Stratasys fortus 900mc 3d printer price

Stratasys receives largest ever F900 3D printer order from AM craft

0Shares

3D printer manufacturer Stratasys has received its largest-ever to date orders after aerospace firm AM Craft purchased four of its F900 3D printers.

AM Craft’s order adds to its existing portfolio of four Fortus F450mc 3D printers and will boost production capacity. Following the company’s recent investment, AM Craft is now one of the largest independent aerospace-focused 3D printing service providers in Europe, the Middle East, and Africa (EMEA).

AM Craft CEO and Co-founder Jānis Jātnieks explained the impact of using Stratasys’ 3D printing technology: “One of the mainstay pillars that enables us to realize this business case into real-world application is Stratasys’ highly-repeatable FDM based 3D printing technology in conjunction with aerospace-grade materials like ULTEM 9085 resin. It allows us to meet strict rules and regulations around certification that require the highest level of repeatability and traceability with every part manufactured. ”

The Stratasys F900 3D printer

Stratasys’ flagship F900 Fused Deposition Modeling (FDM) system has been in production for ten years and has undergone three generations of improvement. Based on the foundations on the Fortus 900mc, the F900 is a convenient fit for manufacturers because it supports a wide spectrum of applications. According to Stratasys, the 3D printer’s main features include rapid production, internal cameras, and diverse material selection, lending itself to aerospace, automotive and industrial applications.

Wayne Benson, Director of Manufacturing Product Management at Stratasys described the 3D printer as “the most versatile, reliable, and repeatable on the market today.” It is Stratasys’ largest system and thanks to its elevated oven temperature capacity, the FDM system is capable of printing high-performance thermoplastics. The F900 is also compatible with 14 materials, enabling AM Craft to pursue either basic prototyping with their SA material or high strength printing with the Nylon 12 CF.

F900’s FDM-based technology combined with aerospace-grade materials such as ULTEM 9085 resin, also allows aerospace companies to meet a stringent set of regulations. The flame-retardant, high-performance ULTEM 9085 resin, for example, manages to fulfill the strict flame, smoke, and toxicity (FST) aerospace criteria.

A 3D printed life vest compartment door made from ULTEM 9085. Photo via Reinis Inkens.Remodeling aircraft interiors

AM Craft has installed the F900 systems in order to provide certifiable 3D parts for a wider range of aircraft interior applications, such as remodeling passenger planes or cargo shipments. Jānis explained that the printers have driven profits via the implementation of mobile charging stations and Wi-Fi infrastructure, which have “increased customer safety measures and inflight customer service.” AM Craft’s investment will also enhance the already existing hardware line up of four Fortus F450mc 3D printers. Collectively, the aerospace company will now operate with eight FDM-based machines, at its new facility in Riga. The complex, which is dedicated to fulfilling AM Craft’s application requirements, is expected to be fully operational in Q4 2020.

The complex, which is dedicated to fulfilling AM Craft’s application requirements, is expected to be fully operational in Q4 2020.

AM Craft’s new systems will enable it to fabricate a new range of aircraft interior components such as aircraft seating, paneling, and ducting. The Stratasys 3D printers will also allow its customers to customize their cabins. According to Yann Rageul, Director of Manufacturing Solutions at Stratasys this will be possible thanks to the “repeatable, cost-effective, low volume manufacturing” offered by Stratasys FDM technology.

One step ahead

Following the F900 3D printer order, Rageul said: “As the COVID-19 pandemic caused the world to re-think supply chain strategies, AM Craft was already a step ahead.” Raguel added that just as Stratasys FDM technology had rapidly adjusted to producing Personal Protective Equipment (PPE), aerospace companies should also advance their goals for in-cabin customization. “Repeatable, cost-effective, low-volume manufacturing, that’s exactly what AM Craft has invested in with Stratasys,” said Rageul.

