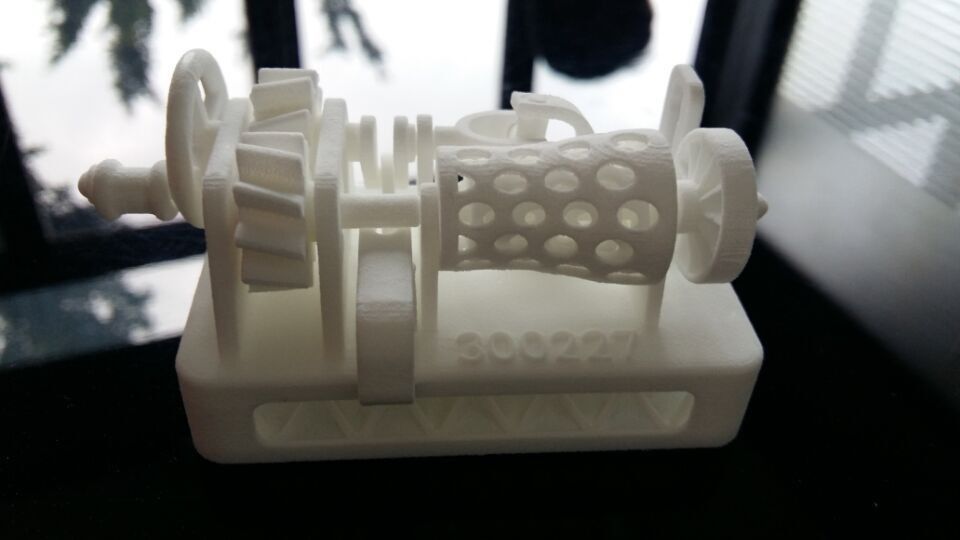

Rapid prototyping services 3d printing

Tech Data - Rapid Prototyping ServicesRapid Prototyping Services

Widest Range of Real Thermoplastics

Rapid Prototyping Services, LLC manufactures parts in real, durable thermoplastic materials. Parts can be manufactured for a wide range of applications such as prototyping, functional testing, high heat and medical applications. End use parts are available using the materials below.

| ABSplus-P430 | ABSi | ABS-M30 | ABS-M30i | ABS-ESD7 | PC-ABS | PC-ISO | PC | NYLON 12 | ULTEMTM-9085 | PPSF | |||||||||||||||||||||||||||||||||||||||||||||

| Layer Thickness | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.013 Inch (0.330 mm) | x | X | X | X | — | X | X | X | X | X3 | X4 | ||||||||||||||||||||||||||||||||||||||||||||

| 0.010 Inch (0.254 mm) | X | X | X | X | X | X | X | X | X | X | X | ||||||||||||||||||||||||||||||||||||||||||||

| 0. | X | X | X | X | X | X | X | X | X | — | — | ||||||||||||||||||||||||||||||||||||||||||||

| 0.005 Inch (0.127 mm) | — | X1 | X1 | X1 | — | X1 | — | X1,6 | — | — | — | ||||||||||||||||||||||||||||||||||||||||||||

| Support Structure | Soluble | Soluble | Soluble | Soluble | Soluble | Soluble | BASS | BASS, Soluble | Soluble | BASS | BASS | ||||||||||||||||||||||||||||||||||||||||||||

| Available Colors |

|

|

|

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||

| Tensile Strength | 5,300 psi (37 MPa) | 5,400 psi (37 MPa) | 5,200 psi (36 MPa) | 5,200 psi (36 MPa) | 5,200 psi (36 MPa) | 5,900 psi (41 MPa) | 8,265 psi (57 MPa) | 9,800 psi (68 MPa) | 7,000 psi (48 MPa) | 10,390 psi (72 MPa) | 8,000 psi (55 MPa) | ||||||||||||||||||||||||||||||||||||||||||||

| Elongation Strength | 3. 0 % 0 % | 4.4 % | 4.0 % | 4.0 % | 3.0 % | 6.0 % | 4.3 % | 4.8 % | 30 % | 5.9 % | 3.0 % | ||||||||||||||||||||||||||||||||||||||||||||

