3D printer xyz printing

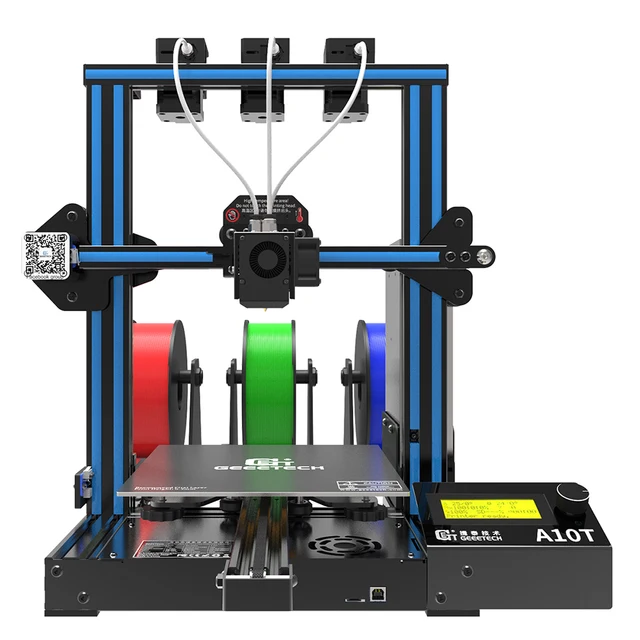

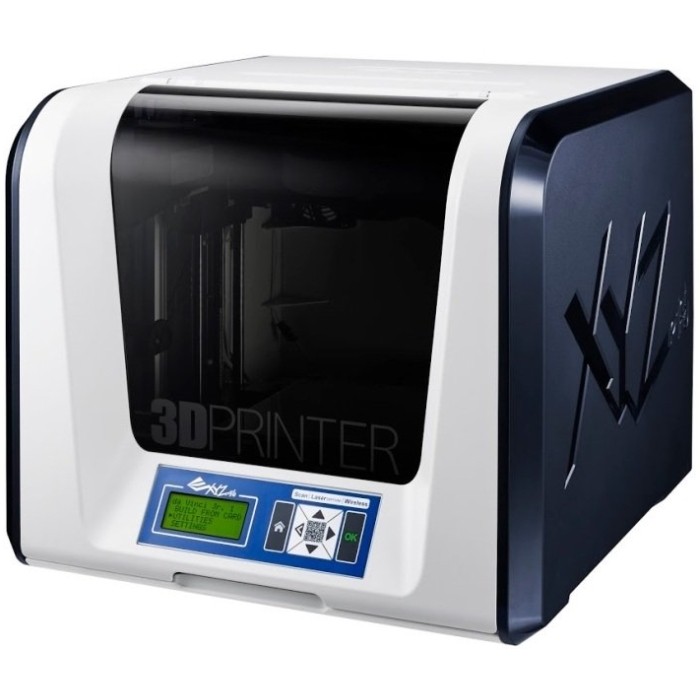

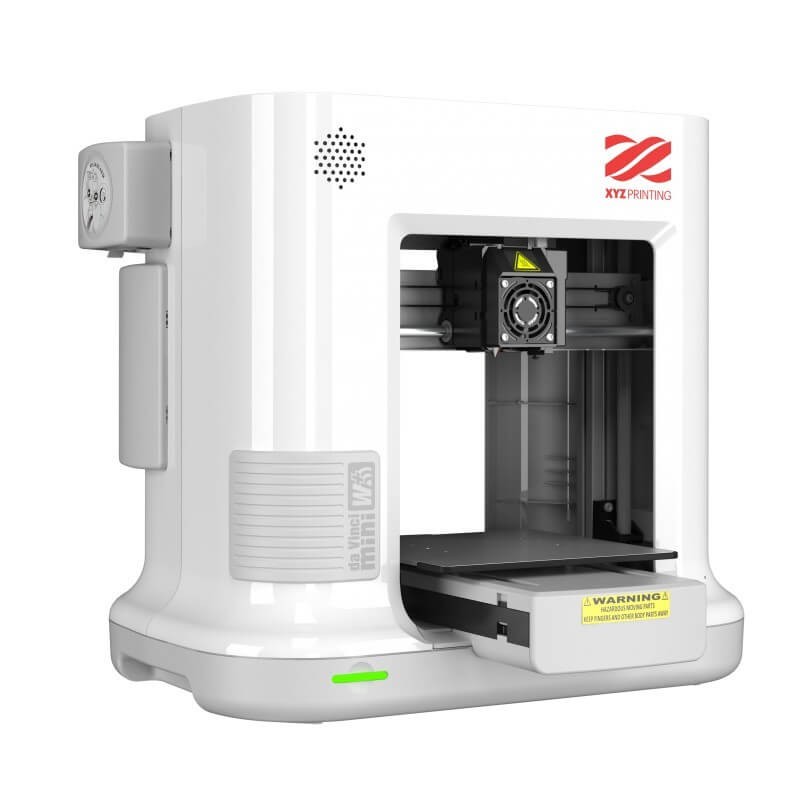

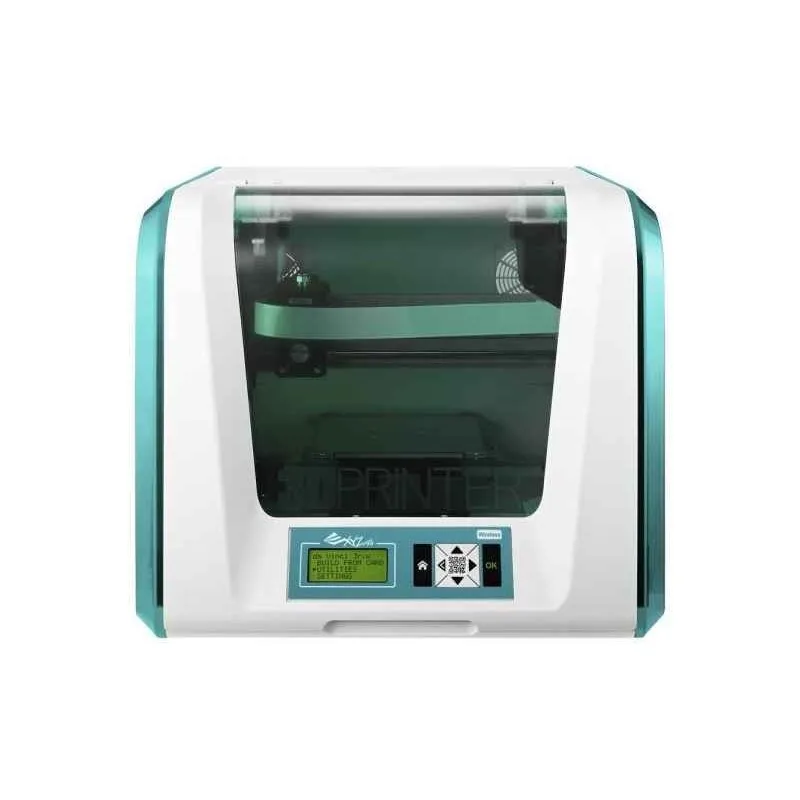

XYZPrinting Da Vinci Mini Review 2022

Heard about XYZPrinting Da Vinci Mini 3D printer? We did as well and decided to test one of them to see if they're worth it. Here are our findings!

By Justin Evans

4

See Price

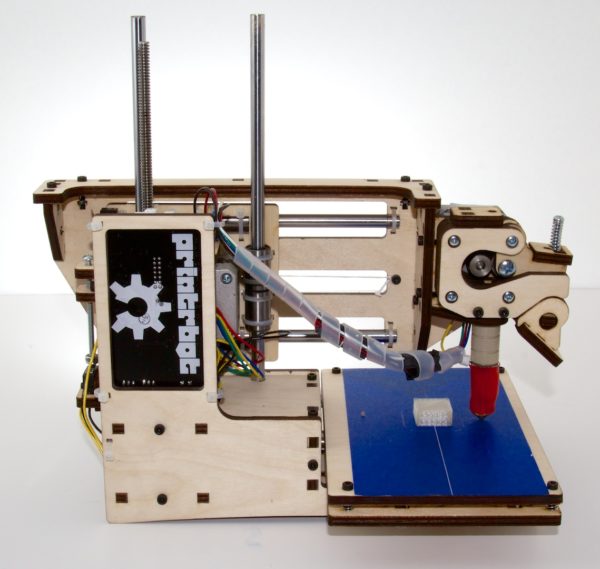

So you’ve decided to get into the world of 3D printing. Where do you begin? There are printers for every possible requirement, and there’s a lot of jargon floating around that makes it hard to accurately compare different models. Relax – we’re here to help.