Applications of Stratasys’ 3D printing technology

In the industrial sector, the packaging solutions company Marchesini Group S.p.A , is also customizing production through 3D printing. Mirko Fortunati, responsible for Coordinating the Mechanical Workshops explained that “Integrating our industrial-grade FDM 3D printers into our production process has drastically reduced our part lead times from several weeks to a few days.”

Multinational aerospace company BAE Systems, has installed Stratasys F900 systems, and recently purchased its fourth F900 printer. The company believes the printer “plays an important role in this initiative, as it helps us meet our overall company objective to reduce costs and time-to-market.” Elsewhere, automotive manufacturer, General Motors has incorporated 17 Stratasys FDM 3D printers in its operations, elucidating their “speed, weight, reduction and cost-efficiency” as the core advantages.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows AM Craft Co-founders Jānis Jātnieks and Didzis Dejus next to Stratasys F900. Photo via Reinis Inkens.

Tags AM Craft BAE Systems General Motors Janis Jatnieks Marchesini Group S.p.A Mirko Fortunati Stratasys Wayne Benson Yann Rageul

Ippolita Magrone

Stratasys F900 Production 3D Printer

THE STRATASYS

Industrial Strength, Durability & Scale

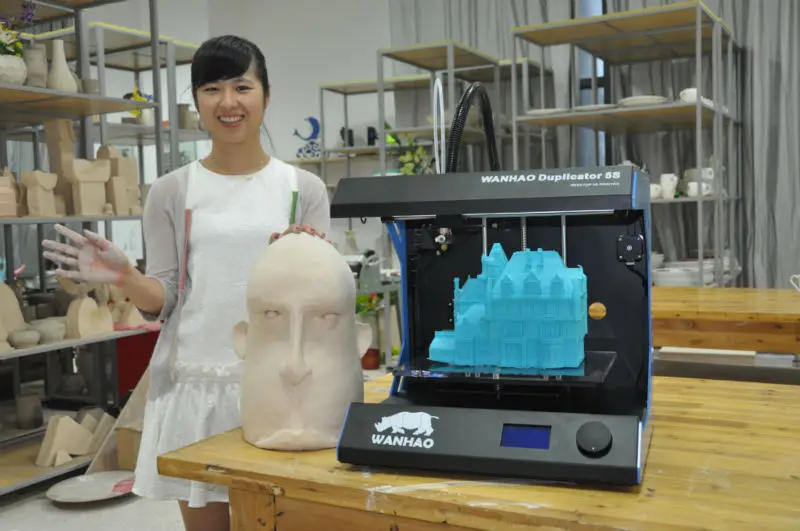

The Stratasys F900 is the most capable and powerful FDM system available, delivering remarkable production agility and high return on investment. Produce demanding functional prototypes, production parts, jigs, fixtures and factory tooling with unmatched accuracy, repeatability, and predictability. The Fortus 900mc from Stratasys is your own in-house factory, welcome to the future of direct digital manufacturing.

Produce demanding functional prototypes, production parts, jigs, fixtures and factory tooling with unmatched accuracy, repeatability, and predictability. The Fortus 900mc from Stratasys is your own in-house factory, welcome to the future of direct digital manufacturing.

View Video Brochure Request Demo Request a Quote

- Overview

- Key Features

- Advantages

- Materials

- Specifications

- Request a Quote

Think Big, Print Big

The Fortus 900mc from Stratasys is the ultimate manufacturing-grade production 3D printer. With the largest build envelope of any Fortus 3D printing system you can handle the most demanding manufacturing applications. With unmatched accuracy, repeatability and precision with a wide variety of engineering grade thermoplastics you can tackle a range of industrial applications. This Gen II system boasts new mechanical, electromechanical and electrical systems as well are powerful control software and heavy-duty hardware to deliver superior throughput and reliability.

This Gen II system boasts new mechanical, electromechanical and electrical systems as well are powerful control software and heavy-duty hardware to deliver superior throughput and reliability.

Explore the Fortus 900mc by watching the video

Build Size

The largest build envelope and highest throughput with a tray size of 36 x 24 x 36 inches

Production-Grade Materials

Build with many of the same standard, engineering-grade and high-performance thermoplastics you use in traditional manufacturing processes.

