Extruders for 3d printers

3D Printer Extruders | MatterHackers

Finding the best extruder upgrade or replacement for your 3D printer can take the quality of your 3D printed parts to the next level. The extruder is responsible for how much and at what speed your 3D printer pushes filament into the hotend. MatterHackers can help you find the perfect extruder for your 3D printer to help you get the best 3D printed parts possible.

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

How to Succeed when 3D Printing with Polycarbonate Filament

Follow these helpful steps to start successfully printing with this extremely tough, professional grade material.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

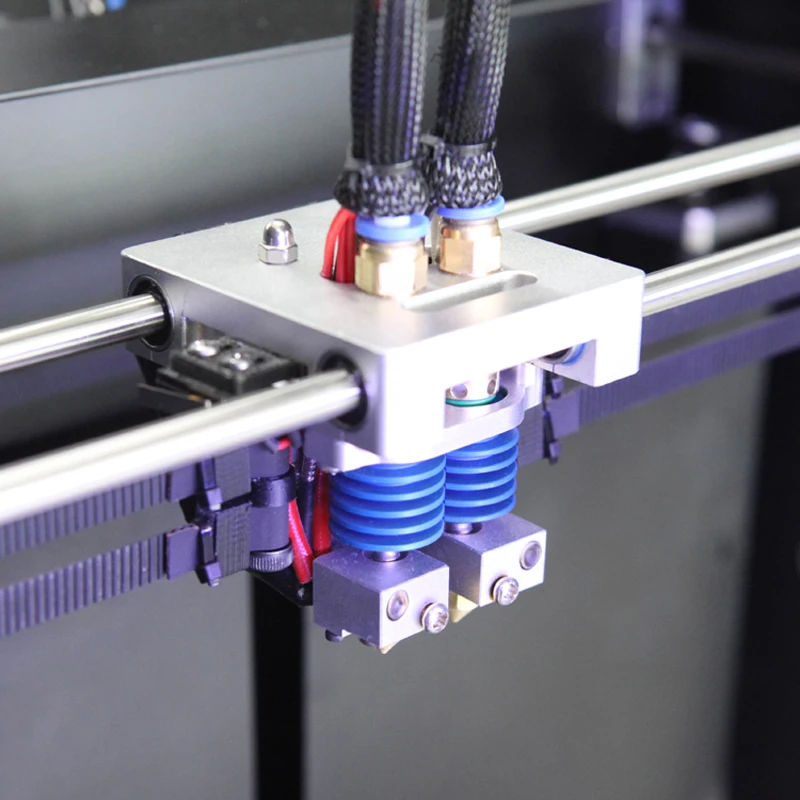

Bondtech Extruders | MatterHackers

Bondtech is a Swedish manufacturer of high-quality 3D printer parts and accessories. Their signature product is the LGX Dual Drive extruder, which is designed for increased filament grip and smoother 3D printing. They also offer a range of CHT (Bondtech High Flow) nozzles, which are designed for faster melting and higher flow rates. For users of the popular Prusa i3 3D printer, Bondtech offers an upgrade kit that incorporate linkageages for increased torque and precision.

Their signature product is the LGX Dual Drive extruder, which is designed for increased filament grip and smoother 3D printing. They also offer a range of CHT (Bondtech High Flow) nozzles, which are designed for faster melting and higher flow rates. For users of the popular Prusa i3 3D printer, Bondtech offers an upgrade kit that incorporate linkageages for increased torque and precision.

- Quality 3D printer extruder gears

- Patented CHT technology for faster printing

- Prusa i3 compatible extruder gear upgrade kit

3D Printer Extruders

Browse Extruders by Manufacturer

View the different makers of FDM 3D Printer Extruders

Browse Extruders by Drive Gears

Choose between an Idled or Dual-Drive extruder for your 3D printer

Browse by Hobb Material

Choose the extruder component perfect for your application

Browse Extruder Accessories

Keep your extruder performing it's best with maintenance or upgrades

Guides & Articles

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

How To Succeed When 3D Printing With PLA Filament

Discover the best practices for 3D printing with PLA filament - from finding the right temperature, to which surfaces to 3D print on, this step-by-step guide will help you succeed with 3D printing PLA.

