Spectra 3d scanner

Spectra™ 3D Scanner - CAD CAM for Prosthetics & Orthotics

Fast, accurate, easy

3D patient scans for orthotics and prosthetics of all types

The Spectra™ handheld optical scanner enables you to electronically capture a high-resolution 3D model of your patient in seconds – without any patient contact or the mess and discomfort of plaster. Your patients and staff will love you.

The complete Vorum integrated CAD/CAM solution for prosthetics and orthotics includes 3D scanners, computer-aided shape modification software, and automated carvers.

Faster turnaround. Happier patients

Easy to learn, easy to use

01

Plug Spectra™ in and open the software application

02

As you scan, the software displays the 3D patient shape on your screen in real-time.

03

Move and rotate the image on your computer, restart a scan from anywhere, add landmarks, and much more!

04

You can then modify the shape using the Canfit™ P&O Design software.

Portable cranial scanning

Spectra for STARband® helmets

Orthomerica’s process to fabricate STARband Cranial Remolding Orthoses now has FDA 510(k) Clearance to use our affordable, handheld, blue-light Spectra scanner to capture 3D head shape data.

Spectra is light and compact. Combine it with a laptop for a portable scanning solution that’s perfect for satellite offices, remote patient visits, and to add a flexible scanning capability to your main clinic.

“[Spectra] uses just a white light that’s used in an average camera so it’s very safe. This will be crucial in making the liners and the custom portion of the prosthesis.”

Wilder Lafond

“Optical scans are more accurate than plaster. We now make orthotics and prosthetics that fit better. ”

”

Martin Kaufmann

“Vorum enables us to grow our business. We will now acquire the detailed shapes of children and spinal trauma patients without the risk and discomfort of traditional casting procedures.”

Nolan Hayday

With 0.1 mm resolution, you can capture every bump and contour for better fitting custom devices.

Obtain design-ready scans for all types of prosthetic and orthotic devices in less than five minutes.

Uses a safe, high quality blue light projector and single camera to capture the 3D image.

The detailed 3D patient shape can be electronically stored indefinitely and referred to for reimbursement justification and device replacement or repair.

Scan your patient in a bed or wheelchair.

The 3D shape emerges on screen as you scan.

Lightweight and portable

A versatile mobile scanning solution for the practitioner on the go

Spectra is compact and comes with a rugged backpack. A single cable connects it to your laptop or desktop computer running the easy-to-use Spectra software.

A single cable connects it to your laptop or desktop computer running the easy-to-use Spectra software.

Contact us to arrange a demonstration

Part of the Vorum integrated CAD/CAM

solution for prosthetics and orthotics

We pioneered CAD/CAM for custom prosthetics, orthotics, and footwear over 30 years ago, and we have helped over 800 clinics, hospitals and central fabricators to successfully boost productivity and improve service.

Contact us

CA/USA: (800) 461-4353

Int: +1 (604) 321-7277

Vorum

8765 Ash Street, Suite 6

Vancouver, British Columbia

V6P 6T3

Canada

© 2022 Vorum Research Corp. All Rights Reserved.

Search for:Hit enter to search or ESC to close

We use cookies to ensure that we give you the best experience on our website. By continuing to browse, you agree to the use of cookies.I understandPrivacy policy

RangeVision Spectrum

RangeVision Spectrum У вас отключен JavaScript. Это пугает.

Это пугает. Partners

-

Scanner of consistently high resolution and accuracy

-

Best price for a semi-professional solution

-

Portable and compact

-

Universal 3D scanner for miniature, medium and large objects

-

Our bestseller

One scanner - a wide range of features

Choose and customize the scanner capabilities for your challenge

Sign up for a free online demo!

Get a unique opportunity to test RangeVision Spectrum 3D scanner online before making a decision. Learn a great deal about its capabilities!

Extensive features with stable scanning accuracy

Three scanning modes

For convenient work with different types of objects

Choose the right mode for your needs

-

Scanning on a rotary table

Quick and easy 3D scanning of an object on a rotary table platform.

When an object is rotated, its model fragments are combined automatically.

When an object is rotated, its model fragments are combined automatically.

