Cube 3d printer refill

Cube 3D Printer Review 2022

3.5

See Price

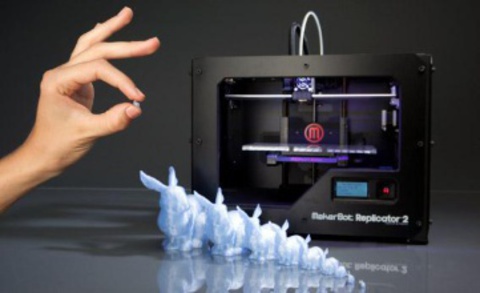

Since the popularization of 3D printers, and give the inherent difficulty of 3D printing, there’s been demand for affordable, easy to use models that work out of the box.

3D Systems and the widely popularized Cube 3D printer strive to plug that gap. Does it live up the hype? Let’s investigate as we pull apart the secret inner workings of the most stylish printer on the market.

| Printing Area | 152x152x152mm |

| Print Tech | Plastic Jet Printing |

| Supported Filament | ABS and PLA |

| Extruders | 2 |

| Layer Thickness | 70 microns and 200 microns |

Table of ContentsShow

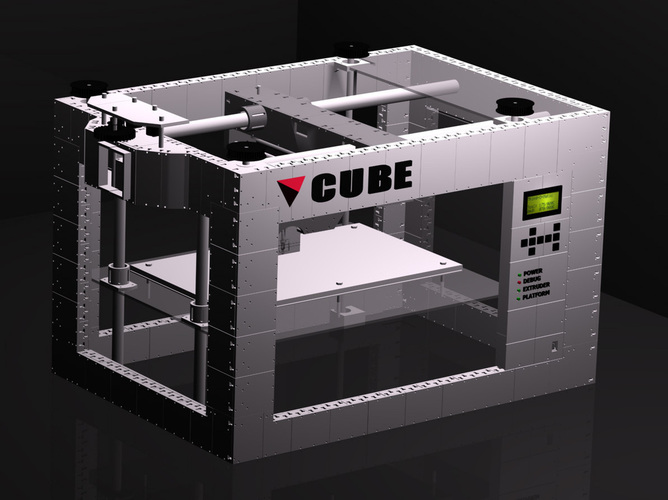

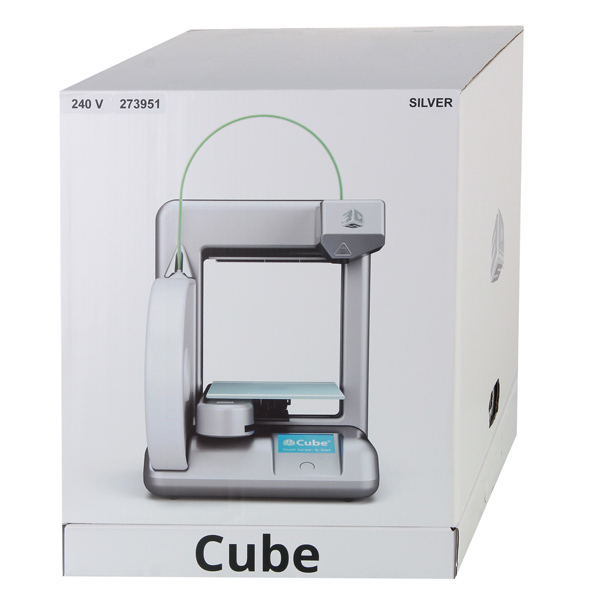

Design

3D Systems is onto its third generation of the Cube with all the enhancements this encompasses. An all-in-one cube casing houses the printer, hence the name, and is advertised primarily as a user-friendly personal desktop model. With simplicity in mind, it aims to introduce first-timers to the world of 3D printing without the oft-complicated installation of entry-level DIY models.

Straight out of the box, the Cube is a piece of engineering bliss. Aesthetically pleasing, compact, classy, and dare we say, beautiful, it resembles a product distributed by Apple, where functionality and ease of use are as much a consideration as design.

The sleek white exterior panels are miles away from the functional, bare-bones design of plenty rival models. So much so that the Cube is very much at home sitting alongside other home office devices rather than confined to a workshop. The self-contained shell means keeping track of diverse components isn’t a factor.

The print area is a modest 152x152x152mm, providing enough working space for most small scale projects, especially for beginners trying their hand at 3D printing for the first time. With both 0.2mm and 0.07mm (200 and 70 microns) print resolution layers, the Cube offers a degree of versatility, but not enough to cater for a large variety of print projects.