| Flexural Stress | 7,600 psi (53 MPa) | 8,980 psi (62 MPa) | 8,800 psi (61 MPa) | 8,800 psi (61 MPa) | 8,800 psi (61 MPa) | 9,800 psi (68 MPa) | 13,089 psi (90 MPa) | 15,100 psi (104 MPa) | 10,000 psi (69 MPa) | 16,700 psi (115 MPa) | 15,900 psi (110 MPa) | ||||||||||||||||||||||||||||||||||||||||||||

| IZOD Impact, notched | 2.0 ft-lb/in (106 J/m) | 1.8 ft-lb/in (96 J/m) | 2.6 ft-lb/in (139 J/m) | 2.6 ft-lb/in (139 J/m) | 2.1 ft-lb/in (111 J/m) | 3.7 ft-lb/in (196 J/m) | 1.6 ft-lb/in (86 J/m) | 1.0 ft-lb/in (53 J/m) | 3.74 ft-lb/in (200 J/m) | 2.0 ft-lb/in (106 J/m) | 1.1 ft-lb/in (59 J/m) | ||||||||||||||||||||||||||||||||||||||||||||

| Heat Deflection | 204°F (96°C) | 188°F (87°C) | 204°F (96°C) | 204°F (96°C) | 204°F (96°C) | 230°F (110°C) | 271°F (133°C) | 280°F (138°C) | 180°F (82°C) | 333°F (167°C) | 372°F (189°C) | ||||||||||||||||||||||||||||||||||||||||||||

| Unique Properties | Variety of color options | Translucent material | Variety of color options | ISO-10993 USP Class VI5 | Static dissipative, target surface resistance of 107 ohms† | High impact resistance | ISO-10993 USP Class VI5 | Highest tensile strength | Fatigue resistant, high elongation at break | Flame, smoke, toxicity (FST) certified | Highest heat and chemical resistance |

†Actual surface resistance may range from 109 to 106 ohms, depending upon geometry, build style and finishing techniques.

1 0.005 inch (0.127 mm) layer thickness not available for 900mc.

2 See individual material spec sheets for testing details.

3 0.013 inch (0.330 mm) layer thickness for ULTEM not available on 400mc.

4 0.013 inch (0.330 mm) layer thickness for PPSF not available on 900mc.

5 It is the responsibility of the finished device manufacturer to determine the suitability of all the component parts and materials used in their finished products.

6 PC can attain 0.005 inch (0.127mm) layer thickness when used with SR-100 soluble support.

Rapid Prototyping Services by Sculpteo and 3D Object Prototyping

Prototyping is an essential part of your product development. Do you need parts as quickly as possible to validate a project? We will manufacture your parts immediately in our factory-certified ISO 9001.

- ISO 9001

- Fast Turnaround

- Secure File Upload

Benefit from the flexibility of the Additive Manufacturing technology for your prototyping process!

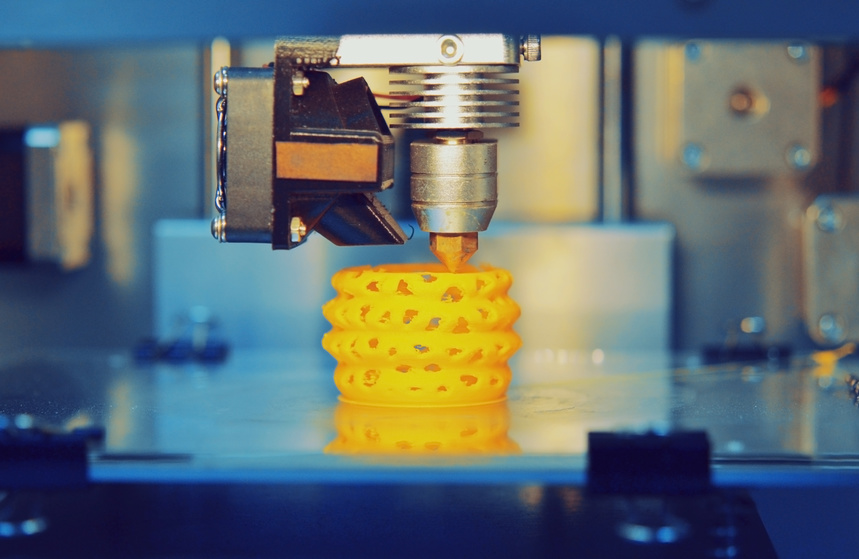

3D Printing is the shortest path between your ideas and a functional prototype in your hands and it can be used at each stage of your manufacturing process. More specifically, 3D printing can be a strong ally at the early stages of your product development. Prototype and iterate with Stereolithography (SLA), Selective Laser Sintering (SLS), HP Multi Jet Fusion (MJF) Fused Deposition Modeling (FDM) or other technologies. Make as many iterations as needed with a great precision and speed up your prototyping process.

