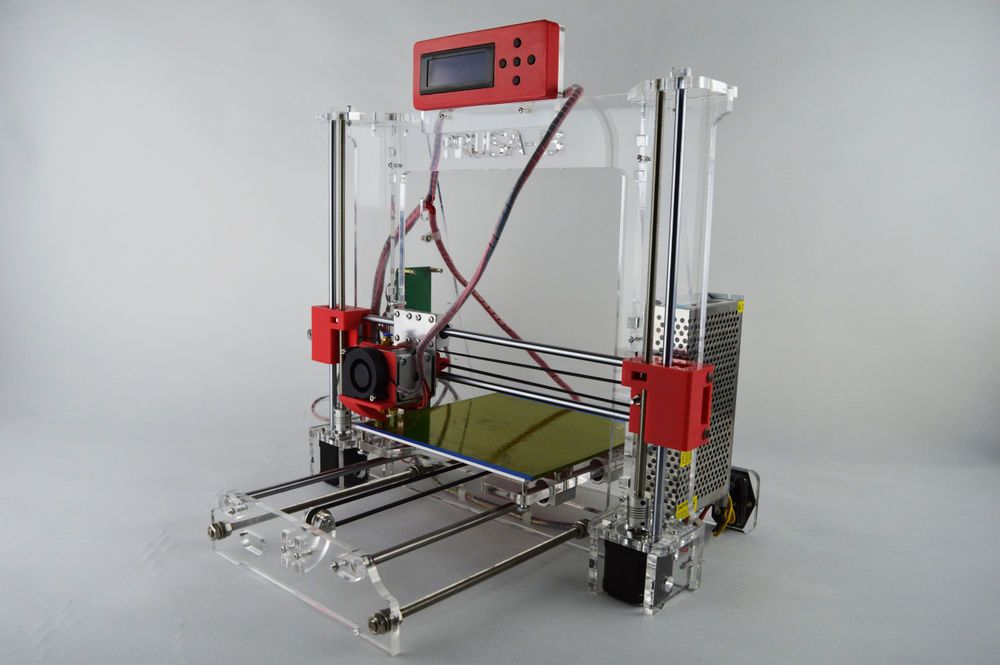

Fractal 3d printer

Industries- Automotive - Fracktal

3D Printing in Automotive industry

Automotive sector uses some of the most cutting edge tech in manufacturing. Automotive companies stand at forefront of innovation, revolutionizing manufacturing systems. As part of industry 4.0 major changes are coming up in the automotive sector when is comes to production. Along with production parameters like Fasters production and reduced costs additive manufacturing has also let the engineers make designs and parts which where not possible to manufacture using traditional methods, which will have a major impact on the design of cars.

Casting is one of the oldest and valued manufacturing process in which preparing the sand cast is the most vital step for getting the best products. The use of digital sand casting for preparing sand casts to enable the reduction of subassemblies has started nowadays. 3D printing enabled custom cast can bring about a significant development even before metal casts can directly produce large metal parts.

The improvement in sand 3D printing processes to improve upon the traditional casting industry’s possibilities could become increasingly mainstream as it can support high throughput production as required by the automotive segment.

Car manufacturers tend to have a verification of process before starting mass production of any model. Verification of the process is done to ensure that all of the individual components are manufactured and assembled correctly as per design. The initial prototype run also offers an opportunity to train workers on the production line and find out problems and solutions before any significant commitments are made. If anything goes wrong, the manufacturer has a chance to remedy the situation and fine-tune the process before the start of production.

All this will reduce the cost significantly and reduce the lead time for an electric car. These benefits will enable this sector to grow more and make electric vehicles more affordable to ordinary people, and allow the planet to have a more sustainable and green future.

Design and concept communication: Highly detailed, accurate to micro levels, and smooth scale models printed by 3D printing technology is often used to showcase design ideas. These models also help in situations where CAD models are not sufficient for identifying design issues.

Personalization: 3D printing allows you to create a broad range of styles that can be further customized to your customers’ requirements with anything from a small texture on your dashboard to an utterly personalized exterior.

Rapid Prototyping: The base of research & development (R&D) is prototyping, and 3D printing has provided that R&D base to the electric vehicle industry. Allowing changes to be made with a click of a button, new and new ideas and designs can be quickly tried out. This is not possible in traditional manufacturing, and 3D printing saves a lot of costs, time, and effort over here.

Lower Capital Investment: On a more prolonged time shelf, 3D printing technology is very cost-efficient and takes up less infrastructure than a traditional manufacturing set-up cost.

