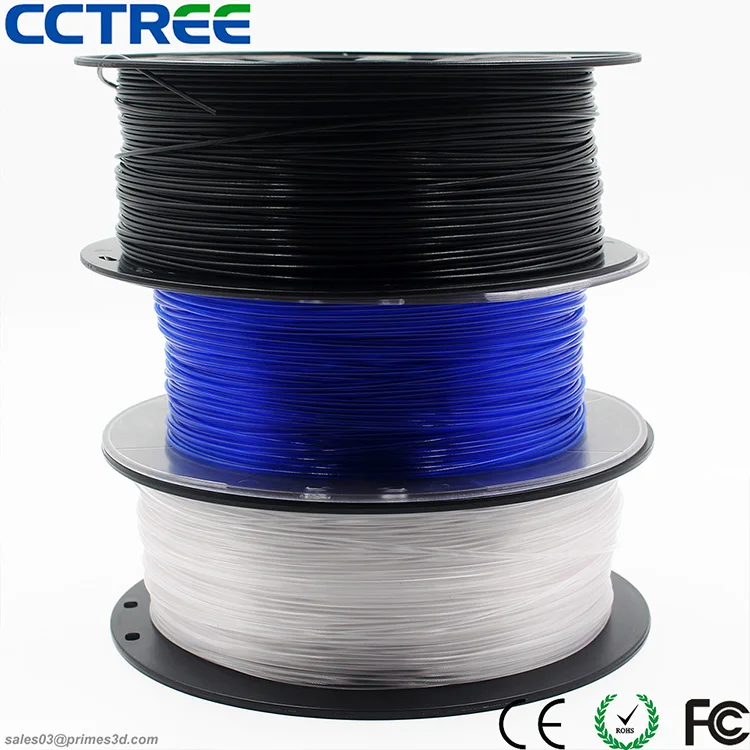

3D printer filament specifications

Filament Specs – 3D Printer Filaments

ABS filament colors 1kg/spool RepRap 3D printer

ABS is commonly used in 3D printing, has the following characteristics:

(1) High strength, good toughness;

(2) Density is small, when printing larger volume model lighter, save money;

(3) Cost-effective can be processed in a wide range temperature;

(4) Softer than PLA;

(5) Diameter of 2.85mm/1.75mm, variations + /-0.1mm, roundness + /- 0.05mm;

(6) 1 kg /plastic spool packaging;

(7) To be applied to a variety of 3D printer, MakerBot, Creality, FlashForge, and more.

Our ABS Filament:

| ABS-1.75mm | ABS3.0mm | ABS-clear | |

|---|---|---|---|

| Natural Color | Milk white | Milky yellow | Clear |

| Processing temperature | 185deg for 3mm,230 deg for 1. | 230 degfor3mm>230 deg for 1.75mm, can process at 260 deg | 230 deg for 3mm>230 deg for 1.75mm, can process at 260 deg |

| Odor | Low smoke, tasteless, good for printing indoor | White smoke, concentrated flavor, not very good for indoor | Strong smell, not good printing indoor |

| Roundness | +/-0.05mm | +/-0. 05mm 05mm

| +/-0.05mm |

| Variety | +/-0.1mm | +/-0.1mm | +/-0.1mm |

Available colors:

Clear, natural, white, black, red, sky blue, dark blue, fluorescent green, dark green, fluorescent yellow, dark yellow, orange, purple, pink, grey, brown, glow in dark etc…

ABS grade imported from Taiwan Chimei properties:

| Property | Unit | Test Method | Test Condition | ABS |

|---|---|---|---|---|

| Tensile Strength | 2kg/cm(MPa) | ASTM D-638( ISO527) | 23℃ | 220 (22) |

| Tensile Elongation | % | ASTM D-638( ISO527) | 23℃ | 40 |

| Flexural Strength | 2kg/cm(MPa) | ASTM D-790( ISO178) | 23℃ | 440 (43) |

| Flexural Modulus | 2 4kg/cm*10(MPa) | ASTM D-790( ISO178) | 23℃ | 2. 3 (2260) 3 (2260) |

| Izod Impact Strength | kg-cm/cm( J/m) | ASTM D-256( ISOR180) | 23℃1/4'' | 1. 0 (108) |

| Vicat Softening Temperature | ℃ | ASTM D-1525 (ISO306B) | Annealed80℃×2Hr1/8'' | 95 |