More specifically, 3D printing can be a strong ally at the early stages of your product development. Prototype and iterate with Stereolithography (SLA), Selective Laser Sintering (SLS), HP Multi Jet Fusion (MJF) Fused Deposition Modeling (FDM) or other technologies. Make as many iterations as needed with a great precision and speed up your prototyping process.

Benefit from the flexibility of Additive Manufacturing for your prototyping process!

3D Printing is the shortest path between your ideas and a functional prototype in your hands. 3D printing can be a strong ally at the early stages of your product development.

Prototype and iterate with Stereolithography (SLA), Selective Laser Sintering (SLS), or Fused Deposition Modeling (FDM) technologies.

Sculpteo was the partner we needed for producing Tundra, being able to 3D print parts made it possible to create a customizable drone. Our partnership with Sculpteo was an essential part in the creation of this machine.

Alexandre Labesse Hexadrone CEO

3D printing gives us the ability to get our parts quickly, compared to other manufacturing techniques. We can also manufacture complex parts with a finished appearance, which could not be machined. We have been working with Sculpteo since 2014 and the quality keeps improving. Our contacts with the team are regular in order to find the best compromises regarding our needs.

Nicolas RigauxMechanical engineer at Microfilms

At the small scale of the cargo projects we run, 3D printing is the only economical production method for the geometries we need. Using Sculpteo’s service allows us to produce a much more professional quality product than we could achieve in-house, at a much lower time investment.

Jürg GermannHead of Engineering at WeRobotics

We are always looking for performance for our robots, and this fundamentally involves reducing the weight of the various fittings linked to the robots such as their grippers. 3D printing is a solution for us to combine performance, rigidity and mass of these assemblies. We have been working with Sculpteo for 4 years, the quality of the prints has always been very satisfactory and the proximity of our account manager allows us to save time and improve our performance in the realization of our projects.

3D printing is a solution for us to combine performance, rigidity and mass of these assemblies. We have been working with Sculpteo for 4 years, the quality of the prints has always been very satisfactory and the proximity of our account manager allows us to save time and improve our performance in the realization of our projects.

Anthony MOUTEAU Designer / SAS I.D.E.C

3D printing is an opportunity to easily reproduce the structure of a robot. More and more robots are being produced thanks to 3D printing. Additive manufacturing is a long-term trend for the robotic market, just as it is for aeronautic and automobile businesses

Jérôme LAPLACEDirector, Génération Robots / HumaRobotics

Previous

Next

500 +

Parts printed per day

1000 +

Happy customers each year

0 +

Technologies and finishes

0 +

Industrial 3D Printers

Order your 3D printed parts in just a few clicks!

Upload 3D file30+ File formats accepted

Review PrintabilityAutomatic file analysis and repair

Instant Quote75+ material and finishing combinations

Receive Your PartsShipped to your door in just a few days

CUSTOMER STORY

Koovea is a startup based in Montpellier, south of France, specializing in connected temperature monitoring for the logistics of temperature-sensitive products. Their challenges? Develop rapidly a sensor resistant to extreme temperatures and respond to their client’s needs faster by offering customized versions of their products.

Their challenges? Develop rapidly a sensor resistant to extreme temperatures and respond to their client’s needs faster by offering customized versions of their products.

Read more >

Materials Adapted To Prototyping

Benefit from an extensive catalog of 3D printing technologies, from Stereolithography to Selective Laser Sintering and HP Multi Jet Fusion. Using our online 3D printing service, you will access cost-effective and accurate 3D printing materials to give life to your proofs of concept and functional prototypes. Powder-based or resin options are available for your RP process.