Lower Operational Expenditure: 3D printing will allow us to use digital libraries replaced modern-day physical inventories. The parts can be printed as and when needed. This will enable shorter assembly times and increase the possibility of Just-in-time manufacturing.

Often, the sweet spot for additive manufacturing is in low-volume, high value, long lead-time parts. Why? 3D printing reduces lead times and allows you to avoid the high up-front costs of traditional manufacturing: supply chain, tooling, and setup.

On the cost side, 3D printing often eliminates tooling and setup costs associated with traditional manufacturing. These lowered fixed costs mean that production at low volumes becomes economically viable. The graph below shows visually why this happens:

There’s a time benefit too: Since additive manufacturing doesn’t require setup or tooling, 3D-printed parts can often be produced with lead times in days versus weeks or months for traditional manufacturing.

3D Printed Electric Cars:

A Hong Kong-based design firm named “XEV” is developing small and compact, entirely 3D printed electric cars. The company especially thanks to the 3D printing technology; the vehicle costs just around $7,500. Apart from tires, chassis, windows, and seats, the entire car is built using a 3D printer. The costs are reduced here due to no need for inventory, tooling, or assembly lines. The technology also ensures the car is lightweight.

Image Source: https://www.x-ev.net/

HVAC for Model Y of Tesla

HVAC is known as heating, ventilation, and air conditioning, used in a car for ACs, heating, and proper air circulation. The vehicle’s airbox, a sizeable injection-molded component of the “Model Y” car, might be a 3D printed part – as evident from the picture below.

Image Source: https://3dprintingindustry.com/news/tesla-fixes-model-y-hvac-system-using-3d-printing-171017/

3D Printed Prototypes and parts by FORD:

The car uses 3D-printed prototypes for design validation and functional testing. The 2020 Shelby GT500 will also feature two structural brake components printed using Carbon’s Digital Light Synthesis (DLS) 3D printing technology. All these components manufactured using this 3D printing technology have passed all of Ford’s performance standards and requirements.

The 2020 Shelby GT500 will also feature two structural brake components printed using Carbon’s Digital Light Synthesis (DLS) 3D printing technology. All these components manufactured using this 3D printing technology have passed all of Ford’s performance standards and requirements.

Image Credit: (Ford) Ford’s parking brake bracket is manufactured with Carbon 3D printing technology

Reduction in number of parts: Tesla Model Y

3D printing technology and its advanced prototyping features enabled the Model Y rear underbody to go from almost 70 different parts to just two and, eventually, with the advancement of technology to a single metal piece. It probably is prototyped using additive manufacturing (like 3D printing). Experts also say that, in the future, a hybrid additive-subtractive metal deposition technology may be used as a preferred method to produce a part of this size (it would make very little sense to cut this part from whole entirely) as a single component.

Image Source: https://www.3dprintingmedia.network/tesla-shows-massive-generatively-designed-3d-printed-part-in-model-y-underbody/

The Impact

That Matters.

Reduction in cost

Reduction in Time

Supply Chain

Inventory & warehousing

Sign up for a free Discovery Session and understand 3D Printing's ROI in your Industry

“One of the main applications they use 3D printing for is custom workpiece holders which mount on the machine conveyors.”

- Inventory can be managed smartly adding value to the service and maintenance teams efforts.

- Mistake-proofing and inadvertent error prevention can be implemented on the factory floor

- Developments timelines of such parts are much more faster when implemented using additive manufacturing

Play Video

Learn More About 3D Printing

3D Printing is set to revolutionaize the way several industries work, from Medicine to Space Exploration to Education.

Learning and adopting 3D Prinring in your field may just be the Next Big Thing in your industry or workplace

YouTube Channel

The Beauty of Math! These 3D Printed Fractals Will Blow Your Mind - 3DPrint.com

When I was in school, I admittedly was not a fan of mathematics. It was just something about numbers that turned me away. While my grades held up, and I never failed a single math class, I must admit that when I finally graduated, I never missed the subject. However, not everyone feels the same. Mathematics can be fascinating to others, especially when geometric figures called fractals are involved.

