Get something 3d printed uk

Materials | 3D Print Direct

Skip to contentMaterialsLewis Parkinson2022-11-16T13:20:29+00:00

Graphite SLS

A cost-effective reinforced PA12 material with an excellent black surface finish and mechanical properties. Lighter than comparable glass-filled nylon materials.

Temperature resistance °C: 176

Density g/cm3: 1.10

Impact strength (notched) J/m: 37

Tensile strength MPa: 58

Tensile modulus MPa: 4,240

Minimum features: 0.8mm

Smallest hole: 1.5mm

Minimum wall thickness: 0.8mm

Minimum clearance: 0.1mm (for parts that need to fit together)

Minimum gap between merged parts: 1mm

SLS Typical Tolerances: ±0.

50% (min ±0.30mm)

Carbon SLS

A specialised carbon-fibre filled PA12, ideal for functional components that need to be light and strong. It has the highest strength-to-weight and stiffness-to-weight ratios of any 3D printed SLS plastic.

Temperature resistance °C: 176

Density g/cm3: 1.09

Impact strength (notched) J/m: 53

Tensile strength MPa: 76

Tensile modulus MPa: 7,100

Minimum features: 0.8mm

Smallest hole: 1.5mm

Minimum wall thickness: 0.8mm

Minimum clearance: 0.1mm (for parts that need to fit together)

Minimum gap between merged parts: 1mm

SLS Typical Tolerances: ±0.

50% (min ±0.30mm)

50% (min ±0.30mm)

PA12 (MJF)

A robust thermoplastic that produces high-density parts with balanced property profiles and strong structures.

Temperature resistance °C: 175

Density g/cm3: 1.01

Impact strength (notched) J/m: 35

Tensile strength MPa: 48

Tensile modulus MPa: 1,800

Minimum features: 0.7mm

Smallest hole: 1.0mm

Minimum wall thickness: 0.6mm

Minimum clearance: 0.1mm (for parts that need to fit together)

Minimum gap between merged parts: 5mm

MJF Typical Tolerances: ±0.50% (min ±0.

35mm)

35mm)

PerFORM (Ceramic-like) SLA

High accuracy, low shrinkage, stable and temperature resistant epoxy. This material can also give an exceptionally smooth surface finish when sanded.

Temperature resistance °C: 132

Density g/cm3: 1.61

Impact strength (notched) J/m: 17

Tensile strength MPa: 70

Tensile modulus MPa: 10,500

Minimum wall thickness: 0.5mm

SLA Typical Tolerances: ±0.40% (min ±0.25mm)

Clear ABS-Like (DSM Watershed XC 11122)

A general purpose plastic with excellent elongation to break, water resistance and optical clarity.

Temperature resistance °C: 50

Density g/cm3: 1.12

Tensile strength MPa: 50

Tensile modulus MPa: 2,770

Find out more about our SLS and SLM materials, processes and expertise.

More Info

Instant QuotesClick here to receive an instant quote to 3D print your parts.

GET A QUOTE

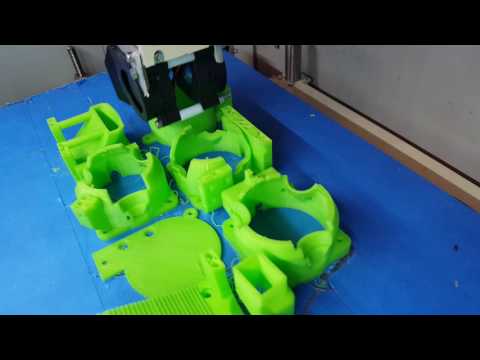

GalleryBeautifully engineered parts in market leading materials.

View Our Gallery

FAQs | 3D Print Direct

Skip to contentFAQspR1n@CT42022-06-16T20:23:14+01:00

If you’re new to the exciting world of 3D Printing, there is a minefield of technical terms, materials and processes to consider. We have set our FAQ section to answer most questions.

If you have a question that isn’t covered on our FAQ’s please get in touch.

What clearance do you recommend for fitting parts?pR1n@CT42018-03-12T09:19:54+00:00

What clearance do you recommend for fitting parts?

We would recommend a 0.1mm clearance in the design for assemblies. If you are wishing to combine parts together for building, then leave at least a 1mm gap.

Does Graphite-SLS have anti-static properties?pR1n@CT42017-04-04T14:29:25+01:00

Does Graphite-SLS have anti-static properties?

