Straumann 3d printer

Digital 3D Printing Solutions | Digital Solutions for Dental Labs

Country / Region*

-- Please Select -- Afghanistan Albania Algeria American Samoa Andorra Angola Anguilla Antarctica Antigua And Barbuda Argentina Armenia Aruba Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belgium Belize Benin Bermuda Bhutan Bolivia Bosnia And Herzegovina Botswana Bouvet Island Brazil British Indian Ocean Territory Brunei Darussalam Bulgaria Burkina Faso Burundi Cambodia Cameroon Canada Cape Verde Cayman Islands Central African Republic Chad Chile China Christmas Island Cocos (Keeling) Islands Colombia Comoros Congo Congo, The Democratic Republic Of The Cook Islands Costa Rica Cote D’ivoire Croatia Cuba Cyprus Czech Republic Denmark Djibouti Dominica Dominican Republic East Timor Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia Ethiopia Falkland Islands (Malvinas) Faroe Islands Fiji Finland France French Guiana French Polynesia French Southern Territories Gabon Gambia Georgia Germany Ghana Gibraltar Greece Greenland Grenada Guadeloupe Guam Guatemala Guinea Guinea-bissau Guyana Haiti Heard Island And Mcdonald Islands Holy See (Vatican City State) Honduras Hong Kong Hungary Iceland India Indonesia Iran, Islamic Republic Of Iraq Ireland Israel Italy Jamaica Japan Jordan Kazakstan Kenya Kiribati Korea, Democratic People's Republic Of Korea, Republic Of Kosovo Kuwait Kyrgyzstan Lao People's Democratic Republic Latvia Lebanon Lesotho Liberia Libyan Arab Jamahiriya Liechtenstein Lithuania Luxembourg Macau Macedonia, The Former Yugoslav Republic Of Madagascar Malawi Malaysia Maldives Mali Malta Marshall Islands Martinique Mauritania Mauritius Mayotte Mexico Micronesia, Federated States Of Moldova, Republic Of Monaco Mongolia Montenegro Montserrat Morocco Mozambique Myanmar Namibia Nauru Nepal Netherlands Netherlands Antilles New Caledonia New Zealand Nicaragua Niger Nigeria Niue Norfolk Island Northern Mariana Islands Norway Oman Pakistan Palau Palestinian Territory, Occupied Panama Papua New Guinea Paraguay Peru Philippines Pitcairn Poland Portugal Puerto Rico Qatar Reunion Romania Russian Federation Rwanda Saint Helena Saint Kitts And Nevis Saint Lucia Saint Pierre And Miquelon Saint Vincent And The Grenadines Samoa San Marino Sao Tome And Principe Saudi Arabia Senegal Serbia Seychelles Sierra Leone Singapore Slovakia Slovenia Solomon Islands Somalia South Africa South Georgia And The South Sandwich Islands Spain Sri Lanka Sudan Suriname Svalbard And Jan Mayen Swaziland Sweden Switzerland Syrian Arab Republic Taiwan Tajikistan Tanzania, United Republic Of Thailand Togo Tokelau Tonga Trinidad And Tobago Tunisia Turkey Turkmenistan Turks And Caicos Islands Tuvalu Uganda Ukraine United Arab Emirates United Kingdom United States United States Minor Outlying Islands Uruguay Uzbekistan Vanuatu Venezuela Viet Nam Virgin Islands, British Virgin Islands, U. S. Wallis And Futuna Western Sahara Yemen Zambia Zimbabwe

Data usage agreement*

I acknowledge that my data will be processed according to the terms and conditions of the privacy notice.

Read our privacy notice.

Straumann® CARES® P series

Strike a chord with precision and productivity.

Contact us

The CARES® P series delivers a new dimension in fast and professional 3D printing to allow you to produce top-quality dental products in-house and on-demand. The CARES® P series provides new functions to improve quality, flexibility, productivity and efficiency.

The professional 3D printer entry-level system for dental labs.

