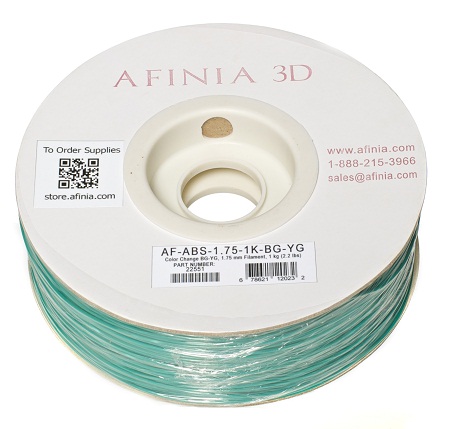

Abs filament for 3d printers

3D Printing ABS Filament - Gizmo Dorks

Gizmo Dorks

$20.95

Size *

1.75mm 3mm (2.85mm)

Color *

Pick one...BeigeBlackBlueBrownColor Change Blue to White (Heat Activated)Color Change Green to Yellow (Heat Activated)Color Change Grey to White (Heat Activated)Color Change Purple to Pink (Heat Activated)Conductive BlackDark BlueDark PurpleFluorescent Blue (Black Light Reactive)Fluorescent Green (Black Light Reactive)Fluorescent Hot Pink (Black Light Reactive)Fluorescent Orange (Black Light Reactive)Fluorescent Yellow (Black Light Reactive)Glow in the DarkGoldGreenGreyGrass GreenOrangePinkPink RosePurpleRedRed LavaSilverTransparentVioletWhiteYellowLight Yellow

Qty:

Share:

Add to Wishlist

Current stock: 0

ABS Filament

ABS (Acrylonitrile Butadiene Styrene) plastic filament is a polymer used in 3D printing because it can be molded and engineered. It falls under a family of other plastics known as thermoplastics. These plastics have the ability to become soft and moldable when heated at high temperatures and returning to it's normal solid state when at cooler temperatures, making it an ideal 3D printing filament.

ABS filament is a favorite for 3D printing because it is light weight and durable. It can be injection molded which makes it perfect for 3D printing extruders. It has a high glass transition temperature to reduce deformation but low enough to be safely attainable with 3D printers. ABS filament needs to be printed on a heated bed because the filament will curl upwards of the surface. The heated build platform as well as a smooth flat surface helps reduce the deformation.

ABS filament is a hard strong plastic with some flexibility when compared to PLA filament. It is also soluble in acetone, and it can be easily sanded and machined. It has ideal strength, machinability, and temperature resistance making it a favorite filament among 3D printer users.

Please store ABS filament in a cool dry place. ABS, if exposed to moisture, will bubble and spurt from the extruding nozzle. ABS filament can be dried from a food dehydrator, oven, or from any source of hot air.

ABS Filament Specifications

- **Net weight: 1 kg or 2.2 lbs

- Diameter: +/- 0.05mm

- Roundness: +/- 0.07mm

- Print Temperature: 230 - 250°C

- Heated Bed Temp: 110°C

ABS Filament Colors Types and Sizes

We have 21 normal colors of ABS filament and an additional 9 specialty colors. All 30 color variants come in two sizes.

- 1.75mm ABS filament

- 3mm (2.85mm) ABS filament

The 9 specialty colors of ABS filament can be categorized into the 4 following types.

Conductive ABS filament

Right now there is one color for conductive ABS filament, which is black. The filament can be used for anti-static, dissipative, or the conduction of electric current. Sizes come in 1.75mm ABS and 3mm ABS.

Sizes come in 1.75mm ABS and 3mm ABS.

Glow in the dark ABS filament

As the name implies, the glow in the dark ABS filament will shine in the dark. Please allow the filament or print to retain light or charge in regular light first. Currently, we have one color for glow in the dark, which is green. We experimented with glow in the dark blue, but the blue version did not glow brightly. Sizes come in 1.75mm ABS and 3mm ABS.