| Heat Deflection Temperature | ℃ | ASTM D-648(ISO75/A) | Annealed80℃×2Hr1/8'' | 88 |

| Melt Flow Index | g/10 min | ASTM D-1238( ISO1133) | 200℃×5Kg( 49N) | 5. 5 5 |

| Residual Monomer | ppm max. | 700 | ||

| Molding Shrinkage | % | FCFC Method | 23℃ | 0.4~0.6 |

| Specific Gravity | ASTM D-792( ISO1183) | 23℃/23℃ | 1. 04 04

| |

| Flammability | UL-94 | FILENO. E162823 | 1/16"HB NC |

3D Printing ABS Filament - Gizmo Dorks

Gizmo Dorks

$20.95

Size *

1.75mm 3mm (2.85mm)

Color *

Pick one...BeigeBlackBlueBrownColor Change Blue to White (Heat Activated)Color Change Green to Yellow (Heat Activated)Color Change Grey to White (Heat Activated)Color Change Purple to Pink (Heat Activated)Conductive BlackDark BlueDark PurpleFluorescent Blue (Black Light Reactive)Fluorescent Green (Black Light Reactive)Fluorescent Hot Pink (Black Light Reactive)Fluorescent Orange (Black Light Reactive)Fluorescent Yellow (Black Light Reactive)Glow in the DarkGoldGreenGreyGrass GreenOrangePinkPink RosePurpleRedRed LavaSilverTransparentVioletWhiteYellowLight Yellow

Qty:

Share:

Add to Wishlist

Current stock: 0

ABS Filament

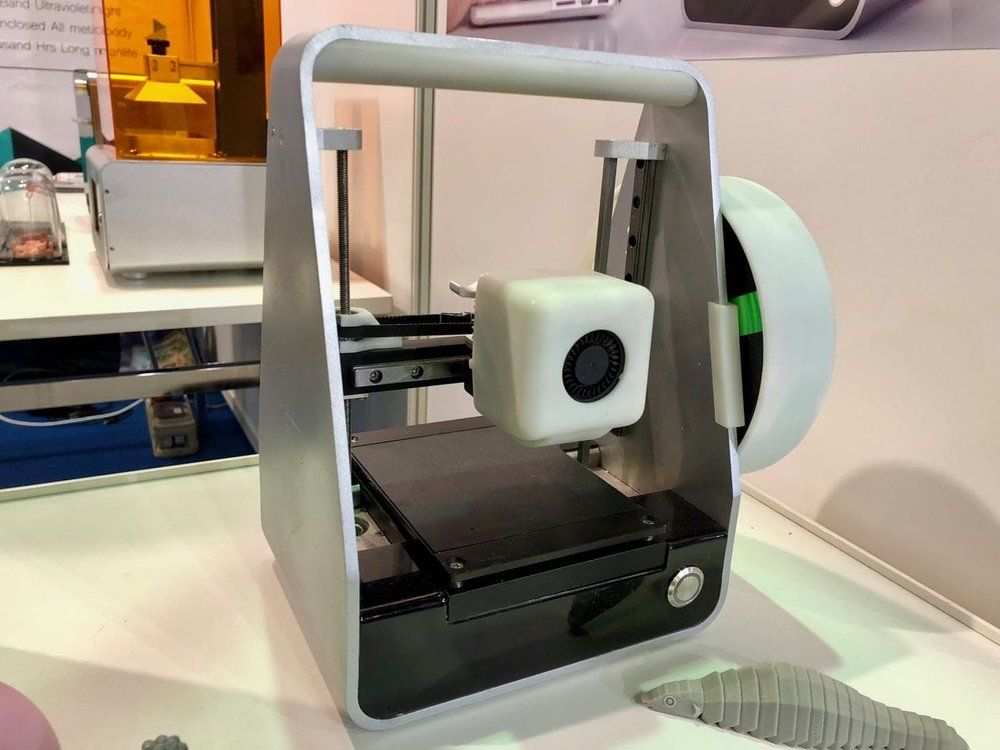

ABS (Acrylonitrile Butadiene Styrene) plastic filament is a polymer used in 3D printing because it can be molded and engineered. It falls under a family of other plastics known as thermoplastics. These plastics have the ability to become soft and moldable when heated at high temperatures and returning to it's normal solid state when at cooler temperatures, making it an ideal 3D printing filament.

