Hpq and 3d printing

HP sees double-digit 3D printing revenue growth in h2 2022 as printed parts top 130 million

0Shares

Multinational printing firm HP (HPQ) has announced that its revenue rose 3.9% in Q2 2022, thanks in part to the strong performance of its 3D printing division.

During the course of Q2 2022, HP generated $16.5 billion, some $600 million more than the $15.9 billion it managed to bring in over Q2 2021. While the firm’s Printing segment continued to be impacted by supply issues and COVID-related office closures, this was partially offset by its industrial graphics and 3D portfolio, which delivered double-digit revenue growth over h2 2022.

“We delivered a solid quarter of revenue and non-GAAP EPS growth, while returning significant capital to shareholders,” said Enrique Lores, HP’s President and CEO. “Collectively, our key growth businesses grew double digits and drove $5.6 billion in revenue in the first half of the year. Our consistent performance in the face of a volatile macro environment gives us confidence in our plans to build a stronger HP. ”

HP’s Q1 2022 financial results

HP reports its financials across two core segments: Personal Systems and Printing. The former includes any revenue generated by the company’s workstations, notebook or desktop systems, and the latter covers income gained from its supplies business, in addition to that brought in by either its consumer or commercial hardware offerings.

During Q1 2022, HP’s Personal Systems continued to be its highest earner, bringing in $11.5 billion, a 9.3% rise on the $10.6 billion it generated in Q1 2021. However, the impact of the division’s performance on the firm’s numbers was slightly diminished by a 6.8% decline in its Printing revenue, caused by supply and lockdown issues, which led its commercial unit sales to fall 17% and consumer unit sales to drop 24%.

Although HP doesn’t report in any detail on the financial performance of its 3D printing business, it does occasionally issue updates on the segment’s top-line numbers. Over h2 2022, for instance, the company’s 3D division is said to have achieved double-digit revenue growth, and alongside the firm’s workforce solutions and industrial graphics offerings, delivered a total revenue of around $5.6 billion.

Over h2 2022, for instance, the company’s 3D division is said to have achieved double-digit revenue growth, and alongside the firm’s workforce solutions and industrial graphics offerings, delivered a total revenue of around $5.6 billion.

This figure, which puts HP on-course to reach its $10 billion FY revenue target for these businesses, also saw its cumulative part output for the period rise by more than 50%, and pass the 130 million mark. Having agreed a partnership with the Legor Group in Q2, the firm now intends to develop new metals for jewelry and fashion customers, something it sees as an ‘important milestone’ in its 3D printing plans.

| Revenue ($) | Q2 2021 | Q2 2022 | Difference (%) | h2 2021 | h2 2022 | Difference (%) |

| Personal Systems | 10.6bn | 11. 5bn 5bn | +9.3 | 21.2bn | 23.7bn | +12.1 |

| Printing | 5.3bn | 5bn | -6.8 | 10.4bn | 9.8bn | -5.5 |

| Total | 15.9 bn | 16.5bn | +3.9 | 31.5bn | 33.5bn | +6.3 |

Tracking HP’s 3D printing progress

Following on from the 9% revenue growth it achieved in Q1, HP’s Q2 2022 results reflect a period of continued growth for the firm, in which it has managed to expand on both the breadth and application of its 3D printing portfolio. Back in January, it was revealed that grocery delivery company Ocado had begun 3D printing parts of its pick-and-pack robots using HP’s MultiJet Fusion (MJF) technology.

Plastics technology developer Oechsler has also entered into a seven-figure partnership with HP and AMT, as a means of building on its serial 3D printing capabilities. While the sale is likely to only have had a limited impact on HP’s result given the verticals its vast portfolio addresses, the move has now allowed MJF units to better serve Oechsler’s industrial, automotive and sporting goods clientele.

Moving forwards, the performance of HP’s 3D printing division is likely to not only be boosted by the materials that come from its work with the Legor Group, but by its Choose Packaging acquisition. Wrapped up in Q1, the deal has seen the company buy into a technology that enables the creation of paper-based plastic bottle alternatives, which it plans to use to disrupt what it sees as a $10 billion market.

