Daihatsu 3d printing

Daihatsu to Create Customizable Effect Skins for Cars

January 26, 2022

Daihatsu Motor Company paves the way for customizing and supplying parts to customers with 3D printing.

Designed by consumers with help from Stratasys.

Many consumers choose a car as a means of expressing themselves. But most of the time, it is the vision of the vehicle’s designer that the customer selects, rather than their own. Daihatsu Motor Company, a manufacturer of small and lightweight cars based in Ikeda, Osaka, Japan, wanted to place more customization and design freedom directly into the hands of its customers. The automaker relied on Stratasys 3D Printing technology and expertise to bring the customer into the design process in a totally new way.

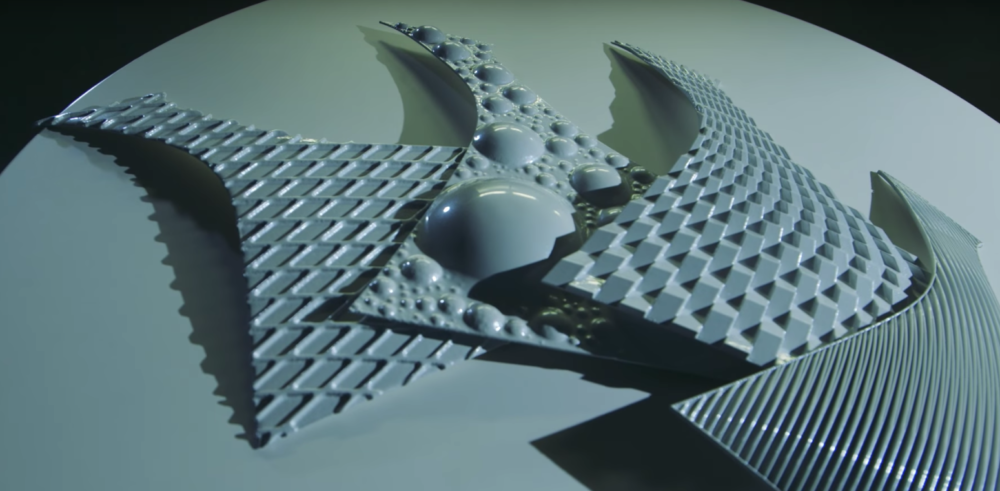

A man inspecting a 3d part with texture.Stratasys partnered with leadership at Daihatsu, along with outside design partners, to create Effect Skins – intricate, tactile patterns built with Stratasys 3D Printers. When placed on the front and rear bumpers of the Daihatsu Copen, a popular two-door convertible, the Effect Skins frame the head and tail lights, creating a flash of expression as the “face” of the car.

Osamu Fujishita, general manager of the product planning division for Daihatsu, said the automaker chose the Copen model for the Effect Skins because owners are enthusiasts who have a tremendous passion for their cars, and enjoy sharing it by customizing them. This project harnessed direct digital manufacturing to produce production parts – instead of prototypes – engineered to withstand real-world conditions on the exterior of the car.

Design freedom for customer personalization.

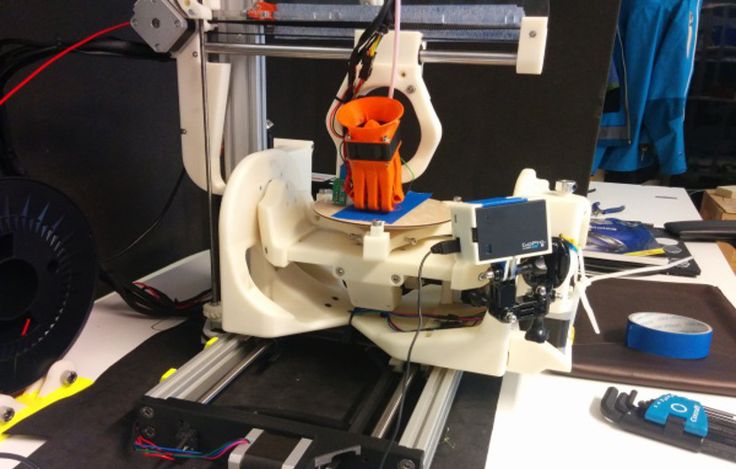

Bringing the Effect Skins to life required a team of automotive insiders and outsiders to work collaboratively with Stratasys experts.

