3D printer temperature sensor

Temperature sensors used in 3D printers

This post will help you understand the differences and the operation of most common temperature sensors used in 3D Printing.

Each type of sensor has many key performance aspects and the goal of this topic is to compare them in details.

Part 1 will explain the most common sensor types and will take a look at the boards.

Part 2 will go in details about the performance between sensors while keeping in mind the 3D printer application.

Part 3 will provide explanations regarding our choice to go with a thermistor. Finally, some common mistakes are explained regarding temperature sensors.

Do not hesitate if you have any comments or suggestions that could improve this blog.

The most common sensor types are the following:

Thermistor

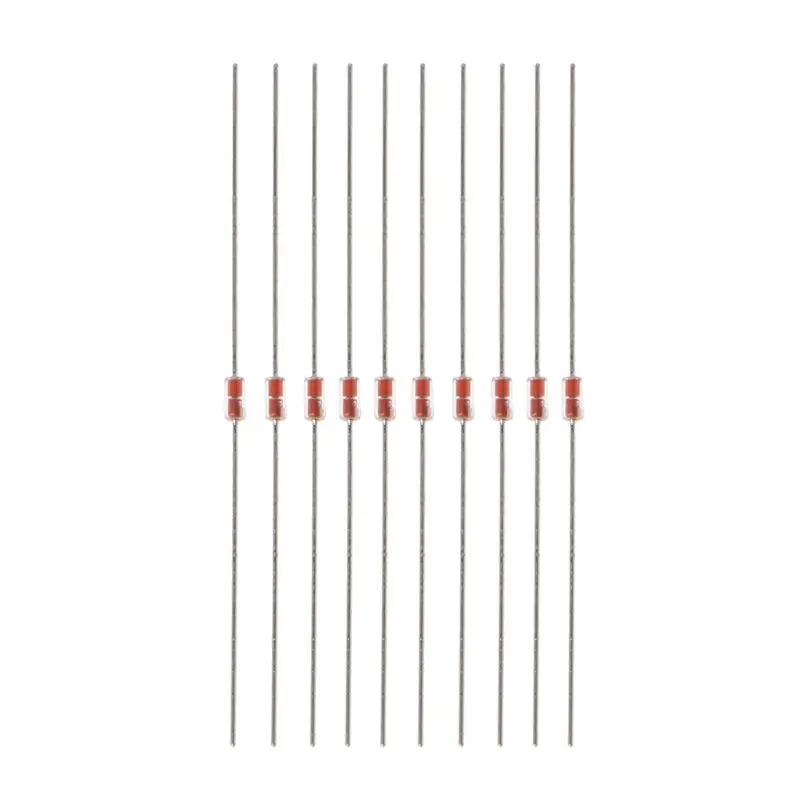

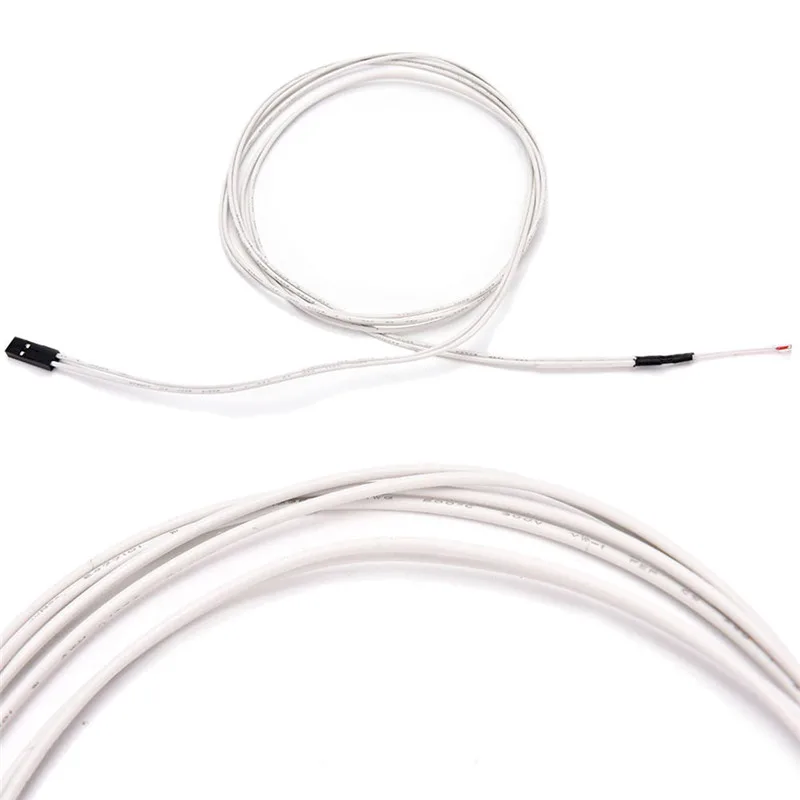

Thermistor are resistor whose resistance changes with temperature. Most commonly used type in 3D printers is NTC, standing for “Negative Temperature Coefficient”. When the temperature increase, the resistance decrease.

