Spark 3d printing

Spark3DPrinting - Etsy Canada

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Announcement Thanks for visiting! If you have any questions or custom prints, be sure to send us a message and we will gladly assist you in your next project~

Announcement

Last updated on 21 Dec, 2022

Thanks for visiting! If you have any questions or custom prints, be sure to send us a message and we will gladly assist you in your next project~

Request Custom Order7464 Sales

340 Admirers

Report this shop to Etsy

You reported this shop

Etsy automatically translates most text on the site to your preferred language.

See in original language Translate into English

Loading

Featured items

All Items

Etsy automatically translates most text on the site to your preferred language.

See in original language Translate into English

Reviews

Average item review

5 out of 5 stars

(1232)

Loading

-

5 out of 5 stars

Was great! holds well over all! no complaints.

Shirt Clip Compatible With Leap Motion

Shirt Clip Compatible With Leap Motion

-

5 out of 5 stars

Amazing ⚡️

Puzzle Escape Box For Gift, Money, Surprises

Puzzle Escape Box For Gift, Money, Surprises

-

Yimby on 03 Jan, 2023

5 out of 5 stars

fast shipping, met my expectations. I should have bought another one!

Book Page Holder For Finger/Thumb Keep Pages Open

Book Page Holder For Finger/Thumb Keep Pages Open

-

Kim on 31 Dec, 2022

5 out of 5 stars

Works as the listing intends

Book Page Holder For Finger/Thumb Keep Pages Open

Book Page Holder For Finger/Thumb Keep Pages Open

-

Helen on 31 Dec, 2022

5 out of 5 stars

Kids got them in their stockings, and they really enjoyed playing with them.

Fast delivery.

Fast delivery.Puzzle Escape Box For Gift, Money, Surprises

Puzzle Escape Box For Gift, Money, Surprises

-

Luna on 30 Dec, 2022

5 out of 5 stars

always perfect, 2nd one ordered, great quality

Shirt Clip Compatible With Leap Motion

Shirt Clip Compatible With Leap Motion

-

4 out of 5 stars

The article was fantastic! This created a lot of hours of fun before managing to open it completely. The only thing is that we had 6 silver notes to put in and it was very difficult to insert them. In addition, the height of the item did not allow us to lower it completely because of the height of the ticket.

It is for his reasons that we give 4 stars. Other than that, it was perfect!!!

It is for his reasons that we give 4 stars. Other than that, it was perfect!!!L’article était fantastique! Cela a créé beaucoup d’heures de plaisir avant de réussi à l’ouvrir complètement. La seule chose est que nous avions 6 billets d’argent à mettre dedans et ce fut très difficile à les insérer. De plus, la hauteur de l’article ne nous permettait pas de le descendre complètement à cause de la hauteur du billet. C’est pour ses raisons que nous donnons 4 étoiles. Autre que cela, c’était parfait!!!

3 Levels Russian Doll Maze Box, Labyrinth Puzzle Stash, Gift Box

3 Levels Russian Doll Maze Box, Labyrinth Puzzle Stash, Gift Box

-

5 out of 5 stars

Works perfectly, now I know the cat can't accidentally start the fireplace! The shop sent it very quickly too.

Safety Light Switch Guard and Cover For Rocker Switches

Safety Light Switch Guard and Cover For Rocker Switches

-

Mai on 29 Dec, 2022

5 out of 5 stars

Awesome product! Highly recommend it! Also great communication with the seller

5-10pc - Wooden Train Dobone for Brio, Wooden Train, Thomas, Ikea, Imaginarium, Lillabo

5-10pc - Wooden Train Dobone for Brio, Wooden Train, Thomas, Ikea, Imaginarium, Lillabo

-

5 out of 5 stars

The toy was fun I gave it to my nephews for Christmas they enjoyed it

Puzzle Escape Box For Gift, Money, Surprises

Puzzle Escape Box For Gift, Money, Surprises

About Spark3DPrinting

Sales 7,464

On Etsy since 2020

shop-websiteShop members

Shop policies

Last updated on 16 Oct, 2020

Delivery

See item details for estimated arrival times.

Customs and import taxes

Buyers are responsible for any customs and import taxes that may apply. I'm not responsible for delays due to customs.

Learn more

Payment options

Secure options

PaypalVisaMastercardApple PayKlarnaGift cardAccepts Etsy Gift Cards and Etsy Credits

Etsy keeps your payment information secure. Etsy shops never receive your credit card information.

Returns & exchanges

See item details for return and exchange eligibility.

Cancellations

Cancellations: not accepted

Please contact the seller if you have any problems with your order.

Privacy policy

See this Seller Handbook article for a sample privacy policy you can customise for your shop.

If you deliver to the EU or offer your listings to buyers there, you're required to have a GDPR-compliant privacy policy by 25th May 2018.

Shoppers won't see this field until you add a privacy policy.

Etsy prohibits the use of buyer information for unsolicited messages. See our Privacy Policy for more info.