It falls under a family of other plastics known as thermoplastics. These plastics have the ability to become soft and moldable when heated at high temperatures and returning to it's normal solid state when at cooler temperatures, making it an ideal 3D printing filament.

ABS filament is a favorite for 3D printing because it is light weight and durable. It can be injection molded which makes it perfect for 3D printing extruders. It has a high glass transition temperature to reduce deformation but low enough to be safely attainable with 3D printers. ABS filament needs to be printed on a heated bed because the filament will curl upwards of the surface. The heated build platform as well as a smooth flat surface helps reduce the deformation.

ABS filament is a hard strong plastic with some flexibility when compared to PLA filament. It is also soluble in acetone, and it can be easily sanded and machined. It has ideal strength, machinability, and temperature resistance making it a favorite filament among 3D printer users.

Please store ABS filament in a cool dry place. ABS, if exposed to moisture, will bubble and spurt from the extruding nozzle. ABS filament can be dried from a food dehydrator, oven, or from any source of hot air.

ABS Filament Specifications

- **Net weight: 1 kg or 2.2 lbs

- Diameter: +/- 0.05mm

- Roundness: +/- 0.07mm

- Print Temperature: 230 - 250°C

- Heated Bed Temp: 110°C

ABS Filament Colors Types and Sizes

We have 21 normal colors of ABS filament and an additional 9 specialty colors. All 30 color variants come in two sizes.

- 1.75mm ABS filament

- 3mm (2.85mm) ABS filament

The 9 specialty colors of ABS filament can be categorized into the 4 following types.

Conductive ABS filament

Right now there is one color for conductive ABS filament, which is black. The filament can be used for anti-static, dissipative, or the conduction of electric current. Sizes come in 1.75mm ABS and 3mm ABS.

Sizes come in 1.75mm ABS and 3mm ABS.

Glow in the dark ABS filament

As the name implies, the glow in the dark ABS filament will shine in the dark. Please allow the filament or print to retain light or charge in regular light first. Currently, we have one color for glow in the dark, which is green. We experimented with glow in the dark blue, but the blue version did not glow brightly. Sizes come in 1.75mm ABS and 3mm ABS.

Fluorescent ABS filament

The fluorescent ABS filament colors will glow under UV light, which is also known as black light. We have four fluorescent colors, which are fluorescent orange, fluorescent green, fluorescent yellow, and fluorescent blue. We did have a fifth fluorescent color which was fluorescent red, but it did not shine brightly under UV light. We renamed fluorescent red to red ruby. Sizes come in 1.75mm ABS and 3mm ABS.

Color change by heat ABS filament

This type of ABS filament (hyper color) will change colors depending on the temperature of the filament. The ABS filaments change color at approximately 31°C (88°F). Below 31°C the filaments are one color; above 31°C the filaments are a different color. Therefore, this ABS filament is heat activated. The easiest way to visualize this change is to simply blow a hair dryer on the filament. We currently have three variants of this type of ABS filament, which are green to yellow, gray to white, and purple to pink. Please see the below video for illustration of the color changing effect. Sizes come in 1.75mm ABS and 3mm ABS.

The ABS filaments change color at approximately 31°C (88°F). Below 31°C the filaments are one color; above 31°C the filaments are a different color. Therefore, this ABS filament is heat activated. The easiest way to visualize this change is to simply blow a hair dryer on the filament. We currently have three variants of this type of ABS filament, which are green to yellow, gray to white, and purple to pink. Please see the below video for illustration of the color changing effect. Sizes come in 1.75mm ABS and 3mm ABS.

- Videos

Videos

account Account wishlist Wishlist cart Shopping bag3D Printable Nylon

- 1 Description

- 2 Specifications

- 3 Advantages and disadvantages of nylon

- 3.

1 Features

1 Features - 3.2 Disadvantages

- 4 3D printing use

- 5 Use of available materials

Description

Nylon is attractive as a material for 3D printing due to its high wear resistance, affordability and excellent slip coefficient, which allows the use of nylon in bearings and other similar mechanisms, often without the use of lubricants. nine0025

An example of a model created using Stratasys Nylon 12

Despite the widespread use of nylon in the industry, the use of this material in 3D printing is quite limited due to certain technological difficulties. However, in recent years, specialized nylon consumables have appeared, focused on use with SLS and FDM printers.

