Songbird 3d printed pistol

The Songbird 3D Printed Pistol with a Nylon BarrelThe Firearm Blog

Posted in Editorial, Pistols, Rimfire by Luke C. with No Comments

Tags: 22LR, 3d printing, Songbird, The Rimfire Report

Hello and welcome back to The Rimfire Report! This weekly series focuses on the rimfire firearm world and its various ammunitions and sports in addition to the wealth of rimfire firearms out there. This week we’re taking a look at a 3D printed 22LR firearm – The Songbird. The Songbird was created by 3D printers and is made from nearly 100% 3D printed parts but also makes use of some simple office supplies as part of its operation.

A big hurdle in the effort to disconnect homemade firearms from the mainstream firearms industry is the need for quality barrels and other items. We’ve seen in more recent times that practices such as electrochemical machining to make rifled barrels with homemade supplies. Although this practice exists, it is still far more complicated and time-consuming than most 3D printers are willing to put into their homemade firearms.

The Songbird takes a unique approach in that this particular design makes use of almost 100% 3D printed parts – including the barrel. The barrel itself is made from Taulman Bridge Nylon. This material takes the strength properties of standard Nylon 645 and combines it with the price points of ABS and PLA plastics. In addition Bridge Nylon also provides a lab certified measure of tensile strength which is something that the 3D printing community was in high demand for.