More

-

Scanning with markers

Automatic alignment of model fragments is based on markers applied to an object surface. Used to improve 3D scanning accuracy. Supports an external photogrammetry system.

More

-

Scanning in basic mode

Used for 3D scanning of objects that cannot be digitized the other way, e.g. museum exhibits. Model fragments obtained from different angles are combined according to the features of the object surface geometry.

More

3D scanning of objects from 1 cm to 3 m

- Small size

- Medium size

- Large size

Application

Recommended for educational programs and institutions

Order Spectrum for educational purposes

Spectrum is convenient to work with

10 questions before purchasing a 3D scanner

Examples of 3D models

-

Car manifold Просмотреть на сайте

-

Lighter Просмотреть на сайте

-

Dragon Просмотреть на сайте

-

Chinese guardian lion Просмотреть на сайте

-

Pedal Просмотреть на сайте

-

Deer sculpture Просмотреть на сайте

-

Skull ring Просмотреть на сайте

-

Ceramic decorative tiles Просмотреть на сайте

-

Breastplate Просмотреть на сайте

-

Inkwell Просмотреть на сайте

-

Barelief Просмотреть на сайте

-

Bust Просмотреть на сайте

-

Helmet Просмотреть на сайте

-

Turtles figurine Просмотреть на сайте

-

Wooden baluste Просмотреть на сайте

-

Collectible figurine Просмотреть на сайте

-

Housing part of a glue gun Просмотреть на сайте

Technical specifications

|

Scanning technology |

structured light |

||

|

Resolution |

1280 х 800 |

||

|

FOV size, mm |

520х400х400 |

320х250х220 |

135х100х100 |

|

Working distance, m |

1. |

0.6 |

0.3 |

|

Accuracy, mcm up to |

120 |

60 |

40 |

|

3D resolution, mm up to |

0.25 |

0.15 |

0.06 |

|

Object size |

from 1 cm to 3 m |

||

|

Ability to capture texture |

yes |

||

|

Cameras resolution |

3. |

||

|

Modes alignment |

by markers, by geometry |

||

|

3D mesh formats |

OBJ, PLY, STL, WRL, ASCII |

||

|

Power source for scanner |

100-230V |

||

|

Minimum computer requirements |

Intel Core i5 6500 or better, 8 GB RAM |

||

|

Interface |

HDMI, 2xUSB 2.0 USB 2.0 for a rotary table |

||

|

Supported OS |

Windows 8. |

||

|

Rotary table |

yes |

||

|

Platform table diameter |

20 cm |

||

|

Max rotary table load capacity |

20 kg / 44 lb |

||

|

Power source for rotary table |

220 V – 12V/1A |

||

|

Case dimensions |

530х430х200 mm |

||

|

Weight |

1.65 kg/ 3.64 lb |

||

|

Full package in case weight |

8. |

||

|

Certificats |

CE |

||

|

Warranty |

1 year |

||

Note: Product design may differ from the photos on the website.

They trust us

User Reviews

David Wohanka

EngineerWe have considered different scanners for reverse engineering and prototyping but we chose Spectrum because it is one of the best offers on market by price to performance ratio. We really liked the ability to work with markers and changeable scanning zones. We can use Spectrum to scan different objects, including those with complex geometry. Perhaps we can agree that Spectrum is three scanners in one.

Lukáš Mlynář

Project managerWe specialize in creating visualizations. Spectrum is ideally suited for these purposes: resolution, accuracy, the ability to scan in color - everything fully meets our needs. We can use it both in the office and on site (we often cooperate with museums and it is much easier to scan on their territory than to transport the exhibits to our office). We really liked that the scanner comes with everything you need to work in different modes - it seriously saved our budget.

Spectrum is ideally suited for these purposes: resolution, accuracy, the ability to scan in color - everything fully meets our needs. We can use it both in the office and on site (we often cooperate with museums and it is much easier to scan on their territory than to transport the exhibits to our office). We really liked that the scanner comes with everything you need to work in different modes - it seriously saved our budget.

