Smoothing nylon 3d print

How to 3D Print Nylon Filament Like a Pro – Ultimate Guide & FAQ – 3D Printerly

Learning how to 3D print with Nylon can pay off heavily when you want to make mechanically strong parts with diverse applications. However, Nylon is no easy filament to print with, and you’re definitely going to need to know what kind of settings and improvements you need to make for printing top-quality Nylon parts.

To 3D print Nylon, you should use a printing temperature between 225-270°C and a bed temperature between 70-90°C for the best results. Do not use cooling fans with Nylon and use a print speed that is between 25-50mm/s. Nylon is prone to absorbing moisture in the air, so store in an airtight container when not in use.

This article is going to be a simple, yet in-depth guide on how to 3D print Nylon filament just like the pros do, so stick around to see how it’s done and get your questions answered.

What is Nylon Filament for 3D Printing & What is it Made of?

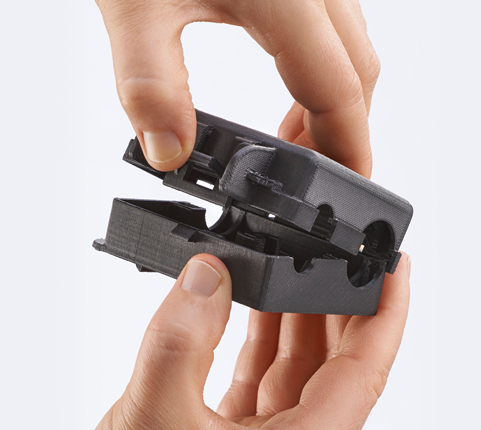

Nylon filament or Polyamide in 3D printing is an exceptionally strong and durable thermoplastic filament that boasts high flexibility, great heat resistance, and even better toughness than ABS. It’s great for functional and mechanical parts that go through a lot of movement, like hinges and joints.

When we talk about what Nylon is made of, it is generally a synthetic polymer belonging to a family of polyamides. In a polyamide, many amides join with each other using a peptide bond. When several polyamides connect, Nylon is formed.

Nylon is an ideal choice for printing tools, RC cars, and everything of the like. It has a low coefficient of friction that makes it much more resistant to wear and tear than ABS, which is quite famous as well for such properties.

What Temperature Should You 3D Print Nylon?

The best nozzle temperature for printing Nylon is anywhere between 225-270°C depending on your 3D printer set up. Filament brands that manufacture Nylon also contain recommended temperature ranges. The eSUN ePA Nylon filament’s is 230-260°C while the OVERTURE Nylon’s is 250-270°C.

The best heat bed temperature for Nylon usually falls in the range of 70-90°C. You can try experimenting with different heat bed temperatures to figure out the perfect value that suits your Nylon filament and your 3D printer. Manufacturers will also send in their recommended bed temperature range for you to try out.

You can try experimenting with different heat bed temperatures to figure out the perfect value that suits your Nylon filament and your 3D printer. Manufacturers will also send in their recommended bed temperature range for you to try out.

A bed temperature of 60°C brought great results for one user who bought the taulman3D Nylon filament. Similarly, one customer remarked that a bed temperature of 110°C worked best for his Dremel Nylon filament.

Let’s now look at some top-rated Nylon filaments and their recommended nozzle and bed temperature ranges.

eSUN ePA NylonNozzle Temperature: 230-260°C

Bed Temperature: 70-90°C

Dremel Nylon

Nozzle Temperature: 230-250°C

Bed Temperature: 80-110°C

OVERTURE Nylon

Nozzle Temperature: 250-270°C

Bed Temperature: 25-50°C (though people report higher bed temperatures, around 80° C work better)

Taulman3D Nylon

Nozzle Temperature: 250-255°C

Bed Temperature: 55-70°C

What Printing Speed Should I Use for Nylon?

The recommended printing speed for Nylon is between 30-60mm/s. You can go beyond that, as long as your 3D printer is tuned up well and can handle faster speeds. Print quality usually declines when you go past 70mm/s for Nylon as it requires time to heat up and extrude evenly. Increasing printing temperature can help.

You can go beyond that, as long as your 3D printer is tuned up well and can handle faster speeds. Print quality usually declines when you go past 70mm/s for Nylon as it requires time to heat up and extrude evenly. Increasing printing temperature can help.

Nylon isn’t like PLA that flows easily out of the nozzle and can be printed at higher speeds. You’ll have to go slow with Nylon if you intend to prioritize part quality.

That said, Delta 3D printers are capable of printing at more than 100mm/s as they are generally more speedy and stable when it comes to 3D printing.

When you have large 3D prints that don’t require the highest of detail, using faster print speeds should work out just fine with an increase in your printing temperature by 5-10°C. Smaller 3D prints with more detail should ideally use a print speed of around 40mm/s.

Does Nylon Need a Cooling Fan?

Nylon does not need a cooling fan to make successful 3D prints, though some people use low cooling fan settings with good results. It’s not usually recommended to use a cooling fan with Nylon since it is prone to warping due to being a high temperature filament. An enclosed print chamber is ideal when using cooling.

It’s not usually recommended to use a cooling fan with Nylon since it is prone to warping due to being a high temperature filament. An enclosed print chamber is ideal when using cooling.