The considered “safe” range for materials (between Conductive and Dissipative) is 100k Ohms – 35M Ohms. We have measured Graphite-SLS to be within this range at 280k – 485k Ohms. (Carbon-SLS is 20k – 100k).

Are the materials certified food safe?pR1n@CT42017-04-04T14:30:04+01:00

Are the materials certified food safe?

No, the materials have not been certified and therefore we would recommend avoiding contact with food or drink.

Are my files treated as confidential?pR1n@CT42017-04-04T14:30:41+01:00

Are my files treated as confidential?

Yes, this is extremely important to us. We understand that the majority of parts we see are a new product design or prototype. Confidentiality for our customers is critical. We have industry standard security on site, and we will not release images or any data without customer approval.

Can I specify orientation of the part?pR1n@CT42017-04-04T14:31:26+01:00

Can I specify orientation of the part?

If you pre-orientate the part as you would like it built, it would normally be kept in this orientation. However, we may change the orientation for nesting optimisation.

Can I get any additional discount?pR1n@CT42017-04-04T14:32:45+01:00

Can I get any additional discount?

The prices on 3D Print Direct are already heavily discounted and close to cost price. The only way we can keep part price so low is to be able to 100% pack our machines with parts and having a semi automated ordering process. By having longer lead times we can more efficiently pack many orders together. Shorter turnaround times and technical support are what we offer through Graphite Additive Manufacturing but costs are higher. There is a comparison chart on our homepage.

The only way we can keep part price so low is to be able to 100% pack our machines with parts and having a semi automated ordering process. By having longer lead times we can more efficiently pack many orders together. Shorter turnaround times and technical support are what we offer through Graphite Additive Manufacturing but costs are higher. There is a comparison chart on our homepage.

Can I combine parts together to reduce cost?pR1n@CT42021-10-20T15:45:06+01:00

Can I combine parts together to reduce cost?

Yes you can with this service, but in some cases it can increase the cost. We may choose to build and ship the parts contained in a sinterbox (cage). This may restrict our ability to clean powder from the parts compared with cleaning components individually. For merged parts, leave at least a 1mm gap on SLS and 5mm gap for MJF.

Will you hollow my part?pR1n@CT42021-04-30T09:14:57+01:00

Will you hollow my part?

This is only necessary for MJF Pa12 as the material produces defects at thicknesses above 10mm. Therefore, we will hollow MJF Pa12 that are thicker than 10mm to a wall thickness of 3mm. We will also add a honeycomb lattice structure inside the void to retain the strength of a solid part. Unsintered powder will be left inside the part so your part will weigh as much as a solid piece, this does mean that cutting into the part will release this powder.

Therefore, we will hollow MJF Pa12 that are thicker than 10mm to a wall thickness of 3mm. We will also add a honeycomb lattice structure inside the void to retain the strength of a solid part. Unsintered powder will be left inside the part so your part will weigh as much as a solid piece, this does mean that cutting into the part will release this powder.

What is the smallest hole size you can produce?pR1n@CT42017-04-04T14:35:12+01:00

What is the smallest hole size you can produce?

For short holes that are open both ends, around 2mm.

What is the minimum wall thickness?pR1n@CT42017-04-04T14:36:07+01:00

What is the minimum wall thickness?

All geometry should be at least 0.8mm thick to build. Ideally though, we’d recommend 1.2mm to give stronger parts.

What file formats do you accept?pR1n@CT42017-04-04T14:36:49+01:00

What file formats do you accept?

STL files and we’d recommend a resolution set to 0. 01mm. (Set to Binary rather than ASCII if you have the option)

01mm. (Set to Binary rather than ASCII if you have the option)

What is the largest size of part?pR1n@CT42017-04-04T14:37:35+01:00

What is the largest size of part?

We can 3D print parts up to 300mm long in one piece. If your part is larger, we may cut it and ship in sections. We would aim to cut the part in a sensible location and add features to aid gluing for you where possible.

What is the accuracy?pR1n@CT42022-01-07T14:19:21+00:00

What is the accuracy?

MJF Typical Tolerances: ±0.50% (min ±0.35mm)

SLS Typical Tolerances: ±0.50% (min ±0.30mm)

SLA Typical Tolerances: ±0.40% (min ±0.25mm)

How quickly can parts be made?pR1n@CT42017-09-29T17:17:34+01:00

How quickly can parts be made?