Where to buy

Articles and reviews

Creating a template for cutting brains using a 3D scanner and a 3D printer

UMATEX Rosatom uses a RangeVision 3D scanner to create a sports body kit for a Kawasaki Puccetti Racing team motorcycle

How to solve the problems of the Shelby Cobra body geometry using the RangeVision Spectrum 3D Scanner

RangeVision Spectrum: temperature compensation algorithm

RangeVision Spectrum 3D scanner Promo Video

Any questions?

↑Thank you for your question!

Our manager will contact you soon

Thank you for leaving a request!

Our manager will contact you soon

This website uses cookies as well as similar tools and technologies to understand visitors' experiences. By Clicking ACCEPT or continuing to browse the site you are agreeing to our use of cookies. See our Privacy Policy here.

By Clicking ACCEPT or continuing to browse the site you are agreeing to our use of cookies. See our Privacy Policy here.

Range Vision Spectrum

Range Vision Spectrum You have disabled JavaScript. It scares.Partners

-

Scanner for consistently high resolution and accuracy

-

Best price for semi-professional solution

-

No analogues on the Russian market

-

Universal 3D Scanner - for miniature parts, medium and large objects

nine0005

Our bestseller in the Russian Federation and in the world market

One scanner - a range of options

Choose and customize scanner options for your application

Sign up for a free online demo!

Get a unique opportunity to test the RangeVision Spectrum 3D scanner online before choosing. Convince yourself of its capabilities!

Versatile with stable scanning accuracy

Three scanning modes

For convenient work with different types of objects

Choose the right mode for your tasks

-

Scanning on a turntable

Quickly and easily scan an object mounted on a turntable platform with the push of a button.

When the object is rotated, the fragments of the model are aligned automatically.

When the object is rotated, the fragments of the model are aligned automatically. Read more

nine0005 -

Basic Scan

Used to scan objects that cannot be digitized in other ways, such as museum exhibits. The fragments of the model obtained from different angles are combined according to the features of the object surface geometry. nine0003

Read more

Scanning with markers

Automatic alignment of model fragments by markers applied to the surface of the object. Used to improve scanning accuracy. External photogrammetry systems are supported.

Read more

Scanning objects from 1 cm to 3 m

- Small size

- The average size

- Big size nine0008

Applications

Recommended for educational programs and institutions

Order Spectrum Educational

Spectrum scanner that is easy to use

10 questions before buying a 3D scanner

3D model examples

-

Automotive manifold View on site nine0003

-

Lighter View on site

-

Dragon View on site

-

Lion figurine View on site nine0003

-

Pedal View on site

-

Sculpture of a deer View on site

-

Skull ring View on site nine0003

-

Tiled View on site

-

badge View on site

-

Inkwell View on site nine0003

-

Bas-relief View on site

-

Bust View on site

-

Helmet View on site

nine0008 -

Turtle figurine View on site

-

Wooden baluster View on site

-

Collectible figurine View on site nine0003

-

Glue gun body View on site

Specifications

| Scan technology | structured illumination nine0003 | ||

| Projector Resolution | 1280 x 800 | ||

| Scan area, mm | 540x400x400 | 320x220x220 | 135x100x100 |

| Working distance, m | 0. | 0.56 | 0.26 |

| Error, µm | 120 nine0188 | 60 | 40 |

| 3D resolution, mm | 0.25 | 0.15 | 0.06 |

| Ability to capture texture nine0003 | eat | ||

| Camera resolution | 3.1 MP | ||

| Model stitching | by markers, by geometry | ||

| Received formats nine0003 | OBJ, PLY, STL, PTX, ASCII | ||

| Scanner Power | 100-230V | ||

| Minimum PC requirements | Intel Core i5 6500 or better, 8 GB RAM | nine0193 ||

| Connection interface | HDMI, 2 x USB 2. USB 2.0 for desk | ||

| Supported OS | Windows 8.1/10/11 64bit | ||

| Rotary table nine0003 | eat | ||

| Table platform diameter | 20 cm | ||

| Maximum table load | 20 kg | ||

| Table food nine0003 | 220V - 12V/1A | ||

| Dimensions of the scanner in the case | 530x430x200 | ||

| Scanner weight | 1.65 kg | ||

| Weight of the scanner in the case nine0003 | 8.5 kg | ||

| Certificates | EAC, CE | ||

| Guarantee | 1 year | ||

Note: Product appearance may differ from website photos. nine0003

nine0003

We are trusted

User Testimonials

David Wohanka

EngineerAfter reviewing the various offerings on the market for reverse engineering and prototyping, we chose Spectrum. We really liked the ability to work with markers and changeable scan zones. We can use Spectrum to scan various objects, including those with complex geometry. Perhaps we can agree that the Spectrum is three scanners in one. nine0003