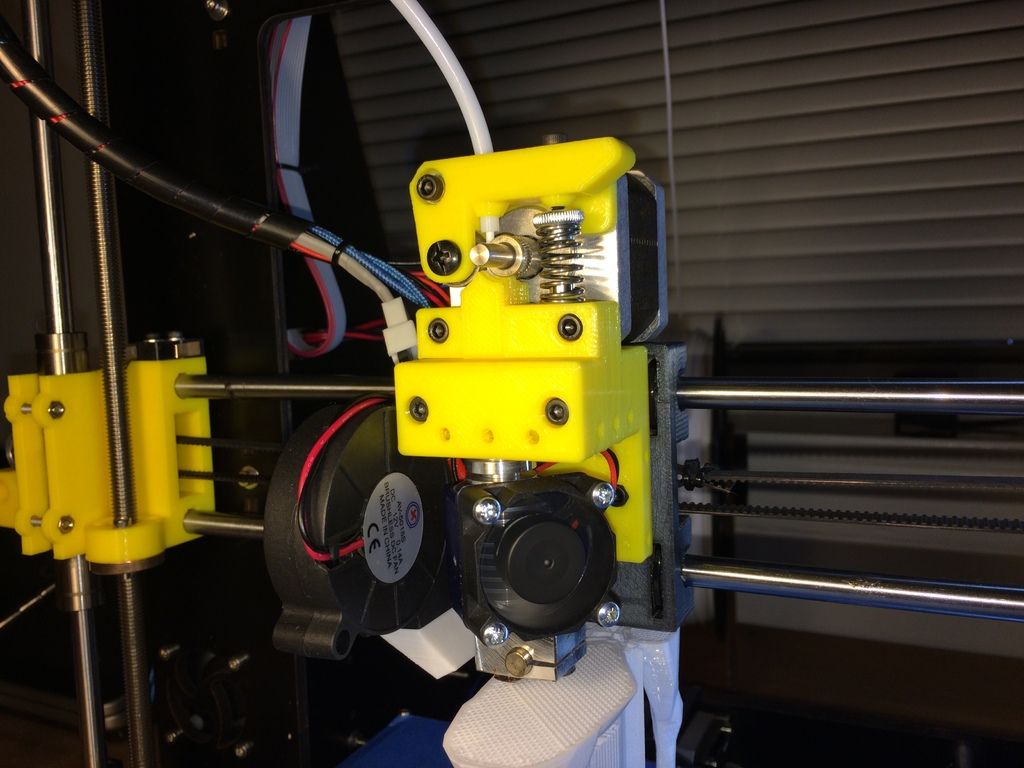

The print head ensures the X-axis, while the PrintPad (read build plate) manages the Y and Z axis. The PrintPad is removable for easy cleaning in hot soapy water. Every print job requires the application of Cube Glue, a weak adhesive produced by 3D Systems that assists the printed filament to solidly in place on the build plate. It takes some practice to apply the appropriate amount, and you need to wait for it to dry enough or suffer the consequences as we did.

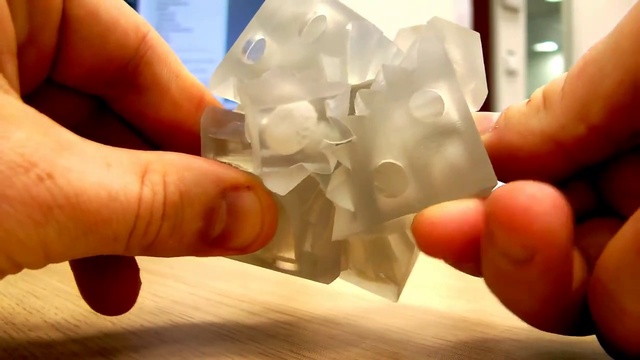

The Cube sports dual extruders for simultaneous double color or material prints housed in out of sight purpose-built plastic casings that sit inside the vertical outer side panels. ABS and PLA are the only supported materials, and the Cube only works with 3D Systems proprietary filament Smart Cartridges that come in a selection of twenty-three colors.

These are significantly more expensive than generic filament bought from a hobbyist retailer, which was a big con for us when assessing the Cube 3D printer. These materials are of a higher quality, ostensibly, to justify the higher cost. To give 3D Systems its due, the ABS provided is recyclable, while the PLA is compostable, which softens the blow for the environmentally conscious maker. The company also asks users to ship back empty cartridges for recycling.

To give 3D Systems its due, the ABS provided is recyclable, while the PLA is compostable, which softens the blow for the environmentally conscious maker. The company also asks users to ship back empty cartridges for recycling.

Each cartridge includes its own integrated, snap-in nozzle, which it must be said, is incredibly simple to install and, in theory, foregoes the need to battle with removing debris and build up from the extruders every time. Two cartridges come as standard with each new device.

Connectivity through a USB port mounted on the bottom of the side casing (the package includes a USB flash drive) and a WiFi connection allowing the user to trigger prints from their computer or via a flash drive, gives options.

3D Systems have even designed a dedicated Cubify mobile app for both Android and iOS (plus MacOS and Windows through the Cubify software) packed with printing ideas, blueprints, and guides. The software converts into the required file type and forwards the instructions to the printer. It cannot be used to design prints though.

It cannot be used to design prints though.