Oechsler’s Ansbach-Brodswinden facility. Photo via Oechsler.Predicting macroeconomic turbulence

As HP moves into Q3 2022, it has raised its FY 2022 non-GAAP net EPS guidance to between $4. 24 and $4.38, reflecting the confidence of its leadership that market conditions will improve moving forwards. That being said, this doesn’t include an anticipated $0.45 cost per diluted share in the coming period, related to restructuring, acquisition, amortization, tax adjustment and Russia-related charges.

24 and $4.38, reflecting the confidence of its leadership that market conditions will improve moving forwards. That being said, this doesn’t include an anticipated $0.45 cost per diluted share in the coming period, related to restructuring, acquisition, amortization, tax adjustment and Russia-related charges.

In the process of concluding her prepared remarks on HP’s Q2 earnings call, CFO Marie Myers explained how its fortunes in h3 will hinge on macroeconomic conditions. According to Myers, the firm is set to benefit from China’s plans to ease lockdowns in June, however, ceasing trade with Russia could cost it $1 billion in revenue per year, and she expects to see its Print supply chain issues continue.

“In Print, we expect solid demand in consumer, favorable pricing, disciplined cost management and further normalization in mix, as commercial gradually improves through 2022,” concluded Myers. “But with regards to supply chain, we expect things to be similar to Q2, with component shortages and logistics delays constraining revenue. We expect these conditions to continue at least through 2022, but with some improvement into the latter part of the year.”

We expect these conditions to continue at least through 2022, but with some improvement into the latter part of the year.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an engineer using a HP MultiJet Fusion 3D printer. Photo via HP.

Tags AMT Choose Packaging Enrique Lores HP Legor Group Marie Myers Ocado oechsler

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

HP Industrial 3D Printers - Leading The Commercial 3D Printing Revolution

Contact an HP 3D Print expert

Choose the phone number for your country to speak to a local HP 3D Printing sales expert today.

België/Belgique

+32 78 48 44 69

Czech Republic

+420 239 050 531

Deutschland

+49 7031 986 90 13

+49 7031 986 90 17

España

+34 93 003 45 95

France

+33 6 28 78 35 59

Italia

+39 02 8295 2406

Nederland

+31 20 241 5685

Norway

+47 23 96 00 13

Österreich

+43 720 117035

+43 1424 0091

Romania

+40 376 300 174

Sweden

+46 8 446 891 49

Suisse/Switzerland

+41 44 511 2308

+41 44 511 2333

United Kingdom

+44 20 7365 8158

United States

+1 877 468 8369

Data courtesy1

Integrity.

Adaptability. Innovation.

Adaptability. Innovation. Production ready

and reliable

Together, we can take revolutionary designs seamlessly from prototype to production grade.

Ability meets

agility

Let’s implement production processes that allow you to rapidly develop unique solutions while remaining flexible.

Reimagining

realities

Now we have the power to customize like never before and produce wherever, whenever your product is needed.

The possibilities are endless

Partnership makes anything

possible

Breakthrough digital technology alone isn’t enough. Today, you need a trusted partner who knows how to apply it effectively to help solve your specific supply-chain challenges.

Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices.

Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

- Data courtesy of Bastian Solutions & Fast Radius, Heygears, Avular, Breezm, Volkswagen and Cupra Racing

- Data courtesy of GoProto and Ropes Edge

- Data courtesy of Gimatic

- Data courtesy of SmileDirectClub

- Data courtesy of Volkswagen

- Data courtesy of Invent Medical

- Data courtesy of Cobra Golf

- Data courtesy Addit.ion

- Data courtesy of Hopkins, J., Lobete, A., Remacha, C.