Lukasz Mlynar

Project Manager We specialize in creating visualizations. The Spectrum was perfect for these purposes: the resolution, the accuracy, the ability to scan in color - all perfectly matched our needs. And the equipment made it possible to use it both in the office and on field work (we often cooperate with museums and it is much easier to scan on their territory than to transport exhibits to our office). We really liked that the scanner comes with everything you need to work in different modes - it saved our budget a lot. nine0003

nine0003

Articles and reviews

Creating a Brain Cutting Template Using a 3D Scanner and a 3D Printer

UMATEX Rosatom uses RangeVision 3D scanner to create a sports body kit for Kawasaki Puccetti Racing motorcycle

How to Solve Shelby Cobra Body Geometry Problems with RangeVision Spectrum 9 3D Scanner0046

RangeVision Spectrum:

Temperature Compensation AlgorithmRangeVision Spectrum 3D Scanner:

promo video

Any questions?

↑Thank you for your question!

Our manager will contact you shortly

Thank you for your application!

Our manager will contact you shortly

This site uses cookies. By clicking ACCEPT or by continuing to browse the site, you consent to their use. More.

By clicking ACCEPT or by continuing to browse the site, you consent to their use. More.

16.04.2021

Content

-

- What is 3D scanning and why it is used by

- How 3D scanner

- 3D scan technologies

- 3D methods 3D methods -scans

- Contact 3D scanners

- Non-contact 3D scanners

- Types of 3D scanners by usage

- Advantages and disadvantages of 3D scanners

- Things to consider when choosing a 3D scanner

- Applications

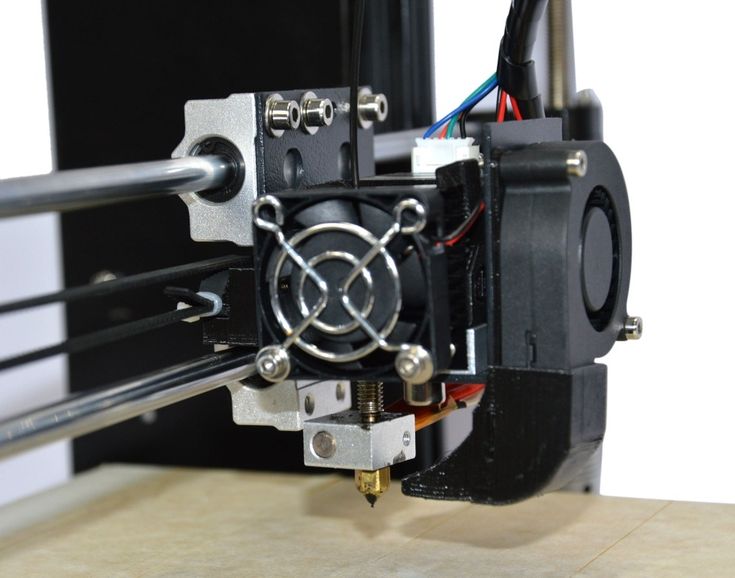

Currently, few people are not familiar with such a concept as 3D printing. Many companies are using modern 3D printers with might and main, recreating layouts of various shapes and sizes with their help. There are also those that recreate whole objects - not only small ones (for example, phone cases, souvenirs, sneakers), but also large ones (houses, engine parts, etc. ). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more. nine0003

). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more. nine0003

What is 3D scanning and what is it used for

Three-dimensional scanning is a technology that appeared back in the 60s of the 20th century. It was created with the aim of transferring the physical parameters of an object into a digital format in the form of a three-dimensional model. The need for this naturally arose when people around the world increasingly began to use computers both in everyday life and in production.

