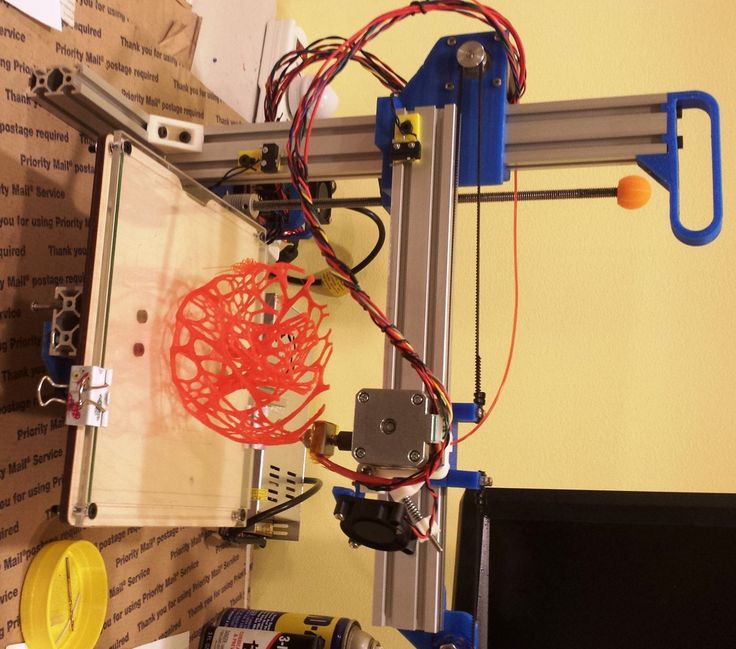

Sliding 3d printer

The Sliding-3D PLUS High-Temp Infinite 3D Printer « Fabbaloo

By Kerry Stevenson on April 25th, 2019 in printer

Tags: belt, continuous, high temperature, infinite, robotfactory, sliding-3d

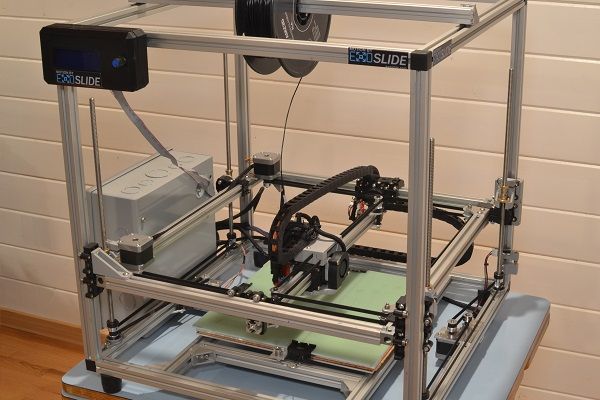

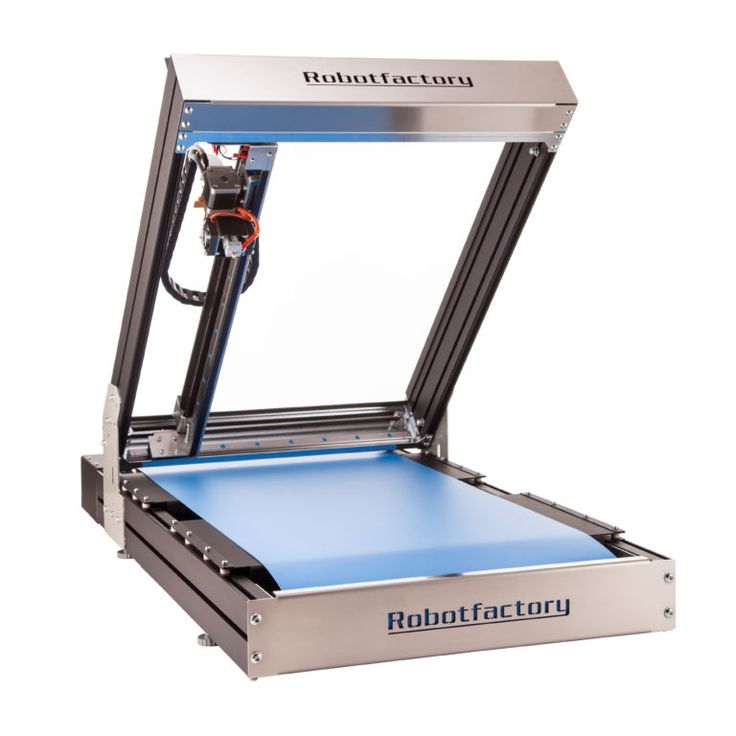

The Sliding-3D PLUS High-Temp Infinite 3D Printer [Source: Robotfactory]Robotfactory announced a higher-temperature version of their infinite 3D printer.

