Mandalorian 3d print

Mandalorian best 3D printing models・Cults

Baby Yoda - Grogu Christmas Ornament

€0.81

Knife from the Mandalorian S2 E10

€20

Heresy Empire - Hired Mercenary Squad

€12.59

Christmas Yoda

€2

Star Wars Tatooine Market Fruit Stand

€1.43

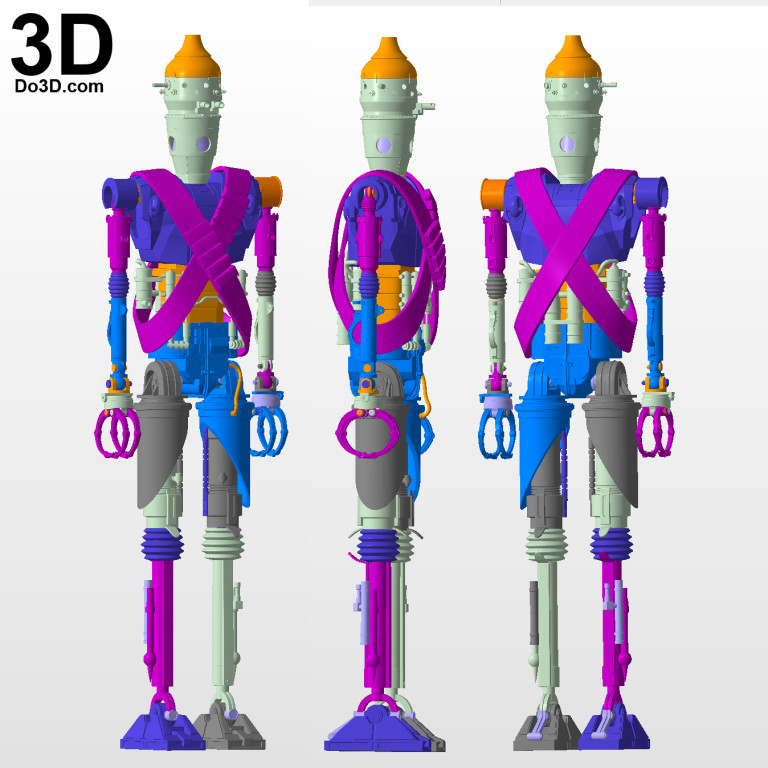

FELUCIAN BATTLE RANCOR NO RIDER MINIATURE MODELS SET FOR SCIFI OR FANTASY GAMES DND RPG

€7.05

attack

€6.25

Jawa Carrying Mudhorn Egg

€5.70

Fennec Shand Bust

€7.41

Tusken Raider Holding Krayt Dragon Egg

€7. 41

Star Wars Mandalorian Forge Diorama for 3.75" figures

€3.93

Star Wars DARTH VADER Planter 3D Print Stl Files Pack For 3D Printers

Free

Boba Fett Blaster Pistol - 3D Print .STL File

€8.93

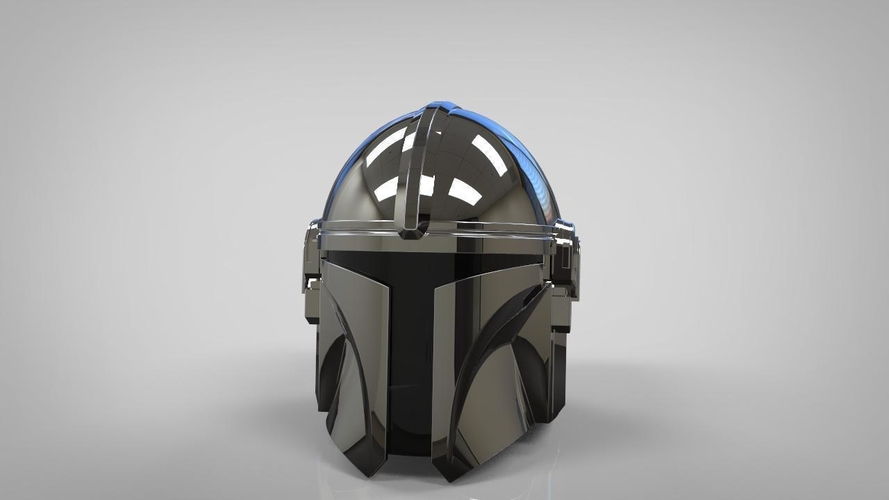

Boba Fett helmet 1to1 scale

€15.01

Grogu

€9

Mandalorian Cosplay Accessory Pack - 3D Print .STL File

€8.93

Mandalorian Westar 35 Blaster Pistol - 3D Print .STL File

€8.93

Ahsoka Tano White Lightsabers w. Stand - 3D Print .STL File

€4.46

Mandalorian Vibroknife - 3D Print .STL File

€4.46

Star Wars 3D Logo

€1

Mandalorian Darksaber - 3D Print .

