3D print engagement ring

$100 3D Printed Engagement Ring

Conventional wisdom says to spend one to three month's salary on your engagement ring. My fiancée and I are ardent Mustachians, and found this figure to be both ludicrously large (we'd much rather max out our Roth IRA's with that kind of money) and rather impersonal.

With this in mind, we decided to forgo a diamond (Have you ever tried to sell a diamond?) with an identical looking cubic zirconia stone purchased on ebay for about 1/1000th of what a similar sized diamond costs. The trouble then was finding a good setting.

Classical ring 1 from pinterestClassical ring 2 from pinterestElisa had, conveniently, already been hard at work researching styles of rings she liked. She favored a classical look, but try as I might, I couldn't find the original source of the rings she'd found, only rings that were similar, but not perfect. Through lots of google image reverse image searching and random combinations of keywords, I stumbled on this ring pretty close to the ones Elisa liked that actually was for sale:

3-Stone Vine Engagement Ring from http://rosestonejewelry.This ring came with an accompanying blog post that showed exactly how it was custom made. From the original sketches:

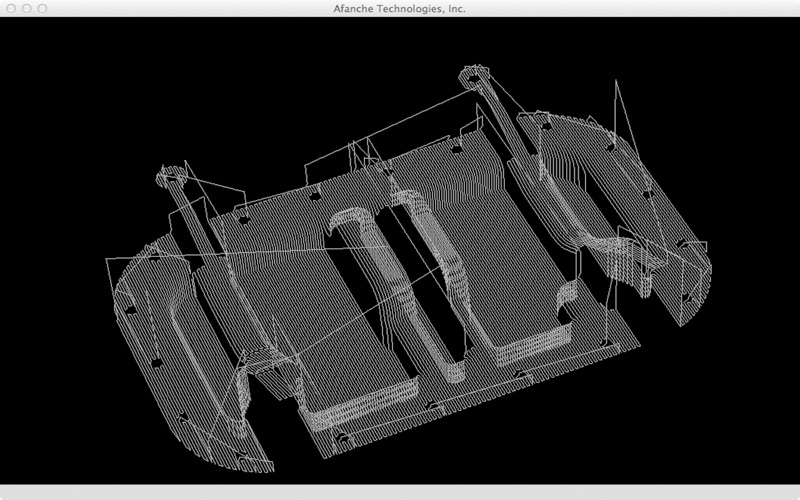

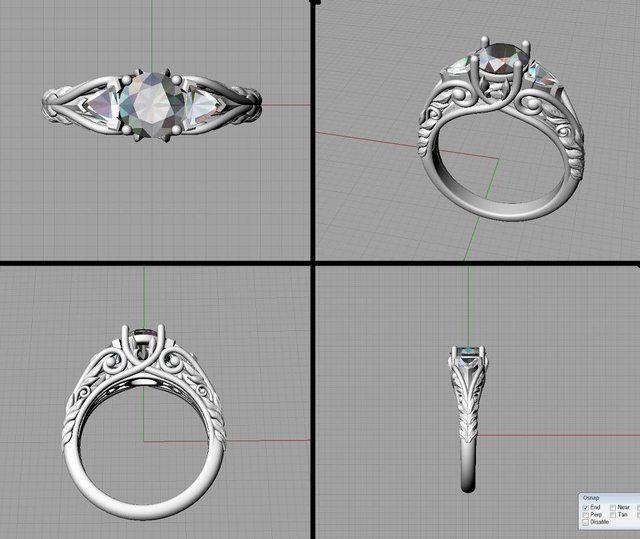

original sketches of 3-Stone Vine Engagement Ringto the 3D sketch:

3D sketch of 3-Stone Vine Engagement Ringthen 3D printed in wax:

wax mold of 3-Stone Vine Engagement Ringthen put in a lost wax casting plaster mold, filled with molten gold, and then dunked in a bucket of water so the plaster dissolves away:

gold filling of 3-Stone Vine Engagement Ringtaken out of the mold in a gold tree:

gold tree of 3-Stone Vine Engagement Ringcleaned:

raw 3-Stone Vine Engagement Ringthen polished:

polished 3-Stone Vine Engagement Ringfinal 3-Stone Vine Engagement RingThe post went on to describe an additional 12 hours of detailing (chasing and engraving) that was done on this particular ring before setting the gem - a very expensive and labor intensive process that added some detail, but Elisa and I actually preferred the smoother non-engraved look.

