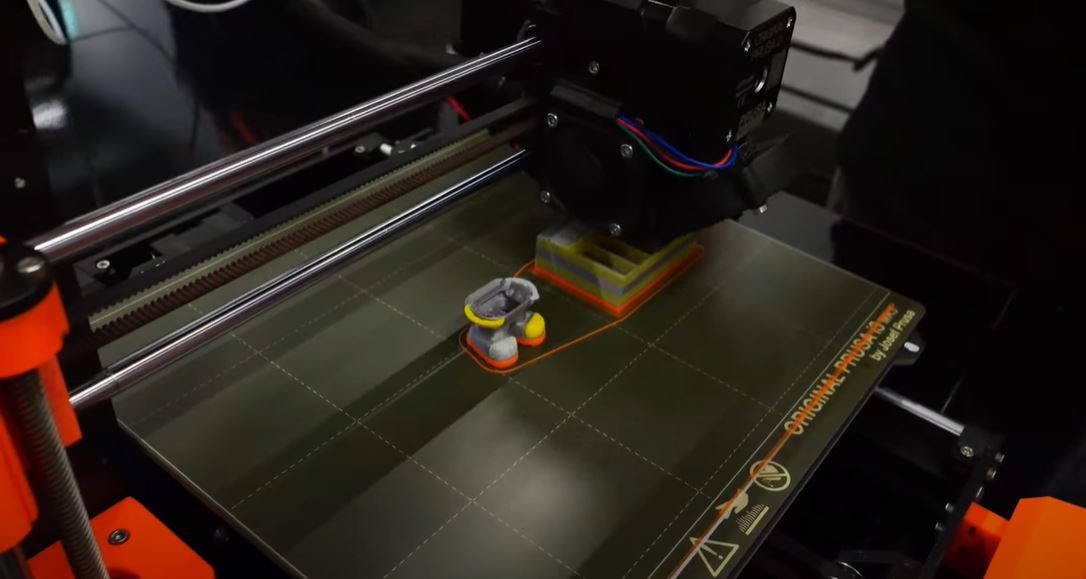

2023 3d printing trends

5 important trends for industrial 3D printing in 2023

With the year 2022 coming to conclusion, we turn towards what 2023 has in store for industrial 3D printing. We’ve broken down the five most important trends in the development of the additive manufacturing industry that will help to scale production.

It has been a challenging three years for manufacturing industries worldwide, and it looks set to continue into 2023 with uncertainty over fuel and production costs and the continuing war in Ukraine. Despite these challenges, Additive Manufacturing (AM) has played a vital role in helping manufacturers overcome supply chain disruption while also enabling them to produce final products that are stronger, lighter, and redesigned to contain fewer parts.

The industrial 3D printing market has been seeing strong growth, which is expected to continue according to CONTEXT, which predicted in its Q1 2022 Additive Manufacturing and 3D Printing Report that 3D printing materials, hardware, and services sales combined will rise from $12 billion in 2021 to an estimated $38 billion by 2026. These are incredible figures, but the market is developing in other ways as confidence increases around Additive Manufacturing and associated digital manufacturing technologies. Here is our take on the trends for 2023 and beyond.

The Additive Manufacturing world still falls into two groups: Advanced users who are invested in 3D printing technologies and want increased reliability and performance from their printers. And exploratory users that can see the value of Additive Manufacturing but need support on how to deploy it and overcome their manufacturing status quo.

Additive Manufacturing will continue to build industrial acceptance, and therefore competitive business opportunities will accelerate across large and small manufacturers. The advantages of Additive Manufacturing, being promised and realized for years in smaller manufacturers, will start to be discovered on a larger industrial scale. Training and upskilling will be a core component of this. We expect to see continued growth in demand for online and virtual training and education and requests to visit our digital manufacturing facilities, where customers can experience how a full-scale digital manufacturing production line can operate.

We expect to see continued growth in demand for online and virtual training and education and requests to visit our digital manufacturing facilities, where customers can experience how a full-scale digital manufacturing production line can operate.