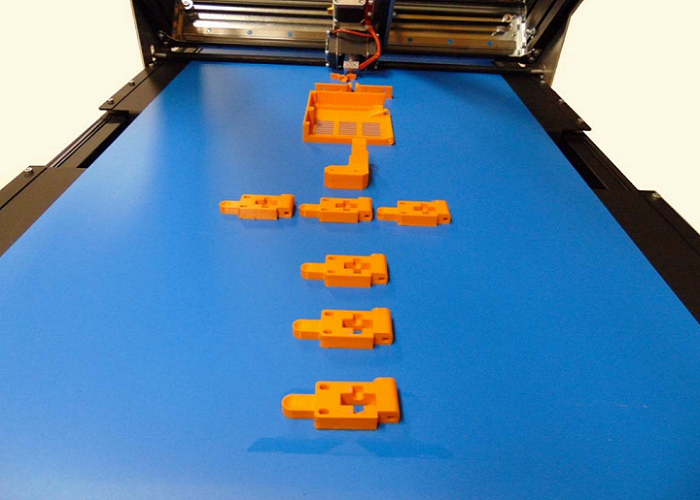

The Sliding-3D device is a rarity in the industry, as it provides a practical way of printing objects infinitely. This is achieved through its use of a rolling belt as its print surface. Objects are printed at an angle as the belt slowly moves. When the completed object reaches the end of the belt, it peels off and falls into a bucket.

As long as you keep supplying the machine with filament, it will continue to print and fill your bucket with wonderful 3D prints. When we say “infinite”, we mean it. Another way to put this is that its build volume is 410mm x 380mm x infinity!

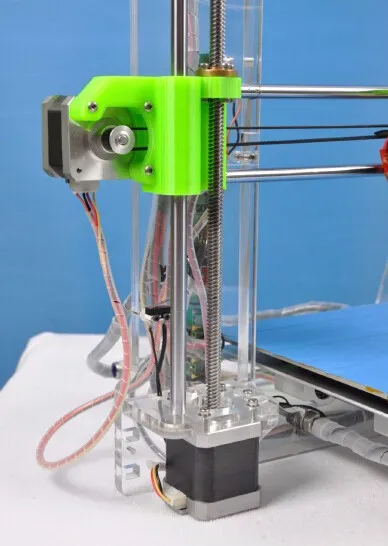

The belt-printing concept on the Sliding-3D PLUS 3D printer [Source: Robotfactory]Now the company has announced a tweaked version of the device they call the “PLUS”.

It is essentially the same machine, except that it has a hot end that can handle much higher temperatures. The Standard version tops out at 280C, but the new PLUS can hit 480C.

The 480C-capable hot end on the Sliding-3D PLUS 3D printer [Source: Robotfactory]This means that the PLUS can theoretically print higher-temperature materials. Robotfactory says the PLUS can handle: “Carbon Fiber, Glass Fiber, PPS, Therme, PEEK, Ultem, PLA, Nylon, PETG, HIPS, TPU and other.”

The print bed, or should we say belt, is also heated and can be as high as 130C. This high temperature will also be very helpful when printing high-temperature materials.

They published a video of the PLUS printing an object in PPS-CF material:

This device is very interesting, but there seem to be some missing features on this device. As every 3D printer operator knows, high-temperature materials can be very tricky to print. The problem arises in the massive temperature differential between the hot end and previously extruded material that has cooled to ambient levels.

The problem arises in the massive temperature differential between the hot end and previously extruded material that has cooled to ambient levels.

The temperature difference frequently results in warping due to the thermal expansion characteristics of many high-temperature materials. If the warping is significant, the print could dislodge from the bed and cause a print failure.

All high-temperature 3D printers I am aware of attempt to overcome this phenomenon by increasing the temperature of the ambient air in the build chamber. This is done by enclosing the build chamber and heating it explicitly. In some cases the build chamber’s atmosphere can be as high as 100C. This tends to minimize the thermal difference and reduce warping effects.

