of plastics.

Direct feeding scheme

Heated table or not?

The heating of the table improves the adhesion of the first layer of the model. And engineering plastics cannot be printed without a heated table.

Many manufacturers add useful additional features. They do not affect the quality of the print, but save time and nerves. The most useful additional functions are the filament presence sensor and remembering the print location after a power outage.

Filament sensor.

It will automatically pause printing if the plastic runs out. When there is a little plastic left on the spool, this feature will allow you not to stand over the guard printer until the old spool runs out in order to have time to push in a new bar “on the go”.

Power outage protection.

Remembering where to print when the power goes out can save you a lot of nerves when printing large models. You won't have to worry that after a power outage, you will have to run the model again for many hours or cut and reprint a piece of the model. It is especially disappointing to throw away a complex underprinted model with supports due to a one-minute outage.

You won't have to worry that after a power outage, you will have to run the model again for many hours or cut and reprint a piece of the model. It is especially disappointing to throw away a complex underprinted model with supports due to a one-minute outage.

There are also many extras. features that make using the printer more comfortable. For example, automatic calibration, touch screen, Wi-Fi and others.

Rating of the best FDM 3D printers for home

Anycubic Mega Zero 2.0

Inexpensive model with Pryusha kinematics. Good for getting started with 3D printing without a big investment. Despite the low cost, Anycubic Mega Zero 2.0 has a heated table and a resume function after a power outage. Thanks to direct feed, printing with soft materials should not be difficult.

Creality3D Ender 3 Pro

A very popular device due to its low price. But despite this, the Ender 3 Pro has a heated table and a decent print area. Can be sold assembled or as a DIY kit.

Can be sold assembled or as a DIY kit.

Flash Forge Finder

Small home appliance intended for children or educational institutions. The Finder doesn't have a heated table, but it does have a calibration assistant, a Wi-Fi module, and other extras that make getting to know it a lot easier. All moving and heated elements are hidden as much as possible in the case so that the child cannot get burned.

Wanhao Duplicator 6 Plus

Wanhao Duplicator 6 Plus was based on Ultimaker kinematics, but instead of bowden feed, they made direct. Because of this, it will not be possible to print super fast, without quality loss, but there will be no problems with printing with soft types of plastics. There are 2 trim levels - with a closed case and without.

Flashforge Dreamer

The Dreamer is a closed body dual extruder printer with MakerBot kinematics. Thanks to this, he can cope with printing models of any complexity. Using a second extruder for soluble support, models with complex geometries can be produced. A good choice for engineers and those who like to experiment with different materials.

Using a second extruder for soluble support, models with complex geometries can be produced. A good choice for engineers and those who like to experiment with different materials.

FlyingBear Ghost 5

Most commonly sold as a kit (assembly kit). Assembly usually does not cause any great difficulties, even for people far from electronics or mechanics. Flying Bear is equipped with a filament sensor, a function to resume printing after a power outage and Wi-Fi connectivity.

The Flying Bear makes a great first printer for the novice user who is ready to build their own printer.

Totals

In order for the printer not to become a useless toy, you should clearly understand what it is for.

For a fan of miniatures or detailed figurines, a photopolymer printer is a good choice. A small work area is more than offset by the detail that cannot be obtained using other technologies.

For an engineer or a fan of experiments, an FDM machine with a closed chamber and two extruders is well suited. This will allow you not to limit yourself in the choice of plastics and comfortably experiment with any materials.

This will allow you not to limit yourself in the choice of plastics and comfortably experiment with any materials.

For a beginner who has not yet decided whether he needs 3D printing, you can opt for inexpensive machines with slick kinematics. Due to their great popularity, you can find a lot of upgrades and reviews on them. In the future, it will be possible to modify the printer for specific tasks or change it to a more suitable model.

For a child, safety is paramount. As the first children's printer, models without a heated bed are suitable, in which the main emphasis is on printing with safe PLA plastic. Or models in which all moving and heating mechanisms are hidden in the case.