Fluorescent ABS filament

The fluorescent ABS filament colors will glow under UV light, which is also known as black light. We have four fluorescent colors, which are fluorescent orange, fluorescent green, fluorescent yellow, and fluorescent blue. We did have a fifth fluorescent color which was fluorescent red, but it did not shine brightly under UV light. We renamed fluorescent red to red ruby. Sizes come in 1.75mm ABS and 3mm ABS.

Color change by heat ABS filament

This type of ABS filament (hyper color) will change colors depending on the temperature of the filament. The ABS filaments change color at approximately 31°C (88°F). Below 31°C the filaments are one color; above 31°C the filaments are a different color. Therefore, this ABS filament is heat activated. The easiest way to visualize this change is to simply blow a hair dryer on the filament. We currently have three variants of this type of ABS filament, which are green to yellow, gray to white, and purple to pink. Please see the below video for illustration of the color changing effect. Sizes come in 1.75mm ABS and 3mm ABS.

The ABS filaments change color at approximately 31°C (88°F). Below 31°C the filaments are one color; above 31°C the filaments are a different color. Therefore, this ABS filament is heat activated. The easiest way to visualize this change is to simply blow a hair dryer on the filament. We currently have three variants of this type of ABS filament, which are green to yellow, gray to white, and purple to pink. Please see the below video for illustration of the color changing effect. Sizes come in 1.75mm ABS and 3mm ABS.

- Videos

Videos

account Account wishlist Wishlist cart Shopping bagWhich 3D Filament is Better?

Apr 26, 2020

PLA vs ABS or ABS vs PLA? These are two of the most commonly used 3D printing filaments.

So, how should you decide between the two when planning a print? While PLA and ABS filament are both very popular, they both have unique properties that make them ideal for different projects.

In this article, we’ll explain the main differences of ABS vs PLA, and break down their diverse properties and uses.

What is PLA?PLA stands for polylactic acid. It is a sustainable 3D printing filament made from organic sources. As one of the most commonly used 3D printing materials, PLA filament is popular due to its ease of use and lower price point.

PLA is a standard filament that features an opaque, glossy finish and is commonly used for complex and detailed prints. PLA filament is a great starter material for beginners. This material is commonly used for prototyping and architectural mockups as it can print difficult or complex features.

What is ABS filament?ABS, which stands for acrylonitrile butadiene styrene, is a thermoplastic filament. As opposed to PLA filament, ABS is a bit more technical and may be more challenging for new 3D printing users. ABS is a stiff 3D printing material and it is impact and heat resistant. Common applications for ABS include end-use tools, moving parts, and parts that have to withstand high mechanical stress.

As opposed to PLA filament, ABS is a bit more technical and may be more challenging for new 3D printing users. ABS is a stiff 3D printing material and it is impact and heat resistant. Common applications for ABS include end-use tools, moving parts, and parts that have to withstand high mechanical stress.

Both ABS and PLA have unique properties and applications. Let’s get a bit more specific.