In its standard configuration the PLUS, like the original version, does not include an enclosure. Thus it is impossible to overcome the thermal gradient between hot end and ambient air, and considerable warping is therefore possible. Robotfactory does offer a “Protective Box” made from polycarbonate, but this seems far less robust than some of the purpose-built metal enclosures of other high-temperature 3D printers.

Robotfactory does offer a “Protective Box” made from polycarbonate, but this seems far less robust than some of the purpose-built metal enclosures of other high-temperature 3D printers.

It’s also possible that buyers of the PLUS might be able to overcome warping effects by simply placing the PLUS into a heated chamber of their own design. However, this means that the device’s delicate electronics and motion system will be unexpectedly heated. This could cause damage to the device either immediately or over a longer period.

Another aspect I am concerned about is the viability of the belt material itself. If repeatedly exposed to extremely high temperatures up to 480C, is there a danger of it being softened and distorted itself? I don’t know what the belt is made of but in order to survive high temperatures, it must he made of something very temperature resistant. Robot factory says it is made of new materials, but we’re not sure exactly what they are.

Warping tends to occur more frequently when objects are large, and so it may be possible to successfully 3D print smaller objects on the PLUS. It could be that the PLUS might be an ideal machine for printing larger quantities of smaller sized objects in high-temperature materials.

It could be that the PLUS might be an ideal machine for printing larger quantities of smaller sized objects in high-temperature materials.

Via Robotfactory

Kerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

View all of Kerry Stevenson's posts.

Robot Factory premiers Sliding-3D continuous 3D printer, technical specifications and pricing

0Shares

From October 12 through 14 2018 Robot Factory, an Italian 3D printer manufacturer showcased its Sliding-3D printer at Maker Faire Rome.