Top 3 reasons to use 3D printing for prototyping

Rapid prototyping with 3D printing will help you bring your project to the next level in no time, bringing your ideas to reality efficiently and reliably. Benefit from the rapid prototyping tools offered by additive manufacturing:

- Short Lead Times

- Quick Iteration

- On-Demand Manufacturing

Start your rapid prototyping process today with Sculpteo

Choose a prototyping partner with short lead times and experienced advice using our innovation-oriented point of view. Sculpteo is dedicated to helping you succeed and using additive manufacturing in a way adapted to your business's needs.

Sculpteo is dedicated to helping you succeed and using additive manufacturing in a way adapted to your business's needs.

With 10+ years of expertise in additive manufacturing for production and prototyping, Sculpteo also offers rigorous quality control. With our online 3D printing service and our advanced platform, you get professional 3D printing at your fingertips. Create a free account, upload your 3D files, select your material, technology, and post-processing options, and order online.

We'll take care of the rest in our industrial ISO 9001 factory.

Stop wasting time, start your rapid prototyping process now

Prototypes are an essential step in your product development. Before a more costly step of production, you need to evaluate the design and functionality of your product. An excellent rapid prototyping technique is just what you need! Rapid prototyping allows engineers and designers to manufacture and test their products faster and iterate as much as necessary. Whether to create a scale model of a physical part to validate the shape or its visual aspect, try out an assembly, or build functional features and test them, rapid prototyping will help you achieve your goals in time. Some game-changing technologies, such as additive manufacturing, allows you to create your high-fidelity prototypes,

Whether to create a scale model of a physical part to validate the shape or its visual aspect, try out an assembly, or build functional features and test them, rapid prototyping will help you achieve your goals in time. Some game-changing technologies, such as additive manufacturing, allows you to create your high-fidelity prototypes,

concept models and functional prototypes with an excellent surface finish. Additive manufacturing technology can become your true ally, for all kinds of applications with advanced technologies such as SLS, MJF, Binder Jetting, Polyjet and other technologies. Get rid of the disadvantages of manufacturing technologies such as CNC machining and benefit from the flexibility you deserve to grow your projects.

Additive manufacturing can boost your company, not only thanks to rapid prototyping. Discover how you could benefit from a more scalable, flexible, and resilient manufacturing process for prototyping and production.

What is design for additive manufacturing (DfAM), and what are the benefits? We are going to see how this design could be a real asset for your business.

3D printing prototypes: what are the advantages? Discover how 3D printing can help you develop advanced prototypes thanks to a large variety of materials.

How to identify 3D printing opportunities for your business? Find out our 10 best tips and see how 3D printing could be a great asset for your business!

What are the advantages of rapid prototyping?

Rapid prototyping reduces design and time development, which leads to a reduction in product development costs. This is also offering more room for iteration and testing. Rapid prototyping has a beneficial impact on your overall manufacturing process.

This is also offering more room for iteration and testing. Rapid prototyping has a beneficial impact on your overall manufacturing process.

Is rapid prototyping the same as 3D printing?

Rapid prototyping is allowed by manufacturing techniques such as 3D printing. Rapid prototyping is the technique to create a prototype model from a 3D model. We can say that additive manufacturing is the process, and rapid prototyping is the end result.

Where is rapid prototyping used?

Rapid prototyping can be used by everyone, and by every kind of industry. Moreover, rapid prototyping can be used at any stage of the product development cycle for any product.

Moreover, rapid prototyping can be used at any stage of the product development cycle for any product.

Services for companies working with 3D equipment

Supplier of 3D equipment since 2010

[email protected] a call+7 495 646-15-338 800 333-12-82

3D scannersSoftware3D printers

About the CompanyClients and ProjectsDemo HallPublic ProcurementDeliveryService3D Encyclopedia

BlogContacts

Globatek not only sells 3D equipment, but also provides additional services for the selection of technical solutions, service and post-warranty maintenance, personnel training - remote or face-to-face.

