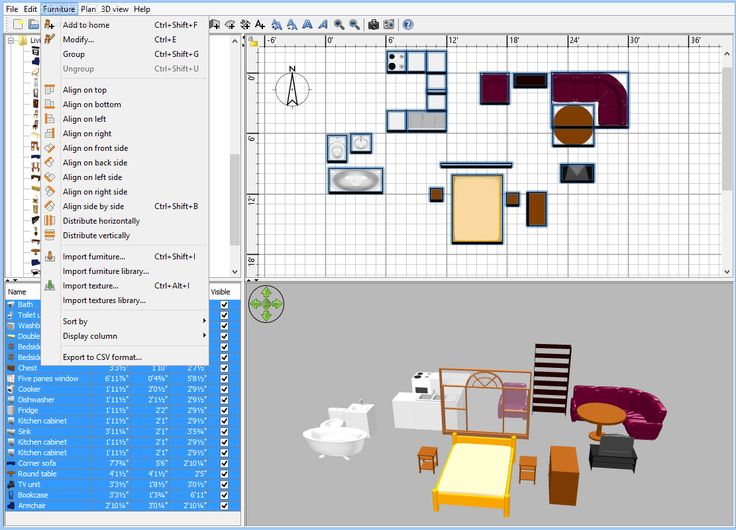

Stratasys fortus 450mc 3d printer

Fortus 450mc 3D Printer for High Performance

Harness the speed, cost and material advantages of industrial FDM additive manufacturing. The Fortus 450mc delivers accurate, reliable performance that lets you transform supply chains, accelerate manufacturing and reduce production costs.

REQUEST A QUOTE

Fortus 450mc

Product Brochure

Prototypes, tooling and production parts.

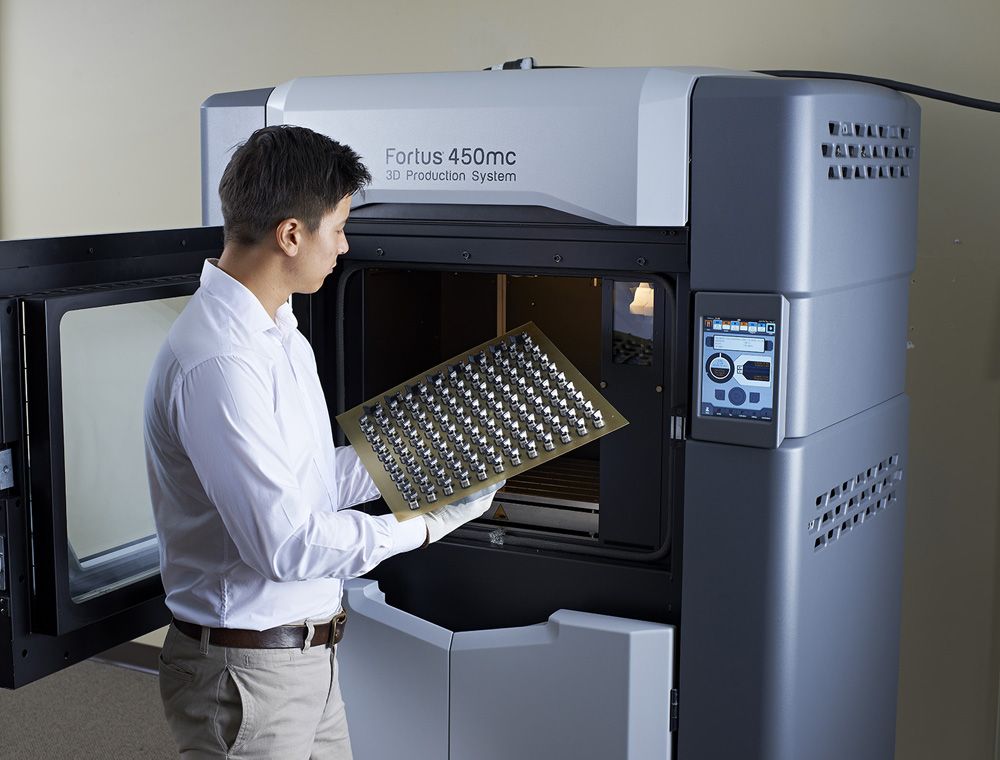

Whether you need accurate prototypes, strong manufacturing aids or on-demand end-use parts, the Fortus 450mc can tackle your application. It offers the materials you need to meet demanding production applications in any industry. From soft jaw tooling to ESD-capable space components, the Fortus 450mc is the additive manufacturing multi-tool.