Typically 7-21 working days depending on material and service selected.

Can you print in any other materials not listed?pR1n@CT42017-04-04T14:39:41+01:00

Can you print in any other materials not listed?

No, as we are not using cheaper filament type machines, we cannot offer multi materials.

What is the difference in materials?pR1n@CT42017-04-04T14:40:27+01:00

What is the difference in materials?

Graphite-SLS is a reinforced material with excellent performance to price ratio. The Carbon-SLS has the best stiffness to weight ratio of any 3D printed plastic. Both materials are slightly conductive. More information can be found at our other site here: Graphite-AM

I have another question that is not listed herepR1n@CT42017-07-18T13:09:00+01:00

I have another question that is not listed here

Please contact us on 01296 488122 and we will do what we can to help.

We pride ourselves on the quality of our carefully selected materials and beautifully engineered parts. We have worked hard to select the finest materials and employ the best industry practises. Sit back upload your files and let us bring your ideas and creations to life.

GET A QUOTE

InfoFind out more about our SLS and SLM materials, processes and expertise.

More Info

Instant QuotesClick here to receive an instant quote to 3D print your parts.

GET A QUOTE

GalleryBeautifully engineered parts in market leading materials.

View Our Gallery

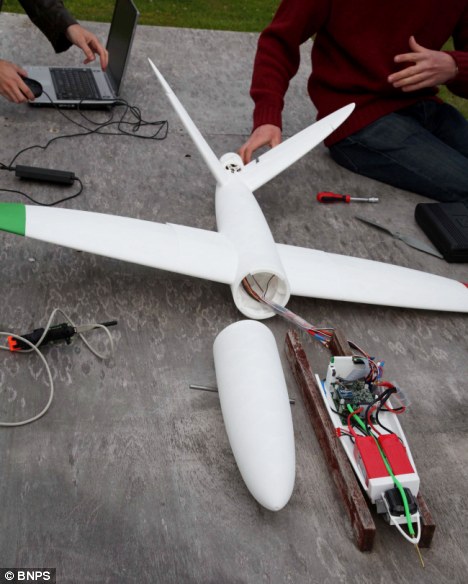

Research shows that the UK 3D printing market could be £2.9 billion in the future Kids toys.

According to OnePoll, over 5 million adults are willing to spend around £500 on a 3D printer if it's easy to use. About 49 live in the UKmillion adults (ONS data). If 1.8% of residents are willing to spend about £500 on a 3D printer, then the UK 3D printing market will be worth £2.9 billion.

However, there are some doubts about the practical value of a 3D printer, as 4 out of 10 people admitted that they had no idea what to do with it.

Chris Elsworthy, CEO of the Robox company, said: “3D printing has already made its mark on the world of technology. As far as the average person is concerned, we still have a long way to go.” nine0003

As far as the average person is concerned, we still have a long way to go.” nine0003

“We found that the British are becoming more and more interested in new technologies, but as with any unfamiliar subject, it takes time for them to understand what a home 3D printer can be useful for.”

"The consumer is unlikely to be able to use most existing printers: they are too expensive, difficult to manage and too large to put on the table."

"On the other hand, we've learned that more and more people want a printer that's relatively inexpensive, nice looking, and easy to use." nine0003

In a study of 1,000 people, it turned out that many would like to get creative and print something unusual. A third of those surveyed said they would rather use homemade items such as pipe brackets, holders and doorknobs instead of going to the store to get them.

In addition, a quarter of the respondents admitted that they do not have time to run around the shops in search of gifts for friends and relatives, and they think that a hand-made gift will make an equally pleasant impression. nine0003

nine0003

One fifth of the respondents liked the idea of printing their own case for their phone or tablet. The same number of people would 3D-print a kitchen and print coffee cups, knives, and utensils.

