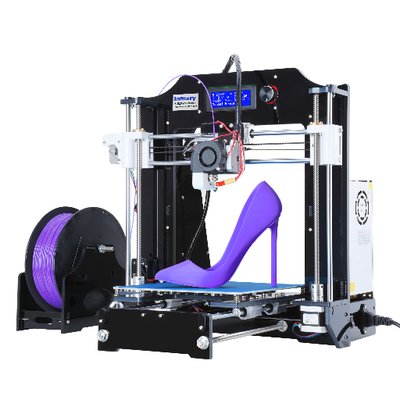

3D consumer printer

The Best Cheap 3D Printers for 2022

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

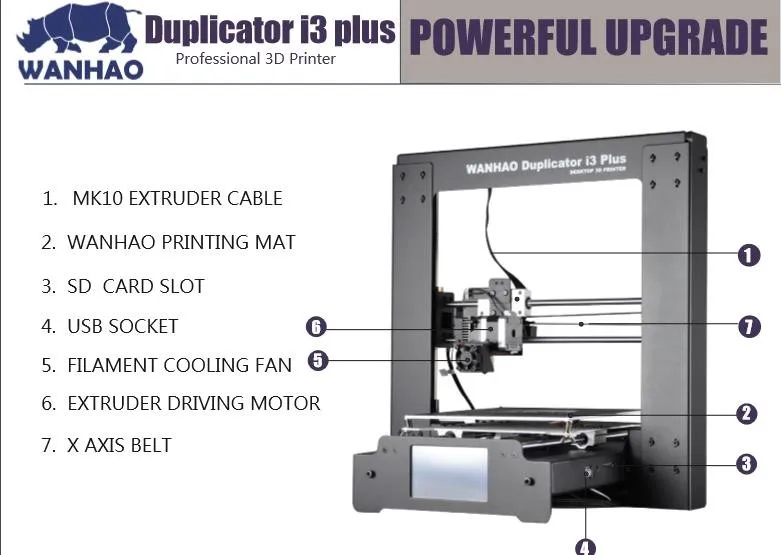

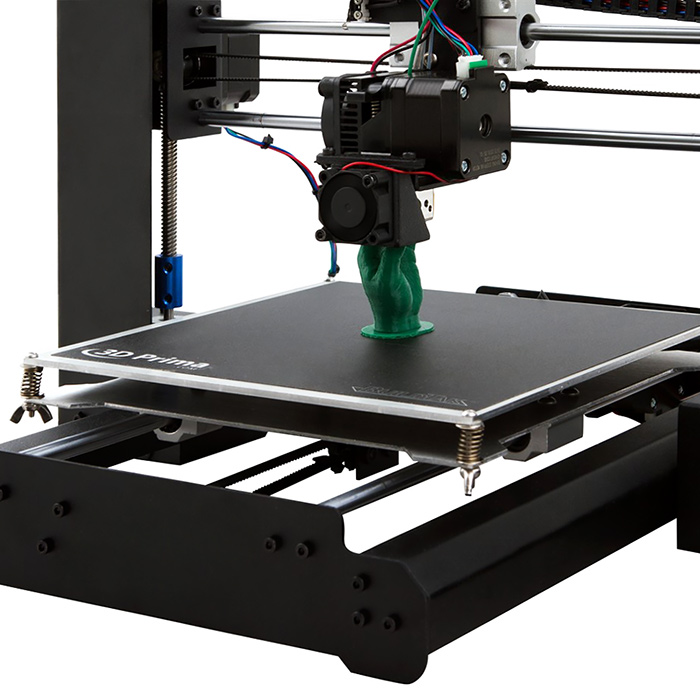

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

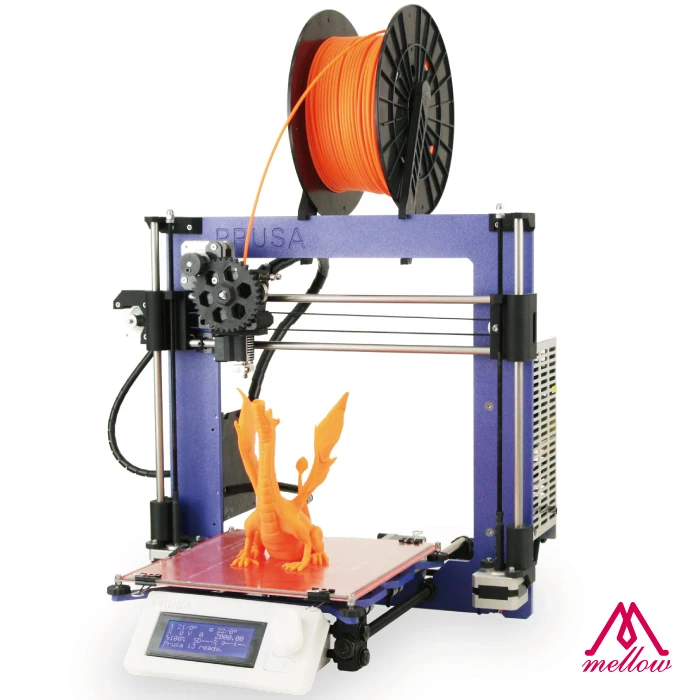

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399.00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

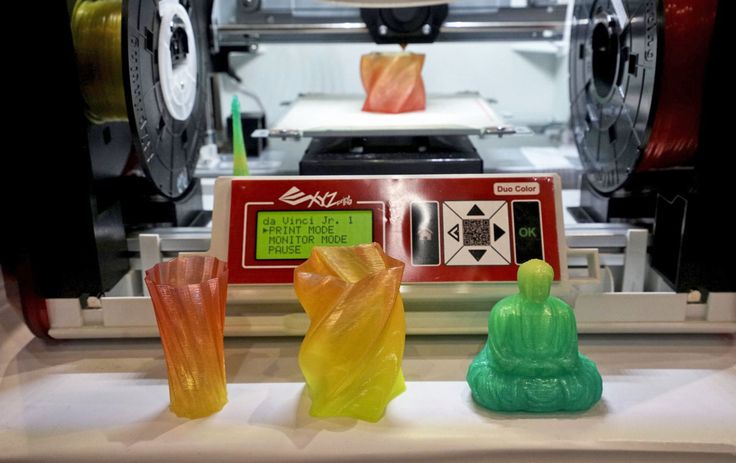

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Walmart | $199.95 | $199.95 | See It (Opens in a new window) |

| Amazon | $199.95 | $199.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

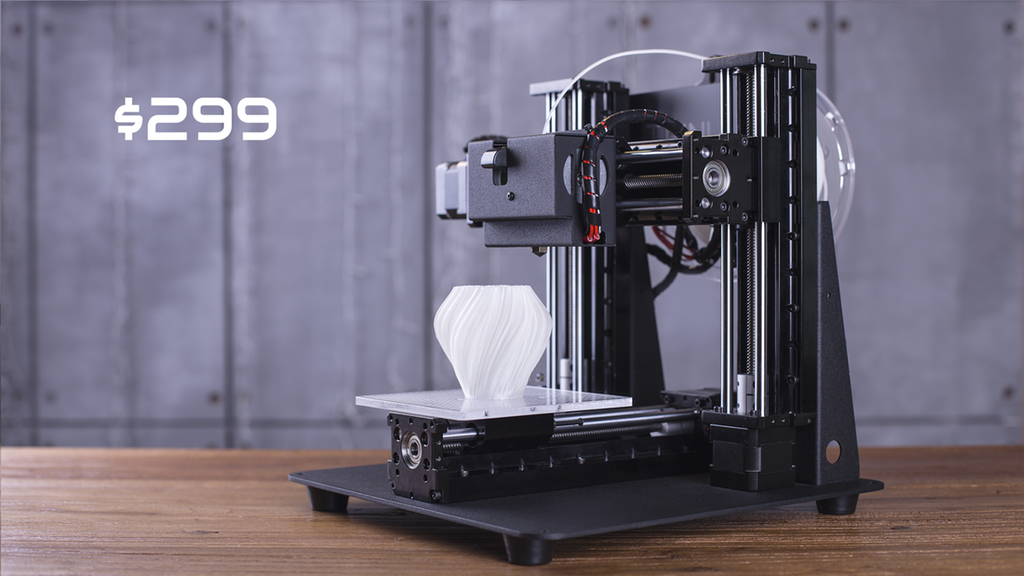

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.00 | $299.00 | See It (Opens in a new window) |

| Toybox Labs | $379.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $279.99 | $279.99 | See It (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

