3D printed prosthetics video

Developing titanium 3D-printed prosthetic jaw

SHARE:

FacebookTwitter

Know about the development of titanium 3D-printed prosthetic jawLearn about a titanium 3D-printed prosthetic jaw.

© University of Melbourne, Victoria, Australia (A Britannica Publishing Partner)DR. GEORGE DIMITROULIS: So before 2008, I had to use the patient's ribs to rebuild their jaws. And that was quite major surgery, particularly for elderly patients that were under the knife, and under general anesthetic, for about four to five hours at a time.

So I sat down on the kitchen table one day and started doing a few drawings. And eventually, I got to the concept of, hey, I've got this nice streamlined joint that I think would work. And that's where it stopped. And I thought, well, I can't take it any further because I'm a surgeon, I'm not an engineer, I'm not a designer. And I thought I'd come to the University of Melbourne.

DR. DAVID ACKLAND: And asked us if we were interested in developing a prosthetic jaw joint replacement. Really was a very close collaboration from the very beginning. As engineers, we have expertise in using software and computational modeling tools.

DIMITROULIS: There was a lot of engineering research that went into it, to perfect it, to modify it, to make it a particular joint that would work comfortably in patients, and also be able to take the loads.

ACKLAND: Initially, when we developed our prosthesis, we 3D printed it in plastic. And we had it placed in a cadaver for biomechanical testing. More, recently, with the advent of 3D printing in titanium, we've actually been able to fabricate biocompatible implants and place them in cadavers and inside human patients.

DIMITROULIS: Whilst I was thinking about my very first patient that I was going to put it on, he walked through the door. And he had exactly the type of deformity, which was rare, that he needed not just a prosthetic joint, but he also needed his whole face reconstructed.

PATIENT: An x-ray last year discovered that I didn't have a condyle. It was sitting into my socket, so the top of the jaw bone was just resting on the joint socket. What was painful was on the opposite side all my muscles were straining and were shortening. So eating, chewing-- if I was already stressed at work for a long period of time I would just get so much pain on this side.

I was really nervous before the operation. It's a serious operation. There was a lot of anxiety leading up to it. It was really good to know that the jaw was developed just across the river at Melbourne Uni, and then printed out down in Port Melbourne, and then put in to me [INAUDIBLE]. It's this real Melbourne team.

ACKLAND: Huge benefits in fabricating implants using 3D printing technology, not just because the design can be tailored to a patient's anatomy, but incredible cost savings. We can fabricate an implant for less than $500. Now we know it's been placed in three patients and with many more patients queuing up to have this surgical procedure.

DIMITROULIS: There's also tremendous export potential. We're creating a center of excellence at St. Vincent's Hospital, part of the University of Melbourne. And from that we're hoping it will mushroom into a wider market as more and more people are trained to use the Melbourne prosthesis.