Fortus 450mc applications:

Prototyping

Bypass the high cost and lead time of traditional prototyping. Accelerate product development with 3D printed functional prototypes made with durable polymers. Carbon fiber, polycarbonate, PEI and PEKK are some of the strong materials available for fast prototyping to validate your design.

Jigs, fixtures and workholding

Reduce CNC machine setup time by up to 80% and free up CNC capacity using 3D printed workholding tools. The Fortus 450mc’s design freedom and carbon fiber material let you make workholding tools faster and for less cost. Other 3D printed jigs and fixtures offer lightweighting and ergonomic benefits over machined metal tooling in addition to time and cost savings.

End-use parts

The Fortus 450mc is the ideal on-demand solution for cost-effective manufacture of low-volume and bridge-to-production parts. Tool-less 3D printing means parts can be produced much faster and for lower cost, bypassing the traditional supply chain.

The alternative to CNC machining.

When challenged to find alternative solutions to traditional manufacturing methods, the team at UK-based John Crane looked to 3D printing and settled on the Fortus 450mc. It wasn’t long before that investment made an immediate impact on the manufacturer’s production process. See how the industrial grade Fortus 450mc helps John Crane overcome traditional manufacturing challenges and grow its 3D printing capability from tooling to production parts.

It wasn’t long before that investment made an immediate impact on the manufacturer’s production process. See how the industrial grade Fortus 450mc helps John Crane overcome traditional manufacturing challenges and grow its 3D printing capability from tooling to production parts.

Read the Case Study

Fortus 450mc materials.

View all materials

Exploit a broad range of materials to handle applications in virtually any industry. Standard thermoplastics support general 3D printing applications and also include ESD compliant and biocompatible versions of ABS. Engineering and high-performance materials including nylon, carbon fiber, PEI and PEKK provide the right properties for demanding applications.

ULTEM™ is a registered trademark of SABIC or its affiliates.

Standard thermoplastics

ASA, ABS-M30, ABS-M30i, ABS-ESD7

Engineering thermoplastics

PC, PC-ABS, PC-ISO, FDM Nylon 12

High-performance thermoplastics

ULTEM™ 9085, ULTEM™ 1010, Antero 800NA, Antero ESD, FDM Nylon 12 CF, ST-130

Creating opportunity with the Fortus 450mc.

Creating opportunity with the Fortus 450mc.

East/West Industries is a tier-one manufacturer for major aerospace OEMs. It maximizes the utility of its Fortus 450mc, employing it for multiple applications to better serve its customers. Watch the video to see how East/West leverages additive manufacturing to help it achieve top supplier status.

Fortus 450mc delivers:

Demonstrated industrial performance.

Demonstrated by over 1800 worldwide installations, Fortus 450mc printers deliver results that manufacturers rely on. Tool up, prototype and produce faster and for lower cost compared to traditional manufacturing.

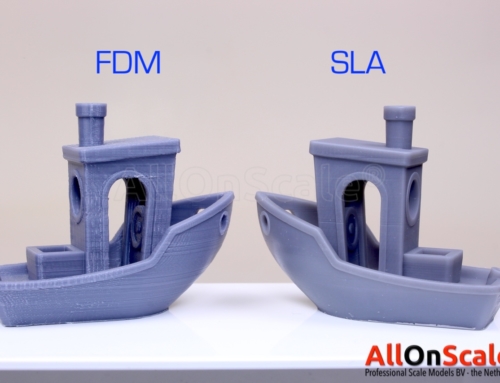

Accurate and repeatable results.

Stratasys FDM printers set the standard for repeatable print results that accurately reflect your CAD model. For consistent production in industrial printing applications, you can rely on the Fortus 450mc.

Data protection.

ProtectAM data security safeguards sensitive printer system information and provides ongoing security of information processing. This includes U.S. DOD STIG compliance, enabled by Red Hat® Enterprise Linux® software.

Red Hat is a registered trademark of Red Hat, Inc. in the United States and other countries.

Compare the Fortus 450mc printer.

F370

F770

Fortus 450mc

F900

Tray size and build plate shape

Tray size and build plate shape

14 x 10 x 14 in.

(355 x 254 x 355 mm)

39 x 24 x 24 in.