How To Succeed When Printing With ABS

ABS filament is a versatile material that's a great option for when you need your 3D-printed parts to be strong and heat-resistant. Learn how to print this material like a Pro in this in-depth guide.

Printing Tips & Tricks: ABS Bed Adhesion

ABS: stronger, more durable, and more heat-resistant than PLA. An excellent 3D printing material, but ABS is prone to warp. Stop warping on your ABS prints, and create strong bed adhesion to produce flat prints by following these tips.

Living Hinge: Design Guidelines and Material Selection

Bring your prints to life by adding an additional degree of motion to your designs - living hinges are the foundation of expanded mechanical solutions.

Printing with Bronzefill

Bronzefill filament is made with real bronze powder and offers a unique look and feel for your decorative 3D printed parts

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

3D Printer Filament Comparison Guide

There are many different kinds of 3D printer filament, and each one has it's own strengths for different projects. Knowing these differences is key to a successful 3D printing experience and so we have created a Filament Comparison Guide with everything you need to know about every type of filament available.

Bondtech was established in 2014 by Martin Bondéus, who had previously used the 3D printing technology in his work as a product developer. Today, Bondtech manufactures Bondtech Dual Drive extruders and other innovative 3D printing products to users and retailers across the world.

Today, Bondtech manufactures Bondtech Dual Drive extruders and other innovative 3D printing products to users and retailers across the world.