The Additive Manufacturing industry is moving to better remote training, but we have seen demand continuously rise for visits to our facilities, too. Production organizations of all sizes now see Additive Manufacturing as an integral part of their factories and not just a rapid prototyping capability in the corner of the factory.

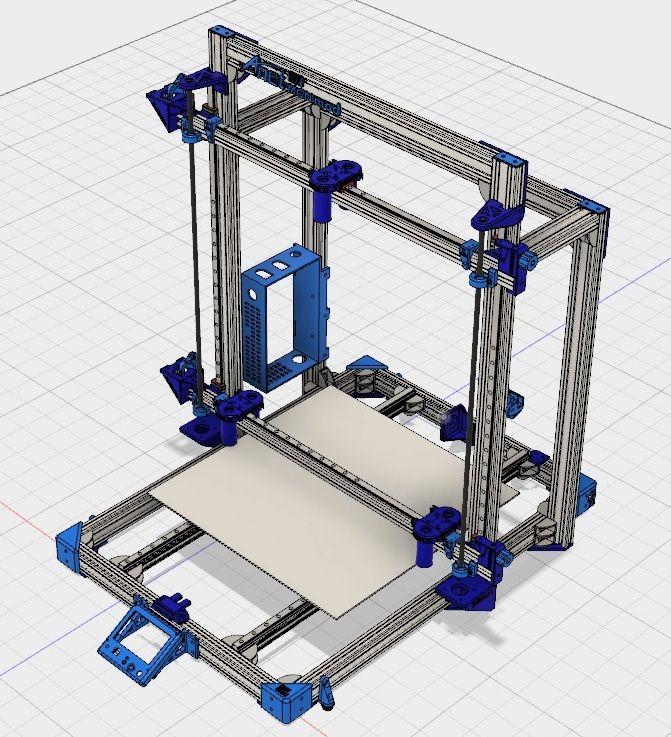

A trend that will start to gain further traction is that factory concepts are application-driven. This will require the optimization of the industrial 3D printers, periphery, and post-processing to maximize throughput and minimize cost. Optimizing an Additive Manufacturing production line can move a business case from an unviable to a viable scenario or increase the potential for profit and design innovation. This will mean a change for many manufacturers, as only some 3D printing application combinations would have the same optimized solution.

This will mean a change for many manufacturers, as only some 3D printing application combinations would have the same optimized solution.

Today EOS is helping customers design their future factory concepts to ensure they can exceed the expectations they had with traditional manufacturing solutions. Reliable, repeatable, and transferable industrial 3D printing equipment is vital to enable plug-and-play scalability in future factories.

With Additive Manufacturing, manufacturers are now connecting the physical supply chain with a digital thread that allows them to manage products more efficiently from concept to end-of-life. Manufacturing can be distributed across any location with a digital manufacturing system in place, simply by sending a file. This decentralization enables a more collaborative, transparent and efficient supply chain, as was highlighted by the role of Additive Manufacturing during the Covid-19 pandemic in overcoming supply chain challenges.

If a disaster hits, natural or man-made, industrial 3D printing will be able to right itself and move forward much more quickly than traditional manufacturing by transferring manufacturing to another site with the same equipment.