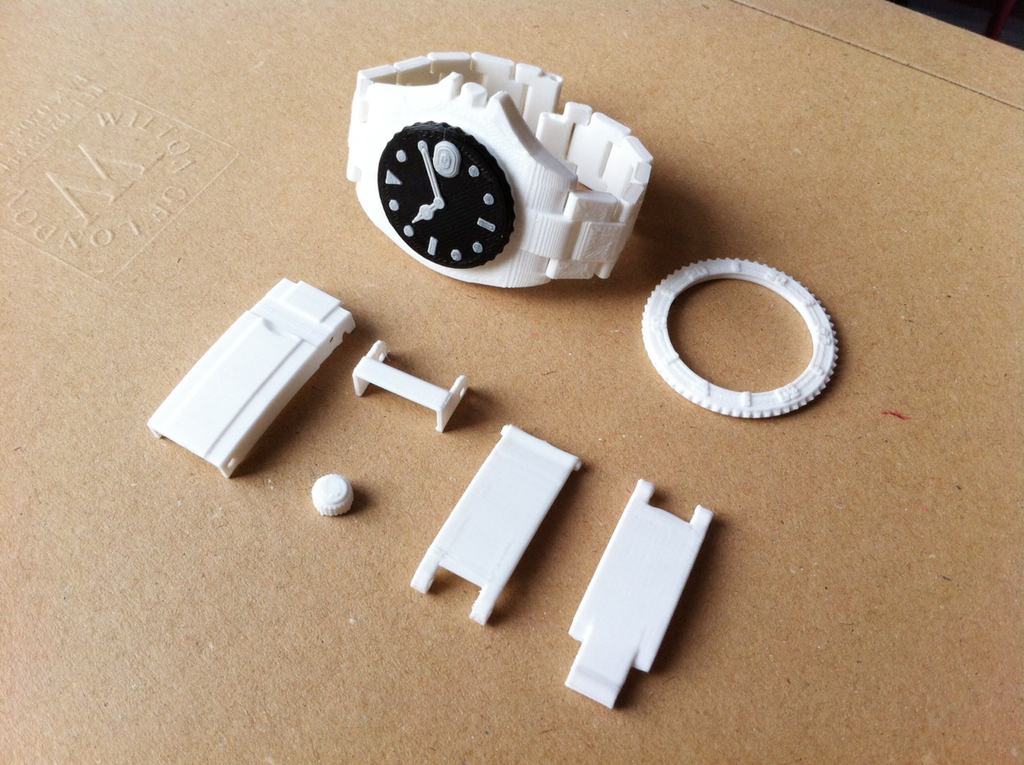

ABS vs PLA Uses- While PLA and ABS are both plastics, they are often used for very different applications. ABS is often used for engineering and manufacturing purposes as it is a rigid material that can withstand high impact. Its durability makes it common for end-use products, especially as protective cases, like on suitcases or phone cases.

- PLA is a popular filament for prototypes. It is great for understanding the visual and aesthetic properties of prototypes, especially when it comes to small, complex details.

PLA filament is also commonly used by beginners who are getting familiar with the world of 3D printing. It is also odorless, making it a suitable fit in an office or school environment.

PLA filament is also commonly used by beginners who are getting familiar with the world of 3D printing. It is also odorless, making it a suitable fit in an office or school environment. - PLA does best in projects that are not mechanically or thermally demanding, as it has low solvent and water resistance. This means that PLA is perfect for concept models, casting molds, and mockups. It allows you to visually compare different designs without burning through your wallet or creating a burden on the Earth, as PLA is biodegradable.

- If you need the prototype to be strong or technically functional, opt for using ABS. ABS is better suited for more technical applications and moving parts.

Is ABS stronger Than PLA?

When it comes down to the strength of both materials, ABS filament is definitely the winner. ABS is stiff, impact-resistant, and durable. It can take a blow or vibrations much better than PLA can. Even at lower temperatures, ABS has a higher impact resistance than PLA. ABS is also more water-resistant than PLA.

Even at lower temperatures, ABS has a higher impact resistance than PLA. ABS is also more water-resistant than PLA.

PLA tends to be more rigid and fragile. However, PLA filament does have good UV resistance and good tensile strength. Both PLA and ABS have a lower resistance to solvents, as compared to other filaments.

PLA vs ABS Melting TemperaturePLA can withstand operating temperatures of 50°C and has a glass transition temperature of 57°C. Generally, PLA is not able to withstand high temperatures. On the opposite hand, ABS has a much higher temperature resistance. As it is amorphous, it does not completely melt, but it has a glass transition temperature of 80° and 114°C.

Final Thoughts regarding ABS vs PLAUltimately, when it comes down to choosing ABS vs PLA, your final decision will always depend on your reason for printing. If you are a beginner at 3D printing or need to print detailed projects that don’t require a lot of functionality, consider PLA.

On the other hand, if you need a material that can withstand impact and is highly functional, ABS will be the best option of the two. Each filament has its own unique strengths that make it ideal for certain types of projects.

ABS for 3D printing

The high strength of ABS makes it suitable for structural applications

ABS (Acrylonitrile Butadiene Styrene, ABS) is a high-impact thermoplastic that has become very popular in industry and additive manufacturing.