A 3D printer is a handy tool, and whether it brings joy or frustration depends on the user.

A small guide for choosing a 3D printer for beginners / Sudo Null IT News

The reason for writing this article was the article “ I wanted to buy an inexpensive 3D printer, but I looked at YouTube and got sick of ”, at the end of which the author asks to answer a few questions. I will try to answer from the point of view of my seven years of experience as a 3D modeler and 3D printer. First, a few caveats.

I will try to answer from the point of view of my seven years of experience as a 3D modeler and 3D printer. First, a few caveats.

This article will not contain advice: “Buy a printer from manufacturer X - it is good, but do not take manufacturer Y under any circumstances”, only general recommendations.

Informal classification of printers, adopted in the domestic segment of printers.

Everything written is based on the personal experience of the author and is his personal opinion.

If these warnings do not scare you - welcome under cat.

First, let me introduce myself: my name is Maxim and I bought the first printer back in 2013. It was a Chinese clone of Makerbot 2 with the hilarious name "Migce Cuble".

Photo from the personal archive There was almost no information on 3D printing on RuNet, only one topic on the “Roboforum” and several scattered articles about what a cool thing it is - 3D printing, so to master it I had to google a lot in English, come up with their crutches and delve deeply into the physics and technology of the printer. We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti-covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti-covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

Currently, two types of printers are mainly used at home: printing using FDM (FFF) technology - layer-by-layer plastic fusing, which is fed in the form of a rod and SLA (LCD) - printing with a photo-curing polymer. FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

To be honest, I almost never did SLA printing and I still don’t have an LCD printer in my home zoo (but it may appear soon), so I will mainly talk about FDM printers. They can be divided into 3 main categories according to the type of mechanics:

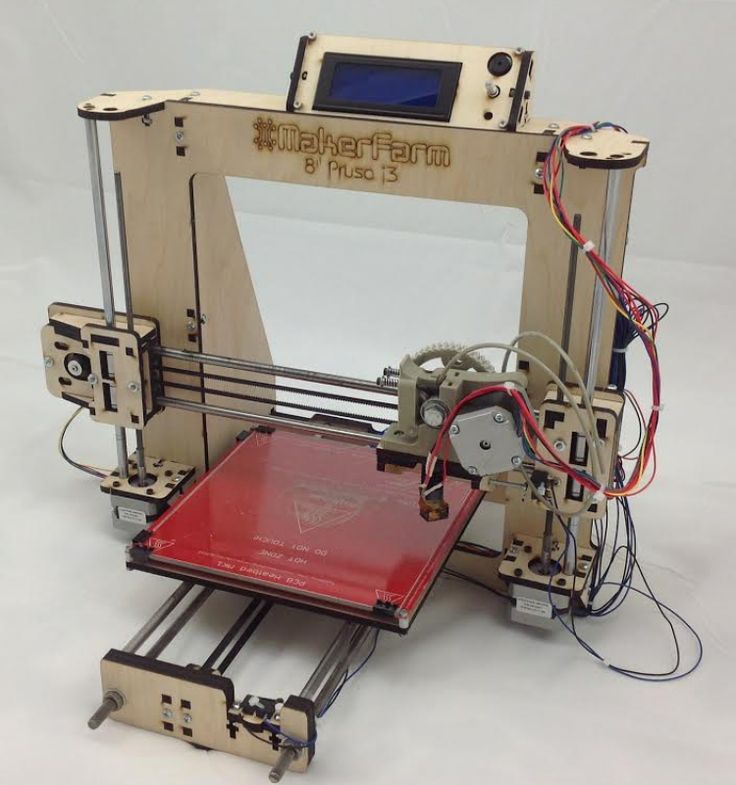

Drygostov - printers with a table movable horizontally. Perhaps the most common printer model. It is distinguished by low cost of components, ease of assembly and adjustment, for which it is loved by the Chinese and printers. The disadvantages include the difficulty of creating a closed body and printing thin, tall parts that begin to wobble as the height increases, especially if the part is printed from flexible plastic such as TPU.