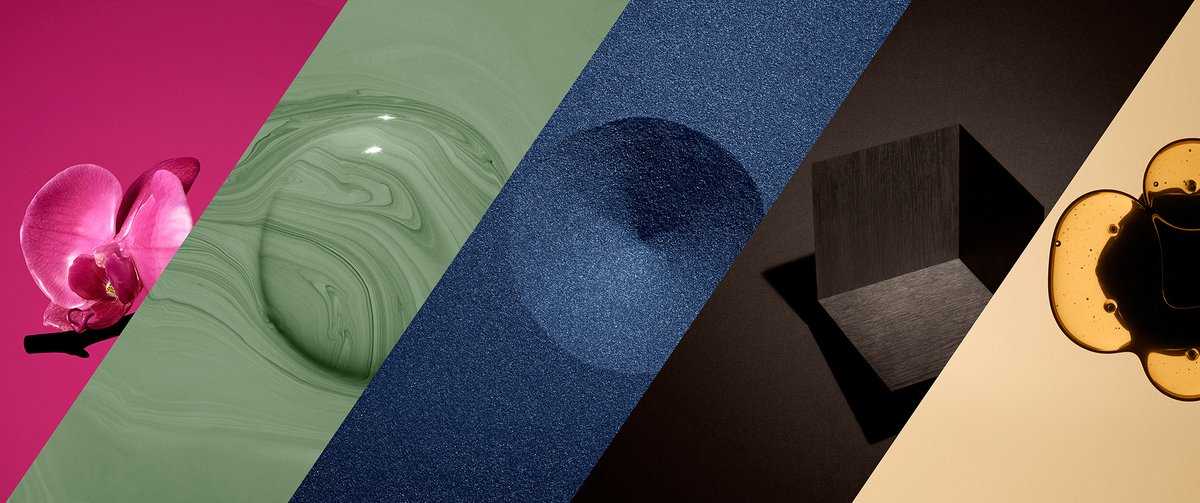

Going forward, we will continue to see an actual acceleration of the synergy between material science, manufacturing, and technology – unlocking innovation opportunities that have not been conceived before. While substantial investments in all parts of the Additive Manufacturing ecosystem are fueling growth, it would be hard to overstate the significance of 3D printing materials.

We will start to see the availability of hybrid 3D printing materials, uniquely engineered and application-specific, to meet the needs of different challenges that each industry faces. Material characteristics such as ductility and tensile strength can be modified by adjusting process parameters at different points in the additive build process.

Hybrid materials will transform a new generation of applications, especially in heavily regulated industries such as medical and aerospace.

Environmental sustainability has been an important trend for several years as manufacturers and brands move to lessen their impact on our world. There has been lots of action on lowering energy consumption, reducing waste in manufacturing, and steadily removing non-recyclable materials from products and packaging. End customers are now starting to demand evidence of sustainability credentials of the products and services they buy.

People want to lead more sustainable lives, and new industries such as renewable energy, electromobility, and changes in the lifestyle sector, mean that sustainability is undoubtedly here to stay, and manufacturers are realizing this.

For the Additive Manufacturing industry, we will see continued innovations throughout 2023 to support this trend. While Additive Manufacturing is more sustainable than traditional manufacturing by definition, we’ll also see more manufacturers using the data machines produce on the manufacturing workflows and processes to help them evidence the efficiency of their manufacturing processes for customers.

EOS and other manufacturers are constantly working to make 3D printers and materials more energy efficient and sustainable, supporting the circular economy model with improved recyclability and biodegradability.

Like many other sectors, global manufacturing is being substantially affected by events on the world stage. It is hard to predict how it will fare in 2023, but every time the industry has faced challenges, it has shown how tenacious and innovative it can weather the storm. Additive Manufacturing has proved itself in recent years to give manufacturers and supply chains a vast amount of flexibility and is set to become the dominant manufacturing technique.

back to blog articles

-- loading ... --

Be inpired. Stay up to date.

Join our Monthly Newsletter Now!

Look for Major Advances in 3DP During 2023

Image courtesy of Alamy

Here are the trends in additive manufacturing that will have a profound impact in 2023.

Rob Spiegel | Dec 06, 2022

Watch This Webinar

We’re seeing several additive manufacturing trends that will become major factors in 2023. These trends have been growing during the last few years. What we’ll see in 2023 is the maturity of the technology. We’ll see 3D printing take a permanent place in the choices of production methods. 3D printing companies continue to experiment with methods and materials, but the core technology has achieved acceptance in mainstream manufacturing. We’ll see the implications of this play out again and again in the coming year.