This blew me away - I had no idea you could just make a ring by 3D printing it. I thought they were hand engraved by people with really tiny hands or something, but apparently this is now a common practice in jewelry making. Here's an excellent video on the entire process:

I contacted the designer of this ring, Jeshua Rosestone, and asked for a quote for a ring without the blue side stones (neither Elisa or I liked them) resized for her finger. He promptly emailed back and explained that that ring was a custom order for $2,600, but that he could make the alterations and deliver a similar ring for us for $1,890.

This was still considerably more than I would have liked to spend on a ring (less money available to invest for retirement), so I asked how much a ring would be without the detailing. He emailed back understandably perturbed, but offered $250 for the raw 3D design and $200 for the gold casting, or $450 total.

He emailed back understandably perturbed, but offered $250 for the raw 3D design and $200 for the gold casting, or $450 total.

This was considerably better, but I got a strong feeling that he wouldn't be too happy about this deal (it would be an order of magnitude lower than his typical jobs) and may be difficult to work with if we wanted to go through a few iterations. With this in mind, I ventured off to get quotes from other 3D modelers that I could work closer with, with plans of trying to learn the lost wax casting and metal molding myself (knowing that wax models could be 3D printed online).

I went through the top three 3D printing online services (i.materialise, shapeways, and sculpteo) and tried to find designers that had made rings before that may be open to contract work. I found a great forum page on i.materialise of designer profiles and emailed every single one asking if they'd be interested.

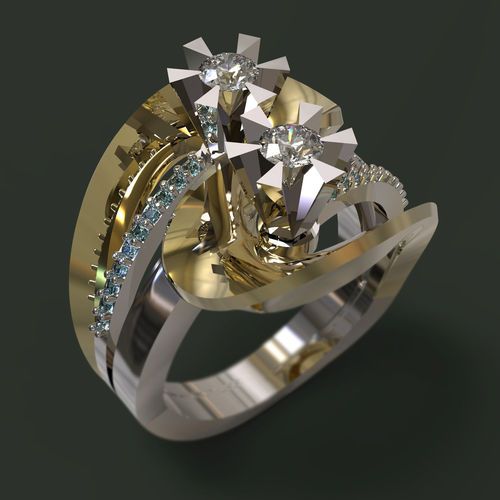

Dani Epstein's detailed work.I got a lot of rejects, and quotes all over the map: $200 to $600 (and remember, this is just for the design). I settled on moving forward with a designer named Dani Epstein, who had a very impressive portfolio including a piece of jewelry that had a lot of classical detail work.

I settled on moving forward with a designer named Dani Epstein, who had a very impressive portfolio including a piece of jewelry that had a lot of classical detail work.

He was also one of the lowest bids: he only charged £20 GBP (~$40 USD) per hour, and gave an initial quote of 4 hours (£80 GBP, or $160). Through our email correspondence, I felt he was a guy that I could work back and forth with for tweaking.

I sent him images of all of the rings we liked and tried to sketch out what I wanted the end result to look like. After only two hours, he came back with this:

first draftI was blown away, and made a mental note to get really good at 3D modeling one day (I asked him for some resources to get started and he recommended the free Blender program).

Dani came back the next day with a design that was exactly what I'd sketched out:

second draft3D file is too thin in some placesWhen seeing it all together, I didn't love the detail on the shoulders of the ring - the leafs were a little too much visually. Additionally, the 3D file had some trouble being printed (shapeways and i.materialise said a lot of areas were too thin).

Additionally, the 3D file had some trouble being printed (shapeways and i.materialise said a lot of areas were too thin).

We went back and forth a few times on various design changes and errors in the print process. The most embarrassing of which was that the ring was initially created with a 15.53mm radius instead of diameter. When this was fixed, the 6.5mm space for the stone was also shrunk by half, which we didn't discover until ordering a test print in plastic:

test print in plasticThis was especially evident when compared with a 1 carat ring I bought on ebay for $12:

diamond size is too smallA quick edit later and this too was fixed:

diamond resizedTotal, Dani charged £170 GBP, or about $290 USD. For all the customizing we did, and the willingness and help Dani gave through the process, I'm incredibly happy with how much I spent and how it turned out.

silver 3D print arrived!With this small change, I crossed my fingers and ordered the ring to be printed in silver (turns out the 3D printing companies will do the lost wax casting and polishing for you). The day this arrived I was elated.

The day this arrived I was elated.

The level of detail was much better than in the plastic prints, likely from the polishing process. It looked like a real ring! The last step was figuring out how to get the cubic zirconia on there.

I searched on youtube to see if it was something I could just do. Some videos made it look pretty easy, but for the quality and style of this ring it looked pretty complicated. I opted to have it professionally done at a local jewelry store.

They initially quoted $45, but Sophia (my sister) and I talked them down to $35.

