Anycubic photon sla 3d printer

Anycubic Photon Series LCD-Based SLA Resin 3D Printers – ANYCUBIC 3D Printing

Anycubic Photon Series LCD-Based SLA Resin 3D Printers – ANYCUBIC 3D Printing Skip to contentSort SortFeaturedBest sellingAlphabetically, A-ZAlphabetically, Z-APrice, low to highPrice, high to lowDate, old to newDate, new to old

- Anycubic Photon M3 Series

- Anycubic Photon Series🆕

- Anycubic DLP Series🆕

- Anycubic Wash & Cure Station

- Anycubic AirPure

Quick view

Anycubic Photon M3 Premium

ANYCUBIC

from $639.00

Save $100

Quick view

Anycubic Photon Mono 4K

ANYCUBIC

Regular price $289.00 Sale price from $189.00

Save $230

Quick view

Anycubic Photon Mono X

ANYCUBIC

Regular price $529. 00 Sale price from $299.00

Save $100

Quick view

Anycubic Photon Mono X2

ANYCUBIC

Regular price $429.00 Sale price from $329.00

Save $280

Quick view

Anycubic Photon Mono X 6K

ANYCUBIC

Regular price $689.00 Sale price from $409.00

Save $60

Quick view

Anycubic Photon M3

ANYCUBIC

Regular price $299.00 Sale price from $239.00

Save $140

Quick view

Anycubic Photon M3 Max

ANYCUBIC

Regular price $1,099.00 Sale price from $959.00

Save $260

Quick view

Anycubic Photon M3 Plus

ANYCUBIC

Regular price $699.00 Sale price from $439.00

Save $80

Quick view

Anycubic Photon D2

ANYCUBIC

Regular price $679. 00 Sale price from $599.00

00 Sale price from $599.00

Save $20

Quick view

Wash & Cure Machine 2.0

ANYCUBIC

Regular price $149.00 Sale price from $129.00

Save $30

Quick view

Anycubic Wash & Cure Plus Machine

ANYCUBIC

Regular price $249.00 Sale price from $219.00

Sold Out

Quick view

Anycubic Photon Mono SE

ANYCUBIC

$419.00

Save $310

Quick view

Anycubic Photon Ultra

ANYCUBIC

Regular price $599.00 Sale price from $289.00

Sold Out

Quick view

Limited Edition Photon Mono X 6K

ANYCUBIC

Regular price $659.00 Sale price $429.00

Sold Out

Quick view

Anycubic Photon Mono

ANYCUBIC

$269. 00

00

Sold Out

Quick view

Anycubic Photon Mono SQ

ANYCUBIC

$169.00

Sold Out

Quick view

Wash & Cure Machine

ANYCUBIC

$219.00

Sold Out

Quick view

Anycubic Photon

ANYCUBIC

from $279.00

Sold Out

Quick view

Anycubic Photon S

ANYCUBIC

$379.00

Anycubic Photon - LCD/DLP/SLA 3D Printer

The colorful touch screen equipped with Photon system and bring new functions. You could pre-view the model in SD card just like you saw pictures in Windows OS. Real-time display printing process function is available now. 2560*1440(2k)HD LCD make the details down to few micrometers.

- Touch Screen

- Easy manipulation, real-time previews of printing status.

- Unique Resin Vat

- Easily adjust and replace the FEP film to save your cost of use.

- Off-line Print

- the Photon supports offline print with built-in operational system, improve print stability.

- Easy Leveling

- 3-step Leveling.