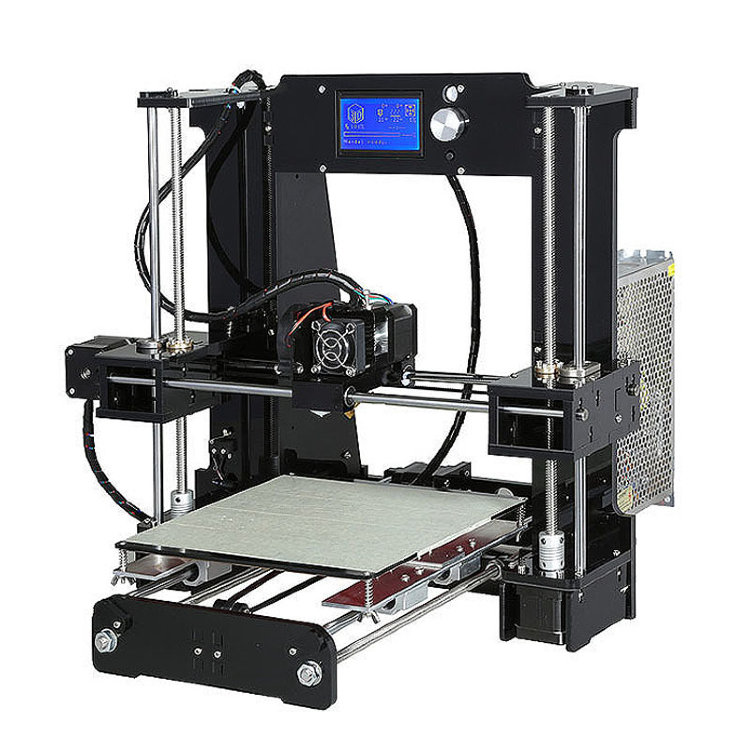

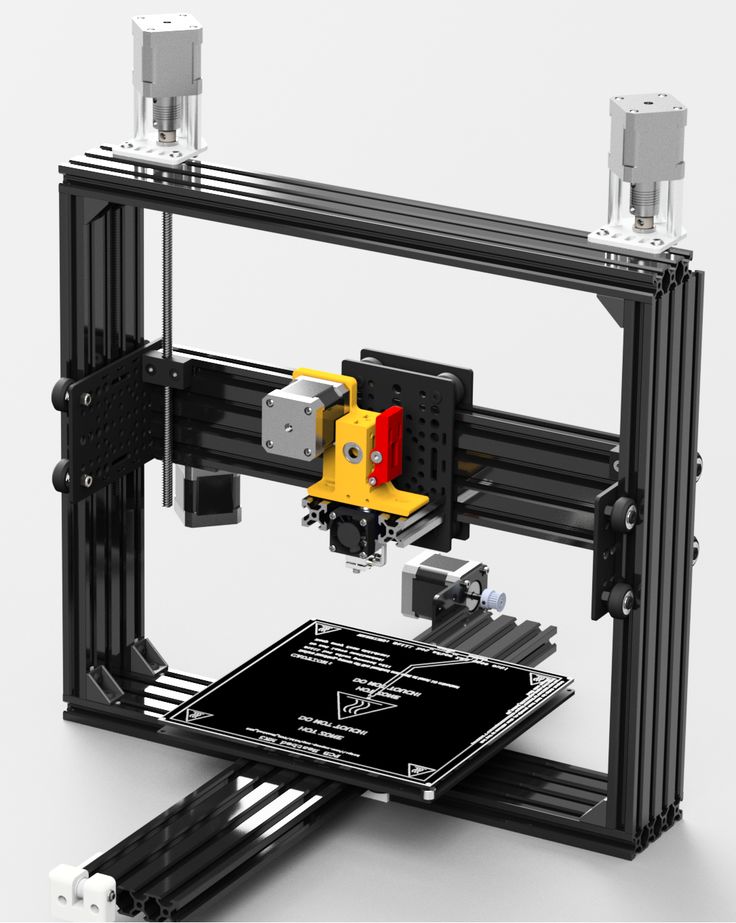

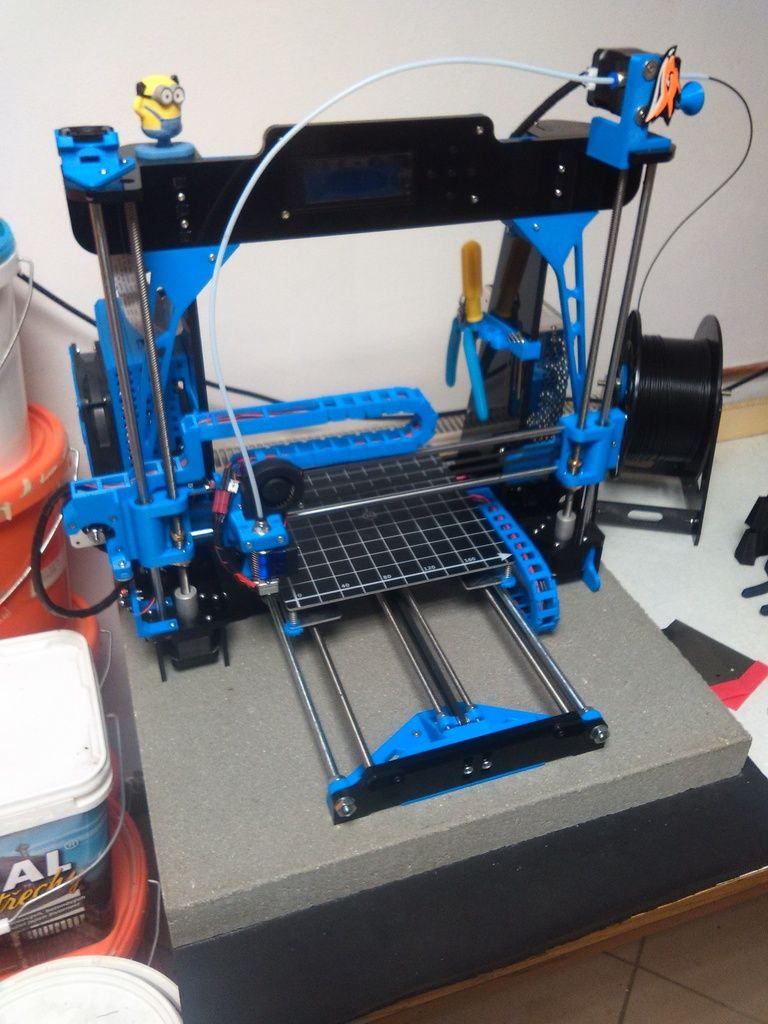

A so-called ‘infinite’ build 3D printer, the Sliding-3D uses a 45° angle extruder and a conveyor belt as a build platform. Robot Factory calls its Sliding-3D printer “a sort of “desktop factory.” With its continuous 3D printing feature, the company also says that the 3D printer is more time and cost-efficient compared to traditional fixed-build FDM printers.