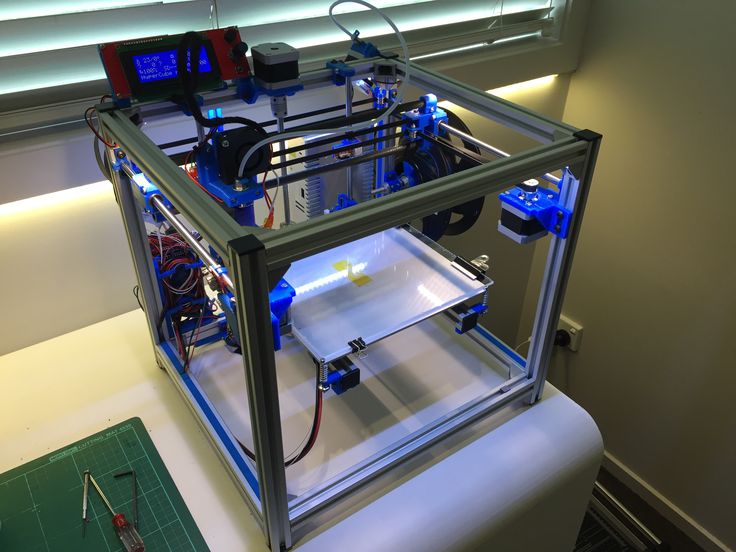

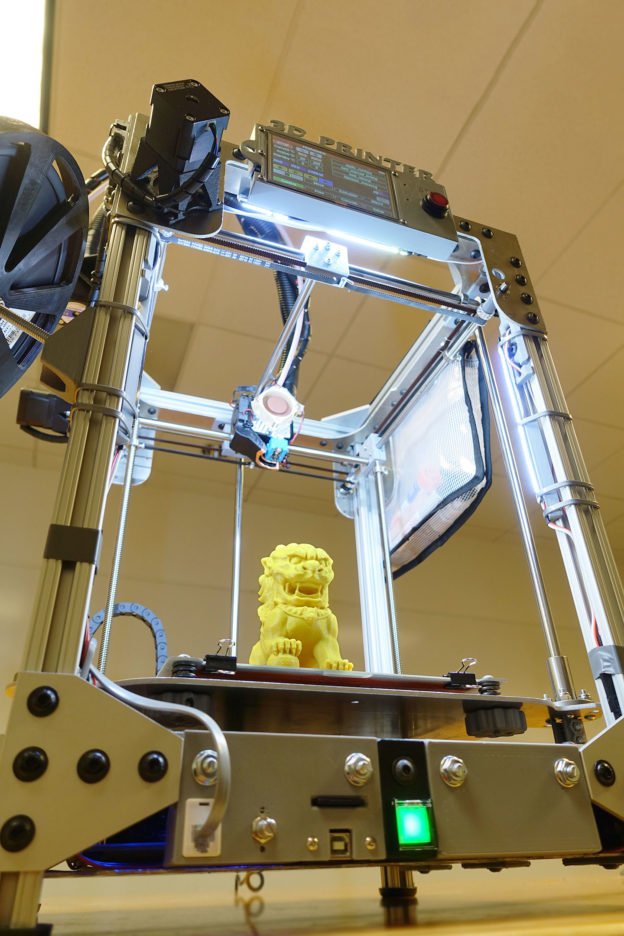

Cubes - printers in which the table travels vertically. The cost of such printers is higher, as are the requirements for straightness of hands during assembly and setup. But a properly designed die delivers faster print speeds while maintaining print quality. At the same time, the design of the printer is very easy to make closed, which allows printing with engineering plastics such as ABS and Nylon. This type of design is often used in semi-industrial and industrial grade printers. Some manufacturers manage to shove the drygost into the body of the cube, but this does not bring any special advantages for printers.