STL File

STL File€4.46

Star Wars Black Series Dark Trooper Charging Station Dock

€25.19

Darth Maul character Skull from star wars ready to print

€20.14

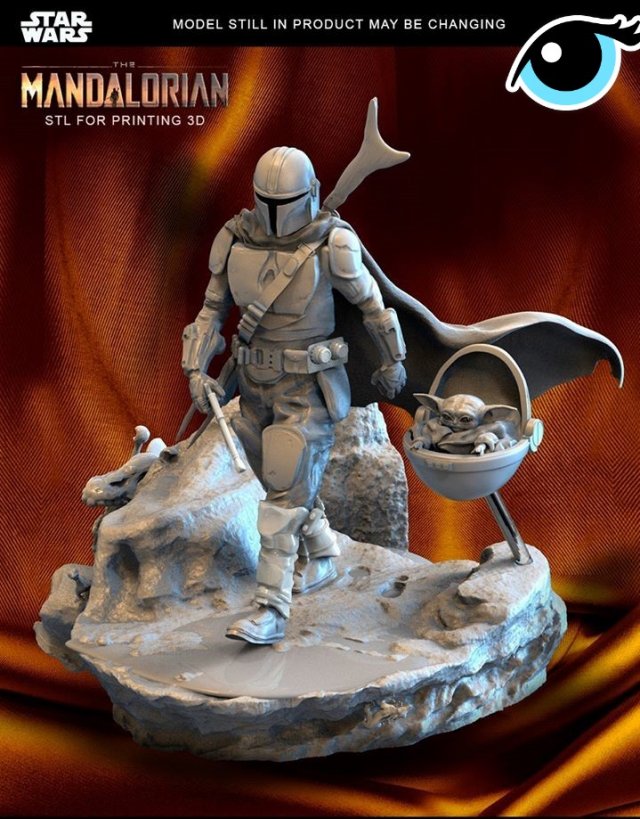

THE MANDALORIAN

€35

CR90 Space Ship

€32.54

Obi Wan Kenobi head 1/6 scale

€2.50

Cobb Vanth Speeder scaled for Black Series figure

€12.59

Ornament star wars mandalorian disney

Free

Hera Syndulla Blurrg Blaster Holster 3d digital download

€3.02

Hera Syndulla Blurrg-1120 Holdout Blaster 3d digital download

€10.07

5 Star Wars 2 Keychains

€2

Tauntaun Lowpoly

€0. 65

65

Boba Fett Helmet/ Book Of Boba Fett Helmet 3d digital download

€20.15

Rancor Lowpoly

€0.65

Boba Fett tools

€5

Beskar Easter Egg

Free

The Darksaber

Free

Mudhorn keychain

Free

Mythosaur keychain

Free

Boba Fett Mask

€1.01

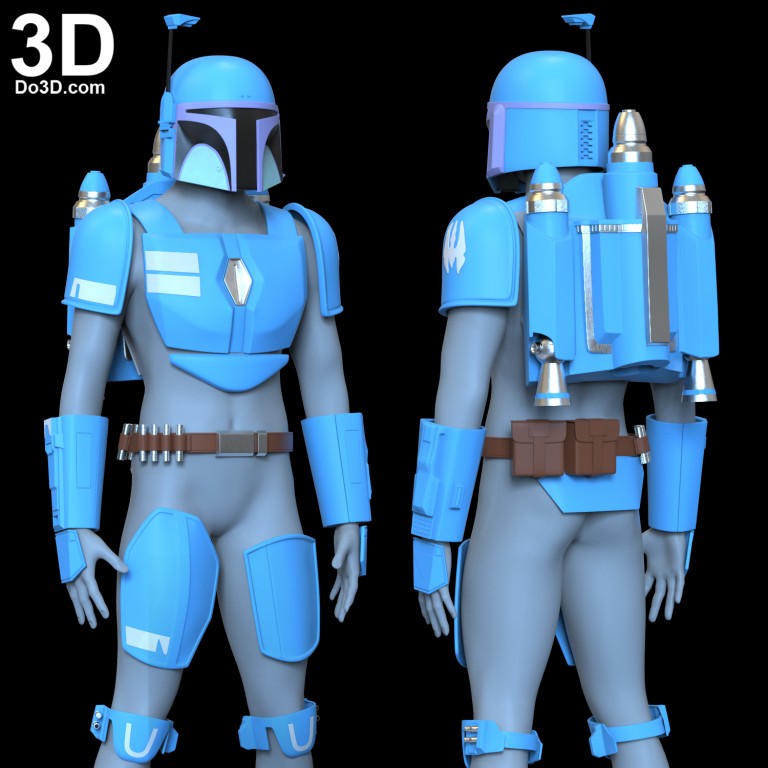

Imperial Super Commando Galaxy of Heroes Model

Free

Imperial Credit

Free

GRINDER R2D2 - GRINDER R2D2 - CHOPPER R2D2

€1.27

FELUCIAN RANCOR WITH RIDER MINIATURE MODELS SET FOR SCIFI OR FANTASY GAMES DND RPG

€7. 05

05

Mandalorian Night Light

€0.65

mandalorian gun

€1.84

mandalorian bracelet

€2.50

Grogu (yoda baby) LED

Free

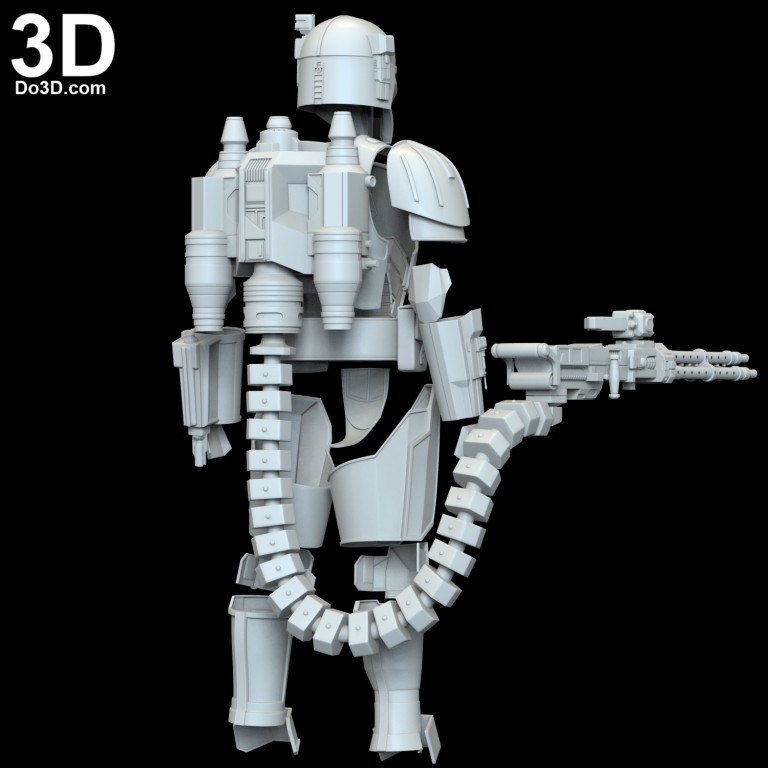

Gambody 1/12 Mandalorian 3D Print Kit Build Review

PROUDLY SPONSORED BY:

NOTICE:

The appearance of U.S. Air Force, U.S. Army, U.S. Navy, U.S. Marine Corps, U.S. Coast Guard, Department of Defense, or NASA imagery or art does not constitute an endorsement nor is Cybermodeler Online affiliated with these organizations.

FOLLOW US:

| Date of Review | February 2022 | Manufacturer | Gambody (Barry Crane) |

|---|---|---|---|

| Subject | Mandalorian | Scale | 1/12 |

| Kit Number | N/A | Primary Media | STL files (digital) |

| Pros | Beautiful details and fit | Cons | Nothing noted |

| Skill Level | Experienced | MSRP (USD) | $24. 95 95 |

Build Review

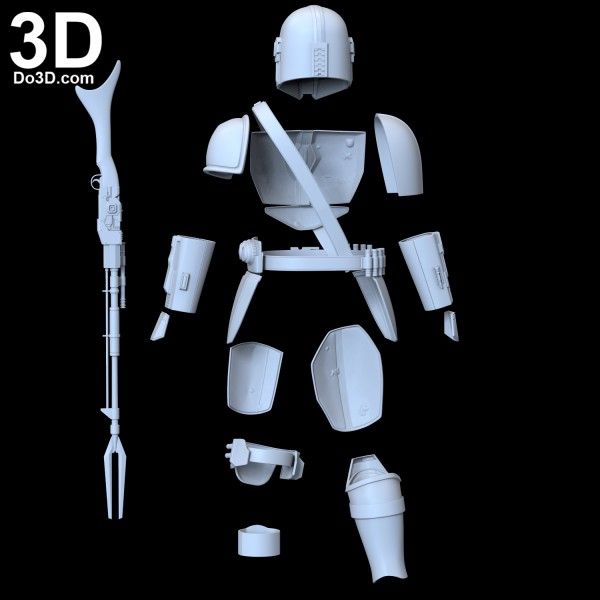

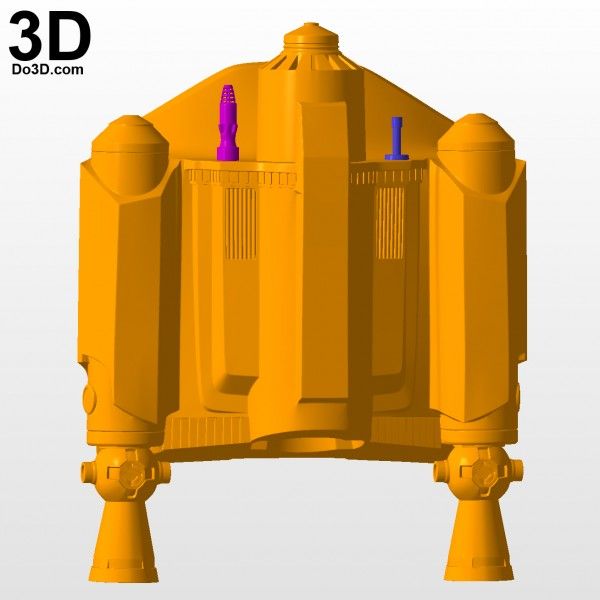

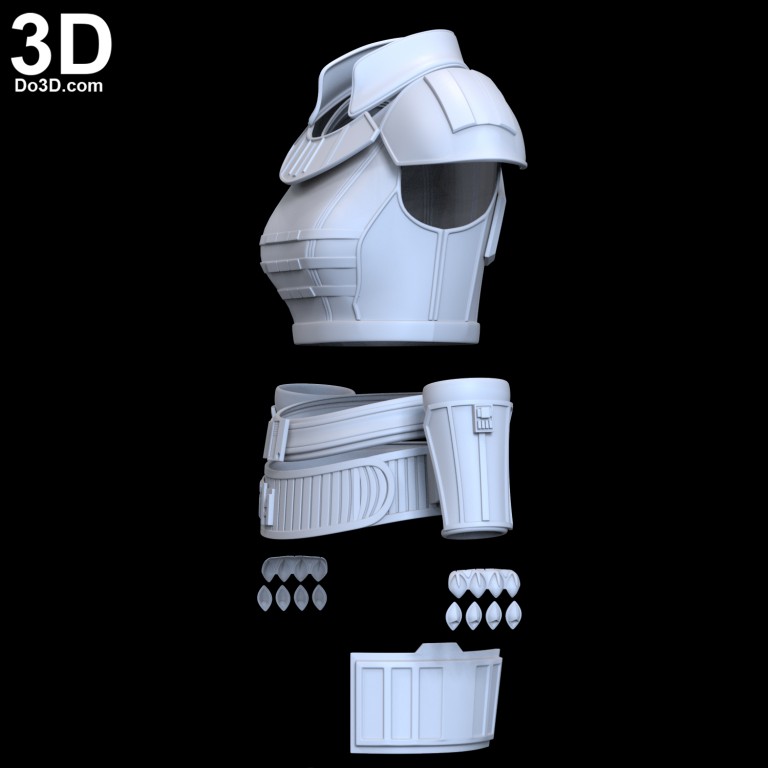

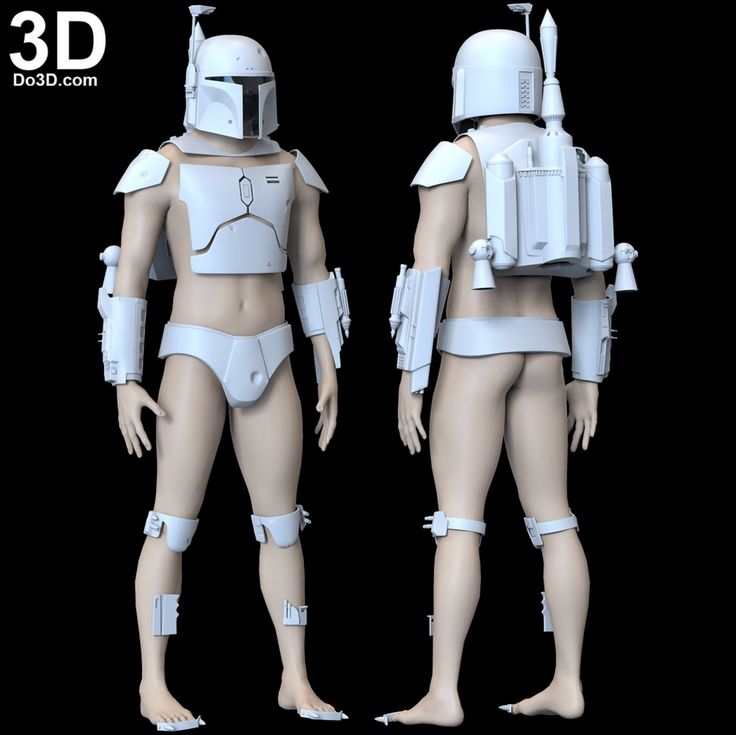

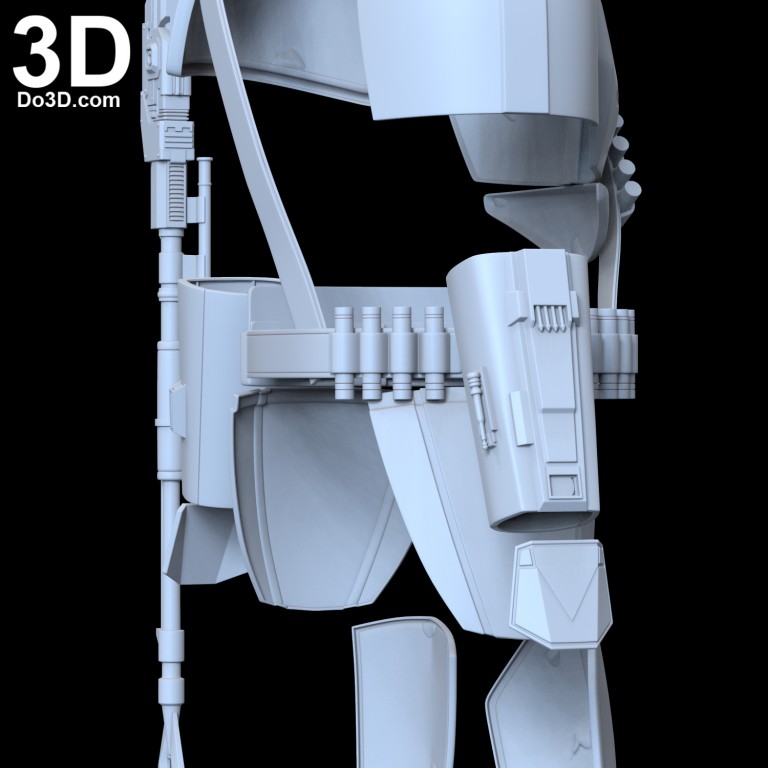

Here is the Mandalorian figure available on Gambody. The STL file I am using is the SLA version for resini printers and comes out to 1/16 scale (just like the Boba Fett figure we previously built). The fit of the Boba Fett figure was exquisite and I opted to print and assemble it as a first test of these series of products from Gambody. What's more, I was curious if there were any painting issues working with 3D printer resin and the gray primer I applied to Boba Fett adhered to the resin with no issues with masking or scratching paint back off.