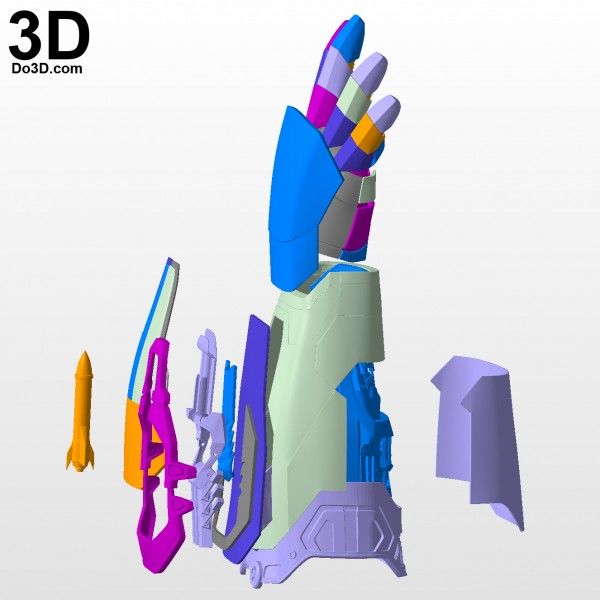

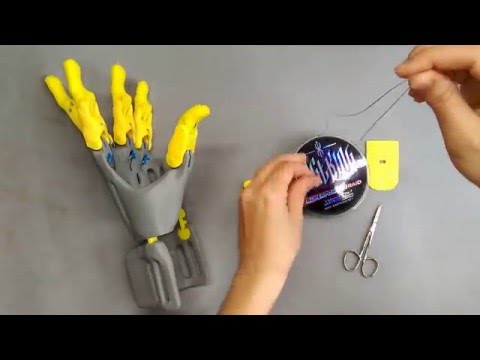

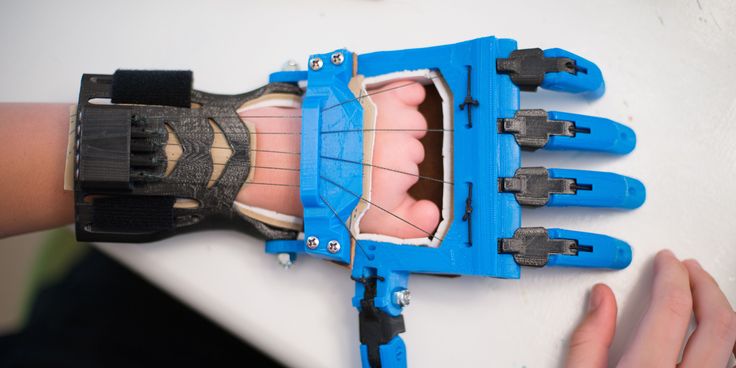

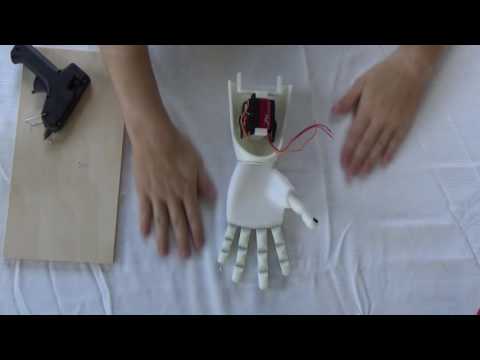

BUILD A HAND – Enabling The Future

Find the files and assembly instructions you need to build a hand!

The e-NABLE community has developed a collection of different 3D-printable assistive devices that are free for download and fabrication by anybody who would like to learn more about the designs or fabricate a device for somebody in need.

If you are interested in building your own 3D printed upper limb device and have access to a 3D printer, here is the information you will need to get started:

- Decide which kind of device is recommended for the limb different person in need.

Visit our Which Design page to see what your options are and choose from the designs that are currently available and recommended for those types of limb differences. Please note, that the e-NABLE Community does not currently have designs for above elbow limb differences, so the recipient or user must have a functional wrist or elbow to make these devices function properly.

Please note, that the e-NABLE Community does not currently have designs for above elbow limb differences, so the recipient or user must have a functional wrist or elbow to make these devices function properly. - Make sure to take photographs correctly to ensure a proper fit. Watch the tutorial video to learn how to take images that will help you get the measurements you need to create a device that will fit properly.

- Refer to the e-NABLE Device Sizing page to learn how to properly size an e-NABLE device.

- Check out our e-NABLE Devices page for tutorials, assembly kits and other helpful information!

If you have any questions along the way, feel free to ask our volunteers by posting a message in the forum.

If you would like to make your own device but do not have access to a 3D printer, check our our e-NABLE Chapters page, which includes a searchable map of e-NABLE Chapters. This map includes many libraries and makerspaces that may have 3D printers available for public use. You can also check this Google Map for libraries with 3D printers available.

This map includes many libraries and makerspaces that may have 3D printers available for public use. You can also check this Google Map for libraries with 3D printers available.

Please note: It is very important that you work with your physician, occupational therapist, physical therapist or prosthetist when using a 3D printed open-source e-NABLE device.

ACCEPTANCE

By accepting any design, plan, component or assembly related to the so called “e-NABLE Hand” , I understand and agree that any such information or material furnished by any individual associated with the design team is furnished as is without representation or warranties of any kind, express or implied, and is intended to be a gift for the sole purpose of evaluating various design iterations, ideas and modifications. I understand that such improvements are intended to benefit individuals having specific disabilities and are not intended, and shall not be used, for commercial use. I further understand and agree that any individual associated with e-NABLE organization shall not be liable for any injuries or damages resulting from the use of any of the materials related to the e-NABLE hand.

