Stratasys dental 3d printer

Dental 3D Printing | Solutions For Dentistry

Dental 3D Printing | Solutions For Dentistry - Stratasys Stratasys Invests in Axial3D to Make Patient-Specific 3D Solutions Available to All - Learn MoreUSA & Canada

Select your country and region

- Americas

- English

- Español (México)

- Português (Brasil)

- EMEA

- English (United Kingdom)

- Deutsch

- Español

- Français

- italiano

- APAC

- 中文(简体)

- 日本語 (日本)

- 한국어(대한민국)

- English (India)

USA & Canada

3D Printing Solutions for Digital Dentistry

Deliver Faster With a Complete Digital Workflow

APPLICATION

Orthodontic Models

PRODUCTS

Stratasys J5 DentaJet, Stratasys J700 Dental, Stratasys Dental Materials

Enhance the patient experience and your business with digital dentistry. No more wasted time, materials or storage space. Even the smallest labs can now go straight from intraoral scan to in-house production with a seamless digital workflow. Cut days off delivery times and produce more accurate, comfortable and effective orthodontic appliances. Turn your lab into a clear aligner production machine with the Stratasys J700.

DynaFlex Case Study

Streamline Production

APPLICATION

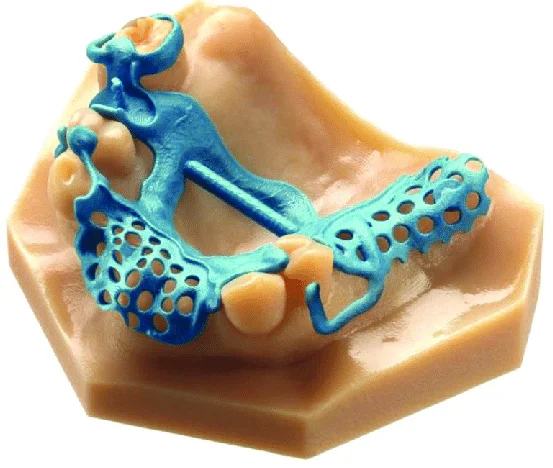

Cast Partial Frames

PRODUCTS

J5 DentaJet, Stratasys Dental Materials

Mainstream the manufacturing process of cast chrome partials with 3D printing and PolyJet material MED610. Manufacturing removable partial dentures is traditionally labor-intensive, but 3D printing decreases labor and cost per part while increasing productivity of reliable models. Our solutions integrate with leading intraoral scanners and software to ensure predictable and repeatable results that provide perfect fit and in less time.

Biogenic Case Study

Valuable Versatility

APPLICATION

Implant Models

PRODUCTS

J5 DentaJet, Stratasys Dental Materials

Improve clinical outcomes with the highest level of realism using multi-material implant models. Stratasys dental solutions are ideal for creating implant models that mimic gum textures and color. Get reliability and the ability to print complex geometries with accurate detail visualization, perfect for strong, accurate and durable models.

Vulcan Case Study

Improve Surgical Outcomes

APPLICATION

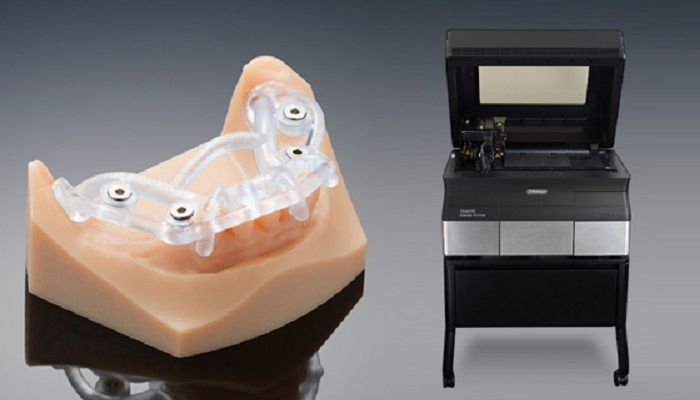

Surgical Guides

PRODUCTS

J5 DentaJet, Stratasys Dental Materials

Advance patient outcomes by making optimal decisions for every surgery with 3D printed dental guides. Replicate real-life conditions and produce customized tools, improving surgical planning, which minimizes patient discomfort and speeds up recovery. Produce patient-specific models and end-use oral fixtures in very fine detail with smooth surfaces, enabling better procedures and outcomes.