Typical cubes Delta - printers with the so-called delta kinematics, when the print head is attached to carriages moving along vertical guides using a system of rods. The cost of the mechanics of such printers is comparable to the cost of dry-tables. Can print at very high speeds. But they are very demanding on the correctness of keeping the dimensions, the straightness of the hands during assembly and adjustment, and the speed of the “brains” due to the complex mathematical calculations of the trajectory of the head movement.

Strongly not recommended as a first printer, although the widespread use of the table level sensor somewhat reduces the requirements for straight hands during setup and operation.

Typical deltasBy availability on the market, 3 main categories can also be distinguished:

Chinese (cheap Chinese printers) are almost always designers, even if they come assembled.

-

The advantages include low cost, wide distribution and uniformity, which allows you to buy failed parts in the nearest radio shop or on well-known Chinese sites. Popular models gather around a relatively large number of users who actively share their experience in the field of self-repair and improvement of this type of printer. The most popular models will most likely be printed right out of the box, but will require improvements during more or less long-term operation.

-

The downsides include the quality of the components/assembly and the need to refine these printers to obtain acceptable print quality/speed.

It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

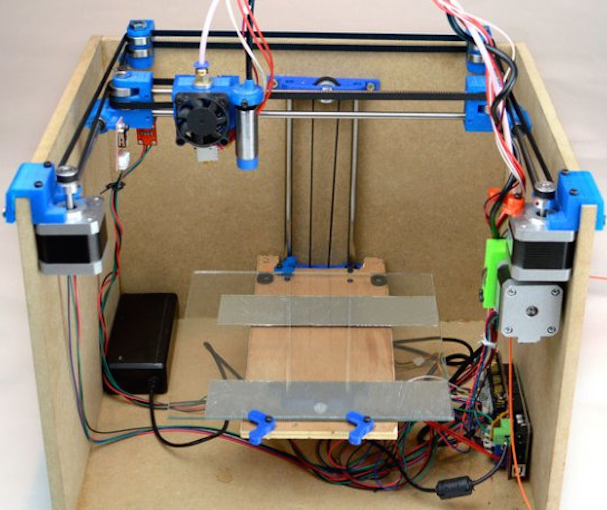

Kits (assembly kits, mainly domestic production) - google for the words “ ZAV ”, “ UlTi ”, “ UlTi ”, etc. Usually they are a set for assembling a plywood cube. Recently, options with metal cases have appeared. Supplied in different versions - from a kit for building a case with printed parts, ending with completely finished assembled products.

-

The advantages include a fairly good engineering study, the ability to choose the components for the mechanical and electronic parts and make the printer completely to your requirements. With good components, they provide fast, stable and high-quality printing. The price is somewhat more expensive than Chinese printers, but cheaper than semi-professional printers of domestic or European / American manufacturers.

-

The disadvantages include a decent amount of time spent on assembly and waiting for components if you decide to save money and order these components yourself from different sellers and assemble a printer from them. When assembling, direct hands are required.

factory printers (domestic or US/European semi-professional printers). There are a lot of models, the designs are very different.

-

The advantage of this class of printers is printing with acceptable quality out of the box. In addition, you get operational reliability and warranty support from the manufacturer.

-

The main disadvantage is the price. It is often not clear what factors it depends on. You can buy a high-quality printer relatively inexpensively, or you can take something incomprehensible for a high price. The second disadvantage is the presence of specific solutions that are incompatible with popular solutions on the market: these can be nozzles with their own thread pitch, special fans, electronics, belts, and even slicers.

Some are demanding on the quality of plastic, there are models that work only on chipped coils.

Some are demanding on the quality of plastic, there are models that work only on chipped coils.