I further understand and agree that any individual associated with e-NABLE organization shall not be liable for any injuries or damages resulting from the use of any of the materials related to the e-NABLE hand.

Like this:

Like Loading...

The world's lightest prosthesis was made on a 3D printer and installed in Lviv

The world's lightest prosthesis printed on a 3D printer was installed at the Indestructible National Rehabilitation Center. It was received by 33-year-old Yuri Bakhir. He lost his arm due to a mine-explosive injury.

This was reported to Ukrinform in the press service of the First Medical Association of Lviv.

“The lightest 3D-printed prosthesis in the world was installed at the Indestructible National Rehabilitation Center of the First Medical Association of Lviv. It was received by 33-year-old Yuri Bakhir. He lost his arm as a result of a mine-explosive injury. This is the second such prosthesis in the world, installed to a Ukrainian. The first in the United States, with the assistance of the first lady of Ukraine Olena Zelenskaya, received 9-year-old Sasha from Bucha," the medical facility informed.

The first in the United States, with the assistance of the first lady of Ukraine Olena Zelenskaya, received 9-year-old Sasha from Bucha," the medical facility informed.

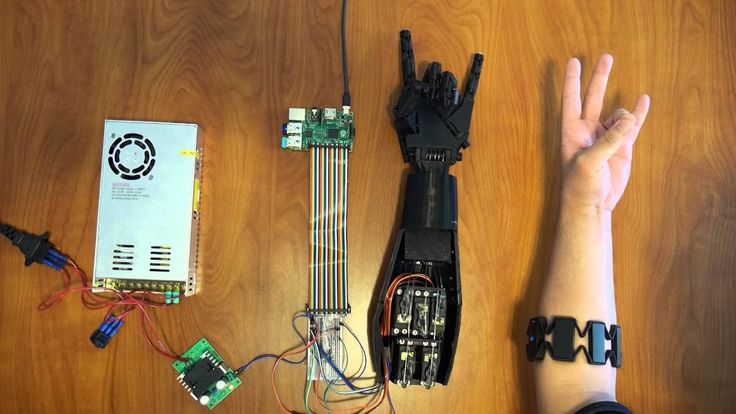

Earlier it was reported that the first bionic arm prosthesis was installed in the National Rehabilitation Center "Indestructible" of the First Medical Association of Lviv. This is the primary prosthesis. It can be installed immediately after the healing of wounds on the amputated limb. Thanks to special sensors, by contracting the muscles, the patient can control the prosthesis and move his fingers. nine0003

In Lviv, they made and installed the world's lightest prosthesis on a 3D printer / Photo: Press service of the First Medical Association of Lviv

The Enduring National Rehabilitation Center has partnered with bionic arm manufacturer Unlimited Tomorrow to expand its prosthetic program. In the future, thanks to the global organization Singularity Group, the Ukrainian Red Line Foundation and the leading creative agency Tabasco, it is planned to provide hundreds of Ukrainians with such prostheses. nine0003

nine0003

“Prosthetics is now one of the priorities of our work, because hundreds of patients need functional limbs. Our duty is to take care of them. And now we can do it using the most modern technologies. It is highly respected that partners provide Ukrainians with bionic prostheses for free,” said Oleg Samchuk, General Director of the First Medical Association of Lviv.

There are several Ukrainian defenders on the TrueLimb waiting list. Among them is 41-year-old Alexander Yashuk. The man lost a limb in the battles near Chernobyl. He says he needs a functional prosthesis to be useful and independent. nine0003 Read also: Surgeons from the USA will operate on Ukrainian soldiers in Ivano-Frankivsk

“There, in the battle, when I saw that there was no hand, I was actually glad that at least I myself was alive. That I will still be with my relatives, I will see them, and they will see me. And now this hand for me is a chance to be independent and useful. I can ride a motorcycle and lift honey frames in the apiary. This is important,” says Yashuk.