The Many Faces of Sustainability

One advantage of 3D printing is its eco-friendliness. That's apparent in designs, prototypes, tools, molds, and final products. There is less waste, and the processing method requires less energy. Much of the waste can be instantly recycled. Products can be designed with less material. Items can be lightweighted, thus providing energy savings during the product's lifecycle. Whole assemblies can be printed, reducing the need for printing multiple individual parts.

Whole assemblies can be printed, reducing the need for printing multiple individual parts.

An engine part prototype requires far less material to 3D print than to machine from a block of metal. A plastic prototype can be 3D printed as one part instead of injection molded from three separate molds and then assembled.

Autodesk has put together a sustainability site that includes a database of materials, manufacturing methods, and other elements of product design and manufacturing to help with additive manufacturing sustainability. The site uses data to analyze the sustainability of a product design. The site can also recommend alternatives to increase a product’s sustainability without diminishing quality.

Advances in 3DP for Medical

University and corporate research departments are developing 3D printing techniques for human tissue. As an example, the 3D Printing and Imaging Laboratory at the University of Minnesota – a collaborative research group within the university's Department of Radiation Oncology – has brought together specialists across multiple disciplines including medical physics, clinical radiation oncology, and veterinary medicine.

The group is using advanced imaging, computational modeling, and artificial intelligence to 3D print human tissue. They are using stem cells from the patient to 3D print skin patches. Their first aim for a complete internal organ will be a human kidney. They are also using advanced technology to improve the effectiveness of cancer therapies.

Additive Manufacturing Automation

While 3D printing automates part development, manufacturers utilize digital workflows and automation systems to further streamline additive manufacturing lines. Automated part processing eliminates manual intervention after component production, increasing production throughput.

Many startups are offering printer-agnostic design and processing software and hardware solutions that automate additive manufacturing processes. They enable high-speed part development, on-demand manufacturing, and rapid prototyping while enhancing print flexibility and minimizing waste. Further, automated 3D printing lines reduce labor costs and eliminate manual errors.

Novel Materials

Investments in additive manufacturing materials are fueling growth in additive manufacturing possibilities. According to Jabil, “You can’t overstate the significance of new materials. Outside of the high cost of the equipment, the next big barrier is materials and closed additive manufacturing ecosystems, which have stymied the 3D printing industry’s growth. Numerous types of 3D printing materials are on the market today, but few are advanced enough to meet the quality or regulatory requirements of industries.”

Feedstock material and binder properties are significantly impacting the mechanical properties of the printed product. Startups are developing novel materials to apply additive manufacturing in various use cases. Moreover, smart materials, ceramics, electronics, biomaterials, and composites find use in developing components with advanced properties. They enable 3D printing of unconventional products like medical devices, consumer electronics, and bioartificial organs. Further, startups are extracting high-value 3D printable materials from waste streams to reduce virgin material requirements and emissions.

Further, startups are extracting high-value 3D printable materials from waste streams to reduce virgin material requirements and emissions.

Rapid Prototyping to Production

Additive manufacturing has come of age as a dependable and efficient form of manufacturing. As major companies in aerospace, automotive, and medical adopt additive manufacturing as part of everyday manufacturing, the technology has earned a permanent – not experimental – place among production choices.

3D printing use for jigs, fixtures and tooling, bridge production, and production parts has grown remarkably over the last few years. In that time, the heavy equipment and industrial machines industries have seen the highest adoption of use cases for jigs, fixtures, and tooling; healthcare has been the biggest adopter of bridge production, and the orthopedics and industrial machines industries have seen the highest adoption rates in using 3D printing for production parts.

Making the Supply Chain More Resilient

The pandemic revealed weakness in the supply chain. While some of those problems have cleared, weakness still persists and will continue for some time. Additive manufacturing came to the rescue during worldwide shortages of PPE and ventilators. The technology will continue to be called upon to bridge supply chain disruptions.

While some of those problems have cleared, weakness still persists and will continue for some time. Additive manufacturing came to the rescue during worldwide shortages of PPE and ventilators. The technology will continue to be called upon to bridge supply chain disruptions.

