3D printed fabrics

3d Printed Fabric - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

3D printing on fabric - Art and new techniques

3D printing on fabric: an innovative technique

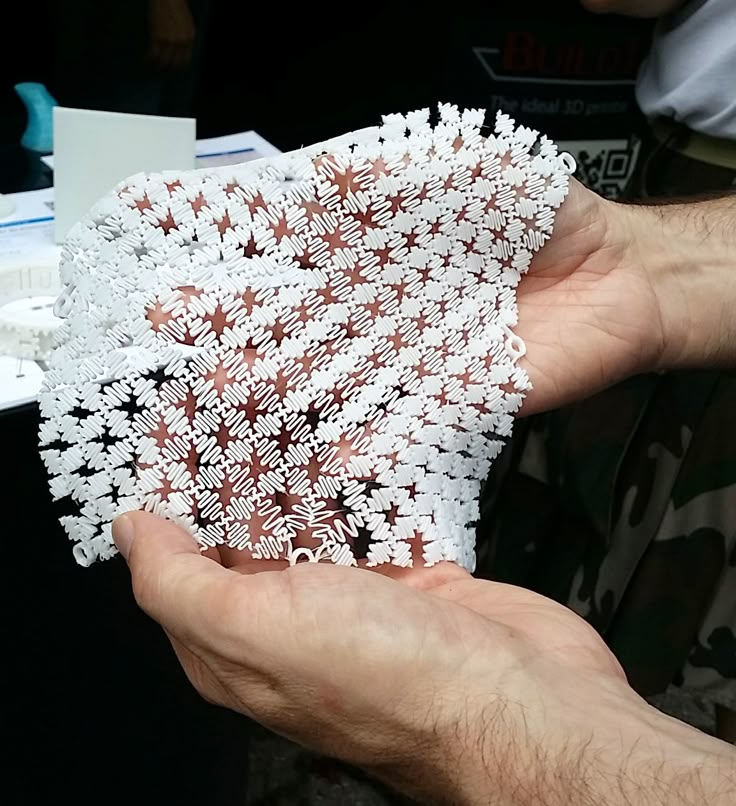

3D p3D printing always surprises us with its wide range of applications: here, we’ll discover a new technique to create shapes. It’s an innovative way to design: algorithms are used to generate patterns of curves that, through tensions, develop structures.

Design is always influenced by manufacturing, and the change in a process also changes the way to think about shapes that can be reached. The progress of technology permits to rethink of esthetics and creates new cultural values.

Can 3D printers print on fabric?

3D printers can print on fabric, and It is effortless to do! You can easily create new shapes or give a new life to your old fabrics with any printer you have. Here are some tips to print and some case studies from which you can get inspiration.