Taulman and Stratasys nylon threads are the most popular examples. nine0002

Specifications

| Taulman 618 | Taulman 645 | Stratasys Nylon 12 | |

| Density | 1. 134 g/cm³ 134 g/cm³ | – | – |

| Hygroscopicity | 3.09% | 3.09% | – | nine0048

| Tensile strength | 65.99 MPa | 85.68 MPa | 48.26-53 MPa |

| Elongation at Break | Over 300% | Over 300% | 9.5-30% |

| Melting point | 218°C | 214°C | 178°C | nine0048

| Glass transition temperature | 49.4°C | 68.2°C | – |

| Extrusion temperature | 235-260°C | 235-260°C | – |

| Pyrolysis temperature | 350-360°C | 350-360°C | – |

Stratasys Nylon 12 is designed for use with Fortus brand 360mc, 400mc and 9 professional rigs00mc, while Taulman's nylon filaments are designed to work with any home and office 3D printer optimized for the popular ABS plastic. In addition, Taulman is testing a range of laser sintered nylon materials, including a powder version of Taulman 618.

In addition, Taulman is testing a range of laser sintered nylon materials, including a powder version of Taulman 618.

Advantages and disadvantages of nylon

Advantages of

- High wear resistance

- High elasticity

- Resistant to most organic solvents

- High temperature resistance

- Easy to machine

Disadvantages

- High hygroscopicity

- Release of toxic fumes during pyrolysis

- Taulman brand nylon threads available in 1.75mm and 3mm diameters

3D printing use

Taulman brand nylon filaments are available in 1.75mm and 3mm diameters

Nylon printing technology is similar to ABS printing, but with some differences. Like ABS, nylon is prone to twisting and warping when cooled unevenly, requiring the use of a heated bed.

The nylon layers have excellent adhesion, which minimizes the chance of delamination of models. Users of Taulman plastics note the durability of models at the level of analogues made by traditional injection molding. nine0025

Users of Taulman plastics note the durability of models at the level of analogues made by traditional injection molding. nine0025

Nylon is almost impossible to bond, which makes it difficult to manufacture large-sized parts from components. Alternatively, it is possible to connect nylon parts by melting the surfaces to be joined.

Nylon can be dyed with acid-based dyes.

Nylon does not adhere to glass or other smooth surfaces, so it is recommended to apply painter's tape to the desktop or use a wood backing when printing. nine0025

Due to the high hygroscopicity of nylon (the ability to absorb moisture), it is recommended to dry the nylon filament immediately before printing. Otherwise, water vapor may be released from the nozzle, which is not catastrophic for the extruder, but may affect print quality.

Use of scrap materials

Some hobbyists prefer to use inexpensive nylon line for printing, which is fraught with some unpleasant consequences. As a general rule, trimmer line is preferred, available in 3mm diameter, which is the same diameter as commercially available ABS filaments for FDM printing. However, these "nylon threads" are not pure nylon, which is evident due to their excessive stiffness, which is not characteristic of nylon. The reason for this is additives - usually in the form of fiberglass. Additives are designed to both increase stiffness and reduce the cost of the material. It should be borne in mind that the melting point of fiberglass is much higher than the melting point of nylon and, in fact, exceeds the pyrolysis temperature of nylon. Thus, it is impossible to achieve complete melting of such composite materials. As a result, tough glass fiber particles will contribute to increased wear and clogging of the extruder nozzle. nine0025

As a general rule, trimmer line is preferred, available in 3mm diameter, which is the same diameter as commercially available ABS filaments for FDM printing. However, these "nylon threads" are not pure nylon, which is evident due to their excessive stiffness, which is not characteristic of nylon. The reason for this is additives - usually in the form of fiberglass. Additives are designed to both increase stiffness and reduce the cost of the material. It should be borne in mind that the melting point of fiberglass is much higher than the melting point of nylon and, in fact, exceeds the pyrolysis temperature of nylon. Thus, it is impossible to achieve complete melting of such composite materials. As a result, tough glass fiber particles will contribute to increased wear and clogging of the extruder nozzle. nine0025

Go to the main page of the Encyclopedia of 3D Printing

Filament Do Drukarki 3D (Rodzaje, Cena) / Materiał Do Drukarki 3D

Available threads

ABS-42

UNIVERSAL INDUSTRIAL MATERIAL

Standard ABS-42 filament with high versatility, strength and mechanical strength. It is also known to be a material that is easy to process. ABS is used, in particular, in production, especially in prototypes of elements of increased rigidity.