The excellent mechanical and physical properties of ABS plastic make it possible to use this material to create all kinds of objects of practical value. ABS plastic is widely used in the automotive, medical and souvenir industries, in the production of sports equipment, plumbing, bank cards, furniture, toys, etc. nine0006

The relatively low cost of ABS plastic and the relative ease of use as a consumable have led to ABS's high popularity among 3D printing enthusiasts. ABS is one of the most popular materials for FDM/FFF printing.

ABS is one of the most popular materials for FDM/FFF printing.

Safety ABS

ABS is relatively safe and does not pose a threat under normal conditions. However, heating ABS releases toxic acrylonitrile fumes, which means you need to take some precautions when 3D printing. Evaporation is generally low due to the relatively slow material consumption of FDM printing. To ensure a completely safe environment, only good ventilation of the room or an extractor is required. It is also worth bearing in mind that ABS plastic reacts with ethanol, which leads to the release of styrene. nine0006

Do not use finished ABS products to store hot food and drinks or alcohol at any temperature.

ABS Specification

| Glass Transition Temperature | About 105°C |

| Flexural strength | 41 MPa |

| Tensile strength | 22 MPa |

| Tensile modulus | 1627 MPa |

| Elongation | 6% |

| Shrinkage on cooling | Up to 0. 8% 8% |

| Material density | Approx. 1.05 g/cm³ |

Please note that the actual dimensions of the 3D printed ABS will depend on the manufacturer's specifications. In many cases, ABS is blended with other thermoplastics (such as polystyrene), resulting in changes in extrusion temperature, resistance to certain solvents, etc. nine0006

Advantages and disadvantages of ABS

The main disadvantage of ABS is its relatively low resistance to direct sunlight. In addition, the potential toxicity of the material somewhat limits its use in the manufacture of toys, food packaging and medical instruments.

A wide range of colors is demonstrated with Lego bricks made from ABS plastic

At the same time, ABS plastic has a number of positive qualities: nine0006

- Almost unlimited colors

- Moisture resistant

- Acid resistance

- Oil resistance

- Relatively high heat resistance, reaching up to 115°C in some material grades

- Non-toxic at relatively low temperatures and in the absence of alcohol exposure

- Increased impact resistance

- High elasticity

- High durability in the absence of direct sunlight

- Easy to machine

- Good affordability

- High solubility in acetone

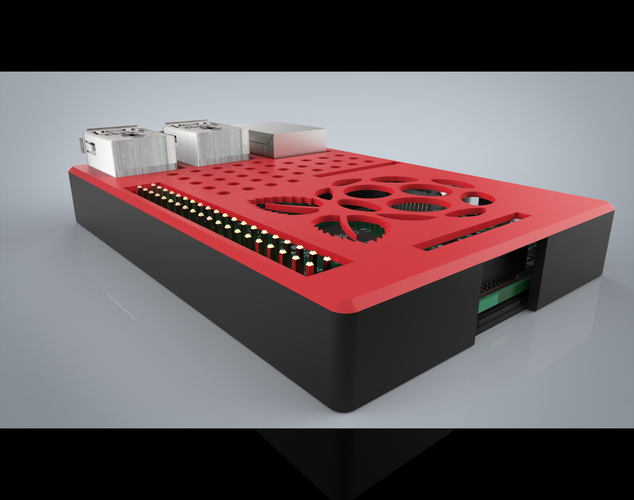

Use in 3D printing

The result of processing a model from ABS plastic with acetone vapor

Printing with ABS plastic is associated with certain technological difficulties due to a rather high tendency to shrink, that is, to loss of volume during cooling. As a result, the formation of deformations and delamination of models is possible. This point is taken into account by manufacturers optimizing 3D printers for ABS printing by installing heated work platforms and providing varying degrees of climate control in the working chamber. Some methods for dealing with deformations are described in the section "How to avoid deformation of models when 3D printing". nine0006

As a result, the formation of deformations and delamination of models is possible. This point is taken into account by manufacturers optimizing 3D printers for ABS printing by installing heated work platforms and providing varying degrees of climate control in the working chamber. Some methods for dealing with deformations are described in the section "How to avoid deformation of models when 3D printing". nine0006

In addition to being machinable, ABS is easily soluble in acetone and some other solvents, which makes it possible to produce fairly large models from component parts by gluing. In addition, the processing of finished models with acetone vapor allows you to smooth the outer surfaces and achieve complete tightness. For more information on processing with acetone, see the "Processing 3D Printed Models" section.