11 years of supplying 3D equipment to various industries

2200+ supply of professional 3D solutions

Experts with experience in production and research

Own equipment fleet and service engineers

3D-service center in Moscow 9002 9002 to order

-

Own equipment park

-

Technologies: SLA, FDM, SLM, CJP

-

Materials: plastic, polymers, metal

-

term-from 1 day

3D scanning to order

-

OCIPTIONS OF Objects of any size and geometry

27 -

Experienced engineers 9000 9000

7

9000

Ceaking on Russia 9000

Ceaking on Russia

reverse engineering

3D modeling

-

Creation of 3D models from drawings, sketches, photos

-

Refinement of models

-

Preparing for 3D printing

3D to order

-

Equipment Park

-

Technologies: SLA, FDM, SLM, CJP

-

Materials: Plastic, Metal, Metal

-

Current-From 1 day-1 day of 1 day

Custom 3D scanning

-

Digitization of objects of any size and geometry

-

Reverse engineering

-

Team of experienced engineers

-

Departure in Russia

3D-modeling

-

Create 3D models according to drawings, sketches, photo

-

Model 9000

-

Preparation for 3D printing 9000 900

3D equipment to fit your needs and budget

Free consultation on choosing 3D equipment

-

Identifying your needs

-

Selecting 3D technology

-

Selection of equipment for task

-

Commercial offer

Demonstration of 3D equipment capabilities

-

Primary demonstration of various 3D technologies 9000

-

Products for your model

- 9000 9000 9000

-

Performing work at the customer's site

Calculation of payback for 3D printers and 3D scanners

-

Determination of your tasks

-

Equipment and materials 3D printing

27

Investments Calculation

-

-

Calculation of ownership

Free consultation for the choice of 3D equipment

- 9000 9000 9000 9000 9000 9000

-

Selection of 3D technology

-

Selection of equipment for the task

-

Preparation of a commercial offer

Demonstration of 3D equipment capabilities

-

Primary demonstration of various 3D technologies

-

Product Products according to your model

-

Carrying out test scan

-

Completion of work at the Customer Customer 9000

Calculating the payback of 3D printers and 3D scanners

-

Determining your goals

-

Selecting 3D printing equipment and materials

-

Investments Calculation

-

Calculation of the cost of ownership

Organize the appetite production of turnkey metal products

Step 1.

Evaluation of the feasibility of implementation

Evaluation of the feasibility of implementation - 9000 9000 Calculation test samples, quality approval of products

-

Evaluation of the acceptability of using SLM/LMD technologies for the production of products

Step 2. Development of a solution for additive production

-

Selection of a 3D printer and its options for your tasks

-

Selection of peripheral equipment for equipping a turnkey technological line

-

TK Development, TK Development, TK, planning and regulatory documentation

Step 3. Complex supply of equipment and training

-

Equipment supply, installation, commissioning

-

Personnel training

-

Adaptation of your 3D models to additive production

-

Development of 3D models with an integrated or generative design of

-

3D printer operation and maintenance

-

3D scanner operation

-

Working with software for the processing of digitized data

-

Primary demonstration of various 3D technologies

-

Printing

- 9000

Carrying out tetty tamping 9000

-

On-Site Work

-

Determination of your tasks

-

Equipment and materials 3D printing

-

Calculation of investments

-

Calculation of the cost of ownership

-

Work with 3D work with 3D printer and its maintenance

-

3D scanner operation

-

Digital data processing software

-

Primary demonstration of various 3D technologies

-

Products according to your model

-

Carrying out test scan

-

Completion of work at the Customer's facility

-

Identifying your needs

-

Selecting 3D printing equipment and materials

-

Investment calculation

-

Calculation of the cost of ownership

-

Delivery printing / 3D scanning

-

Warranty service

-

Official warranty service

-

Service contract conclusion

-

Supply of consumables from warehouse

-

Technical support in format 8/5, 12/7, SLA at

-

Service: diagnostics, calibration, repair

-

Delicate move

-

Supply of original spare parts

-

Supply of consumables from the warehouse

-

Delivery of equipment and installation, commissioning of equipment

-

Tetvaya 3D scanning

-

Equipment warranty service

-

Official warranty service

-

Service contract conclusion

-

Supply of consumables from the warehouse

-

Technical support in 8/5, 12/7, SLA

-

Service: diagnostics, calibration, repair

-

Delicate move

-

Original spare parts supply

-

Supply of consumables from stock

- About the center

- 3D printing technologies

- What we print

- Our works

- About the center

- 3D printing technologies 90 0027 Our work

-

smooth surfaces

Tiny elements

-

Metal powders

-

Titan, aluminum, alloy, et al.

-

High strength

-

Any geometry

- Low cost of finished products compared to traditional production methods

- Significant increase in production flexibility

- Increasing the competitiveness of production

- Reduced production costs, especially for small batch production

- Reduced time to market for new products

- Integration of computer technology and CAD systems

- You can make changes to the product during the 3D modeling phase.