They are made from semiconductors, mostly silicon and germanium, and their resistance value can vary by many order of magnitude in their temperature range. A 100k NTC thermistor has a resistance of 100kΩ (100 000Ω) at room temperature (20°C) and drops as low as 100Ω at 300°C.

RTD

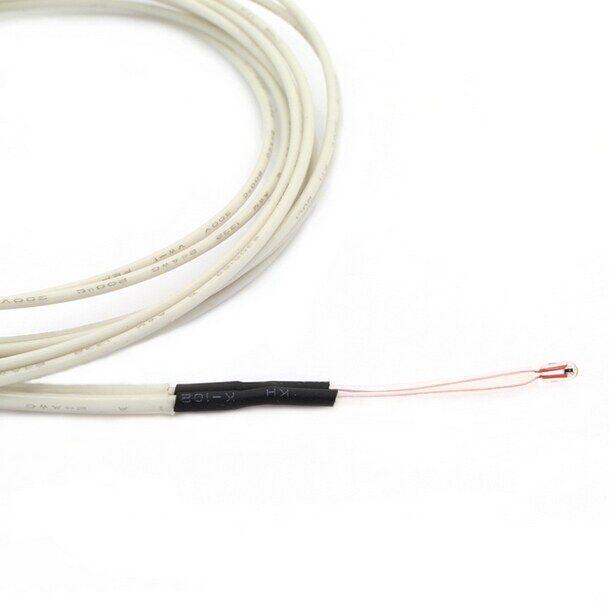

RTD are very similar to thermistors in term of operation. Rather than having a semiconductor, these are made from metals, mostly platinum, nickel or copper. RTD stands for “Resistance Temperature Detectors”. Most commonly used type in 3D printers is PT100. It has a resistance of 100Ω at 0°C.

With an RTD sensor, the resistance slowly increases with temperature. At 400°C, a PT100 will reach 250Ω. The variation is almost linear.

Thermocouple

Thermocouple operates in a totally different way than the other sensors. They are made from two different metals which generate a very small voltage depending on temperature. The most common type used in 3D printers is K and is made from chromel and alumel.

The voltage increase from 0mV to 20mV from 0°C to 500°C. As with PT100, the variation is almost linear at 41 µV/°C.

Please note that the picture shows a welded bead sensor which shouldn’t be used inside a 3D printer. The actual thermocouple should be inside an electrically insulated housing to prevent any noise or ground effect. A housing can be threaded, cylindrical or flat (crimped).

3D Printers manufacturer and motherboard sensor table

Here is a list of 3D printer manufacturers with the sensor types they are using.

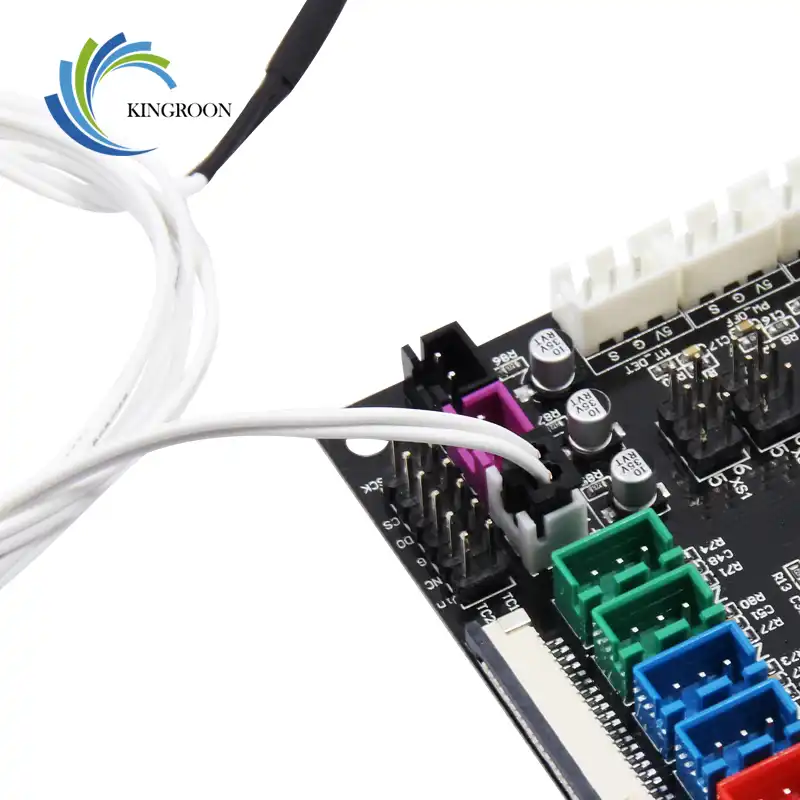

The main driving part inside a printer for sensor choice is the motherboard. Each motherboard has unique components which decide what sensor is meant to be used. The most common is the thermistor, which only requires a pull-up resistor to work.