Produce patient-specific models and end-use oral fixtures in very fine detail with smooth surfaces, enabling better procedures and outcomes.

Iverson Dental Laboratories Case Study

Compatible 3D Printers

J5 DentaJet

J5 DentaJet is a compact and powerful dental 3D printer for dental lab use. Designed to reduce costs, maximize efficiency and create more dental parts with less handling — all with the precision, accuracy, and realism you can expect from Stratasys.

Click Here to Learn More

Origin® One Dental

Scale your business and maximize production across a number of applications with materials from Industry leading partners. With user-friendly software that is simple to manage and learn, Origin One Dental streamlines your digital workflow and maximizes throughput.

With user-friendly software that is simple to manage and learn, Origin One Dental streamlines your digital workflow and maximizes throughput.

Click Here to Lean More

Similar Solutions for Other Industries

Aerospace

3D Printing Solutions for Aerospace enable faster iteration, decision making, and response to market changes. Fly with less weight, reduce complexity.

View more

Consumer Products

3D Printing Solutions for Consumer Products help you get to market faster with speedier design cycles.Go from design to prototyping in hours, not days.

View more

Automotive

3D Printing Solutions for Automotive take you from design to factory floor quickly and efficiently. Prototype test and produce tools jigs and fixtures.

View more

Medical

Stratasys 3D Printing Solutions for medical validate device performance on patient-derived 3D printed anatomical models versus existing models such as animals and cadavers.

View more

Aerospace

3D Printing Solutions for Aerospace enable faster iteration, decision making, and response to market changes. Fly with less weight, reduce complexity.

Fly with less weight, reduce complexity.

View more

Consumer Products

3D Printing Solutions for Consumer Products help you get to market faster with speedier design cycles.Go from design to prototyping in hours, not days.

View more

Automotive

3D Printing Solutions for Automotive take you from design to factory floor quickly and efficiently. Prototype test and produce tools jigs and fixtures.

View more

Medical

Stratasys 3D Printing Solutions for medical validate device performance on patient-derived 3D printed anatomical models versus existing models such as animals and cadavers.

View more

Transforming Dentistry With 3D Printing

Transforming dentistry

Digital dentistry is not the future, it’s now. Traditional methods prevent dental and orthodontic labs from meeting growing demand. By fully embracing digital dentistry, labs can grow their businesses, produce exceptional quality models, and shorten turnaround time, all without adding staff or time.

For labs that realize the value of 3D printing, the next advancement is multi-material 3D printing. A dental 3D printer with multi-material capabilities is like having three printers in one. The versatility opens your lab to multiple application offerings. It offers the ability to print a range of cases from implant models with soft tissue and custom-fit surgical guides or aligner setups and indirect bonding trays, or a variety of restoration mock-ups and more, at the same time. This simplifies work flow, reduces scheduling burden, and 3D printer management.

drive dental lab growth multi material 3d printing

This simplifies work flow, reduces scheduling burden, and 3D printer management.

drive dental lab growth multi material 3d printing

Crown & bridge

Accelerate your business with end-to-end solutions

Produce precise models in high-resolution materials in a fraction of the time. 3D printing eliminates the delays and inaccuracies of manual labor, enabling faster production and higher-quality crown and bridge models with fewer remakes.

This quality capability led Iverson Dental Laboratories to embrace 3D printing. Iverson Labs cut appliance turnaround time and improved accuracy with precise, highresolution 3D printing. Precise appliances mean little to no adjustment is needed. That allows dentists to seat crowns and bridges in less than five minutes, minimizing chair time. And less chair time means dentists can see up to five more patients per day on average.

“3D printers help us maintain one of the lowest average remake (rates) in the industry,” said Cody Iverson, company president.