Buy now

Contact us

For dental labs who want to start using 3D printing technology with minimum investment | Peace of mind with reproducible precision and high quality | Easy-to-use, plug-and-play features | For labs who want material solutions tailored to their needs

How can we help you?

Get in contact

The economic 3D printing solution for small labs.

Buy now

Contact us

Professional 3D printing solution with low investment | Economic, multiple use consumables reduce storage requirements and inventory

How can we help you?

Get in contact

Fast, flexible and semi-automated 3D printing for dental labs.

Buy now

Contact us

For medium-volume production | With high efficiency, reproducibility, precision and quality | Meets the needs of a broad range of indications and applications | Flexible open system facilitates manual adjustment and control

How can we help you?

Get in contact

Semi-automated professional solution for high-volume 3D dental printing.

Buy now

Contact us

For high-volume production | With maximum efficiency, reproducibility, precision and high quality | Meets the needs of a broad range of indications and applications

How can we help you?

Get in contact

Increase efficiency by automating the wash cycle.

Buy now

Contact us

Fully automatic cleaning in approx. 6–8 minutes | No contact with sticky resins and cleaning liquids | Touch display control | Computer-controlled programs ensure effective use of cleaning liquids

How can we help you?

Get in contact

The automated curing and finishing solution to ensure maximum performance.

Buy now

Contact us

Precise wavelength of light emission from integrated light source | Revolutionary table ensures consistent, even curing | Protective gas supply not required

How can we help you?

Get in contact

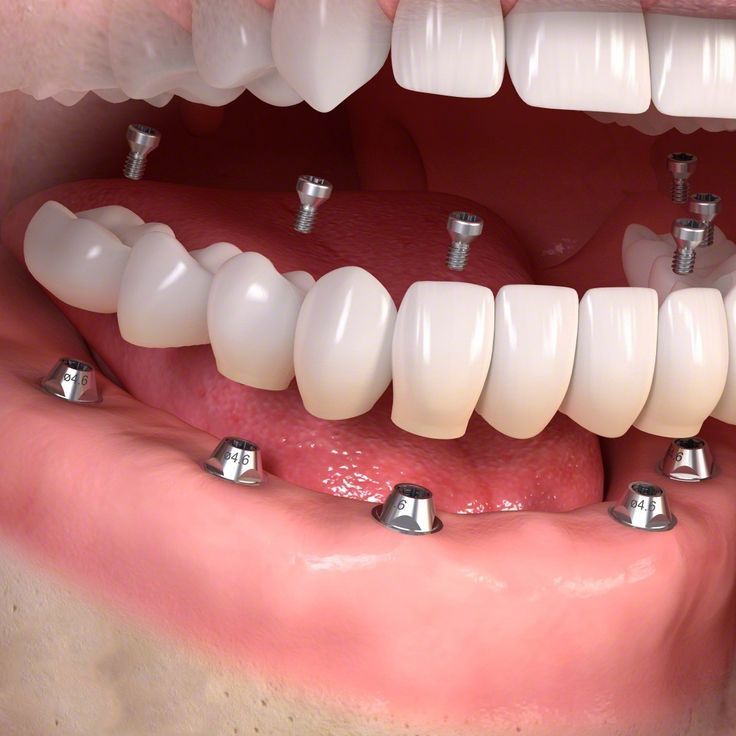

A range of resins (available and planned):

Master model – Aligner model – Gingiva mask – Cast – Indirect bonding tray – Tray – Surgical guide – Bite splint – Try in – Denture base – Crown & bridge for temporary restaurations

Buy now

Contact us

Downloads

In-house lab

• Large retrospective clinical study: 2,244 implants in over 400 patients. (1)

(1)

• High long-term implant survival: 99.7% after 5 years. (1)

• No early implant loss was observed in this study.(1)

• High degree of predictability with complete restorations (4 to 6 or more in the maxilla and 4 to 5 in the mandible) even with using angled implants.(1)

1. Sartori IAM, Latenek RT, Budel LA, Thomé G, Bernardes SR, Tiossi R. Retrospective analysis of 2,244 nimplants and the importance of follow-up in implantology. Journal of Research in Dentistry. 2014 Nov-Dez;2(6):555-564.