Turning your cooling fans off when 3D printing Nylon tends to result in stronger parts, while low cooling fans can lead to better surface quality and textures.

People usually set their fan speed at 50% or even lower when printing with Nylon. This is a filament that likes constant, ambient temperature that’s best achieved within an enclosure.

However, cooling fans can be quite useful when you need to print overhangs, and bridges in your prints. An easy way to do this is by implementing scripts that can be found in the Cura slicer, so the cooling fans turn on at specific intervals.

While warping is a key issue for 3D printed parts, the temperature of your environment also matters drastically when printing with Nylon. Avoid printing in a cold room, and try to use an enclosure.

What Are Advantages of 3D Printing Nylon?

- Can give sharper detail than ABS or PLA

- Creates mechanically durable, strong, and tough parts that are second to none

- Highly flexible when printed thin

- Top-notch impact resistance

- Resistant to wear and tear, and abrasion as well

- Easy post-processing with dyes and paints due to its hygroscopic nature

- More UV and chemical resistant than ABS or PLA

- Offers low friction for making high-quality moving parts

- Great for display and aesthetic models

What Are the Disadvantages of 3D Printing Nylon?

- Difficult to print with and not recommended for beginners

- Works best with an enclosure and a heated bed, unlike PLA

- Being hygroscopic also means that it accumulates moisture quickly when not stored somewhere dry

- For the best results, Nylon requires pre-drying, which can be bothering at times

- Prone to warping due to its high melting point

- Parts can shrink during printing if it’s cooled

- The majority of Nylon brands have a low shelf life

- An all-metal hot end is used to print Nylon and not all 3D printers come equipped with it

What Bed Surface Should I Use for Nylon Filament?

The best bed surface for printing Nylon filament is glass. A heated glass build plate with a layer of PVA glue or blue painter’s tape on it works great for adhesion. You can also use other advanced bed surfaces like garolite or PEI. These surfaces are known to work well for Nylon 3D prints.

A heated glass build plate with a layer of PVA glue or blue painter’s tape on it works great for adhesion. You can also use other advanced bed surfaces like garolite or PEI. These surfaces are known to work well for Nylon 3D prints.

Getting Nylon to properly adhere to the build plate can be tricky. However, you can certainly use different bed surfaces to see which one performs the best for you.

Generally, a glass bed is known to work wonders for Nylon. That is when you pair the bed with heating, and an adhesive like glue, or tape.

Some users have even used poplar wood and cardboard as a build plate for Nylon. However, that is not the most ideal option to go with.

I’d recommend getting yourself a good quality garolite or PEI bed surface. You can find a good garolite build surface on MatterHackers.

The LayerLock Garolite Bed Surface is a top-rated build plate that doesn’t require heating to print Nylon successfully. It is lamented with an epoxy resin for improved adhesion. You can also use 220 grit sandpaper on this bed to further improve the textured surface.

You can also use 220 grit sandpaper on this bed to further improve the textured surface.

In terms of a good PEI surface, these are available directly from Amazon for a competitive price. I’d recommend going for the Gizmo Dorks PEI 3D Printer Build Surface from Amazon.

In the following YouTube video, a user demonstrated how garolite works for Nylon.

How Strong is 3D Printed Nylon?

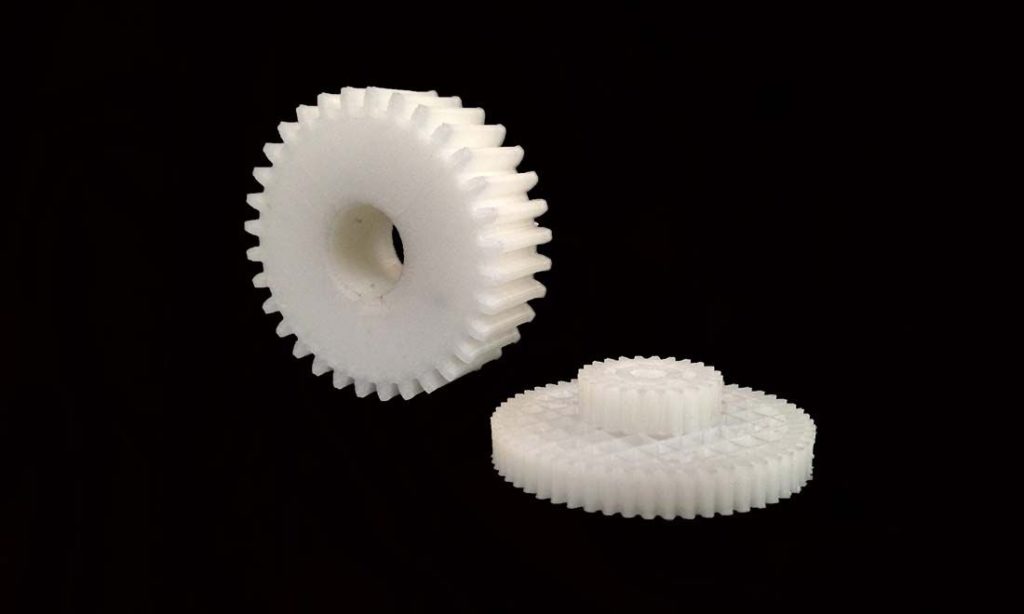

Nylon is popular for its durability and toughness. It’s more durable than ABS and boasts a high tensile strength of 7,000 psi. It is also highly flexible when printed thin, due to amazing impact and abrasion resistance. Military equipment such as tents, ropes and parachutes are made with this material.