Now that we have decided on the classification of printers, we can proceed to the procedure for choosing a printer for yourself, your loved one. If you are on fire with the purchase of a 3D printer, first decide what you are going to take it for, the type and configuration of the printer depends on it. Let's analyze a few typical situations:

I want to do something for myself and my family - if you don't plan to print products from engineering plastics that can withstand decent loads and temperatures, a Chinese drygostol or a cube will suffice. If you have a budget and want to figure out how the printer works before starting, and not during printing, you can look in the direction of domestic assembly kits - with them you can get the best quality and painlessly switch to engineering plastics.

I can't do anything with my hands, but I have to. Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

I want to print for sale - a farm of the same type of printers, depending on the budget. If there is no budget, but there are resources for regular tuning / repair - you can even from Chinese drygosts. Additionally - a printer with a large print area, a printer with a closed case and a heated table for printing engineering plastics, an SLA / LCD printer for printing products with a high degree of detail.

Whether at work or at home, the need arises to design and print enclosures and parts. If only small prototypes are planned - an LCD printer, if functional products - a closed cube with the ability to print with engineering plastics.

Kids are growing up and this is the technology of the future, I want you to master - see what printers are used in prototyping competitions in your area. Take the same one. May be used.

I want to make figurines for desktops, beautiful little things for home - LCD printer.

I want to figure out what kind of technology and how it works in general - a kit for assembling a domestic manufacturer. By the time you collect it, you will understand.

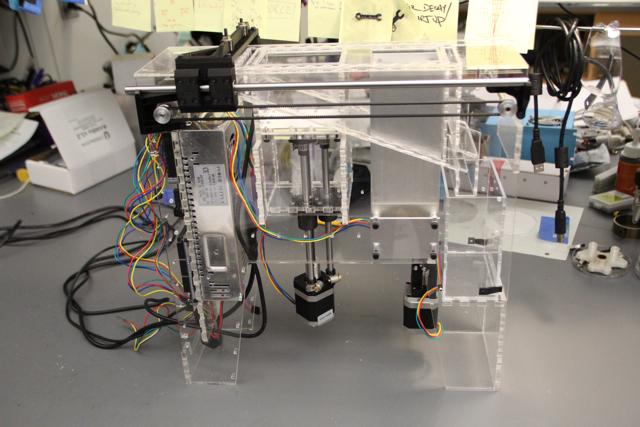

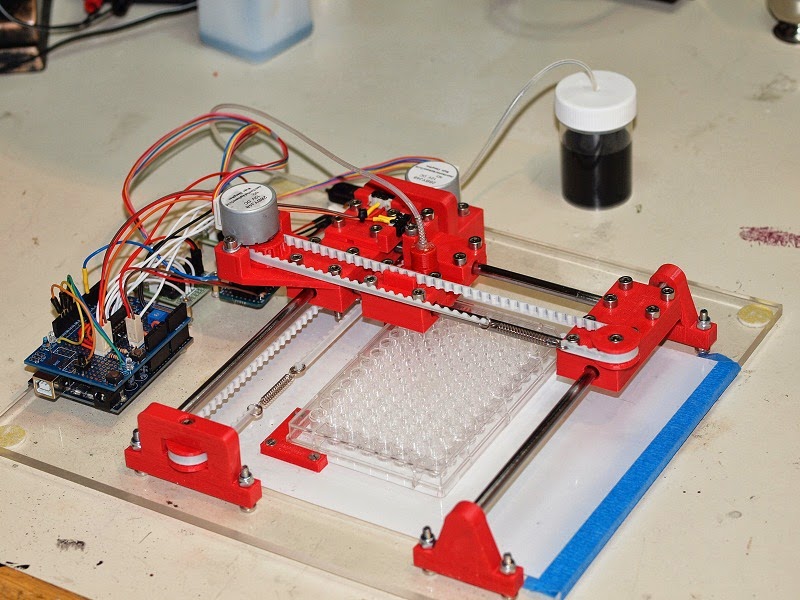

There is no money at all, but I want to print, I will collect it myself from scratch - it will turn out better and cheaper than the Chinese. Strange as it may seem, no. The cost of components with Ali will be more expensive than a printer with Ali. Of course, if there is a machine park, the ability to use it, a set of iron, shafts and electronics lying around in the corner of the workshop, it can burn out. There are options for building printers from boards and furniture rails, but their print quality is, to put it mildly, lame. For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

If you want to completely build your printer from scratch, then it's better to treat this as a separate hobby and accept that it will not turn out very cheap. Well, or look in the direction of used printers.