- Data courtesy of Lumenium

- Data courtesy of Breezm

ten million 3D printed products per year

News

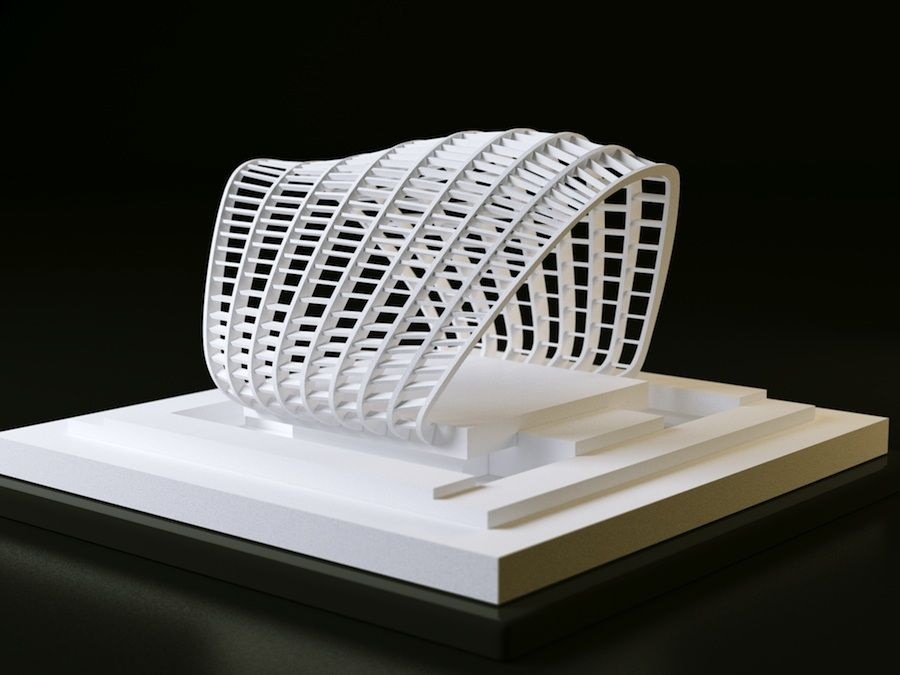

HP Inc. there is something to brag about: in the last year alone, industrial 3D printers using proprietary HP Multi Jet Fusion technology have printed over ten million products.

Until now, the case was limited to polymers, but now it's time to 3D print metals.

Until now, the case was limited to polymers, but now it's time to 3D print metals.

