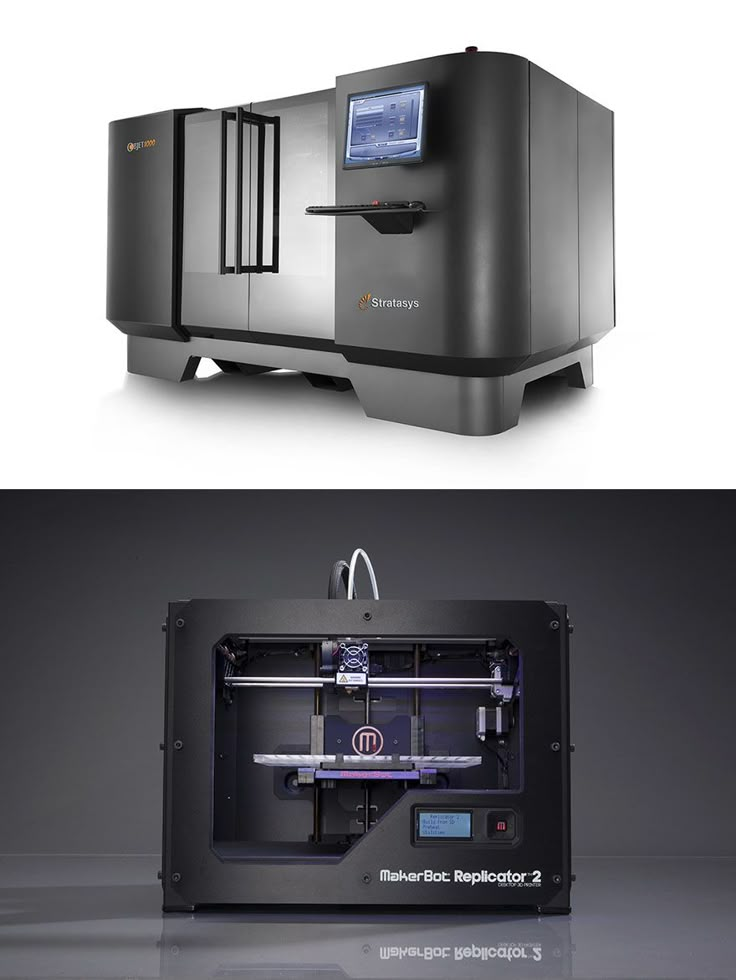

Stratasys polyjet 3d printer

PolyJet High Resolution 3D Printing Technology

PolyJet 3D Printing Technology

PolyJet technology is renowned for its outstanding realism and breathtaking aesthetics. The technology works similarly to traditional inkjet printing, but instead of jetting ink onto paper, a print head jets liquid photopolymers onto a build tray where each droplet cures in a flash of UV light.

Every PolyJet 3D Printer offers sharp precision, smooth surfaces and ultra-fine details. And, by combining a variety of photopolymers in specific concentrations and microstructures the most sophisticated PolyJet systems can simulate everything from plastics and rubber to human tissue — and produce a full gamut of colors. You can now create prototypes, models, textures, and patterns that are incredibly detailed and with 1000s of material options to choose from you can incorporate diverse material properties and aesthetics.

Synonyms and similar technologies: multijet printing, photopolymer jetting

Multiple materials in a single print

High resolution down to 16-microns

Full-colour with overlays and textures

Over-mold without tooling

How Polyjet Works

Polyjet 3D printing technology works by jetting layers of curable liquid photopolymer onto a build tray.

- Pre-Processing: Preparation software determines the arrangement of photopolymers to be cured and support material from a native 3D CAD file automatically.

- Production: Polyjet printers instantly cure the droplets of liquid photopolymer using UV. Thin layers accrue onto the build tray to create the 3D part(s). Where support is needed, the printer will jet removable support material.