I was curious if I could scale up these figures using the Chitubox software, and with the print volume of the Phrozen Sonic Mini 4K printer I have, I can scale up Boba Fett to 200% (1/8 scale), but due to the design of the Mandalorian figure, the best I could do with this printer is 150% (1/12). The legs and rifle are too long to fit inside my available print volume at 200%. Once that was settled, I printed each of the parts and primed them using Stynylrez Black. While I was waiting for all of the parts to be finished, I decided to do an experiment with GaiaNotes Premium Silver Plate to use for the Beskar armor. The Silver Plate goes on over the primer but doesn't have the reflective qualities I was looking for. I expect it would do better over gloss black, but I had another idea for Beskar. What I was pleased about is that I can mask over the Silver Plate finish using yellow Kabuki masking tape with no paint pull-up. I was using another brand's silver on an F-4 project and that build came to a halt with that silver did pull up using yellow tape masks. Duly noted!

While I was waiting for all of the parts to be finished, I decided to do an experiment with GaiaNotes Premium Silver Plate to use for the Beskar armor. The Silver Plate goes on over the primer but doesn't have the reflective qualities I was looking for. I expect it would do better over gloss black, but I had another idea for Beskar. What I was pleased about is that I can mask over the Silver Plate finish using yellow Kabuki masking tape with no paint pull-up. I was using another brand's silver on an F-4 project and that build came to a halt with that silver did pull up using yellow tape masks. Duly noted!

I test-fit the parts together and am quite impressed how well everything fit. I also took note of several potential issues, namely the build order of the assembly - torso, then the baby pouch, and then the cape, with one end of the pouch strap dropping over a tab on the cape to be glued when finished.

I spent a fair amount of time either looking at photos from the Mandalorian series or watching excerpts of the series from Disney+. One thing I noticed was that most of the series was shot indoors, even many of the 'outdoor' scenes were done indoors using their wraparound video set technology. As a result, there were few opportunities to see the Mandalorian costume in daylight so that cameras could pick out the details and colors of the costume. Fortunately, I have a copy of "The Art of Star Wars - The Mandalorian" handy so I could see each of the four phases of costume (armor) development during the first season. Based upon what I found, I pick out a detail or two, go to the bench and paint it, and repeat. Eventually I worked through the various aspects of the armor, weapons, and protective clothing to get this model finished. Of course there is one detail that needed serious attention, that was the Beskar armor. After the attempt with GaiaNotes, I remembered a secret weapon I had stashed away - Molotow Chrome Pens. Sure enough, Molotow works great with the resin and goes down nicely. While the finish isn't perfect, it isn't bad for my first full-up figure.

One thing I noticed was that most of the series was shot indoors, even many of the 'outdoor' scenes were done indoors using their wraparound video set technology. As a result, there were few opportunities to see the Mandalorian costume in daylight so that cameras could pick out the details and colors of the costume. Fortunately, I have a copy of "The Art of Star Wars - The Mandalorian" handy so I could see each of the four phases of costume (armor) development during the first season. Based upon what I found, I pick out a detail or two, go to the bench and paint it, and repeat. Eventually I worked through the various aspects of the armor, weapons, and protective clothing to get this model finished. Of course there is one detail that needed serious attention, that was the Beskar armor. After the attempt with GaiaNotes, I remembered a secret weapon I had stashed away - Molotow Chrome Pens. Sure enough, Molotow works great with the resin and goes down nicely. While the finish isn't perfect, it isn't bad for my first full-up figure.

The final result is pleasing to the eye given the contrasts in colors and details. Even Grogu turned out okay. When I get a larger printer, I want to do this project over at 200% (1/8 scale), but in the meantime, this is the way...

Best 3D Printable Mandalorian・Cults

Baby Yoda - Grog's Christmas decoration

0.81 €

Mandalorian knife S2 E10

20 €

Heresy Empire - Mercenary Mercenary Squad

12.59 €

Christmas Yoda

2 €

Fruit stand Star Wars Tatooine Market

1.43 €

FELUCIAN BATTLE RANCOR NO RIDER SCIFI OR FANTASY GAME MINIATURE SET DND RPG

7,05 €

attack

6. 25 €

25 €

Java, laying the Madhorn egg

5.70 €

Fennec bust of Shand

7.41 €

Tusken Raider holding Krayt's dragon egg

7.41 €

Star Wars Mandalorian Forge Diorama for 3.75" figures

3.93 €

Star Wars DARTH VADER Planter 3D Print Stl Files Pack For 3D Printers

Free

Boba Fett Blaster Pistol - 3D Printable .STL file

8.93 €

Boba Fett helmet 1to1

15.01 €

Grog

9 €

Mandalorian Cosplay Accessory Pack - 3D printed .STL file

8,93 €

Westar 35 Mandalorian Blaster Pistol - 3D Print .