How to 3D print on fabric

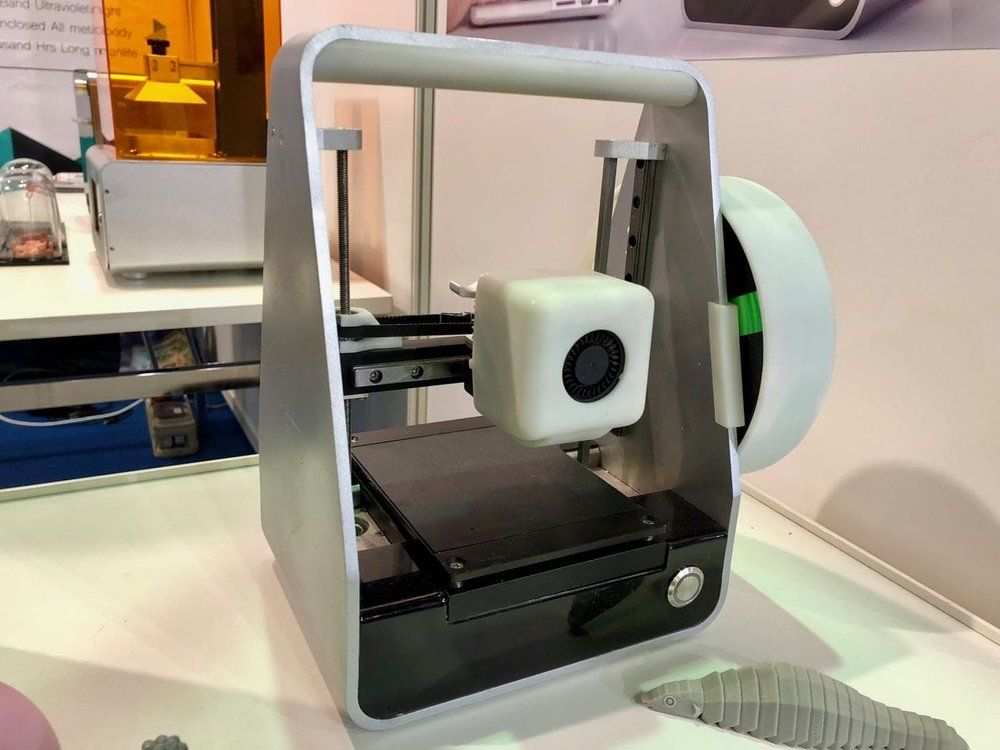

3D printing on fabric is easy, and it doesn’t require many other additional components. The only things you need are pins and, in some cases, a platform to raise the printing bed. In this workshop, students learned how to print on textile with their small printers, Delta WASP 2040 PRO. Trying small pieces before shifting to a larger scale is really useful.

Trying small pieces before shifting to a larger scale is really useful.

The more difficult part is the design process: when you print you don’t see the final result until you release the tensions of the pins on the textile. This can be really exciting, for the continous experiments and the discovery of new shapes. It’s a totally different way to design.

The textile needs to be stretched on the bed and fixed well to print the layer of curves in the same way. If it is not tested regularly, It can lead to deformed geometry.When the melted filament is deposited on the fabric, it merges with the material, and with the cooling, they are united forever.

Click here to see the full workshop article

Fashion industry: 3D printed clothes

We will see how 3D printing is revolutionizing the fashion industry. It’s a new technology in this field, so not many people know how and why to use it. Plus, the design of the clothes is complex: it requires knowledge of 3D modeling and 3D printing. But it’s also a new way to visualize the artwork more realistically.Until now, it has been confined to Haute Couture, artists, and passionate hobbyists.

But it’s also a new way to visualize the artwork more realistically.Until now, it has been confined to Haute Couture, artists, and passionate hobbyists.

As we expected, the knowledge and enthusiasm are spreading worldwide, and there are many examples also in the mass fashion market. Other than accessories, 3D printing is used more for shoes, bags, and functional clothes. Also, NASA has its research laboratory where scientists study how to upgrade spacesuits with 3D printing.

Flexible filament

The materials that suit the creation process of 3D printed clothes are those with flexible features. TPU is the most used filament to create objects that need to be in contact with skin because it adapts its shape to body curves. So it is widespread in medical and fashion fields. For example, Balenciaga released new pair of 3d printed decolletè, all made in transparent TPU.

Haute couture: Iris Van Herpen

Iris Van Herpen is for sure one of the most iconic example of 3d printed artworks in fashion industry. Her stunning dresses are famous worldwide, worn by actors and singers in gran galà and other important events. Her creations are unique pieces, like sculptures.

Her stunning dresses are famous worldwide, worn by actors and singers in gran galà and other important events. Her creations are unique pieces, like sculptures.

She has always combined art and technology, inspired by Leonardo Da Vinci mindset. Nature is her biggest counselor and all colors and shapes combinations come from animals and plants. This interest in nature and eco-systems leads Iris to care about sustainability and the purpose to create pieces environment-friendly.

Fashion and sustainability

Sustainability is one of our generation’s battles: choosing the suitable materials to produce in a more respectful way for the planet. Fashion is under pressure for the continuous turnover of new clothes production every season.

Fast fashion is one of the problems of these times, so everybody is now focused on trying to reduce the impact of the industry. 3D printing is a valid partner to face it because it permits avoiding waste of materials and can use recycled materials.

A student creates her 3D printed fashion line

Milan-based student of Politecnico di Milano, Chiara Giusti, has designed and produced a clothing line for her University project. She printed her collection at Superforma, Milan WASP Hub, using WASP’s large-scale 3D printer 3MT.

Chiara aims to create fashion and comfortable clothes, adding complex 3D printed patterns to textiles. This example demonstrates that 3D printing clothes can be done by everyone simply at home (with a little bit of practice).

Art, design and architecture

3D printing on textile is interesting to create something to wear, but it can also be a way to build remarkable structures and furniture pieces. The rigidity that 3D printed curves bring to the textile creates a steady system that can sustain itself.