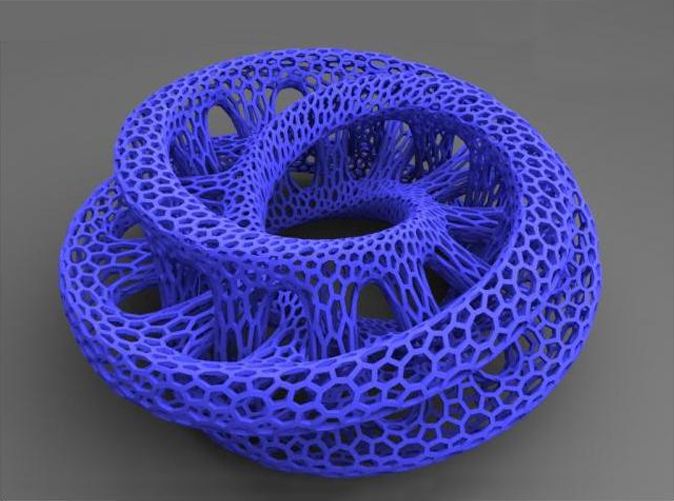

Fractals are curves or geometric figures made up of parts which have the same statistical character as the whole. They are mysteriously found in nature as are they in many man-made formations and objects. For one man, named Jérémie Brunet, fractals have always been fascinating.

“Fractals have fascinated me since the 80s when I was a teenager,” Brunet tells 3DPrint.

com. “My father offered me a book entitled ‘The beauty of fractals’ which I still cherish to this day. I used to program fractals on my early computers and draw them by hand. About 5 years ago, a new generation of 3D fractals emerged from a collaborative work on fractalforums.com and I became hooked again.”

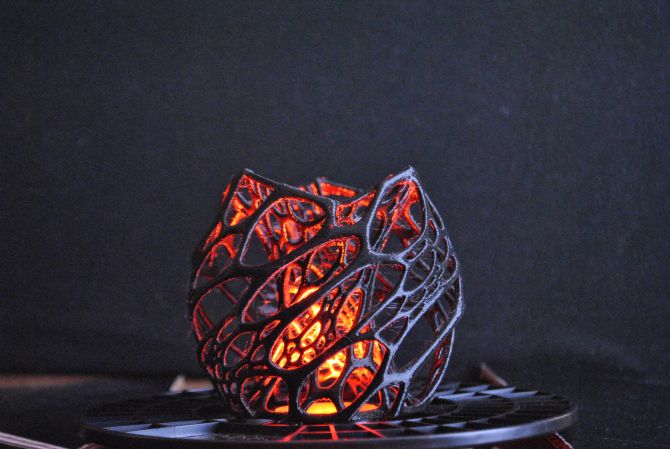

Image copyright: Coandco

One day, Brunet stumbled upon Shapeways and immediately it became evident that he had to “give physical substance to these strange mathematical creatures.”

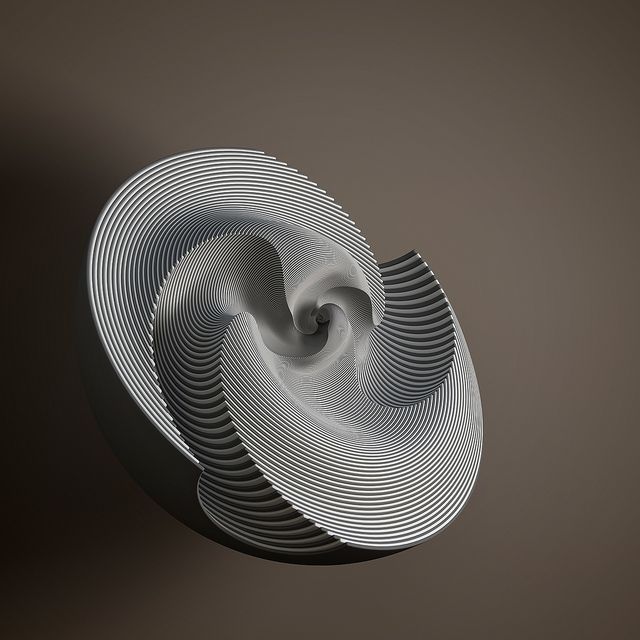

“I like to push the boundaries of fractal art, and 3D printing was the perfect technology to that end,” Brunet explains. “To me, they are a way to visualise the beauty of nature, the elegant laws of the universe and the emergence of complexity through simple rules and fundamental ingredients. Today, creating 3D printed fractals still represents many challenges, as these objects bear infinite details by definition, but my passion is to keep on pushing the limits in the 3D fractals domain.

”

Currently Brunet has about a hundred different fractals available for various prices on his Shapeways shop. Some are priced at under $10, while others are hundreds of dollars. They range from large plastic 3D prints to smaller pieces of jewelry made of precious metals like gold, silver, and bronze. Brunet relies on Shapeways, opting not to print his designs on desktop FFF-based 3D printers, simply for the fact that those machines can’t provide him with the intricate details needed.