(1,000 x 610 x 610 mm)

16 x 14 x 16 in.

(406 x 355 x 406 mm)

36 x 24 x 36 in.

(914 x 610 x 914 mm)

Materials

(printed synonymously)

Materials

Cartridge capacity

Cartridge capacity

Up to 90 cu in.

200 cu in.

Up to 500 cu in.

Up to 500 cu in.

Download spec sheetLower production costs with new 3D printed materials.

The days of believing 3D printing isn't a manufacturing technology are over. As polymer material advancements continue, more manufacturers are realizing the cost benefits of additive manufacturing in lieu of traditional methods. This white paper highlights how several companies are using the Fortus 450mc and its material capabilities to develop and produce products faster and for lower cost.

Read the White Paper

Fortus 450mc 3D Printer for large-sized parts & volume production

Fortus 450mc Specifications

Fine details. Smooth surface finishes. Accuracy. Strength.

| Feature | Fortus 450mc Specification |

|---|---|

| Material delivery | Two bays each for material and support canisters Auto changeover between canisters |

| Build Envelope | 406 x 355 x 406 mm (16 x 14 x 16 in. ) ) |

| Layer thickness | 0.254 mm (0.010 in.) or 0.330 mm (0.013 in) |

| Software | All Fortus systems include Insight™ and Control Center™ job processing and management software. Compatible with GrabCAD Print for use with job reports, scheduling and remote monitoring. |

| Workstation compatibility | Windows OS |

| Size and weight | 129.5 cm x 90.2 cm x 198.4 cm (51 x 35.5 x 78.1 in.) 601 kg (1325 lbs.) |

| Power requirements | 208VAC 3 phase, 50/60 Hz, consumes 18 Amps |

| Regulatory compliance | CE |

| Achievable Accuracy | Parts are produced within an accuracy of ± .127 mm (± .005 in.) or ± .0015 mm/mm (± .0015 in/in), whichever is greater). Z part accuracy includes an additional tolerance of -0.000/+slice height. Note: Accuracy is geometry dependent. Achievable accuracy specification derived from statistical data at 95% dimensional yield. |

| Material | Layer Thickness | Support Structure | Colours | |||

|---|---|---|---|---|---|---|

0. 330 mm 330 mm (0.013 in.) | 0.254 mm (0.010 in.) | 0.178 mm (0.007 in.) | 0.127 mm (0.005 in.) | |||

| ABS-ESD7 | Soluble | Black | ||||

| ABS-M30 | Soluble | Ivory, White, Black, Red, Blue, Dark Gray | ||||

| ABS-M30i | Soluble | Ivory | ||||

| Antero 800NA | Breakaway | Natural | ||||

| ASA | Soluble | Black, Dark Blue, Dark Gray, Green, Light Gray, Yellow, White, Orange, Ivory, Red | ||||

| FDM Nylon 12 | Soluble | Black | ||||

| FDM Nylon 12CF | Soluble | Black | ||||

| PC | Breakaway, Soluble | White | ||||

| PC-ABS | Soluble | Black | ||||

| PC-ISO | Breakaway | Translucent Natural, White | ||||

| ULTEM® 9085 resin | Breakaway | Tan, Black | ||||

| ULTEM 1010 resin | Breakaway | Natural | ||||

| ST-130 | Only available in 0. 330 mm (0.013 in.) 330 mm (0.013 in.) | Breakaway | Tan | |||

3D printer Fortus 450mc from manufacturer Stratasys Ltd )

Construction area, mm: 406x355x406

Printing material: ABS-M30, FDM Nylon 12, ABS-ESD7, ABS-M30i, PC ISO, ULTEM 9085, asa, ULTEM 1010,

All specifications

Description of the 3D printer "Fortus 450mc"

Fortus 450mc is a 3D manufacturing system that allows you to create accurate, reproducible parts: mounting elements, fasteners, factory tools and final parts, as well as functional prototypes that withstand rigorous testing. The Fortus 450mc molds complex parts faster than its predecessors, saving you the most time. The model has a completely new touch interface for easy operation and maintenance. nine0005

The Fortus 450mc molds complex parts faster than its predecessors, saving you the most time. The model has a completely new touch interface for easy operation and maintenance. nine0005

About the Fortus 450mc printer

Materials

- ABS-M30 in six colors for improved tear, flex and impact resistance

- ABS-M30i - Biocompatible

- ABS-ESD7 - provides static dissipation

- ASA - provides UV resistance and the best aesthetic parameters;

- PC-ISO - ensures biocompatibility and high strength

- PC - Provides excellent mechanical and thermal properties

- FDM Nylon 12 - Provides maximum strength;

- ULTEM 9085 for high tensile strength and favorable FST (flame, smoke, toxicity). ULTEM 1010 compatibility available in 2015

Fortus 450mc Owners Articles

More

Popular 3D Printers

Anet A8

1464 articles 1719 owners

Anet A8 3D printer is a budget 3D printer from China. Region...