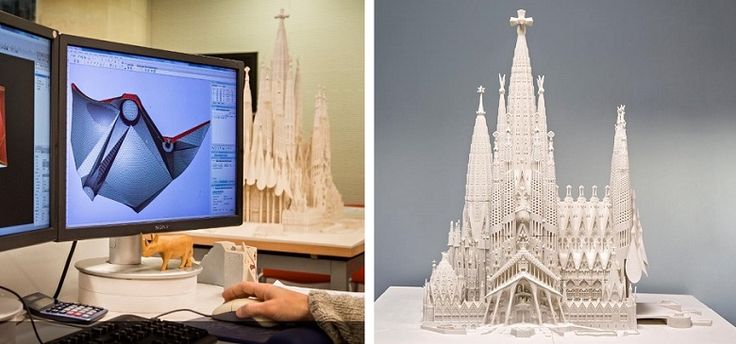

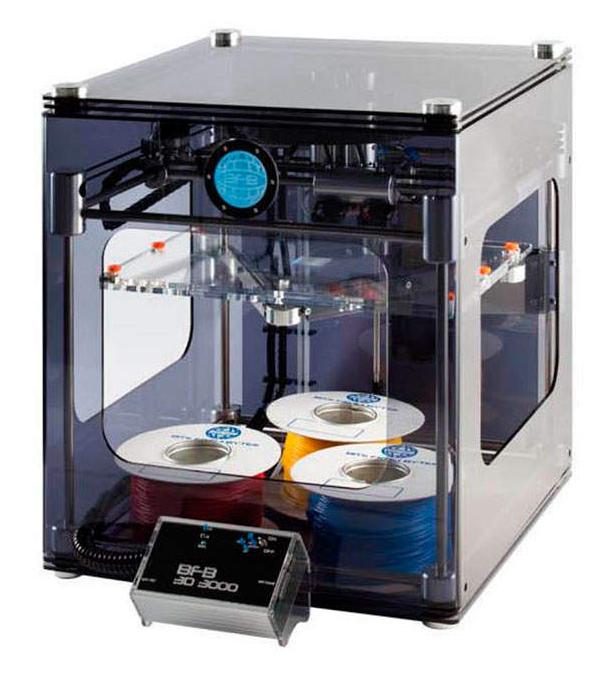

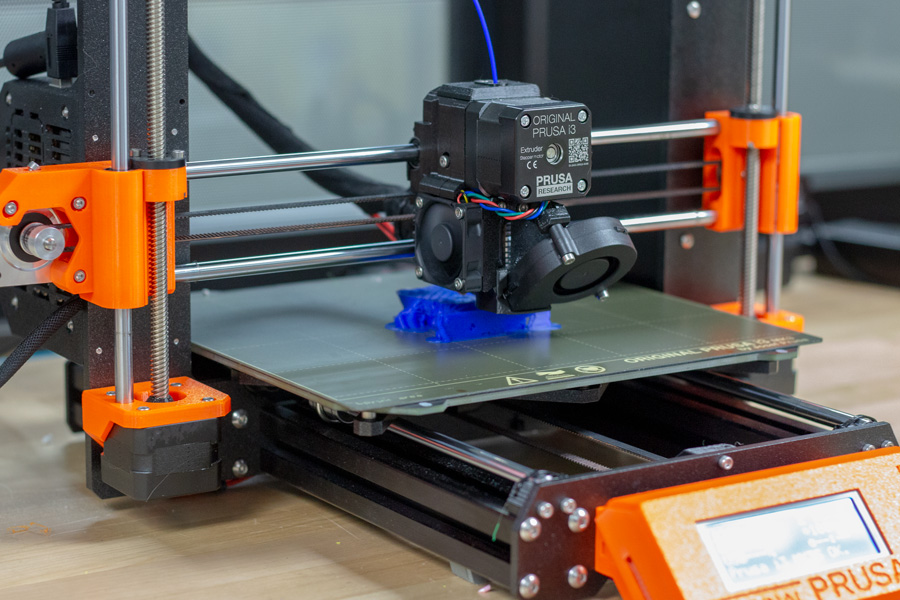

SPARK Product Development | 3D Printing Technology

How New 3D Printing Technology Improves YOUR ProductAdditive manufacturing (better known as 3D printing) is a modern marvel that even in its youth is changing the face of manufacturing and product development.

The first 3D printer was a Star Trek fantasy. In the show, “matter synthesizers” called Replicators condensed energy into food, clothing, weapons, etc for the characters. Then they’d put their dirty dishes back into the replicator and it would unravel the quantum particles back into potential energy. Can’t one dream of a future without dish duty?

But the first real 3D printers were the Rapid Prototyping machines that appeared in the mid-1980s—though it was some time before industrial interest was piqued. As for who did first spot the utility of 3D printing for rapid prototyping…?

As for who did first spot the utility of 3D printing for rapid prototyping…?

You guessed it: product developers like SPARK.