Brunet’s 3D printed fractals (image copyright: Coandco)

“I like to try all the possible colours and materials at my disposal,” he tells us. “I’m sure that one day, affordable and fine resolution metal desktop 3D printers will be available, then I’ll probably invest.”

As for designing his individual fractals, they require a lot of hard work and time. The workflow is complex, involving the exportation of voxel stacks from Mandelbulb3D, which is a freeware fractal generator. The stacks are then combined into a triangle mesh in a process referred to as a “marching cubes” algorithm, and then they are post-processed and optimized in Meshlab. Recently Brunet has begun using another software package called Incendia EX, which provides a special feature that allows exporting directly to STL files.

The stacks are then combined into a triangle mesh in a process referred to as a “marching cubes” algorithm, and then they are post-processed and optimized in Meshlab. Recently Brunet has begun using another software package called Incendia EX, which provides a special feature that allows exporting directly to STL files.

Brunet tells us that, while he sells quite a few of his fractals on Shapeways, he really has spent more on buying them himself than he has earned through sales. He hopes to break even one of these days, perhaps this year or next. Regardless, his 3D printed fractals are gaining him quite a bit of attention.

“Most recently, one of my sculptures has been shown at the Brown Symposium at Southwestern University in Texas as part of an art exhibit dedicated to 3D printing called ‘What Things May Come‘. Even if this is just a hobby, my next large scale project in 3D printing is to collaborate on the build of a massive 3D printed fractal temple for the Burning Man festival in Nevada, hopefully in 2017.

Stay tuned!”

Even though I don’t have an interest in mathematics, like Brunet does, I certainly have an appreciation for the designs that he has created. I may just end up buying a few of his incredible fractals for myself. What do you think about Brunet’s fractals? Have you purchased any yourself? Discuss in the 3D Printed Fractals forum thread on 3DPB.com. Also be sure to check out Brunet’s YouTube channel, as well as some additional photos below.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed fractal • 3d printed fractals • 3d printed math • fractals • incendia • mandelbulb3D • math • mathematics • MeshLab • shapeways

Please enable JavaScript to view the comments powered by Disqus.

3D printed fractals - a childhood dream!

3D printing

Subscribe author

Subscribe

Don't want

17

I welcome everyone!

We recently talked about fractals in the article Mega Art Projects in 3D Printing, FRACTALS. (part 3).

(part 3).