Nylon is known to be ten times more impact-resistant than ABS. It’s on a whole new level than PLA in terms of toughness. Nylon is also flexible. Premium-grade cable ties are made out of Nylon and are extremely flexible.

If you’re printing Nylon with appropriate settings, you can count on it to tolerate significant impacts and abrasion. For that, make sure you’re using the right amount of infill and wall thickness.

For that, make sure you’re using the right amount of infill and wall thickness.

Best Nylon Filament to Buy for 3D Printing

Nylon has a reputation in the 3D printing space for its physical prowess and characteristics. Several manufacturers have this advanced filament up for grabs, but not all of them are worth the purchase.

Let’s have a look at some of the best Nylon filaments you can buy right now for 3D printing.

OVERTURE Nylon

OVERTURE Nylon is a high-class filament that promises to take away some complications associated with printing this material. It tends to warp lesser than other Nylon brands, and still offers the same excellent strength.

With a 4.5/5.0 overall rating on Amazon at the time of writing, OVERTURE Nylon is well-admired within its user base. 71% of the people who bought it have left a 5-star review lauded with praise.

It’s also priced conveniently at $31, and that’s even cheaper than the sub $55 cost of MatterHackers PRO Series Nylon. If you’re on a budget, there’s no other Nylon filament I’d rather recommend than this one.

If you’re on a budget, there’s no other Nylon filament I’d rather recommend than this one.

The manufacturer also includes a 200 × 200mm build surface for each spool of filament you buy from them. This surface is easily customizable to varying lengths to suit the size of your 3D printer.

One extremely satisfied customer was delighted to find out how easy it is to print with the OVERTURE Nylon. They even compared the ease-of-operation to PLA, minus the ventilation and temperature settings.

Buy OVERTURE Nylon directly from Amazon today.

SainSmart Carbon-Filled Nylon

SainSmart Carbon-Filled Nylon is an incredibly strong filament that has a formula built for rigidity and performance. It has a ratio of 75% Nylon to 25% Carbon Fiber, which is still easy to 3D print and provides an excellent surface finish.

For any projects that require some real resistance and strength, it would be a good idea to get yourself a spool of this filament.

It has a low shrinkage rate along with high strength and even less warping compared to normal Nylon filament. You can get some amazing dimensional accuracy, as well as solid functionality and stiffness for your 3D prints. Many people also enjoy how heat-resistant the filament is.

You can get some amazing dimensional accuracy, as well as solid functionality and stiffness for your 3D prints. Many people also enjoy how heat-resistant the filament is.

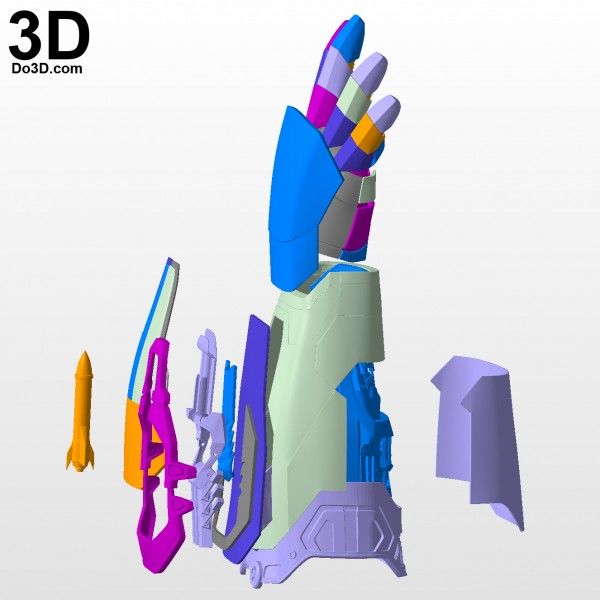

Some key examples of uses for this type of material would be things like prosthetics, cosplay, hinges, and even medical equipment. Do keep in mind that Carbon Fiber is an abrasive material, so it’s advised to use a hardened steel or stainless steel nozzle to handle it.

Using an enclosure is likely to give you the best results, since a constant ambient temperature is ideal.

Do be careful not to sand this material without using a respirator mask, as sanding it will create tiny dust particles that are irritating to breathe in. Additionally, it’s best to use spray paint and primer to paint SainSmart Nylon.

Buy SainSmart Nylon directly from Amazon today.

MatterHackers Pro Series Nylon

The MatterHackers Pro Series Nylon was one of the first filament brands to introduce a variety of colors for Nylon, which was previously known to be available in a few colors only.

This is a top-rated brand that has thousands of happy customers. You’re getting a cost-effective, insanely durable, and strong solution for all your functional and mechanical part requirements by purchasing this Nylon filament.

With an overwhelming majority of positive reviews, MatterHackers Pro Series Nylon is something that continues to deliver beyond expectations through accurate filament tolerance, and premium-grade build quality.

MatterHackers mentions that Kawasaki’s Supercross Racing Team Engineers also purchase the PRO Series materials from which this Nylon filament is made for their motorcycles.

If you require even tougher Nylon with extra resistance and durability, you have the MatterHackers PRO Series Carbon Fiber and glass-infused Nylon as well.