STL file

STL file 8,93 €

Ahsoka Tano's white lightsaber with stand - 3D printable .STL file

4.46 €

Mandalorian vibroknife - 3D printed .STL file

4.46 €

Star Wars 3D logo

1 €

Mandalorian Darkxaber - 3D Print .STL file

4.46 €

Star Wars Black Series Dark Trooper 9 Charging Station Dock0003

25.19 €

Darth Maul Character Star Wars Skull Ready to Print

20.14 €

MANDALORIAN

35 €

Spacecraft CR90

32.54 €

1/6 scale Obi Wan Kenobi head

2,50 €

Cobb Vant Scale Speeder for Black Series Figure

12. 59 €

59 €

Star Wars The Mandalorian Ornament Disney

Free

Hera Syndulla Blurrg Blaster Holster 3d digital download

3.02 €

Hera Syndulla Blurrg-1120 Holdout Blaster 3d digital download

10.07 €

5 Star Wars 2 key rings

2 €

Tauntaun Lowpoly

0.65 €

Boba Fett Helmet/ Boba Fett Helmet Book 3d digital download

20.15€

Rancor Lowpoly

0,65 €

Boba Fett's Tools

5 €

Beskar Easter Egg

Free

The Darksaber

Free

Mudhorn Keyring

Free

Mythosaurus Keyring

Free

Boba Fett Mask

1. 01 €

01 €

Imperial Super Commando "Galaxy of Heroes" Model

Free

Imperial loan

Free of charge

GRINDER R2D2 - GRINDER R2D2 - GRINDER R2D2

1,27 €

FELUCIAN RANCOR WITH RIDER SCIFI OR FANTASY GAME MINIATURE SET DND RPG

7,05 €

Mandalorian night light

0.65 €

Mandalorian weapons

1.84 €

Mandalorian bracelet

2,50 €

Grog (baby Yoda) LED

Free

The Complete Guide to 3D Printing [Part 2]

3D printing is used in a variety of industries, both for rapid prototyping and short-term production.

In various industries, a key application of 3D printing is the rapid prototyping of new parts during R&D. No other technology has the capability to instantly produce plastic or metal parts - even in non-factory conditions.

3D printers can be used in-house by companies, while some businesses prefer to order 3D printed prototypes through service bureaus.

Medicine

3D printing can be used to make medical components such as titanium implants and surgical guides (SLM), 3D printed prostheses (SLS, FDM) and even 3D bioprinted human tissues. Components for medical equipment and technology - X-ray machines, MRI, etc. - can also be made by 3D printing.

SLA and SLS technologies are also widely used in the dental industry for model making, prostheses and restorations.

Aerospace

The aerospace industry has become a major consumer of 3D printing technology because it can produce very light parts with an excellent strength to weight ratio. Examples include things as simple as cab bulkheads (SLS) and down to revolutionary engine components (SLM) such as the 3D printed fuel injector tip designed and manufactured by GE.

Examples include things as simple as cab bulkheads (SLS) and down to revolutionary engine components (SLM) such as the 3D printed fuel injector tip designed and manufactured by GE.

Cars

Automotive companies regularly use 3D printers to make one-off parts and repairs, as well as rapid prototypes. Common 3D printed automotive parts include brackets, dashboard components, and antennas (FDM).

More extreme examples include vehicles with large 3D printed metal structural components, such as early models from automotive startup Divergent.

Jewelry and art

3D printing technologies such as SLA are widely used (as an indirect fabrication process) in the production and repair of jewelry, while almost all types of 3D printers can be used to create art and sculpture.

Engineering

Advances in additive manufacturing with high quality workmanship have expanded the scope of applications in construction and architecture. Concrete 3D printing, which is a bit like FDM but with very wide nozzle extruders, plays an important role in this industry, but more common 3D printing technologies such as SLM can be used for products such as bridge structures.

Concrete 3D printing, which is a bit like FDM but with very wide nozzle extruders, plays an important role in this industry, but more common 3D printing technologies such as SLM can be used for products such as bridge structures.

3D printing file formats:

3D printing parts can be designed with standard CAD software, but 3D printers can only read certain file formats. There are four main file formats for 3D printing.

STL: The most common file format for 3D printers, STL contains part geometry information in the form of tessellated triangles. It does not contain information such as color, material, or texture. The file size is proportional to the detail, which can be a problem.

OBJ: Less common than STL, the OBJ file format encodes the geometry of a 3D model and can include curves and free-form surfaces in addition to tessellation. It can also contain color, material, and texture information, making it useful for full color processes.

3MF: Invented by Microsoft, 3MF is an XML-based format with small file sizes and a good level of error prevention. It has not yet been widely adopted, but is supported by companies such as Stratasys, 3D Systems, Siemens, HP, and GE.

AMF: The successor to the STL format, AMF is much more compact and allows you to tessellate both curved and flat triangles, making it much easier to encode parts of various shapes. Since its inception, the format has been slowly adopted.

3D printing settings and specifications:

3D printing uses specific terminology that may not be clear to beginners. These terms refer to printer settings and/or specifications that can affect how 3D printed parts turn out.

Infill

When making 3D printed parts, it may be necessary to specify an infill percentage, which refers to the internal density of the part. A low infill percentage will result in a mostly hollow part with minimal material holding the mold together; a high infill percentage will result in a stronger, denser, and heavier part.

Layer Height

Layer height, sometimes referred to as z-resolution, is the distance between one 2D part layer and the next. A smaller layer height means finer resolution (and higher possible level of detail) along the z-axis, i.e. top down. A low layer height is an indication of a high quality printer, but users can set a higher layer height for faster, more economical printing.

Print speed

The printer's print speed, measured in millimeters per second, indicates the speed at which the machine can process the source material. Like the layer height, this value can either be a measure of the printer's maximum speed or be user-defined: slower print speeds usually result in more accurate prints.