Implantology

It’s about more than forming a better smile.

It’s about forming a better business

Simplify the complexity of implantology by printing the model, surgical guide and soft gingival mask in different materials simultaneously on the same tray. Multi-material 3D printing is ideal for creating implant models that mimic gum textures and color.

Like many dental manufacturers, Vulcan Custom Dental is challenged with balancing workloads, optimizing production and staying competitive. By 3D printing substitutes for gypsum models, prosthetic prototypes, splints and surgical guides, Vulcan can now deliver same-day results. Its Stratasys printers reduced model production time 75% compared to competitor 3D printers.

“The Stratasys 3D printer offers substantial time savings. It only requires a few minutes of setup time and we can print as many as four high-precision jobs a day,” said Boris Simmonds, director of technology development at Vulcan. drive dental lab growth multi material 3d printingdrive dental lab growth multi material 3d printing

drive dental lab growth multi material 3d printingdrive dental lab growth multi material 3d printing

Orthodontics

Formfitting solutions to get teeth, and your bottom line, aligned

Go straight from intraoral scan to in-house production with a seamless digital workflow. Cut days off delivery times and produce more accurate, comfortable and effective orthodontic appliances. Expand your lab with new service lines by offering 3D printed indirect bonding trays or producing clear aligners from 3D printed arches. Plus, digital storage allows for appliance production without needing new impressions from patients, saving on space and chair time.

“What we’ve needed is a faster printer, one that could produce on-demand and didn’t require high levels of expertise to operate. We were anxiously awaiting the opportunity to get our hands on a Stratasys J700 so we could meet customer demand,” said DynaFlex CEO Darren Buddemeyer. Because the J700 is optimized for accurate, high-output of clear aligners, Dynaflex can produce 40-60 arches per print tray and more than 400 arches per day on a single J700.

Removables

The speed, precision, and customization to outperform traditional dentistry

Mainstream the manufacturing process of cast chrome partials with automation that cuts down on labor. Predictable and repeatable results reduce patient visits and resets with precise frameworks, denture and partial try-ins produced in less time in smooth, biocompatible materials.

Adapting to a shortage of skilled labor, Biogenic Dental Corporation adopted 3D printing for cast partial frame patterns to replace traditional hand wax-ups. By switching to Stratasys printers, they realized a 50% increase in output in half the time, allowing Biogenic to redeploy workers to other duties.

Digitize the entire workflow by 3D printing multiple parts in multiple materials for different applications at the same time. Increase your productivity by eliminating many production steps and create unrivaled dental models and appliances leading to faster turnaround times and fewer remakes. The added capabilities of Stratasys dental solutions help labs expand into new areas of business.

The added capabilities of Stratasys dental solutions help labs expand into new areas of business.

| Solutions | Value |

|---|---|

| The Objet30 Dental Prime™ |

|

| Objet260 Dental™ |

|

| The Objet260 and Objet500 Dental Selection™ |

|

| The Objet Eden260VS Dental Advantage™ |

|

| The Stratasys J700 Dental™ |

|

The Stratasys difference:

- Professional-grade printers deliver unmatched quality, reliability, and productivity.

- Multi-material models enable better clinical outcomes due to realism and versatility to support a range of cases on the same production run.

- Fast time-to-part that requires less labor, post-processing, and handling.

- System reliability, model repeatability.

For more information on how Stratasys 3D Printing solutions create growth opportunities for dental labs, contact:

E [email protected] / STRATASYS.COM

drive dental lab growth multi material 3d printing

Stratasys Dental 3D Printers

Dental 3D printing has revolutionized dentistry, resulting in a whole new class of specialized dental 3D printers. The adaptation of spatial modeling technologies (both 3D scanning and 3D printing) has led to an explosive growth in sales of this equipment specifically for dental clinics, institutes and even small private offices. Today, the annual market growth exceeds 35%. All leading dental clinics and specialists working in them have already recognized that digital dentistry is the future of the industry. The flexibility of additive manufacturing, speed and accuracy make the digital process not just an alternative, but a real replacement for traditional technologies for prosthetics, crowns and orthodontic appliances. The forecast is unequivocal - in the next 10 years, 3D printing with PolyJet technology or laser sintering of metals will become the only method for the production of all dental solutions. A huge impetus to this was the emergence of special biocompatible dental materials for 3D printing. What can a dentist print on a 3D printer? Below are a few examples of how 3D printing is used by dentists, orthodontists and prosthodontists. nine0003