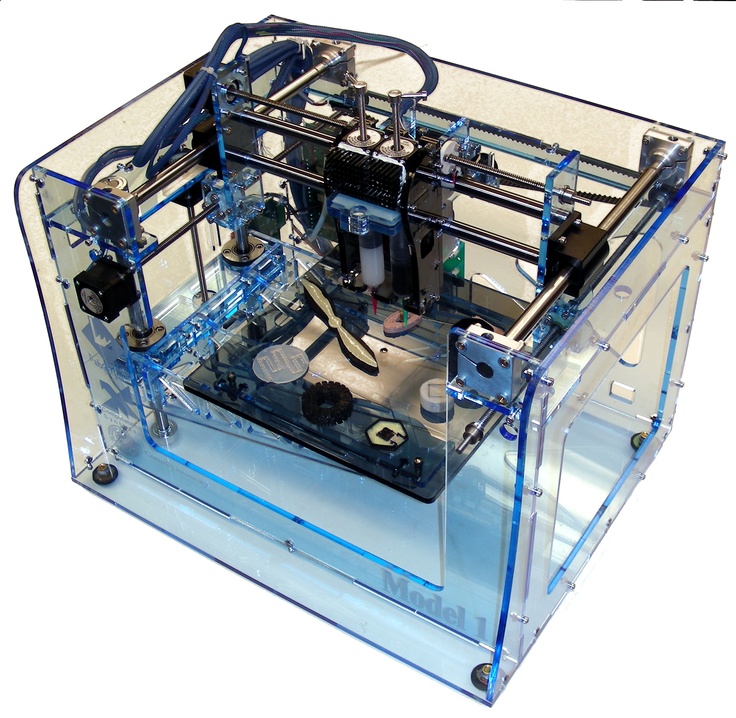

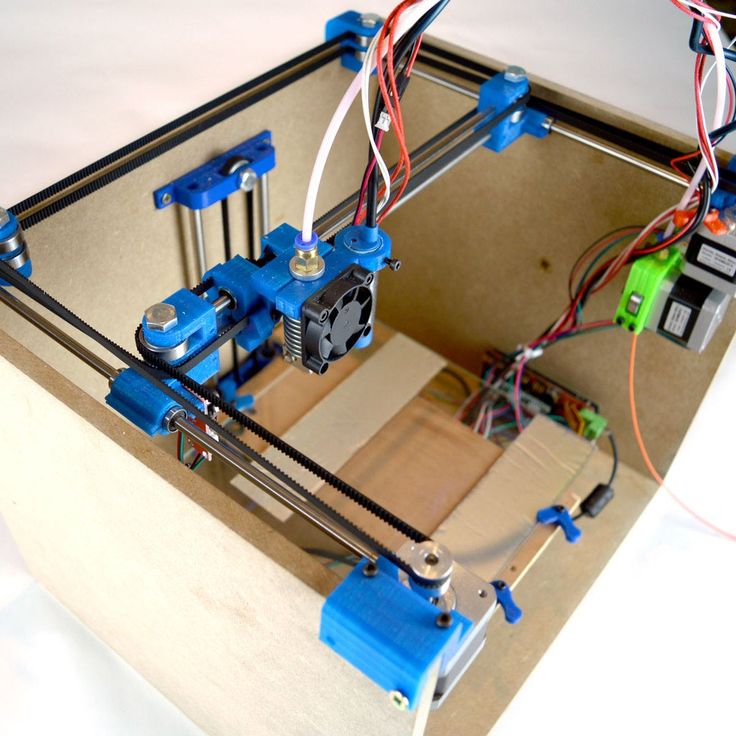

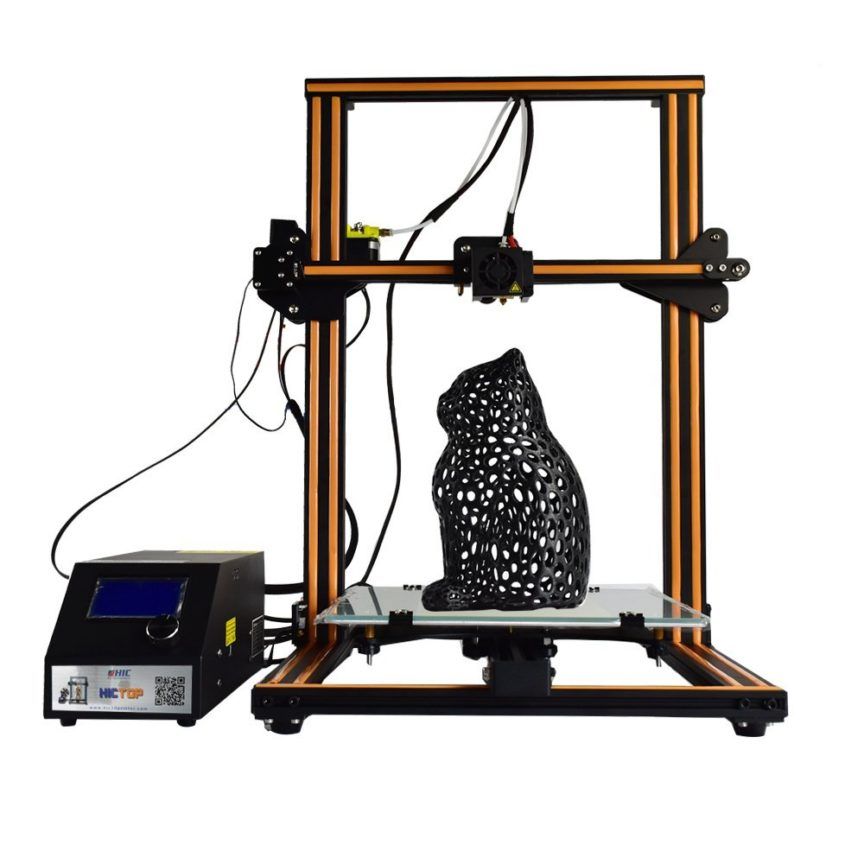

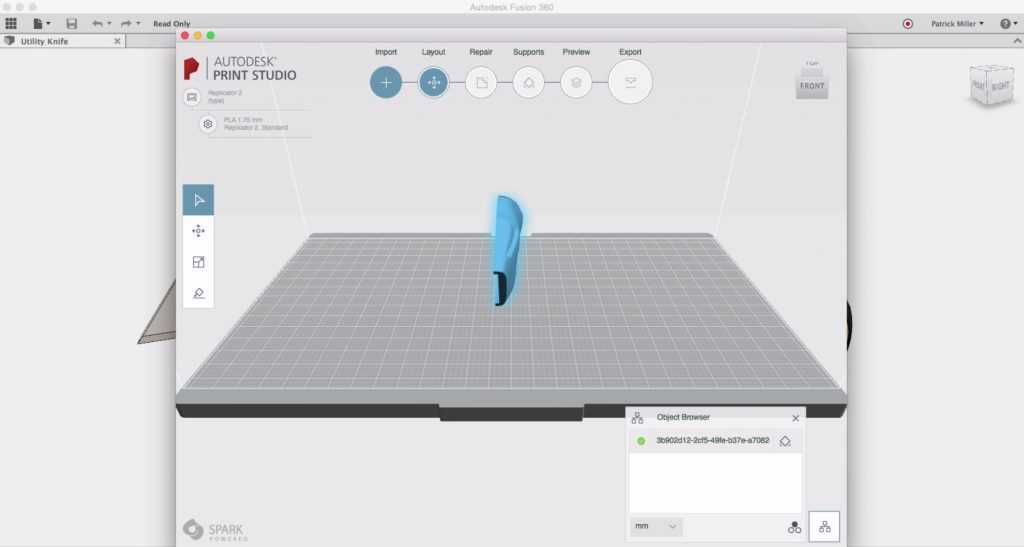

How basic 3D printing worksCurrent 3D printing isn’t quite as complex or magical as the fictional version—but the technology has come a long way in the past several years since 2009, when the technology patent expired for fused deposition modeling (FDM). With the floodgates open, the price fell dramatically. Now you can get a home 3D printer kit for a few hundred dollars.

Basic FDM 3D printing is a pretty simple process:

1. Designers upload a CAD file which the computer divides into horizontal cross-sections.

2. A nozzle moves back and forth according to the cross-section, extruding polymer from a spool or reservoir running through a heating element.

3. It lays down layer by stacked layer until the model is complete.