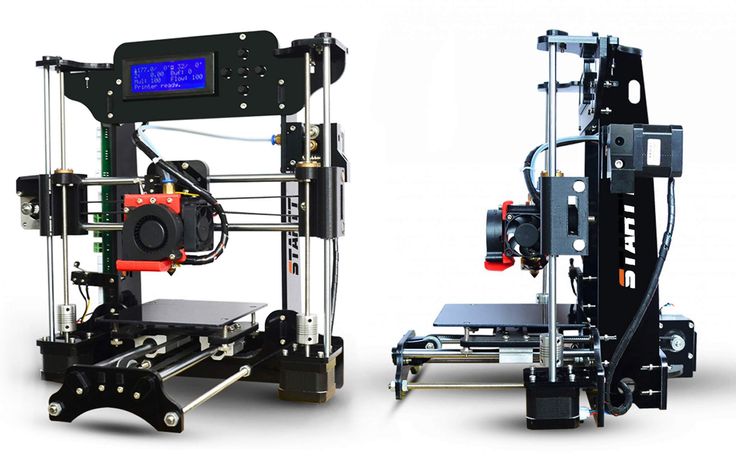

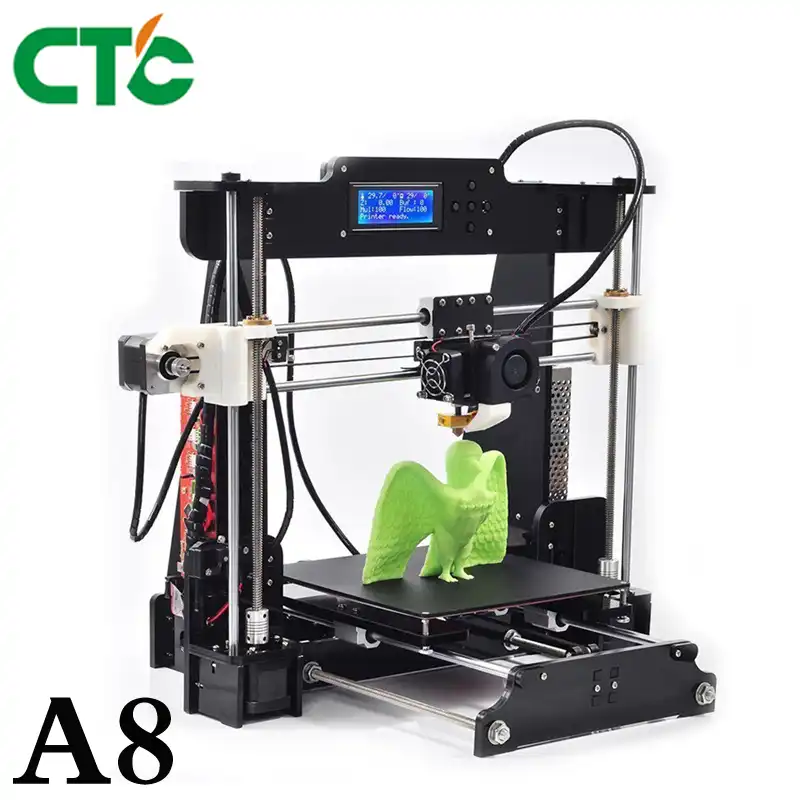

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | Check Stock (Opens in a new window) |

| AnyCubic | $279.00 | $279.00 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $339. 99 99 | $339.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

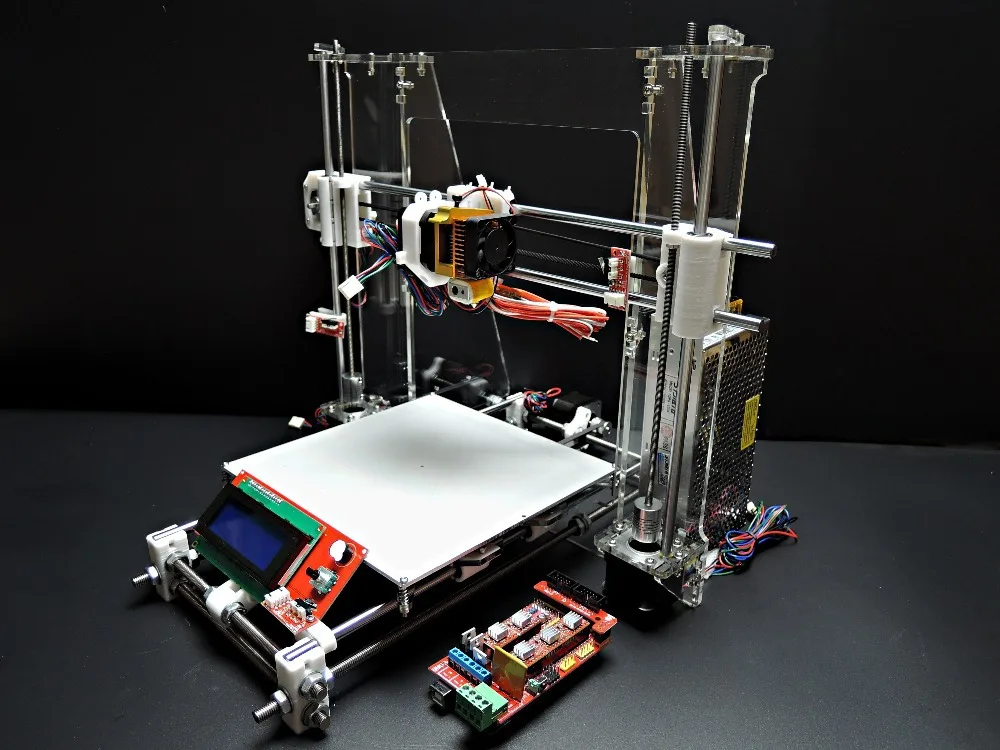

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $246.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $729.00 | $729.00 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

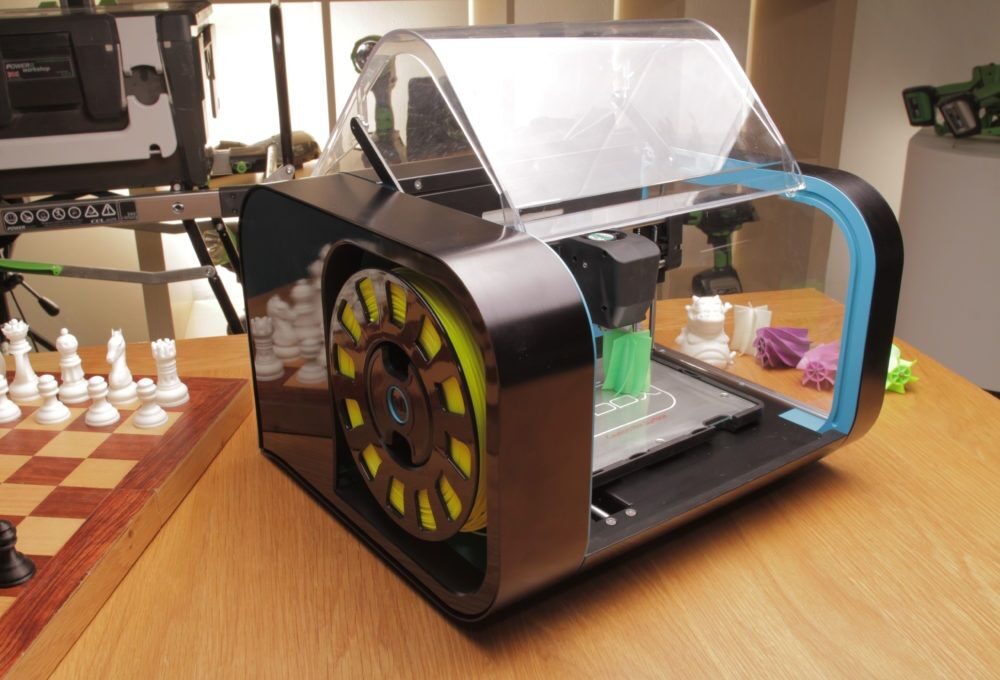

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

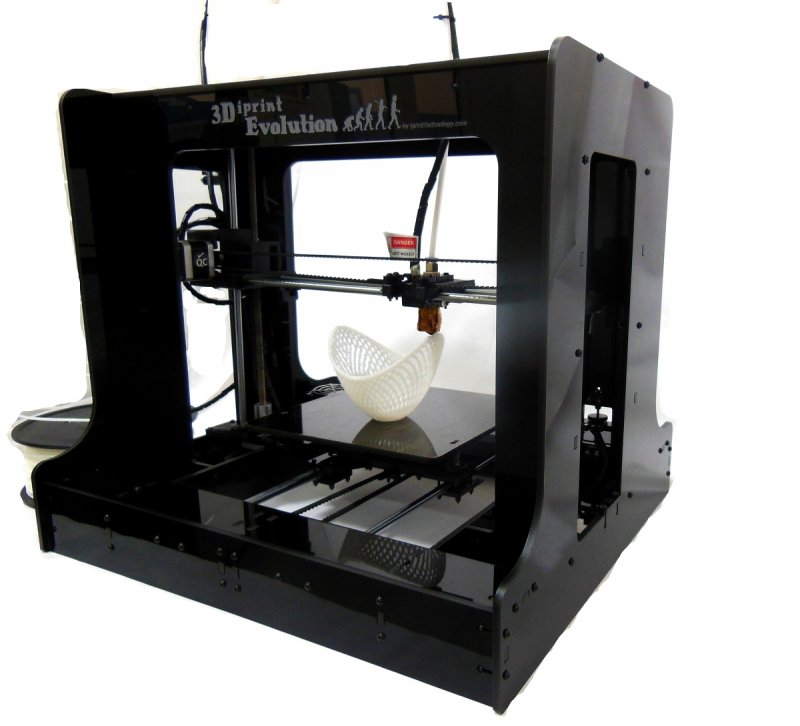

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.95 | $199.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $449.99 | $369.26 | See It (Opens in a new window) |

| Walmart | $429.99 | $369.26 | See It (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2022