The user interface, we love. Inviting and perfectly intuitive, it’s hard to go wrong using the in-built 2.5” color touch screen LCD. Beginners should find getting around the settings and options a breeze. Indicators such as how much material is left are welcome additions for users who might not have yet developed the skills to gauge how much filament a project requires.

Printing

For a 3D printer touted as an out of the box solution, the printing process was hit or miss. The first few prints went well, especially for smaller prints. The results were generally error-free and full of detail with smooth contours and layers with few flaws. Ghosting was all but absent.

However, the Cube starts to struggle with larger projects that more often than not end in a bundle of filament only good for the landfill. The waste is especially hard to stomach given the exorbitant cost of the cartridges. The Cube Glue did little to fix the issue but works well for smaller prints.

Overall, the Cube is ideally suited to small jobs and is relatively economical with the material when it works correctly. From what we can gather, the lack of a heated plate, and the fact the software didn’t factor in the need for supports worked to the detriment of larger prints that require stability and uniform heat distribution as vertical layers build up.

The Cube is loud, to the point that it can become an annoyance by reverberating into adjacent rooms. For such a little machine, the noise is disproportionate possibly due to clanks bouncing off the casing.

Where our opinion of the Cube shifted drastically was when we encountered systematic jamming in the jet on the print head. The problem appeared to happen after only a handful of jobs using a brand new cartridge. Either the filament reacts badly to being exposed and goes brittle, or warehouse storage is conducive to the chemical properties of the plastic to harden more than necessary while sitting in the cartridge. It was hard to tell.

It was hard to tell.

Regardless, we have here a serious design flaw; feeding the filament through a tube doesn’t work well. Once a jam occurs, the nozzle does nothing but churn the plastic into a clumpy mess. If it isn’t a jam, the filament breaks inside the cartridge. There’s not much that can be done other than load in a replacement.

Speed wise, the Cube isn’t remarkable and gets the job done within acceptable limits.

Small prints can take anywhere from four to ten hours depending on the size, while bigger jobs were a bust most of the time, so we were never able to finish them to know how long the process takes.

Assembly

The Cube comes pre-assembled and only requires the user to install the cartridges, a straightforward procedure. The Cube is packaged well and comes with a quick start manual, USB key, cabling, glue, spatula, plyers, power supply, and the printer itself.

The Cube self-calibrates by make sure the build plate is perfectly level and at the right distance from the print head via a set of magnets under the plate, although the device asks the user to tweak the plastic circular knobs below the plate as required. The instructions are straightforward and won’t daunt even the most unversed user.

The instructions are straightforward and won’t daunt even the most unversed user.

That aside, the Cube allows you to be up and printing within 45 minutes after unboxing the device, unheard of for printers in this price range where hours of assembly are the name of the game.

Support

3D Systems has discontinued the Cube, and the model is no longer in production, arguably due to lackluster reviews caused by the filament jamming issue.

As a consequence, the Cube is now available at a fraction of the cost of its initial retail price, around the $1000 mark. You can pick one up for around $200-$300 on Amazon, if not less. 3D Systems continues to sell cartridges for the time being, although third-party manufacturers have popped up selling them at a fraction of the cost.

Support wise, 3D Systems offers a 90-day warranty for parts and labor, but no refunds whatsoever due to discontinuing the product. Specific resellers may offer different refund policies.

3D Systems has a robust after-sales support service with a dedicated phone team that can help with the jamming issue by walking through a variety of detailed fixes. They’ll also walk through updating the Cubify software to the latest firmware which helps with printing problems to a certain degree. Alongside are forums, guides, and articles about getting the most out of the Cube.

They’ll also walk through updating the Cubify software to the latest firmware which helps with printing problems to a certain degree. Alongside are forums, guides, and articles about getting the most out of the Cube.

Verdict

The Cube isn’t a bad printer overall and produces some quality results for smaller projects. The design is the model’s strongest asset, and it’s hard to find fault with the look, feel, and ease of use (bar the jamming issue).

At a much-reduced price, the Cube is an ideal no-nonsense first time 3D printer for those who want to experience the joys of printing without the hassle and tinkering of similarly priced DIY equivalents. The dual extruder setup is also a bargain.

The cartridges are a downside, but if you buy them from a third-party, the costs are more palatable. There’s also a DIY fix for the jamming problem, which isn’t particularly difficult to perform and is an excellent way to introduce a beginner to the modification aspect of the hobby.

The Cube isn’t ideal, but its hard to argue with for the bargain price.

Ekocycle Cube - Protocom s.r.o.

3D Printing. Recycle. Remake.

"Waste is only waste if we waste it."- will.i.am

Exclusively printing in post-consumer waste, the EKOCYCLE Cube 3D printer recycles what you use, so you can remake into new, meaningful, beautiful and better things.

Zero waste + unlimited style

The EKOCYCLE Cube 3D printer lets you stylize your digital world and make it real, printing in high resolution, fast speeds and with beautiful complexity only matched by nature. It unlocks the limits of your style.