4. Sometimes lasers, chemicals, or other methods cure and/or fuse material between the layers

It has its place, but FDM is generally pretty low quality—basically a hot glue gun moved around by a computer to make a model.

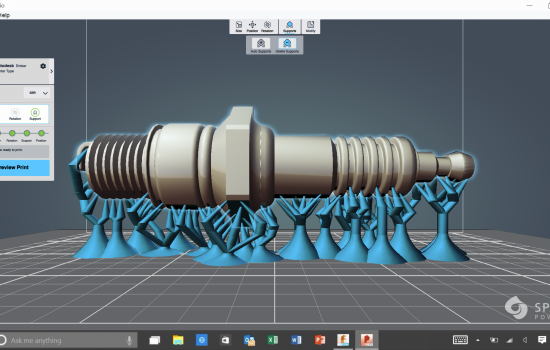

Fortunately filament extrusion isn’t the only way to get the job done. A number of parallel technologies use dramatically different methods for 3D printing. Instead of extruding polymer in layers, some use lasers to harden loose material in layers. Or there’s Hewlett Packard’s new Multi Jet Fusion (MJF) process which is becoming our favorite method at SPARK for general use (see video below).

Inventors and 3D printingWhat some people don’t realize is that even basic 3D printing requires a properly formatted CAD file—which means at some point a designer must enter the ring.