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

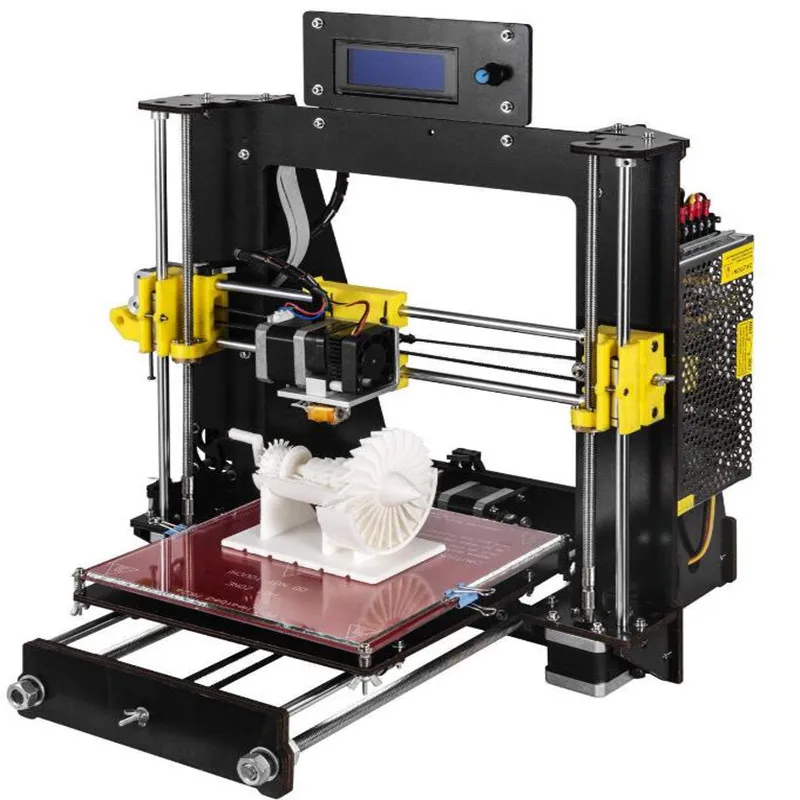

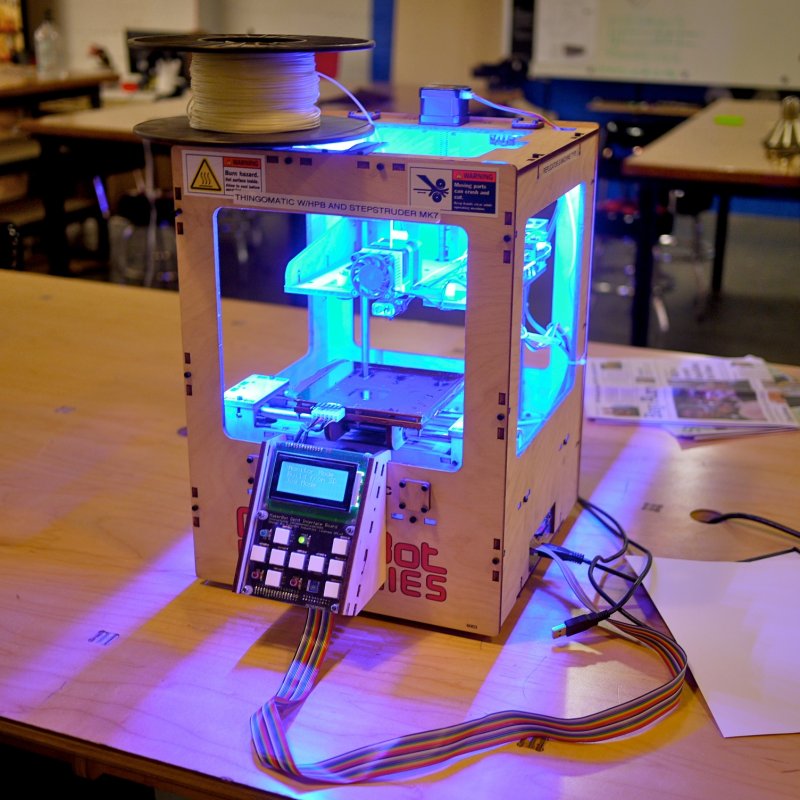

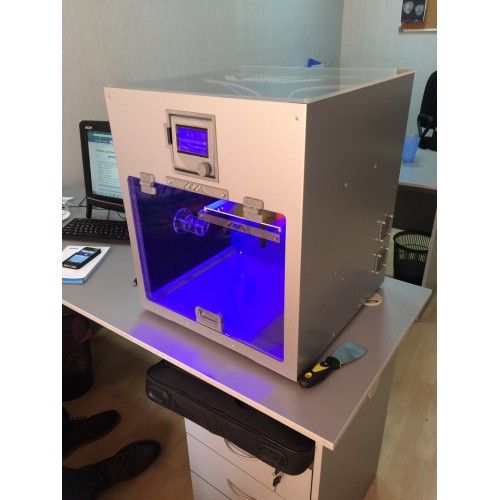

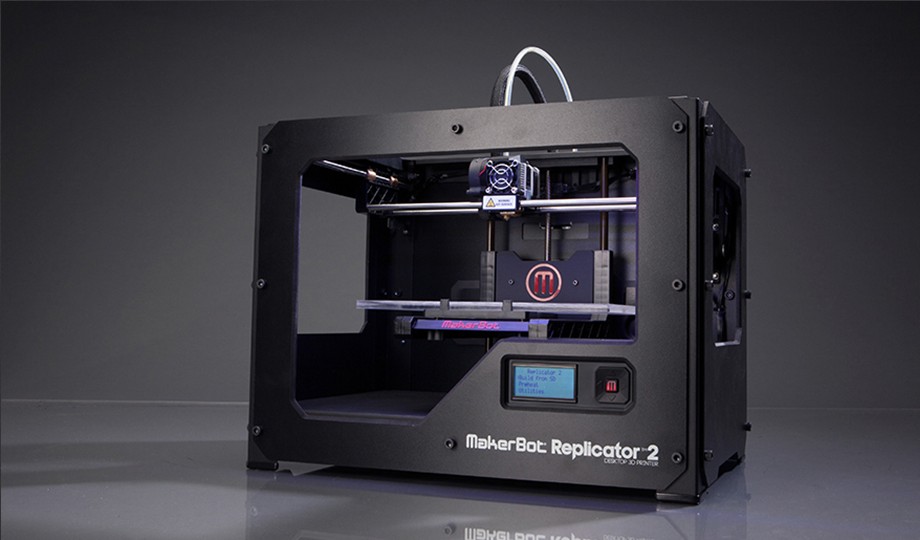

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

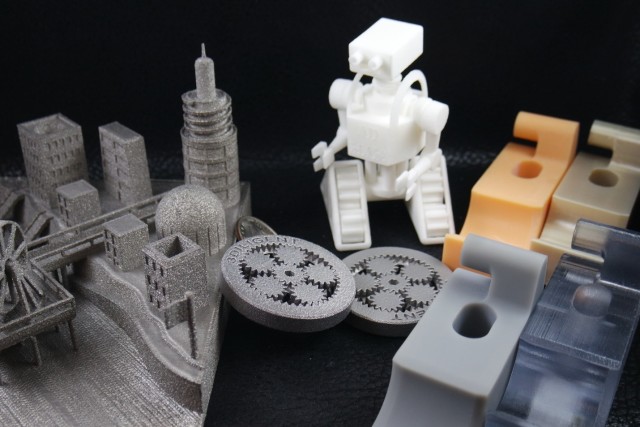

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

Best 3D Printer for 2023

In this article:

- What to consider before buying a 3D printer

- Best 3D printers

- Best 3D printers for beginners

- Midrange 3D printers

- High-end and professional 3D printers

- 3D scanners

- 3D printing FAQs

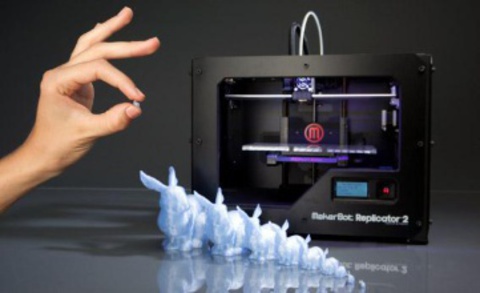

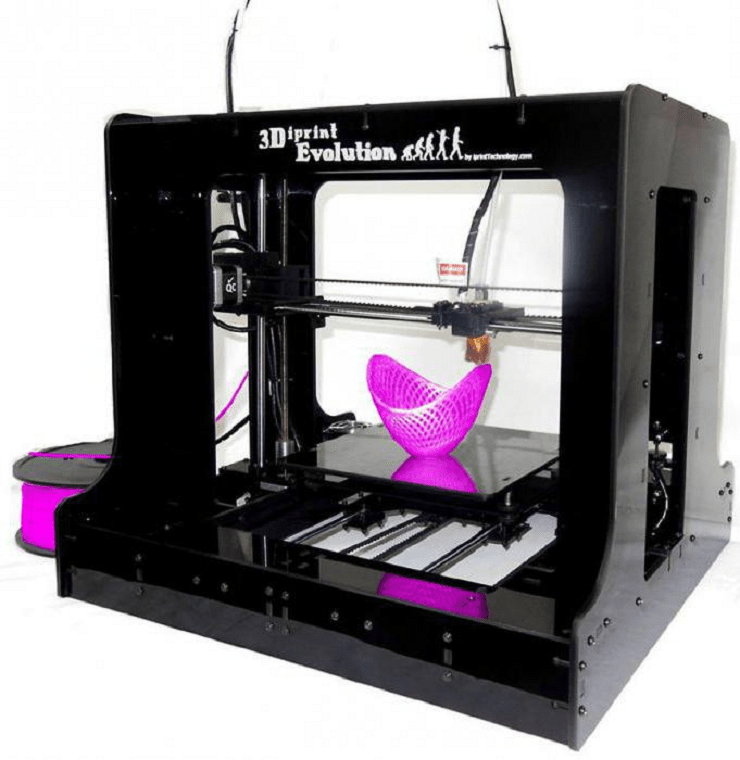

It's a brand new year, and what better time to pick up a new hobby? In the last few years, 3D printing has become much more commonplace and accessible for hopeful hobbyists. If you like miniatures, figurines and cosplay, 3D printing is an excellent vocation to take on. And there are a ton of great 3D printers you can buy and have in your home -- no trip to the library or store necessary.

If you like miniatures, figurines and cosplay, 3D printing is an excellent vocation to take on. And there are a ton of great 3D printers you can buy and have in your home -- no trip to the library or store necessary.

Because 3D printing technology has come a long way in recent years, I've doubled down on being creative and gotten into 3D scanning and laser cutting as well, which lets you sculpt real-world designs from leather and wood. Advanced makers are also using resin machines that create amazingly detailed prints.

Current 3D printers, which range from affordable (under $300) to high-end (over $4,000), are great gifts for a creative person in your life. Even better, they're great for you to craft your own personalized designs if you're looking to open an Etsy shop or something similar.

These models by Fotis Mint are extremely detailed.

James Bricknell/CNETWe've taken a deep dive into many of the best 3D printers available today. This list includes both small and large 3D printers, with attention paid to print speed, the size of the build plate, the cost of PLA filament, the kind of print head included and other important details. And once you've decided to take the plunge into additive manufacturing -- that's what 3D printing essentially is -- there's an FAQ below.

This list includes both small and large 3D printers, with attention paid to print speed, the size of the build plate, the cost of PLA filament, the kind of print head included and other important details. And once you've decided to take the plunge into additive manufacturing -- that's what 3D printing essentially is -- there's an FAQ below.