Setting a new standard for how we make things

Each EKOCYCLE cartridge turns the equivalent of 3 bottles into your next wearable fashion, music accessory or desktop décor. With a simple tap you get to decide how it's made, where it's made and when it's made with your EKOCYCLE Cube 3D printer.

EKOCYCLE Filament Cartridge contains 25% of post-consumer recycled materials, using an average of 3 assorted recycled 20oz PET plastic bottles.

"Things don't have to end. They can begin again."- will.i.am

The EKOCYCLE cartidge prints with the strongest flexibility possible from PJP (Plastic Jet Printing) coupled with durability and a curated color palette for your 3D prints.

What's your EKO-style?

Print to fit you or power your passions with 3D printing, either way, it's about finding your EKO-style. Discover what you love to 3D print on Cubify.

- Cube safety data sheet Glue.pdf (pdf - 198 kB)

Technical Specifications

| Material | Each EKOCYCLE cartridge contains 256 % post-consumer recycled materials, using an average of 3 assorted recycled 20 oz. PET plastic bottles. |

|---|---|

| Operating Envelope | 28.9(w) × 20.6(h) × 15.8(d) inches / 73.4(w) × 52.3(h) × 40.1(d) cm |

| Wireless | Print over WiFi with the Cubify app for Mac OS × and Windows Learn more |

| Wired | Transfer print files with the USB stick (supplied with the Cube) |

| Mobile devices | Print direct with the Cubify app for iOS and Android (available soon for free download) |

| Technology | Plastic Jet Printing (PJP) |

| Print jets | Dual jets |

| Maximum design size | 6 × 6 × 6 inches / 15. 25 × 15.25 × 15.25 cm 25 × 15.25 × 15.25 cm |

| Supports | Fully Automated, easy to peel off |

| Dual cartridges | Each cartridge prints 13 to 14 mid-sized creations |

| Room temperature | 16–29 °C (60–85 °F) |

| Non-condensing relative humidity | 30–60 % |

| Description | Comes with software to create cube readable files |

| Windows requirements | Cube software runs on 32 and 64-bit Operating Systems on Windows 7 and above Minimum screen resolution: 1024 × 768 Minimum IE version: 10 and above |

| Mac OSX requirements | Cube software runs on Mac OSX 10.9 and above Minimum screen resolution: 1400 × 900 |

| Android Phone/tablets requirements | Cubify App is available in the Play Store for your Android phones/tablets running Android 4. 0 (Ice Cream Sandwich) and above 0 (Ice Cream Sandwich) and above |

| iOS requirements | Cubify App is available in the App Store for your iPhone running iOS 7 and above |

| Minimum hardware requirements | Processor: Multi-core processor - 2 GHz or faster per core System System RAM: 2 GB Open GL for mobile platforms:Open GL ES 2.0 and above Open GL for desktops: OpenGL 3.0 and above |

| Dimensions (W×D×H) | |

| 3D Printer Crated | 26.3(w) × 20(h) × 14.5(d) inches / 66.8(w) × 50.8(h) × 36.8(d) cm |

| 3D Printer Uncrated | 13.2(w) × 13.5(h) × 9.5(d) inches / 33.5(w) × 34.3(h) × 24.1(d) cm* |