2. Martin C, Thomé G, Melo AC, Fontão FN. Peri-implant bone response following immediate implants placed in the esthetic zone and with immediate provisionalization-a case series study. Oral Maxillofac Surg. 2015 Jun;19(2):157-63.

3. Barros RR, Novaes AB Jr, Muglia VA, Lezzi G, Piattelli A. Influence of interimplant distances and placement depth on peri-implant bone remodeling of adjacent and immediately loaded Morse cone connection implants: a histomorphometric study in dogs. Clin Oral Implants Res. 2010;21(4):371-8.

Clin Oral Implants Res. 2010;21(4):371-8.

4. Castro DS, Araujo MA, Benfatti CA, Araujo Cdos R, Piattelli A, Perrotti V, et al. Comparative histological and histomorphometrical evaluation of marginal bone resorption around external hexagon and Morse cone implants: an experimental study in dogs. Implant Dent. 2014;23(3):270-6.

5. Novaes AB Jr, Barros RR, Muglia VA, Borges GJ. Influence of interimplant distances and placement depth on papilla formation and crestal resorption: a clinical and radiographic study in dogs. J Oral Implantol. 2009;35(1):18-27.

6. Siqueira RAC. Avaliação do índice de sucesso e comportamento dos tecidos periimplantares de implantes cone morse equicrestais ou subcrestais em arcos inferiores. [dissertation for a master's degree, published on the Internet]. [Curitiba(Brazil)]: ILAPEO; 2013. [Cited 28 August 2015] 126 pp. Available at: http://www.ilapeo.com.br/ Monografias_e_Dissertacoes/Dissertacoes_turma2011/Rafael_Amorin_Cavalcanti_de_Siqueira.pdf

7. Sotto-Maior BS, Lima Cde A, Senna PM, Camargos Gde V, Del Bel Cury AA. Biomechanical evaluation of subcrestal dental implants with different bone anchorages. Braz Oral Res. 2014;28.

Sotto-Maior BS, Lima Cde A, Senna PM, Camargos Gde V, Del Bel Cury AA. Biomechanical evaluation of subcrestal dental implants with different bone anchorages. Braz Oral Res. 2014;28.

8. Coppedê AR, Bersani E, Chiarello de Mattos MG, Rodrigues RCS, Sartori IAM, Ribeiro RF. Fracture resistance of the implant-abutment connection in implants with internal hex and internal conical connections under oblique compressive loading: an in vitro study. Int J Prosthodont. 2009 May-Jun;22(3):283-6.

9. Bernardes SR, da Gloria Chiarello de Mattos M, Hobkirk J, Ribeiro RF. Loss of preload in screwed implant joints as a function of time and tightening/untightening sequences. Int J Oral Maxillofac Implants. 2014 Jan-Feb;29(1):89-96.

10 Jorge JR, Barao VA, Delben JA, Assuncao WG. The role of implant/abutment system on torque maintenance of retention screws and vertical misfit of implant-supported crowns before and after mechanical cycling. Int J Oral Maxillofac Implants. 2013 Mar-Apr;28(2):415-22.

11. dos Anjos CM, Harari ND, Reis RSA, Vidigal Junior GM. Analysis in vitro da infiltração bacteriana na interface de pilares protéticos e implantes cone-morse / In vitro analysis of bacterial leakage at the interface between Morse taper implant platform and prosthetic abutments. ImplantNews. 2011 8(2):239- 243.

12. Sartoretto SC, Alves AT, Resende RF, Calasans-Maia J, Granjeiro JM, Calasans-Maia MD. Early osseointegration driven by the surface chemistry and wettability of dental implants. J Appl Oral Sci. 2015. May-Jun;23(3):279-87.