Kota Nezu, whose Tokyo-based company Znug Design manages planning and design for industrial products, such as cars and motorcycles, served as a facilitator between Daihatsu and Sun Junjie, a 3D modeling artist. Junjie had extensive experience in the fashion industry as well as a deep understanding of Stratasys technology but was a newcomer to the automotive industry. That perspective was a perfect fit for the Effect Skins project and helped open up a world of design possibilities.

Junjie had extensive experience in the fashion industry as well as a deep understanding of Stratasys technology but was a newcomer to the automotive industry. That perspective was a perfect fit for the Effect Skins project and helped open up a world of design possibilities.

Using Stratasys 3D printing technology to customize and supply parts to customers and to allow self-expression within a single car is, I believe, a first.

Osamu Fujishita, Daihatsu Motor Company

Effect Skin designs created using ASA thermoplastic.Drawing inspiration from nature and fashion, Junjie and Nezu developed 15 patterns, with themes ranging from geometric to organic. Because the customer can adjust the parameters of the designs themselves, there are exponentially more styles and preferences that can be personally customized.

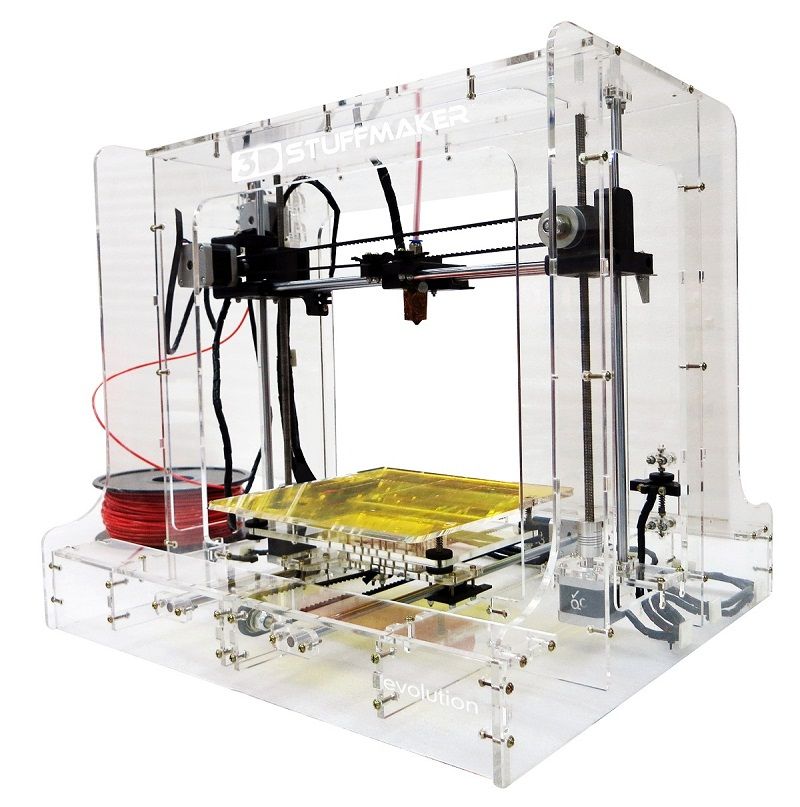

Daihatsu 3D printed the Effect Skins in ASA thermoplastic, which is durable and enables thin, but sturdy walls. It is also available in 10 colors, allowing for even more design possibilities. The ability to quickly 3D print and test design concepts and iterations empowered Junjie to experiment with many different design algorithms and iterate numerous styles quickly.

The ability to quickly 3D print and test design concepts and iterations empowered Junjie to experiment with many different design algorithms and iterate numerous styles quickly.