| Weight | |

| 3D Printer Crated | 22 lbs / 10 kg |

| 3D Printer Uncrated | 17 lbs / 7. 7 kg* 7 kg* |

* with cartridge

Video

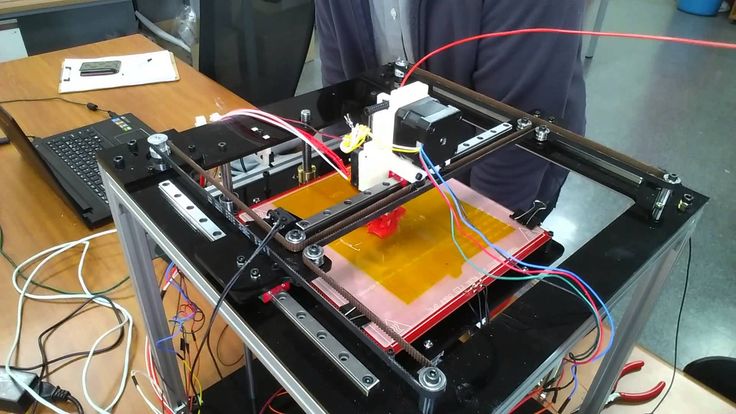

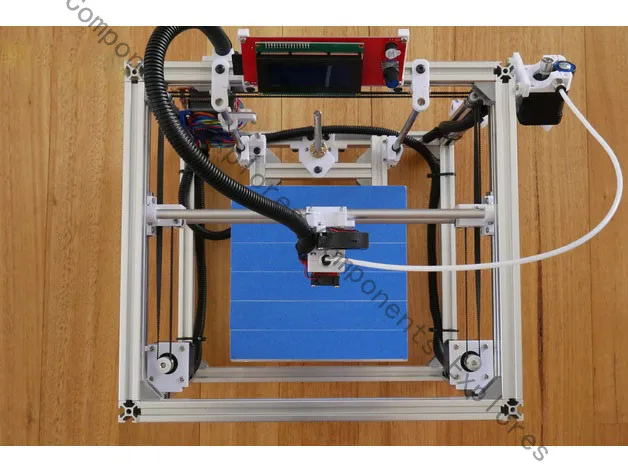

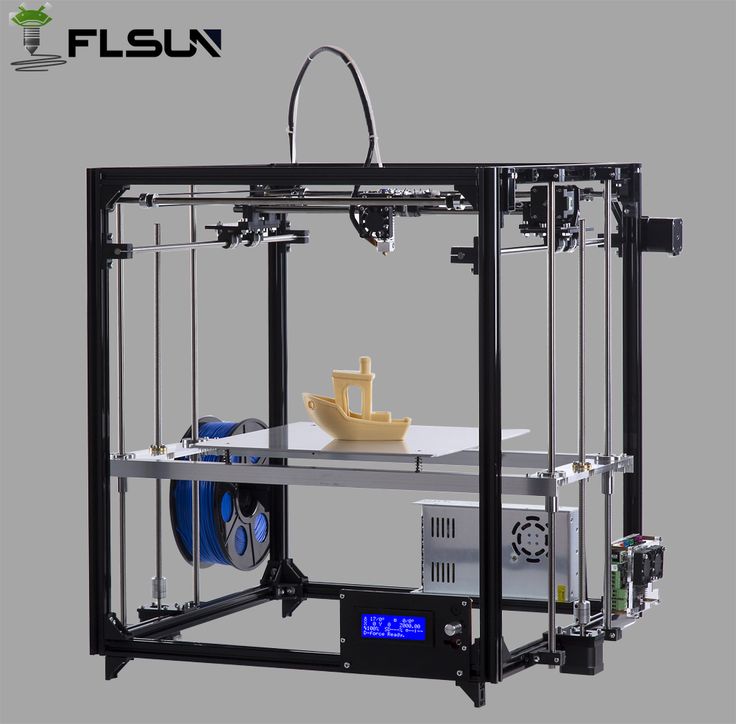

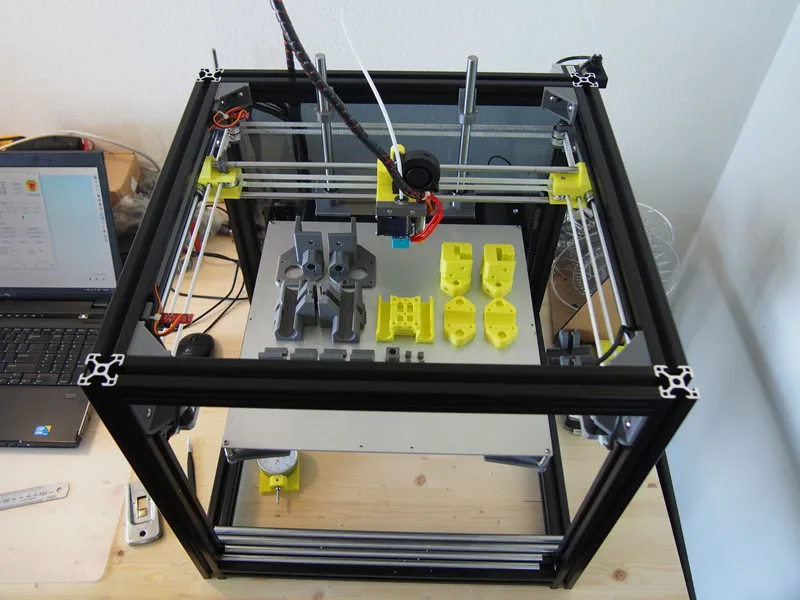

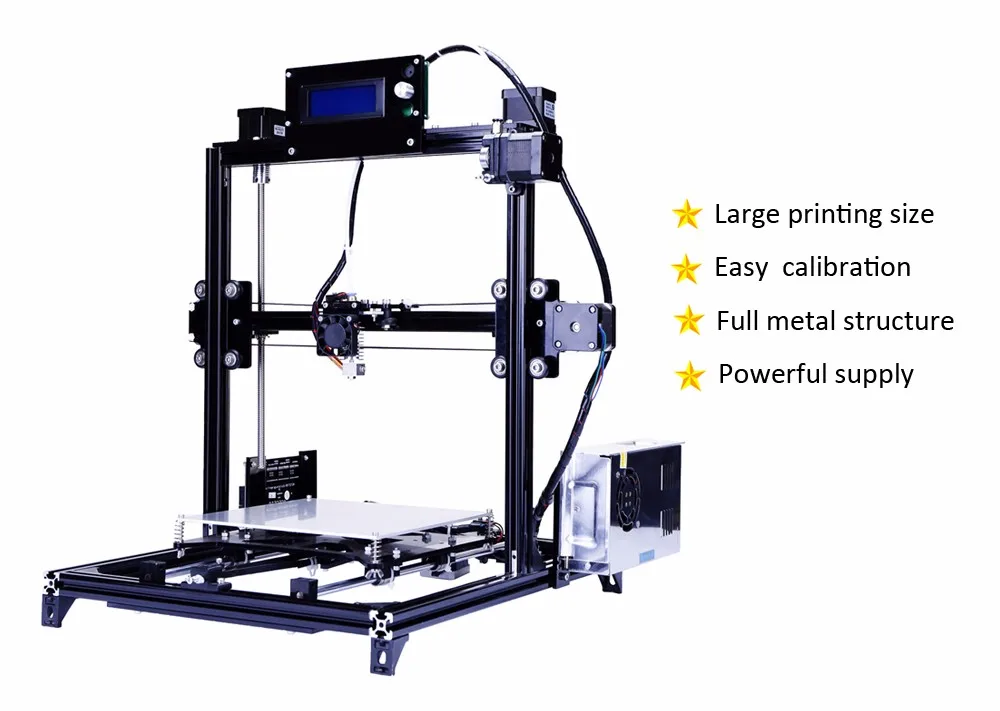

Affordable 3D printer

3D printing is actively developing these days. 3D printing devices allow you to create almost any object that must first be modeled in a software environment. Such devices open up truly endless possibilities. On a 3D printer, you can print device parts, various layouts, and even entire buildings. However, a single user will not be able to enjoy this device due to its high price. nine0003

Models of such printers cost from several hundred thousand hryvnias and more, so only large enterprises can afford them. However, a small compact printer model has appeared on the market at an affordable price. This is the da Vinci Mini, which costs $290.

This machine was designed by XYZ Printing brand. This company was founded quite recently - in 2013, however, in a short period of its existence, it managed to make a splash in the market. The firm is backed by a major electronics giant, the Kinpo Group. It has research centers in many countries of the world on four continents, and the staff of engineers has more than eight thousand people. Da Vinci Mini is a device in the form of a cube with sides of 15 centimeters. This printer is designed for use in education (for university students) and small businesses. Despite its low cost, this printer boasts outstanding performance. The product has received many international awards at computer exhibitions, such as CES and COMPUTEX Taipei 2016.

The firm is backed by a major electronics giant, the Kinpo Group. It has research centers in many countries of the world on four continents, and the staff of engineers has more than eight thousand people. Da Vinci Mini is a device in the form of a cube with sides of 15 centimeters. This printer is designed for use in education (for university students) and small businesses. Despite its low cost, this printer boasts outstanding performance. The product has received many international awards at computer exhibitions, such as CES and COMPUTEX Taipei 2016.