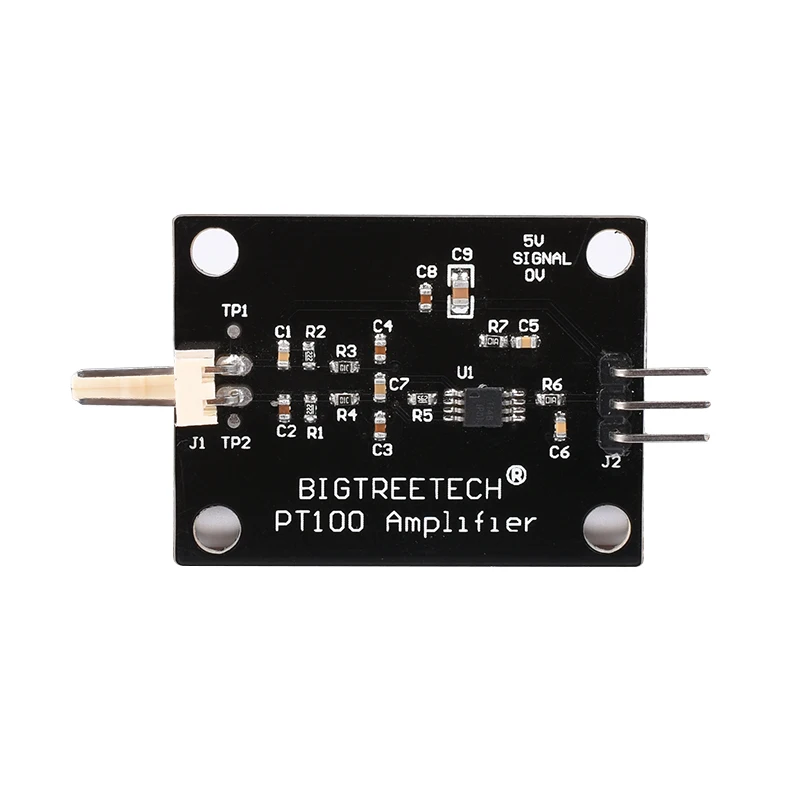

Both RTD and thermocouple require an IC (Integrated Circuit) built for processing their respective signal. These add-on boards are compatible with most boards via I2C and SPI pins for communication, or analog pins. Some specialized boards, such as the Duet Wifi, offer specialized add-on board to enable thermocouple and RTD readings.

Some specialized boards, such as the Duet Wifi, offer specialized add-on board to enable thermocouple and RTD readings.

| Thermistor | RTD | Thermocouple | |

|---|---|---|---|

| Printers | Prusa, Robo3D, BCN3D, Kossel, Makergear, MendelMax, LulzBot, Printrbot, Mendel90, And many more RepRap… | Ultimaker | MakerBot, FlashForge, CTC, Wanhao Duplicator |

| Motherboards 8 bits | RAMPS, Rambo RUMBA, Melzi, Sanguinololu, Generation 6, Azteeg X1, Azteeg X3 | Ultimaker PCB, Ultimaker Board | MightyBoard, Azteeg X3 Pro, Megatronics |

| Motherboards 32 bits | Smoothieboard, AZSMZ, R2C2, Generation 7, Duet, Replicape | Alligator Board | RADDS |

Thermal sensor performance

Below is a graphical comparison for certain key aspects of temperature sensing in 3D printers. Please note that these values are based on the most common microcontroller configuration used in 3D printing, which is 8 bits microcontroller with 10 bits ADC. Having a higher resolution will improve resolution. Most 32 bits microcontroller benefit from a 12 bits ADC.

Please note that these values are based on the most common microcontroller configuration used in 3D printing, which is 8 bits microcontroller with 10 bits ADC. Having a higher resolution will improve resolution. Most 32 bits microcontroller benefit from a 12 bits ADC.

Better resolution can be obtained with specialized measurement devices, such as MAX31855, AD595, MAX6675 for thermocouple and MAX31865 for RTD, these are considered with both the RTD and thermocouple, as they are required.

The key performance aspects will be explained and detailed in part 2.