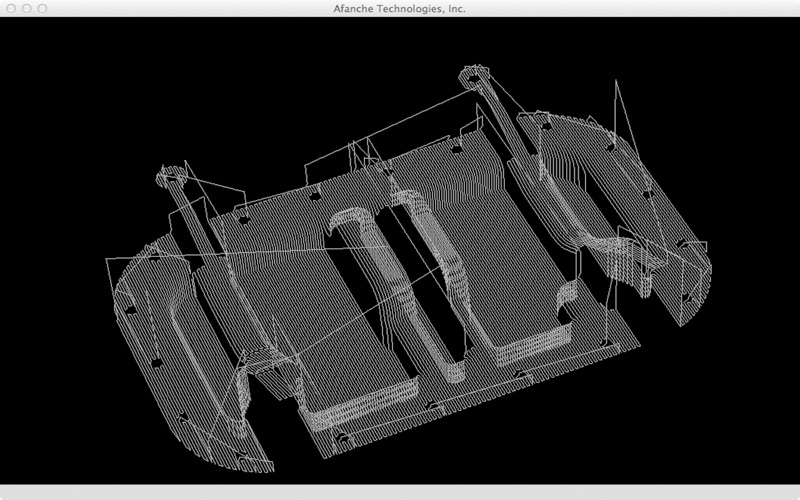

“Normally, there is a gap in the process in going from data created with 3D CAD to producing the object—the modeling and the actual sculpting are different areas,” Junjie said. “This project would not have been possible with traditional manufacturing or tooling methods,” Nezu said.

Stratasys 3D printing allowed Sun Junjie and Kota Nezu to create multiple quick design iterations.<p>Customers can personalize their own Effect Skins.</p>A collaborative partnership.

Nezu and Junjie said there were many benefits of working with Stratasys beyond the technology itself. Stratasys application engineers made suggestions throughout the development process and provided expertise on both the technology and material capabilities.

“It’s much more than Stratasys producing something that we requested. We think of ideas together to make things work better to reach the final goal,” Nezu said. “We can form that sort of a team with them. That’s one of the biggest benefits.”

We think of ideas together to make things work better to reach the final goal,” Nezu said. “We can form that sort of a team with them. That’s one of the biggest benefits.”

Efficient, on-demand production.

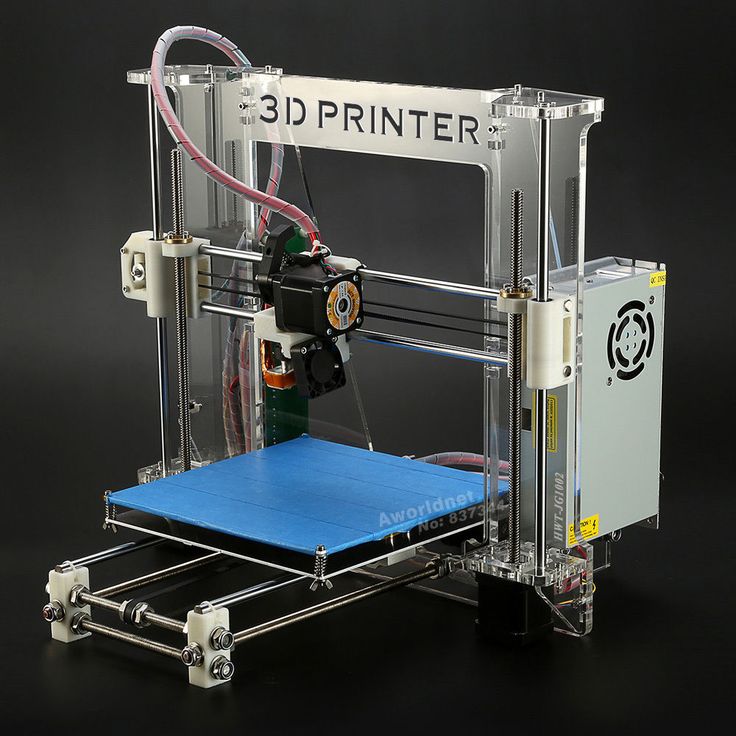

The traditional manufacturing method of reducing costs is the mass production of parts to take advantage of economies of scale. But this Effect Skins project illustrates the power of Stratasys 3D printing when it comes to creating both on-demand and cost-effective production parts.