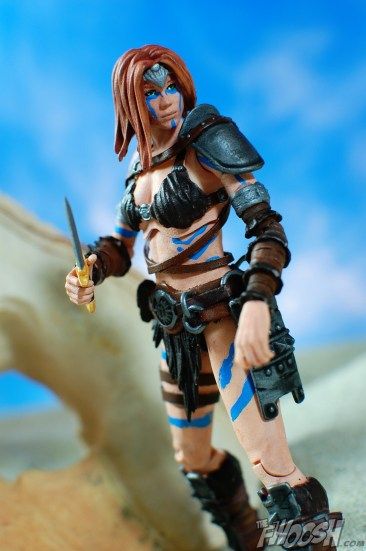

We welcome a lot of business from inventors who want to see their idea in hand but aren’t necessarily ready for the full development process. Basic 3D printing is a fast, cost-effective way to get a tangible prototype—because the only expense is CAD time and 3D print-on-demand service. Once an inventor has a CAD file from our designers, they can shop around the many service bureaus that provide 3D printing.

One of the early major players in democratizing 3D printing was Shapeways. Users can easily upload their CAD file, select their material and method, and wait for their item. Perfect for one-off projects or investor presentations.

Universities also offered some of the first 3D printing services for students and instructors building models for education. Funded by the schools, people could access the technology who otherwise couldn’t afford it.

And in 2009 a startup called MakerBot started selling 3D printers as DIY kits, which busted the extruded filament game wide open. Now it’s an established hobbyist industry.

What materials can be used for 3D printing?Short answer: just about any material that can be liquified, extruded, and cured.

The full answer is much more complex and depends on what you need it for. You might use wax for casting precious metals. Concrete for building construction. Various plastics for attributes like flexibility, durability, or UV resistance.

Various plastics for attributes like flexibility, durability, or UV resistance.

Some resins have other materials mixed in—like glass, metal, or ceramics—for strength, weight, or conductivity. Some, like the popular polylactic acid (PLA) are derived from biodegradable material, which has positive implications for the future of our planet.

Some processes like Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) start with a layer of powder which is melted or sintered by lasers in the cross-section pattern of the design, adding subsequent layers of powdered material for each sintering pass.

With metallic powders, lasers can actually melt parts into shapes of solid metal rather than fused layers, which means you can create a solid metal piece with internal passages and spaces that would otherwise be impossible to machine.

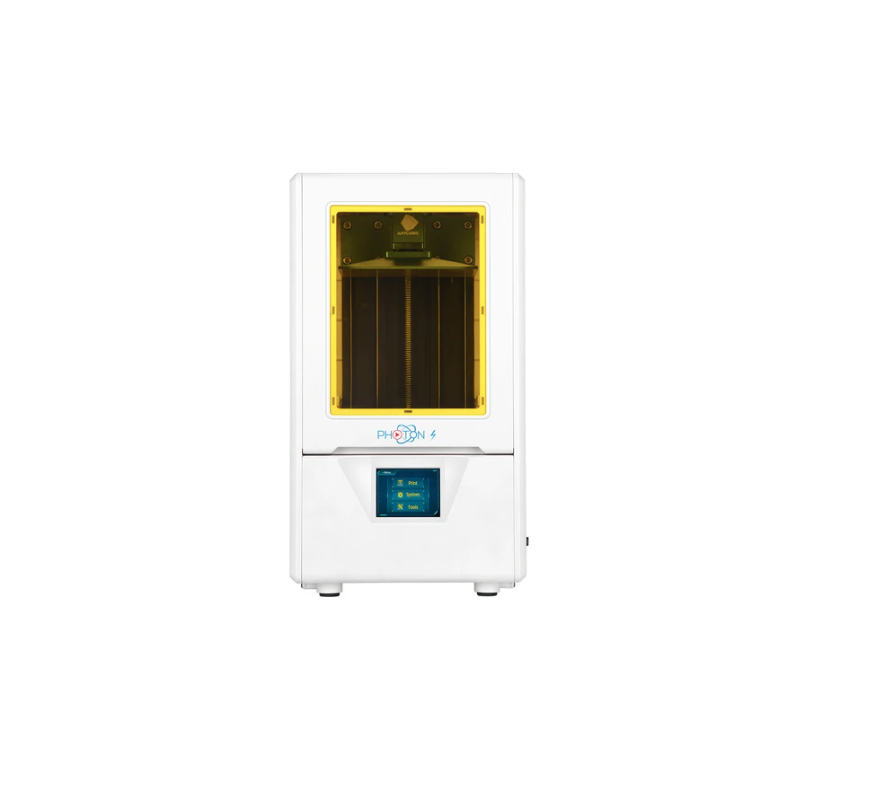

3D printing on a human hairFor the finest detail and precision, we must turn again to lasers. One of the earliest methods of 3D printing, Stereolithography (SLA) uses lasers shining through a transparent reservoir of photo-reactive resin that hardens at microscopic focal points in layers.

One of the earliest methods of 3D printing, Stereolithography (SLA) uses lasers shining through a transparent reservoir of photo-reactive resin that hardens at microscopic focal points in layers.

Because it uses lasers in an unmoving medium, SLA is precise enough to print on a human hair. Think of the possibilities for the future of medical product design! But on a more macro level, SLA can produce more complex designs and component parts than other methods. That’s why it’s our preferred process for precise designs like injection-molded parts.