Check out the MatterHackers Pro Series of Nylon filaments on their official website store.

How Do You Dry Nylon Filaments?

Nylon filaments can be dried by heating them in an oven or leaving them to dry in any moisture-free container. You can also purchase a dedicated filament dryer to eliminate unwanted moisture from your Nylon filament. If you have a food dehydrator at home, you can use that too to keep Nylon dry.

You can also purchase a dedicated filament dryer to eliminate unwanted moisture from your Nylon filament. If you have a food dehydrator at home, you can use that too to keep Nylon dry.

One of Nylon’s most undesirable traits is its tendency to take up moisture from the air at an alarming rate if not stored in a dry place. This alone can make a day and night difference when printing with Nylon.

The following video is a brief explanation of printing with wet Nylon filament vs a dry one.

I recommend opting for something more professional if you want to make high-quality Nylon prints. The SUNLU Upgraded Filament Dryer is an excellent option that you can purchase right now from Amazon.

It allows you to get rid of all the built-up moisture in your filament in a few hours, offering better quality and consistent prints. As the dryer comes fully assembled, you don’t have to put any effort into setting it up.

As the dryer comes fully assembled, you don’t have to put any effort into setting it up.

One of the best features of this filament dryer is its ability to allow 3D printing when the filament is being dried. This attributes to a productive experience and top-notch Nylon prints.

How Do You Smooth Nylon 3D Prints?

To smooth Nylon 3D prints, you want to use a combination of sanding with low and high grit sandpaper, then polishing with an epoxy resin. You should start with a coarse sandpaper (50-100 grit), then work your way up to finer sandpaper (300-600 grit). Finish by applying epoxy resin for a shiny surface.

If there are any gaps or holes, the epoxy resin can also fill them in.

You cannot use methods like acetone smoothing with Nylon since it is extremely chemical resistant. Your best bet is to sand it for smoothing out Nylon 3D prints.

How to Dye, Paint, or Polish 3D Printed Nylon

The best way to dye or paint 3D printed Nylon is to use an RIT fabric dye. People usually submerge their Nylon print in a tank containing hot water and the fabric dye for about 5 minutes, and then cool the print down in another tank full of cold water. This locks in the dye on the print and brings amazing results.

People usually submerge their Nylon print in a tank containing hot water and the fabric dye for about 5 minutes, and then cool the print down in another tank full of cold water. This locks in the dye on the print and brings amazing results.

You can also use a combination of primer and spray paint to paint 3D-printed Nylon.

Nylon is notorious for quickly absorbing moisture from the air and getting wet in a matter of minutes. This is obviously bad news for makers and enthusiasts, but Nylon’s hygroscopic nature also lends it a plus point.

You can easily post-process Nylon as primers, spray paints, and dyes tend to stick to it well. Where PLA and ABS would take many coats of paint for a great, shiny look, Nylon demands considerably fewer.

MatterHackers has created this highly useful video to illustrate how to dye Nylon 3D printed parts.

The following items are required to dye Nylon prints:

- A Nylon 3D printed part

- A container to hold water at a high temperature

- An RIT dye (works best for Nylon and is easy to get as well)

- Another container filled with cold water

- Pliers or anything similar to handle the dye

- Weight of some sort to keep the filament submerged inside the container

- A thermometer to measure the temperature of the water

- A stove or a hot plate

- Some tissues or paper towels

Before you dye your Nylon filament, the first thing to do after creating a Nylon 3D print is to clean it up, remove any support structures using an X-acto knife or Flush Cutters (Amazon), and smooth it for the best results.

Begin with coarse sandpaper that’s somewhere between 50-100 grits to eliminate large print artifacts and imperfections.

After you’ve plucked out the big ones, continue to finer sandpaper of 200-400 grits for smoothing the surfaces of your Nylon part. It’s recommended to use wet sandpaper for a more refined experience.

The Austor 102 Pcs Wet & Dry Sandpaper Assortment (60 to 3,000 Grit) from Amazon is a great choice to go with for your 3D prints.

In addition, be sure to clean out the bottom of the part for any residual glue, hairspray, or tape. Once done, take any cloth or toothbrush to take care of any visible dust. Now that your Nylon part is all ready, it’s time to dye the filament.

First, you’ll have to tie your model with the weight and set it down inside the container to measure how much water it’s going to take. Then, simply take out the model, fill in water at the specified level, and then add the dye.

You’ll now place this container on your hot plate or stove and start heating it. A temperature of 70°C is known to work best.

A temperature of 70°C is known to work best.

Side by side, you’ll take your second container and fill it with cold water. This will be later used to maximize the effects of the dye and lock them in.

It’s advised to first use test prints for dyeing to see how much time they take to catch the dye in the hot water container.

5 minutes is known to work for most people, but you can also use 3-5 test prints, and submerge them each with 30-second increments to evaluate the best time for your Nylon model.

After leaving your part submerged in your hot water and dye tank for the desired time, take it out using pliers, and sink it inside the cold water container.

Leave it there for about 5-7 minutes and after taking it out and drying for a couple of minutes, enjoy a beautifully colored Nylon 3D print.

Does Nylon Filament Emit Fumes? Is It Toxic?

Yes, Nylon emits fumes as it melts at a high temperature. It is known to emit a volatile organic compound called Caprolactam and Styrene, both of which are dangerous upon inhalation and can cause headaches and breathing problems. It’s highly advised to print Nylon with an enclosure and a proper ventilation system.