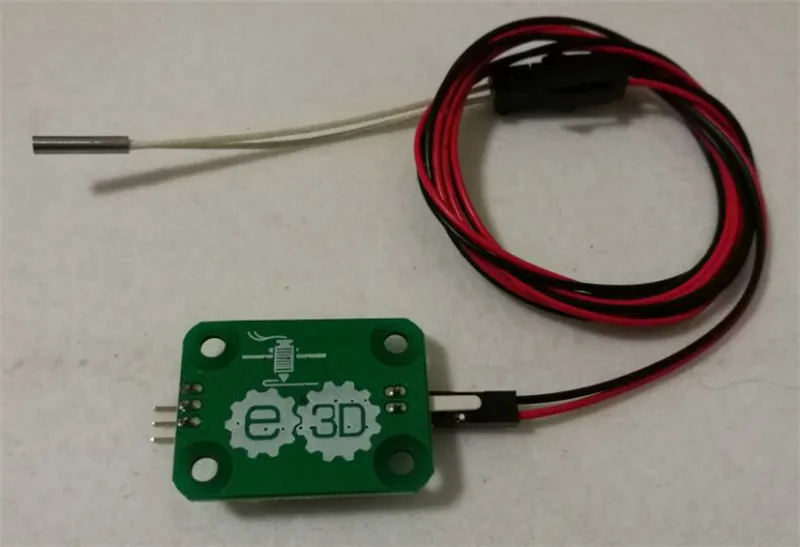

Thermistor

RTD

Thermocouple

Conclusion

Thanks for reading! This part was a short summary of thermal sensors used in 3D printer.

Follow on the next part, there will be a lot of interesting details about performance and in depth analysis!

Source

Sources

Control Engineering : Temperature tutorial

Improving the accuracy of temperature measurements

Overview of temperature sensors

RTD and thermistor comparison

PT100 tolerance classes

Thermocouple accuracy

Thermistor Accuracy

3D Printer Thermistor Guide – Replacements, Problems & More – 3D Printerly

The thermistor on your 3D printer serves an important function, though some people can get confused on what exactly it does, and how it helps out. I wrote this article to set people on the right path on thermistors so they can understand it better.

I wrote this article to set people on the right path on thermistors so they can understand it better.

In this article, we are going to explain all about thermistors to you. We’ll show you everything you need to know, from how to calibrate your thermistor to how to change.

So, let’s get started with a simple question, “What do thermistors do?”.

What Does a Thermistor Do in a 3D Printer?

A thermistor is an important component in FDM printers. Before we talk about its job, let’s define what a thermistor is.

Thermistors – short for “Thermal Resistors”- are electrical devices whose resistance varies with temperature. There are two types of thermistors:

- Negative Temperature Coefficient (NTC) Thermistors: Thermistors whose resistance decreases with increasing temperature.

- Positive Temperature Coefficient (PTC) Thermistors: Thermistors whose resistance increases with an increase in temperature.

The sensitivity of thermistors to changes in temperatures makes them suitable for temperature-sensitive applications. These applications include circuit components and digital thermometers.

These applications include circuit components and digital thermometers.

How Is A Thermistor Used In 3D Printers?

Thermistors in 3D printers serve as temperature sensing devices. They are found in temperature-sensitive areas like the hot end and the heated bed. In these areas, they monitor the temperature and relay the data back to the micro-controller.

The thermistor also serves as a control device. The printer’s micro-controller uses the thermistor’s feedback to control the print temperature and keep it within the desired range.

3D printers mostly use NTC thermometers.

How Do You Replace & Attach a Thermistor to a 3D Printer?

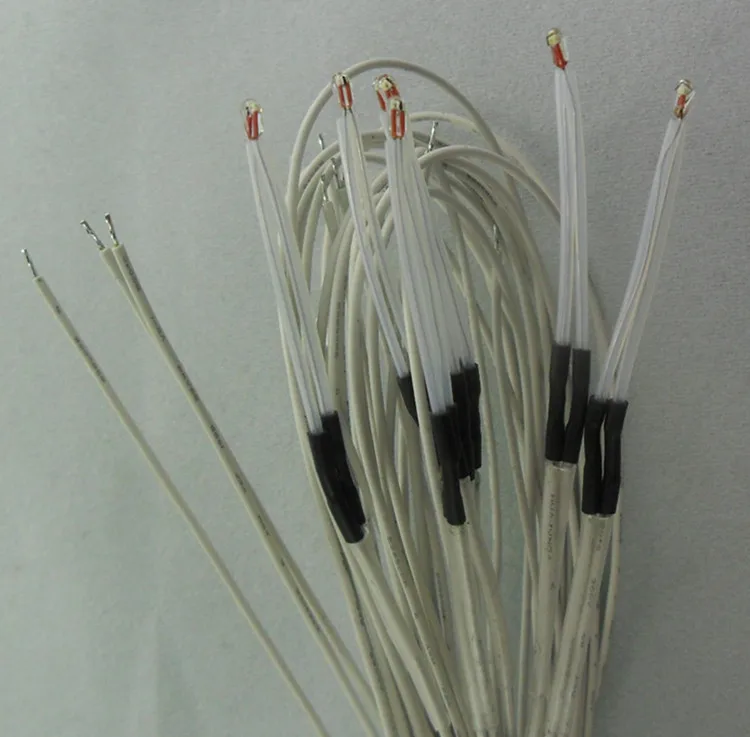

Thermistors in 3D printers are very fragile instruments. They can break or lose their sensitivity easily. Thermistors control important parts of the printers, so it’s necessary to make sure they are in tiptop shape all the time.

Thermistors in 3D printers are often in hard to reach areas, so removing them can be a bit tricky. But don’t worry, as long as you exhibit caution and follow the steps carefully, you will be fine.