Training personnel Effectively use 3D equipment

Basic training work with 3D work with 3D work with 3D work with 3D work with 3D printer or 3D scanner

Continuing training of 3D printing operators

Advanced SLM

Basic training with a 3D printer or 3D scanner

Continuing training of 3D printing operators

We will repair and maintenance

commissioning

Technical support for equipment

Post-warranty service and warranty extension

Equipment commissioning

Equipment technical support

post-Garant service and extended warranty

Related services

Globatek not only sells 3D equipment, but also provides additional services for the selection of technical solutions, service and post-warranty maintenance, personnel training - remote or face-to-face.

About Globatek

Clients and projectsAudit of production

Development of terms of reference

Selection of leasing programs

Participation in tenders FZ-44, FZ-223, FZ-275

Organization of delivery in Russia and the CIS

Additional guarantee

About Globatek

Clients and projectsGet expert advice 82

Write to WhatsAppLeave a request for a call

Come to our demo hall

Learn moreI confirm the accuracy of the information I entered and agree to the processing of my personal data in accordance with the privacy policy and user agreement.

- +7 495 646-15-338 800 333-12-82

2010–2022, Globatek JSC. All rights reserved.

Privacy policy and personal data processingPrices on the site are for reference only. Not an offer.

3D printing services in Moscow

Supplier of 3D equipment since 2010

3d@globatek. ruWhatsAppRequest a call

ruWhatsAppRequest a call +7 495 646-15-338 800 333-12-82

SoftwareServices 3D-scanners

0003About the CompanyClients and ProjectsDemo HallGovernment ProcurementDeliveryService3D Encyclopedia

BlogContacts

Globatek offers 3D printing services in Moscow and the region, as well as delivery of finished products throughout Russia. Materials: plastic, polymers, metal.

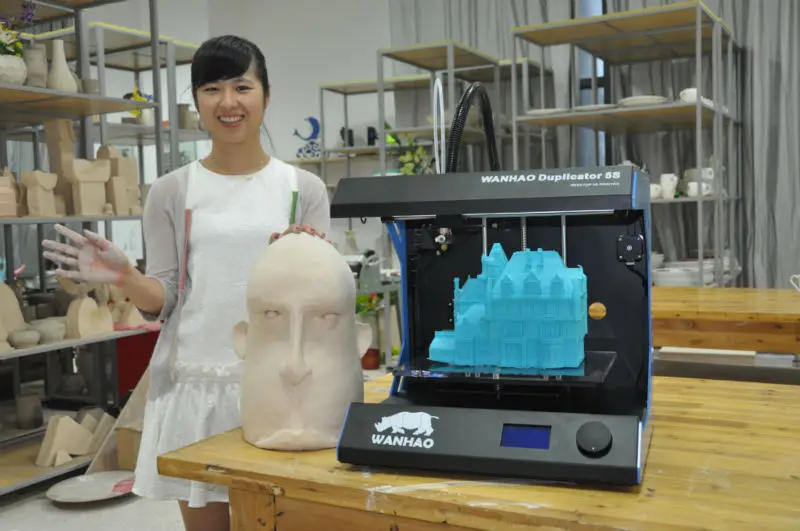

Additive manufacturing center

Globatek operates an additive manufacturing center. We have a fleet of industrial 3D equipment and a team of experienced engineers capable of solving any prototyping and small-scale production tasks. We specialize in projects for industrial enterprises, research institutes, universities, large and medium-sized businesses. The center is located in Moscow, but delivery and departure are possible throughout Russia.

The center is located in Moscow, but delivery and departure are possible throughout Russia.

Do you need to print a sample on a 3D printer? Call the Globatek Prototyping Center at 8 (495) 646-15-33 or email [email protected].

Additive Manufacturing Center

Globatek operates an additive manufacturing center. We have a fleet of industrial 3D equipment and a team of experienced engineers capable of solving any prototyping and small-scale production tasks. We specialize in projects for industrial enterprises, research institutes, universities, large and medium-sized businesses. The center is located in Moscow, but delivery and departure are possible throughout Russia.

Do you need to print a sample on a 3D printer? Call the Globatek Prototyping Center at 8 (495) 646-15-33 or email [email protected].