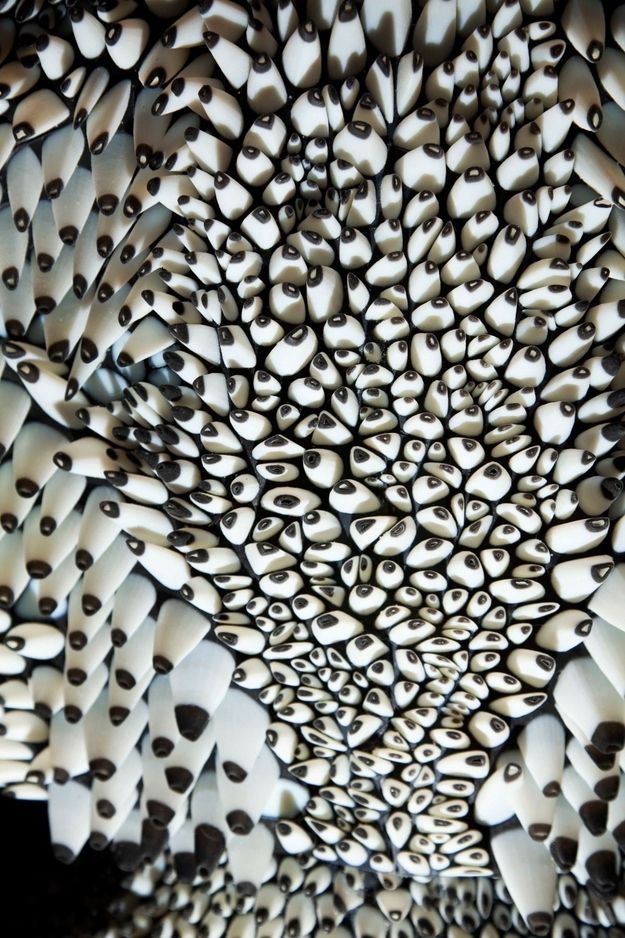

The shapes created on fabric are also interesting for furniture pieces like lamps. In these examples, created by Drag and Drop Design studio, emerges the structure and the articulate shape achievable with this process.

This large-scale piece exemplifies how 3D printing on fabric can also be applied to significant structures and challenge how we build installations and structures. This effect of soft spikes comes from the tensions of printed layers on the textile.

Large scale 3D printer

Delta WASP 3MT INDUSTRIAL 4.0All these masterpieces have been created with the 3MT 3D printer. This is the best printer for creating medium-large pieces thanks to its wide printing bed area of 1m in diameter.

3D print on fabric

Application

Follow the author

Follow

Don't want

17

Yes, it happens, but not exactly like in the recent video from Pryusha.

The idea is good, but very confusing. And not the fact that reliable. Especially when the print is miniature - uniform T-shirts for Zhong Li and his girlfriend (yes, hair bands are also uniform).

The original plan was to use a paper stencil like the old fashioned way. I cut out the inscription and painted it over. The method requires very fine work with a piece of paper, and the result ... it is more likely not there than it is. The paint tends to leak under the template in a random place, even if applied too carefully. nine0003

And then I was offered to print a stamp on a 3D printer. After a little thought and poigraph with fusion, I received both a stamp and a holder. The main thing - do not forget to mirror the die itself, you can in the slicer. It was printed from TPU and the holder from PETG. Here in the photo it is painted over with a marker for dark fabrics.

Modelka here

It is risky to transfer to the finishing fabric, so I mark the fabric with a special self-disappearing marker, I also color the stamp with it and print it. The contour is already much clearer. nine0003

Then this contour must be painted over from the inside with the paint from the marker - I draw it on the brush, act slowly and carefully, then you can’t wash it off. The marker is mandatory for dark fabrics, opaque. I paint over the white inscription TODAY after the red background has dried.

The marker is mandatory for dark fabrics, opaque. I paint over the white inscription TODAY after the red background has dried.

3Dtoday is ready to accept new users into its ranks:

Now you can try on a darker fabric. A simple one-color drawing, I decided to make a stamp in two versions for the experiment. A very primitive model, only the logo in svg needs to be downloaded from the web. nine0003

The experiment showed that a stencil with a hole will not work, so you have to use the same principle of a mirror stamp. Here, the self-disappearing marker is hard to see, so there remains a risky option with an acrylic marker.