But don’t worry, as long as you exhibit caution and follow the steps carefully, you will be fine.

Two main 3D printer components contain thermistors- The hot end and the heated print bed. We’ll be taking you through the steps for replacing thermistors in both.

What You’ll Need

- Set of screwdrivers

- Tweezers

- A set of Allen keys

- Pliers

- Kapton tape

Replacing the Thermistor on Your Hot End

When replacing a thermistor in the hot end, unique procedures exist for different printers. But for most models, these procedures are the same with a little variation. Let’s go through them:

Step 1: Consult the datasheet for your printer and get the appropriate thermistor for it. You can find more information about this in the article.

You can find more information about this in the article.

Step 2: Before you start, make sure you follow the appropriate safety tips.

- Make sure the 3D printer is powered down and disconnected from all power sources.

- Ground yourself if necessary.

- Make sure the hot end is cooled to room temperature before you attempt to disassemble it.

Step 3: Remove the hot end from the printer’s frame.

- This might not be necessary if the thermistor’s position is accessible from the outside.

- Remove all the screws holding the hot end and its wires in place.

Step 4: Remove the old thermistor from the hot end.

- Loosen the screw holding it in place on the bloc and remove it.

- Sometimes, there can be caked plastic on the block preventing this. You can use a heat gun to melt this away.

Step 6: Disconnect the thermistor from the micro-controller.

- Open the processing unit of the printer.

- Access the micro-controller and remove the thermistor connection with a tweezer.

- Be careful to make sure you remove the right wire. Consult your manufacturer’s specifications to make sure you know the wire to remove.

Step 7: Install the new thermistor

- Plug the end of the new sensor into the micro-controller.

- Carefully place the head of the new thermistor in its hole in the hot end.

- Screw it in place lightly. Be careful not over-tighten the screw so as not to damage the thermistor.

Step 8: Finish up

- Cover up the printer’s processing unit.

- You can use the Kapton tape to hold the wires firmly together to avoid movement.

- Re-attach the hot end to the printer’s frame.

Replacing the Thermistor on Your Print Bed

If your 3D printer comes with a heated print bed, there’s a good chance that it also has a thermistor there. The steps for replacing the thermistor on a print bed varies from model to model, but it’s mostly similar. Let’s how you how to:

The steps for replacing the thermistor on a print bed varies from model to model, but it’s mostly similar. Let’s how you how to:

Step 1: Follow the appropriate safety tips before starting.

Step 2: Remove the print bed

- Disconnect the print bed from the PSU (Power Supply Unit).

- Remove all the screws holding it to the frame of the printer.

- Lift it up and away from the frame

Step 3: Remove the insulation covering the thermistor.

Step 4: Remove the thermistor

- The thermistor can be arranged in many ways. It can be secured to the bed with Kapton tape or secured with a screw.

- Remove the screws or the tape to free the thermistor.

Step 5: Replace the thermistor

- Cut off the legs of the old thermistor from the sensor’s wire.

- Attach the new thermistor to the wire by joining them together.

- Cover the connection with electrical tape

Step 6: Finish up

- Attach the thermistor back to the bed

- Replace the insulation

- Screw the print bed back onto the frame of the printer.

How Do You Check the Resistance of a Temperature Sensor?

Resistance is not a value that can be measured directly. To find the thermistor’s resistance, you’ll have to induce current flow in the thermistor and measure the resulting resistance to it. You can do that with a multimeter.

Note: It’s a thermistor, so the reading will vary across temperature. It’s best to take your reading at room temperature (25℃).

Let’s go through the steps on how to check the resistance.

What You’ll Need:

- A multimeter

- Multimeter probes

Step 1: Expose the legs of the thermistor (strip away the fiberglass insulation).

Step 2: Set the Multimeter range to the rated resistance of the thermistor.

Step 3: Apply the multimeter probes to both legs, and the multimeter should display the resistance.

Most 3D printing thermistors have a resistance of 100k at room temperature.

How to Calibrate Your 3D Printer Thermistor

An uncalibrated thermistor is very bad for 3D printing. Without accurate temperature measurement and control, the hot end, and the heated bed cannot function properly. So, as part of routine maintenance, you should make sure your hot end is always calibrated properly.

Let’s show you how to do it:

What You’ll Need:

- A thermocouple equipped multimeter

Step 1: Test the multimeter’s thermocouple.

- Boil a small amount of water.

- Dip the thermocouple into the water.

- It should read 100℃ if it’s accurate.

Step 2: Open the printer’s firmware.

- In the printer’s program file, there’s going to be an Arduino file controlling the hot end.

- You can check with your manufacturer or on online forums to find the file’s location for your printer.

Step 3: Attach the multimeter’s thermocouple to the hot end.

- Find a space between the hot end and the nozzle and stick it in.

Step 4: Open the temperature table in the firmware.

- This is a table containing the values of thermistor resistance versus temperature.

- The printer uses this file to determine the temperature from the resistance measured.