Continuous 3D printing

Though a novel concept, the Sliding-3D is not an entirely new concept. AMy other manufacturers have been seeking similar solutions to ramp up 3D printing for production-scale output.

In 2017, Brooklyn-based 3D print bureau Voodoo Manufacturing introduced a robotic arm in its workspace. The automated arm collects finished models from a stack of 3D printers and places them on a conveyor belt. Without stopping the 3D printer begins the next task in the queue. And the process continues. According to Voodoo, this has reduced the cost of production by 90%.

Stratasys has its solution in the Infinite Build System, a continuous production FDM printer.

And Dutch research institute TNO is working on the nicknamed “Sushi printer” with BigRep.

In appearance, Robot Factory’s Sliding-3D printer is most similar to the Printrbelt which was in development at the now-defunct Printrbot. Printrbot founder Brook Drumm, however, has hinted that more 3D printer experiments could be yet to come from him.

Printrbot founder Brook Drumm, however, has hinted that more 3D printer experiments could be yet to come from him.

Environmentally friendly infinite 3D printing

Weighing 36 kg, Sliding-3D is an FDM/FFF printer with a conveyor belt build platform. Due to its forward-moving build platform, there are no limitations as to how long in length the Sliding-3D can print. The size of a print can range from 41 cm x 38 cm to ∞infinite.

Finished objects keep moving down the conveyor belt until they drop into an attached basket. This process can go on endlessly without interruptions and without a need for a machine operator.

Robot Factory also boasts of the environmental-friendly side of the Sliding-3D. It prints horizontal overhangs which require no support structure. Due to this, postprocessing takes less time and leaves less plastic residue.

The Sliding-3D extruder can handle temperatures of up to 280°C. Compatible materials include PLA, ABS, PETG, and other composites such as nylon, fiberglass, carbon fiber.

Compatible materials include PLA, ABS, PETG, and other composites such as nylon, fiberglass, carbon fiber.

For high-temperature printing and protection against environmental effects, the 3D printer can be insulated with the Sliding-3D Box, a protective glass cell measuring 94 x 67 x 81 cm.

A 3D printed guitar with Sliding-3D. Image via Robot FactoryTechnical specifications and pricing

Pricing of the Sliding-3D system is available on request. Full technical specifications can be found below.

3D printing technology: FDM/FFF

Printer measurements: 1.100mm x 570mm x 770mm

Build size: 41 cm x 38 cm x ∞ (infinite)

Layer resolution: 0.15 – 1.0 mm

Extrusion temperature: 280 °C

Supported filament materials: PLA, ABS, PETG, and other composites such as Nylon, High Impact Polystyrene (HIPS), Fiberglass, Carbon fiber

Recommended filament diameter: 1.75 mm

Extruder: A 45° angle single extruder

Weight: 36 kg

Connectivity: USB, SD card

Control device: PAD Esterno

For all of the latest 3D printer releases, subscribe to our 3D printing newsletter. You can also join us on social media: Facebook and Twitter.

You can also join us on social media: Facebook and Twitter.

Visit our 3D Printing Jobs to start a new career.

Featured image shows Robot Factory’s Sliding-3D printing. Image via Robot Factory

Tags conveyor belt Infinite 3D printing Robot Factory Sliding-3D

Umair Iftikhar

50 Cool Things to 3D Print / Sudo Null IT News

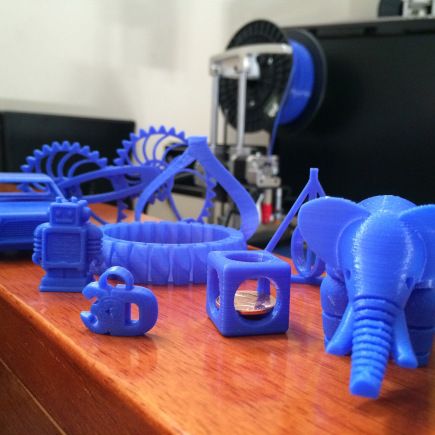

No ideas for 3D printing? Tired of worthless trinkets? Here is a list of 50 cool really useful things for 3D printing.