- Technical Specifications

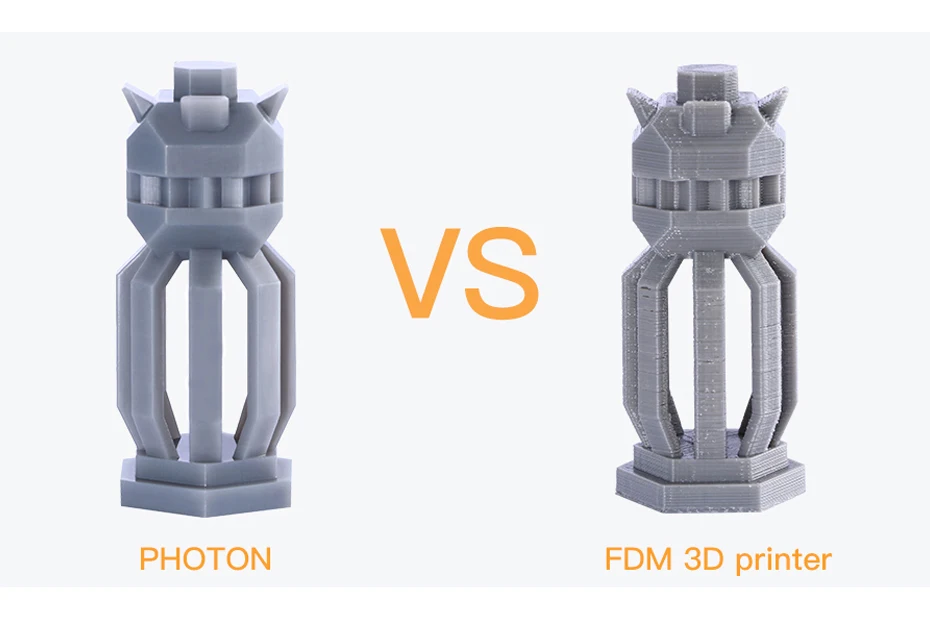

- ● Printing Technology: LCD-based SLA 3D Printer

- ● Light-source : UV integrated light(wavelength 405nm)

- ● XY DPI : 47um (2560*1440)

- ● Y axis resolution : 1.25um

- ● Layer resolution : 25 ~ 100um

- ● Printing speed : 20mm/h

- ● Rated Power : 40W

- ● Printer size: 220mm*200mm*400mm

- ● Printing volume : 115mm *65mm *155mm (4.52″*2.56″*6.1″)

- ● Printing material : 405nm photosensitive resin

- ● Connectivity :USB

- ● Package Weight: 6.6kg

- 2k LCD Screen

- 2560*1440 HD LCD, printing details down to few micrometers.

- Quick Slicing

- Self-developed slicer software, quick to slice and easy to use.

- Easy Leveling

- Lower the platform down to the screen; Feel the resistance when pulling the paper in-between; Tighten one screw; Leveling done.

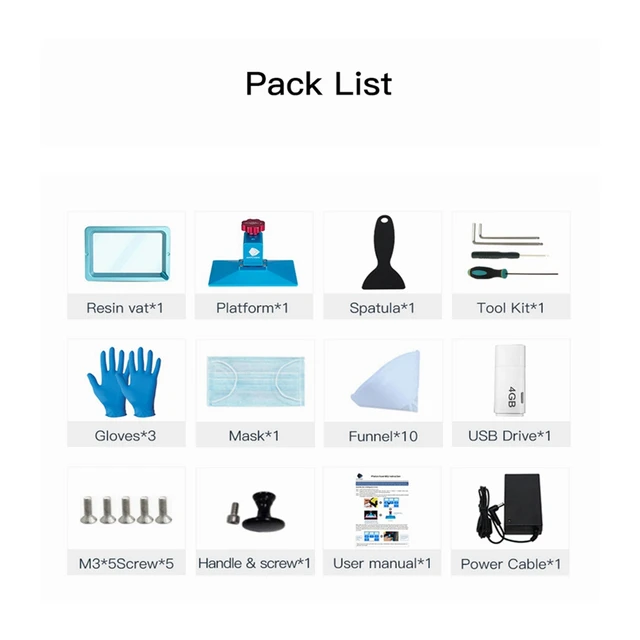

Package List

Srews(M5)*5

Scraper

Tool set

USB Drive

Glove

Resin Vat

User manual

Funnel

Power cord

|

|

| |

| Printing Technology | LCD-based SLA Printing | LCD-based SLA Printing | FDM (Fused Deposition Modeling) |