The work platform is made of aluminum for fast cooling. This platform is not heated, as the printer is refilled with non-toxic biodegradable PLA plastic. Compared to the da Vinci Jr. 1.0, this printer is one-third smaller. The device supports Wi-Fi wireless data transfer technology, connection via USB port (version 2.0), and comes with special software. In the center of Kyiv, to refuel Da Vinci Mini printers, you will only need to purchase a new roll of consumable PLA plastic. nine0003

nine0003

Sales of the printer started on October 21st. Absolutely everyone can buy it on Amazon.com or the official website of the manufacturer. Many of the devices are already in use at several universities around the world. The printers are said to have received positive reviews. For those who have an ordinary laser printer and who need to refill the cartridge, we advise you to contact the Tonfix service. Our workshop has been refilling cartridges for many years and has a wide staff of highly qualified specialists. Tonfix offers a wide range of services for the maintenance and repair of office equipment. An order can be made by phone, the masters are personally ready to go to any district of Kyiv and promptly replace and refill the cartridge. You can pay on the spot in cash or by bank transfer. nine0003

Ten models for 3D printer calibration.

top sellers

-

Bearing 604UU U604ZZ

U-bearing U604ZZ 604UU 4*13*4

35.

00 UAH

00 UAH - nine0014 Thermal mat for 3D printing 200 x 200 mm

3D printing thermal pad

UAH 150.00

-

Buy epo3d+ 3D printer nine0015

Epo3d+ Ukrainian FDM 3D printer on HIWIN rails. Thanks to reliable...

UAH 35,000.00

-

ABS granules

ABS granules for extrusion

400.00 UAH nine0003

-

PLA

PLA environmental plastic from Plexiwire.

100% advance payment....

100% advance payment.... UAH 375.00

-

Buy ABS plastic (ABS) nine0015

ABS plastic from Plexiwire. 100% prepayment. Free shipping...

UAH 220.00

-

Mini motor reducer 12v 100 rpm

high torque mini electric motor. Its size...