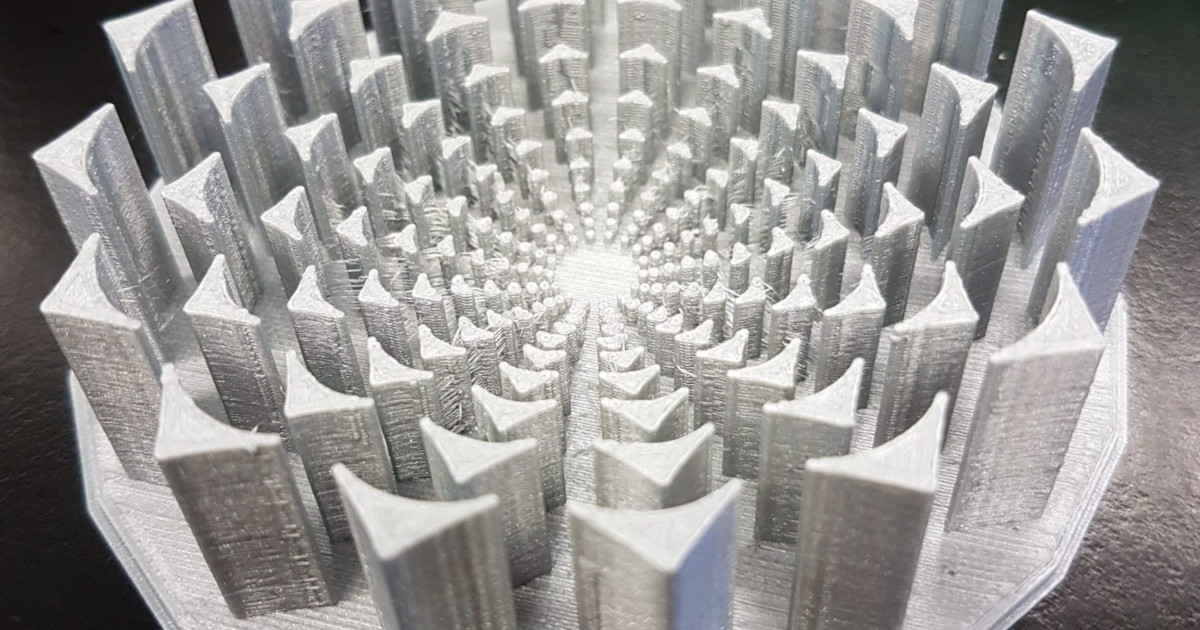

The infinite variety of which is amazing. Now many people can make a digital fractal in 2D format, since there are a lot of programs that generate fractals with one click. But not many people can print a fractal, turn a unique miracle in their hands - a mathematical sculpture. The main reason is the difficulty in extracting a 3D fractal from the software that created it.

Let's look at one way to create, extract and print a fractal.

We need a couple of programs that are freely available.

Mandelbulb 3D program (in this program it is easy to create fractals, it is with one click that you can export the finished fractal voxel to a PNG image sequence).

Fiji program (and this program will allow us to convert our PNG sequence to the long-awaited OBJ format).

And look at the instructions (Thanks to Svetlana!)

And then, post-processing in your favorite editor (ZBrush or Mudbox or MeshLab or another. ..)

..)

Here you can also read the lesson and see how the primitive fractal was printed.

Well, whoever is friends with 3DSMAX can run a new script for modeling fractals in Max. Although not complex shapes, but with the help of splines, great opportunities open up.

The script can be found here. (free access)

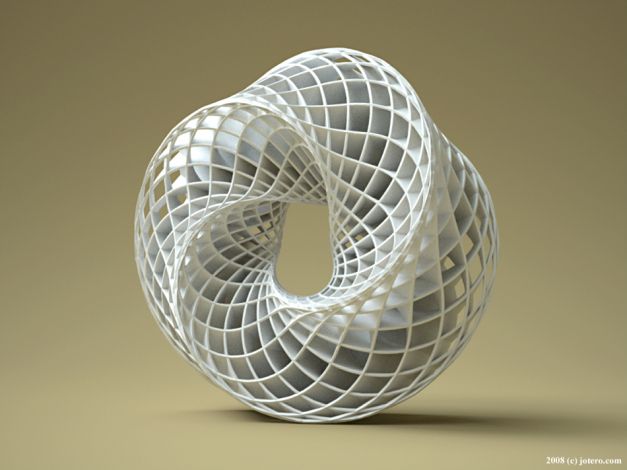

An unplowed field for creative experiments. Started the formula, played with the parameters. I generated such a thing, it remains to 'take out' this fractal from the program and, if desired, immediately send it to the slicer or additionally process the 3D model.

And these are also fractals obtained in Mandelbulb:

But I warn you right away that it is very problematic to print such a fractal (computer power) and even we are not talking about printing, but about detailed export.

Well, any computer can handle such forms of fractals.

Follow author

Follow

Don't want

17

More interesting articles

brtv

Loading

10/16/2022

1375

9

Subscribe to the author

Subscribe

Don't want

Hello my friend! Today I decided to assemble a simple pneumohydraulic generator or Generator...

Read more

Dima_pb

Loading

04.02.2016

74469

157

Follow author

Subscribe

Don't want

Everyone knows about the rollback, but few understand where to start to manage it properly. ...

...

Read more

dagov

Loading

11/17/2017

68762

141

Subscribe to the author

Subscribe

Don't want

In continuation of the previous post for novice users of 3D printers.

This time...

Read more

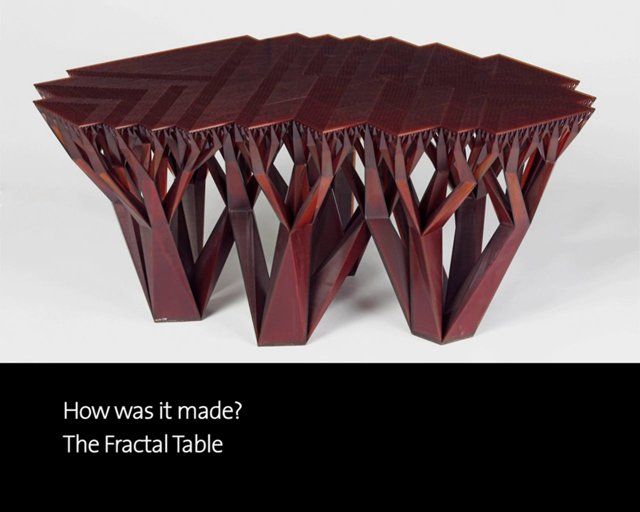

Mega Art projects in 3D Printing, FRACTALS. (part 3)

Creativity

Subscribe to the author

Subscribe

Don't want

8

Hi all!