This is important,” says Yashuk.

According to Easton LaChapelle, CEO and founder of Unlimited Tomorrow, the partnership with the Indestructible Rehabilitation Center was the result of a common interest in helping victims in Ukraine and supporting as many people with prosthetic limbs as possible. nine0003

"We see this as a step forward in our vision of improving the quality and availability of prostheses on a global scale," added LaChepelle.

Read also: First stem cell transplantation performed in Lviv The center "Indestructible" of the First Medical Association of Lviv installed the first bionic prosthetic arm. It was received by 33-year-old Mikhail Yurchuk. The defender lost an arm and a leg near Izyum in the spring, and today he can move his fingers again. nine0003 Since hundreds of wounded Ukrainians are waiting for prosthetics, the Indestructible National Rehabilitation Center, together with the dobro.ua charity platform, launched the Prostheses for the Indestructible charity project. Thanks to the project, at least fifty Ukrainians will receive state-of-the-art bionic prostheses. To help them, you need to raise 100 million hryvnia.

Thanks to the project, at least fifty Ukrainians will receive state-of-the-art bionic prostheses. To help them, you need to raise 100 million hryvnia.

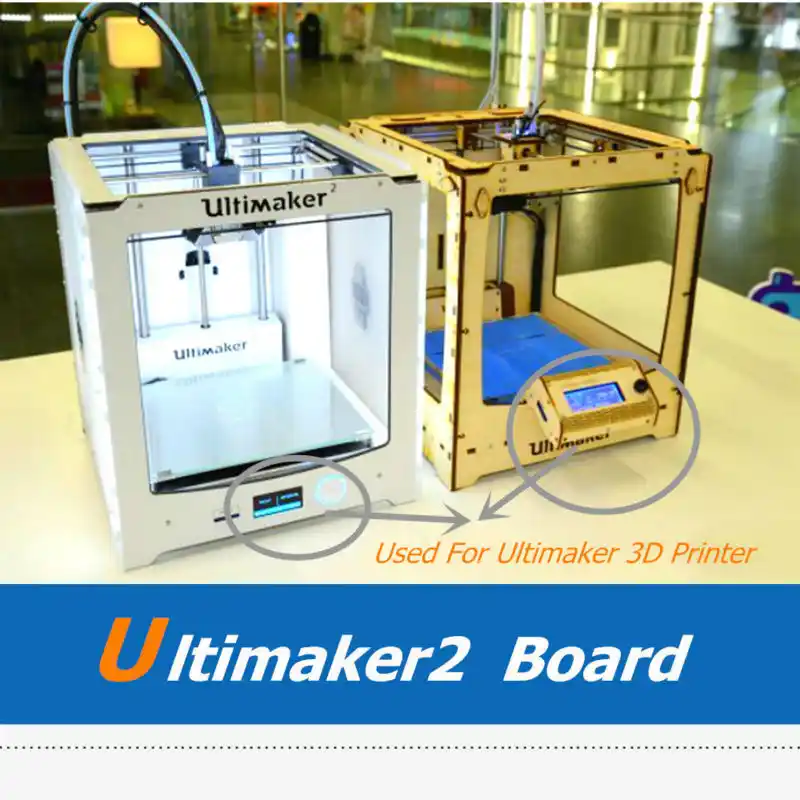

How to choose the right 3D printer for dentistry

How 3D printing can be used or is already being used in medicine and, in particular, in dentistry, quite a lot of notes and articles have been written, a large number of reports and lectures have been held. Almost all the participants in these disputes are aware of the advantageous prospect and inevitability of the arrival of 3D printing in most areas of dentistry. nine0003

But there are few places where the technical and economic specifics are voiced when choosing this equipment, and even more so, the obvious shortcomings of a particular 3D printer or 3D printing technology are pointed out.