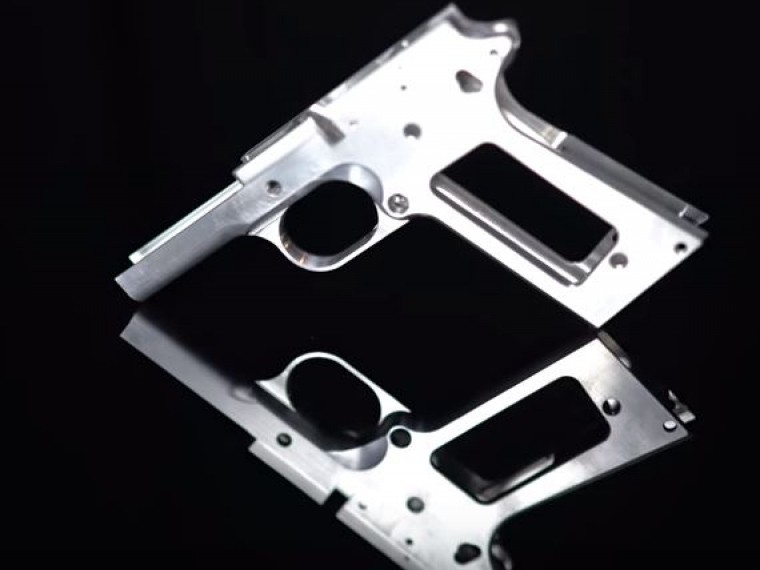

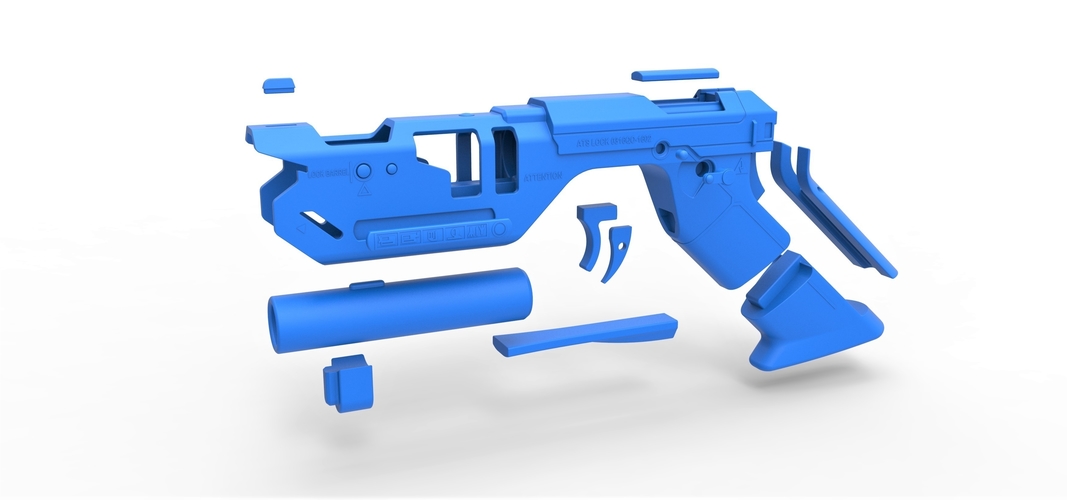

The parts for the Songbird are simple. While the barrel is printed from the Bridge Nylon, the frame as well as the other parts including the trigger pins, trigger assembly, and grip are all made from regular ABS filament. The pistol is printed from the side (as if you were laying the gun on a table) and is one uniform piece. This design necessitates the need to remove several support structures leftover from the printing process.

The remainder of the pieces including the “spring” and firing pin are made from rubber bands and a roofing nail respectively. In order to make the firearm legal within the United States, there is a required certain weight of the metal in the firearm in order to make it legal. See the Undetectable Firearms Act of 1988 for more information on that.

The legally required amount of metal was epoxied into the grip of the pistol.

Durability

Many 3D printed firearms tend to break easily due to the inherent weakness of 3D printed plastics when compared to their more conventional steel and aluminum counterparts. This probably is even more pronounced for pressure bearing parts such as the barrel and chamber. However, using the Bridge Nylon, YouTube user “Guy in a garage” was able to get upwards of 60+ rounds through his nylon printed barrel. For those curious, the infill density of the barrel was pushed to 100% for maximum strength.

In fact, the barrel was so durable, he decided to upgrade the system to handle 357 magnum loads. Initial tests on this design had the structure fail but subsequent tests after repairs allowed him to fire several Federal 357 hollow points through the repaired gun without sustaining any additional cracks.

Initial tests on this design had the structure fail but subsequent tests after repairs allowed him to fire several Federal 357 hollow points through the repaired gun without sustaining any additional cracks.

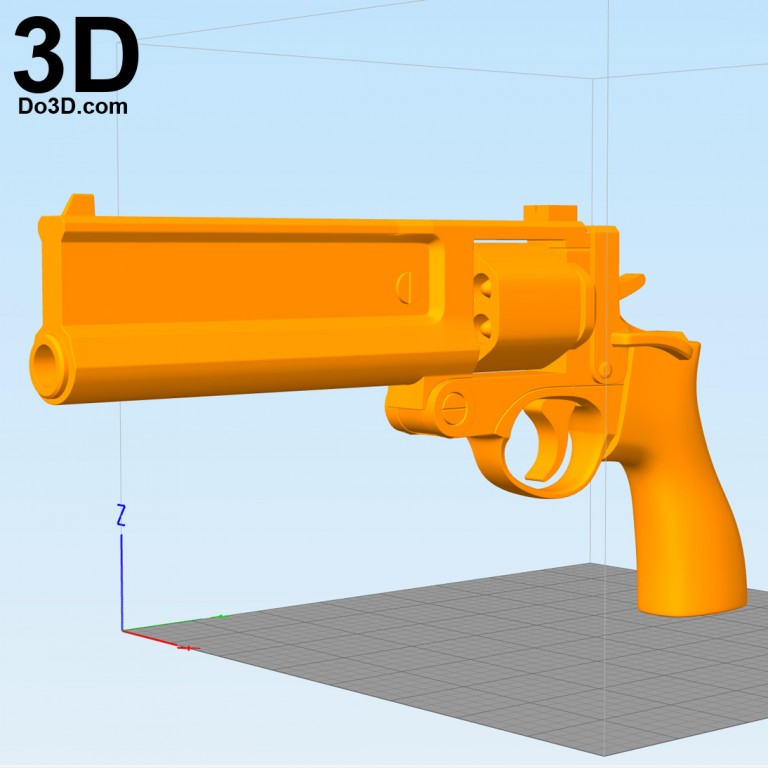

The 357 Magnum version of the Songbird

Although this is promising, the big negative to the 3D printed nylon barrel is that it does not stabilize the bullets in any way shape, or form despite rifling being incorporated into the print. In a pinch this may not be a problem, however if you’re planning on using the Songbird as a target pistol I’d rethink the 3D printed barrel.