Two days later and the finished ring was in my hands! A short while later, after engagement preparations had been made (parents' permission asked, time and place arranged, trying to hide everything from Elisa until the final moment, etc.) and it was finally on her finger:

if you like it then you should put a ring on itHere's a blurry closeup:

blurry closeupTotal cost:

- 1 carat CZ wedding ring (for emergency backup): $13.

41

41 - Handful of Cubic Zirconia stones in different sizes: $41.76

- Design by Dani Epstein: $290

- Handful of 3D printed rings to test different materials and size: $34.30

- Test print in plastic: $28.05

- Silver Print: $66.25

- Ring mounting: $35

- Total: $508.77

However, if we wanted to print an identical copy, the marginal cost would only be:

- 1 carat CZ stone: $5

- Silver Print: $66.25

- Ring mounting: $35

- Total for another ring: $106.25

the happy engaged couple

It was a lot of back and forth through uncharted territory, and a lot of unnecessary expenses, but I'm incredibly glad I went this route. The final ring - even with the extra overhead of learning the process as I went - was a fraction of the cost it would have been the traditional route, and feels like a much more personal token. At the same time, if the ring were ever lost, stolen, or damaged, we could sleep easily knowing we could have an identical copy made - perhaps even in a different material or with a different sized stone - in about two weeks for a hundred bucks.

Plus, now I have a perfect 3D model of Elisa's ring if we ever wanted to do something clever like make a chocolate mold out of it for wedding party favors or something.

tl;dr: 3D printed an engagement ring because we're living in the future. A++ would print again.

Update: I also 3D printed my own wedding ring as a plain wedding band, modeled in OpenSCAD. Here's what it looks like:

my 3D printed plain wedding band2019-06-14 Update: wow! I've had so many people reach out to me asking about this process. Several have 3D printed rings of their own. If you've 3D printed your ring from the advice in this article, send me a picture and I'll add it below!

3D printed ring from Sam O.Buy 3D Printed Engagement Ring Online I LACE Wedding Ring Collection

Buy 3D Printed Engagement Ring Online I LACE Wedding Ring Collection Skip to contentThis site has limited support for your browser. We recommend switching to Edge, Chrome, Safari, or Firefox.

Congratulations! Your order qualifies for free shipping Spend $100 more for free US shipping.

Carbon Collection Available now here!

the LACE Sampling Program Available now here!

A departure from tradition, the LACE by Jenny Wu wedding collection reinvents the classic symbol of timeless love.

View collection

Introducing

An innovative approach to your wedding rings, from design to finish.

The LACE Wedding Collection embraces a bold, elevated take on the traditional wedding ring. Each engagement ring and wedding band is designed as the perfect set, to stack seamlessly on your hand. Our digitally crafted pieces are made to order and never mass produced. Each ring carries the detail and precision that only 3D printing technology can accomplish, and finished off by our master craftsmen in Downtown Los Angeles.

SHOP NOW

LACE Engagement Rings

Our 4 Signature Sets - Your ring should reflect who you are.

We designed 4 unique rings, each with a distinct personality. Learn more about each ring, and find the perfect one for you.

Statement - RHEA AND HERA SET

Statement - RHEA AND HERA SET

Quiet Luxury - Iris and Agnes set

Quiet Luxury - Iris and Agnes set

New Classic - CLIO AND LYRA SET

New Classic - CLIO AND LYRA SET

Bold - Amare and sera set

Bold - Amare and sera set

I fell in love with the Amare engagement ring and ended up buying an entire set for my husband and I.

Thank you for creating such unique, beautiful designs. I feel special every day wearing them.

Valerie Victoria Customer

These jewelry pieces are like no other. They're stunning in their geometry and form, fascinating in production and material - all rendering something very thoughtful and special.

Shelley Tupac customer

Love the art of each piece. A true unique collection in the way it’s made - an innovative staple in your jewelry wardrobe.

Rachel Flanagan customer

Have questions?

Contact our team to find the perfect ring, get help with sizing, styling, or just to chat!

Message us here!

Cart

Congratulations! Your order qualifies for free shipping Spend $100 for free shipping

No more products available for purchase

Your cart is currently empty.