Like us, you're excited about the possibilities of 3D printing. But, unfortunately, the horizon is littered with trinkets, trinkets and other unnecessary things. We are in danger of being buried under a heap of useless rubbish.

Throw off the shackles of mediocrity! Let's create really useful things! Here is a list of cool things that you can make on a 3D printer right now. Prove to your family and loved ones that this wonderful technology can be used daily and in practice.

No access to 3D printer? No problem. Just upload your files to our 3D printing price comparison system and choose the best price, ONLINE!

Download from Myminifactory

Cool thing for 3D printing No. 29: Form for Snegles

Download from ThingiVerse

Cool 3D Printable Item #30: Wine Bottle Protector

Download from MyMiniFactory170004

Cool thing for 3D printing No. 31: Pocket ashtray

download from Myminifactory

Cool Press No. 32: Rodist Rodper 9000 9000 9000 9000 download from MYMINIFACTORY

3D Printable Cool Item #33: Apple Remote Stand

Download from MyMiniFactory

3D Printable Cool Item #34: Key Holder

Download with Myminifactory

Cool thing for 3D printing No. 35: Holder of the cutlery for people with disabilities

Download from Myminifactory

Current Passing No. 36: Cover wine bottle

Download from MyMiniFactory

Cool thing for 3D printing #37: Paper cup holder

download from Myminifactory

Cool thing for 3D printing No. 38: Case for blades

38: Case for blades

download from Myminifactory

Cool thing for 3D printing No. 39: Holder for a children's bottle 9000 from MyMiniFactory

3D Printable Cool Item #40: Towel Rack

Download from MyMiniFactory

3D Printable Cool Item #41: Holder for a glass

Download with Myminifactory

Cool thing for 3D Press No. 42: Holder for a phone in the shower

download from Myminifactory

Twisting thing for 3D printing No. 43: Holder No. 43: Holder No. 43: for beer glasses

Download from MyMiniFactory

Cool thing for 3D printing #44: MacBook Pro stand

download from Myminifactory

Cool thing for 3D printing No. 45: Protection for SD-Cart

download from Myminifactory

Cool thing No. 46: BATERIOUS 9000

Download from MyMiniFactory

3D Printable Cool Item #47: Ice Cream Cone Holder

Download from MyMiniFactory

Printable Cool Item #40016 shower set

Download from Myminifactory

Cool Spring No. 49: Evacal separator

49: Evacal separator

download from Myminifactory

Cool Press No. 50 for 3D:

Download from MyMiniFactory

Want more exciting news from the world of 3D technology?

Follow us on social. facebook networks:

Large Area 3D Printer

Create functional plastic items up to 2.5 meters!

Learn more

Discovery 3D Printer is a range of industrial 3D printers made in Spain for creating large-sized products and prototypes using FFF/FDM technology.

Discovery 3D Printer Additive Machines produce high-strength thermoplastic objects for industries ranging from shipbuilding and automotive to architecture and medicine.

Problems solved

Replacement of spare parts or lost parts in engineering, shipbuilding, oil and gas and energy enterprises

Production of small and medium series of products as an alternative to injection or molding of plastic parts automotive, shipbuilding and oil and gas industries

Creation of objects of exterior and interior design and design products for construction, production of facing materials

Production of functional prototypes for R&D and design bureaus in mechanical engineering, shipbuilding and aircraft construction

Production of large-sized stencils or burnt master models for metal casting and metallurgy or trolleys)

Looking for a 3D printer for your needs?

Leave a request for a personal consultation!

Solutions catalog

3D printers

3D printer Discovery 3D Printer 2021

Compact solution for 3D printing of large-sized products

Read more

3D printer Super Discovery 3D PRINTER COMPACT

Cocal

More details

Super Discovery 3D Printer Hybrid

Advantages of printing with granules and filaments in one device

More details

Super Discovery 3D Printer 3D Printer

Large build chamber and print speed up to 6 kg/h

More details

Super Discovery 3D Printer 3D Printer Workstation

3D printer combination: unique 2 in 1 large format printer combination and milling systems

More details

Your unique 3D printer

Do you need to print a product larger than 6 meters?

We will develop an individual solution with any build chamber for your needs. tasks - for printing products of any size!

tasks - for printing products of any size!