What to consider before buying a 3D printer

Purchasing your first 3D printer can be nerve-wracking but don't worry; we are here to help. There are a few main areas that you should consider when choosing the best 3D printer and we have them covered here.

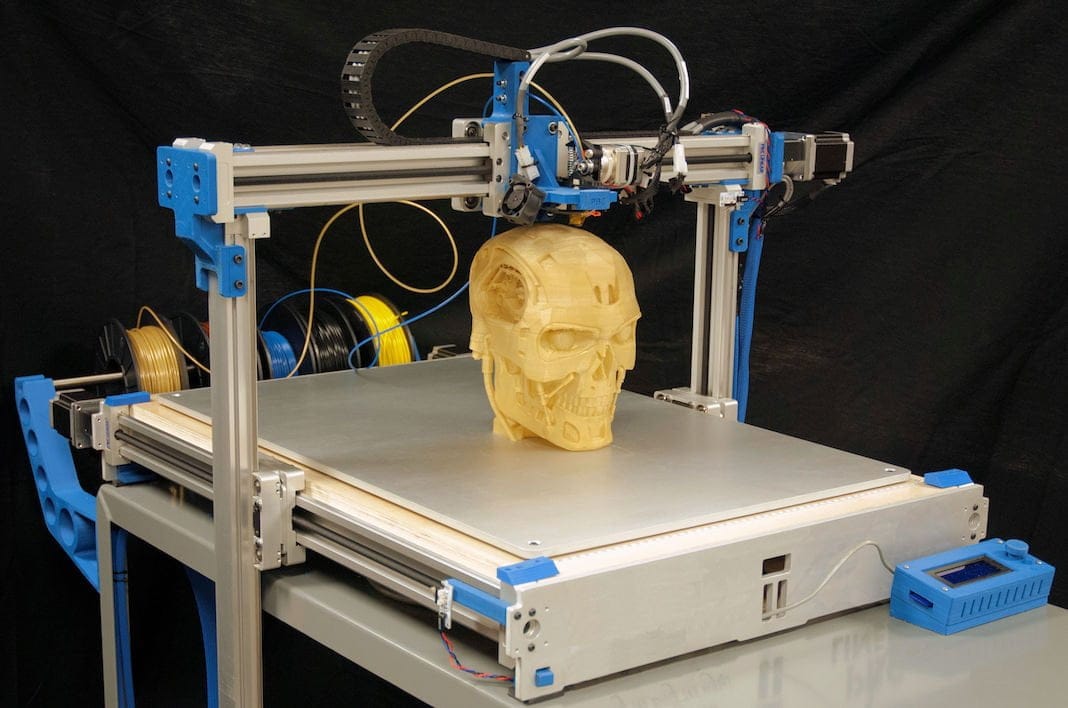

What am I 3D printing?

When deciding on what 3D printer to buy you first have to know what type of things you want it to print. Resin 3D printing is good for highly detailed models such as character busts, dental work or tabletop miniatures. Even jewelry can be made using a resin 3D printer.

For almost every other application, an FDM, aka filament, 3D printer is likely the best choice. Filament 3D printing is versatile in the types of material you can use and offers much larger build volumes to work on models. Cosplay armor and helmets, practical parts and large-scale models are best printed on an FDM printer.

Filament 3D printing is versatile in the types of material you can use and offers much larger build volumes to work on models. Cosplay armor and helmets, practical parts and large-scale models are best printed on an FDM printer.

Read more: What Is 3D Printing?

What is build volume?

Build volume is the amount of space a printer has to produce a model. Often calculated in millimeters cubed, it is the combination of the width, height and depth that your printer's nozzle can reach. This is not always the same as the internal volume of a 3D printer because the wiring and other mechanical parts can get in the way of the nozzle, reducing the area available.

Most FDM printers have a build area of around 220 by 220 by 250mm, though some of the best 3D printers have larger and a few of the best budget 3D printers have smaller. I think the 220 by 220mm build plate is a good size for starting out as it has room for large, practical pieces or several smaller models at once.

Should I wait for a deal to buy a 3D printer?

3D printers are often available throughout the year at a discount price. Special days like Prime Day, Black Friday and Cyber Monday are great occasions to pick yourself up a new machine, but there are still plenty of deals to be had on a normal day. Make sure you stay fluid and choose your 3D printer deal based on the availability of the machine and what your research has told you is the best.

Best 3D printers

Dan Ackerman/CNET

Creality Ender-3 S1

Best 3D printer for beginners

I'd avoided Ender-3 printers for a long while, because they came in kit form and required many hours of assembly, setup and fine-tuning to use. For just a little more than the kit versions, the newer Ender-3 S1 comes nearly fully preassembled, and with high-end features like a direct drive extruder and self-leveling bed.

Print quality even out-of-the-box was excellent, although a lot of that comes down to having good models to work from. I'd love it to have a touchscreen and Wi-Fi, but apart form those missing features, this is a great way to get polished results from a $400 3D printer.

Read our Creality Ender-3 S1 review.

$399 at Amazon

$340 at Creality3d

You're receiving price alerts for Official Creality Ender 3 S1 3D Printer with Direct Drive Extruder CR Touch Auto Leveling High Precision Double Z-axis Screw Silent Board Printing Size 8.6X8.6X10.6in, Upgrade Ender 3 V2 for Beginners

James Bricknell/CNET

Prusa Mk3S Plus

The standard candle for home 3D printing

No best 3D printer list is really complete without the Prusa MK3S Plus. For nearly a decade it has dominated the market and continues to be the go-to printer for anyone looking to make a business from 3D printing. It is fast and creates quality prints every time. I can count the number of print fails from MK3 on one hand, and I have had it for nearly seven years. If you have the $800, you should buy one of these.

It is fast and creates quality prints every time. I can count the number of print fails from MK3 on one hand, and I have had it for nearly seven years. If you have the $800, you should buy one of these.

$800 at Prusa Research

James Bricknell/CNET

AnkerMake M5

Speed and quality combined

The AnkerMake M5 is a new breed of 3D printer. Its speed is unrivaled on this list and the quality of the end product is on par with anything I've seen. When you can get this quality level in a 3D print job in around half the time of its closest competitor, it's hard to recommend anything else for someone with the money to buy one.

Read our AnkerMake 5 review.

$799 at AnkerMake

Dan Ackerman/CNET

Anycubic Vyper

Best for out-of-the-box printing

The Anycubic Vyper FDM printer attempts to be both an affordable 3D printer and easy to use. It's a tricky needle to thread. Plenty of 3D printers offer automatic bed leveling and calibration to make sure prints come out even and firmly anchored to the print bed. This, however, is the first time I've seen a 3D printer run its bed leveling once, with zero manual input from me, and be totally good to go. I printed a 3D test file from the included SD card within minutes of powering on, and I've never seen a first print from a 3D printer come out so perfectly.

It's a tricky needle to thread. Plenty of 3D printers offer automatic bed leveling and calibration to make sure prints come out even and firmly anchored to the print bed. This, however, is the first time I've seen a 3D printer run its bed leveling once, with zero manual input from me, and be totally good to go. I printed a 3D test file from the included SD card within minutes of powering on, and I've never seen a first print from a 3D printer come out so perfectly.

Read our Anycubic Vyper review.

$359 at Anycubic

Anycubic

Anycubic Kobra Max

Best to make big projects easily

The Anycubic Kobra Max earned a 9 out of 10 in our recent review, in large part because it's one of the most enjoyable printers I've used in years. The build area is large enough to print entire helmets for cosplay, and the auto-bed-leveling system makes setting the machine up a breeze. The Kobra Max is the best choice for a large build area printer, bar none.

The Kobra Max is the best choice for a large build area printer, bar none.

Read our Anycubic Kobra Max review.

$529 at Anycubic

Best 3D printers for beginners

These 3D printers are excellent for anyone just starting out in 3D printing. Check out our expanded list of the best budget 3D printers for more in this category.

Prusa Research

Prusa Mini Plus

Small but mighty

The Mini Plus is one of the best small-footprint printers you can buy. It has everything you would expect from a Prusa machine: Auto bed leveling, crash detection and great print quality, all for under $450. Building it with my son gave us a lot of good insights into how a 3D printer works, and potentially how to fix one.

$429 at Prusa Research

Sarah Tew/CNET

Anycubic Mono

Best inexpensive resin 3D printer

Resin printers are the next step up in rapid prototyping design technology when you want your printing to look as high quality as possible. Just be warned: The liquid resin is harder to work with, and it requires both good ventilation and a portable UV light to properly cure. This model is extremely popular with board game hobbyists who want to print pro-looking miniatures, and sometimes you'll see it fall in price. Note that you can save $20 at Amazon by activating the instant coupon on the product page.

Just be warned: The liquid resin is harder to work with, and it requires both good ventilation and a portable UV light to properly cure. This model is extremely popular with board game hobbyists who want to print pro-looking miniatures, and sometimes you'll see it fall in price. Note that you can save $20 at Amazon by activating the instant coupon on the product page.

$280 at Amazon

You're receiving price alerts for ANYCUBIC Photon Mono 4K, Resin 3D Printer with 6.23" Monochrome Screen, Upgraded UV LCD 3D Printer and Fast & Precise Printing, 5.19" x 3.14" x 6.49" Printing Size

Dan Ackerman/CNET

Monoprice Mini Delta V2

Best for tiny desks

I had high hopes for this dirt-cheap 3D printer with a tiny footprint. It's usually under $200 and requires no additional assembly. And I do like it, but it's for a specific audience. This is not the great low-cost entry-level printer I was hoping for. It required some tweaking and troubleshooting to get up and running. The included microSD card was so cheap and corrupted it never worked, the built-in Wi-Fi was never able to connect to my network, and the machine's arms got caught on some poorly installed plastic wire covers (I just ripped the paper-thin covers off).

This is not the great low-cost entry-level printer I was hoping for. It required some tweaking and troubleshooting to get up and running. The included microSD card was so cheap and corrupted it never worked, the built-in Wi-Fi was never able to connect to my network, and the machine's arms got caught on some poorly installed plastic wire covers (I just ripped the paper-thin covers off).