Everything is fine, we print and paint.

White in 2-3 thin coats, and if you want it to be very beautiful, you can apply reflective paint on top.

As a result, in a couple of hours, we managed to repeat our own model of 10 years ago. Specifically, she only has a 3D printed arm, everything else is cast from polyurethane. nine0003

nine0003

What happens if you take a larger scale? A fellow doll modeler wanted to make a shopper with the Our Flag Means Death logo. Fusion hardly swallowed such a bait (translation to svg), but somehow managed. The stamp came out in the whole ender:

And the result is not quite clear for habit, but this makes the pirate flag only more colorful:

So the method is quite working, albeit with limitations. The main thing is not to splatter an excess of paint and at the same time prevent it from drying out. And don't be afraid to experiment! nine0003

3D printed mesh fabric

Prologue

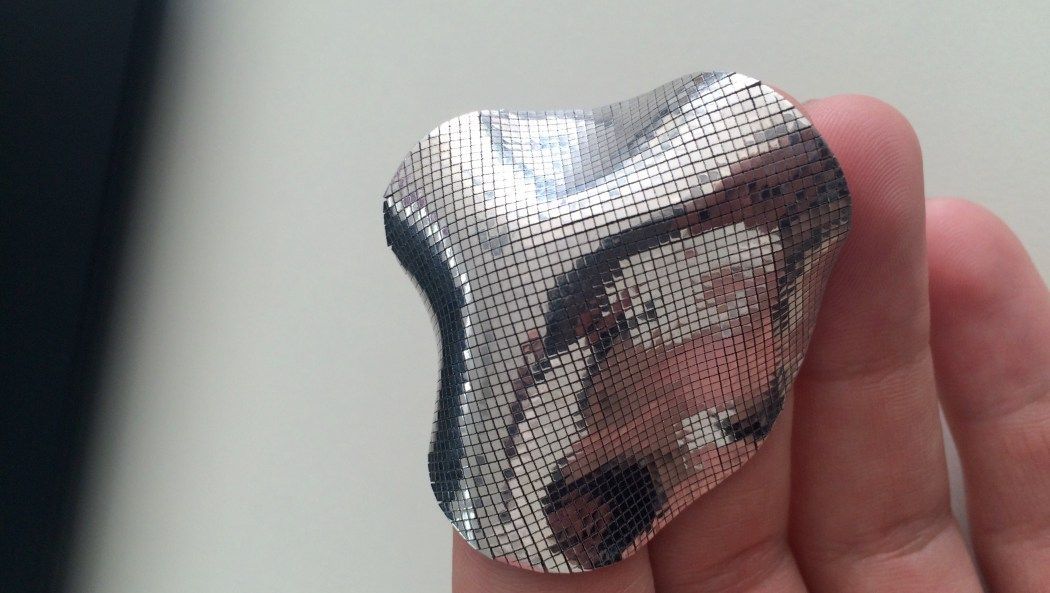

Hello everyone! I am developing "smart sequins" - electromechanical color-reproducing devices for designer clothes. Our team is passionate about the idea of creating clothes and accessories that can change their color at the request of the owner or depending on environmental conditions.

In this article I would like to talk about how we used 3D printing in our project, share our experience and tools. nine0003