13. da Silveira BM. Analises tomográfica, microtomográfica e histológica entre enxertos em bloco autógeno e xenógeno nas reconstruções ósseas de maxila. [master's thesis published online].[Curitiba(Brazil)]: ILAPEO; 2013. [Cited June 15, 2014] 133 pp. Available at: http://www.ilapeo.com.br/biblioteca-detalhe/tomographic-microtomographic-and-histological-analysis-between-grafts-in- autogenous-andxenogeneic-- C162410.html

14. Mendonça G, Mendonça BD, Oliveira SL, Araujo AC. Efeitos da diferenciação de células-tronco mesenquimais humanas sobre superficies de implantes hidrofílicas. ImplantNews. 2013 Nov-Dez 10(6a):111-116.

Efeitos da diferenciação de células-tronco mesenquimais humanas sobre superficies de implantes hidrofílicas. ImplantNews. 2013 Nov-Dez 10(6a):111-116.

Resin and parameters compatible with Rapid Shape D20+ and Straumann P20+

Support > Printer settings

Rapid Shape GmbH was founded over 10 years ago and built its first 3D printer back in 2011. Its parent company, Schultheiss GmbH, was in the jewelry business and at that time did not find a suitable printing solution on the market. Therefore, RapidShape decided to create their own printers. now, more than 10 years later, Rapid Shape is part of the Straumann Group and manufactures several printers for dentistry, jewelry, hearing aids and industrial applications. One of their prototypes is the Rapid Shape D20+ / Straumann P20+, which offers a flexible and certified resin 3D printing solution for laboratories through its open material system with proven workflows. The printer is distinguished not only by first-class quality, but also by a large print area and short production times. Optional high-speed Force Feedback technology further reduces print times to a minimum. Liqcreate partners optimized some resins on RapidShape D20+ / Straumann P20+, these materials were processed with open material settings, settings can be found here. If you do not have material settings open, our resins cannot be run on Straumann/Rapid Shape printers. Contact us if you need support or have any questions.

Optional high-speed Force Feedback technology further reduces print times to a minimum. Liqcreate partners optimized some resins on RapidShape D20+ / Straumann P20+, these materials were processed with open material settings, settings can be found here. If you do not have material settings open, our resins cannot be run on Straumann/Rapid Shape printers. Contact us if you need support or have any questions.

| FEATURES | D20 + | D30 + |

|---|---|---|

| Assembly volume (L x W x H) | 133 x 75 x 115 mm | 133 x 75 x 155 mm 133 x 75 x 70 mm (active ASM) |

| Own pixel | +/- 34 µm | +/- 34 µm |

| Wavelength | 385 nm | 385 nm |

| approval | Full HD | Full HD |

| Dimensions (W x D x H) | 335 x 349 x 541 mm | 480 x 410 x 690 mm |

| Switching | Ethernet, WLAN, USB | Ethernet, WLAN, USB |

| Control | 7" touch screen | 10" touch screen |

Contact us

Read these instructions first

Liqcreate partners have optimized some resins for Rapid Shape D20+ / Straumann P20+. These materials were printed with the material settings open. Options for setting open content can be found in this article. If you do not have material settings open, our resins cannot be run on Straumann/Rapid Shape resin printers. Contact us if you need support or have any questions.

These materials were printed with the material settings open. Options for setting open content can be found in this article. If you do not have material settings open, our resins cannot be run on Straumann/Rapid Shape resin printers. Contact us if you need support or have any questions.

20D print settings with Rapid Shape D20+ and Straumann P3+ resin.

| Layer thickness | Energy (mJ/dm2) | Offset (micron) | Shrinkage (in percent) | Z compensation (microns) | Burn-in ratio (in percent) | |