- Terminates grinding problems

- Improved handling

- Increase reliability

- Eliminates under extrusion

- Perfect extrusion

- Increased printing speed

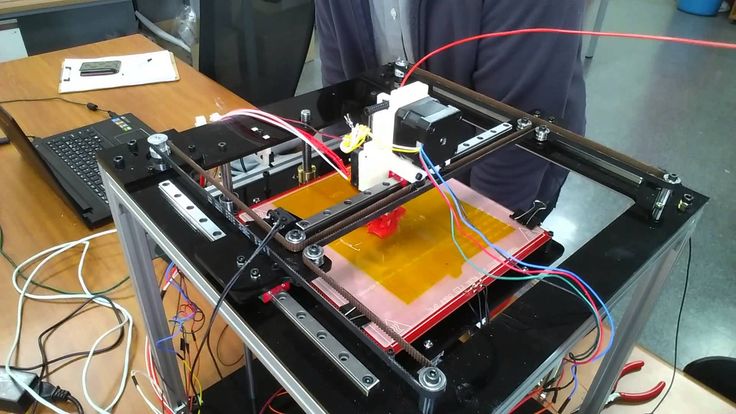

Techno Print 3D Company

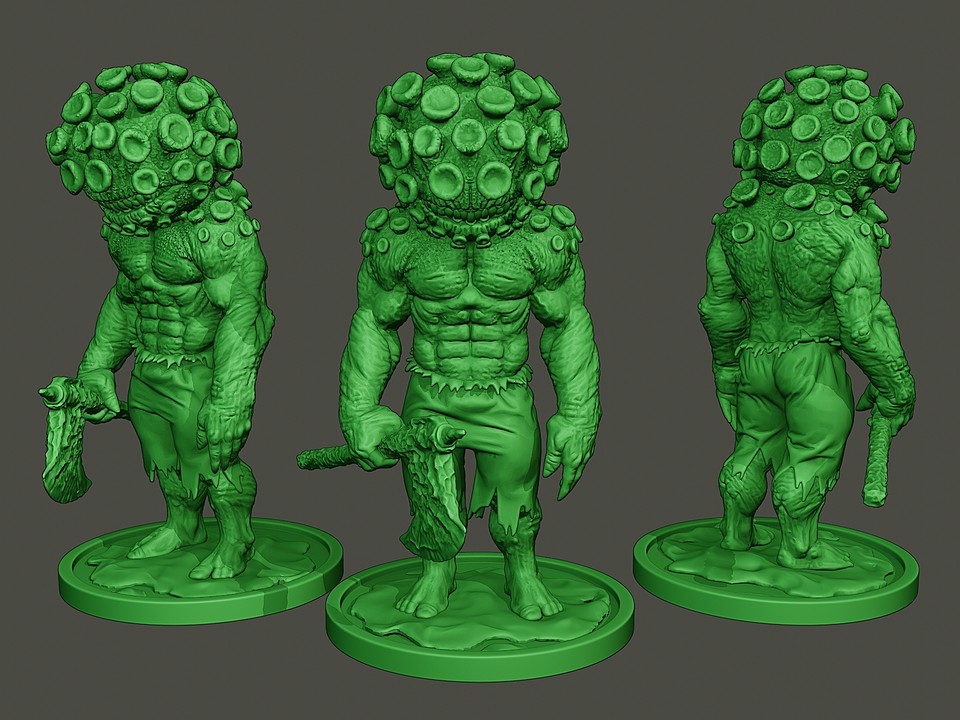

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

How to choose an extruder for a 3D printer

3DPrintStory 3D printing process How to choose an extruder for a 3D printer

Hello friends. Today we will talk about choosing an extruder.

Today we will talk about choosing an extruder.