nine0003

3D printing on fabric

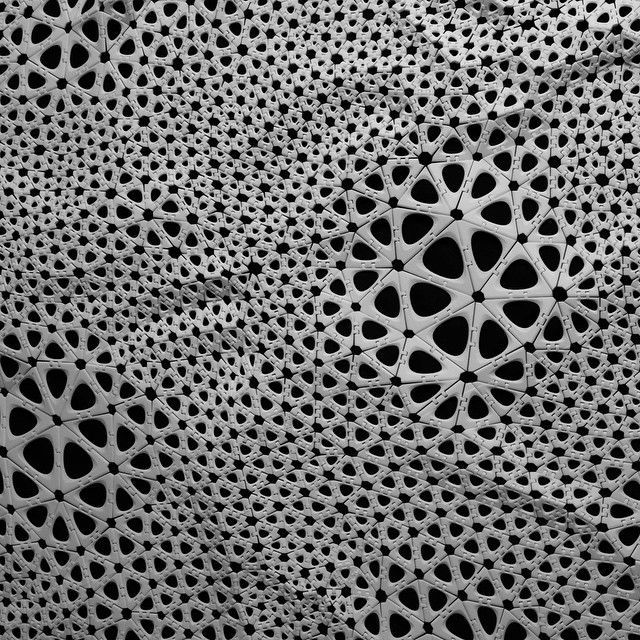

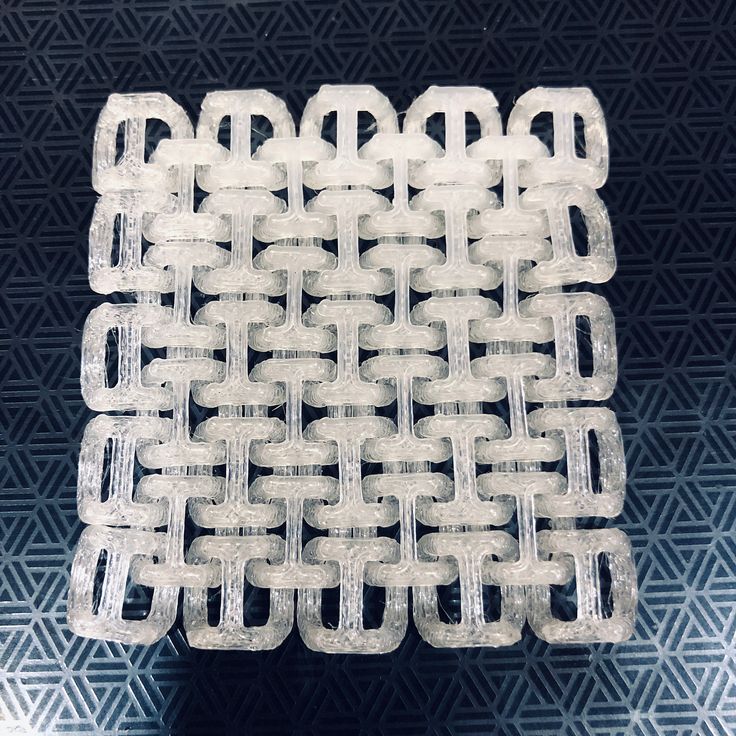

One of the tasks that I had to solve was to figure out how to make an elastic fabric out of plastic sequins, which in its properties would resemble textile materials. At the same time, it is necessary to provide for the possibility of easily creating electrical connections between the sequins.

There are quite a few articles and materials about making clothes on a 3D printer. Many different methods have already been invented, from creating hinges right in the printing process to printing with elastic plastics. nine0003