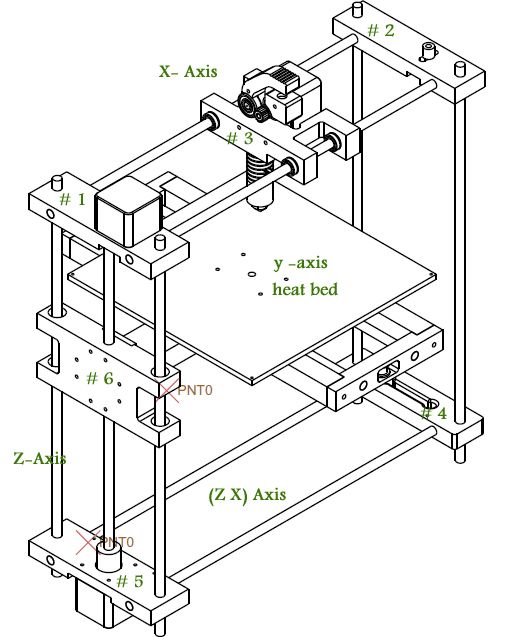

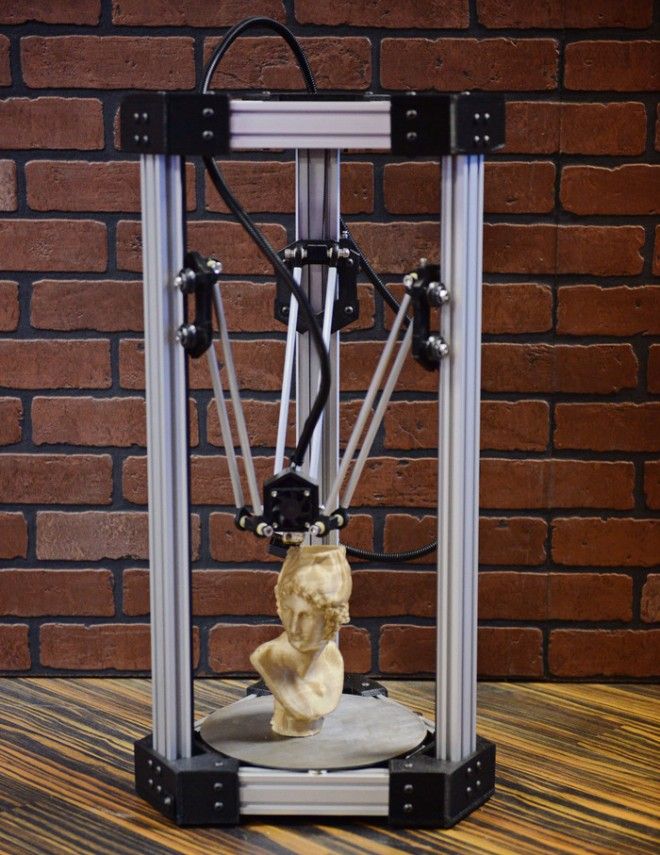

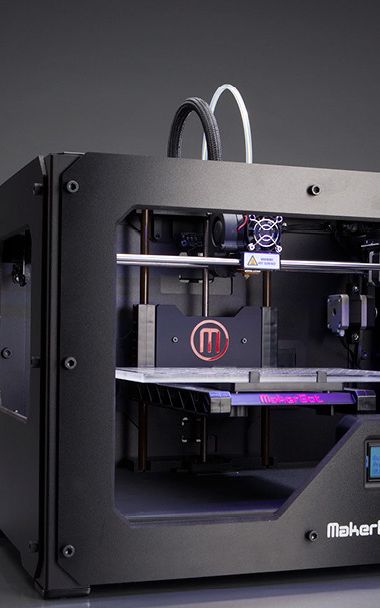

3D printing systems FDM and SLA

3D printing systems FDM and SLA

Which 3D printing technologies we use

SLA

SLM

helps production and business 9002

How 3D printing helps manufacturing and business

- Low cost of finished products compared to traditional production methods

- Significant increase in production flexibility

- Increasing the competitiveness of production

- Reduced production costs, especially for small batch production

- Reduced time to market for new products

- Integration of computer technology and CAD systems

- You can make changes to the product during the 3D modeling phase.

Learn more