But once I had all the problems ironed out, it was a reliable little machine for quick jobs. It would make a great second 3D printer, or if you need to fit one into a small space. I especially liked the auto-leveling, which worked well, and the color touchscreen, which is a feature that often gets chopped from low-cost models. If you're willing to put a little effort into getting it set up correctly, it's a great printer for the price.

$180 at Amazon

Midrange 3D printers

James Bricknell/CNET

Elegoo Saturn 2

The best resin experience right now

The Elegoo Saturn 2 is an almost perfect upgrade from the original Saturn. It is bigger and more powerful, with better quality prints than its predecessor and my No. 1 choice for a midrange resin 3D printer. If you are looking to print serious details or a lot of tiny models, this is simply the best choice. It's $671 on Amazon, but you can get it for $60 off when you apply a coupon at checkout.

It is bigger and more powerful, with better quality prints than its predecessor and my No. 1 choice for a midrange resin 3D printer. If you are looking to print serious details or a lot of tiny models, this is simply the best choice. It's $671 on Amazon, but you can get it for $60 off when you apply a coupon at checkout.

$671 at Amazon

You're receiving price alerts for ELEGOO Saturn 2 8K MSLA 3D Printer, UV Resin Photocuring Printer with 10-inch 8K Monochrome LCD, 8.62x4.84x9.84 Inch Larger Printing Size

James Bricknell/CNET

Flashforge Adventurer 4

Best 3D printer for ease of use

The Flashforge Adventurer 3 has long been one of CNET's favorite midprice 3D printers. The updated Adventurer 4 brings a handful of iterative improvements that make for a winning evolution. The Adventurer 4 is a fully enclosed unit, which helps control the temperature and block drafts. The build area is 220 by 200 by 250mm, and it has a system for easily swapping out nozzles -- all good features to have in a mid-level to high-end printer.

The build area is 220 by 200 by 250mm, and it has a system for easily swapping out nozzles -- all good features to have in a mid-level to high-end printer.

$849 at Amazon

You're receiving price alerts for Flashforge Adventurer 4

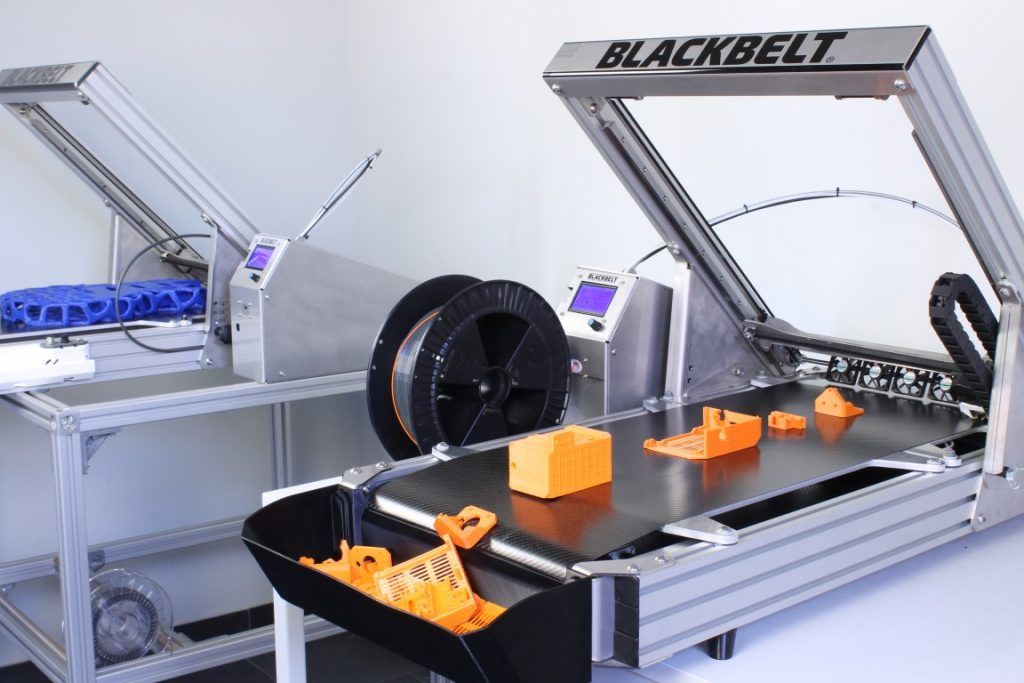

High-end and professional 3D printers

Creality

Creality CR-30

Best for small biz or pro cosplayers

A word of warning; the CR-30 is not for the beginners out there. It is a complicated machine, and you will need some 3D-printing knowledge to really get the hang of it. It's also a very different beast, and instead of printing on a static-sized build plate, it uses a conveyor belt to create an "endless Z-axis." That lets you print very long things or lots of things over and over again.

If you are a cosplayer looking to make weapons or large armor pieces, the CR-30 gives you a lot of room to create. I've managed to print Squall's Gunblade from Final Fantasy VIII as well as the Whisper of the Worm from Destiny 2 (both were printed in two halves and attached together). It's great for small businesses looking to mass-produce small parts, and with just two CR-30s you could create a small empire on Etsy or Shopify. --James Bricknell

It's great for small businesses looking to mass-produce small parts, and with just two CR-30s you could create a small empire on Etsy or Shopify. --James Bricknell

$982 at Amazon

You're receiving price alerts for Creality CR-30

Sarah Tew/CNET

Glowforge 3D Laser Cutter

Best for woodworkers

I can't begin to tell you how much I love the Glowforge. Laser cutters can create projects from wood, leather, lucite and other materials, making it an interesting creation alternative to filament-based 3D printers. Even better, what would take a 3D printer hours to do takes just minutes in the Glowforge.

With it, I've created laser-etched LED lights, birch wood tool caddies, and even a three-tier box for my Nespresso sleeves. There's a robust community of makers creating and sharing files, but pretty much any line drawing you can create in something like Adobe Illustrator can be turned into a project.

The software is all cloud-based, which adds a layer of complication (you need internet service to use it), but the ability to create amazing gifts and more from simple 0.125-inch or 0.25-inch cheap plywood is pretty empowering.

See some of my laser cutter projects (and download my SVG files) here.

$3,995 at Glowforge (Glowforge Basic)

$4,995 at Glowforge (Glowforge Plus)

3D scanners

Revopoint

Revopoint Pop 2

Incredible details

While the software has a pretty steep learning curve, the end result is extremely detailed. I've really enjoyed using the handheld version to scan larger models while the included turntable makes scanning smaller objects a breeze. If you are looking for a professional-grade scanner and can spend some time on the software, the Pop 2 is a great choice.

$689 at Amazon

You're receiving price alerts for Revopoint Pop 2

Sarah Tew/CNET

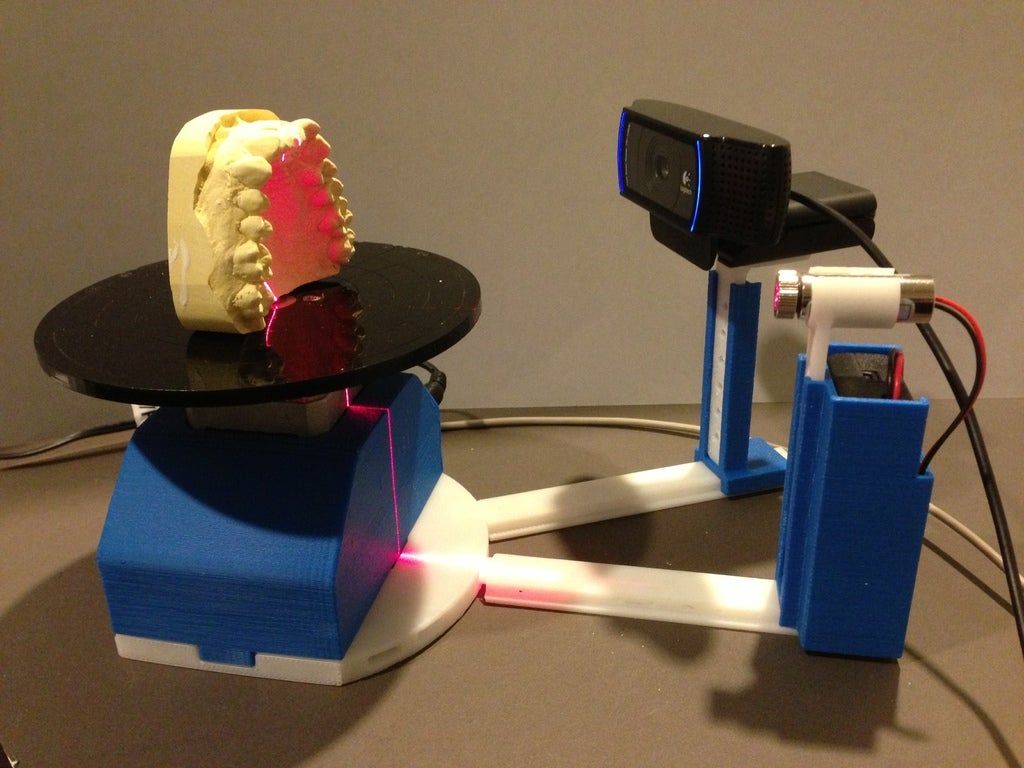

SOL Desktop Laser 3D Scanner

Best 3D scanner for easy replicas

Recreate pretty much anything by putting it on this 3D scanner, where a rotating base and built-in camera create a 360-degree copy, which is then editable in any 3D program and printable on your 3D printer. Simply scan the object, import the scan into your slicing software for cleanup, and print. The included software alerts you of next steps in the printing process with either sound or texts. Scan quality and print resolution are great, and setup is easy, although you might want to clean up your 3D model a bit in a 3D software app after.

Simply scan the object, import the scan into your slicing software for cleanup, and print. The included software alerts you of next steps in the printing process with either sound or texts. Scan quality and print resolution are great, and setup is easy, although you might want to clean up your 3D model a bit in a 3D software app after.

$799 at Amazon

You're receiving price alerts for SOL Desktop Laser 3D Scanner

3D printing FAQs

What material should I use to print with?

Most home 3D printers use PLA or ABS plastic. Professional printers can use all sorts of materials, from metal to organic filament. Some printers use a liquid resin, which is much more difficult to handle. As a beginner, use PLA. It's nontoxic, made mostly of cornstarch and sugarcane, handles easily and is inexpensive. However, it's more sensitive to heat, so don't leave your 3D prints on the dashboard of a car on a hot day.

Which brand of PLA is best?

Generally speaking, Hatchbox has never let me down and runs about $25 for a full 1kg spool on Amazon. Some of the printers I tested only accommodate narrower 0.5kg spools. In those cases, I sometimes used a larger Hatchbox roll with a separate spool-holder. Other times, I had good luck with AIO Robotics 0.5kg spools, which are a little more expensive, at $14 for 0.5kg. Amazon Basics and Monoprice can also be good, but for any brand, weird colors like metallic or glow-in-the-dark filament can be hit-or-miss. Note that a 1kg roll prints a lot of stuff.

Some of the printers I tested only accommodate narrower 0.5kg spools. In those cases, I sometimes used a larger Hatchbox roll with a separate spool-holder. Other times, I had good luck with AIO Robotics 0.5kg spools, which are a little more expensive, at $14 for 0.5kg. Amazon Basics and Monoprice can also be good, but for any brand, weird colors like metallic or glow-in-the-dark filament can be hit-or-miss. Note that a 1kg roll prints a lot of stuff.

What settings should I use?

Most 3D printers include or link to recommended software, which can handle converting 3D STL or other files into formats supported by the printer. Stick with the suggested presets to start, with one exception. I've started adding a raft, or bottom layer of filament, to nearly everything I print. It has cut down dramatically on prints that don't adhere to the bed properly, which is a common issue. If you continue to have problems, rub a standard glue stick on the print bed right before printing.

What are supports?

Your 3D models probably need some help to print properly, as these printers don't do well with big overhangs -- for example, an arm sticking out from a figure. Your 3D printer software can usually automatically calculate and add supports, meaning little stands that hold up all those sticking-out parts of the model. After the print is done, clip the supports off with micro cutters and file down any nubs or rough edges with hobby files.

Where do I find things to print?

Thingiverse.com is a huge online repository of 3D files for anything and everything you can think of. Pokemon chess set? It's there. Dyson vacuum wall mount? You bet.

When you're ready to create your own designs, there are a ton of software packages to choose from, but it's easiest to start with the browser-based free TinkerCad app from Autodesk.

Crazy things I've made on a 3D printer

+15 more See all photosMore creative recommendations

- Best 3D Printer Filament

- Best Budget 3D Printer

- Best Laptops, Desktops and Tablets for Designers and Creatives in 2023

- Best Vlogging Camera for 2023

- Best 3D Printer Resin

Photopolymer 3D printer: which one to choose | Equipment

Until recently, photopolymer printing was an expensive and inaccessible way to reproduce three-dimensional figures. Only professionals from narrow fields of activity could purchase powerful equipment. Today, with more offerings and lower printer costs, high-quality 3D printing has become more affordable. All equipment on the market can be classified according to the printing method and the raw materials used. Photopolymer 3D printers are especially popular. They are equipped with a high-quality matrix with the most smooth outer surface. Thanks to this, the final products, even the smallest ones, have the correct shape with a detailed drawing. nine0003

Only professionals from narrow fields of activity could purchase powerful equipment. Today, with more offerings and lower printer costs, high-quality 3D printing has become more affordable. All equipment on the market can be classified according to the printing method and the raw materials used. Photopolymer 3D printers are especially popular. They are equipped with a high-quality matrix with the most smooth outer surface. Thanks to this, the final products, even the smallest ones, have the correct shape with a detailed drawing. nine0003

Consumables at a glance

Photopolymer 3D printing will require special resins (liquid plastic) that harden when exposed to light. They are sensitive to ultraviolet radiation, which determines the design features of 3D printers. The physical properties of consumables vary widely. After polymerization, they can be hard or flexible, matte or transparent. Consistency, exposure time (curing), colors also vary. Both biologically safe resins and technical options can be selected based on the intended use of the final products. The cost of consumables is quite high, so when choosing equipment, it is worth considering the available range of compatible polymer raw materials. nine0003

The cost of consumables is quite high, so when choosing equipment, it is worth considering the available range of compatible polymer raw materials. nine0003

SLA Technology (Laser Stereolithography)

Photopolymer 3D printing originated from this technology in 1984. The essence of the process lies in the fact that the curing of raw materials occurs under the influence of a high-precision laser.

Design features. The classic model of a photopolymer 3D printer consists of a resin tank, which is located under the platform. It is driven (raised, lowered and rotated) by a special mechanism. In some cases, the cuvette itself is driven. The laser emitter and mirror deflection system are located on the top of the equipment. nine0003

Printing method. During the operation of a laser stereolithographic 3D printer, the platform is immersed in a cuvette with consumable material to a depth of one layer. Due to the rather thick consistency of resins, a leveling mechanism can be used to speed up printing. This is followed by a progressive point process of illuminating the material with a laser irradiator. The direction of the beam in the horizontal and vertical planes is determined by the movement of the deflecting mirror system. Upon completion of drawing and polymerization, the platform is immersed in the cuvette for one more layer, and the process is repeated. This is how the entire digital model is formed step by step. nine0003

This is followed by a progressive point process of illuminating the material with a laser irradiator. The direction of the beam in the horizontal and vertical planes is determined by the movement of the deflecting mirror system. Upon completion of drawing and polymerization, the platform is immersed in the cuvette for one more layer, and the process is repeated. This is how the entire digital model is formed step by step. nine0003

Technology features. SLA-3D printers have very high precision and print quality. They are reliable and pretty straightforward to use. In addition, the equipment is compatible with many photopolymer resins on the market.

DLP Technology (LED Stereolithography)

This method of creating 3D models is very similar to SLA technology. The difference is that instead of a laser emitter with a mirror system, a digital LED projector is used. nine0003

Design features. The equipment consists of a glass platform with a vertical Z axis, a photopolymer resin cuvette, a glass substrate and a digital LED projector located below. An important difference between the equipment is the material from which the cuvette is made. It is completely transparent to ultraviolet radiation.

An important difference between the equipment is the material from which the cuvette is made. It is completely transparent to ultraviolet radiation.

Printing method. With the help of a digital projector, the templates are polymerized at once as a whole layer, and not pointwise, as is the case with SLA equipment. A feature of a photopolymer 3D printer with DLP technology is the ability to invert, or reverse, print an image. In this case, the platform is not immersed in the consumable, but rises along the Z axis, gradually stretching the layers of exposed resin. nine0003

Technology features. Printing objects using LED stereolithography does not take much time. In addition, the absence of a delicate mirror system makes the equipment more resistant to physical impact and has a positive effect on printing accuracy, allowing you to get a higher resolution along the Z axis. The size of the projection and the models themselves can be quite significant in height, since it is not limited by the depth of the cuvette. This allows you to get a more voluminous build area without increasing the dimensions of the printer. During operation of the equipment, unwanted flare may occur, and as the print area increases, accuracy and speed decrease. Consumables are quite diverse and have an affordable cost. nine0003

This allows you to get a more voluminous build area without increasing the dimensions of the printer. During operation of the equipment, unwanted flare may occur, and as the print area increases, accuracy and speed decrease. Consumables are quite diverse and have an affordable cost. nine0003

LCD technology (direct ultraviolet illumination)

This method of photopolymer 3D printing is based on the same principles as LED stereolithography. The difference lies in the fact that a special LCD panel is used as the illumination pattern (matrix).

Design features. A transparent resin cuvette is located under the Z-axis glass platform. Next, a matrix (LCD panel) and a Fresnel lens are layered. At the bottom of the equipment is an ultra-bright LED, which provides the resin polymerization process. nine0003

Printing method. Fresnel lens evens out the glow of a powerful LED. The LCD panel inside the equipment creates a white outline of the object and a rich black background. The black color does not transmit powerful radiation, while the white contour is freely illuminated. Due to this, each polymer layer quickly hardens.

The black color does not transmit powerful radiation, while the white contour is freely illuminated. Due to this, each polymer layer quickly hardens.

Technology features. The equipment does not contain complex and expensive components (laser sources, moving reflectors), so LCD printing technology is considered the least expensive. The cost of equipment is lower than the price of analogues. The working area of polymerization is limited only by the resolution of the matrix and the dimensions of the equipment. At the same time, a weak illumination force increases the polymerization rate compared to DLP technology. Flare may occur during printing. In addition, due to the features of the formation of the mask, the wall contour can be fuzzy. nine0003

What to look for when choosing

When choosing a photopolymer 3D printer, it must be taken into account that any equipment, regardless of the printing technology, tends to leave some of the original resins in the cuvette upon completion of work. If there is a need to use different raw materials at the same time, in order to reduce their consumption, additional tanks can be purchased. The larger the printable area of the equipment, the higher the resin consumption will be. nine0003

If there is a need to use different raw materials at the same time, in order to reduce their consumption, additional tanks can be purchased. The larger the printable area of the equipment, the higher the resin consumption will be. nine0003

- First you need to decide on the purpose of buying equipment. If semi-professional and professional printing is required, you can consider the middle price segment. Industrial 3D printers are suitable for large-scale polymerization of complex products.

- Based on the printing tasks, the appropriate technology is selected. For smaller and more precise objects, classic high-precision laser stereolithography (SLA) models are suitable. Larger products, the surface of which can be additionally processed, are usually printed on LED stereolithographic photopolymer 3D printers (DLP). For medium-sized objects without complex embossed surfaces, direct ultraviolet illumination (LCD) models can be selected. An important nuance is that in models with SLA and DLP printing, the products are partially cured, which is necessary to maintain their physical shape.