Go to the main page of the 3D Printing Encyclopedia nine0006

ABS, PLA, HIPS, PTEG filaments for 3D printer

Super price!

ABS plastic ESUN 1. 75 mm 1kg., black (ABS175B1)

75 mm 1kg., black (ABS175B1)

Buy ABS plastic ESUN 1.75 mm 1kg., black (ABS175B1) at the best price with free delivery throughout Russia in the official store with a guarantee

2200

2500

0006

Free in Russia

ESUN ABS plastic coil 1.75 mm 1kg, purple (ABS175Z1)

a store with a guarantee of

2200

006

ABS plastic ESUN 1.75 mm 1kg., red (ABS175R1)

Buy ABS plastic ESUN 1.75 mm 1kg., red (ABS175R1) at the best price with free delivery throughout Russia in the official store with a guarantee

2200

RUB

2500

RUB

| More details |

| Buy |

| Deteestrum |

| Buy |

Free in Russia

Plastic ABS Esun 1. 75 mm 1kg., Golden (ABS175J1)

75 mm 1kg., Golden (ABS175J1)

2200

RUB

2500

9000 You can buy ABS plastic ESUN 1.75 mm 1kg., green (ABS175G1) at the best price with free delivery throughout Russia in the official store with a guarantee2200

rub

2500

RUB

| More details |

| Buy |

Super price!

ESUN ABS plastic coil 1.75 mm 1kg, natural white (ABS175N1)

warranty

2200

rub

2500

rub

| Read more |

| Buy |

Free in Russia

9000 ) at the best price with free delivery throughout Russia, you can in the official store with a guarantee0027| Buy |

Free in Russia

ABS-plastic ESUN 1. 75 mm 1kg., Silver (ABS175S1)

75 mm 1kg., Silver (ABS175S1)

Buy plastic ABS ESUN 1.75 mm 1kg. ABS175S. price with free delivery throughout Russia is available in the official store with a guarantee0031

Free in Russia

Esun eABS MAX Plastic 1.75mm - 0.5kg (EABS_MAX175B05)

Buy Esun eABS MAX Plastic 1.75mm - 0.5kg Black (EABS_MAX175B05) The whole of Russia can be in an official store with a guarantee of

2500

rub

2950

068

Free in Russia

Plastic ESUN Bamboo 1.75 mm 0.5 kg (EBAMBOO175N05)

In the official store with a guarantee of

2500

rub

2900

rub

| more |

| Buy |

Free in Russia

Plastic Esun eSmooth. 1.75 mm - 0.5 kg., natural (ESMOOTh275N05)

Buy Esun eSmooth plastic. 1.75 mm - 0.5 kg., Natural (ESMOOTH275N05), at the most favorable price with free delivery throughout Russia, you can in an official store with a guarantee of

2960

3800

rub

| more than |

| Buy |

Free in Russia

Coil ESUN PLA 1. 75mm 1kg., Black (PLA175B1)

75mm 1kg., Black (PLA175B1)

Buy ESUN PLA 1.75mm 1kg., Black (PLA175B1), at the best price with free delivery throughout Russia, you can in the official store with a guarantee

2200

rub

2500

002

Buy ESUN 1.75 mm PLA 1 kg., Green (PLA175G1), at the best price with free delivery throughout Russia, you can in an official store with a guarantee of

2200

9000 9000 9000 9000 9000 9000 9000

| Read more |

| Buy |

Free in Russia

Esun PLA 1.75 mm 1kg., Gray (PLA175H2)

9000 9000 , at the best price with free shipping throughout Russia, you can in the official store with a guarantee of

rub

2500

rub

| more |

| Buy |

Super price!

Coil ESUN PLA 1.75 mm 1kg., White (PLA175W1)

2200

RUB

2500

rub

| more |

| Buy |

9000 1.