| XY Resolution | 3840*2400 px | 5760*3600 px | None |

| Build Volume | 132mm*80mm*165mm | 197mm*122mm*245mm | 245*245*260mm |

Max. Printing Speed Printing Speed | 50mm/h | 80mm/h | 100mm/s |

| Print Materials | 405nm UV Resin | 405nm UV Resin | PLA, ABS, PETG, Wood |

| Z axis Accuracy | 0.01mm | 0.01mm | 0.002mm |

-

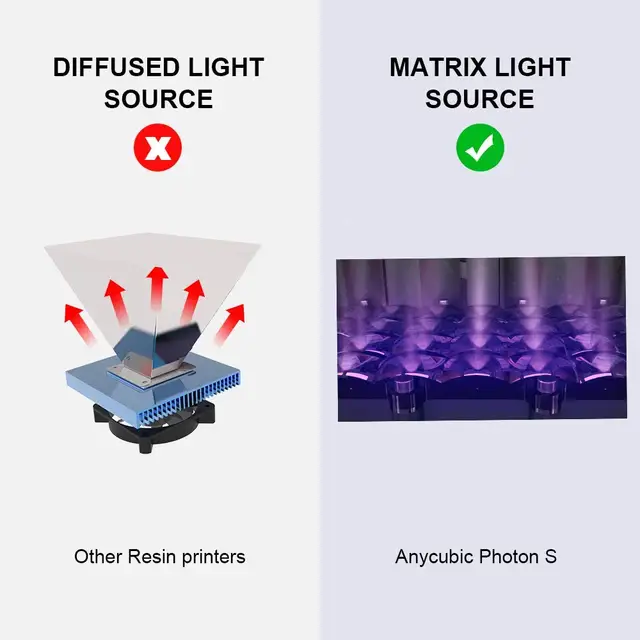

- Photon

- LCD-based SLA

- Build Area: 115x65x155mm

- Filament:405nm UV Resin

- Diffusion Illuminant

- Single Z-axis

-

- Photon S

- LCD-based SLA

- Build Area: 115x65x165mm

- Filament:405nm UV Resin

- Matrix Illuminant

- Double Z-axis

-

- 4Max Pro

- FDM (Fused Deposition Modeling)

- Build Area: 270x205x205mm

- Filament: PLA, ABS, HIPS, PETG,

Wood and TPU - Titan Extruder

Suspended Filament Rack - Single Z-axis

Anycubic Care

Firmware

1. V5.0.2 [ChangeLog]

V5.0.2 [ChangeLog]

(Photon Upgraded Only)

2. V4.2.19

Driver

/

Slicer

V2.1.26-Mac

V2.1.26-Win X86

V2.1.26-Win X64

Manual

Test model

1. Test_model_1

2. Test_model_2

Manual

1. Photon_Manual_en

please click on it to download.

Service

We offer excellent after-sales service. Please click here for details.

We use Cura for printing on SLA Photon

3D printing

duplicate...