The downside of the SLA printing process is that models can be brittle and it can also be very expensive.

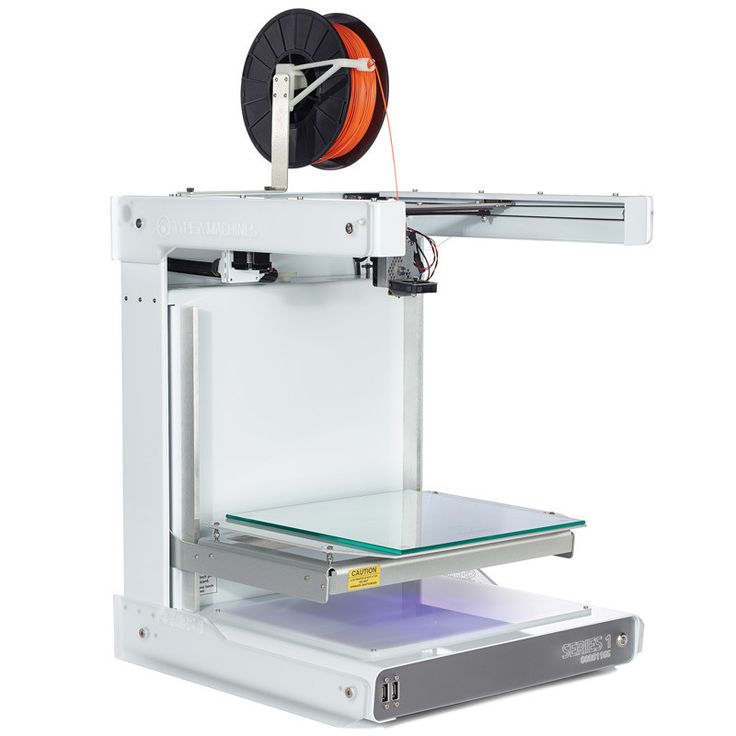

New multi jet 3D printing technologyHewlett Packard has poured their heart and soul—and millions of dollars—into pushing the envelope of printing technology. Their Multi Jet Fusion (MJF) printers measure a design in voxels (like pixels with volume) and spray each layer in a continuous horizontal pass, rather than pinpoint extrusion. It’s similar to how your office inkjet works, except the ink is thicker and it gets sandwiched between layers of nylon powder.

It’s similar to how your office inkjet works, except the ink is thicker and it gets sandwiched between layers of nylon powder.

In their video they explain that future iterations of the technology will be able to lay down material and agents to control the properties of each voxel. So one model could feature multiple colors, textures, and even transparency.

Imagine if you will, a contact lens with a microscopic circuit board.

Yes, it’s giddily cool—and it’s not much of a stretch to imagine multi-jet technology in every home just like sci-fi. But what makes MJF really exciting is that it lets you print multiple parts simultaneously, which drives down the cost and hints at a possible future of 3D printing for manufacturing.

Though MJF can’t print as high-resolution as SLA, it costs less and takes less time to finish a model. At SPARK we use MJF to create fully functional prototypes that aren’t as brittle as alternative methods. Meaning we can better test real-world use and stressors before sending a product to manufacturing.

At SPARK we use our own FDM printers for inexpensive prototyping at the roughest level. Sometimes it’s helpful to hold a design in your hands to see what’s working and what isn’t before you invest in more valuable prototypes. But because FDM models are essentially stacked strings of plastic, they don’t reflect attributes like the multi-directional structural integrity of an injection molded part—sometimes they can peel apart.

When it’s time for a more functional, full-scale prototype, we typically outsource to 3D printing specialists who can produce exactly what we need for a more reasonable price. That’s good news for our clients, because if we bought our own MJF printer, we’d have to use it all the time to justify the price tag—even if another method might make more sense. And running machines isn’t a good use of our clients’ money.