- Support Removal: Material is easily removable by hand, with water or in a solution bath. No post-curing is required as the 3D printed part is ready to handle straight off the build tray.

Advantages

Printed parts with Polyjet technology are smooth, polished and accurately detailed.

- Polished, smooth and detailed prototypes that simulate end use parts.

- Detailed and precise parts such as realistic teeth and gums, implant models, and even maxillofacial models

- Create complex shapes, intricate detail, and delicate features.

- Integrate a wide variety of materials and colors into individual models for unmatched efficiency.

Materials

PolyJet Technical Specifications

Maximum Accuracy | Maximum Accuracy0.1-0.3 mm |

Layer Resolution | Layer Resolution16 microns, or 0.016mm/0.0006"X/Y resolution of 0.0017 |

Minimum Wall Thickness | Minimum Wall Thickness1mm |

Maximum Part Dimensions (Single Build) | Maximum Part Dimensions (Single Build)490 x 390 x 200 mm (19.3 x 15.35 x 7.9 in.) |

Shore Hardness Ranges | Shore Hardness Ranges27A - 95A |

Finishes | Finishesmatte or glossy, additional finishes available as a service |

Desktop Design Series

Print small, precise models in a single material, right on your desktop.

Design Series

Gain efficiency and design freedom with more material options and hands-free support removal.

Objet Eden260VS

Objet260 Connex3

Production Series

Bring agility and aesthetics to every stage of product development with the widest range of colors and material properties for prototypes and tooling.

Introducing three new PolyJet 3D Printers from Stratasys

Stratasys recently released three new PolyJet 3D printers to add to the portfolio. These additions expand capabilities for designers and allow for better quality, full colour, functional prototypes.

New PolyJet Stratasys 3D Printers (J55 Prime, J35 Pro, J5 MediJet)

Stratasys J35 Pro

Let’s start with the Stratasys J35 Pro, a low-cost all-in-one 3D printer. This office friendly 3D printer offers full colour, multi-material printing for designers and engineers in a much smaller compact package. Use up to three different materials separately or simultaneously to produce concept models, functional prototypes, jigs, fixtures, and more.

The J35 Pro allows prototypes to look, feel, and function like the final product. Designs that were once outsourced can now be created in-house in a fraction of the time, which saves both time and budget. Start iterating earlier, correct errors easily and verify designs more efficiently, so you can get your design to market faster.

Learn More

Stratasys J55 Prime

The new Stratasys J55 Prime extends the J55 outstanding modeling offering from the visual full colour to tactile, textual, and feeling sense. Includes the ability to combine rubber-like shore (elastico), high-impact (D-ABS), VeroContact (Biocompatibility) materials together with the full-colour Pantone validate capabilities.

If you are familiar with the Stratasys J55 3D printer, the key differences in the J55 vs J55 Prime are:

- Addition of more than 140K colour space

- Opaque colours

- High tough – D-ABS (Ivory)

- Flexible/Shore – Elastico (Clear and Black)

- Biocompatibility (VeroContact Clear)

The addition of VeroUltra opaque colours is perfect for the following applications:

- Toys & Figurines: High fidelity modeling with fine detail simulation for the toy industry

- Consumer Electronics: ideal solution for fine thin plastic models with textures simulating fabrics or wood for consumer electronics.

- Consumer Goods: saturated colours, smooth tones, and fine textures allows consumer goods to be modeled to the highest realism for appearance.

- Automotive: perfect for expo models with the capabilities for transparent parts, back-lit panels, and buttons.

- Packaging: ideal for simulating simple and complex packaging including all textures, text, and logos.

Learn More

Stratasys J5 MediJet

The last addition is the Stratasys J5 MediJet. This economical, compact 3D printer is ideal for the medical industry.

The new J5 MediJet PolyJet 3D printer has multi-materials and multi-colour capabilities allowing academic medical centres, hospitals, and medical device companies to create vivid anatomical models and drilling and cutting guides that are sterilizable and biocompatible.