Region...

3 offers from 12000 ₽

Anet A6

1129 articles 1608 owners

Anet A6 3D printer - Chinese version of RepRap project P...

3 offers at the contractual price

Ender 3

1165 articles 1003 owners

Creality Ender 3 is a budget 3D printer from Chinese manufacturer...

6 offers from 14500 ₽

Show more

What is a 3D printer?

Stratasys Fortus 450mc - 3D printer for printing FDM plastics

Digital Direct Manufacturing

Transfer your designs from files to real models in hours, not weeks. Functional prototypes, close tolerance parts, heavy duty tools. The Fortus 450mc 3D Manufacturing System will allow you to get it all, taking speed, quality and precision to the next level. nine0005

Functional prototypes, close tolerance parts, heavy duty tools. The Fortus 450mc 3D Manufacturing System will allow you to get it all, taking speed, quality and precision to the next level. nine0005

The range of thermoplastics is constantly expanding. This applies to both standard engineering plastics and materials with improved mechanical properties. This expands the possibilities of using 3D printing, increasing the competitive advantage.

High Performance FDM System

With the Fortus 450mc, you can quickly produce and reproduce accurate models. Produce tooling, fasteners, production tools and end parts. And the functional prototypes obtained in this 3D system are suitable for mechanical testing. With four layer thicknesses to choose from, you can strike the right balance between durability, detail and best print times in Technology

FDM. The Fortus 450mc prints intricately shaped parts much faster than its predecessors, saving significant time. The model supports a new touch interface, thanks to which operation and maintenance become simple and clear.

Fortus 450mc

Print parts up to 406 x 355 x 406. The Fortus 450mc works with 9 standard engineering thermoplastics and high performance plastics.

Specifications

| Construction area size (XYZ) | 406 x 355 x 406 mm |

| Number of cartridges | 2 Cartridges of Model Material and 2 Cartridges of Support Material |

| Support structure | mechanically removed for PC-ISO and ULTEM; nine0005 dissolves and removes mechanically for PC soluble for all other materials |

| Layer thickness | 0.330 mm; 0.254 mm; |

| Attainable accuracy | +/- 0. |

| Supported materials |

|

| Dimensions (WxHxD) | 127 x 90.17 x 194.31 cm |

| System weight | 601 kg - loose 680 kg - with packaging |

| Power requirements | 220V; 50 Hz; 20 A |

| Network connection | Ethernet, 10/100BaseT |

| Software |

|

| Meets the requirements of | CE |

| Special requirements | Temperature 18-25 deg C Humidity 30-70% |

Materials

Supported materials

System works with the following industrial grade thermoplastics:

- ABS-M30 in 6 colors - excellent impact, flex and tensile strength

- ABS-M30i - biocompatibility

- ABS-ESD7 - Static Dissipation

- ASA - UV stability and excellent appearance

- PC-ISO - biocompatible and good rigidity

- PC - excellent mechanical properties and heat resistance

- FDM Nylon 12 - maximum strength

Does this model also work with ULTEM 9085 and ULTEM 1010? which allows to achieve a high strength-to-weight ratio and the required FST rating. nine0005

nine0005

Insight Software

Insight Software

Insight Software prepares your STL file from a CAD program for Fortus printing by automatically layering and generating support structures and material extrusion paths. For maximum control, the user can manually adjust the parameters that determine the appearance, strength and precision of parts, as well as the speed and material used in the FDM process.

With Insight you can:

- Optimize build orientation for maximum strength and smoothest surface finishes

- Customize support for quick and easy removal and material management

- Program pauses in printing for a specific purpose, such as inserting a device or chart

- Manipulate toolpath for better control of part properties

Insight also comes with Control Center. This carefully designed software links the user's workstation to the Fortus system, allowing them to manage print jobs and monitor production status.

127 mm or

127 mm or