“We believe on-demand production offers definite benefits to supply chain efficiencies and allows easy access for customers,” Fujishita said. “So we see it as essential in growing the market for these products and that’s how we are moving forward.”

Nezu observes two primary advantages for manufacturers that use 3D printing: the ability to develop multiple designs in a short amount of time, and just as importantly, the ability to bring customers into the production process itself.

“What really interests me is making cars even better, more enjoyable products for their customers,” he said. “That’s where I sense a lot of possibility — cars could become more open-source products where the customer or a third party can come in and help make the automobile industry more customizable. And with Stratasys 3D printing technology, open and innovative manufacturing is now possible.”

3D Printed Mass Customization for Daihatsu's Copen Cars

Customers Will be Able to Customize Their Copen Convertibles with Stratasys 3D Printed Effect Skins

Daihatsu Motor Company, known for manufacturing compact, lightweight cars, will offer customers customized design elements for car exteriors. Stratasys FDM 3D printing technology was used to “build” these three-dimensional patterns, called Effect Skins, for the front and rear bumpers of Daihatsu’s Copen 2-door convertible. “Using Stratasys 3D Printing technology to customize and supply parts to customers and to allow self-expression within a single car is, I believe, a first,” said Osamu Fujishita, General Manager, Corporate Planning Department, Brand DNA Office, Daihatsu Motor Co. , Ltd.

, Ltd.

Daihatsu Copen owners will be able to choose from 10 Stratasys ASA 3D printing material colors and 15 base patterns to create their own signature designs

The auto experts at Daihatsu collaborated with designer Kota Nezu and 3D modeling artist Sun Junjie. Nezu’s firm, Znug Design, manages planning and design for industrial products, such as cars and motorcycles. Junjie has had extensive experience in fashion, as well as a deep understanding of what Stratasys 3D printing solutions have to offer, but had never worked with the automotive industry. The pair developed more than a dozen base patterns of Effect Skins in 10 different colors; customers can tweak the geometric patterns for truly unique signature designs for their car’s exterior.

Click here to keep up to date with the latest 3D printing breakthroughs for the automotive industry.

Examining an Effect Skins 3D Printed on the Stratasys Fortus 450mc Production 3D Printer

Nezu and Junjie explained that there were many benefits of working with Stratasys beyond the technology itself. Stratasys application engineers made suggestions throughout the development process and provided expertise on both the technology and material capabilities. “It’s much more than Stratasys producing something that we requested. We think of ideas together to make things work better to reach the final goal,” Nezu said. “We can form that sort of a team with them. That’s one of the biggest benefits.”

Register for a free webinar on the benefits and processes involved in 3D printing end-use parts.

Designer Kota Nezu (on right) and 3D modeling artist Sun JunjieDesigner Kota Nezu (on right) and 3D modeling artist Sun Junjie

Bringing customers into the design process is a great draw for Nezu. “What really interests me is making cars even better, more enjoyable products for their customers,” he said. “That’s where I sense a lot of possibility—cars could become more open-source products where the customer or a third party can come in and help make the automobile industry more customizable.”

“What really interests me is making cars even better, more enjoyable products for their customers,” he said. “That’s where I sense a lot of possibility—cars could become more open-source products where the customer or a third party can come in and help make the automobile industry more customizable.”

Watch the Daihatsu video case study

Daihatsu 3D printed the Effect Skins in ASA thermoplastic, which is durable and enables thin, sturdy walls. The ability to quickly 3D print and test design concepts and iterations allowed Junjie to experiment with many different designs and try and test numerous styles quickly.