It is also known to be a material that is easy to process. ABS is used, in particular, in production, especially in prototypes of elements of increased rigidity.

USE: prototypes, tools and equipment, gadgets and toys, decorative accessories.

Read more

Available colors

Technical characteristics

Press temperature

23-255 ° C

Table temperature

70-110 ° C

ASA-39

INCREASED WEATHER RESISTANCE

ASA-39 is used where weather resistance, especially UV, is required. High temperature resistance allows you to test models in direct sunlight without the risk of deformation or discoloration. nine0025

APPLICATIONS: models requiring UV resistance, automotive industry, elements used in the field.

Read more

Available colors

Technical characteristics

Press temperature

240-260 ° C

80-90 ° C

65 ° C

65 ° ° C

° ° ° C

° ° TO LOAD

CF PA-12

FLAMEMENT FOR RIDERS

CF PA-12 is a material that will not let you down on the track. Polyamide 12 (PA 12) matrix composite reinforced with carbon fibers. It is characterized by exceptional strength, high rigidity and tear resistance. The latter feature is especially important - carbon fiber has more than 2.5 times the strength of the popular ABS-42.

Polyamide 12 (PA 12) matrix composite reinforced with carbon fibers. It is characterized by exceptional strength, high rigidity and tear resistance. The latter feature is especially important - carbon fiber has more than 2.5 times the strength of the popular ABS-42.

APPLICATIONS: high strength and lightweight components, drone and automobile parts, intake manifolds for racing cars, prototypes, tools. nine00.

HIPS-20

BASE AND SUPPORT MATERIAL

HIPS-20 is used as both a support material and a material suitable for 3D printing. Elements printed with this filament can be further processed such as glued, sanded or painted. A safe material commonly used in the manufacture of packaging suitable for food contact. nine0025

Application: housings, industrial parts, functional prototypes, decor elements, large-sized models

Read more

Available colors

Technical characteristics

Press temperature

210-230 ° C

table

700 C

APPLICATION

DOWNLOAD DOCUMENTS

ODS-20

SOLUBLE SUPPORT MATERIAL

ODS-20 is an acrylate-based polymer blend soluble in a mild alkaline solution - Agent ODS Solve Removal. nine0002 As a result, printed elements are less sensitive to moisture, have a longer shelf life and stable quality over time. ODS-20 is characterized by very good adhesion to models made of e.g. PEEK, PA, PC, ABS/PC, TPE, ASA, ABS or PET.

nine0002 As a result, printed elements are less sensitive to moisture, have a longer shelf life and stable quality over time. ODS-20 is characterized by very good adhesion to models made of e.g. PEEK, PA, PC, ABS/PC, TPE, ASA, ABS or PET.

USE: facilitates printing of complex geometries.

More details

COLORS AVAILABLE

SPECIFICATIONS

Print temperature

210-230°C

Table temperature

60°C

Chamber temperature

55°C

APPLICATION

HIGH STRENGTH NYLON

PA-12 is a versatile material with very high tensile, impact and abrasion resistance. Resistant to a wide range of chemicals including acids and alkalis.

APPLICATION: automotive industry, electronics, mechanical parts such as gears, guides, technical elements: nuts, 900. LOADINGS

PA-6/66 HD

ADVANTAGES OF TWO POLYAMIDES - PA 6 and PA 66

PA-6/66 HD High strength nylon. It is hard, flexible and elastic. It has properties similar to those of materials used by engineers to produce end products. nine0025

It has properties similar to those of materials used by engineers to produce end products. nine0025

APPLICATION: machine, electrical, automotive, transport and mechanical engineering.

Read more

Available colors

Technical characteristics

Press temperature

220 - 250 ° C

Table temperature

0 - 80 ° C

Documents for loading

PC

DURABLE PLASTIC

PC-ABS-47 filament with high mechanical and temperature resistance, guarantees durability and stability of printouts. Resistant to various chemicals including salts, acids and alkalis. The material is ideal for prototyping, custom tool printing and finished parts production. nine00. °C

Print speed

30 - 55 mm/s

APPLICATION

DOCUMENTS TO LOAD

PEKK-A

MATERIAL FOR THE MOST DEMANDING

PEKK-A is designed for industrial applications. It is chosen by engineers who need a material with very high mechanical, chemical and temperature resistance. Excellent resistance to a wide range of chemicals such as those used in the oil and gas, automotive, aerospace, industrial and chemical industries. It is highly resistant to abrasion, stretching, compression and radiolucency.