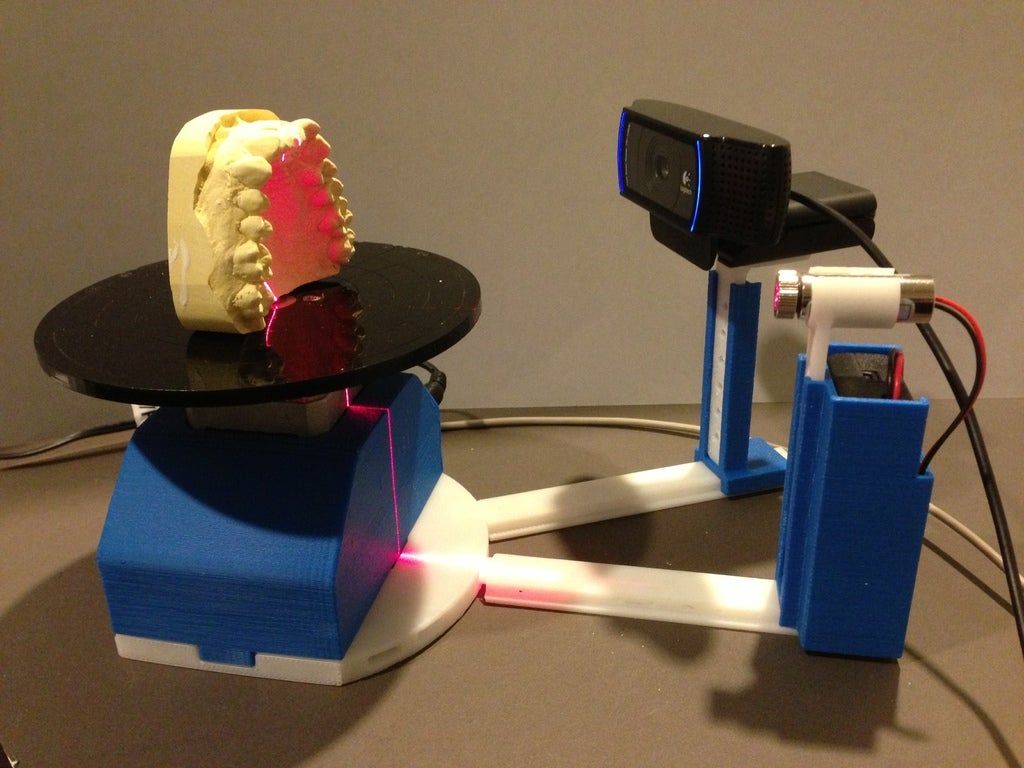

The future of 3D printingThe leaps and bounds we’ve seen in recent years leave no doubt that the future of 3D printing is wide open for pioneers with the vision to see the potential. From prototyping to extrusion-construction, from custom dental parts to cheap, biodegradable plasticware… The path leads forward in all directions.

From prototyping to extrusion-construction, from custom dental parts to cheap, biodegradable plasticware… The path leads forward in all directions.

Though it’s not yet efficient enough for scale manufacturing, 3D printing is indispensable in product development. The amount of money we’ve saved clients by catching flaws pre-manufacturing via advanced prototyping—well we have better things to do than count our successes.

At SPARK we’re always on the lookout for advances and technologies that will help us serve our clients. We’ve been using 3D printing since it became available, and each evolution of the technology helps us to develop even better products.

When 3D printing does become viable for manufacturing, everything will change. No more cutting expensive injection molds… No more centralized fabrication… No more designing around draft, part thickness, pull direction, etc… It will be a total gamechanger. And when that breakthrough happens, we’ll be sure to let you know!

***

Have an idea you’d like to prototype?

Get in touch.

Produced with Quillpower

Iskra Mini (without legs)

Iskra Mini is a complete Arduino platform, only small: only 33x20mm. If size matters for your project, Iskra Mini is the right choice.

Use the platform to shove your device where nothing seems to be and couldn't fit.

This version of the Iskra Mini comes with simple tinned hole pins. You will have to solder wires to them, pin connectors or other connectors to interact with the platform. nine0003

For more comfort, but at the expense of small size, take the Iskra Mini with legs.

The board is based on the ATmega328 microcontroller, the same as on the popular Arduino Uno. The board is made by Amperka in Russia.

Connection and firmware The

Iskra Mini is programmed with the Arduino IDE. Please note that on the board no native USB port. Therefore, for its firmware you will need an intermediary. They can be:

- USB-UART converter; nine0018

- Arduino Uno;

- ICSP programmer.

More details on how to connect and flash Iskra Mini, read our wiki article.

Power supply

Iskra Mini's native voltage level is 5 volts. We also installed a voltage regulator on the board, so that any external voltage in the range from 5.3 to 9 volts can be applied. Regulator delivers up to 150 mA of current. This makes it trivial to connect batteries or accumulators.

It is possible to power the board with 5 volts, which is known to be even, through any +5V pin. Arbitrary external voltage - through the VIN pin. nine0003

Features

- Microcontroller: ATmega328

- Clock frequency: 16 MHz

- Flash: 32 KB (2 KB used by bootloader)

- SRAM: 2 KB

- Non-volatile EEPROM: 1 KB

- Operating voltage: 5 V

- Input voltage: 5-9V

- General purpose I/O ports: 20

- PWM ports: 6

- Ports connected to the ADC: 8 nine0017 ADC bit depth: 10 bits

- Hardware interfaces: UART, SPI, I²C (on unsoldered pins)

- Maximum current per output 40 mA

- Maximum current from pin +5V: 150 mA

- Dimensions: 33×20 mm

- Size 33×20 mm

- Working voltage 5 V

- Input voltage 5–9 V

- ADC bit depth 10 bit

- SRAM 2 KB nine0018

- Clock frequency 16 MHz

- Flash memory 32 KB (2 KB used by bootloader)

- microcontroller ATmega328

- PWM ports 6

- Ports connected to the ADC eight

- Maximum current from pin + 5V 150 mA

- EEPROM memory 1 KB

- I/O ports twenty nine0018

- Interfaces UART, SPI, I²C (on unsoldered pins)

ISKRA mobile application for collecting statistics, analyzing key indicators and managing production

Similar presentations:

3D printing and 3D printer

Quality management systems requirements. Development of the ISO 9001

standardOperating system. Purpose and main functions of

Adobe Photoshop

AutoCAD history and features

Microsoft Excel

Cloud technologies

Microsoft Corporation and Features

Web Design

Topic 2. Application packages

Application packages

ISKRA mobile application

for collecting statistics, analyzing key indicators and

managing production

All participants in the production process are united and

interact online

Head of production

Work plan

Date: 01.01.2019

Artist: Ivanov I.I.