XYZPrinting is known for creating some of the best entry-level 3D printers around. Today, we’ll be looking for any strengths or weaknesses that the Da Vinci Mini might have– it’s a small printer, but it’s certainly capable. However, is it right for you and your needs? You’ll have to read on to find out.

| Filament Diameter | 1. |

| Extruders | 1 |

| Supported Materials | PLA |

| Connectivity | USB, WiFi |

| Printing Speed | 100mm/s |

| Build Volume | 5.91 x 5.91 x 5.91” |

Table of ContentsShow

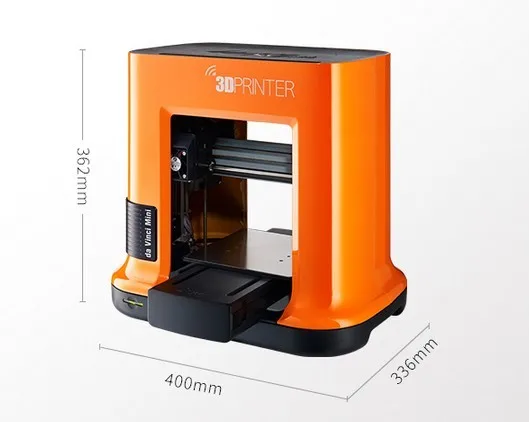

Design

The XYZPrinting Mini comes pre-assembled, so there’s no need to factor in build time. It’s a small-sized unit, perfect for sitting on your desktop, but this does mean that the build area is similarly restricted. Don’t get us wrong – you’ll be able to print decent-sized models, but nothing too huge.