The first samples of 3D scanners were quite simple and did not have wide functionality. Gradually, they became more complex and improved, making it possible to achieve an ever clearer image of the object. This has become especially relevant with the advent of lasers. nine0003

3D scanners allow you to transfer object data into digital format

3D scanning has opened up new opportunities in various areas of human activity - from the automotive industry and the military industry to design, medicine and cinema.

How a 3D scanner works

A 3D scanner is a device that examines an object by digitizing it using sensors and using the information received to create a three-dimensional model. In fact, a 3D scanner creates a digital copy of a physical object of any configuration and complexity. In this, it fundamentally differs from its predecessors - conventional scanners that can only read information from documents and photos. nine0003

The scanning process itself can take place in different ways - depending on the type of 3D device and the technology used, as well as on what object you want to process with it - moving or static.

3D Scanning Technologies

There are 2 main types of 3D scanners - laser and optical. Their fundamental difference lies in how and with the help of what the “removal” of data takes place. Let's take a closer look at both.

Laser 3D scanning, as the name implies, uses a laser and can be carried out both at short and long distances from the object. nine0003

nine0003

Laser Scanner

For the most part, 3D laser scanners work on the principle of triangulation, when the camera finds a beam on the surface of an object and measures the distance to it, after which a cloud of points is created, each of which has its own coordinates in space, and a 3D model is built. Their "advantages" are affordable price and ease of use combined with high scanning accuracy. Of the "minuses" - there are restrictions on the remoteness and size of the object. nine0003

Another type of laser scanner works by measuring the response time of a beam from the surface of an object - the so-called laser range finder. They are widely used where it is necessary to create 3D models of various buildings and structures. It is not advisable to use them at short distances, since in such cases the response time is very short and the accuracy of the data is reduced. Otherwise, this type of scanner is characterized by high scanning speed and the ability to read all the details. nine0003

nine0003

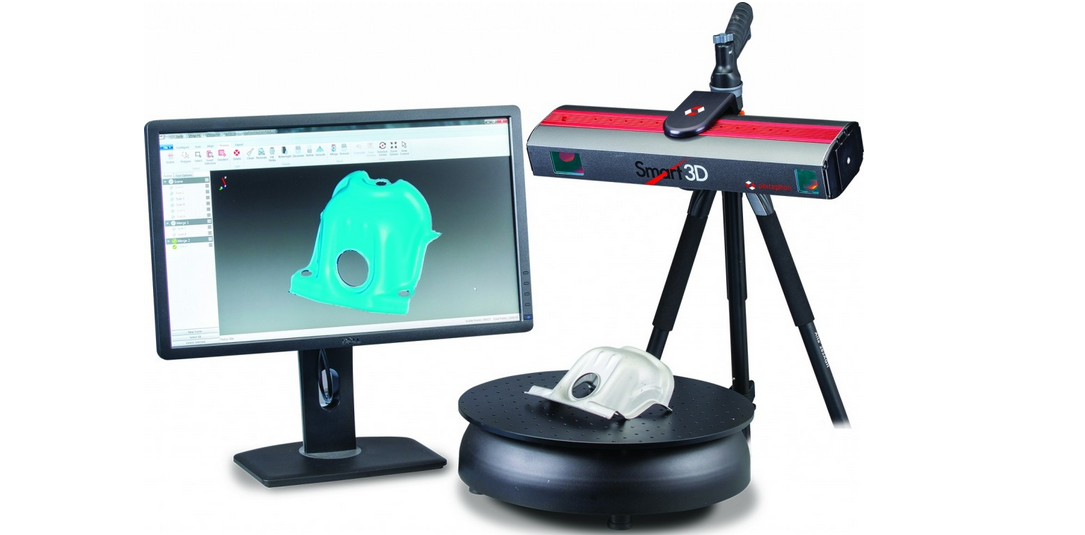

The disadvantage of laser scanners is the impossibility of their use on moving objects. Then optical 3D scanners come to the rescue, which shoot with one or more cameras from different angles an object illuminated by a special projector. Based on the received image, a three-dimensional image is built.