It’s highly advised to print Nylon with an enclosure and a proper ventilation system.

Nylon is one of the most toxic 3D printer filaments out there. It does not emit foul-smelling odors during printing, but can pose a health risk when printed without precautionary measures.

You can check out my article called 3D Printer Enclosures: Temperature & Ventilation Guide, which goes through some of the key information that you’ll want to know.

Is Nylon Hard to Print With?

Nylon is an advanced filament that is known to be hard to print with due to a number of reasons. It has a high melting point that most 3D printers cannot achieve without an all-metal hot end. It is also extremely hygroscopic and will absorb moisture from the air quickly if not stored somewhere dry.

Ideally you should have an enclosure and a heated bed to 3D print Nylon successfully.

It can take a fair amount of time to get the hang of printing Nylon without running into print failures.

You also want to have the right settings, a capable 3D printer with an all-metal hot end, a suitable printing environment, and a place to store your filament and prevent it from getting dry.

Following the settings and process in this article should make Nylon easier to 3D print with.

Once you get everything right, your chances of getting amazing Nylon prints will increase dramatically.

Does Nylon Need an Enclosure?

Yes, it’s highly recommended to print Nylon with an enclosure. Nylon has a high melting point that makes it vulnerable to warping. Using an enclosure minimizes the chances of warping and provides Nylon the constant, ambient temperature that it needs to thrive and make stunning prints.

An enclosed print chamber increases print quality and keeps the temperature generated from the nozzle and the bed regulated with minimal fluctuations. Therefore, using an enclosure when printing with Nylon can bring great results.

Improving the look & feel of your parts with Chemical Smoothing

3D Learning Hub

See all categories

Contents:

- Introduction

- What is Chemical Smoothing?

- Which materials work with this process?

- Technical information for Chemical Smoothing

Introduction

Additive Manufacturing comes with different processes that can maximize the aesthetic aspects of 3D printed parts. With a painting post-process for instance, 3D printing projects can be complemented with several colors for visually appealing parts. But can finishing options improve both the look and feel of 3D printed objects?

With a painting post-process for instance, 3D printing projects can be complemented with several colors for visually appealing parts. But can finishing options improve both the look and feel of 3D printed objects?

With Chemical smoothing, it is possible. As its name suggests well, it provides 3D printed parts with professional, smooth finished surfaces and can also be done with a dyeing process.

How does Chemical Smoothing work? How can it build on the strengths of your 3D printing project? Let’s get into all the information you need to know about it.

What is Chemical Smoothing?

This process is the result of years of development and has been patented as a finishing option for laser-sintered thermoplastics.

How does it work?

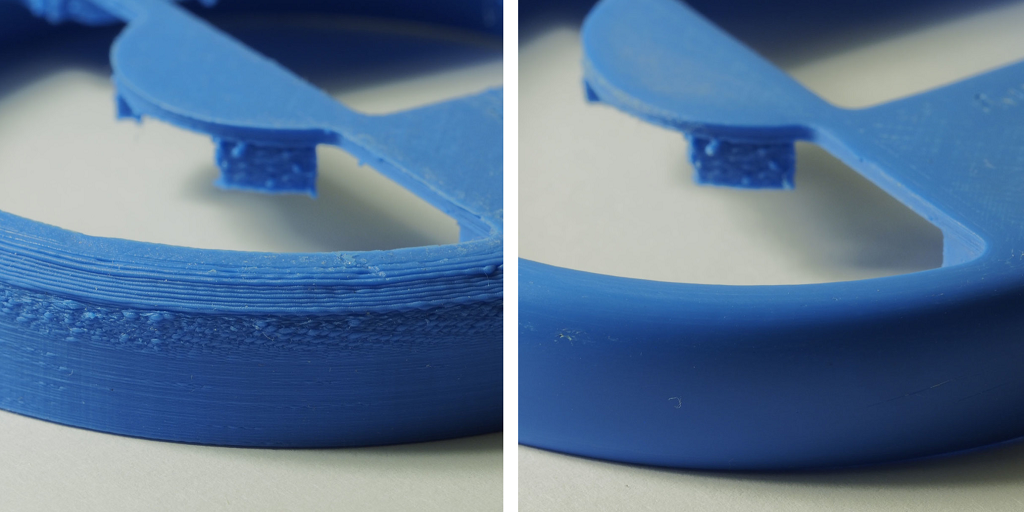

This process relies on specialized technology in which parts are introduced. A steam-solvent is diffused throughout the chamber and the smoothing process then begins. As the solvent condenses on parts, a physicochemical reaction reflowing parts takes place. This allows to even out irregularities and the characteristic ridges of 3D printing.

This allows to even out irregularities and the characteristic ridges of 3D printing.

Once over, this stage gives way to a curing phase which solidifies and turns surfaces shiny. After the drying process, the solvent is evaporated, and the parts are ready.

Why choose this finishing option?

As mentioned earlier, the first and key reason why one would resort to chemical smoothing is the fine surface finish it can give to parts. Indeed, 3D printed objects undergoing this process get a sleek, glossy surface and the feel of injection molding. To illustrate how fine chemically smoothed parts can be, the RA of the surface finish that this technology can achieve could be as low as one micron, depending on the specificities of the parts. This, in turn, allows for better looking and more professional parts.