In this article, we will try to analyze in more detail the main nuances when choosing a professional 3D printer for dentists, taking into account the most important factors - the optimal 3D printing technology, quality, reliability and, most importantly, the affordability of a 3D printer in the Russian market. We will also find out what today influences the choice in favor of 3D printing using the example of one dental clinic. nine0003

We will also find out what today influences the choice in favor of 3D printing using the example of one dental clinic. nine0003

Choosing SLA

The very first professional 3D printing technology was stereolithography (SLA), which turned 30 this year. SLA remains the most versatile and cost effective 3D printing technology. In its favor speaks a large selection of photopolymers with different physical and chemical properties. The laser system has a much longer life than the similar DLP technology, which is based on light sources such as LEDs or projector lamps, which require periodic replacement and financial investment. For a long time, the main patents for the use of SLA technology (exactly in the form in which it was invented) were owned by the American company 3D Systems. Each time, making small changes, it extended the validity of patents, remaining an absolute monopolist in the market for professional and industrial 3D printers using SLA technology. nine0003

In 2014-2015, the situation changes dramatically and after the end of all kinds of "copyrights", many manufacturers of 3D printers using SLA technology appear on the market. First of all, these are Asian analogues / clones of famous brands without making any design changes. With an attractive cost from $1,000 to $4,000, but giving out completely non-profile results. Therefore, this category cannot be attributed to the professional line due to the discrepancy between the print quality and the internal equipment of the equipment itself. nine0003

First of all, these are Asian analogues / clones of famous brands without making any design changes. With an attractive cost from $1,000 to $4,000, but giving out completely non-profile results. Therefore, this category cannot be attributed to the professional line due to the discrepancy between the print quality and the internal equipment of the equipment itself. nine0003

No matter how advertising articles or online store managers convince you of the opposite, most of them just read the text of the same advertising article, you will simply lose money, time and even be disappointed in the correctness of your choice in favor of 3D printing. Therefore, we only consider 3D printers that really meet the accuracy and quality parameters declared by the manufacturer.

Price gap

And so the price range of really high-precision and reliable 3D printers (SLA) in Russia starts from $6,500. It is affordable and suitable for small-scale printing of one-off models from rigid, transparent or burn-out polymers. nine0003

nine0003

But here it is important to understand that if the manufacturer of 3D printers (SLA) does not position its model as a direct 3D printer for dentistry, but presents its equipment as allowing it to be used in all production areas equally effectively and as profitably as possible, this printer , most likely has software and technical limitations. For example, such as not being able to place models vertically, but only at 45°, significantly reducing the working area of the table. To date, there simply are no multi-purpose 3D printers that are equally suitable in their starter kit for printing, for example, color building models and surgical templates for dentistry. Therefore, if you are interested in getting full-fledged performance from a 3D printer without losing quality in dentistry, we also ignore this line of 3D printers. nine0003

The next price range for professional 3D printers (SLA) for dentistry starts from $45,000 to $800,000.

This is no longer a small financial investment, which also requires the loading of equipment to reduce its payback period, which can reach several years.

This class of equipment has a number of disadvantages, which are sometimes ignored by the supplier:

- Binding to the use of only their own consumables. nine0073 High cost of printing.

- Completely closed software.

- Special conditions for the operation of a 3D printer.

- Need to buy additional hardware.

- Expensive post-warranty service, long delivery time for components, etc.

3D printer Basic (Dental) - golden mean

We offer you the most optimal and cost-effective solution on the market of professional 3D printers (SLA) for dentistry. nine0003

The Basic (D) 3D printer is not positioned with well-known brands of desktop 3D printing options. This is a more affordable option for professional and expensive equipment, capable of continuously high-volume printing, while having unique control functionality and a set of excellent features. What Basic (D) offers you really doesn't fit any 3D printer (SLA).

Here are just a few of the Basic (D) justification factors:

- The Basic (D) 3D printer and its software are designed specifically for dentists.

- Vertical layout of models without loss of quality when printing at 25 microns.

- The highest print speed among competitors.

- Not linked to consumables. A unique system for adjusting the laser illumination speed allows you to achieve high precision results using any third-party photopolymer (405 nm). nine0074

- Five print modes (25\30\50\75\100 microns).

- Low cost printing.

- Direct printing of scanned models in STL format.

- 80% of all service calls are resolved by remote connection using software, without requiring a service engineer to visit.

- The most favorable combination of price / quality on the Russian market of 3D printers for dentistry.