Pair With

Add Order Notes

Leave a note about your order

Estimate Shipping

First Name

Last Name

Company

Address1

Address2

City

Country

Province

Postal/Zip Code

Phone

Items $0.00

Subtotal $0.00

Shipping, taxes, and discount codes are calculated at checkout

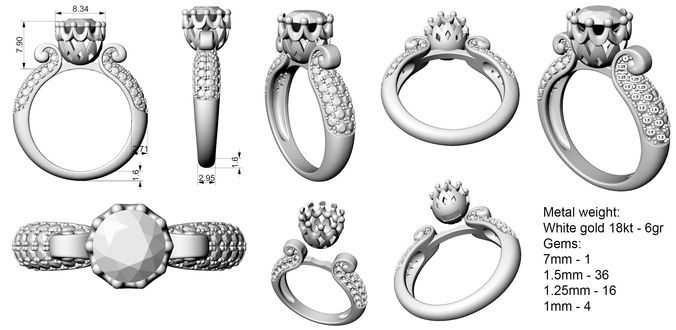

Custom jewelry

Custom jewelry1

Feel free to send us your ideas. This can be a freehand sketch or a photo with the desired design

2

The fashion designer will create a 3D model of your future jewelry according to your sketch

3

After agreeing on all the details, the jeweler will make the jewelry of your dreams according to the 3D model

Art. 12119

12119

15.1 g nine0005

Women's ring with chrysolite tree branch CHRYSOLITE WOMAN SIGNET

from 158 320 ₽ for one

Order

Art. 30303

20.4 g

Slavic amulet rings with diamonds

Insert: diamond

from253 870 ₽ per pair

Order

new

Art. 30504

130.2 g

Runic male pendant-talisman with tsavorites RUNIC AMULET

Insert: diamond

from 147 440 ₽

Order

Art. 30406

30406

0 g

Men's neck chain

Insert: without insert

Price on request

Order

Art. 12381

25 g

Male signet with family coat of arms

Insert: no insert

from 151 730 ₽ for one

Order

Art. 14832

14 g

Wedding rings with flowers and leaves pattern

Insert: without insert

from 100 870 ₽ per pair

Order

Art. 30280

30280

8 g

Wedding rings with an ornament on the inside

Insert: no insert

from 144 290 ₽ per pair

Order

Art. 10349

17 g nine0005

Wedding rings with butterflies BUTTERFLIES

Insert: diamond

from 130 660 ₽ per pair

Order

Art. 9144

20 g

Men's signet with a Roman eagle and coat of arms

Insert: no insert

from27 300 ₽ for one

Order

Art. 30273

30273

35 g

Male cross with a crucifix MAN CROSS I

Insert: without insert

from 180 920 ₽

Order

Art. 30275

13 g

Pendant Scorpion SCORPION

from 106 170 ₽

Order

Art. 302751

16 g

Scorpion platinum pendant SCORPION PLATINUM

Insert: sapphire

from 288 650 ₽

Order

Art. 15978

8 g

Wedding ring PUZZLE

Insert: without insert

from57 620 ₽ for one

Order

nine0004 Art. 30326

30326 4.2 g

Original GREEN BOTTLE earrings

Insert: swarovski

from30 790 ₽

Order

Art. 30336

8.3 g

Diamond skull earrings PRETTY SKULLS

Insert: diamond

from 145 020 ₽

Order

Art. 30323

23.5 g

Designer platinum brooch with ruby DRAGON

Insert: ruby

from285 360 ₽

Order

Art. 30311

14.5 g

Platinum wedding rings with diamonds

Insert: diamond

from268 060 ₽ per pair

Order

Art. 30459

30459

2.2 g

Yellow gold pendant with a large pearl and diamonds ROYAL PEARL

Insert: diamond

from80 940 ₽

Order

Get Married in New York: American Startup 3D Prints Wedding Rings

- Technologies

- Amy Feldman Author

Holden's young founders offer inexpensive, uniquely designed rings, all thanks to 3D printing

Two college friends set up a small jewelry business to create fine jewelry. Based on it, they came up with the Holden project, a brand of inexpensive engagement rings with a unique design made of an alloy of platinum or gold, the price of which starts at $250 - all thanks to 3D printing. nine0005

Based on it, they came up with the Holden project, a brand of inexpensive engagement rings with a unique design made of an alloy of platinum or gold, the price of which starts at $250 - all thanks to 3D printing. nine0005

Finished reading here

Andrew Lim, 26, and Simon Zhang, 25, met in Dartmouth during an internship at a marketing company in Connecticut. There they not only worked, but also lived together. “We came home, cooked dinner together, played basketball and got to know each other very well,” recalls Lim.