Choose the right solution for you - compare Specifications by model

Compare 3D Printer

Solutions catalog

3D Printing Consumables

Do you have questions about 3D printing media?

Set them to our experts online!

Discovery 3D Printers work with all thermoplastics, including:

- PLA / PLA

- biodegradable polymer provides a smooth and gliding surface products. Designed to obtain detailed and ready-to-use objects

- ABS / acrylonitrile butadiene styrene

- impact-resistant material is able to withstand heavy loads and high temperature, resistant to heat, moisture and various alkalis

- PET / polyethylene terephthalate

- is a hard and strong material with high abrasion resistance.

Excellent suitable for making gears, carriages and guides

Excellent suitable for making gears, carriages and guides - PA / polyamide

- hard engineering plastic with excellent mechanical properties characteristics. Widely used in various industries

- ASA / acrylonitrile styrene acrylate plastic

- analogue of ABS, characterized by increased weather resistance, minimal shrinkage and high impact strength

- Nylon

- is flexible, wear-resistant and remarkably durable. Good suitable for printing functional parts and mechanisms

- HIPS / polystyrene

- Lightweight, alkali and acid resistant polymer. deserved popular in traditional manufacturing due to its impact resistance

Benefits of Discovery 3D Printer Solutions

ISO 9001 Certified Products

3D printers with the largest build chamber in the world

Ability to design a custom printer

The only 3D printer on the market with an integrated CNC system for finishing milling a part after printing

Accelerate the creation of new products thanks to the dual extrusion system

Repairs and replacements are faster and more cost-effective than contractors

Ability to use a large number of third-party materials

Platform self-leveling function for automatic compensation of irregularities

Case Studies

FDM 3D Printing of Airbus Parts

| Industry: | Aircraft industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | CFRP SABIC LNP™ THERMOCOMP™ AM EZ006EXAR1 |

Created a strong mold for autoclave forming parts with a sealed surface and a low coefficient of thermal expansion.

3D printed car bumper

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Prototype car bumper printed, measuring 1800 x 600 x 4500 mm and weighing 12 kg.

Large format 3D printed chair

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | 3D850 |

Printed design armchair measuring 45 x 50 x 95 cm and weighing 18 kg.

3D printed architectural statue

| Industry: | Architecture |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with cellulose fiber |

Printed solid statue, 1. 87m high and 45kg weight.

87m high and 45kg weight.

3D printing of railway components

| Industry: | Railway industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | plastic |

The front part of a tram for CAF was made in one printing session.

Helicopter seat 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed helicopter seat measuring 120 x 70 x 45 cm and weighing 20 kg.

3D printed internal combustion engine

| Industry: | Engineering |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | Premium PLA |

Prototype of an internal combustion engine was created, the dimensions of which were 100 x 60 x 50 cm and the weight was 5. 5 kg.

5 kg.

3D printed exclusive piece of furniture

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS plastic |

A custom and exclusive chair created without the need for any further finishing.

Architectural 3D printed in durable ABS with cellulose

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS plastic |

A street sculpture has been made that fully implements the initial decorative idea of the project.

Dior boutique window dressing

| Industry: | Advertising |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | plastic |

Huge bottles 3D printed for exclusive display at Dior's flagship stores.

FDM Cap Prototype

| Industry: | Design |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | 3D850 |

Printed prototype cap measuring 29 x 19 x 4.5 cm and weighing 146 g.

A prototype modular toilet is printed, measuring 2200 x 1700 x 1200 mm and weighing 250 kg. At the same time, the weight of the product was reduced by almost 50%.

3D printed marine ventilation grille

| Industry: | Shipbuilding |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Ventilation grill printed 59 x 89 x 4. 5 cm and weight 3500 g.0687 Industry:

5 cm and weight 3500 g.0687 Industry:

Printed motorcycle part measuring 42.5 x 16.5 x 4.5 cm and weighing 165 g.

Prototype printed with support measuring 10 x 9 x 2.5 cm and weighing 18 g.

Created a square mold that measures 10 x 10 x 2 cm and weighs 67 g.

Printed fender for a wheel measuring 55 x 16 x 20 cm and weighing 645 g.

3D printed and post-processed high-strength mold for wind turbine blades.

3D printed car wheel

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A wheel for a car was made, the diameter of which was 440 mm, and the weight of the product was 5 kg.