Lights-Out Production

An internal camera lets you monitor progress remotely. Plus, you can get up to two weeks of unattended build time with dual material bays and high-capacity material options.

3D Print Fast

The special acceleration kit for the Fortus 900mc comes with the T40A extrusion tip designed to help meet production demands with ease.

Certified for Production

Standard certifications are included with the system and reduce the workload required to qualify 3D printers for a production floor.

No Special Requirements

The Fortus 900mc does not require any special facilities, ventilation, or specific skill sets from operators. It is designed to be an easy-to-use advanced manufacturing solution.

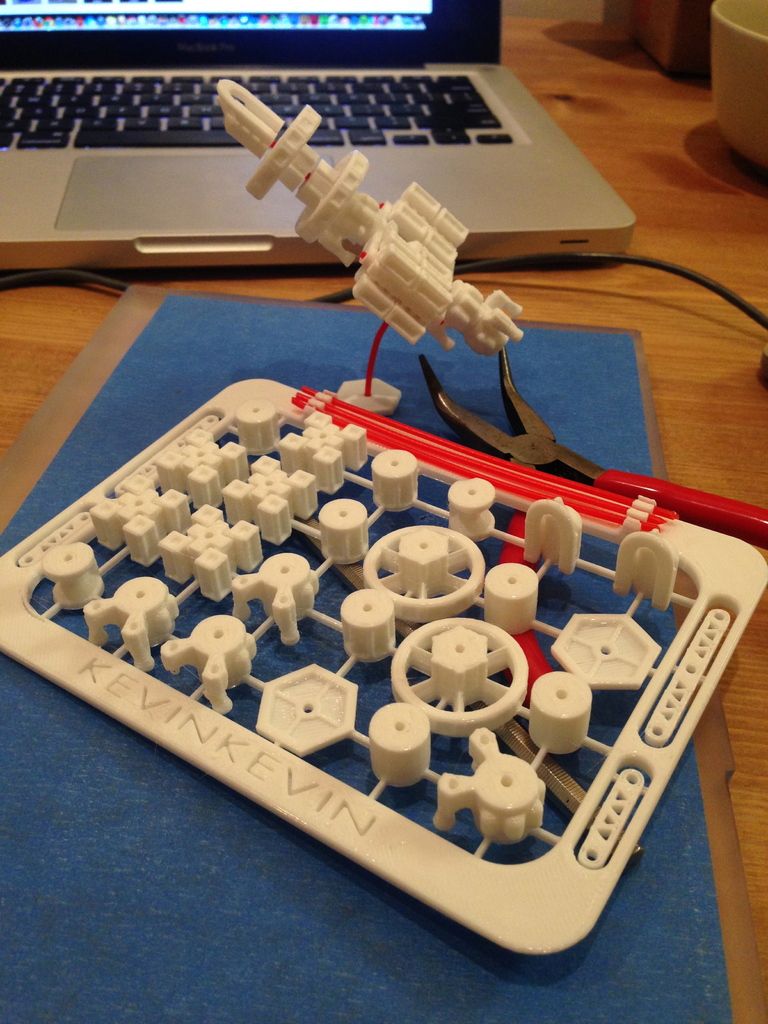

FDM builds parts in production-grade thermoplastics, enabling the most durable parts. Fortus systems use a wide range of thermoplastics with advanced mechanical properties so your parts can endure high heat, caustic chemicals, sterilization and high-impact applications

LEARN MORE ABOUT FDM

Opening the Way for Real Possibilities

Fortus 3D Production Systems can streamline processes from design through manufacturing, reducing costs and eliminating traditional barriers along the way. With the Fortus 900mc, you can build assembly tools, tooling masters, and eliminate tooling costs for short runs. You can produce robust production parts, large jigs and fixtures, and functional prototypes all in-house on one versatile machine.