| Dental Model Pro Beige | 50 µm Precision | 250 | 0 | 0.6 | 100 | 200 |

| 50 µm Smooth | 450 | 0 | 0.6 | 100 | 200 | |

| Premium White | 100 µm | |||||

| 50 µm | 200 | 0 | 0. 6 6 | 100 | 200 | |

| Deep Blue | 100 µm | |||||

| 50 µm | ||||||

| Stone Coal Black | 100 µm | |||||

| 50 µm | ||||||

| Flexible-X | 100 µm | |||||

| 50 µm | ||||||

| Premium Black | 100 µm | |||||

| 50 µm | ||||||

| Premium Model | 100 µm | |||||

| 50 µm | ||||||

| Premium Tough | 100 µm | |||||

| 50 µm | ||||||

| Wax Castable | 100 µm | |||||

| 50 µm | ||||||

| Clear Impact | 100 µm | |||||

| 50 µm | ||||||

| Tough-X | 100 µm | |||||

| 50 µm | ||||||

| Hazard Glow | 100 µm | |||||

| Composite-X | 100 µm | |||||

| 50 µm |

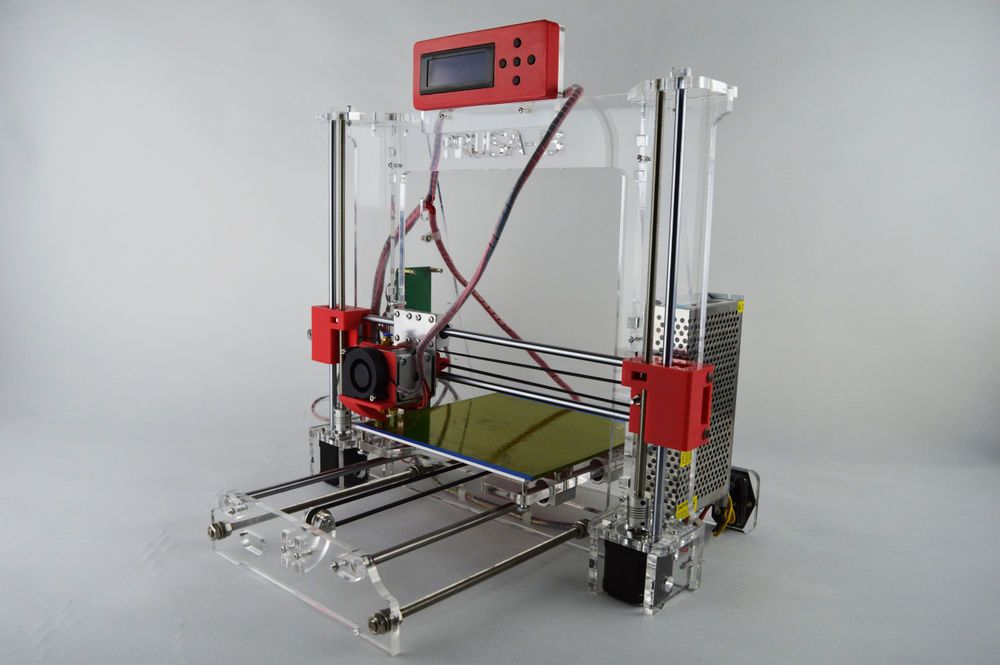

About the Rapid Shape D20+ / Straumann P3+ 20D resin printer.

D20+ supports the printing of dental parts in small labs, which simplifies the process. Drill templates, splints, braces, crowns, dentures and more can be made without special 3D printing skills. According to Rapid Shape, the open material system as well as remote control make media selection and the printing process easier. Printing consistently high quality and creating thinner support structures is made possible by our optionally selectable and patented force feedback technology. It measures the forces acting on the part to improve workflow efficiency and reduce delivery times.

3D Print Image & Rapid Shape: Rapid Shape D20+ / Straumann P3+ resin 20D printer.

Specifications for Rapid Shape D20+ / Staumann P3+ 20D Resin Printer.

- Highlights Rapid Shape D20+ / Straumann P20+

- - Build volume 133 x 75 x 115 mm (L x W x H)

- - Native pixel size +/- 34 microns (Natural pixel size is a minimum precision specification and in most cases defined as pixel size/2)

- - Wavelength 385 nm

- - Full HD resolution (1080*1920 pixels)

Contact us if you have any questions or need help with settings for the Rapid Shape D20+, Straumann P20+ or other resin 3D printers.