On top of these aesthetic benefits, chemical smoothing has another advantage of sealing and removing porosity from parts, hence to turn them more resistant to liquids and easier to clean. This suggests that apart from making parts more professional, chemical smoothing also helps improve their functionality for certain applications.

This suggests that apart from making parts more professional, chemical smoothing also helps improve their functionality for certain applications.

Which materials work with this process?

This process has been designed for thermoplastics and can be used along with multiple materials. Now that you know what the benefits of chemical smoothing are let’s talk about how it applies to different plastic materials.

SLS Nylon PA12

This plastic material is used for applications across a wide variety of industries. When it comes to chemical smoothing, this technology is often combined with parts printed in Nylon PA12 such as electronic enclosures, figurines, or objects designed with organic shapes. Indeed, items designed with straight lines are usually homogenous, while parts with curves and round edges tend to display ridges that may need some refinement, hence the usefulness of this finishing option. Going further with its applications, Nylon PA12 is also prized for its bio-compatibility and is a nice fit for medical equipment production. Note that chemical smoothing doesn’t have any bearing on this property, as the technology has been certified for medical uses and as parts processed with it don’t show any cytotoxic effect.

Note that chemical smoothing doesn’t have any bearing on this property, as the technology has been certified for medical uses and as parts processed with it don’t show any cytotoxic effect.

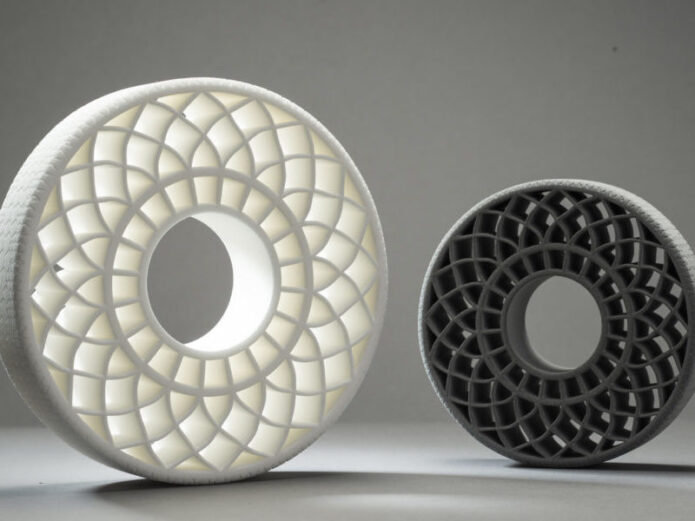

Objects printed with Nylon PA12 come out white and with a granular aspect. Chemical smoothing can be employed to refine the surface and turn it glossy, or, with dying to apply color and smooth the surface.

Ultrasint® TPU01

This elastomer is a high-performance material and can be utilized for high flexibility applications in industries such as sports equipment or Automotive.

Ultrasint® TPU01 has been developed for HP’s Jet Fusion technology and is utilized for mechanical part production projects. It can be complemented with chemical smoothing without risk of degrading mechanical properties. Parts processed with this technology are sealed and perform better with fluids, and still benefit from the flexibility and sturdiness of TPU.

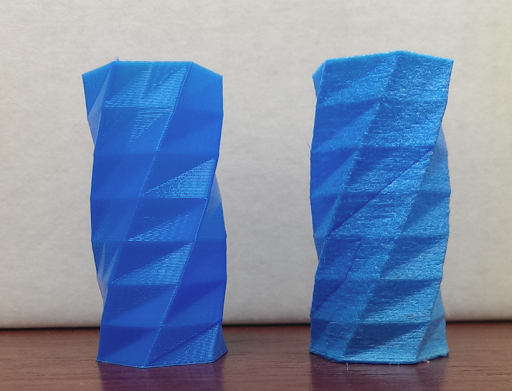

Ultrasint® TPU01 comes out grey, and once processed with chemical smoothing, it becomes black with a glossy look. The difference in results before and after the process is drastic, as chemical smoothing significantly improves the surface finish of Ultrasint® TPU01 and completely removes its original granular look.

The difference in results before and after the process is drastic, as chemical smoothing significantly improves the surface finish of Ultrasint® TPU01 and completely removes its original granular look.

Processed Ultrasint® TPU01 part (right) and raw part (left)

Raw Ultrasint® TPU01 part (left) and processed part (right)

Technical information for Chemical Smoothing

If based on the benefits we have covered, you have identified how you can take advantage of chemical smoothing, here are the requirements you need to know about:

Parts intended for this finishing option must have minimum dimensions of 15 x 25 x 0.5 mm, and with maximum dimensions of 450 x 250 x 200 cm. Also, chemical smoothing can’t apply to hollowed parts due to the powder excess that can’t be removed from within.

As the process itself takes 2 business days to be completed, chemical smoothing isn’t available for express and economy production. Processed parts can be delivered from 7 days after the order.

Processed parts can be delivered from 7 days after the order.

If you have a project in mind and wish to experiment how this finishing option can showcase your parts, or if you’re looking for pricing information, you can upload your 3D file on our online 3D printing platform. If you need some specific aspects of your project to be addressed, you can also get in touch with our sales team for more support.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

3d printing with nylon: properties, application, equipment (educational program)

Now let's talk about 3d printing with nylon - let's talk about the variant of technology and material, about the products obtained by this method of printing, and also say a few words about used equipment.