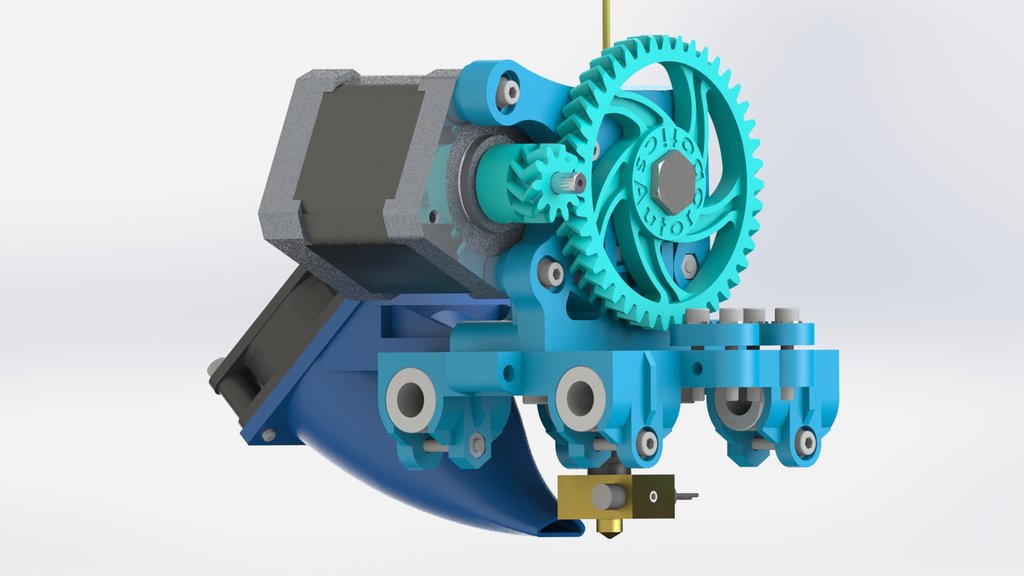

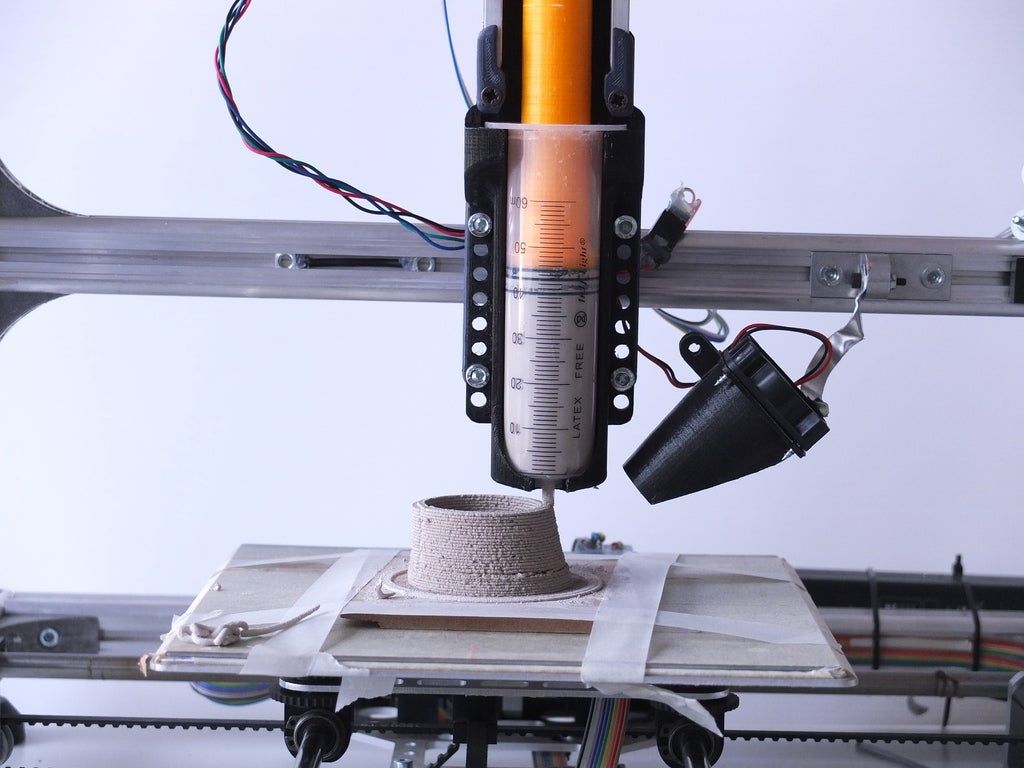

In simple terms, an extruder is a mechanism whose task is to feed molten plastic into the printing zone. It consists of a feeding mechanism and a print head.