J5 MediJet applications include:

- Hospitals & Academic Medical Centers: Patient: specific 3D printed medical models can help improve patient outcomes by allowing medical professionals to train and better plan for surgical procedures.

- For Medical Device Companies: Enhance training and education programs and improve product quality. Create consistency in new medical device development and testing to enhance product quality, reduce costs and accelerate time to market.

- For Doctors & Surgeons: Improve clinical outcomes, increase efficiency, and reduce waste using models based on real patient anatomy.

Learn More

Stratasys professional 3d printers at factory price with shipping

industrial 3d printers

professional 3d printers

finished product post-processing

metal powder production and processing

3d scanners

3D printer Stratasys Polyjet J55 Prime

Article Polyjet J55 Prime

- Manufacturer: Stratasys

- Print technology: PolyJet

- Printing area (WxDxH), mm: up to ⌀1174 cm2; height 190 mm

- Minimum layer thickness, µm: 18

Call for price

3D printer Stratasys F120

Article strat-f120

- Manufacturer: Stratasys

- Print technology: FDM, FFF

- Print material: Plastic

Ask price

Stratasys F170 3D printer

Article strat-f170

- Manufacturer: Stratasys

- Print technology: FDM, FFF

- Print material: Plastic

Get price

3D printer Stratasys F270

Article strat-f270

- Manufacturer: Stratasys

- Printing technology: FDM, FFF

- Printing material: Plastic

Ask price

3D printer Stratasys F370

Article strat-f370

- Manufacturer: Stratasys

- Print technology: FDM, FFF

- Print material: Plastic

Get price

3D printer Stratasys Polyjet J35 PRO

Article Polyjet J35 PRO

- Manufacturer: Stratasys

- Print technology: PolyJet

- Print area (WxDxH), mm: up to ⌀1174 cm2; height 158 mm

- Minimum layer thickness, µm: 18

Ask for price

3D printer Stratasys J5 Medijet

Article J5 Medijet

- Manufacturer: Stratasys

- Print technology: Polyjet

- Printing Material (SHGGHV), Memim: 140x20021

- , MM: 140x190

- 18

Ask for price

3D printer Stratasys J5 Dentajet

Article J5 Dentajet

- Manufacturer: Stratasys

- Print technology: Polyjet

- Printing Material (SHGGGHV), MM: 140x20021

- , MM: 140x190

- 18

Ask for price

3D printer Stratasys J850 TechStyle

Article J850 TechStyle

- Manufacturer: Stratasys

- Printing technology: PolyJet

- Printing material: Photopolymer

- Printing area (WxDxH), mm: 460x360x50

- Minimum layer thickness, microns: 27

Ask price

3D printer Stratasys Fortus 450MC

Article strat-ft-450

- Manufacturer: Stratasys

- Print technology: FDM, FFF

- Print material: Composite-filled materials, Plastic

Ask for price

3D printer Stratasys J850 digital anatomy

Article strat-j750

- Manufacturer: Stratasys

- Print technology: PolyJet

- Print material: Photopolymer

3D printer Stratasys F770

Article Stratasys F770

- Manufacturer: Stratasys

- Print technology: FDM, FFF

- Print material: Plastic

- Print area (WxDxH), mm: 1000x610x610

Get price

3D printer Stratasys J850 Pro/Prime

Article strat-j850

- Manufacturer: Stratasys

- Printing technology: PolyJet

- Printing material: Photopolymer

3D printer Stratasys J826

Article strat-j826

- Manufacturer: Stratasys

- Print technology: PolyJet

- Print material: Photopolymer

Get price

3D printer Stratasys F900

Article strat-f900

- Manufacturer: Stratasys

- Print technology: FDM, FFF

- Print material: PEEK / ULTEM, Plastic

3D printer Stratasys J700 Dental

Article strat-j700d

- Manufacturer: Stratasys

- Print technology: PolyJet

- Print material: Photopolymer

Get price

3D Printer Stratasys J720 Dental

Article Strat-J720d

- Manufacturer: Stratasys

- Printing Technology: Polyjet

- Print material: Photopolymer

Learn the price0001

Supplier of 3D equipment since 2010

+7 495 646-15-338 800 333-12-82

3D scanners3d-printer-printer-service

On the Cli-Zakopupkupovsancyclopedia 3D

Contact

Contact

Block - printing based on the layer-by-layer curing of a liquid photopolymer material under the influence of ultraviolet radiation. Used in Stratasys 3D printers.

Used in Stratasys 3D printers.

- Function

- Advantages

- Press examples