To reveal the topic, we talked with employees of the company SIU System (official website https://siusystem.ru/), which specializes in the development of additive technologies in Russia and the CIS. Here's what we were able to find out. nine0009

Meet Nylon

The first thing to remember is that nylon is a polymer, which means it is a plastic with long, heavy molecules made up of short atoms.

Today, along with ABS and PLA plastics, nylon is one of the most popular materials for 3D printing.

Nylon is a tough thermoplastic and in our opinion one of the most versatile materials currently available.

Nylon properties

To describe this material in a nutshell, we should mention its exceptional abrasion resistance, good flexibility and high strength.

Nylon is an incredibly strong and durable material widely used for 3D printing. It is abrasion resistant, heat resistant and has a low coefficient of friction. It is flexible for thin printing, firm for thick printing, and provides excellent dimensional stability during the printing process. Nylon does not stick to glass or metal surfaces, has a low odor, and prints with a surface similar to smooth sandpaper. It is usually available in clear and black. nine0009

It is flexible for thin printing, firm for thick printing, and provides excellent dimensional stability during the printing process. Nylon does not stick to glass or metal surfaces, has a low odor, and prints with a surface similar to smooth sandpaper. It is usually available in clear and black. nine0009

Nylon 3D Printing Applications

Nylon is best suited for industrial and engineering applications such as high performance machine parts, tools and moving hinges. It is also strong and stable enough to be machined and drilled without warping or splitting.

The downside of nylon is that it is not very stiff. ABS is a tougher material than nylon, though not as strong. To create super-rigid 3D printed nylon parts, the nylon must be reinforced. Some printer models do this by reinforcing nylon parts with continuous filaments of a composite material such as carbon fiber. nine0009