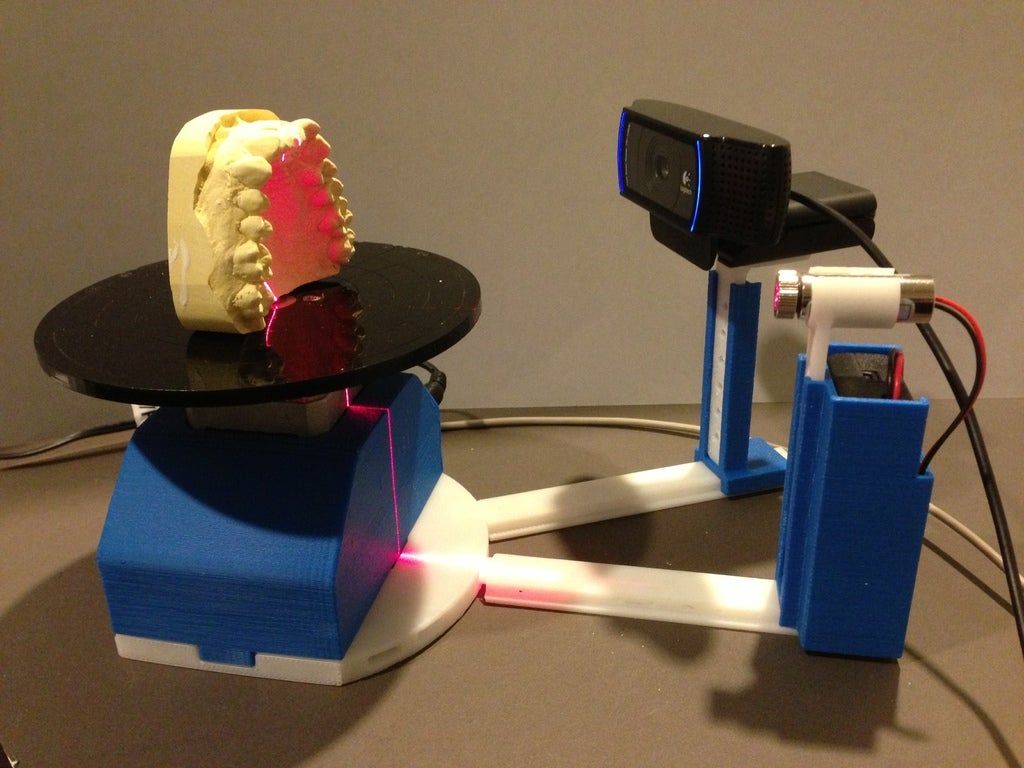

As it happens, I decided to study new 3D printing technologies and bought a Photon 3D SLA printer, but its software, namely the slicer (AnyCubic Photon Slicer), leaves much to be desired, it is very weak (in my opinion, in principle, and others, in principle, have not gone far, but the best of them now is CHITUBOX, at the time of this writing, I did not feel it). There is no fill control, supports are poorly managed, etc... In general, I decided to bypass this matter using Cura, I just decided that it might work and I could use it. .. I searched the web for a description of the Photon format, it turned out to be quite simple. .. While I was looking for information on it, I thought about creating all the controls from scratch, but then I found the Photon File Editor project, which already implements a lot ... And I decided that I would just create a converter with gcode into a set of images that can then be used by this project ... And this is what came out of it:

.. I searched the web for a description of the Photon format, it turned out to be quite simple. .. While I was looking for information on it, I thought about creating all the controls from scratch, but then I found the Photon File Editor project, which already implements a lot ... And I decided that I would just create a converter with gcode into a set of images that can then be used by this project ... And this is what came out of it:

Understanding gcode quickly drew a program that implements this business, printed a couple of models everything is OK, and I decided that this study and tests can help someone and decided to share with you the result of my work

And so the slices are generated based on gCode and write your own files (an example of a cut below):

final model enlarged by 70% with 5% Cura infill and dimensions x=4.93cm y=7.6cm z=12.41cm weighs only 51g. In total, we get that the size is 70% larger, but the weight is only 19%. It seems even a little nice :D

The final printing took place with the settings of 1 sec screen off and 7 sec illumination:

Photos of the final print:

Model with full (100%) filling and dimensions: x=2. 9cm y=4.5cm z =7.3cm weight 43g

9cm y=4.5cm z =7.3cm weight 43g

Model with 5% chicken filling and dimensions x=4.93cm y=7.6cm z=12.41cm weight 51g

the internal grid of filling will be noticeable:

Final result:

- Using a familiar slicer including using their extensive features.

- Reduce model weight and save resin.

Of the minuses:

- Long time to form a photon file.

- More time is needed for the final "drying" under UV light to dry the insides, which may and most likely will remain a slight resin residue.

So how to do it:

Step #1. Initially, you need to create a new printer with the following parameters:

Step #2. Then specify layer height Z=0.05 and wall thickness=0.047:

Step #2.1. Cut into layers, we will see something like this:

You can make sure that everything is cut correctly and the filling is correct:

Step #3. Run the script by giving it gcode

Run the script by giving it gcode

Step #3.1. If everything is good, you can see the work process:

Step #3.2. All layers will be saved to their own files /layers/layer_xxxxxx.png

Step #4. Run [Photon File Editort](https://github.com/Photonsters/PhotonFileEditor/) and create a new file:

Step #5. In the editing menu "Edit" choose to import images "Import bitmaps":

Step #6. Select the directory in which the files with the image of the layers are located:

Step №7. Enjoy the work done and apply your settings

If you don’t want to change it every time, you can fix the file with presets located in the PhotonFileEditor/resources/resins.txt directory

All the developments are on the github (link)

I myself use GNU / Linux, so if you need For more detailed information on running under Windows, I can describe this case, in the future I plan to file a self-sufficient plugin for Cura;)