Since the complete polymerization process takes a long time, after manufacturing, the models must be subjected to additional irradiation. To do this, you can use special cameras with ultraviolet lamps or transparent quartz glass boxes exposed to direct sunlight. nine0070

Since the complete polymerization process takes a long time, after manufacturing, the models must be subjected to additional irradiation. To do this, you can use special cameras with ultraviolet lamps or transparent quartz glass boxes exposed to direct sunlight. nine0070 - An important aspect is the ease of subsequent operation. Modern equipment does not provide a wide choice in print settings. As a rule, it is focused on the manufacture of specific samples. So, if the device is chosen for photopolymer 3D printing of narrow-profile small-sized products, then polymerization of other, larger workpieces can be difficult. The size of the chamber and the compatibility of the source materials come into play here. The degree of automation is also quite important. Features such as automatic resin feeding system, material level sensor, quick-release build platform can greatly speed up and simplify the process of setting up and tracking the print status. nine0070

Today, a wide range of photopolymer 3D printers from different manufacturers is presented on the market, which allows you to choose a model that is suitable for the price and most fully meets the requirements. Our store presents both new models of industrial 3D printers from leading manufacturers, as well as used equipment in good working condition.

Our store presents both new models of industrial 3D printers from leading manufacturers, as well as used equipment in good working condition.

3D Printers - All About 3D Printers and 3D Printing Technology / Sudo Null IT News0003

Articles Authors Companies

Show first

Rating threshold

Computer hardware 3D printers DIY or DIY Life hacks for geeks Electronics for beginners

From the sandbox

There was a need to submit a bunch of handwritten notes in a short time, I wanted to automate the process, and now, what came out of it. nine0003

Read more

Total votes 32: ↑32 and ↓0 +32

Views 3. 5K

5K

Comments eight

kulhaker478

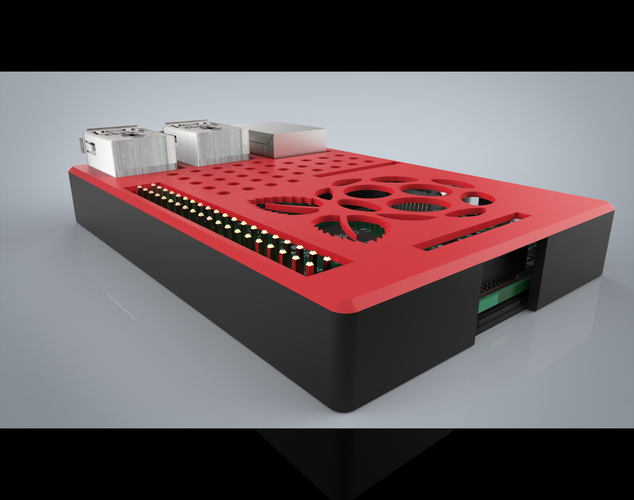

AdminVPS company blog Network technologies *Production and development of electronics *3D printers DIY or DIY

Happy Khabrovchan! There is an opinion that a device without a case cannot be considered complete and without it it will lie disassembled, collecting dust. Therefore, in this final part, we will model and print our case on a 3D printer. nine0003

And finally - let's sum up the results of the project, how much finance was spent, mistakes were made, and I will also share with you my plans for Habr and not only.

Enjoy reading

Total votes 22: ↑20 and ↓2 +18

Views5.9K

Comments 2

Aleksandr8

3D printers

From the sandbox

3MF is a file format created to replace the STL and featuring improved usability and enhanced functionality. Briefly explain the benefits. nine0003

Read more

Total votes 9: ↑4 and ↓5 -1

Views3.4K

Comments fourteen

MechanikArtem

Working with 3D graphics *Cyberpunk 3D printers Wearable electronics Processing *

Tutorial

Hello everyone! We develop "smart sequins" - electromechanical color-reproducing devices for designer clothes.

Today I will tell you how we printed our first dress on a 3D printer! nine0003

Read more

Total votes 22: ↑22 and ↓0 +22

Views 6. 8K

8K

Comments eight

smart_alex

Timeweb Cloud company blog For me, as a hobbyist to make something, from time to time he provides invaluable services in prototyping and creating various parts (bushings, holders, cases for equipment, etc., etc.). nine0003

But there is one problem: the printer is quite bulky (40x60x60 cm), plus consumables and a repair kit - all this takes up a lot of space and turns any room into a kind of production workshop. If you have, for example, a free garage or other similar premises, then there are no problems, but in other cases you have to put up with this foreign element for any residential interior.

For a long time I tried to somehow solve this problem and finally I managed to find, as it seems to me, a rather harmonious solution, which I want to share with you, maybe it will help someone "pass between Scylla and Charybdis" - to have in their a valuable tool and at the same time not disfigure your living space. nine0003

nine0003

So…

Read more →

Total votes 22: ↑20 and ↓2 +18

Views8.4K

Comments 37

sand77777

Working with 3D graphics *Old hardware 3D printers DIY or DIY

✏️ Technotext 2022

Did you dream of turning a real ship's wheel as a child? Just imagine: the sea, salt spray, wind-filled sails are buzzing in the wind above your head, you have a helm in your hands, and your fast clipper rushes towards the horizon ...

This steering wheel is a clock. It is silky and coppery (the exposed copper of the printed circuit board, the unique and peculiar texture of this master’s favorite material), twist and imagine how time ran in the opposite direction, to the past, where the salt spray and the sails of your childhood dreams. Or maybe this is the entrance to a parallel reality?

Or maybe this is the entrance to a parallel reality?

Joke. But still, turn the steering wheel, and suddenly ...)

We turn further)

Total votes 15: ↑13 and ↓2 +11

Views4.3K

Comments fifteen

compas_3d

ASCON CAD/CAM company blog *Design 3D printers

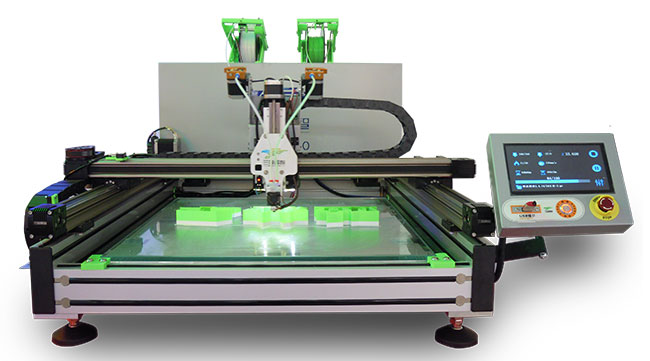

We came to self-propelled machines through aviation. The graduates of the Samara State Aerospace University became the backbone of the future enterprise. We also sprayed fertilizers, but we pollinated the fields from the air on hang-gliders and airplanes. It was difficult and at times risky. Therefore, we decided to design a "ground" machine, which, nevertheless, would be comparable to aviation technology in terms of speed and quality of processing, or even surpass it. Development was carried out according to aviation standards, since we were all pilots. nine0003

It was difficult and at times risky. Therefore, we decided to design a "ground" machine, which, nevertheless, would be comparable to aviation technology in terms of speed and quality of processing, or even surpass it. Development was carried out according to aviation standards, since we were all pilots. nine0003

As a result of these studies, in 2001 we made our first car. Even then, it worked the fields at high speed and was very light.

Learn more

Total votes 35: ↑34 and ↓1 +33

Views5.5K

Comments eighteen

compas_3d

Blog of ASCON company Work with 3D graphics *CAD/CAM *3D printers DIY or DIY

In early September, we released a new version of the KOMPAS-3D Home system for amateur 3D - modeling and home use. Makers, 3D printers, DIYers and bloggers have access to all the features of professional CAD. nine0249

Makers, 3D printers, DIYers and bloggers have access to all the features of professional CAD. nine0249

What's new in KOMPAS-3D v21 Home?

Large detailed article

Total votes 10: ↑10 and ↓0 +10

Views8.6K

Comments 23

Erwinmal

RUVDS.com company blog Reading room Popular science 3D printers The future is here Even in the unexpectedly turbulent 2020s, already challenging the 1920s for the Roaring Twenties, progress is not going to stand still. Technologies are moving further and further, and not all of them are as well-known as conversational and graphical neural networks, neural interfaces, or self-guided combat drones. However, many of them can affect our lives. In particular, these three. nine0003

Read more →

Total votes 47: ↑39 and ↓8 +31

Views12K

Comments 54

Sergiv

Company Blog Special Technology Center Popular Science 3D printers Multicopters DIY or DIY

It was in the evening, there was nothing to do (c)

9029 optimized for "zero" speed (hovering). Your quad will now fly slower, climb slower, more likely to be "dumb" in response to controls, and less able to hold the wind. Vibrations may also appear (the controller is configured for exactly that thrust-rev ratio, but it has become different for you)

In this article I will try to figure out if this is really so, what pluses and minuses will arise, how these propellers will behave in flight.

We flew again

Total votes 19: ↑18 and ↓1 +17

Views5.7K

Comments 25

compas_3d

ASCON CAD/CAM Blog *Cosmonautics 3D printers

In July, the third stage of the international project SIRIUS (Scientific International Research In Unique Terrestrial Station), simulating long-term manned space flights, was completed. For 240 days, the crew of 5 people, representing three countries - Russia, the USA and the UAE, was in complete isolation in conditions that simulate the work of a real expedition on a circumlunar orbital station and the surface of the Moon. The experiment took place in the test complex of the Institute of Biomedical Problems of the Russian Academy of Sciences (IMBP RAS) and assumed full immersion in all stages of the space mission: from entering the Earth's orbit and flying to the Moon to staying in orbit and returning to Earth. nine0003

For 240 days, the crew of 5 people, representing three countries - Russia, the USA and the UAE, was in complete isolation in conditions that simulate the work of a real expedition on a circumlunar orbital station and the surface of the Moon. The experiment took place in the test complex of the Institute of Biomedical Problems of the Russian Academy of Sciences (IMBP RAS) and assumed full immersion in all stages of the space mission: from entering the Earth's orbit and flying to the Moon to staying in orbit and returning to Earth. nine0003

We spoke with the SIRIUS-21 crew commander, head of the department for the creation of integrated simulators for promising transport ships of the Cosmonaut Training Center. Yu. A. Gagarin Oleg Blinov about participation in the experiment, solving various problems using available 3D technologies and, of course, about the everyday life of a future interplanetary flight.