Jabil noted that supply chain management has focused on cost and efficiencies at the expense of resiliency. It’s no wonder that many supply chains failed when faced with disruption as big as the pandemic—COVID-19's supply chain impact was felt across every industry, but especially in healthcare and medical devices. Now, building supply chain resilience is a key objective across industries.

TAGS: 3D Printing Materials 3D Printing Processes Additive Manufacturing

Happy new year 2023 STL file・Model for download and 3D printing・Cults

Best 3D Printer Files in the Miscellaneous Category

Daffy Duck

Free

Femur Bone with Stand

Free

Morgan 3 Wheeler - 1/24 scale kit

18. 80 €

80 €

HUBBLE space telescope

4 €

Darth Vader HQ The Empire Strikes Back 1-3 SCALE 70cm 3D print

22 €

Ripsaw 1/32 by WID

5.06 €

Foldable FFP or N95 mask case

Free

Bestsellers in Miscellaneous category

Mounts for shock absorbers and trx4m escalators

1.90 €

MMPR Dragon Dagger

4.74 €

Charizard - pokemon with flexible articulation (seal in place, without supports)

3 €

Wednesday Addams, The Thing, The Thing

5 €

Articulated Gyarados

1. 99 €

99 €

CHRISTMAS TREE v2

1,50 €

Bunch of Christmas balls ItsLitho

5,70 €

Eeveelution articulated mega pack

10 €

Articulated Raykuase Flexible Dragon Pokémon

1 €

hinged shenron

3 €

5 gnomes (without support)

2.49 €

Mickey Christmas night light Litophane

3,50 €

THING-ENVIRONMENT-COMPANY-HD-PRINT

1,30 €

flexible volute

2 €

4th planet Fighting pre-Olympic god

12 €

TING Addams

8. 53 €

53 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us at maintaining the activities of and creating future developments of is very simple. Here are 4 solutions available to everyone:

-

ADVERTISING: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here. nine0006

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

3D printing trends that could increase profits in 2022

By TY Yap / July 12, 2022 December 20, 2022 / 5 min read / 3d printers, Market trends, New arrivals, Printers, Printer

3D printing is becoming popular these days because it takes the printing process to the next level. It has become an integral part of many industries and is loved by designers for the value it provides as an efficient way to prototype new products. Given the growing popularity of 3D printing, this article will highlight industry trends that will increase profits in 2022. nine0006

It has become an integral part of many industries and is loved by designers for the value it provides as an efficient way to prototype new products. Given the growing popularity of 3D printing, this article will highlight industry trends that will increase profits in 2022. nine0006

Content

3D Printing Market Potential

Popular 3D Printed Items in 2022

Bottom Line

3D Printing Market Potential

is expected to grow at a compound annual growth rate (CAGR) of 22.1% between 2021 and 2030. In addition to these optimistic trends, specialist firms in the industry have also predicted a CAGR of 27% for the 3D printing market, reaching a market turnover of $115 billion by 2030. nine0006

This rapid growth is mainly due to the increased use of 3D printing in prototyping, tooling and design in the manufacturing and industrial fields. This is due to the growing demand and more flexible features offered by various modern 3D printers.

In addition, the expansion of 3D printing applications in many other areas such as healthcare, consumer products and education is likely to become an even bigger driver for the 3D printing industry. And as 3D printers become more affordable and widely available, their use is no longer limited to the traditional manufacturing sector, but is slowly expanding to include home and home use. nine0006

And as 3D printers become more affordable and widely available, their use is no longer limited to the traditional manufacturing sector, but is slowly expanding to include home and home use. nine0006

Popular 3D printed items in 2022

Industrial products

The development of industrial products 3D printing is mainly driven by the growth of the metal 3D printing industry, which has a CAGR of 22.9% from 2021 to 2030 with a market value of $22.6 billion .