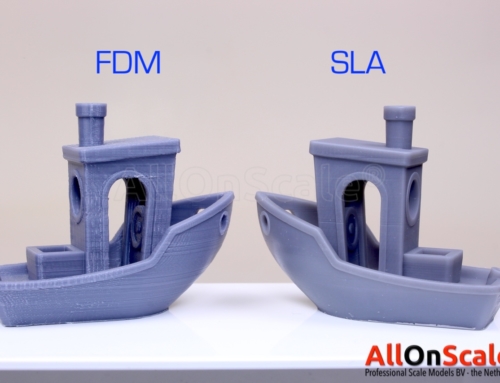

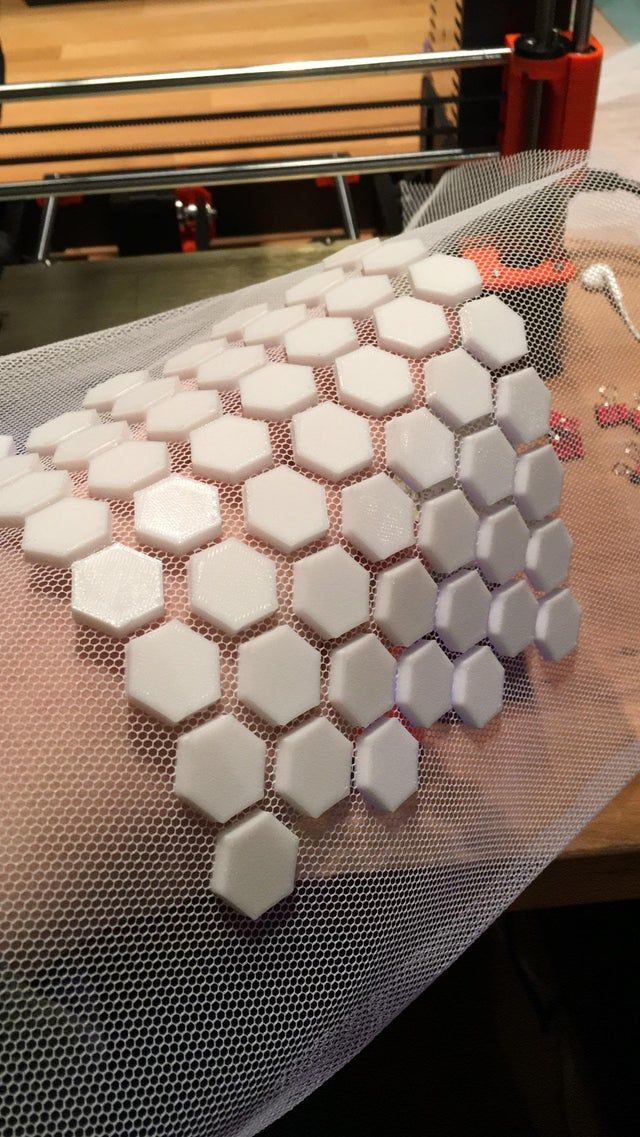

While looking for a solution, I came across this video. From it, I first learned about the method of printing on mesh fabric using a conventional FDM 3D printer.

The author himself claims that he spied the idea here: Shorey Designs.

The essence of the method is very simple. We create a 3D model of a fragment of the future canvas, then arrange a lot of fragments so that we get a whole canvas. We start the slicer and prepare the G-code. Before sending it to the printer, you need to insert a pause and raise the extruder before printing a certain layer. The printer will stop during operation. At this point, we cover the printed layers with a mesh cloth. We continue to print. Due to the presence of large holes in the fabric, the layers of plastic will interlock with each other, as in conventional printing, and the mesh fabric will be firmly integrated into the parts. nine0003

We start the slicer and prepare the G-code. Before sending it to the printer, you need to insert a pause and raise the extruder before printing a certain layer. The printer will stop during operation. At this point, we cover the printed layers with a mesh cloth. We continue to print. Due to the presence of large holes in the fabric, the layers of plastic will interlock with each other, as in conventional printing, and the mesh fabric will be firmly integrated into the parts. nine0003

Modifying G-code

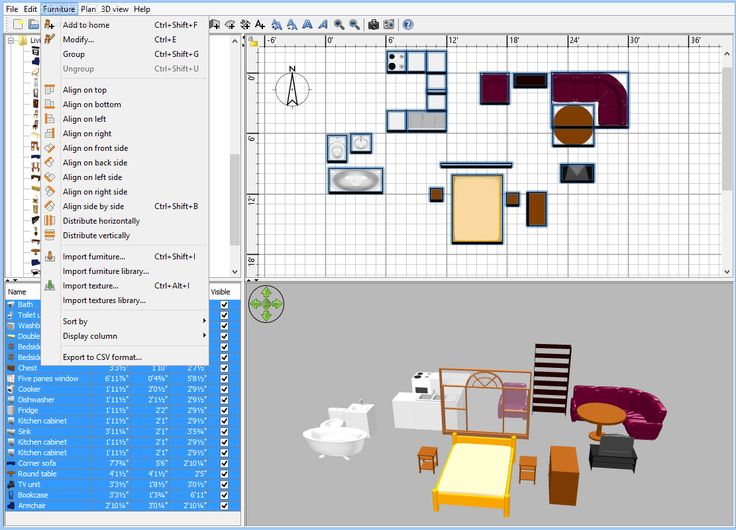

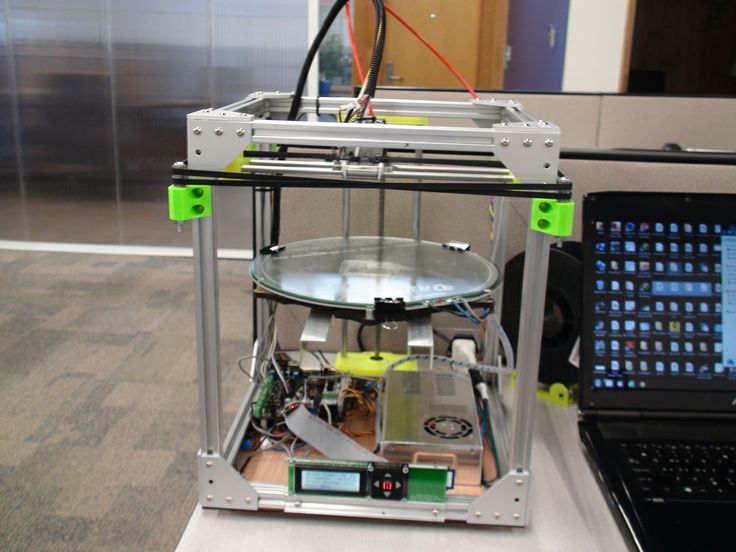

I use Cura version 3.2.1 as a slicer. 3D printer - homemade H-bot controlled by a board based on ATmega2560 (RAMPS 1.4) with Marlin firmware.