3D printed designer vase

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Printed vase in ABS for excellent interlaminar adhesion and minimal warping.

Geometric 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Pyramid printed with an 8mm extruder with a smooth surface thanks to the built-in milling system.

More projects and examples of 3D printing in production - in the blog 3D experts

Go to blog

Useful materials

Webinar on 3D printing large, complex geometries

- How can 3D printing help you optimize production?

- Features FDM-technology for printing products up to 2.

5 meters

5 meters - Benefits of using 3D plastic printing

- Real cases

Large Format Plastic 3D Industrial Printing Brochure

FDM Benefits, Equipment and Consumables Overview, industries and implementation examples - this and much more in one material!

About the manufacturer

CNC Barcenas / Spain

is one of the leaders in the European market for large format 3D printing.

The company specializes in the production of industrial 3D printers Discovery 3D Printer for printing large-sized products and prototypes based on FFF/FDM technology.

discovery3dprinter.com

Take a closer look at Discovery 3D Printer solutions - take a virtual tour of companies!

3D TOUR OF COMPANY

About us

iQB Technologies is a Russian distributor of 3D printers, consumables, 3D scanners and software from the world's leading manufacturers.

We develop complete 3D solutions, provide printing services and scanning, as well as training specialists in the use of 3D technologies in their work.

iQB Technologies is the exclusive distributor of Discovery 3D Printer solutions in Russia.

3D printers are available for order

in this section .

iqb.ru

Why order a 3D printer from iQB Technology?

The best prices for equipment in this class

Training on how to use 3D printers

A wide range of integrated solutions: 3D printer + 3D scanner + software

Provision of services for the implementation, maintenance and repair of 3D equipment throughout Russia

Participation in public procurement and tenders

Still have questions?

Our experts will advise you free of charge on Discovery 3D Printer solutions

Frequently Asked Questions

Which technology to choose: the method of fusing granules (FGF) or polymer filaments (FFF / FDM)?

What are the kinematics and mechanics of the Discovery equipment?

In this respect, all Discovery equipment differs from budget additive solutions. The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

What consumables can be used with Discovery products?

Any material (other than PEEK and PEKK) sold in bars or pellets. First of all, thanks to the heating of the table to 175 ° C and vacuum fixation, as well as due to the installed nozzles made of hardened steel.

How is such a large print platform heated?

A matrix of separate equidistant heaters is built into the platform from the bottom side; these modules carry out uniform heating of the surface of the printing platform. The maximum recorded temperature difference over the entire area is 3°C.

How can I speed up printing on such large dimensions?

There is a special method for properly emptying the internal volume, which you can learn more about from our technical experts. This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

It is important to consider that with a large range of large-sized products, it is better to consider Super Discovery 3D Printer or Super Discovery 3D Printer Workstation with a capacity of up to 11 kg / h (depending on the material used).

Is it possible to upgrade this equipment for a specific enterprise?

Yes. Most of the Discovery machines can be upgraded for a specific production project. This is possible, since the equipment was designed for the tasks of Production 4.0, and our specialists will help to integrate it correctly.

What is the warranty for this equipment?

24 months, which is 1.5 - 2 times more than analogues from Europe, Russia and China. Permanent customer support is provided directly by the vendor or iQB Technologies specialists.

How to get a high quality product so that it can be handed over as a final product?

3D printing is basically a high quality blank process.

You can change the pattern of the inner pallet if you wish.

You can change the pattern of the inner pallet if you wish.  Print it out and give it to your grandmother. She will appreciate this gesture.

Print it out and give it to your grandmother. She will appreciate this gesture.  " Do you have such a business card? Find her a pair in the form of this business card holder, printed in its entirety (yes, already with a hinged lid). Instructions for adding a custom logo are included.

" Do you have such a business card? Find her a pair in the form of this business card holder, printed in its entirety (yes, already with a hinged lid). Instructions for adding a custom logo are included.

It is especially suitable for kitchen plants. The next time you buy fresh herbs for cooking, transplant them into this neat device and they'll stay fresh all week long.

It is especially suitable for kitchen plants. The next time you buy fresh herbs for cooking, transplant them into this neat device and they'll stay fresh all week long.  It’s great if you have water limits set in the height of summer.

It’s great if you have water limits set in the height of summer.  28: Protection for disk

28: Protection for disk