Meet the Demands of Real Production

Fortus systems are as versatile and durable as the real parts they produce. They boast the largest build envelopes and material capacities in their class, delivering longer, uninterrupted build times, bigger parts and higher production run quantities than other additive manufacturing systems. Plus, they are true production workhorses, delivering the high throughput, duty cycles and utilization rates that make direct digital manufacturing (DDM) not only possible, but practical. With production phase optimization you can change designs on the fly, revise production materials and stay on your production schedule.

They boast the largest build envelopes and material capacities in their class, delivering longer, uninterrupted build times, bigger parts and higher production run quantities than other additive manufacturing systems. Plus, they are true production workhorses, delivering the high throughput, duty cycles and utilization rates that make direct digital manufacturing (DDM) not only possible, but practical. With production phase optimization you can change designs on the fly, revise production materials and stay on your production schedule.

Manufacturing Ready Materials

The true test of any production 3D printer is the ability to print in materials that are predictable and repeatable. The Fortus 900mc from Stratasys is designed for exactly that. Its temperature controlled environment can support 3D prints in 13 engineering-grade thermoplastics which have a wide range of mechanical properties suitable for different industries and applications. Your parts will be able to endure high-heat, caustic chemicals, sterilization and high-impact not to mention the strenuous approval and certification process for critical applications.

GKN Aerospace Cuts Costs and Production Times with Additive Manufacturing

Aerospace

GKN Aerospace is a well-known multi-technology tier-one aerospace supplier and distributes to over 90% of the worlds engine and aircraft manufacturers. Over the last 30 years, GKN Aerospace has also gained prominence as a leader in the use of 3D printing, also known as additive manufacturing, for military, space, and commercial markets. Discover how GKN cuts costs and production times with 3D printing.

View Case Study

Sodimas

Heavy Industries

View Case Study View Video

Sodimas

Standard Thermoplastic

Print with standard ABS thermoplastic printing material for great impact and flexural strength. They also come in 10 great colours with great mechanical strength

Engineering Thermoplastic

Print with engineering-grade material to create advanced prototypes and custom tooling for applications that demand high fatigue resistance- with clean, hassle-free FDM technology

High-Performance Thermoplastic

Use the best of the best with outstanding strength and thermal stability making this material ideal for advanced tooling & prototyping applications in industries such as automotive, aerospace, and medical

Meet the Demands of Real Production

Bring production in-house, and experience a higher throughput with longer, uninterrupted build times.

get a quote

Technical Specifications

Build Tray Size | Build Tray Size91.4 x 60.9 x 91.4 cm [36 x 24 x 36 in] |

Layer Thickness | Layer Thickness0.330 mm [0.013 in]0.254 mm [0.010 in] 0.178 mm [0.007 in] |

Model Material | Model MaterialStandard thermoplastic:ABS-M30 ABS-M30i ABSi ABS-ESD7 Engineering thermoplastic: High-performance thermoplastic: |

Support Material | Support MaterialSoluble Support:ABS-M30, ABS-M30i, ABSi, ABS-ESD7, PC-ABS Breakaway Support: |

Power Requirements | Power Requirements230VAC nominal 3-phase service with 5% regulation230VAC as measured phase-to-phase; 50 Hz or 60Hz; 40 Amp circuit |

Machine Size & Weight | Machine Size & Weight277. 2 x 168.3 x 202.7 cm [109.1 x 66.3 x 78.1 in] 2 x 168.3 x 202.7 cm [109.1 x 66.3 x 78.1 in] 2869 kg [6325 lbs.] |

3D printer Fortus 900mc from manufacturer Stratasys Ltd )

Construction area, mm: 914x610x914

Material for printing: PC plastic, ABS-M30, FDM Nylon 12, PC-ABS, ABS-ESD7, ABSi, ABS-M30i, PC ISO, PPSF, ULTEM 9085,

All features

Fortus 900mc 3D printer description

The Fortus 900mc system is the most powerful FDM (Fused Deposition Modeling) system. It is characterized by high flexibility, precision and cost-effectiveness. Two significant benefits: all material options in the Fortus 3D manufacturing system range and a 3D print chamber. Its only competitor is outdated methods and procedures. Fortus 9 3D Prototyping Manufacturing System00mc allows you to create reliable and accurate parts with high repeatability up to 914x610x914 mm. With nine different materials, this system is suitable for creating fixtures, factory tooling and final parts, as well as the most complex 3D prototypes. This machine is equipped with two consumable compartments to ensure maximum continuous production.