- Select 3D printer

- Principle of operation

- Advantages

- Stress Examples

- Select 3D-Printer

What is better to print: Products, tetups, tamped models. models, samples for molding in silicone.

Advantages: high surface quality, accuracy, construction speed, washable support.

Alternative: MJM technology (also based on layer-by-layer UV illumination of photopolymer material).

What is better to print: product prototypes, test models, burnt-out master models, silicone casting samples.

Advantages: high surface quality, accuracy, construction speed, washable support.

Alternative: MJM technology (also based on UV illumination of photopolymer material).

Function

The 3D printer print unit sprays the model material and support material in thin layers (16/30 µm) according to the data of the 3D mathematical model. Each layer is polymerized by ultraviolet light immediately after application. The result is an object that does not require any additional surface treatment. A model printed using PolyJet technology can be used immediately after the printing process is completed.

Each layer is polymerized by ultraviolet light immediately after application. The result is an object that does not require any additional surface treatment. A model printed using PolyJet technology can be used immediately after the printing process is completed.

How it works

The 3D printer print unit sprays the model material and support material in thin layers (16/30 µm) according to the data of the 3D mathematical model. Each layer is polymerized by ultraviolet light immediately after application. The result is an object that does not require any additional surface treatment. A model printed using PolyJet technology can be used immediately after the printing process is completed.

Benefits of Technology

Accuracy and Finished Product Details

PolyJet technology delivers high build accuracy of 0.02-0.085 mm for objects up to 50 mm in size. For objects larger than 50 mm, the construction accuracy varies from 0. 1 to 0.2 mm. Printing accuracy depends on the geometry of the model, the parameters of its construction and orientation, as well as the material used.

1 to 0.2 mm. Printing accuracy depends on the geometry of the model, the parameters of its construction and orientation, as well as the material used.

Large selection of materials with different properties

PolyJet-grown objects have different properties, depending on the material used. Materials differ from each other in mechanical, thermal, electrical and chemical characteristics. The FullCure line of PolyJet printing media offers a choice of rigid, flexible, translucent, transparent, and certified biocompatible media.

Soluble support material

In the process of building complex products, various cavities, overhanging structures are often present. To prevent their collapse, all voids under such elements are filled with a special material - support material. In addition, such material serves as additional insurance when printing thin walls and complex structures. FullCure705 Support is a versatile model support material that can be easily removed with water in an ObjetWaterJet flush station.

Benefits of Technology

Accuracy and Finished Product Details

PolyJet technology delivers high build accuracy of 0.02-0.085 mm for objects up to 50 mm in size. For objects larger than 50 mm, the construction accuracy varies from 0.1 to 0.2 mm. Printing accuracy depends on the geometry of the model, the parameters of its construction and orientation, as well as the material used.

Large selection of materials with different properties

PolyJet-grown objects have different properties, depending on the material used. Materials differ from each other in mechanical, thermal, electrical and chemical characteristics. The FullCure line of PolyJet printing media offers a choice of rigid, flexible, translucent, transparent, and certified biocompatible media.

Soluble support material

In the process of building complex products, various cavities, overhanging structures are often present. To prevent their collapse, all voids under such elements are filled with a special material - support material.