The barrel itself is more or less a smoothbore barrel and thus has no twist to stabilize the bullets. This does make me wonder, however, if projectiles like rifled slugs but miniaturized are on the horizon somewhere as this would eliminate the need for a complicated rifling process.

Field Test/ Accuracy

As stated before, the Songbird features no type of bullet stabilization in the 3D printed barrel. This unfortunately leads to the pistol being very inaccurate even at short distances (in the below video it seems that he’s at a distance of about 5 to 10 yards). “Guy in a garage” did say that the pistol was more accurate when the barrel was freshly printed so perhaps his initial tests had better accuracy results.

This unfortunately leads to the pistol being very inaccurate even at short distances (in the below video it seems that he’s at a distance of about 5 to 10 yards). “Guy in a garage” did say that the pistol was more accurate when the barrel was freshly printed so perhaps his initial tests had better accuracy results.

The Songbird also does not feature any type of extractor and with the exception of the 357 Magnum version of the gun, it seems like each time the gun was fired and the barrel was removed, you had to use a tool to remove the spent casing before loading another one. Once the barrel was loaded, the hammer would need to be pre-cocked before the loaded barrel was placed back into the gun.

Without changing anything with the design I think a great way to make the setup slightly more practical would be to print several barrels and perform a “New York Reload” in-between shots. This would ensure that a fresh barrel was available and provided more accuracy and would reduce reload times between shots.

This would ensure that a fresh barrel was available and provided more accuracy and would reduce reload times between shots.

Can’t Stop The Signal

I love 3D printing for the simple fact that it is a great way for many minds to produce so many different designs. Each print furthers the technology of firearms in one way or another and further subverts the controls put in place to keep arms out of the hands of free people.

Note the roofing nail firing pin.

I love the concept of a sleeveless barrel and I think it has a lot of potential. If there was a way to introduce some sort of stabilization into the projectiles, it would make the Songbird much more practical. Thoughts and comments always welcome below and thanks again for stopping by to read The Rimfire Report!

All pictures and info for this article were gathered from Guy in a Garage, please go check out his work on other 3D printed firearm projects!

3ders.org - Metallic barrel liner strengthens newly developed 3D printed gun Songbird

Oct 2, 2016 | By Andre

3D printed gun has and likely always will raise eyebrows and get a little bit more attention than your typical 3D printing related news story because of the nature of what a gun represents to different people.

This surrounding facination started when Cody Wilson made international news back in 2013 after distributing the 3D model files for his Liberator 3D printed gun. Along with this (the first functional 3D printed gun) came his crypto-anarchy philosophies and eventually an incredible media driven backlash. Cody couldn't have been happier with the world's response.

Fastforward to today and a new 3D printed gun called Songbird that has just been released that incorporates a metallic barrel liner to reinforce the otherwise fully 3D printed gun typical since the release of the Liberator (with the exception of course of Solid Concepts metal handgun).

For the Songbird pistol, it is the metal liner that sets it apart from the rest in that repeatability is supposedly achieved (disclaimer: who really knows). Tests firings using ABS plastic proved that it was indeed strong enough to fire .22 and .357 caliber bullets fairly reliably.

For any gun enthusiasts out there, it’s worth checking out the below example video and others uploaded by Youtube contibuter Guy in a Garage.

After watching some of the videos related to the construction of the gun I was somewhat relieved that it really did seem like a hobbyist contraption. There was no underlying political/philosophical ambition or 2nd Amendment message built in meant to inspire controversy. It’s just someone interested in using new ideas to manufacture a centuries old technology. So that was a relief.