It is characterized by high flexibility, precision and cost-effectiveness. Two significant benefits: all material options in the Fortus 3D manufacturing system range and a 3D print chamber. Its only competitor is outdated methods and procedures. Fortus 9 3D Prototyping Manufacturing System00mc allows you to create reliable and accurate parts with high repeatability up to 914x610x914 mm. With nine different materials, this system is suitable for creating fixtures, factory tooling and final parts, as well as the most complex 3D prototypes. This machine is equipped with two consumable compartments to ensure maximum continuous production.

About the Fortus 900mc printer

Materials include high performance thermoplastics for biocompatibility, static dissipation and resistance to heat and chemicals. You can choose from three layer thicknesses and thus find the right balance between precision of detail and maximum speed of deposition welding. Bandwidth Fortus 900mc is more than twice the bandwidth of the Fortus 250mc. Fortus 900mc creates components from nine production grade engineering thermoplastics: ABS-ESD7 - provides static dissipation ABSi - provides transparency ABS-M30 - provides increased tensile and flexural strength, impact and environmental resistance ABS-M30i - ensures biocompatibility PC - provides excellent physical and mechanical properties and heat resistance PC-ABS - provides maximum impact strength, as well as high physical and mechanical properties and heat resistance at the level of PC and a surface finish at the level of ABS PC-ISO - ensures biocompatibility and high strength PPSF - Provides the highest resistance to heat and chemicals ULTEM 9085 - provides an optimal combination of physical, mechanical, chemical and thermal properties.

Bandwidth Fortus 900mc is more than twice the bandwidth of the Fortus 250mc. Fortus 900mc creates components from nine production grade engineering thermoplastics: ABS-ESD7 - provides static dissipation ABSi - provides transparency ABS-M30 - provides increased tensile and flexural strength, impact and environmental resistance ABS-M30i - ensures biocompatibility PC - provides excellent physical and mechanical properties and heat resistance PC-ABS - provides maximum impact strength, as well as high physical and mechanical properties and heat resistance at the level of PC and a surface finish at the level of ABS PC-ISO - ensures biocompatibility and high strength PPSF - Provides the highest resistance to heat and chemicals ULTEM 9085 - provides an optimal combination of physical, mechanical, chemical and thermal properties. Fortus 900mc Owners Articles

More

Popular 3D Printers

Anet A8

1448 articles 1714 owners

Anet A8 3D printer is a budget 3D printer from China. Region...

Region...

3 offers from 12000 ₽

Anet A6

1121 articles 1611 owners

Anet A6 3D printer - Chinese version of RepRap project P...

3 offers at the contractual price

Anycubic i3 Mega

775 items 975 owners

Anycubic I3 MEGA is a 3D printer from a Chinese manufacturer...

5 offers

Show more

PC (polycarbonate) - plastic for Stratasys 3D printers of the Fortus series. Volume 1510cm.

PC (polycarbonate) - plastic for Stratasys 3D printers of the Fortus series. Volume 1510cm.

Volume 1510cm. - home

- Expendable materials

- iSQUARED

- PC (1510cc)

- Specifications

-

Manufacturer

iSQUARED

-

Suitable for 3D printers

Fortus 900mc

Fortus 900mc Plus

Fortus 450mc

Fortus 400mc

Fortus 400mc Plus

Fortus 380mc

Fortus 360mc

Fortus 360mc Plus -

Available colors

Black, white

-

Tensile modulus

2022 MPa -

Tensile stress, type I, 5mm/min

57 MPa -

Tensile deformation, type I, 5 mm / min

-

Modulus of elasticity in bending 1.

Learn more