- Copy this table and delete the temperature column in the new table.

Step 5: Fill out the table.

- Set the hot end to the temperature value in the old table.

- Measure the correct temperature reading on the multimeter.

- Input this reading to the resistance value on the new table corresponding to the value on the old table.

- Repeat these steps for all resistance values.

Step 6: Replace the table.

- After finding the accurate temperature for all the resistance values, delete the old table and replace it with the new one.

How Do You Know If a Thermistor is Bad on a 3D Printer?

The signs of a malfunctioning thermistor vary from printer to printer. It can be as clear as a diagnostic message flashing on the printer’s interface, or it can be as bad as a thermal runaway.

We’ve compiled a list of some of the most common signs that indicate a problem with your 3D printer’s thermistor. Let’s go through them:

Thermal Runaway

Thermal Runaway is the worst-case scenario for a bad thermistor. It occurs when a faulty sensor supplies the wrong temperature to the printer. The printer then keeps transmitting power to the heater cartridge infinitely until it melts the hot end down.

Thermal runaway can be very dangerous. It can result in fires that can destroy not just your printer but the surrounding areas. Luckily, most manufacturers have included firmware safeguards in place to prevent this from occurring.

Higher Than Usual Print Temperatures

Materials usually come with recommended print temperatures. If the printer requires a higher temperature than the rated temperature to extrude the materials, the thermistor can be faulty.

You can run a diagnostic test on the thermistor to find out.

Symptoms of a faulty thermistor can also include:

- A large number of print errors due to temperature issues.

- Wild variations in temperature readouts.

If your thermistor cracks, it is going to fail so you want to prevent that from happening. Most times, a thermistor would break due to the screw that holds them being too tight, which shorts them out.

The screw should be slightly loose, at around half a turn back from being tight on there, since the thermistor just needs to be held in place rather than securely pressed against the hotend.

The good thing is that thermistors are fairly cheap.

Best Thermistor Replacement for Your 3D Printer

When selecting a thermistor for your 3D printer, there are some key factors to consider to get the right one. Let’s go through them.

Let’s go through them.

The most important of these factors is resistance, the resistance of the thermistor matters. It determines the range of temperature the thermistor will be able to measure. 3The resistance of 3D printer thermistors is mostly 100kΩ.

The temperature range is another important factor. It determines the magnitude of temperature your thermistor will be able to measure. An acceptable temperature range for an FDM printer should be between -55℃ and 250℃.

Finally, the last factor you should look at is the build quality. The thermistor is only as good as the materials used in building it. The materials can have a high effect on sensitivity and durability.

To get the best quality, it’s advisable to go for aluminum thermistors with suitable insulation like fiberglass for the legs. This is because aluminum is very conductive to heat while fiberglass is not.

Using all the factors listed above as a yardstick, we’ve compiled a list of some of the best thermistors on the market for your 3D printer. Let’s have a look at it.

Let’s have a look at it.

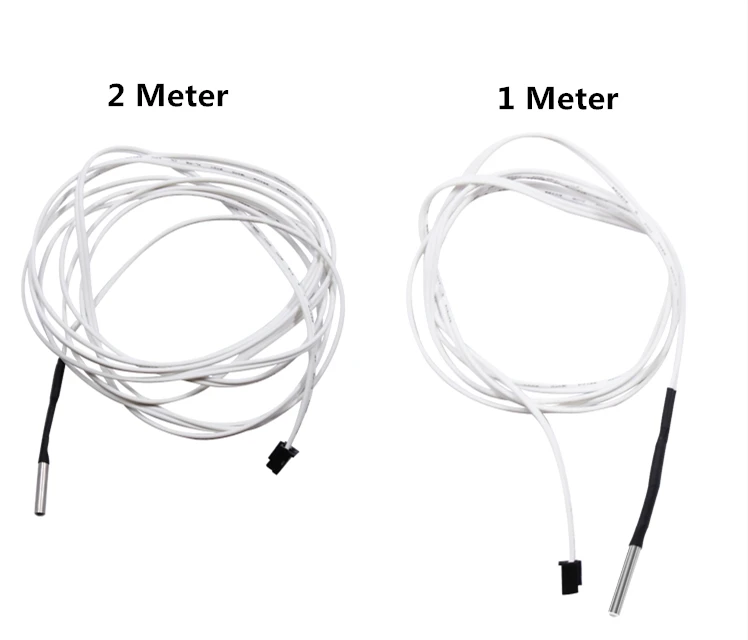

HICTOP 100K ohm NTC 3950 Thermistors

Many people mention just how useful the HICTOP 100K Ohm NTC 3950 Thermistors are after using it on their 3D printers. There is more than enough length for it to suit your needs and is a perfect job for your 3D printer.

You should make sure that your firmware is set correctly beforehand.

If you’ve had the thermistors on your Ender 3, Anet 3D printer or many others out there, then this should work very nicely for you.

These thermistors can fit on a Prusa i3 Mk2s bed without issues. The temperature range is okay to go up to 300°C, then after that kind of temperature, you’ll need a thermocoupler.