Notice how there’s no enclosure? This means that it’ll be a little louder when you print, but all things considered, it’s still fairly quiet since the mechanical parts are mostly covered by the plastic frame. There are also implications for heat retention, but that’s not an issue, as we’ll explain later.

You get exactly what you’d expect from a low-end printer: there’s a single extruder and a maximum speed of 100mm/s. This is fairly standard and just means that you’ll take slightly longer to print. However, as the build area is only around 6” in each direction, you won’t be waiting hours unless you’re trying to print a large, solid cube.

Printing

There are three different speeds to choose from. As expected, the faster you print, the rougher the final quality. We found that the fastest setting resulting in significant stepping on curved surfaces, while if you allow it to take its time, your models look far better, but still not professional-level.

In an attempt to keep things as simple as possible for new users, XYZPrinting has limited the Mini to using PLA filaments. This removes the need for an enclosure but does restrict you somewhat in terms of the things you can build. Still, for beginners, PLA is more than enough to get you started.

The overall quality of the prints is too low for manufacturing, and the build volume too small for mass-production. However, it’s perfect for people looking to print things for their home or office. Better still, it takes any 1.75mm PLA filament – not just those made by XYZPrinting.

However, it’s perfect for people looking to print things for their home or office. Better still, it takes any 1.75mm PLA filament – not just those made by XYZPrinting.

Features

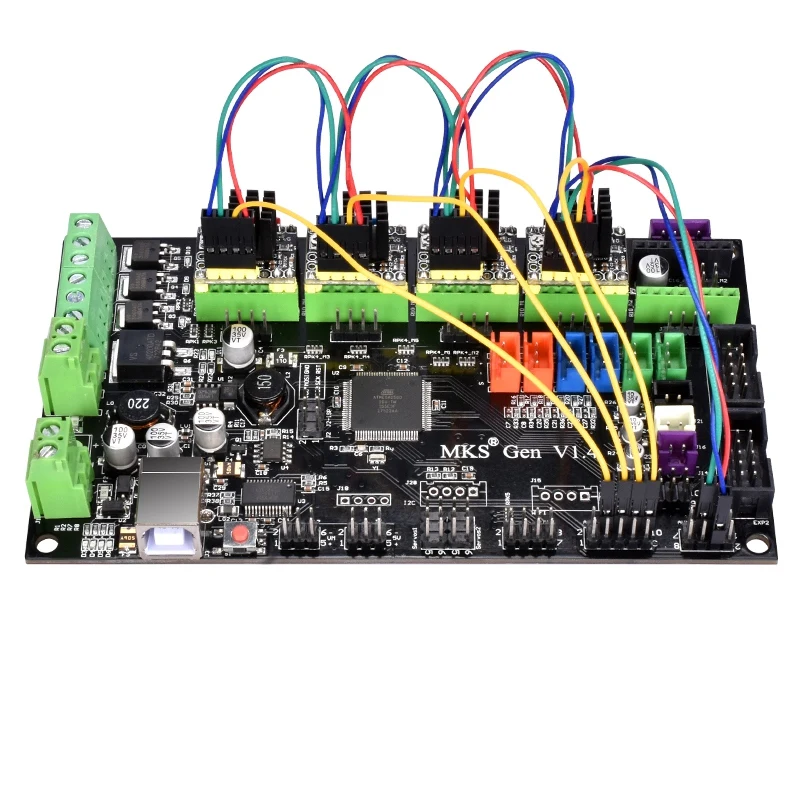

So what other features does the Mini have to make things easier for beginners? Well, instead of adding things, XYZPrinting has removed components. There’s no heated bed, for instance, and no built-in screen. You do have a USB connection, though, and WiFi functionality, which is almost unheard of in low-budget printers.

We were pleased to see that drivers are available for both Windows and Mac computers. On the other hand, there’s no Linux support. It supports four different file types, though, so you’re not really limited to using a particular modeling program, which is great.

Even the interface is simplistic. There’s a single button for starting a print and a status LED that lets you know how your print is going. All in all, it’s easy to use even if you’re not particularly tech literate. Let’s be honest – that’s never a bad thing.

Let’s be honest – that’s never a bad thing.

Cost

Here’s the thing: the Da Vinci Mini isn’t available in the United States. You can buy it from several European locations, though. It costs around $700, which makes it among the cheapest, most robust 3D printers we’ve covered. Of course, you’ll have to find a company to ship it over if you’re in the US.

Running costs are minimal. PLA is among the least expensive materials you can use, and since while third-party filaments aren’t supported, you can easily mod it to accept them. Large spools of PLA often cost less than $20 so really, your monthly material costs will depend on how often you print.