UAH 150.00

-

Nozzle for 3D printer 1.75 mm, for E3D and MK8 hotends

Nozzle for 3D printer 1.75 mm 0.2/0.3/0.4/0.5

35.00 UAH

nine0024 -

PETG plastic for 3D printer

PETG plastic from Plexiwire.

100% prepayment. Free...

100% prepayment. Free... UAH 360.00

-

SHF-20 shaft support nine0015

SHF-20 shaft support is used for CNC

60.00 UAH

-

A4988 stepper motor driver

35.00 UAH

nine0017

Buy epo3d 3D printer

Ukrainian epo3d 3D printer built on the basis of modern kinematics...

UAH 18,000.00

All best sellers

Information nine0003

Ten models for 3D printer calibration.

After reading the all3dp.com article "3D Printer Test Print - Top 10 Models to Test Your 3D Printer", the epo3d team decided to test all the models and print them for you.

1. 3D Benchy

3D Benchy is the flagship of all 3D printer tests. This boat model checks everything from protrusions to extrusion. If you want to put your 3D printer to the test, the benchmark will help you determine the settings for the ideal job. Nearly 3000 Thingiverse users have submitted their samples, Benchy has been printed with hundreds of machines and materials. nine0003

Printed with plastic:PLA.

https://www.thingiverse.com/thing:763622

https://www.thingiverse.com/thing:763622

All-in-one 3D printer test - the name says it all! Canopies, bridges, string, extrusion, temperature, belt tension - this model tests everything. If you want to test your 3D printer on multiple levels, be sure to check it out! After printing, you can find defects by reading the included troubleshooting guide.

Approximately 75 Thingiverse users posted their samples made on different 3D printers in different materials. nine0003

Approximately 75 Thingiverse users posted their samples made on different 3D printers in different materials. nine0003 Printed with ABS plastic.