Two types of extruders

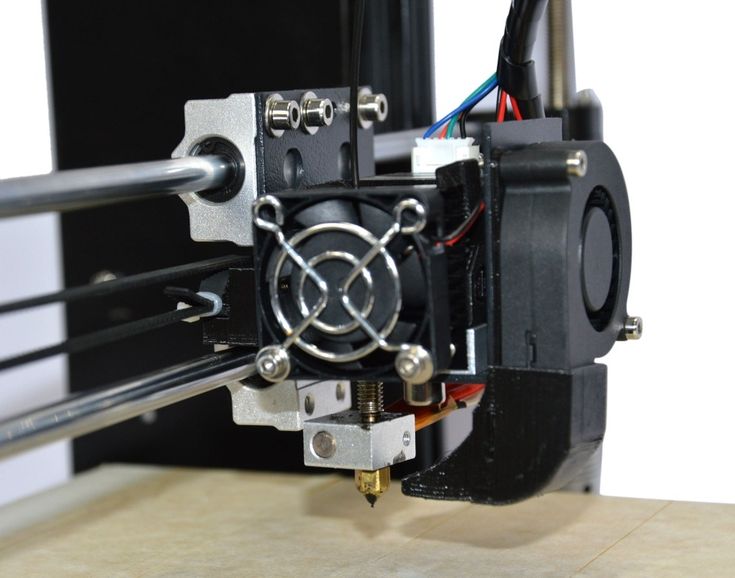

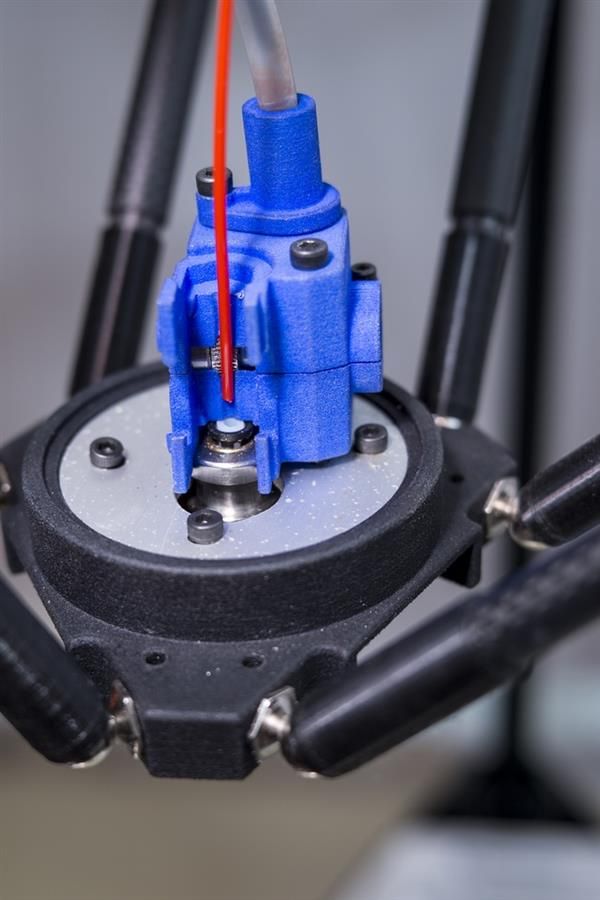

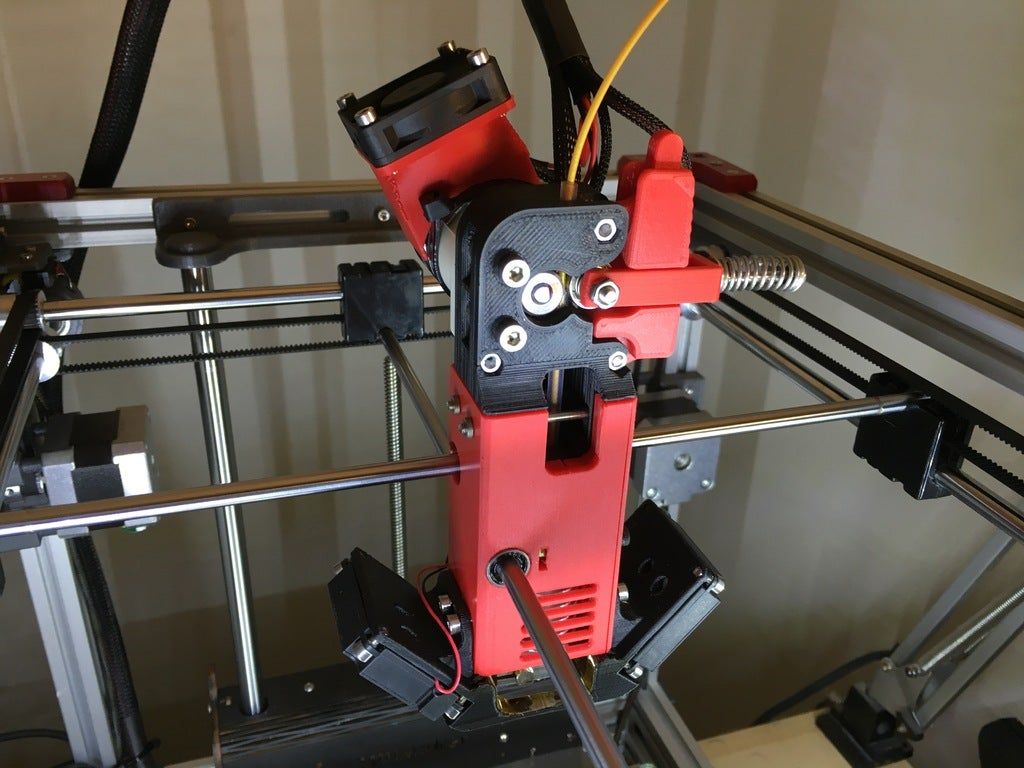

There are two main types of extruders: bowden (bowden) - in the picture on the left and direct (direct) extruder - in the picture on the right. With a direct extruder, the plastic feed mechanism is located in close proximity to the print head. In bowden - at some distance, connected by a Teflon tube. nine0003

The main advantages and disadvantages of the two types of extruders

Both have their advantages and disadvantages.