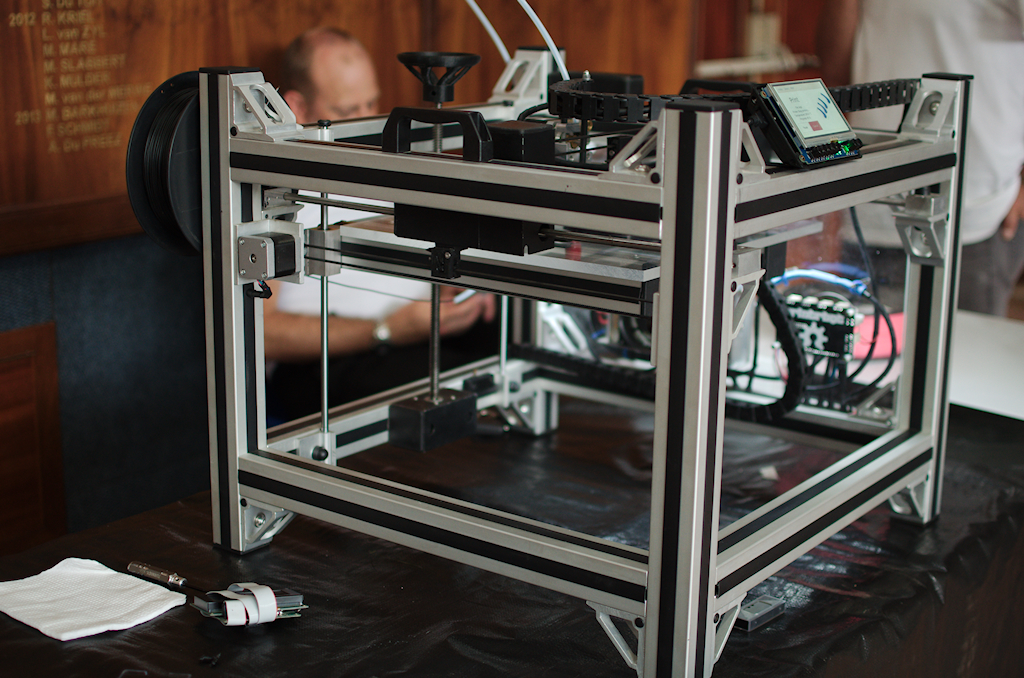

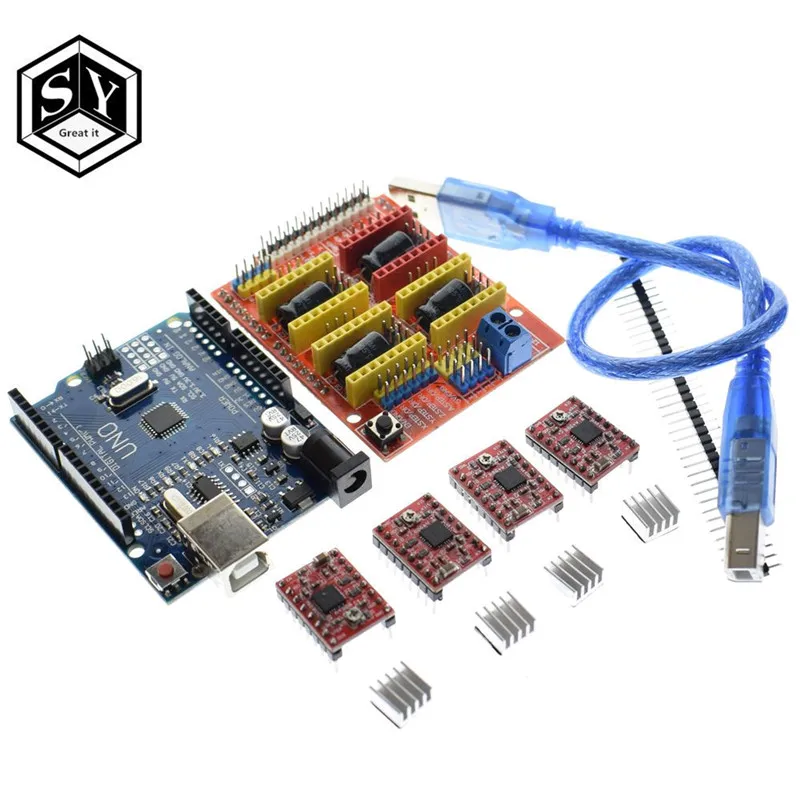

Which 3D printers print with nylon?

Nylon 3D printers must be able to withstand extruder temperatures above 240°C. In addition, these typewriters must have an all-metal hotend because nylon filament prints at over 240°C, the temperature range at which plastic melts like butter.

In addition, these typewriters must have an all-metal hotend because nylon filament prints at over 240°C, the temperature range at which plastic melts like butter.

Solid metal nibs are available for a wide range of 3D printers and some come standard. However, it is important to note that not all FFF/FDM printers can print on nylon. In fact, some manufacturers recommend against printing with it. nine0009

In conclusion, we note that additional information about 3d printing with nylon can be obtained on the website of our today's interlocutors from SIU System.

Noticed an error? Select it and press Ctrl+Enter

Tweet

Nylon Resin: 3D Printing Technologies and Features

Nylon Resin - belongs to the polyamide family, used in 3D printing, has strength and durability. He is very popular in the printing business and for good reason. Plastic has a number of advantages and characteristics that contribute to the high quality of product manufacturing. nine0009

nine0009

How to work with nylon filament before printing

The only problematic nuance when printing with nylon filament may be increased hygroscopicity. Therefore, the material must be dried before printing.

Dry filament will cause good adhesion of the layer, but if moisture gets on it, it will be more difficult to make the product when printing. Dry nylon has a smoother surface and even a sheen. It is recommended to dry nylon in the oven at a temperature not exceeding 82 degrees. Dry bags may not help in this case. It is necessary to print the material in a room where there is no cold and drafts. nine0009

Media warps

Media tends to warp if handled incorrectly, so all necessary process controls must be in place before printing.

What settings must be observed before printing with nylon:

- The extruder must have a temperature of 240 to 260 degrees Celsius.

- Printing must begin at a temperature of 250 degrees.

In the process, you can search for the required temperature to obtain a smooth and even surface. nine0057

In the process, you can search for the required temperature to obtain a smooth and even surface. nine0057 - The bed must have a temperature of no more than 80 degrees.

- Work at a speed between thirty and sixty millimeters per second.

- The fan should not be cooled with a cooling layer.

What are the properties of nylon filament

Nylon filament is one of the best for 3D printing compared to many other similar materials.

Its main advantages are good durability, strength and flexibility, and they are not typical for all threads. Nylon is low friction, durable and cost effective. It is usually used for all types of printing from thin to hard. Available in clear or black material. For printing with nylon thread, printer models corresponding to its capabilities are selected to make it more convenient to work. nine0009

How nylon is used in 3D printing

Nylon is best used in industrial and engineering production. It is used for the manufacture of automotive parts, tools and movable hinges. True, nylon also has its drawbacks - for example, a low level of flexibility. To avoid problems in the production of parts, nylon must be strengthened.

True, nylon also has its drawbacks - for example, a low level of flexibility. To avoid problems in the production of parts, nylon must be strengthened.

Benefits of 3D printing with nylon filament:

This printing material has good properties. Among them are:

- Affordable price

- Durability, strength, aesthetics

- Materials melt well due to high temperature

- No bad odors when applied

- Nylon is UV resistant Level of

is a product. For thin objects, flexibility will be at a fairly high level and vice versa. The material is easily dyed if dyes are added to the filament. You can also paint the finished product, giving it the desired color. nine0009

Among the shortcomings, one can also highlight certain difficulties when working with the material. To be ready for them, you need to have special knowledge. It is better for beginners to engage in materials of this kind and should be entrusted with the work of more experienced craftsmen.

Also among the minuses are noted:

- High hygroscopicity - it is better to avoid moisture on the material and pre-dry the thread before work.

- Pyrolysis releases toxic fumes. nine0057

- Some threads have a very small diameter.

Compared to the advantages, this number of disadvantages is negligible. Therefore, when selecting threads for 3D printing on printers, you can pay attention to this one.

Nylon does not adhere to glass or other types of plastic surfaces, so masking tape must be applied to the work surface before preparation. In order not to be disappointed in the quality of printing or the manufacture of objects, it is necessary to purchase nylon at a relatively high cost, since cheap options can lead to undesirable consequences. For FDM printing, a commercial version of ABC filaments is suitable. Also, during operation, temperature regimes should be controlled so that they are neither higher nor lower than the norm, so that future results of work are not deformed.