models SLA seal Cura anycubic Photon

Subscribe author

Subscribe

Don't want

12

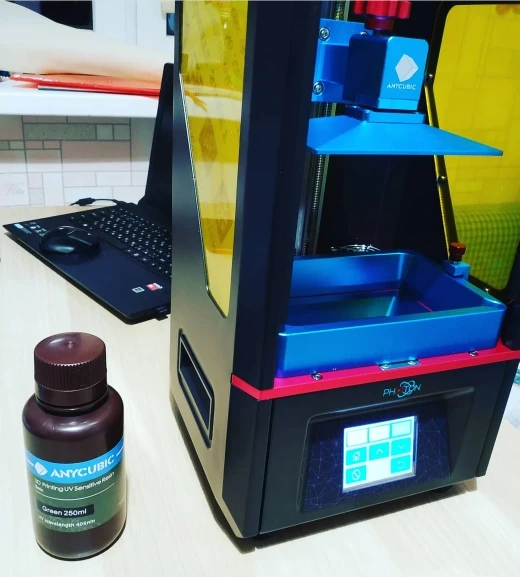

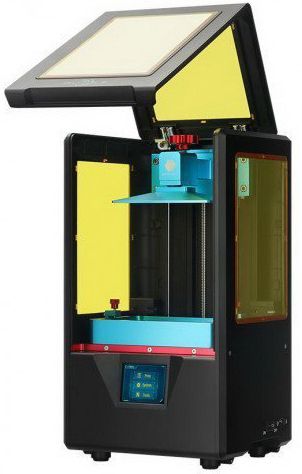

Anycubic Photon Zero 3D SLA printer

My boss has a wonderful tradition to replenish my bins with some interesting toy at Christmas time. Thus, they formed CNC 3040, CO2 laser cutter and much more, less interesting to the general public. This year it was the turn of the SLA printer. Moreover, the prices for them have come to a reasonable bar - there is nothing special to cost in them. 405nm LED backlight - someone will again say that this is not yet ultraviolet, but for some reason they are all called ultraviolet. Between the backlight and the bath with a bottom made of FEP (Fluorinated ethylene propylene) film, there is, in fact, an ordinary LCD. Its effectiveness, to put it mildly, is not very good - color filters do not particularly transmit ultraviolet light. But it's cheap and practical. And working. Well, a lift with a stepper motor - everything is much simpler than with a conventional FDM printer. nine0121 FSC LCD without any filters would really fit here - but something didn’t grow together with marketing and they didn’t go into mass production.

Thus, they formed CNC 3040, CO2 laser cutter and much more, less interesting to the general public. This year it was the turn of the SLA printer. Moreover, the prices for them have come to a reasonable bar - there is nothing special to cost in them. 405nm LED backlight - someone will again say that this is not yet ultraviolet, but for some reason they are all called ultraviolet. Between the backlight and the bath with a bottom made of FEP (Fluorinated ethylene propylene) film, there is, in fact, an ordinary LCD. Its effectiveness, to put it mildly, is not very good - color filters do not particularly transmit ultraviolet light. But it's cheap and practical. And working. Well, a lift with a stepper motor - everything is much simpler than with a conventional FDM printer. nine0121 FSC LCD without any filters would really fit here - but something didn’t grow together with marketing and they didn’t go into mass production.

So, the hero of the day is the Anycubic Photon Zero photopolymer printer with delivery from Germany for less than 100 euros in the amount of

The polymer resin for it is about 30 euros / liter including shipping

By the way, not at all fragile, as often people complains about resin.

Working area 97mm(L) *54mm(W) *150mm(H), resolution 854x480 (480P), pixel size 0.1155mm, which corresponds to 220 dpi - not a lot - but the price! nine0121 Prints the printer from a USB flash drive. But here be careful - the printer is not omnivorous, it did not recognize my old flash drive.

Sorry, there will be no detailed description of the packing box and the process of pulling them out - there are more interesting things.

On the attached flash drive documentation and software. The documentation is very decent - no reviews are required, everything is perfectly described and with pictures.

The printer itself is a match - you turn it on and it works. The tambourine remains idle. Even boring. nine0121 The software, judging by the description, is very good, but only for Windows and Mac. Easy to put under Linux, it refused. I had to download Lychee Slicer - it works on both systems and on MAC OS to boot.

For test printing, I wanted to find a more or less decent and complex figure, but without supports. And she was found - a hooligan girl.

It is better to print not at home - the smell is far from violet. He is far from burning Plexiglas under the laser, but still. nine0121

If you are making an “empty” figurine, do not forget to provide holes so that air can get inside, otherwise the liquid resin will remain inside.

The easiest way to separate the figurine from the aluminum sole is with a cold spray - due to the difference in temperature expansion, the figurine will easily fall off.

Now everything is ready, but I would need to go to the solarium for the final curing of the resin.

Another figurine of a different color and 2 times bigger:

Further photos under the microscope:

After playing around, we will make something not so beautiful looking, but more useful - a holder for a roller pogo pin.

Keep in mind - resin, bath bottom film and LCD are consumables. With resin - and it’s a no brainer why, sooner or later the film will be scratched, darkened or torn, and for some reason LCDs with ultraviolet backlight do not last long.