And while I am generally against the ownership of guns, this project seems like a well-thought out approach to engineering a better and ultimately safer (for the user) 3D printed gun.

As has always been the case, 3D printed guns are not practical in any real sense. There are cheaper and more efficient ways of acquiring a gun if you really wanted one. In addition, the world is not in any major risk of being over run by 3D printed guns any time in the near future.

But, just like every story relating to 3D printed guns the context of what a gun is cannot be ignored and this is evidenced by the comments section on the Hackaday Songbird breakdown.

Beyond the discussion on how practical a barrel liner is, it quickly devolves (as do most internet based discussions on the topic) towards how guns are bad or subsequently how guns are good. Ultimately, the way I see it is that using Taulman Bridge Nylon to print the barrel was a good use of new materials.

Posted in 3D Printing Application

Maybe you also like:

- US Marine test: 3D printed munition proved to be more lethal than conventional

- Colombian e-NABLE shares 'Snow Queen', 'Ninja', 'Cinderella', 'Iron Man' themed 3D printed hand files

- Clemson researchers develop custom-softness 3D printed orthotics for diabetes, arthritis patients

- BioInspiration and SLEM fight shoe pollution with 3D printed compostable footwear

- Synthetic 3D-printed 'hyperelastic bone' induces bone regeneration, could mend broken bones

- 'Making a Difference / A Difference in Making' exhibition showcases 80 unusual 3D printed objects

- See how Paul Braddock created Eddie, the amazing 3D printed steampunk robot

- 3D printed lifelike human body with functioning heart and lungs could train surgeons dealing with emergency trauma

- Kitronik releases free 3D printable desk lamp resources for students

H. Scholten wrote at 10/3/2016 9:14:51 AM:

Scholten wrote at 10/3/2016 9:14:51 AM:

"After watching some of the videos related to the construction of the gun I was somewhat relieved that it really did seem like a hobbyist contraption. There was no underlying political/philosophical ambition or 2nd Amendment message built in meant to inspire controversy. It’s just someone interested in using new ideas to manufacture a centuries old technology. So that was a relief." Why is it a relief that somebody does not realize the social and political consequences of his/her inventions? The social and political implication of 3D printing in general is the most important aspect of the technology and you are happy when inventors are ignorant about that??? A relevant technology ALWAYS has social and political implications. As you can see from the previous comments guns and gun ownership have been politized heavily and ignorance does not change that fact.

RobinLeech wrote at 10/2/2016 11:38:40 PM:

Are you really against the ownership of guns? Or just private ownership? It sounds like you've no problem with people being armed as long as they work for the state and have an unchecked monopoly of force. The JPFO (Jews for the Preservation of Firearms Ownership) would point out that tyrannical governments throughout history were also against private ownership of weapons. So, you basically admit that you'd rather see the people be disarmed and the gestapo have a monopoly of force as the nazis had, rather than checks and balances with private ownership of firearms.

The JPFO (Jews for the Preservation of Firearms Ownership) would point out that tyrannical governments throughout history were also against private ownership of weapons. So, you basically admit that you'd rather see the people be disarmed and the gestapo have a monopoly of force as the nazis had, rather than checks and balances with private ownership of firearms.

is it possible to print pneumatic and firearms

Is it possible to make a gun on a 3D printer and is it legal?

Today's 3D printers offer enormous possibilities. They can print products of almost any complexity. Until quite recently, it was difficult to even imagine that a plastic weapon could shoot. However, it is already possible to make a pistol on a 3D printer, which, although not reliable, still fires live ammunition.

Can firearms be 3D printed?

Back in 2013, a young American gun fighter proved that plastic guns could be 3D printed. He was the first in the world to make a pistol in this way, in which only the striker was made separately from metal. All other parts were printed on an FDM printer.

He was the first in the world to make a pistol in this way, in which only the striker was made separately from metal. All other parts were printed on an FDM printer.

Today's 3D printers are capable of printing any CAD model, and these models of firearms have been available for over 10 years. If in previous years their printing required professional skills, now almost any user can master them. With a 3D printer and a finished model, it became quite possible to print a gun. Another thing is that such "creativity" is punishable by the laws of most countries.