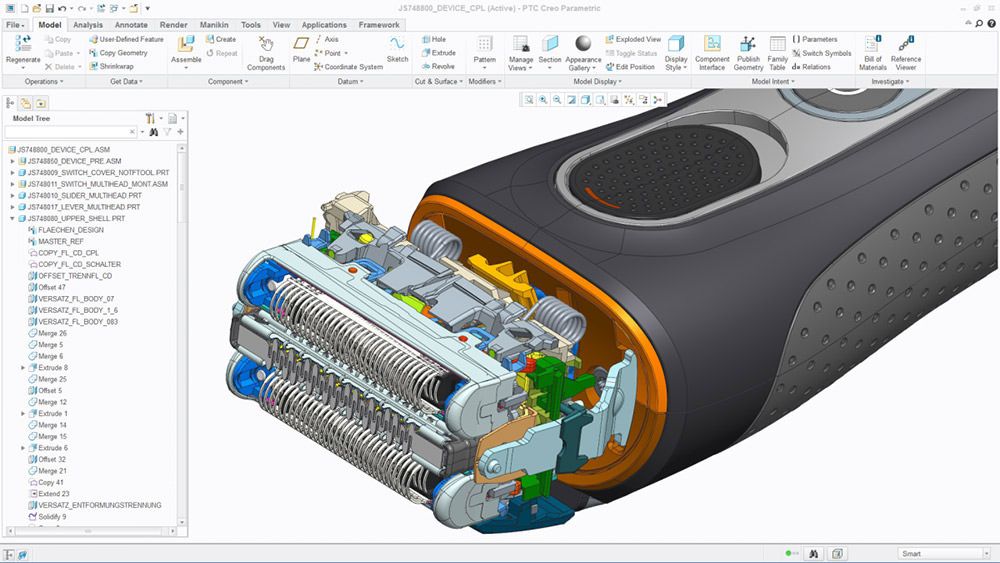

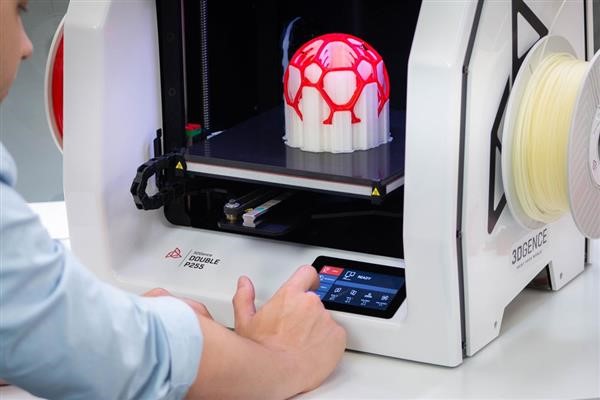

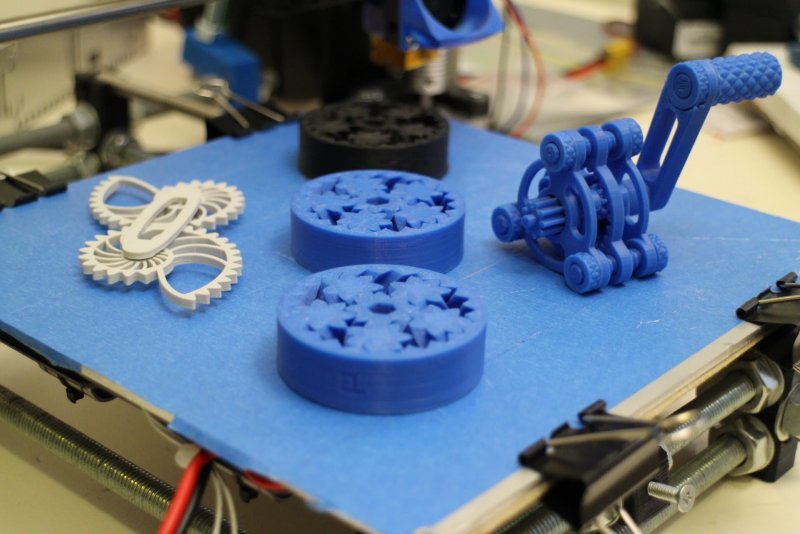

Multi Jet Fusion technology is based on selective thermal sintering of powder materials. Application examples are varied: Daimler Trucks prints prototype truck parts, Unlimited Tomorrow uses 3D printing to produce personalized prostheses, Yanfeng Automotive Interiors customizes car interiors, and Clemson University uses additive technologies in research and teaching projects.

“Over the past year, Multi Jet Fusion has helped produce over ten million parts. We are seeing an explosion in new industrial applications due to the increased design freedom, cost-effectiveness, speed and industrial-grade quality available through the efforts of HP and its partners. By expanding our portfolio of polymer and metal 3D printing solutions for prototyping and additive manufacturing, as well as developing a global partner network, we are helping users save money and reduce time to market,” said Christoph Schell, Head of 3D Printing and digital production company HP Inc.