Metal 3D printing applications are centered around manufacturing processes such as prototyping, tooling, and creating functional parts for the automotive, aerospace, defense, healthcare, consumer electronics, and construction industries. The Asia-Pacific region is the market that is expected to grow the most over the next 5-10 years, given the industrial and construction needs of emerging markets. nine0006

The growth of the 3D metalworking industry is largely due to the fact that the 3D printing process is much faster than the traditional production of parts. This is especially true for some unique items made to specification, such as custom made gears and shafts. 3D printing offers both flexible and customized industry solutions as the designs, sizes and shapes to be printed can be easily customized with the appropriate software. nine0152 And of course, while metal printers may require a large upfront investment, metal 3D printers these days start at a much more economical price, but are still capable of promising high durability and high performance.

This is especially true for some unique items made to specification, such as custom made gears and shafts. 3D printing offers both flexible and customized industry solutions as the designs, sizes and shapes to be printed can be easily customized with the appropriate software. nine0152 And of course, while metal printers may require a large upfront investment, metal 3D printers these days start at a much more economical price, but are still capable of promising high durability and high performance.

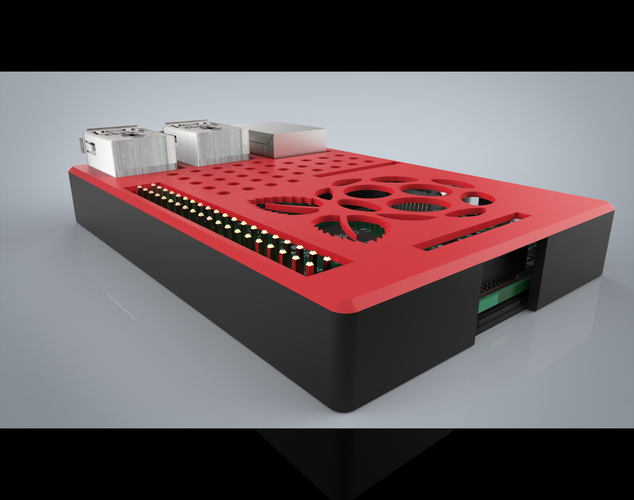

Fortunately, for those businesses that may find it difficult to make an initial investment, there is a good alternative to getting into the industrial goods 3D printing business. That is, by hiring a 3D printing service to have your desired 3D printed products delivered straight to your door. Such highly specialized options often provide not only flexibility in terms of metal 3D printing material, but also versatility in terms of 3D printing technologies. nine0006

nine0006

Medical products

The dental industry is the most prominent specialization in the field of medicine that uses 3D printing technology. 3D printers are used to produce various dentures. The dental 3D printing market is expected to more than double within five years, to $7.9 billion in 2027 from the current estimated market size of $3.1 billion.

Three major factors that have contributed to this growth include: the rise of cosmetic dentistry in line with growing global disposable income, the growing concerns of tooth loss among an aging world population, and the fact that 3D printing in dentistry can help improve overall speed, performance and quality of denture equipment. nine0006

The current average market price for a dental 3D printer is typically around $3,000 per set according to industry experts. However, in the wholesale world, costs are affected not only by volume, but also by the launch of innovative, low-cost technologies, such as the introduction of LCD-based 3D printers. Wholesale dental-grade LCD 3D printers can cost as little as half the average market price, or even well below that.

Wholesale dental-grade LCD 3D printers can cost as little as half the average market price, or even well below that.