Optical scanner

A "contraindication" for the use of this technology are reflective and translucent surfaces - shiny, mirror or transparent. But when scanning a person, they are simply irreplaceable. nine0003

3D scanning methods

Any object can be digitized both by contact and non-contact methods. In the first case, active interaction with the subject is necessary, in the second, accordingly, no. Both of these methods have their advantages and disadvantages.

Contact 3D scanners

They have a mechanical probe with a special sensor that measures parameters and transmits the collected information to the device. To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype. nine0003

To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype. nine0003

Non-contact 3D scanners

This category includes all devices capable of scanning at a distance. This is especially true for objects located in hard-to-reach places.

Non-contact 3D scanner

A stream of radiation (it can be ultrasound, light, X-rays or a laser) is directed to the object and reflected from it, it is recognized by the 3D scanner. They are similar in principle to a video camera and may require the use of additional devices for better lighting. nine0003

Non-contact 3D scanners come in 2 types:

-

Active - work with the help of a laser beam or structured light directed at an object, which, when reflected, give information about the location of the object in the form of coordinates.

-

Passive - use time-of-flight rangefinders that read the time and distance that the laser beam travels to the object, and so - for each point in space, which ultimately allows you to accurately recreate its three-dimensional image. nine0003

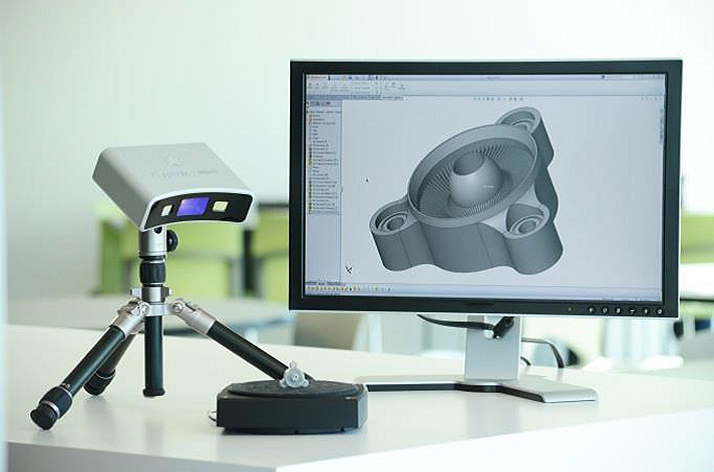

Desktop 3D scanners are very popular and widespread, since they are mostly simple and safe to use, do not require any special technical skills and are quite cheap. The EinScan-SE 3D scanner is one such example. It can be used both at home and in the office. It has access to the API of many popular 3D printers, which makes it possible to immediately print the created three-dimensional model.

Add to compare

Product added to compare Go

| Manufacturer | Thor3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go nine0003

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Range Vision |

Types of 3D scanners according to the principle of use

There is also a variety of species here. Let's highlight the main ones:

Let's highlight the main ones:

- nine0006 Manual: The are handy and simple models that are easy to use as they are quite compact and do not require special skills. True, their technical capabilities may be somewhat limited.

-

Portable: The is mainly used for field work and is convenient to take with you.

-

Desktop: have extended functionality and are used to create high-quality 3D models. Most often used in offices. nine0003

-

Stationary: are used, as a rule, in production, various enterprises, as they can scan a large number of objects of the same type at once. Mounted on special turntables.

Handheld 3D Scanner Calibry

Such a choice of products allows you to select the right model for a specific task. In some cases, scanners independently measure objects, in others - with the help of a person who sequentially moves the device until all the necessary information is collected. nine0003

nine0003

Such options for hand-held 3D scanners as Calibry are in high demand among buyers. Despite the apparent simplicity of execution, it has a high resolution and scanning accuracy, due to which it is able to digitize objects with a length of 0.2 to 10 meters. Objects that have a non-standard surface - dark or shiny, with a large number of corners and small details will not become a problem either. Among other things, its undoubted advantage is its low weight, only 900 grams. nine0003

Advantages and disadvantages of 3D scanners

Surely, many of the potential buyers are wondering: do you really need a 3D scanner to invest a lot of money in it? What can this acquisition give and will such an investment be justified?