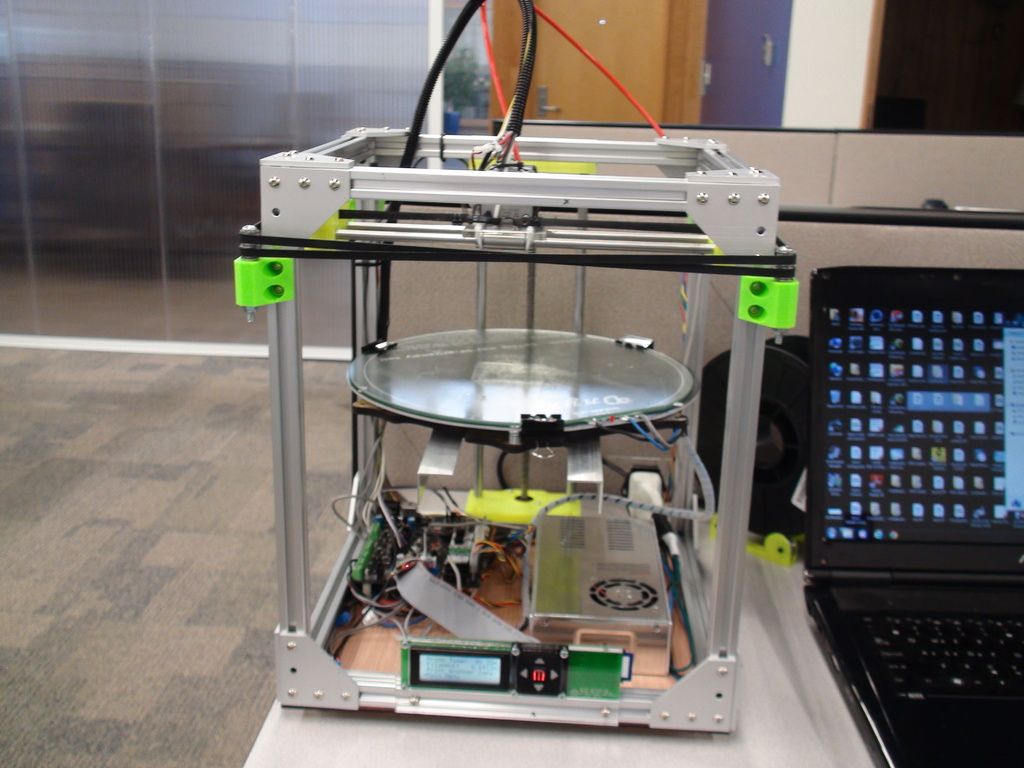

Initially, the technology was created with the expectation of 3D printing of polymer products, but last fall the company announced the development of a “metal” version of the HP Metal Jet, which is generally similar to Binder Jetting systems: the heads selectively apply a binder, forming layers of metal powder, and the resulting 3D printed blanks are sintered. The run-in was carried out by three companies: automotive and aerospace supplier GKN, automaker Volkswagen and powder metallurgy company Parmatech.

At the AMUG 2019 industry conference in Chicago these days, HP Inc. announced a sufficient maturity of the new version of the technology to start accepting orders for 3D printing. The timing of the start of sales of new equipment has not yet been reported.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru.

ru.

Subscribe to the author

Subscribe

Don't want

6

Hewlett Packard is preparing more economical and productive 3D metal printers

You are here

Home

Hewlett Packard has announced a new version of its Metal Jet Fusion 3D printing technology, this time focused on the production of functional metal products. HP claims performance is up to fifty times that of some competitive systems.

HP Metal Jet technology is positioned as an evolution of Multi Jet Fusion, essentially a technology for selective thermal sintering of powder materials. The details of the new process are not entirely clear yet, but in Multi Jet Fusion, layers of detail are rendered using jet arrays that apply "sintering" and "detailing" agents. Thermal lamps are built into the movable heads, which sinter the treated layers immediately after the application of binders. One of the main advantages of the technology is its high performance compared to laser systems that draw layers point by point. In addition, Multi Jet Fusion technology was originally created with a retrospective in mind, namely the ability to print in color: color versions of HP Jet Fusion 3D printers were announced in February this year.

Hewlett Packard says its new HP Metal Jet technology enables mass additive manufacturing of "functional mechanical parts." Most likely, we are talking about a full cycle with the removal of the binder and the subsequent sintering of 3D-printed blanks to obtain full-fledged metal parts, especially since the evaluation of performance and economy is carried out in comparison with selective laser fusion technology (SLM). In this case, the HP Metal Jet can be considered a direct analogue of the Binder Jet Printing technology used in industrial 3D printers manufactured by ExOne and VoxelJet, although the latter's units are mainly used for 3D printing of sand casting tooling. At the end of last year, General Electric Corporation also offered its own version of a high-speed inkjet-powder 3D metal printer.

Competitive advantages of HP Metal Jet over other inkjet additive systems should be increased performance and reliability of inkjet heads, coupled with more economical consumption of binders. Compared to laser systems, productivity is allegedly an order of magnitude higher, in some cases reaching a fifty-fold advantage. The size of the construction area of the first variant in the HP Metal Jet line is 430x320x200 mm. So far, it is possible to print stainless steel products with isotropic characteristics in accordance with ASTM and MPIF standards.

Pilot systems are being tested by automotive and aerospace supplier GKN, automaker Volkswagen and powder metallurgy company Parmatech. Pre-orders have already been placed by pump supplier Wilo, as well as medical instrument manufacturers Primo Medical Group and OKAY Industries.