We think that this 3D printer is appropriately priced. It’s clearly intended for novice users, and the price point helps it stay affordable, unlike more advanced printers that offer user-friendly features. You’ll likely outgrow it in a year or two, but until then, it’ll serve you well.

Support

XYZPrinting’s support section provides customer help telephone numbers for 11 different countries. Best of all, each of these can talk to you in the native language or English. This is almost unheard of, and we’re genuinely delighted to see this level of help being offered for free.

Best of all, each of these can talk to you in the native language or English. This is almost unheard of, and we’re genuinely delighted to see this level of help being offered for free.

The limited warranty period is similarly outstanding. You’re covered from factory defects for up to two years at no extra cost, presuming you bought the printer from one of XYZPrinting’s recommended sellers. There’s no option to extend this warranty, though, which is a bit of a shame.

Customers can consult model-specific FAQs and tutorials in case they need any technical help. There are also different versions of the software, as well as documentation for each printer model here. All in all, it’s one of the most comprehensive support packages offered by any major 3D printing manufacturer.

Cetus 3D Printer Review

Staples® Official Online Store

End of the year deals are here

End the year with a bang and prep for the new year with awesome deals from Staples. Start with Staples Black Friday deals on everything from computers and tech to gaming chairs, printers, and more! The savings continue with a week of Cyber Monday deals you don't want to miss! Use this time to stock up on essentials, update your office, and find gifts they'll love receiving.

Start with Staples Black Friday deals on everything from computers and tech to gaming chairs, printers, and more! The savings continue with a week of Cyber Monday deals you don't want to miss! Use this time to stock up on essentials, update your office, and find gifts they'll love receiving.

With the new year right around the corner, it's the perfect time to refresh your office and replenish your supplies. Get back to work and take advantage of savings on ink and toner, office furniture, packing and shipping supplies, and more. Stock up and save on all kinds of supplies for the office. Get deeper discounts on supplies like copy paper, file folders, and writing supplies when you set up a business account with Staples Business Advantage or order using the Staples AutoRestock feature.

Make sure you're prepared for the upcoming tax season

As the year comes to an end, it's time to get your financial documents in order and prepare for the upcoming tax season. Keep your financial records up to date throughout the year with the right financial software for your personal or company needs. As well as making sure that your office is well stocked with the necessary tax forms and envelopes to get your employees or contract workers their paperwork as soon as possible. See how Staples can help you prepare for your taxes:

Keep your financial records up to date throughout the year with the right financial software for your personal or company needs. As well as making sure that your office is well stocked with the necessary tax forms and envelopes to get your employees or contract workers their paperwork as soon as possible. See how Staples can help you prepare for your taxes:

- Starting with the right financial software can help keep you ahead of the game before the next tax season. With recognized financial brands such as Quicken Finance Software. Take the hassle out of staying financially organized.

- Getting your employees and contract workers' tax forms out to them on time is as simple as just pressing print when you have the appropriate tax forms on hand. From W2, 1099, 1095, and even the envelopes to mail it out, we have your tax form need in mind.

- When it comes time to file your taxes, we can even help you find the right tax software that fits your filing requirements. From software for personal taxes, business taxes, or both, we offer top brands such as Turbo Tax and H&R Block.

With the ability to e-file or print and mail both your federal and state taxes.

With the ability to e-file or print and mail both your federal and state taxes.

From employees' tax forms to software to keep your finance in order, or software to get your taxes done, Staples has you covered this upcoming tax season!

Rest assured it arrives safely & securelyWhether you are sending business documents or customer products, shipping and mailroom supplies from Staples make the process seamless.

Keep packing supplies ready for easy shipping. Padded envelopes and bubble mailers are perfect for shipping small, non-fragile items. Pack larger items in shipping boxes that are slightly larger than the item and use packing peanuts, bubble roll, or other packing materials to keep objects from moving in the box during transport. Choose the right packing tape to seal shipping boxes and keep them sealed. Staples carries clear acrylic packing tape for everyday shipping and reinforced packing tape, or water activated tape for packages that require a heavier duty seal.

Manage the day-to-day office correspondence smoothly with a wide selection of business envelopes, inter-office envelopes, and catalog envelopes in the mailroom. Have finger pads and envelope moisteners on hand for speedy document collation and a quick seal. Choose security envelopes for confidential office correspondence and inter-office communications. If your office or organization sends out large mailings, consider a paper folding machine and self-sealing envelopes to increase efficiency.

Hybrid work just got easier Whether you work in a traditional office, from home, or anywhere in between, the right supplies and technology will keep you working efficiently no matter where you are. Update your tech with a new laptop computer or 2-in-1 tablet for work on the go. Keep important files accessible wherever you are with portable hardrives and USB flash drives that fit easily into a laptop bag. Choose a headset for virtual meetings or noise-cancelling headphones to block out unwanted sounds when working in public.

In your home office, make sure to have a comfortable set up that's built with you in mind. Select an ergonomic office chair or gaming chair, and browse our selection of sit and stand desks for a convertible work area. Add an extra computer monitor to your set up, and choose from our wide selection of mice and keyboards. And don't forget to stock up on office supplies. From notebooks and copy paper, to pens and highlighters, Staples offers flexible AutoRestock options on all the basics, so you can get supplies shipped to your door without having to remember to order.