To pause the printer, there is an M25 command. Command for lifting in Z by 20mm: G0 Z20. It is noteworthy that the M25 must go before the ascent, otherwise the next command is processed first. Why this happens is a mystery to me, apparently somehow connected with the processing of commands by the printer. nine0003

Add commands to G-code:

Operation automation

Manually searching for the required line in the G-code file and inserting commands is not the most modern solution, I thought and wrote a simple program that allows you to open and view toolpaths.

For the convenience of viewing the layers, the "explode" command is provided, which allows you to visually increase the distance between the layers of the model. After pressing the "insert pause" button, the distance between the marked layer (red) and the previous one increases. This means that the print will be interrupted precisely between these layers. nine0003

To understand where one layer ends and the next begins, I used the comments that Cura kindly provides in its output files. The keyword ";LAYER:X" allows you to accurately find the boundaries of layers in a text file.

Pressing the "write file" button allows you to save the modified G-code in the specified location.

Save the file to the SD card and bring it to the printer.

It's funny that only when preparing this article, I came across a video in which they tell how you can do the same thing using standard Cura tools ... But the process is already running, it's too late to slow down! nine0122 Here, starting at 7:30, it is described in detail how to do it.

Well ... hurry up - learn how to parse G-code!

Trying to print

Formation of the first layers. We print on glass. Heated table. Table temperature 60⁰С, printing temperature 220⁰С. The print material is PLA plastic. Layer height 0.2mm.

During the pause, lay down the fabric and fix with magnets. Since the table is aluminum (paramagnetic), we put the magnets on the top and bottom sides of the table. Fixation is made in 4 places, in the corners of the part. This is quite enough. The main thing is not to place them too close to the print area, otherwise the magnets will stick to the print head. nine0003

After 40 minutes, this is the structure. The thickness of each 6 carbon element is 1mm. The gap between the elements is 2mm.

In this experiment, tulle was used as the backing fabric. It is a lightweight mesh fabric of medium stiffness, woven from polyester threads.

Experiments have also been made with mosquito net printing. In the hardware store, there were two types of them: fabric and fiberglass. Fabric mesh is softer than tulle, but has greater mechanical tensile strength, as well as less elasticity. The fiberglass mesh is harder than tulle, its mechanical strength is the highest of all participants in the experiment. nine0003

In the hardware store, there were two types of them: fabric and fiberglass. Fabric mesh is softer than tulle, but has greater mechanical tensile strength, as well as less elasticity. The fiberglass mesh is harder than tulle, its mechanical strength is the highest of all participants in the experiment. nine0003

Hexagonal sequin printing on fiberglass mosquito net. The gap between the elements is 1mm. The matrix is very hard. Clearance is clearly not enough.

Round sequin printing on fiberglass mosquito net. The gap between the circles is 2mm. It has a lot of flexibility, but there is too much unfilled space between the sequins.

After several test prints, the fabric mesh was chosen. She formed the basis of the matrix of smart sequins. The resulting matrix can bend in all directions. nine0003

The video demonstrates the operation of the program, the printing process and the final result.

Conclusion

The method of printing on the mesh fabric proved to be very good. This is an ideal solution for our task, because the fabric substrate allows us to weave conductive threads into it, which are used to provide electrical connection between the individual sequins of the matrix. Moreover, the formation of a “pattern” of conductors can be carried out at the preparatory stage. And the 3D printing itself is later. nine0003

The strength of the resulting structure depends mainly on the strength of the substrate material. But the flexibility will also depend on the distance between the sequins, as well as their shape.

The developed program still needs to be improved. For example, you can finish the retract before lifting, allow the user to adjust the height of the extruder.

Link to the source code for the processing environment.

And also a link to the release with the .exe file of the program.