In addition to the above indicators, we also note the standard features of Basic (D):

- Printed in paraffin-containing photopolymer for post-casting without ash, using standard temperature burnout.

- Rigid/ABS/Rubber/Transparent/White/Natural and many other photopolymers are also available.

- All photopolymers are non-toxic and certified to standard Class IV safety.

- Operating life of the laser system is 10,000 hours, which is confirmed by the warranty statement. nine0074

- Full service support in Russia.

The launch of the Basic (D) 3D printer on the Russian market was preceded by a lot of work by the entire 3D Osnova team. For more than a year, we have been conducting in-depth testing of this 3D printer before offering it to you. Our specialists were trained at the manufacturer's production sites, studied the experience of using this equipment among dentists in other countries, and finally, we added a number of optional changes to adapt this equipment to the requirements of Russian dentists. We really have a lot to be proud of. We also ask you to evaluate the combination of simplicity and reliability in the use of the Basic (D) 3D printer with its high-precision printing and multifunctionality of work performed in the field of dentistry. We are always ready to answer your questions, provide a full consultation and demonstration of the Basic (D) 3D printer. nine0003

We are always ready to answer your questions, provide a full consultation and demonstration of the Basic (D) 3D printer. nine0003

Let the "machines" do the work

Let's look at one specific use case for the Basic 3D printer. Meet this dentist of the highest category Alexander Nikolayevich Romankov (Clinic of Modern Dentistry, Sochi, founded in 1991), who devoted his entire conscious life to his profession, just like many colleagues, passing on his knowledge and experience to future generations, his daughter, also a dentist.

His short story about how he came to use 3D printing in his clinic

"Today, more than 2,500 people are regular patients of our clinic, plus a constant influx of new clients (1-2 daily). Over the past two years, the volume of work performed has increased significantly, taking into account the introduction of fairly new orthodontic services: correction of teeth bite without braces (system of aligners), production of our own surgical templates for implant placement. It is for this work that we planned the introduction of 3D printing. We just want to give the solution of these tasks to machines, thereby reducing the visit time of our clients and significantly saving our strength. Do not forget For example, printing one dental impression on a Basic (D) 3D printer costs us about $ 8, and soon this figure may decrease by another 1.5 times, since we may start using a photopolymer from a Russian manufacturer. we conduct remotely and one course costs about $ 170 for us. Then there is the molding and processing of the mouthguard." nine0003

It is for this work that we planned the introduction of 3D printing. We just want to give the solution of these tasks to machines, thereby reducing the visit time of our clients and significantly saving our strength. Do not forget For example, printing one dental impression on a Basic (D) 3D printer costs us about $ 8, and soon this figure may decrease by another 1.5 times, since we may start using a photopolymer from a Russian manufacturer. we conduct remotely and one course costs about $ 170 for us. Then there is the molding and processing of the mouthguard." nine0003

Tips for choosing a 3D printer supplier

1. It is not recommended to purchase equipment from companies that do not have a demo printer or print samples of this printer.

2. The company must have a full or partial service on the territory of Russia, and not a guarantee from the manufacturer.

3. When purchasing a 3D printer, you must ask the supplier to print their own 3D model for you, or to demonstrate a similar one. A conscientious supplier will not see anything strange in this, and moreover, a company that is confident in its product and has come to the market for more than one day should itself offer you a pre-sale print, albeit for a certain amount, which is deducted from its cost during the subsequent purchase of equipment. nine0003

A conscientious supplier will not see anything strange in this, and moreover, a company that is confident in its product and has come to the market for more than one day should itself offer you a pre-sale print, albeit for a certain amount, which is deducted from its cost during the subsequent purchase of equipment. nine0003

4. Ask for contacts of 1-2 customers who have already purchased this or similar equipment to form an independent opinion about this company and its product.

By following these smart tips, you will weed out unqualified suppliers and save time and money in the future.

What am I overpaying for?!

There is an opinion / practice that it is more profitable to purchase a non-industrial 3D printer directly in the manufacturer's country or order it in Europe or the States. Why overpay local suppliers and dealers when you can just pay extra for shipping. And this is a perfectly reasonable argument in favor of financial gain. But momentary gain can turn into unpleasant moments in the future.