In direct extruders, the weight of the stepper motor with the plastic feed mechanism is added to the weight of the printhead. Excess weight will increase the inertial forces when stopping and accelerating the print heads, which can adversely affect the quality of 3D printing, especially at high speeds, and also causes increased wear of the kinematics of the shafts and bearings. But the supply and rollback of plastic (the so-called retract) is more accurate, which makes tuning easier. nine0003

But the supply and rollback of plastic (the so-called retract) is more accurate, which makes tuning easier. nine0003

Bowden eliminates the disadvantages of direct extruders regarding extra weight, since only the print head runs along the carriage, which makes it possible to print at higher speeds. But in return, we get problems with the exact dosage of plastic, which will complicate tuning and calibration.

Extruder design

All extruders are similar in design and differ only in execution. Let's look at what the extruder consists of using the well-known e3dv6 model as an example.

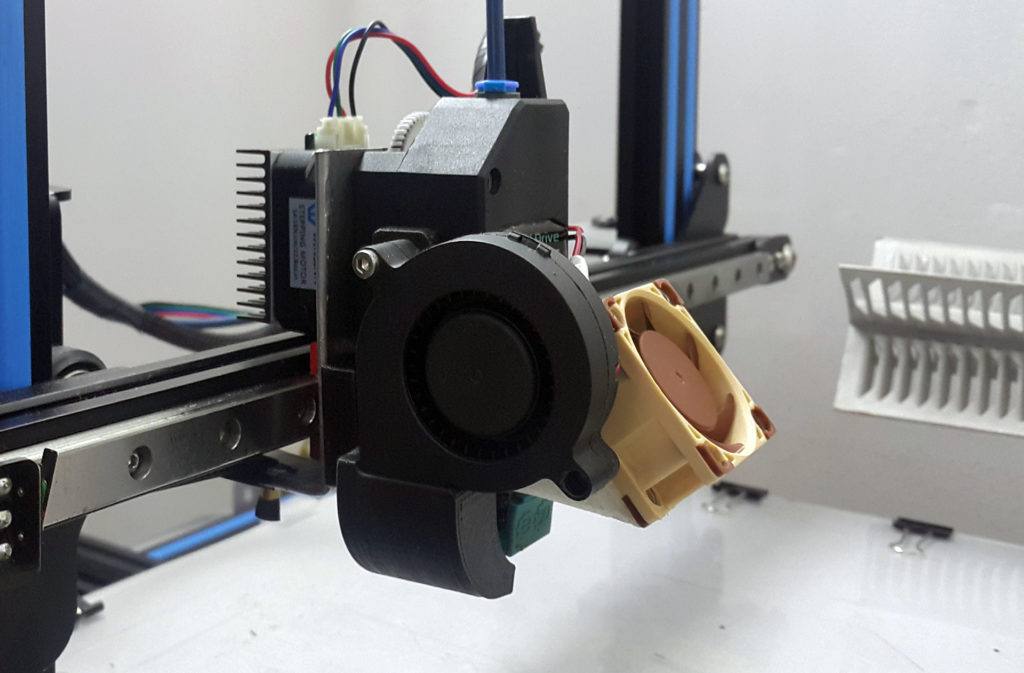

These are three main nodes: cold end (cold part), hot end (hot part), which are connected by a thermal barrier. nine0003

Hot end consisting of:

- Heating element to melt plastic.

- Measuring element (thermistor) for maintaining the desired temperature.

- Aluminum heating block to house them.

- Nozzle with calibration hole from 0.1 to 0.8 millimeters.

Cold end is:

- Aluminum heatsink with fan, which serves to cool the plastic, preventing it from melting prematurely. nine0056

- Thermal barrier that serves to isolate these two elements from each other. Usually it is a stainless steel sleeve, and sometimes plain steel. Stainless steel is still preferable, since it is no worse than ordinary steel in thermal conductivity. By the way, when buying, pay attention to this! Easy to check with a magnet. With a relatively similar weight, stainless steel is not magnetic. The nozzle, on the contrary, should be made of a material that conducts heat well.