Creality 3D Printer NTC Thermistor Temp Sensor

Another set of thermistors that you can go for are the Creality NTC Thermistors, which list down the Ender 3, Ender 5, CR-10, CR-10S and more. Basically any 3D printer that takes a thermistor is good to go with these.

It’s used perfectly with your heated bed or extruder as you desire.

It has the standard 2-pin female connector with a wire length of 1m or 39.4 inches. The package comes with 5 thermistors with a temperature accuracy ±1%.

You should set the temp sensor number to “1” in Marlin for the best results.

If you’ve had some type of minimum temperature error on your 3D printer, these can definitely come to the rescue.

Most people had a positive experience with these, where they fit and work fine, as well as having spares just in case.

One user who purchased an Ender 5 Plus had temperature readings of -15°C or 355°C max. temperature change their thermistor to these and solved the issue.

Some people have complained that they can come up a little short on the Ender 3, and required the wiring for the fans and heater cartridge to be looped above the assembly to use the sleeve and keep it together.

You can splice the thermistor, then solder it in if needed.

Others have used it as a direct plug replacement on the Ender 3 though.

Page not found - Plastic for 3D printing in Yekaterinburg

Nothing found at this address. Use the search or see the links below.

Search:

Discounts

-

Sale!

ABS plastic SEM 1.75mm Burgundy 900g

1450 RUB MoreABS plastic SEM 1.75mm Burgundy 900gr

ABS plastic for 3D printers with a diameter of 1.75 mm from the domestic manufacturer SEM. Designed for the manufacture of parts for housings, various designs, kitchen products, as well as medical supplies. Printed products can be used in water, for example in the manufacture of parts for sanitary ware or aquariums. The material is suitable for various FDM 3D printers.

1450 RUB

-

Sale!

ABS plastic SEM 1.75mm Bronze metallic 900gr

1450 RUB Add to cart1 pc.

in stock

in stock ABS plastic SEM 1.75mm Bronze metallic 900gr

ABS plastic for 3D printers with a diameter of 1.75 mm from the domestic manufacturer SEM. Designed for the manufacture of parts for housings, various designs, kitchen products, as well as medical supplies. Printed products can be used in water, for example in the manufacture of parts for sanitary ware or aquariums. The material is suitable for various FDM 3D printers.

1450 RUB

Popular Items

-

Discount for quantity!

3D printer adhesive 250 ml The 3D “Click” New

590 RUB Add to cart26 pcs. in stock

3D printer adhesive 250 ml The 3D “Click” New

Adhesive for FDM printing. Perfectly solves the problems of poor adhesion of plastic to the table.

How to use: before printing, apply the glue solution to the fabric and wipe the surface of the table of the heated platform with it. For easy removal of the product from the table, after printing, wait for the work surface to cool down to 30°C. Ingredients: isopropyl alcohol, P-complex, water, fragrance. Ingredients: isopropyl alcohol, P-complex, water, fragrance.

How to use: before printing, apply the glue solution to the fabric and wipe the surface of the table of the heated platform with it. For easy removal of the product from the table, after printing, wait for the work surface to cool down to 30°C. Ingredients: isopropyl alcohol, P-complex, water, fragrance. Ingredients: isopropyl alcohol, P-complex, water, fragrance. 590 RUB

-

Nozzle brass 0.4mm MK8 for plastic 1.75mm 5APlus

40 ₽ Add to cart5 pcs. in stock

Nozzle brass 0.4mm MK8 for plastic 1.75mm 5APlus

Brass, size: 13 mm x 6 mm. Thread diameter: 1.75 mm. Thread diameter: 6 mm. Nozzle outlet diameter: 0.4mm

Suitable for 3D printers with MK8 type hotend: Anet A6, Anet A8, Creality CR-10, Ender-3, Ender 5, Ender 5 plus, etc.

40 ₽

-

PETG plastic FDplast 1.75 “Black Raven” 1000g

1650 ₽ Read morePETG plastic FDplast 1.

75 “Black Raven” 1000gr

75 “Black Raven” 1000gr PETG plastic is based on a modified polyethylene terephthalate, which is ideal for a 3D printer and the further creation of three-dimensional three-dimensional models suitable for the production of car parts, architectural objects, models of human body organs.

1650 ₽

-

Nozzle brass 0.4mm V6 for plastic 1.75mm 5APlus

40 ₽ Add to cart13 pcs. in stock

Nozzle brass 0.4mm V6 for plastic 1.75mm 5APlus

Brass, size: 12.5 mm x 7 mm. Thread diameter: 1.75 mm. Thread diameter: 6 mm. Nozzle outlet diameter: 0.4 mm.