The flexibility of additive manufacturing, speed and accuracy make the digital process not just an alternative, but a real replacement for traditional technologies for prosthetics, crowns and orthodontic appliances. The forecast is unequivocal - in the next 10 years, 3D printing with PolyJet technology or laser sintering of metals will become the only method for the production of all dental solutions. A huge impetus to this was the emergence of special biocompatible dental materials for 3D printing. What can a dentist print on a 3D printer? Below are a few examples of how 3D printing is used by dentists, orthodontists and prosthodontists. nine0003

Jaw models for testing crowns and bridges

The 3D printer allows you to quickly create an exact copy of the jaw so that you can check the correctness of crowns and bridges without unnecessary worries and in maximum comfort for the patient. Three-dimensional scanning, as the initial stage, will make this process as accurate as possible and eliminate the need to store bulky prosthesis models made in the material - everything will be in digital form. nine0003

nine0003

Surgical Guides

Successful implantation of dental prostheses depends on the correct position of the implants. In order to do this with maximum precision during the operation, a template is printed on a three-dimensional printer, which will allow the surgeon to freely manipulate the implants, but at the same time install them in exactly the specified positions. Without a 3D printer, such a procedure would be extremely expensive, and still not accurate enough - since only a scan of the oral cavity followed by digital modeling allows you to absolutely accurately produce an individual surgical template. nine0003

Aligner Master Models

Traditional aligner technology is a tedious and uncomfortable procedure for the patient. Three-dimensional modeling technologies practically exclude its participation in the process. With the help of three-dimensional scanning, an absolutely exact copy of the patient's teeth and jaw is created, the three-dimensional model is then printed on a 3D printer, and the orthodontist gets at his disposal the patient's jaw without the patient himself. You can easily calculate the desired shape and number of caps by modeling the jaw not only in statics, but also in dynamics. The aligners themselves are not yet printed on the printer, as there are no suitable materials. But ordinary vacuum casting is done according to a model printed on a 3D printer, and this is already a simple and inexpensive procedure. nine0003

You can easily calculate the desired shape and number of caps by modeling the jaw not only in statics, but also in dynamics. The aligners themselves are not yet printed on the printer, as there are no suitable materials. But ordinary vacuum casting is done according to a model printed on a 3D printer, and this is already a simple and inexpensive procedure. nine0003

Diagnostic models

3D scanning and subsequent printing on a 3D printer makes it possible to produce models for jaw occlusion diagnostics, anthropometric measurements and additional assessment of dentition without the costly and time-consuming procedure of making impressions, which is an integral stage of traditional modeling in dentistry. With 3D additive manufacturing technologies, a model can be produced quickly and with absolute precision. nine0003

Implant test models

The existence of 3D printing materials with different mechanical properties, and especially the advent of digital materials, has given the dentist the opportunity to test implant designs safely and comfortably for the patient. A 3D printer can print a model of a patient's jaw not only exactly repeating the original in size and shape, but also as close as possible to a living jaw in terms of its composition and properties. Imitation of the gums and jaw bone allows you to minimize the risk of unsuccessful implantation. nine0003

A 3D printer can print a model of a patient's jaw not only exactly repeating the original in size and shape, but also as close as possible to a living jaw in terms of its composition and properties. Imitation of the gums and jaw bone allows you to minimize the risk of unsuccessful implantation. nine0003

Soft tissue models

Existing materials for 3D printing allow you to print an exact copy of the patient's gums, including not only color, but also repeating the elasticity of the gum tissue exactly. Any fitting work and testing of prostheses can be carried out without the presence of the patient at all, and the client can be called only for the final procedure.