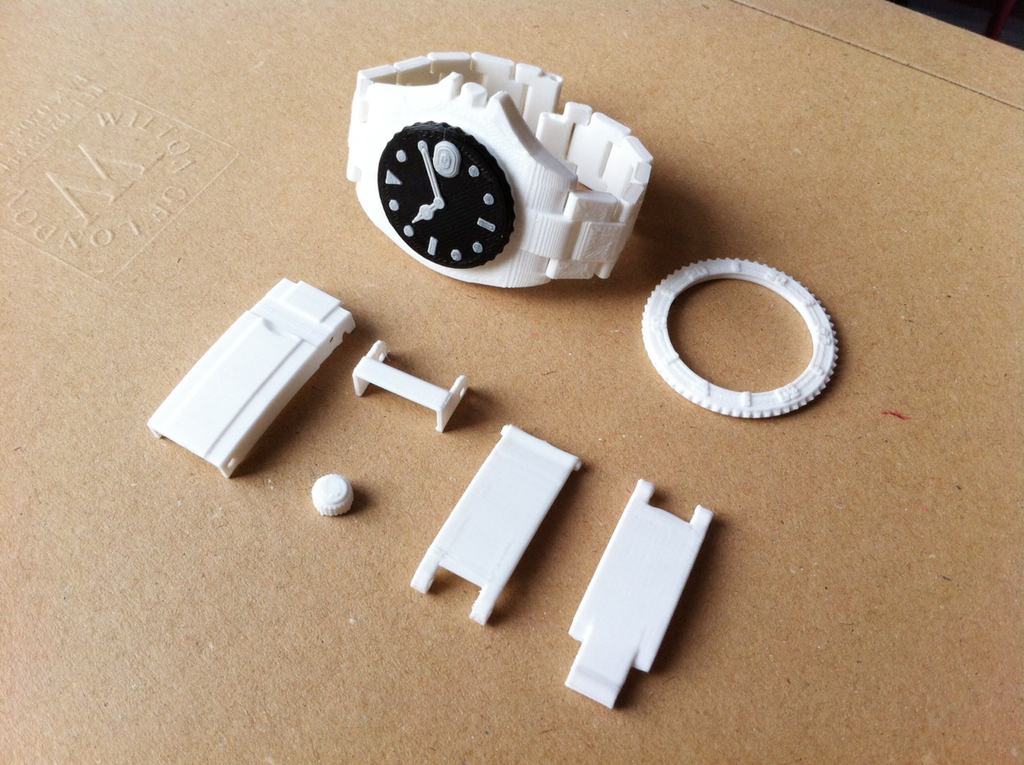

Other uses for 3D printing include picture holders, photo frames, baby shower favors, and all sorts of designer items, including jewelry and belt buckles. All this encourages you to think about buying a 3D printer if it becomes affordable and inexpensive. By the way, some people would also like to save money on children's toys by printing Lego bricks, action figures and lost parts from different games. nine0003

Elsworthy said: “The bottom line is that the possibilities of 3D printing are endless, because you can design or replicate any product from the comfort of your home.”

“We've already received a lot of inquiries from local schools whose students dream of seeing Robox in action. Children are always interested in new technologies. In addition, it is easy for them to explain what and how they can print.

Robox 3D 3D Printer Coming to the UK and US Markets Early 2014 Costing £849pounds / 1364 dollars. The developers position it as a “plug and print” device, which even a beginner can figure out how to manage. This is a stylish 3D printer that is equipped with a revolutionary "FFF based dual nozzle print head". One nozzle is designed for printing surfaces with fine details, while the other is for fast filling. Robox is also equipped with an automatic print platform leveling system, a closed feedback circuit and an extrusion system with double pinch rollers. nine0003

“3D printing is the future, as it will allow many people to educate themselves. The results of this study are incredible, as they prove that people are already interested in 3D printers, although they do not yet have the opportunity to buy them,” said Elsworthy.

The survey also found that men are twice as interested in buying a 3D printer than women, indicating their penchant for all sorts of technical innovations.

It is not surprising that teenagers are also tempted to print things at home, while those aged 18-44 are more interested in mastering new technology than those who are 15-16 years old. nine0003

Interestingly, only 12 percent of those surveyed “do not know” what a 3D printer is.