No.

1

2

3

4

5

6

7

8

10

Task

Produce part 1

Produce part 2

0 9

20

10

0

Head

Production

Time

Time

Total

The beginning of the end

9:00

10:00 60 Min

10:00

10:30 30 Min

10:30

11:15 45 45 min

10:30

11:15

45 min

Masters

Workers

I

2

The production process is fully digitized in Appendix

"Iskra"

1

Master

Comers to

worker

1

1

1

1 9012 3

2

Worker

1. Receives a work plan

for a shift in the

mobile application

2. Performs

Performs

work tasks.

3. Marks the plan -

the fact of implementation.

4. If there are

deviations from the plan

- notes the reasons for

deviations

2

3

9

4

After the work shift

12

3

6

5

Team

1. Summarizes the results of the work shift.

2. Determines

Opportunities for

Improvements

3. Forms

Lessons

12

3

6

4

Master

1. Control

of each worker

online

2. Releases in

ANSTRUCTION OF

ANSTRUCTION ON

deviations from

any point

production

During the working shift

12

9

3

9

3

6

Production manager

growth to improve

the efficiency of processes

5

Continuously

3

4

Work plan

Date: 01.01.2019

Completed by: Ivanov I.I.

No.

1

Task

1 Make part 1

2 Produce part 2

3 to make part 3

4

5

6

7

8

10

I

Time

Start of the end of the end

10:00

10:00

10:30:0:30 9:30:0:0EL 10:30

11:15

I

q

Total

60 pcs

30 pcs

45 pcs

Master

Makes a plan for

shift for each

worker

2

1. Receives plan 2 of shift12 5 90 3 in mobile application 90 3

Receives plan 2 of shift12 5 90 3 in mobile application 90 3

Worker

2. Performs work tasks and

notes the fact of implementation

3. If there are deviations from the plan -

notes the reasons for the deviation

i

Work plan

Date: 01/01/2019

Executor: Ivanov I.I.

No.

No.

Assignment

Assignment

Work plan

Date: 01/01/2019

Performed by: Ivanov I.I.

Plan

Plan

Time

Time

Time

Time Total

Total

start finish

start

finish

9:00

10:00

60 min

1

Make part 1

2

23

34

Make part 2

Produce

Make Detague

Part

10:00

10:30

10:00

Produce part 3

10:30

1 MAKE CARE 1

4

5 9012 7

8

10 Make part 10

10

9:00

10:00

60 pcs

10:30

30 min

11:15

10:30 45 min

30 pcs

11:15

45 45 45 45 pcs

ActualPlan

No.

Target Time TimeTime

Time

Total

The start of the end of the total

The start of the end

1 Make part 1

9:00

10:00

60 min

9:00

10:00

60 pcs

2

3

4

10:00:00

to manufacture part 310: 00 10:30

10:30

10:30

11:15

10:45

30 min

45 min

30

pcs

11:15

45 pcs

5

6

I

16:30 16:30:

17:15

45 min

7

8

9

10 Produce part 10

Work plan

Date: 01/01/2019

Artist: Ivanov I.I.

No.

1

2

3

4

Plan

Time

Time

Deviation

Reason

Total

Produce part 1

10:00

60 Min

: 00

Make part 3-5 min

10:30

Damage

10:30

30 min

Equipments

11:15

45 min

+ 15 min

5

6

16:30

17:15

45 min 45 min.

7

8

9

10 Produce the part 10

16:30

17:15

45 min

6

3

Time: 10:49

Implementation of the work plan

No.

1

Ivanov

2 Petrov P.P.

3 Sokolov S.S.

4

5

6

7

8

10

I

Plan

Time

Copping

Task 3 + 10 min

Task 2 - 15 min

0

I

Q

Q

Q

QA breakdown

equipment

Master

1. Controls each worker online

online

2. Responds online to notification of

deviations from any point of production

4

Team No. 5

Plan-actual task completion

130

+10% +20%

-30 %

110

90

70

50

Ivanov

Petrov

Sidorov

Melov

Bulatov

Brigade No. 5.

Date: 01.01.2019

No.

1

2

Worker

Ivanov

Petrov

3 Sidorov

4 Melov

5 Bulatov

6

7

8

10

fact

100%

100%

70%

110%

Reason

Event

NNE

Purpose

blanks

Team

1. Summarizes the work shift.

2. Identifies opportunities for improvement

3.