Mass production of parts, a traditional manufacturing method of reducing costs, takes advantage of economies of scale. But Stratasys’ participation in the Effect Skins project means that certain parts can be personalized on-demand while remaining cost-effective. “We believe on-demand production with 3D printing offers definite benefits to supply chain efficiencies and allows easy access for customers,” Fujishita said. “So we see it as essential in growing the market for these products and that’s how we are moving forward.”

“So we see it as essential in growing the market for these products and that’s how we are moving forward.”

Follow Stratasys Automotive on our LinkedIn Showcase page for the latest advances in 3D printing for automotive design, engineering and manufacturing.

STL file daihatsu logo・3D printing design download・Cults

mack logo hood ornament

14 €

ford mustang logo 7

9 €

HOOD ORNAMENT Duck

14 €

lamborghini logo

9 €

nine0003 dodge ram hood ornament14 €

chanel logo 2

7 €

gucci logo 3

5 €

porsche logo

9 €

Best 3D Printer Files in the Miscellaneous Category

Smoke for #3DBenchy boat

Free

Skyglobe

12. 59 €

59 €

Coin Holder for Norwegian Kroner (NOK)

Free

VMO DECATHLON MASK ADAPTOR AND FIT 3M FILTER - 3D-PRINTED PROTECTIVE - CORONAVIRUS COVID-19

Free

1:4.5 scale Heinkel He-162 A2 RC giant jet model

17.16 €

Bioreactor - bioreactor

Free

Thwomp

Free

Bestsellers in Miscellaneous category

Addams Thing

1.99 €

Gremlin 640mm FPV 9 Bar0004

0.94 €

Giarados - articulated sea serpent

1,50 €

hinged shenron

3 €

HAND OF THE ADDAMS FAMILY

5 €

Mickey Christmas night light Litophane

3,50 €

Chainsaw Man - Denji

€17. -fifty% 8.94 €  88

88

CHRISTMAS TREE v2

1,50 €

WEDNESDAY HAND THING ADDAMS FAMILY V2

2,50 €

Adderini - 3D printed repeating slingbow / crossbow pistol

12.50 €

Bunch of Christmas balls ItsLitho

5,70 €

ItsLitho "Drop" personalized lithophane Christmas ball

1,90 €

Charizard - pokemon with flexible articulation (seal in place, without supports)

3 €

5 gnomes (without support)

2.49€ -10% 2. 24 €

24 €

Predator-inspired movable mask

6.20 €

flexible volute

2 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are is a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Daihatsu designer leather for cars / 3d print / 3Dmag.

org

org The oldest Japanese manufacturer Daihatsu, in collaboration with Stratasys, will offer their customers a truly unique opportunity: using 3D printing, they created designer skins that can be installed on any part of the car. Moreover, from order to delivery of products takes no more than 2 weeks. Thus, the Japanese auto concern became the first in the world to sell to customers the final product obtained using 3D technologies. nine0181

Eminent designers will also be involved in this difficult task: Kota Nezu from industrial design company Znug Design and 3D creator Sun Junjie, who works in the automotive field. Together they have already come up with 15 variants of "skin". Each pattern contains either a geometric or organic pattern. These small panels can be attached to the front or rear bumpers and fenders of the car. It is in the power of the client to customize the chosen design to his taste, changing the necessary parameters. Samples will be available in 10 colors currently supported by the Stratasys Fortus 3D printer. The "skins" will be made of modern ASA material, which has all the necessary properties: it does not deform, does not fade, and has a good margin of safety. nine0006

The "skins" will be made of modern ASA material, which has all the necessary properties: it does not deform, does not fade, and has a good margin of safety. nine0006

For now, this option will only be available to residents of Japan, but given the prevalence of Stratasys services around the world, expansion is not far off.

Related entries:

-

just4fun

3d printing → Controlled toy car without batteries 0 -

just4fun

3d printing → Ferrari Top Design School Challenge 2015 Winner nine0197 0 - Learn more