Learn more

Total votes 3: ↑3 and ↓0 +3

Views919

Comments 0 nine0003 TilekSamiev

Sales Management *Legislation in IT Business Models *Popular Science 3D Printers

This article is written to introduce the reader to such a phenomenon as the Ghost Gun. The author does not call for anything. Remember, the illegal acquisition, possession and use of weapons is a crime and must be prosecuted to the fullest extent of the Law!

Ghost Gun (ghost gun), a general term for non-serial and homemade firearms, which first appeared in America as a creation of amateur gunsmiths in the late 1980s. But in recent years, thanks to the booming gun industry, they have become more accessible and popular with criminals and intruders. They are inexpensive, easy to obtain, and have long been out of the government's radar. Ghost gun assembly kits are the basis of the vast majority of weapons sold to the public and used in crime in the United States. Many components such as the barrel, bolt and magazine can be legally purchased online in convenient kits without a firearms license

But once the firearm is assembled, the legal threshold is passed because the manufacturer then becomes the manufacturer and owner of the firearm, and this already requires a license and registration certificate.

On August 24, 2022, new federal regulations came into effect to reduce the proliferation of untraceable, privately assembled firearms. But the Biden administration's requirement for serialization of the gost gun and mandatory background checks on sale cannot apply to the millions of weapons already in circulation. nine0078

Read more →

Total votes 14: ↑10 and ↓4 +6

Views6.1K

Comments 32

TimurYanovskiy

Belaya Raduga company blog Scientific and popular Health 3D printers

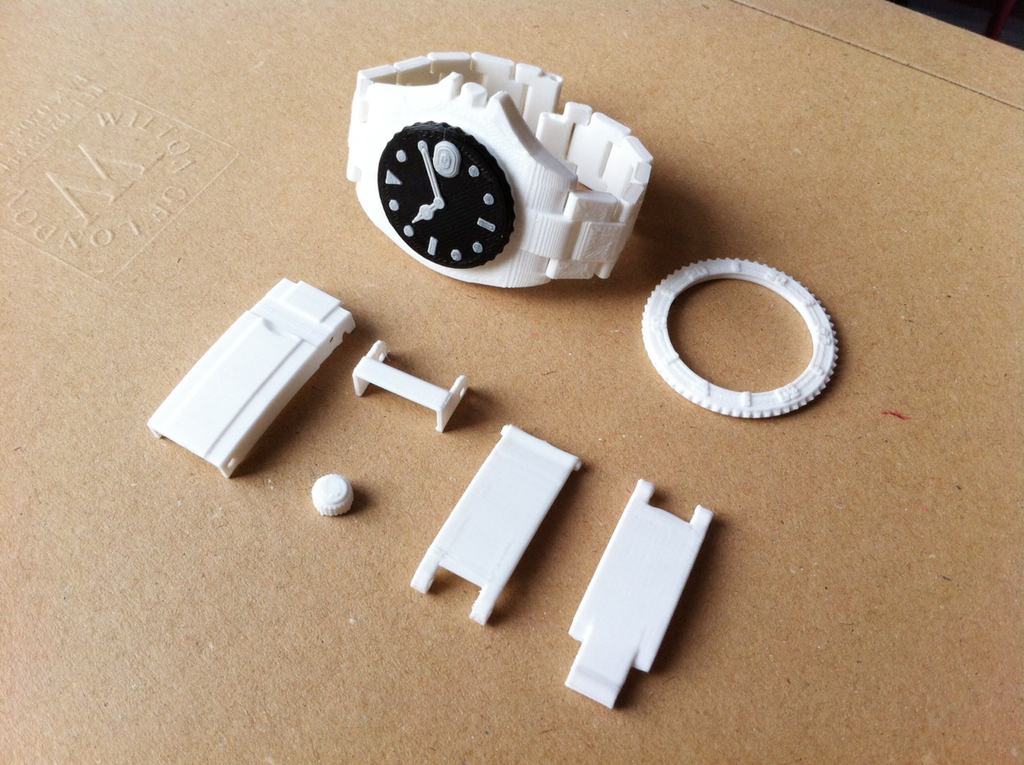

3D printed jaw model with future restorations

We, dentists, constantly need additive manufacturing. Either the patient will meet a tree, then grab the curb with his teeth, or even jump from the third floor onto his face, and some of these patients do not want to wait four months for permanent implantation, but need temporary structures to come out after 40 minutes and smile at a business meeting. We also use 3D printers to print a fragment of you for training before surgery. Plus, today a good dental laboratory has its own 3D printer for printing models, artificial crowns, veneers and caps. nine0003

We also use 3D printers to print a fragment of you for training before surgery. Plus, today a good dental laboratory has its own 3D printer for printing models, artificial crowns, veneers and caps. nine0003

Today we will tell you what features of 3D printing we have. First and foremost, everything that is certified for medicine costs three to ten times more. But there are other features as well.

- What are 3D technologies in dental practice in general, what methods are used.

- How they are applied in orthodontics, orthopedics and surgery.

- How we scan you.

- About materials.

- Why we often prefer more traditional milling. nine0070

- How much do modern dental printers cost.

- How we choose a dental laboratory for model printing and prosthetics.

Read more →

Total votes 44: ↑41 and ↓3 +38

Views7K

Comments 10

vandiemen

3D printers

✏️ Technotext 2022

Hello everyone! Filament prices have not been encouraging at all lately. Also a feature of 3D printing is the fact that some parts have to be reprinted several times to achieve the desired results. The process of developing and printing a part is sometimes quite iterative and meditative)). What if you had unlimited plastic? A kind of "super ability" - a human filament? Would it help you in your 3D craft? nine0003

I present to your attention a compact filament extruder from PET bottles!

Read more

Total votes 87: ↑84 and ↓3 +81

Views21K

Comments 33

Bright_Translate

Company Blog RUVDS. com Arduino Development Rocket modellers often want their creations to perform at their best in a certain category of competition, whether it's egg lifting (when you need to design a rocket that can lift a raw chicken egg to its maximum height and return it intact), duration flights (when the rocket must stay in the air as long as possible) or to the maximum height. nine0003

com Arduino Development Rocket modellers often want their creations to perform at their best in a certain category of competition, whether it's egg lifting (when you need to design a rocket that can lift a raw chicken egg to its maximum height and return it intact), duration flights (when the rocket must stay in the air as long as possible) or to the maximum height. nine0003

Thinking about what kind of new project to pursue, and having a craving for 3D printing, CAD modeling and physics, I decided to design a rocket to reach the maximum height due to the capabilities of the D-class engine. The aim of this project was to evaluate the practical effectiveness of 3D printing in rocket modeling compared to existing model making techniques.

Read more →

Total votes 44: ↑42 and ↓2 +40

Views9.3K

Comments 17 nine0003 Bright_Translate

RUVDS.com Blog The goal of this project was to turn the head massager into an automated device that would massage me by itself. The original idea was to simply use a linear actuator or a single stepper motor with a threaded stud to implement the up/down movement. However, I got carried away, and I decided to make the device move in all directions, for which the Hugh-Stewart platform was chosen, providing 6 degrees of freedom. nine0003

- Isn't that too tricky? Yes!

- Was it expensive? Yes!

- Am I crazy? Yes!

All software and hardware files are available on GitHub

Read more →

Total votes 53: ↑53 and ↓0 +53

Views5.6K

Comments 12

DAN_SEA

RUVDS. com blog0003

com blog0003

image macrovector, freepik

Every hunter wants to know where the pheasant sits every 3D printer owner wants to know how to jack up his printing table. This is what the story will be about below.

Read more →

Total votes 47: ↑44 and ↓3 +41

Views6.7K

Comments 35

additive_rocket_science

Robotics Astronautics 3D printers Chemistry The future is here

And again, video first.

This video shows the Rocket Factory In-a-Box (RFIB) concept from the Air Force Research Laboratory (AFRL) in the USA. A small-sized mobile plant for the production of customized solid rockets in the form factor of a cargo container will allow rockets to be launched anytime and anywhere (Fig. 1). A network of hidden autonomous missile plants (ARZ) will ensure the continuity of high-precision fire impact on demand (an on-demand service for the military), allowing you to get away from dependence on two or three industrial centers for the production of missile weapons that are vulnerable and transparent for intelligence with inflexible logistics of bulky cargo to rapid prototyping and production of missile weapons directly on the front line with flexible logistics, bulk raw materials for which are transported by small-sized highly mobile hidden vehicles. nine0003

1). A network of hidden autonomous missile plants (ARZ) will ensure the continuity of high-precision fire impact on demand (an on-demand service for the military), allowing you to get away from dependence on two or three industrial centers for the production of missile weapons that are vulnerable and transparent for intelligence with inflexible logistics of bulky cargo to rapid prototyping and production of missile weapons directly on the front line with flexible logistics, bulk raw materials for which are transported by small-sized highly mobile hidden vehicles. nine0003

Straight "Supreme Commander" at maximum speed - this is how the Americans are going to fight in the

twenty-first century.

Read more

Total votes 15: ↑12 and ↓3 +9

Views6.1K

Comments 84

5-55

. NET *C# *Soft 3D printers from different manufacturers and is useful for people using/testing a large number of filaments. nine0003

NET *C# *Soft 3D printers from different manufacturers and is useful for people using/testing a large number of filaments. nine0003

Ask

Total votes 6: ↑5 and ↓1 +4

Views1.8K

Comments 12

additive_rocket_science

Robotics Astronautics 3D printers Chemistry The future is here

From the sandbox

3D printing of mixed propellant - we did it. After a hundred experiments, several waves of despair and stages of acceptance of the inevitable. Made and patented. nine0003

The developed technology for the additive production of solid propellant charges (SFC) from mixed propellant fuel (SRT) for a solid propellant rocket engine (SRM) using the FDM printing method includes: a special SPT composition with the required energy and operational parameters, the layer-by-layer synthesis 3D printer itself for printing rocket fuel; and several related technologies.