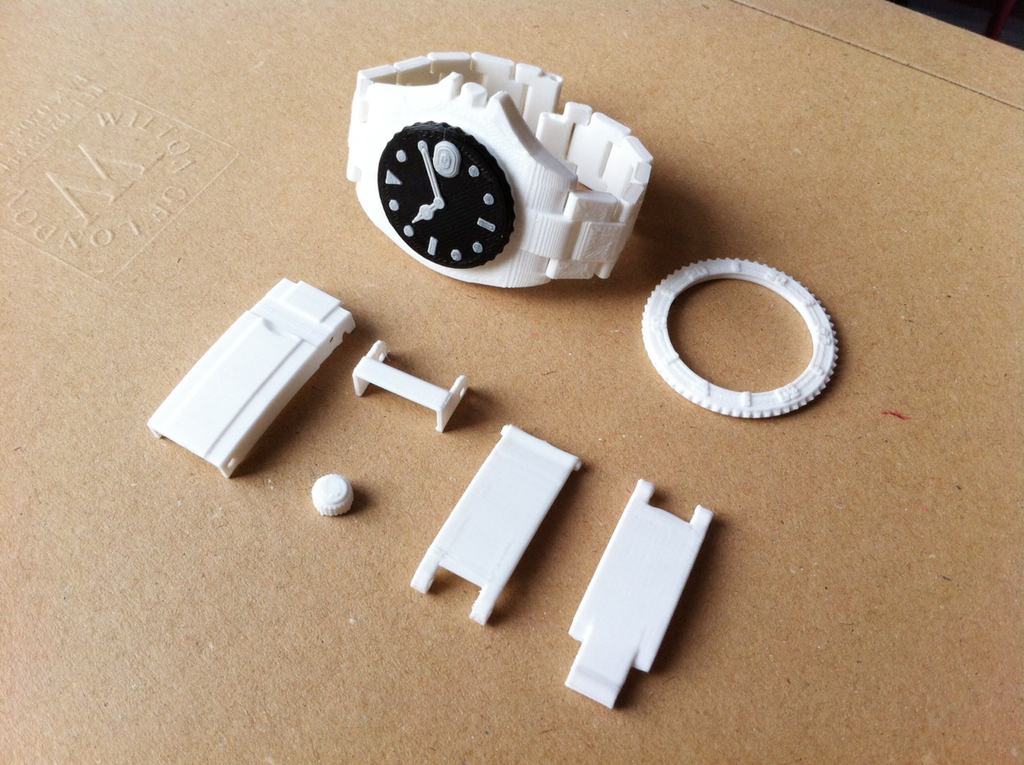

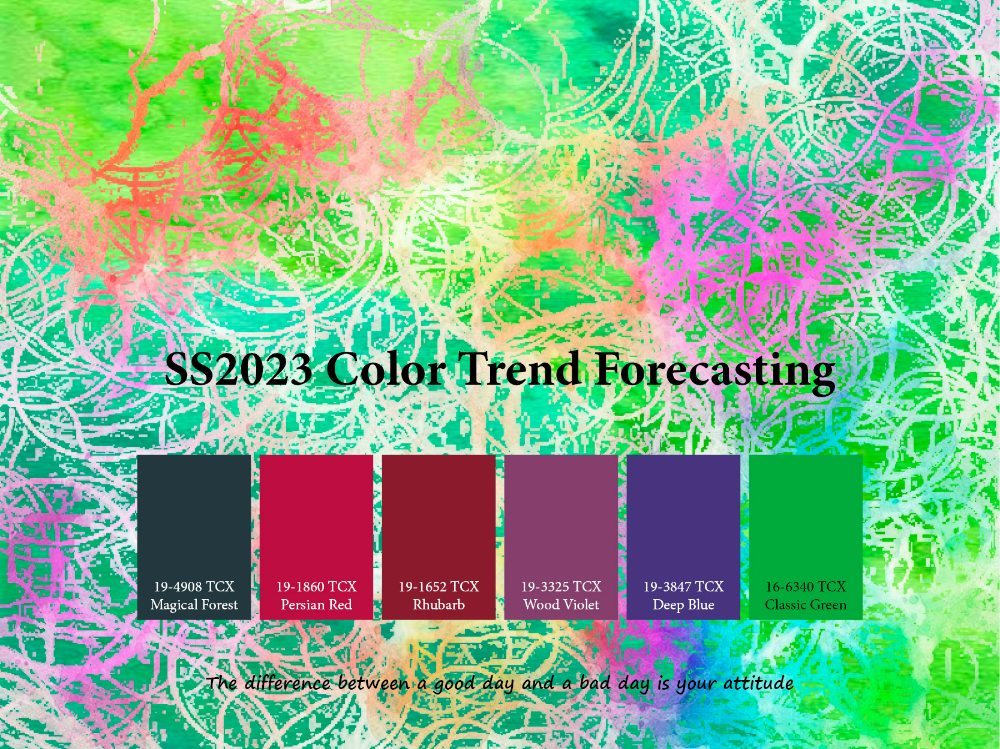

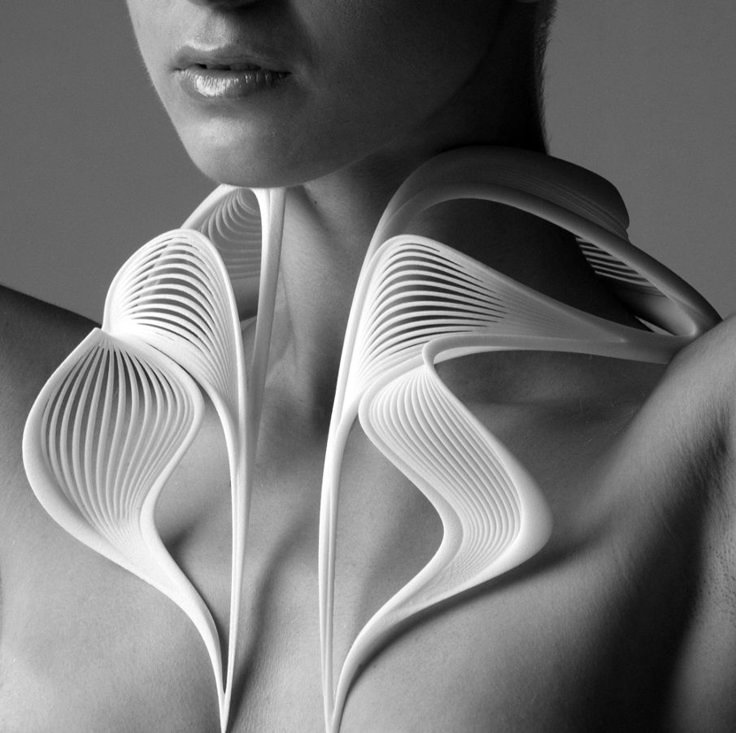

Fashion & Accessories

The exclusivity and customization of 3D printing make it a good alternative for the fashion industry. Among all kinds of fashion products, jewelry stands out as the most suitable item for 3D printing, partly due to the rapid growth of the jewelry market worldwide, with a CAGR of 12.1% between 2019 and 2026. But it is also related to that 3D printers meet the needs of jewelry designers.

Through the use of computer-aided design software, 3D printers can significantly reduce the reliance on the labor-intensive manual process of producing complex jewelry designs. In addition, the precision 3D printing technology ensures optimal precision and detail, which meets the requirements of such jewelry production technologies as engraving and filigree. All in all, this means that 3D printing has made jewelry manufacturing more cost-effective and offers an efficient and time-saving solution to the needs of designers. nine0152 Similar to dental 3D printers, resin printers are most suitable for jewelry 3D printing, and the advent of liquid crystal 3D printing technology has opened up more opportunities for low-cost jewelry 3D printers, for example, this model which is similar to the one in the picture below.

nine0152 Similar to dental 3D printers, resin printers are most suitable for jewelry 3D printing, and the advent of liquid crystal 3D printing technology has opened up more opportunities for low-cost jewelry 3D printers, for example, this model which is similar to the one in the picture below.

Bottom line

Overall, 3D printers offer a unique solution for many industries around the world, and this will drive the growth of the market for 3D printing machines and services. For those interested in entering this market, there are three key products to look out for in order to gain a competitive edge: Industrial, Medical, and Fashion. And the good news is that advances in 3D printing technology have reduced investment opportunities, especially at the wholesale level, making 3D printers more affordable for businesses large and small alike. Those interested in capitalizing on this growing market can take a closer look at these factors or check out the range of 3D printing machines available on Alibaba.