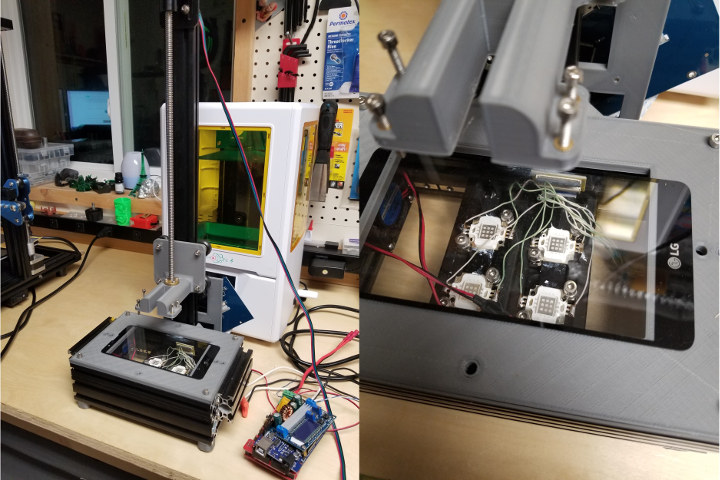

In my article about a laser exposurer, someone was wondering if such a printer could be used to make printed circuit boards. Theoretically - it is possible, practically - problems with the software. Despite YouTube videos and short articles, I was unable to get the printer to output the PCB drawing. I had to make the software myself. The main problem is the lack of a description of the file format for the printer. Each manufacturer both wants and wets. Even from the same manufacturer, the file formats of different printers are different. On the Internet there was some description from one old printer from Anycubic. nine0121 Most of the fields matched, there were errors in the description and an apparently misleading description of the packaging of the layer files.

On the Internet there was some description from one old printer from Anycubic. nine0121 Most of the fields matched, there were errors in the description and an apparently misleading description of the packaging of the layer files.

I had to write a program that parses the format. All fields, in principle, were the same. Variable types are incorrect in some places.

Open file 'CheekyMonkey.pw0'. ANYCUBIC version=1 area=4 header_addr=48 back0=0 preview_addr=144 back1=0 layer_def_addr=75436 back2=0 layer_image_addr=107456 ======================== HEADER ======================== ========= HEADER header_len=80 xyPixel=115.5um Zthickness=0.05000000074505806um NorTime=8.0sec OffTime=1.0sec bottTime=60.0sec bottLayers=3.0 ZUpHeight=6.0 mm ZUpSpeed=3.0 mm/sec ZDownSpeed=3.0 mm/sec Volume=11.491562843322754 mm2 antiCount=16 ResX=480 ResY=854 Weight=11.491562843322754g Price=11.491562843322754 Resin=0 Individual=0 ======================== PREVIEW ========================= ========= PREVIEW PreviewLen=75276 Width=224 * Height=168 ======================= LAYERS ========================= ========= LAYERDEF LayersDefLen=32004 LayersDefLen=1000 layer=0 addr=107456 length=3432 height=6.0 speed=3.0 time=60.0 b0=0x3d4ccccd b1=0x0 b2=0x0 done nine0176

There is no description of the preview format at all, except for the file size. But everything turned out to be simple - there is a usual 16-bit RGB format like BMP with cunningly mixed colors.

Well, okay - the preview does not affect the print.

It turned out to be worse with packing pictures of layers. Something there is clearly from the Sinclair packer.

I meditated on these files for several hours. Then I realized that one format was used for packing black and white fields, and another for grayscale. nine0121

TA-dah! — and the image is unpacked!

Now the inverse task is to pack the PCB drawing into a print file.

Let's convert the picture into a two-color bmp file - my Python software converter is homely simple, not a bit user friendly - it does not recognize other formats.

The graphical interface is missing as a class.However, there are also no classes and the program is as simple as soap.

There is actually a problem with getting the file - all converters arrange torn edges - when the resolution is high - this can be neglected. We have no permission - so this is a big problem. nine0121

If someone tells me how to solve it, my gratitude will have no limits within reasonable limits :)

Next, we roll a piece of photoresist onto the fiberglass, which has lain for three years - we don’t feel sorry for him.

We exhibit for 15 minutes - judging by the type of board, this is not enough. But I don't want to redo it.

We process it in a solution of soda ash and observe this disgrace:

In the dry end - the resolution of this printer can only be enough for microcircuits with a pitch of 1.27 mm at best. Theoretically, 0.8 mm should also be obtained, but here you need to strain and choose the right shutter speed and somehow make the original bmp file without pixel jagged edges.