TOP 10 3D PRINTER APPLICATIONS

- Home items

- Spare parts, fasteners and tools

- Gifts and souvenirs for friends and family

- Decorations for Christmas

- Gadget accessories

- Kitchen utensils

- Jewelry and fashion accessories

- Children's toys

- Office Consumables

- Party & Wedding Favors

Article prepared for 3dtoday.ru

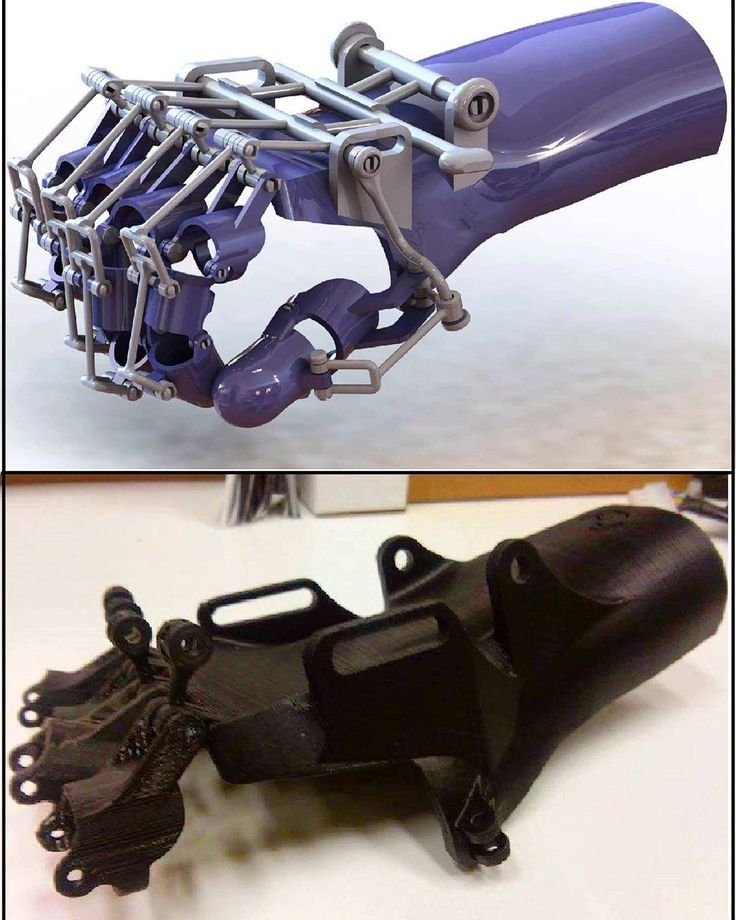

A 3D-printed eye was transplanted to a UK patient for the first time. How the printed organ industry is developing

What happened :

A 3D printed eye was transplanted into a man for the first time in history. nine0003

nine0003

Details:

Scientists note that printing an artificial eye on a 3D printer takes about 2.5 hours.

Context:

Approximately 60,000 people in the UK need regular prosthetic eye replacements. Their printing on 3D printers will reduce the number of people on the waiting list for organ transplants.

Perspective :

The global 3D bioprinting market is currently valued at more than $960 million, and by 2026, according to analysts, it could reach $4.4 billion.

What happened

In the UK, 40-year-old Steve Werba had a 3D printed eye fitted. This operation was the first of its kind in world history. This was reported by the press service of the Moorfields Eye Hospital.

- Prior to this, Verbe, who had lost his left eye, had been using prosthetic eyes for 20 years and had to be replaced every 5 years. The new prosthesis will last longer and look more like a real eye.

- According to the Daily Mail, scientists said that the man did not manage to regain his sight, but he hopes that he will be more confident with such an eye. nine0042

Details

- Printed implant transplanted at the expense of the state "National Health System".

- The British authorities are now considering further research into such operations in order to introduce them everywhere.

- Scientists note that it takes about 2.5 hours to print an artificial eye on a 3D printer, after which the eyepiece specialist takes care of its finishing, polishing and fitting. The entire eye is made within 2-3 weeks. nine0042

- Approximately 60,000 people in the UK require a regular replacement of a prosthetic eye.

Context

In the world, a large number of people are waiting for their turn for organ transplants. For example, in China, there are 1.5 million people on the waiting list, in the United States - 113 thousand. The development of printing organs on a 3D printer can reduce these waiting lists.

The development of printing organs on a 3D printer can reduce these waiting lists.

- There are now over 100 companies in the world that produce 3D printers, which can also print organs. 39% of them are in the USA, 35% in Europe, 17% in Asia, 5% in Latin America.

- 3D Bioprinting Solutions produces such printers in Russia. In addition, in the spring of 2021, a group of students from St. Petersburg State University developed a test sample of a 3D printer capable of printing organs for transplantation.

Perspective

According to experts, transplantation of 3D printed organs is considered one of the main trends of the future. They believe that in 10–15 years, bioprinters and cellular materials will be widely available and this kind of printing will be used even in remote regions. nine0003

- The global 3D bioprinting market is currently valued at more than $960 million, and by 2026, according to analysts, it could reach $4.

Learn more