Jaw models

The jaw model must be as accurate as possible so that the final diagnosis and treatment can be made without annoying errors. Without 3D printing technology, it was almost impossible to make an accurate model of the entire jaw of the client, and not just the dentition and gums, since it is basically impossible to make an impression from the entire jaw (you can’t remove a living jaw from a person!). The combination of computed tomography, 3D scanning and 3D printing technologies makes it possible to make an absolutely exact copy of the jaw bones up to the temporomandibular joint. nine0003

The combination of computed tomography, 3D scanning and 3D printing technologies makes it possible to make an absolutely exact copy of the jaw bones up to the temporomandibular joint. nine0003

Removable dentures and veneers in various shades

The 3D printer made it possible to try on a removable denture before fabrication. You can quickly make adjustments to the geometry of the prosthesis and the finished one will ideally fit the patient. The accuracy and high resolution of 3D printers with PolyJet Matrix technology allows you to go further - the advent of digital materials and biocompatible polymers has made it possible to quickly and inexpensively print veneers of arbitrary shape and any desired shade. nine0003

Full color model from intraoral 3D scanner data

Would you like to know more?

View our catalog of Stratasys professional 3D printers or contact us to select the appropriate model: +7 (495) 739-09-09

, printed models on a 3D printer Objet260 Dental Selection

Brief characteristics:

Printing technology: PolyJet 3D printing Technology

Construction area, mm: 255x252x200

Printing material: MED610, VeroDent Plus (MED690), VeroGlaze (MED620), VeroDent (MED670), VeroWhite, Vero Magenta, tangoplus, tangoblackplus, nine0003

All characteristics

Description of the 3D printer "Objet260 Dental Selection"

Objet260 Dental Selection - maximum versatility for your dental laboratory. The Objet260 Dental Selection 3D printer brings advanced 3-material printing technology to dentistry and orthodontics. Create incredibly realistic-looking and tactile 3D models. The printer is designed to test implants on physical models that mimic real gum textures for accurate evaluation; single models or groups of models, for the manufacture of which it is necessary to use several materials at once without the participation of an operator; Print 3D models of jaws directly from CT scans with excellent detail of teeth, roots and root canals with contrast materials. nine0003

The Objet260 Dental Selection 3D printer brings advanced 3-material printing technology to dentistry and orthodontics. Create incredibly realistic-looking and tactile 3D models. The printer is designed to test implants on physical models that mimic real gum textures for accurate evaluation; single models or groups of models, for the manufacture of which it is necessary to use several materials at once without the participation of an operator; Print 3D models of jaws directly from CT scans with excellent detail of teeth, roots and root canals with contrast materials. nine0003

About the Objet260 Dental Selection printer

Create models with realistic textures for accurate evaluation and a wide range of shades for custom color matching. Print completely realistic models on the Objet260 Dental Selection printer for a range of dental and orthodontic indications, including:

- physical model testing of implants that mimic real gum textures for accurate evaluation;

- single models or groups of models, for the manufacture of which it is necessary to use several materials at once without the participation of an operator; nine0088

- Print 3D models of jaws directly from CT scans with excellent detail of teeth, roots and canals in contrast materials.

The Objet260 Dental Selection supports all color open format intraoral scanners.

Materials

The Objet260 Dental Selection printer works with the full range of PolyJet dental materials. Materials specially developed for dentistry are supplied in convenient sealed cartridges:

- VeroDent (MED670) is a natural peach colored material that provides a high level of detail, strength and durability.

- VeroDentPlus (MED690) is a dark beige material that allows you to create extremely precise components and coatings with excellent strength and durability.

- Opaque white VeroGlaze (MED620) A2 shade designed to provide the best color match in the industry. VeroGlaze is ideal for veneer fittings and diagnostic impressions and is medically approved for temporary placement in the mouth for up to 24 hours. nine0088

- Transparent biocompatible material (MED610) can be used in the manufacture of orthodontic appliances, delivery and positioning aligners and surgical templates for temporary placement in the oral cavity.

Learn more