After graduating, Zhang, a self-taught jeweler, slowly started making bead bracelets like his family's, and soon he and Lim started a unisex jewelry business. Zhang called it Mujo, an expression of the idea of impermanence, characteristic of Zen philosophy. Mujo now makes rings and bracelets and sells them online or at craft fairs, generating roughly $200,000 in sales. Not much, but it was enough for some frugal friends to start Holden. Now they continue to manage both companies located in New York. nine0005

Not much, but it was enough for some frugal friends to start Holden. Now they continue to manage both companies located in New York. nine0005

As Lim recalls, the idea for Holden came from Mujo when customers saw stylish rings and asked if they could order something similar for a wedding. With more than two million marriages in the US every year, Lim says engagement rings are still made and sold in much the same way as they used to be, although other types of jewelry and clothing have gone online, cutting out the middle man and cutting prices. for consumers. A number of new direct-to-consumer jewelry brands such as Noemie, Vrai & Oro and Do Amore sell engagement rings online and offer a wide range of more expensive rings, including models with diamonds and other precious stones. nine0005

Lim argues that Holden's focus on engagement rings, rather than engagement rings, is a larger and more lucrative area that sets Holden apart from the competition. “Now everything is arranged so that you can order a designer ring and pay a fortune, or buy something cheaper, but standard and banal. So when clients contacted us and asked: “Can I add something?” or “Can I engrave?”, we answered: “Yes,” says Lim. When his brother got engaged last year, they went shopping together but eventually gave up: his brother got an original version of one of Holden's first engagement rings. nine0005

“Now everything is arranged so that you can order a designer ring and pay a fortune, or buy something cheaper, but standard and banal. So when clients contacted us and asked: “Can I add something?” or “Can I engrave?”, we answered: “Yes,” says Lim. When his brother got engaged last year, they went shopping together but eventually gave up: his brother got an original version of one of Holden's first engagement rings. nine0005

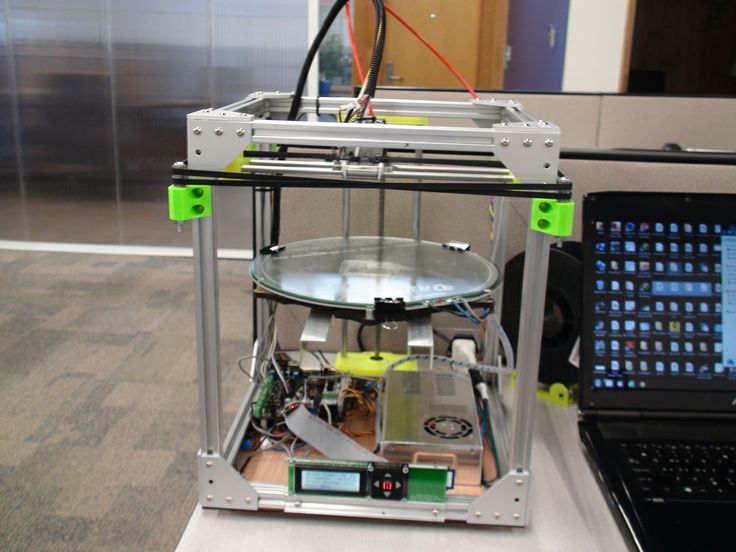

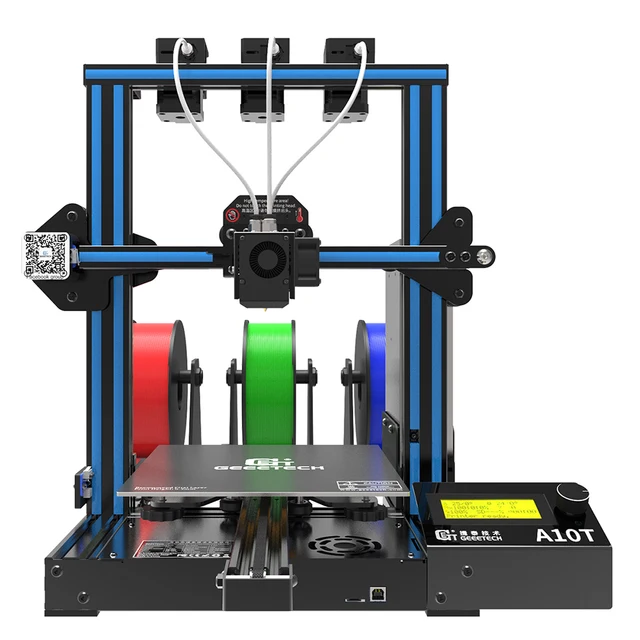

Holden offers six base models and customers can choose from width, metal, finish and optional engraving. The process of making rings begins with a model that is made on a 3D printer from wax. The model is then cast in metal (Holden is assisted by a jeweler-caster from Manhattan), a common procedure in the manufacture of jewelry of all kinds. They do not make blanks, and products can be personalized relatively inexpensively in three to four business days. “Just four years ago, 3D printing was prohibitively expensive for most jewelry,” Zhang says.