We continue the conversation about mega-art 3d printing! You can get acquainted with the first parts here: part 1, part 2.

So, the well-known mystical architecture of geometry, endless with its crushed links and bewitching with its unearthly forms - fractals.

This is a self-similarity mathematical set created by the mathematician Mandelbrot.

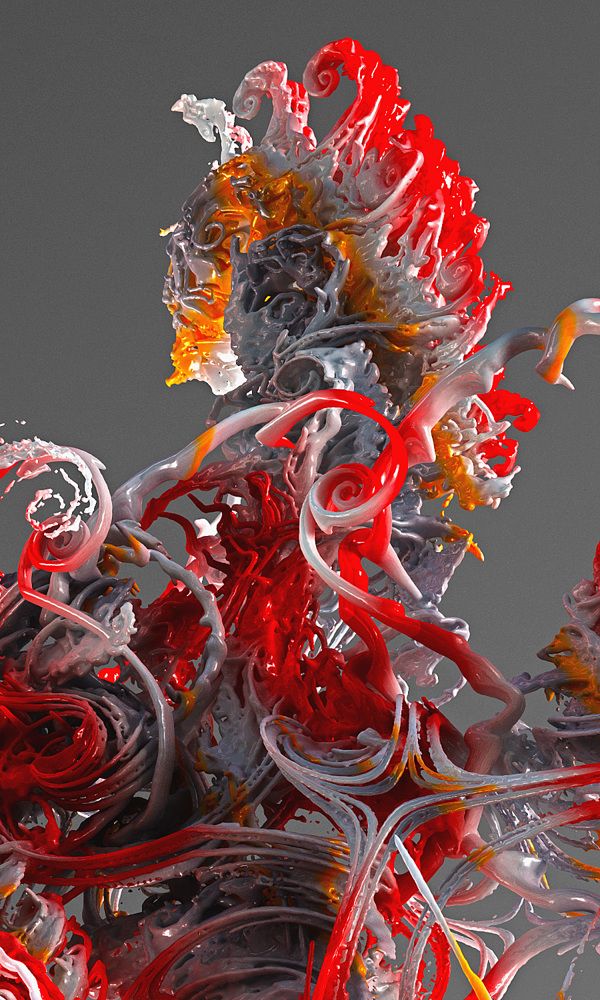

When we look at 3D Mandelbrot fractals, we feel delight and awe from geometry, but calm down from the fact that this is 'in the picture', it means 'computer affairs'. Look at these 3D fractal fragments of 'generative art' so to speak:

Now imagine how it will look if all this generative mathematics is passed through an extruder (!)

Architects Benjamin Dillenburger and Michael Hansmeyer printed a giant art object - 'Arabesque Wall' - generative geometry algorithms for an exhibition in Toronto.

The amount of working materials for printing this 'design' was 50 GB.

The Arabesque wall, 3 meters high, was assembled from 12 printed elements, with a total weight of 800 kg.

The rhythmic, weaves of the Arabesque Wall evoke individual interpretations of the viewers and make them come up and touch the wall to explore all the details and feel new impressions - surprise, excitement or irritation.

Next project 'Digital Grotesque' by architect Michael Hansmeyer.

The concept of this strange architectural object is to mislead the viewer when trying to classify this architecture. Weaving chaos and order, artificial and living, a hopeless search for existing styles. It's all generative geometry.

Digital Grotesque was also printed for an exhibition in Canada.

The dimensions of this art object are amazing.

Everything was printed with sandstone and fixed with resin. Layer thickness 0.2mm.

Process for creating fractal geometry:

There are now many possibilities to create a 3D model of generated geometry or fractals. One of the ways is the famous Java-based Processing.

It allows you to create an amazing world of 'gaudism', which is of course hard to imagine printed without soluble support. You will have to take a printer with two extruders.

Follow author

Subscribe

Don't want

8

More interesting articles

13

Subscribe to the author

Subscribe

Don't want to

I didn't plan to print this model, but everything came out almost as spontaneously as with the state...

Read more

12

Subscribe to the author

Subscribe

Don't want to

Good day gentlemen and ladies!

&nbs...

Read more

daymon

Loading

08/28/2017

30248

148

Subscribe to the author

Subscribe

Don't want

Hi all.