I don’t know why I need a printer, but I want to try - a Chinese or a domestic assembly kit. Can be used. If it doesn't work, you can always resell.

Decided on the type of printer - what to look for first of all when buying ?

-

Firstly, on the rigidity of the structure - the accuracy and speed of printing depend on it. It is in the direction of strengthening the rigidity that your first modifications of the Chinese printer will be directed, since the material “steel plasticine 3 (c)” is considered an unaffordable luxury for the Chinese. In the case of the purchase of domestic kits, the situation is slightly better.

-

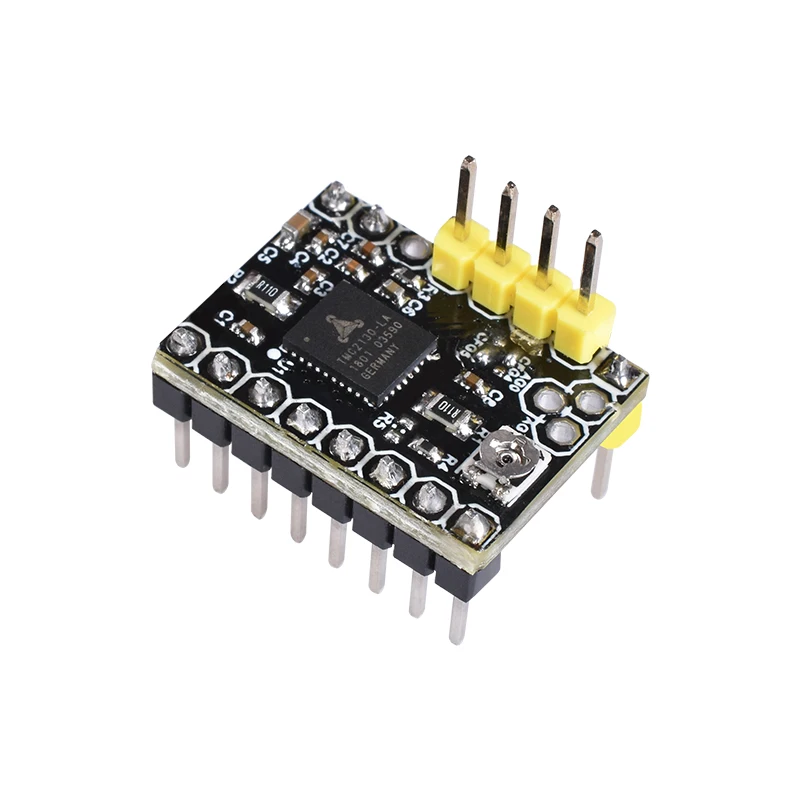

Secondly - if the printer will be in the apartment - "silent" drivers for stepper motors. 3D printing is not a fast process, and having a constant loud enough buzzer under your ear is annoying.

-

Third - the presence of a heated table and ease of modification to a closed case. Over time, the desire (need) to print ABS will come, and it is problematic to do this on an open drygost.

-

Fourthly, the presence of a good plastic blowing system is also important.

-

Fifthly, when choosing printers with CoreXY, H-Bot or Delta mechanics, it is highly desirable to have a 32-bit control board, or you will encounter fading (freezes) at high print speeds.

-

In the sixth, seventh, etc. - there are many nuances in the design of printers. If something is unclear, feel free to ask the community.

In any case, if you are going to buy or have already bought a 3D printer, start learning some 3D editor.