Print temperature

When applied to processes such as FDM, print temperature generally refers to the temperature of the hot end, the part of the print head that heats the thermoplastic filament. Some FDM printers are also equipped with a heated print bed, the temperature of which is specified by the manufacturer. In both cases, the temperature is usually controlled by the user.

In both cases, the temperature is usually controlled by the user.

Resolution

In 3D printing, resolution almost always refers to the smallest possible movement along the X and Y axes (width and depth) of either the laser beam (SLA, SLM, etc.) or the print head (FDM). This value is more difficult to measure than the height of the layer, and it is not always proportional to it.

Shells

Like wall thickness in injection molding, shell (or shell thickness) refers to the outer wall thickness of the 3D printed part. When 3D printing, users usually have to choose the number of shells: one shell = outer walls as thick as a 3D printer nozzle; 2 shells = twice the thickness, etc.

Color 3D printing:

Since 3D printing is primarily used as a prototyping tool, single color prints are sufficient for most applications. However, there are several options for color 3D printing, including high-end material inkjet printers, multi-extruder FDM printers, and post-processing options.

Inkjet Printing Technologies

Major 3D printing companies such as Stratasys, 3D Systems and Mimaki have developed 3D inkjet printers for materials and binders that can print 3D models in full color as well as 2D inkjet printers. However, these machines are expensive and the parts do not always have excellent mechanical properties.

Multi-extrusion

Several FDM 3D printers are equipped with two (or more) printheads, allowing you to simultaneously print on two spools of filament - different colors or even different materials - within the same print job. It's simple and affordable, but usually limited to two colors.

Filament replacement

Single extruder FDM 3D printer can produce multi-color prints. To do this, you need to pause printing at certain points and replace the spool of thread with a thread of a different color. This is a very slow method of applying color and does not allow precise control over where each color goes.

Add color after printing

Many 3D printed parts can be dyed, tinted or painted after printing. While this adds another step to the process, it often strikes the best balance between quality and economy.

3D printed parts post-processing:

Many 3D printed parts require at least some level of post-processing after leaving the print bed. This may include important processes such as the removal of supports, or additional cosmetic processes such as painting. Some processes apply to all or most 3D printing technologies, and some are specific to a particular technology.

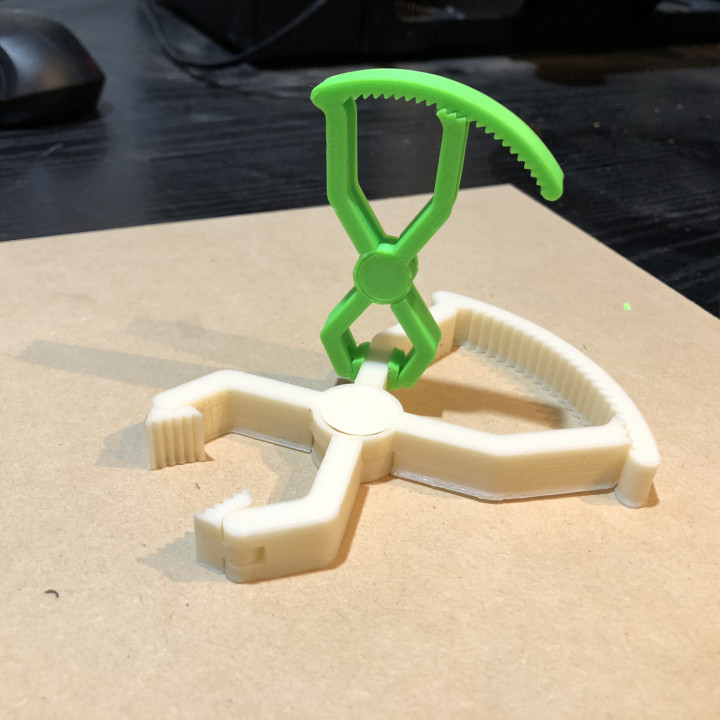

Support Removal

3D printing technologies such as FDM and SLA require the installation of support structures (vertical posts between the printed layer and the part itself) to keep the printed object from breaking during the manufacturing process.

These supports must be removed when the part is finished. Some printers, such as dual-extrusion FDM machines, can print support structures from dissolvable material, allowing the supports to be easily detached from the part using liquid chemicals. Insoluble supports must be manually cut from the part, leaving a mark that may need to be sanded down.

Insoluble supports must be manually cut from the part, leaving a mark that may need to be sanded down.

Wash and remove powder

Some 3D printing technologies (such as SLA) leave sticky marks on parts, while others (SLM, SLS) may leave powder marks. In these cases, the parts must be washed - manually or with a special machine - or the powder removed with compressed air.

Heat treatment

Many key 3D printing technologies print parts from materials that are not yet in their final chemical state after leaving the printing mold. Such details are sometimes called "green".

Many 3D printed metal parts require heat treatment after printing to increase layer fusing and remove contaminants. And bonded inkjet 3D printers, for example, produce parts that need to be stripped and sintered after printing to remove resin bond layers from inside metal parts.

Some 3D printed resin parts require post-curing after printing to increase their hardness and make them usable.

Surface Treatment

3D printed parts can be subjected to a wide variety of surface treatments, from textural treatments such as sanding and smoothing, to visual treatments such as painting and toning. Some technologies, such as FDM, can create a rather rough surface that requires sanding, while others, such as SLA, produce a much smoother surface.