The evolution of 3D printed weapons

Despite all the prohibitions and restrictions, the evolution of 3D printed firearms is moving at a great speed. The beginning was laid by the single-shot plastic pistol Liberator by American K. Wilson, which appeared in 2013. It had a simple design and was chambered for 380 ACP. Already after 10-12 shots, this weapon became unusable. However, the very possibility of printing firearms served as an impetus for the development of the idea. The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

One of the ways to increase the durability of weapons was to increase the number of their barrels. At the beginning of 2014, the Japanese Y. Imura makes a 38 caliber Zig Zag pistol. He was able to fire up to 6 shots non-stop. The author of the weapon was recognized as a criminal and convicted.

The next step was the production of a six-shot revolver by J. Patrick in 2015. The PM522 Washbear has been shown in action on YouTube. The weapon was noticeably safer for the shooter compared to previous versions, but still allowed to fire only a few dozen rounds.

The first semi-automatic pistol for a 9 mm bullet appeared in 2016 under the name Shuty-MP1. It was developed by a handicraft gunsmith who hid under the pseudonym Derwood. It wasn't exactly a plastic weapon. The author used some metal parts from factory pistols - a barrel, a firing pin, a bolt and several springs. This made it possible to ensure a rate of fire of more than 46 rounds / min. However, when changing the store, the plastic case had to be cooled. In 2017, the same master proposed an improved model - Shuty AP-9.

This made it possible to ensure a rate of fire of more than 46 rounds / min. However, when changing the store, the plastic case had to be cooled. In 2017, the same master proposed an improved model - Shuty AP-9.

The main contribution to the development of 3D printed weapons technology was made by Defense Distributed, which united a group of like-minded activists. First, these enthusiasts won legal proceedings in the United States and obtained permission to 3D-print weapons, which greatly expanded their capabilities. Secondly, they were able to set up a professional business with product testing and quality control. As a result, in 2018–19 they developed numerous models of a variety of firearms - from pistols to carbines. They posted over 30 files for printing original gun parts. Most of them were plastic, and the metal parts were not made from purchased, ready-made elements, but from simple metal profiles (tubes, strips, etc.), which are sold in ordinary hardware stores. This made it possible to exclude the use of parts patented by gunsmiths.

This made it possible to exclude the use of parts patented by gunsmiths.

At the moment, the semi-automatic carbine FGC-9, developed on the basis of the Shuty AP-9, has become the pinnacle of "creativity" of Defense Distributed. At the same time, there is not a single factory part in it. The barrel for the 9 mm cartridge is made of steel pipe using electrochemical processing.

Where can I get drawings and what should I look for?

Gun manufacturing bans make it much harder to get blueprints and models of guns for 3D printing. The right to free placement of information was achieved only by Defense Distributed. Their website provides free access to drawings, models and technologies. Other information can be found on the Internet, but they are usually illegal.

When choosing a model, pay attention to the following information:

- material used;

- cartridge for which the model is designed;

- number of cartridges in the magazine, rate of fire;

- operating time before failure.

It is important to clarify which metal parts will need to be purchased separately, in addition to plastic for printing on a printer.

What does the law say in different countries?

The only country where firearms can be 3D printed is the United States. Gun Control Act 19 applies here68, giving Americans the right to make weapons, but only for personal use. Only one limitation is put forward: it must be determined by metal detectors, that is, it must have a metal element. In virtually all other countries, homemade manufacture and repair of weapons for any purpose is prohibited by law. In Russia, printing it on a 3D printer falls under the Criminal Code of the Russian Federation and is punishable by imprisonment.

Should we be afraid of plastic weapons?

The question of how dangerous a weapon printed on a printer is becoming increasingly important. Despite all the prohibitions, it is extremely difficult to control the spread of technology around the world. The availability of 3D printers and the increase in their functionality make it possible to master the production of plastic guns at home. How dangerous is such a weapon?