Take the guess work out of shopping for ink & toner When it comes to selecting the right ink or toner cartridges for your printer, the choices can be confusing. Let Staples Ink and Toner Finder take the guess work out of choosing the right refills for your printer. You can search by model or browse by brand, including top brands like HP, Brother, Canon, and Xerox ink and toner. With cartridges available for over 30 brands, you'll be sure to find what you need to keep printing. When your cartridge is empty, take it to any Staples store for free tech & ink and toner recycling every day!

With cartridges available for over 30 brands, you'll be sure to find what you need to keep printing. When your cartridge is empty, take it to any Staples store for free tech & ink and toner recycling every day!

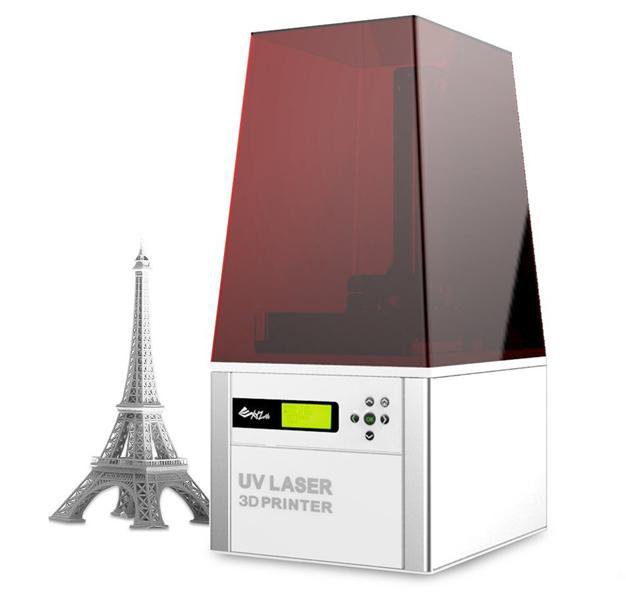

Video review of the professional SLA 3D printer XYZ Printing PartPro150 xP. What Can a Formlabs Competitor Do?

3Dtool

Loading

10/19/2022

912

Reviews

3DTool is with you!

The difficult situation in the 3D printing market makes it necessary to carefully select the equipment for purchase, especially when it comes to analogues of devices subject to trade sanctions or discontinued for one reason or another. Talking about stereolithographic (SLA) 3D printing, we most often remember the unpretentious and high-quality printing Formlabs Form . But what if these devices are no longer available in our market? It's high time to take a closer look at the professional solutions of the global manufacturer of 3D printers based in Taiwan - XYZ Printing.

SLA The XYZ PartPro150 xP 3D Printer is a great example of a balanced desktop solution for the production of complex products that require a higher quality print on the outer surface. Possessing an analogue of the scanning UV illuminating module from Formlabs , the printer shows similar, and sometimes even better print results than the original. What is this device in other aspects? Let's find out more in our new video review!

Buy XYZ Printing 3D printers, other CNC or 3D equipment and consumables, ask your question, or make an offer, you can contact us:

- By phone: 8(800)775-86-69

- E-mail:[email protected]

- Or on our website: https://3dtool.ru/

We also post our materials in the Telegram channel, on Dzen and in our VKontakte group

Article comments

More interesting articles

five

Subscribe to the author

Subscribe

Don't want

This time on the review there are two small boxes designed for 3D printers. The name is already understood ...

The name is already understood ...

Read more

2

Subscribe to the author

Subscribe

Don't want

Introducing the final review of the Snapmaker A250 Bundle Modular 3D Printer!

Available...

Read more

90

Subscribe to the author

Subscribe

Don't want

This post will cover the entire path from the idea of buying a 3D printer to the development of useful ...

Read More

Read Blogs

What Does Resolution Mean in 3D Printing?

Looking for a high resolution 3D printer? “Resolution” is a term from the field of 3D printing and additive manufacturing that is often talked about, while rarely understanding its meaning. How does XY and Z resolution affect the quality of 3D printed models? What is the minimum element size and what layer thickness should I choose?

How does XY and Z resolution affect the quality of 3D printed models? What is the minimum element size and what layer thickness should I choose?

This detailed guide explains how 3D printer resolution affects model printing and how it differs between SLA, FDM and DLP printers. nine0003

For decades, technology manufacturers have been striving for higher resolution than their competitors. TVs have recently quadrupled their pixel count from HD to 4K, but manufacturers are already thinking about pushing the resolution to 8K. Mobile phones, tablets and other devices with screens show resolution as one of the main characteristics, if, of course, they have something to brag about. But this is nothing new. Resolution wars have been fought since digital became popular and the printing industry became one of the first battlegrounds. nine0003

If you lived in the 80s and 90s, you'll remember how Canon, Brother, HP, Epson, and Lexmark (among others) sought to improve print speed and resolution. 100 x 100 dpi quickly grew to 300 x 300, then to 600 x 600. Finally, now the standard resolution is 1200 x 1200 dpi. Then these values were extremely clear, and the use of units of measurement was quite logical. Unfortunately, things get much more complicated when you add another dimension to print. nine0003

100 x 100 dpi quickly grew to 300 x 300, then to 600 x 600. Finally, now the standard resolution is 1200 x 1200 dpi. Then these values were extremely clear, and the use of units of measurement was quite logical. Unfortunately, things get much more complicated when you add another dimension to print. nine0003

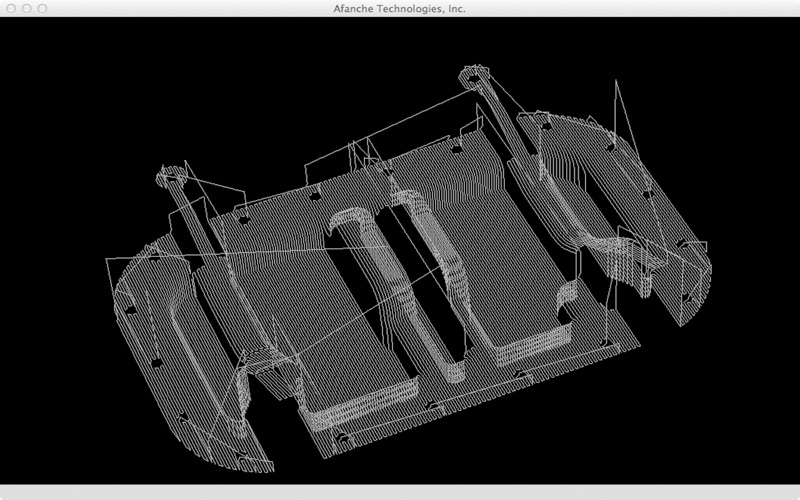

The level of detail of the model depends on the resolution of the 3D printer in all three dimensions.

In 3D printing and additive manufacturing, there are three dimensions to consider: two planar 2D dimensions (X and Y) and a third dimension, Z, which is used for 3D printing. Since planar measurements and Z measurements are usually controlled by completely different mechanisms, their resolutions will differ. Therefore, they must be considered separately. As a result, there is a lot of confusion about the interpretation of the term "3D printing resolution" and false expectations for print quality. nine0003

Experience the quality of stereolithography for yourself. We will send a free sample of the Formlabs stereolithographic 3D printed model directly to your office.

We will send a free sample of the Formlabs stereolithographic 3D printed model directly to your office.

Request a free print sample

Formlabs high-resolution stereolithographic 3D printers feature high Z-axis resolution and a low minimum element size on the XY plane, allowing them to capture fine detail.

What affects the high resolution of a 3D printer? It is impossible to name any one isolated factor. Since 3D printers produce models in 3 dimensions, there are at least two factors to consider: the minimum size of the XY plane elements and the resolution of the Z axis (thickness or height of the layer). Z-axis resolution is easy to determine and is therefore more commonly reported, although it is less related to print and surface quality. The more important XY resolution (minimum element size) is measured with a microscope and is therefore not always found in specifications. nine0003

In practice, this means that the 3D printer must perform well in both categories (in all 3 dimensions).

White Paper

Download our white paper to learn how SLA printing works, why thousands of people use it today, and how this 3D printing technology can help your work.

Download white paper

A lot has changed since the first desktop 3D printers hit the market. Now stereolithographic (SLA) 3D printers such as the Form 3 directly compete for desktop space with Fused Deposition Modeling (FDM) 3D printers. One of the main advantages of SLA 3D printers using polymers as consumables over their plastic-melting counterparts is print quality: SLA printers produce models with a smoother surface and a higher degree of detail. Although stereolithography printers typically produce significantly thinner layers, the reason for the improved print quality is the much higher XY resolution. nine0003

SLA printers (right) have higher resolution and produce models with smoother surfaces and more detail than FDM printers (left).

Unlike 3D printers based on FDM technology, the minimum size of elements in the XY plane in stereolithographic 3D printers is not limited by the dynamics of the flow of molten plastic, but is more determined by the optics and kinetics of radical polymerization. Although the calculations are complex (and beyond the scope of this article), it can be said that the details on models produced by stereolithography printers are about the same size as the diameter of the corresponding laser spots. And laser spots can be very small, especially when compared to nozzles on FDM printers. nine0003

Although the calculations are complex (and beyond the scope of this article), it can be said that the details on models produced by stereolithography printers are about the same size as the diameter of the corresponding laser spots. And laser spots can be very small, especially when compared to nozzles on FDM printers. nine0003

Check out our detailed guide comparing FDM vs. SLA 3D printers to see how they differ in terms of print quality, materials, application, workflow, speed, cost, and more.

Technologies Resin-based 3D printing such as SLA, LFS and DLP provide the highest resolution of all 3D printing processes available for desktop printers. The primary units of measure for SLA and DLP processes are different forms, making it difficult to compare printers based on numbers alone. nine0003

3D printers based on DLP technology have a matrix of pixels that is fixed relative to the work area, while SLA and LFS printers that use a laser can focus the laser beam on any coordinate of the XY plane. This means that laser 3D printers with high optical quality can accurately reproduce the surface of the model, even if the laser spot size is larger than the pixel size in the DLP printer.

This means that laser 3D printers with high optical quality can accurately reproduce the surface of the model, even if the laser spot size is larger than the pixel size in the DLP printer.

Whichever resin 3D printing technology you choose, professional 3D printers should capture the finest details of your creations, from photorealistic models to fine jewelry. nine0003

When printing with SLA and LFS 3D printers (left), layer lines are almost invisible. As a result, surface roughness is reduced, resulting in a smooth surface, and when using transparent materials, models with greater transparency. DLP printers use rectangular voxels to render images, which can result in vertical lines (right).

Learn more about the differences between SLA and DLP technologies in terms of resolution, accuracy, clarity, print volume, surface quality, speed, and how they work. nine0106

In the world of 3D printing, no other factor affects the quality of models more than XY resolution. She is often mentioned, but rarely understood. The definition of XY resolution (or horizontal resolution) differs depending on the 3D printing technology:

She is often mentioned, but rarely understood. The definition of XY resolution (or horizontal resolution) differs depending on the 3D printing technology:

- stereolithographic 3D printers - a combination of laser spot size and the size of the steps with which the beam can be controlled;

- DLP printers - pixel size, the smallest detail that a projector can reproduce in a single layer; nine0040

- FDM printers - the smallest distance that the extruder can move within one layer.

Generally, the lower this value, the finer the detail. But this number is not always indicated in the technical specifications, and even if indicated, it is not always correct. To get an idea of true XY resolution, it is important to understand how a printer works.

How does XY resolution affect the quality of your models? To find out, we decided to test a Form 2 stereolithographic 3D printer. The size of the laser spot in the Form 2 printer is 140 µm (FWHM), which should allow it to reproduce fine details on the XY plane. We decided to check if this ideal resolution corresponds to the truth. nine0003

We decided to check if this ideal resolution corresponds to the truth. nine0003

To check the minimum feature size on the XY plane for the Form 2 printer, we designed a model (left) with lines ranging from 10 to 200 µm thick and printed it using Clear Resin (right).

We first designed and printed the model to check the minimum element size on the XY plane. The model is a rectangular block with lines of various widths in the horizontal, vertical and diagonal directions, which are applied to prevent displacement. The line thickness is from 10 to 200 µm, the lines are drawn at 10 µm intervals and have a height of 200 µm, which corresponds to two layers when printed at a resolution of 100 µm for the Z axis. Made from Clear Resin, the model was washed twice in isopropyl alcohol and subjected to a within 30 minutes. nine0003

The model was photographed and painted green for better visibility. The vertical yellow line with black dots on the right side of the window is for measuring the width of the photographed line.

After the final polymerization, we placed the model under the microscope and took a high resolution photograph for further analysis. Using ImageJ, a free image analysis program from the National Institutes of Health (NIH), we scaled the image pixels and measured the actual width of the printed lines. We collected over 50 data points per line width to eliminate measurement errors and variability. We analyzed three models made on two printers. nine0003

The results show that the Form 2 has the same ideal and actual XY resolution for model elements as small as 150 µm.

As the line width decreases from 200 to 150 µm, the ideal values are within the 95% confidence interval of the measured value. As the expected linewidth becomes less than 150 µm, the measured interval starts to deviate significantly from the ideal. This means that the printer can reliably reproduce elements up to 150 microns in size, as thick as a human hair, on the XY plane. nine0003

The Form 2 printer has a minimum XY feature size of about 150 µm, only 10 µm larger than the spot size of the 140 µm laser installed in it. The minimum element size cannot be less than the laser spot size. There are many factors that affect this value: laser refraction, microscopic contaminants, polymer chemistry, etc. Considering the entire printer ecosystem, a difference of 10 µm is nominal. Not all 3D printers have the reported resolution as the actual resolution, so it's a good idea to do a lot of research before choosing the right resolution for your project. nine0003

The minimum element size cannot be less than the laser spot size. There are many factors that affect this value: laser refraction, microscopic contaminants, polymer chemistry, etc. Considering the entire printer ecosystem, a difference of 10 µm is nominal. Not all 3D printers have the reported resolution as the actual resolution, so it's a good idea to do a lot of research before choosing the right resolution for your project. nine0003

If you want models with fine detail, look for a printer whose XY resolution isn't just listed as a number, but backed up with measured data.

When looking at the specifications of 3D printers, you will find that one parameter appears more often than any other. This is the Z-axis resolution. Also known as layer thickness or layer height, vertical resolution was the first major numerical parameter by which early 3D printers were distinguished. The first such devices struggled to overcome the barrier of 1 mm, but now the layer thickness in FDM-based 3D printers can be less than 0. 1 mm, and even less in LFS and SLA printers. nine0003

1 mm, and even less in LFS and SLA printers. nine0003

Formlabs 3D printers support layer thicknesses from 25 to 300 µm, depending on the material. This range of values allows you to find the perfect balance between speed and print quality. But the main question is what layer thickness will be ideal for your model.

The high resolution of 3D printing affects other parameters. The thinner the layer, the more layers need to be printed, resulting in increased model production time: typically, printing at a resolution of 25 µm takes four times longer than printing at a resolution of 100 µm. In addition, the more layers, the higher the probability of errors. For example, even with a layer success rate of 9A 9.99% fourfold increase in resolution reduces the chances of a successful print of the model from 90% to 67%, provided that the layer with the error leads to rejects.

The thinner the layer, the longer it takes to print and the more likely it is to cause errors and distortion.

Is it true that the higher the resolution (the thinner the layers), the higher the quality of the finished models? Not always. It depends on the model and resolution of the XY 3D printer. As a general rule, the thinner the layer, the longer it takes to print and the greater the chance of distortion and errors. In some cases, printing models at a lower resolution (i.e., with thicker layers) may even result in better quality. nine0003

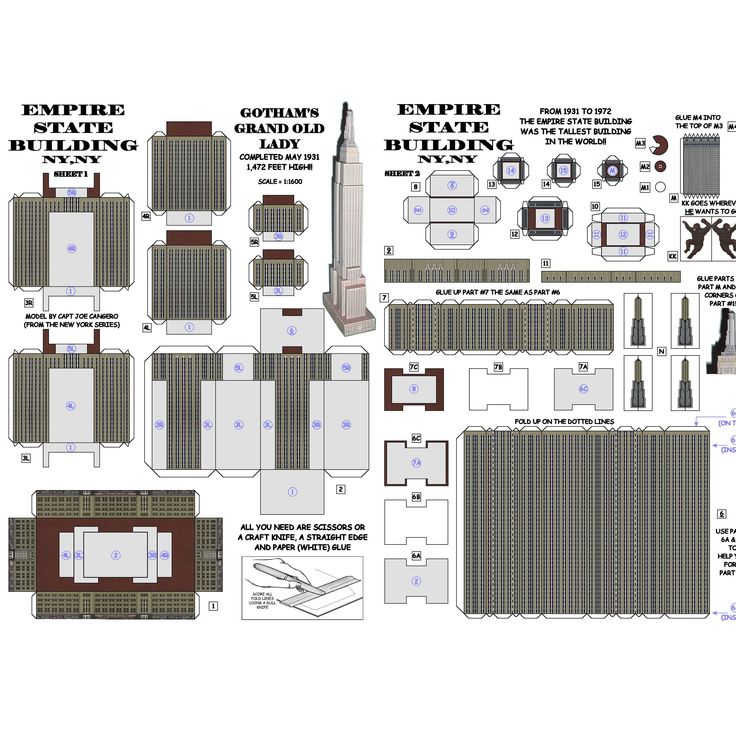

Thinner layers are usually associated with smoother diagonal transitions, causing many users to push Z resolution to the limit. But what if the model consists mostly of vertical and horizontal faces, with right angles and a small amount of diagonal surfaces? In such cases, increasing the number of layers will not improve print quality.

The problem is exacerbated if the printer's XY resolution is not ideal and it "goes out of bounds" when forming the outer edges. The more layers, the more mismatched protrusions will be on the surface. In this case, the finished model will look much worse, even if the Z resolution is higher. nine0003

In this case, the finished model will look much worse, even if the Z resolution is higher. nine0003

There are times when you need to increase the resolution. If you have a printer with good XY resolution and a model with complex features and many diagonal edges, reducing the thickness of the layers will allow you to get a much better quality physical model. Also, if this model is small (no more than 200 layers), then increasing the resolution of the Z axis will lead to a real improvement in quality.

Some design features benefit from higher Z resolution: organic shapes, rounded arches, fine embossing and intricate engraving. nine0186

A tiny model with lots of detail and arches needs a higher Z resolution. This cathedral was printed on a Form 2 printer at 25µm resolution.

Try to stick to this general rule: print thicker layers and increase the Z resolution only when it is really necessary. With the right combination of printer and model type, the higher Z resolution will capture the intricate details of your design. nine0003

nine0003

Gray Resin allows printing at a resolution of 160 microns. Check out the difference in speed for yourself.

Formlabs PreForm software allows you to select the layer thickness. Starting with version PreForm 3.0.3 , Gray Resin can be printed with 160, 100, 50 and 25 µm layer heights. Printing at a resolution of 160 microns will speed up the iteration process and allow engineers to move from design to finished model even faster. And dentists can make more aligners per day without sacrificing quality. nine0003

We hope that once you are familiar with the concept of resolution and understand the differences in 3D printing technologies and results, it will be much easier for you to choose a 3D printer that best suits your needs and workflow.

To learn more about the next generation of stereolithographic 3D printers, check out the Form 3 and Form 3L devices based on LFS technology.

Want to see for yourself what high-resolution prints look like? Order a print sample, which will be delivered directly to your office.