Combination of 3D printing with other technologies:

3D printing does not have to be used as a separate process. Rather than being seen as a competitor to CNC machining and injection molding, it can actually complement these and other manufacturing processes.

Combination examples include:

- 3D print the main body of the part and then CNC mill the thin parts to tighter tolerances;

- 3D printable master pattern for investment casting or vacuum casting;

- 3D print the part and then injection mold using injection molding.

There are hybrid manufacturing systems that combine 3D printing with other technologies. For example, Mazak's INTEGREX i-400 AM and DMG MORI's Lasertec DED can perform both 3D printing and CNC milling.

For example, Mazak's INTEGREX i-400 AM and DMG MORI's Lasertec DED can perform both 3D printing and CNC milling.

Will 3D printing replace other manufacturing processes?

Analysts have long speculated about whether 3D printing could replace other manufacturing processes, including:

- Processing;

- Molding;

- Casting.

However, despite the desire of AM equipment manufacturers to position 3D printing as an end-to-end manufacturing technology, in practice 3D printing is still limited to some specific manufacturing operations, especially low-volume production of specific materials.

In some areas, 3D printing has certainly overtaken other processes. For example, rapid prototyping with inexpensive plastics like ABS now dominates 3D printing, as ABS is cheaper to print than machined. 3D printing also seems to have established itself as the ideal tool for making objects such as patient-specific titanium medical implants: the speed and geometric flexibility of 3D printing is hard to beat in these specific situations.

In addition, 3D printing is an ideal tool for making objects such as patient-specific titanium medical implants.

Despite this, processes such as CNC machining currently remain the best for producing high quality parts and prototypes from engineering materials such as POM, PEI, PPS and PEEK, with surface finishes far superior to 3D printing. . In addition, processes such as injection molding are still infinitely faster for mass production of simple plastic parts.

In addition, while additive manufacturing is one of the most significant technological advances in manufacturing, placing it in a stronger position in manufacturing in general, more established processes such as CNC and injection molding are also being improved to produce higher quality parts. .

3D printing will continue to take an increasing share of manufacturing jobs, but it will not completely replace other technologies.

What did 3D printing look like 10 years ago?

A decade ago, the nascent 3D printing industry was gearing up for what it believed was going to be a 3D printing revolution: a 3D printer in every home, allowing families to print new items they might need, such as a spare part for a refrigerator, a new toy for kids, or even components to build a second 3D printer.

In 2012-2014, FDM 3D printer manufacturers such as MakerBot actively promoted their 3D printers in the consumer market, trying to convince ordinary people that a 3D printer can improve their home life and work. However, it was clear that these companies were trying to exploit the novelty factor of 3D printing and that their products had no practical application; a 2012 MakerBot press release seems to prove it: Make an entire chess set at the touch of a button. Friends, classmates, colleagues and family members will see what you are doing and say "Wow!".

Just a few years later, this so-called 3D printing revolution clearly failed, and many 3D printer manufacturers began to rethink their goals, moving from consumer to professional and industrial markets, where there were more specific (and profitable) applications of additive technology.

In addition, those who were already working in the professional and industrial fields - companies such as 3D Systems and Stratasys - began to try to destroy the image of 3D printing as a prototyping technology, positioning it as a viable mass production tool (which, obviously, , could be more profitable for the 3D printing industry, as manufacturers would have to fill entire factories with 3D printers, buy 3D printer management software, and hire 3D printing consultants).

What will 3D printing look like in 10 years?

3D printing companies have abandoned the prospect of putting a 3D printer in every home. However, in 10 years, they can expect some form of additive manufacturing to appear in more factories.

Although there is less talk about 3D printing today than in 2012, the technology continues to gain momentum in the professional and industrial world.

According to a recent report, market research company 3DPBM Research expects the value of additive metal manufacturing to rise from $1.6 billion in 2020 to $30 billion by 2030, and this is largely due to the repositioning of AM as a manufacturing tool and the development of more high-performance engineering materials. (That said, 3D printing will remain a valuable prototyping tool in many industries, and prototyping applications will benefit just as much from technological advances.)

However, not only metal AM is being developed. Technologies such as HP's Multi Jet Fusion have opened up new possibilities for plastic printing, and innovators such as Carbon have developed new high-speed processes in the photopolymerization category. Niche areas such as 3D bioprinting and micro 3D printing are also regularly opening up new opportunities, and composite 3D printing (such as continuous carbon fiber 3D printing) is also on the rise: IDTechEX predicts that by 2030, the market size of composite 3D printing will be $1.7 billion

Niche areas such as 3D bioprinting and micro 3D printing are also regularly opening up new opportunities, and composite 3D printing (such as continuous carbon fiber 3D printing) is also on the rise: IDTechEX predicts that by 2030, the market size of composite 3D printing will be $1.7 billion

In short, 3D printing will gradually become a serious competitor to other manufacturing processes in many disciplines.

How to outsource 3D printing services?

Investments in 3D printing hardware and software are not suitable for all businesses, so many successful companies outsource their 3D printing needs to third parties, such as online 3D printing service bureaus (for one-time projects) or prototyping partners and production, such as 3ERP (for one-time projects or repeat orders).

When outsourcing 3D printing services, it is important to consider whether your business needs design and manufacturing services or just manufacturing services. (Keep in mind that a poorly executed 3D model may fail for 3D printing).