https://www.thingiverse.com/thing:2656594/makes

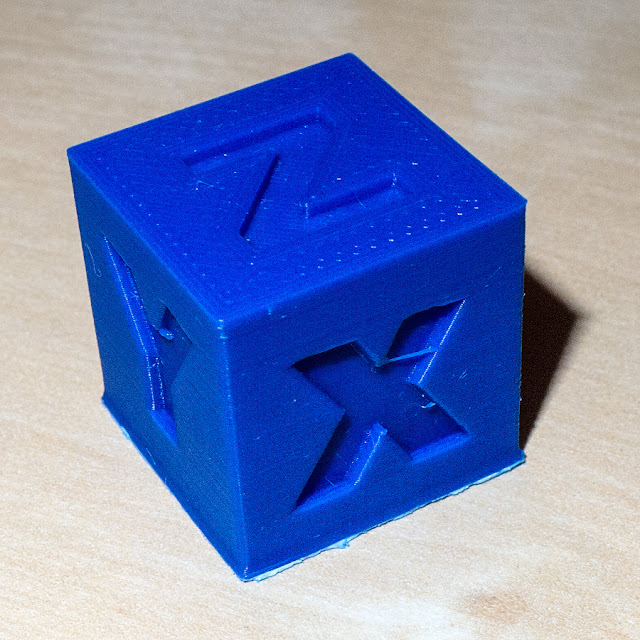

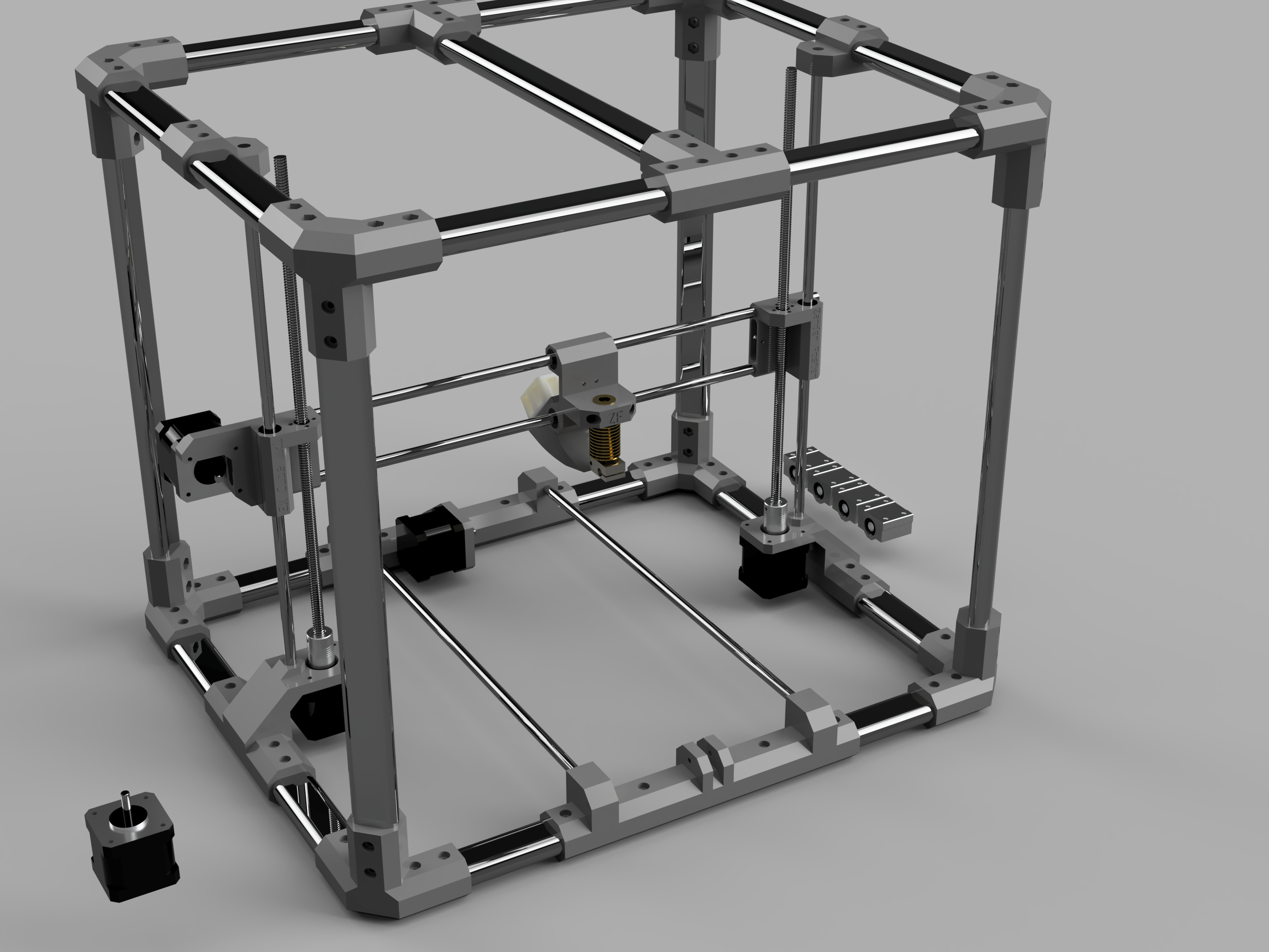

3. Calibration cube 20mm XYZ

This cube is a simple, fast and easy model for testing. Its main purpose is to help dial in the dimension of a 3D printer by customizing its steps in millimeters. But also temperature, extrusion and vibration can be tested. On Thingiverse, it has been printed with countless machines and materials.

Printed with ABS plastic. nine0003

https://www.thingiverse.com/thing:1278865

, extrusion and vibration within an hour! Designed for initial calibration, this cat will set up your 3D printer in no time. Over 250 users have posted their examples.

Plastic printed: Elastan D160.

https://www.thingiverse.com/thing:1545913

5. MatterHackers Mascot Phil A. Ment

Phil A. Ment is an adorable MatterHackers mascot for manufacturers. According to the company's description, "Phil has several features specifically designed for the 3D printer. Its features include small insert details, small relief details, ridges, vertical and horizontal cylinders, fillets, chamfers, bridges, and even a domed helmet.” 84 drawings were published on Thingiverse. PhilA, his record size is 5.1397 mm!

Ment is an adorable MatterHackers mascot for manufacturers. According to the company's description, "Phil has several features specifically designed for the 3D printer. Its features include small insert details, small relief details, ridges, vertical and horizontal cylinders, fillets, chamfers, bridges, and even a domed helmet.” 84 drawings were published on Thingiverse. PhilA, his record size is 5.1397 mm!

Printed with plastic: CoPet.

https://www.thingiverse.com/thing:2557603

plastic.

Plastic printed: Nylon.

7. New test from Autodesk

Andreas Bastian has developed a test procedure to help 3D printer manufacturers better calibrate their machines and demonstrate the capabilities of printers to Kickstarter supporters. A single consolidated STL file verifies the precision, resolution, and size alignment of the printer. For example, poor performance of the "bridge" function shown below will result in a loose and stiff print. A well-tuned printer will do the horizontal function with fewer problems. nine0003

A well-tuned printer will do the horizontal function with fewer problems. nine0003

printed with plastic: PLA

https://github.com/kickstarter/kickstarter-autodesk-3D

8. Polyperal Tower

9000Slotes, Crown, Crown, Crown, Crown, Crown and much more, described as a torture tower with a twist, it will help you calibrate your 3D printer settings.

Printed with plastic: ABS.

https://www.thingiverse.com/thing:2064029

9. Ultra-fast and economical screening test

This is an ultra-fast way to check the temperature, cooling and retraction of your 3D printer. Weighs about 0.23g, and can immediately remove the so-called "strings"!

Printed with plastic: PETG.

https://www.thingiverse.com/thing:2219103

10. Table Calibration Object (Parametric)

Lowering the table is often the most difficult part of printer calibration. This model will help you understand how to improve the first layer for better prints.