Suitable for v5/V6 type 3D printers: Anycubic i3 Mega, Mega-S, 4MAX PRO, Kossel, Predator, Chiron

40 ₽

I3 3D printer system for a detailed explanation - Marlin firmware Chinese introduction

Marlin firmware download

https://github.com/MarlinFirmware/Marlin

More detailed introduction

https://load. download. net/download/qq_3

download. net/download/qq_3

https://github.com/Lighter-z/i3-Printer

Main configuration

Use the Arduino IDE to open Marlin.ino and switch to Configure.h to view and modify the file. Or use any text editor (NotePad, NotPad++, etc.) directly open the configuration. Markin firmware configuration mainly includes several aspects:

Communication baud rate

2. Motherboard type, motherboard type is used

3. Temperature sensor type, including extruded head temperature sensor and 9 temperature sensor0003

4. Temperature Configuration including nozzle temperature and heating temperature

5. PID temperature control parameters including nozzle temperature control and heater temperature control.

6. Limit switch

7. 4 axis step in motor direction

8. X / Y / Z Home position of three coordinate axes

9. Printer movement range

10. Auto leveling

103 Movement speed

12. Each axis movement permission

Each axis movement permission

13. Offline controller

Start to introduce

Computers and printers communicate through serial ports, define ports and baud rates, which are defined here that the port and baud rate of the 3D printing motherboard, the port number uses the default 0 .Marlin Firmware Default The default baud rate is 250,000, or it can be changed to other values such as 115200, which is the standard ANSI baud value.

#DEFINE Serial_Port0

#DEFINE Baudrate250000

Material board is determined below, and Marlin firmware supports various motherboards of 3D, such as general ramps 1.3 / 1.4, Melzi, Partina, Partina, Partina, Partina, Partina, Partina, Partina, Partina etc. It should be noted that different motherboards use different pins and quantities, if this definition is not compatible with the motherboard used in the Arduino IDE, it is definitely

Leading to compilation. The author uses ramps 1. 4 and d8, d9, d10 for controlling the nozzle, heating and heating of the fan, which is defined as 33.

4 and d8, d9, d10 for controlling the nozzle, heating and heating of the fan, which is defined as 33.

#IFNDEF MOTREARD

#DEFINE MOTERBOORD33

#endIF 9000 #endINIF

Next is the number of extruded heads and power type, the author uses a single shot head printer which is defined as 1.

There are two types of power supply for selection, 1 means switching power supply, 2 means X-Box 360 203 volts, commonly used

Therefore, switching power is therefore defined as 1.

#define1

#define POWER_SUPPLY1

Next, define the type of temperature sensor, including the temperature sensor (if it is multi-sample), and the temperature type of the type used for each nozzle, the common temperature sensor has two main categories of thermal and thermistor, and the thermistor is divided into

Failure The current 3D printer mainly uses thermistors. Which thermistor requires you to judge yourself or ask the seller. If you're not coincidentally, it's a 100K Thermistor NTC, which is 1. Depending on the comment, a 4.7K pull-up resistor is required, depending on the reworking of the Wiki, almost all 3D printers use 4.7K thermal resistance. The author observed the circuit diagram of several boards and found that the pull-out resistors are 4.7k, as shown in Figure 1.

If you're not coincidentally, it's a 100K Thermistor NTC, which is 1. Depending on the comment, a 4.7K pull-up resistor is required, depending on the reworking of the Wiki, almost all 3D printers use 4.7K thermal resistance. The author observed the circuit diagram of several boards and found that the pull-out resistors are 4.7k, as shown in Figure 1.

// 1 is 100k thermistor - best choice for EPCOS 100k (4.7k pullup) not used), the heated bed temperature sensor is also configured for 1.

#define TEMP_SENSOR_01

#define TEMP_SENSOR_10

#define TEMP_SENSOR_20003

#define TEMP_SENSOR_BED1

The author explains one by one.

First, this sentence is the maximum value of the double head temperature difference. If the temperature exceeds this value, then the printer will shut down, so this setting must be paid for the dual nozzle printer player.

#define MAX_REDUNDANT_TEMP_SENSOR_DIFF 10

Here are the indicators of the M109 instruction, we know that the M109 instruction sets the nozzle temperature and waits, then when is it? The next three parameters are controlled this time. The first parameter represents the temperature "approaching" the target temperature

The first parameter represents the temperature "approaching" the target temperature

The degree must last 10 seconds, and the second parameter representation and the target temperature difference does not exceed 3 ° to "approach". The third parameter indicates that the temperature is no more than 1 degree of the temperature and the target temperature. From now on, the temperature and the target temperature are still about 10 seconds or so, and the heating is completed.

#DEFINE TEMP_RESIDENCY_TIME 10

#DEFINE TEMP_HYSTERESS 3

#DEFINE TEMP_Window 1

Lower Mine and Upper Lower Tempein If the temperature exceeds the lower limit, then

What is the printer throws Mintemp errors and exits, if the upper limit is exceeded, then the printer throws a MaxTemp error and exits. Marlin protects 3D printers in this way. The bottom temperature is below 5°5°, the maximum nozzle temperature is 275°, and the maximum temperature of the hot bed is 150°.