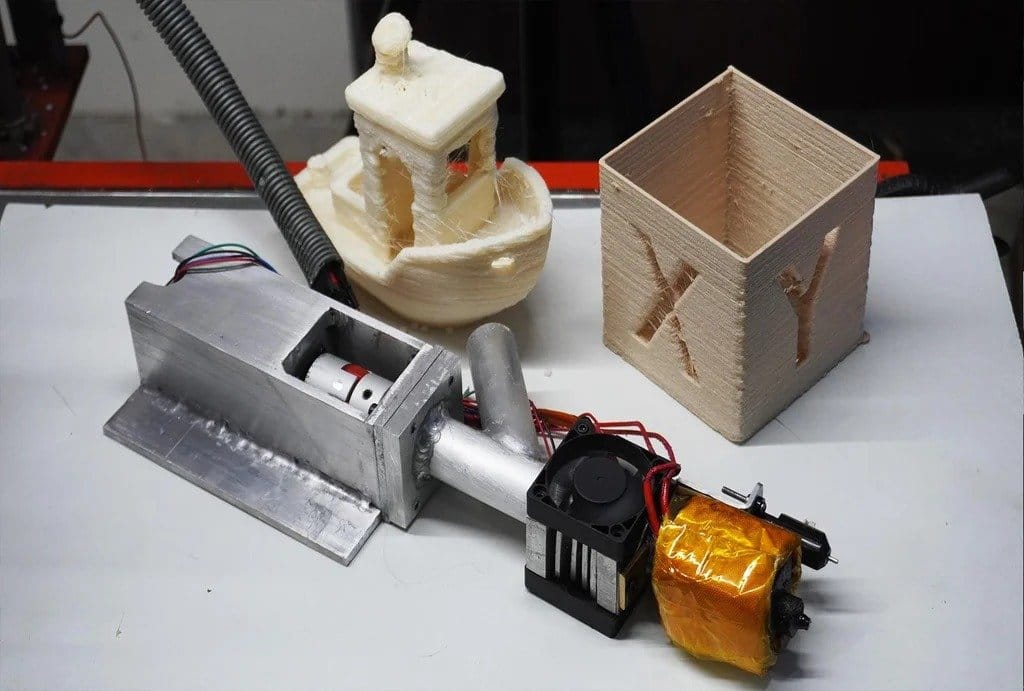

Detailed construction and features of the e3dv6 extruder

In our case, we will consider a bowden extruder based on a Chinese copy of e3dv6.

The Chinese copy works as well as the original, but costs several times cheaper. The difference is only in the quality of processing and the materials used. Please note that there is also an older version of e3dv5. They are very similar in appearance, but still have significant differences. I do not recommend taking e3dv5, since e3 dv6 is an improved version of it. The e3dv5 has a larger heatsink and a slightly different heating block. In e3dv6, the thermistor is placed closer to the nozzle than to the heater relative to e3dv5, which provides more accurate control and maintenance of temperature in the area of \u200b\u200bthe plastic, and not the heater. nine0003

They are very similar in appearance, but still have significant differences. I do not recommend taking e3dv5, since e3 dv6 is an improved version of it. The e3dv5 has a larger heatsink and a slightly different heating block. In e3dv6, the thermistor is placed closer to the nozzle than to the heater relative to e3dv5, which provides more accurate control and maintenance of temperature in the area of \u200b\u200bthe plastic, and not the heater. nine0003

There are versions for different plastic diameters. 1.75 millimeters, which most print or 3 millimeters.

To avoid traffic jams, choose a thermal barrier with a Teflon tube insert for PLA printing. It is smoother and slipperier.

Solid metal is more suitable for printing with nylon, ABS or other plastics that require a higher printing temperature, since the Teflon tube in the middle is already destroyed at a temperature of about 200 degrees. On the Internet they write that the all-metal barrier in the original prints with all types of plastic, since the hole in the middle is well polished and smooth, unlike the Chinese counterpart, in which the hole was drilled with a conventional drill without additional post-processing.