Excellent resistance to a wide range of chemicals such as those used in the oil and gas, automotive, aerospace, industrial and chemical industries. It is highly resistant to abrasion, stretching, compression and radiolucency.

APPLICATION: oil, gas, automotive, aviation, chemical industry. nine00.

DOCUMENTS FOR DOWNLOADS

PET-G-32

FOOD APPROVED

PET-G-32 is a low shrinkage industrial material designed for extreme environments. Differs in high precision of the press. A material used for the production of food and medical packaging due to its sterilization capability. PET-G can be used in printed elements that are resistant to fats, oils and gasoline. nine0025

APPLICATIONS: food packaging, medicine, mechanical elements, prototypes, decorative elements, models requiring chemical resistance.

Read more

Available colors

Technical characteristics

Press temperature

230-250 ° C

0-90 ° C

Documents for loading

9002 RENEWABLE POLYMER

PLA-36 is one of the main materials for rapid prototyping. This is especially appreciated by people who start their printing adventure and 3D printing enthusiasts. Ideal for prints requiring high precision.

This is especially appreciated by people who start their printing adventure and 3D printing enthusiasts. Ideal for prints requiring high precision.

APPLICATIONS: prototypes, consumer models, biodegradable models, architecture.

More details

COLORS AVAILABLE

SPECIFICATIONS

Print Temperature

180-210°C

Table temperature

25-60 °C

APPLICATIONS

PVA-20

PERFECT SUPPORT

PVA-20 polymer is suitable as a support material due to its unique ability to dissolve in warm water. Ideal to work as a support material for printing complex geometries, large overhangs or intricate cutouts. It is often used for the production of, for example, capsule packaging for dishwashers.

USE: Nylon and PLA support material, complex geometries. nine0025

Read more

Available colors

Technical characteristics

Print temperature

200 - 230 ° C

60 PEEK

THERMEC ™ ZED is a material that has very high mechanical, chemical and thermal resistance. A material used to print instruments and devices that are exposed to high temperatures and even require sterilization. Printouts from this filament can be sanded, and its surface is very well covered with paint, so they can be easily painted. nine0025

A material used to print instruments and devices that are exposed to high temperatures and even require sterilization. Printouts from this filament can be sanded, and its surface is very well covered with paint, so they can be easily painted. nine0025

APPLICATIONS: automotive, chemical, oil and gas industries, instruments and devices exposed to high temperatures and even requiring sterilization.

Read more

Available colors

Technical characteristics

Press temperature

300 - 330 ° C

70 - 110 ° C

70 ° C

900 ° C

70 ° C

70 ° C

70 ° C

° C

70 ° C

DOWNLOADS

TPU-93A

MULTICOLOR STRETCH MATERIAL

TPU-93A material, allows printing of flexible, bendable/compressible elements. It features excellent chemical resistance to oils, greases and other substances, as well as weather conditions. Printouts are resistant to mechanical stress and abrasion, and also perfectly compensate for shaking, vibrations and shocks.

APPLICATIONS: bumpers, gaskets, plugs, bumpers, tapes.

Read more

DEVELABLE TOPICS

Technical characteristics

Press temperature

190 - 210 ° C

Table temperature

45 ° C

Use

Ultrafuse ABS Fusion +

ABS Fusion + is characterized by increased temperature, chemical and mechanical resistance. The printout has a matte finish, which significantly improves its functionality and reduces the need for additional processing. The ability to print with PVA gives much more freedom in building the print geometry, i.e. models printed with Ultrafuse® ABS Fusion+ may have more complex shapes. nine0025

USE: automotive parts, tools and equipment.

Read more

Available colors

Technical characteristics

Press temperature

240-260 ° C

100-110 ° C

55 ° C 55 ° ° C

55 ° ° C

55 ° ° C

DOWNLOADS

Do you have questions about our 3D printer filaments?

Contact us for more information about 3D printer materials.