3D scanning has become an integral part of any modern manufacturing process

In order to understand how much you need this equipment, we will list its advantages and disadvantages. nine0003

Benefits:

-

They make it possible to scan objects located at a remote distance and in places inaccessible to the presence.

-

They have the ability to "read" not only colors and images, but also to convey the texture of the surface.

-

Significantly speed up the process of "taking" data from any object, even a very complex one with a large number of planes. nine0003

-

A variety of models allows you to choose the most convenient version of the scanner, including manual or portable, which can be easily taken with you.

Weaknesses:

-

Some scanners are unable to recognize transparent or black and white objects. In this case, their preliminary preparation (treatment with a special composition) is required. nine0003

-

I do not always display complex objects correctly, with a large number of inserts and partitions.

-

To obtain a high-quality result, they require skills and abilities to work with certain computer programs for creating 3D models.

-

If the rules of operation are constantly violated, it may become necessary for expensive repairs to the equipment. nine0003

If you need high-precision and high-quality three-dimensional copies of objects, then you cannot do without a 3D scanner. It makes it possible to work in almost any conditions - indoors and outdoors, and with any objects by type and size. It is not surprising that now these devices are in great demand, which gives rise to the annual release of a large number of models, from which you can always choose the one that suits you in terms of quality and price.

Things to consider when choosing a 3D scanner

The computer equipment market offers a huge amount of all kinds of equipment, including devices for three-dimensional scanning. Navigating that variety is sometimes not at all easy: some buyers are only concerned about the cost, others are interested in the number of options (sometimes completely useless), but the most far-sighted look at the ratio of the first and second.

Choosing the right 3D scanner is a big deal

It is not always easy to take into account all the technical points that can significantly affect what result will be ultimately achieved. We will tell you what you should pay attention to if you are thinking about buying a 3D scanner.

Be guided by the following parameters:

-

How high is the accuracy of the 3D scanner. This is one of the most important features. It needs to be targeted first. nine0003

-

Resolution also plays an important role. It follows from the first, since the accuracy of measurements and the quality of copying depend on the resolution.

-

In what range the device operates, how close / far it can be from the scanned object.

-

The scanning field is the parameters of that object, thing that it is able to process in 1 session. nine0003

-

Does the scanner capture various atypical types of surfaces with complex terrain - channels, partitions, holes, etc.

).

). -

Portability, mobility of the device - how easy it can be moved if desired, taken with you, its size.

-

The time it takes to prepare for work, as well as the duration of the digitization process itself. nine0003

-

The range of possibilities in terms of copying: are there any restrictions on shapes, textures, material, as well as operating conditions - temperature, light, etc.

Of course, the better the quality of the 3D scanner, the more expensive it is. However, you should focus primarily on the tasks that you face, and only then take into account everything else.

Applications

Three-dimensional scanners are in demand in many areas of human life. They are irreplaceable both in the industry, and for household needs. The range of their application is so wide that it is possible to list for a very long time. It's easier to say where they are not needed.

The most common areas of use are, of course, medicine, industry, architecture, construction, film industry and design.

For example, in dentistry, these devices allow you to create ultra-precise three-dimensional models of dentures. One type of such a scanner is Shining 3D's AutoScan DS-EX PRO, which does a great job with a variety of tasks while being quite affordable and reliable. nine0003

Medical 3D Scanner

In engineering, such technologies are also indispensable. Digital building prototypes are now much easier and faster to obtain than before, when it required multiple manual measurements and then entered into a database. Any physical object can now be recreated in three-dimensional form, moreover, in the shortest possible time and with a minimum error.

In cinemas, we can see with our own eyes "revived" fantastic characters, which were created using motion capture technology, which made them as realistic and impressive as possible. This would not have been possible without 3D scanners.

A few decades ago, it was even difficult to imagine all the things that we use all the time today.

05

05

1 MP

1 MP

1/10/11 64bit

1/10/11 64bit

5 kg/17.6 lb

5 kg/17.6 lb

96

96  0

0