The availability of 3D printers and the increase in their functionality make it possible to master the production of plastic guns at home. How dangerous is such a weapon?

Most experts agree that currently printed weapons are more of an interesting toy. It is quite expensive and is designed to carry out only a few dozen shots. Moreover, such pistols are quite dangerous for the shooter himself with live ammunition, because they can explode in their hands.

However, the danger cannot be underestimated. It is easier and cheaper for a "serious" criminal to buy illegal military weapons than to make them on a printer. At the same time, there may be "enthusiasts" who, for their own interest, can make a pistol and try it out in action. Such inadequate people represent an undoubted danger. In addition, the temptation is great for terrorists. Metal detectors do not detect a plastic gun, which means that it is easier to carry it, for example, on an airplane.

Important! Plastic weapons have a very small resource.

At the same time, sometimes just one shot is enough to kill a person.

3D printed firearms have the following advantages:

- the ability to make military weapons at home;

- light weight;

- availability of materials;

- Ability to copy famous weapon models.

Always remember that there are significant disadvantages:

- illegal production;

- high cost of weapons;

- very small resource and limited rate of fire;

- danger to the shooter himself.

Currently, plastic weapons have more disadvantages than advantages, and most importantly, you can get a real prison term for making them.

Prospects for printing weapons

The potential for 3D printing of firearms is far from exhausted. The expansion of equipment capabilities and the development of innovative materials indicate that in the near future such weapons may approach military weapons in terms of characteristics. In the future - a significant increase in the resource and the provision of automatic firing.

In the future - a significant increase in the resource and the provision of automatic firing.

Significantly increases the reliability of printed pistols and carbines SLS technology using metal powder. Such weapons already differ little from the factory metal models. While it is very expensive, which significantly limits the application. However, over time, the material will become cheaper, which means it will become more affordable.

Printing firearms on a 3D printer has become a reality. Despite its extremely low performance and reliability, interest is growing in it. Experts predict that the printing of weapons will become widespread, and it is impossible to stop such production. There comes a time when measures should be taken at the legislative level to establish effective control over this process.

- March 21, 2021

- 3460

Get expert advice

3D printed guns take on a serious look with a metal-barreled pistol

News

Another horror story has appeared in the arsenal of 3D-printed gunsmiths in the form of a 3D-printed gun "Songbird", almost entirely suitable for manufacturing on a 3D printer.

An interesting feature of the new pistol is a separate barrel that can be customized to the desired caliber, and most importantly, modified with metal tabs. It's no secret that simple 3D printed weapons pose more of a threat to users than to anyone or anything else. FDM-printed models somehow suffer from reduced tensile strength due to the layered structure, and therefore a 3D-printed barrel can simply break right in your hands.

The metal liner allows not only to increase strength and, as a result, safety, but also to improve shooting accuracy, because nothing prevents a metal rifled barrel from being inserted into the 3D printed module. On the other hand, if you already use real weapon components, then it is easier and more reliable to make a whole metal gun without resorting to 3D printing. In other words, the project is of purely academic interest.

Nevertheless, even such ideas are met with disapproval from the vigilant public and law enforcement agencies. In the videos below, the maker under the nickname Guy in a Garage did not neglect the metal inserts to comply with the law - the inserts are needed so that the weapon can be detected by conventional metal detector frames.

In the videos below, the maker under the nickname Guy in a Garage did not neglect the metal inserts to comply with the law - the inserts are needed so that the weapon can be detected by conventional metal detector frames.

The body of the pistol is printed in ABS plastic, but the barrel in the first version is made of nylon. A version with a fully polymer rifled barrel withstood about 200 rounds of small-bore .22 rounds. For more powerful ammunition, a barrel with a smooth metal tab was made. Interestingly, the barrel with the liner withstood several rounds of .38 and .357 Magnum cartridges, but the ABS plastic frame still cracked, although the barrel itself was not damaged.

Original full nylon barrel:

upgrade with a trunk made of ABS-plastic and a metal tab for fine-caliber cartridges: